Development of Self-Sustaining Improvement Material for a Mud Film of the Weathered Soil of Red Beds

Abstract

:1. Introduction

2. Research Content and Methods

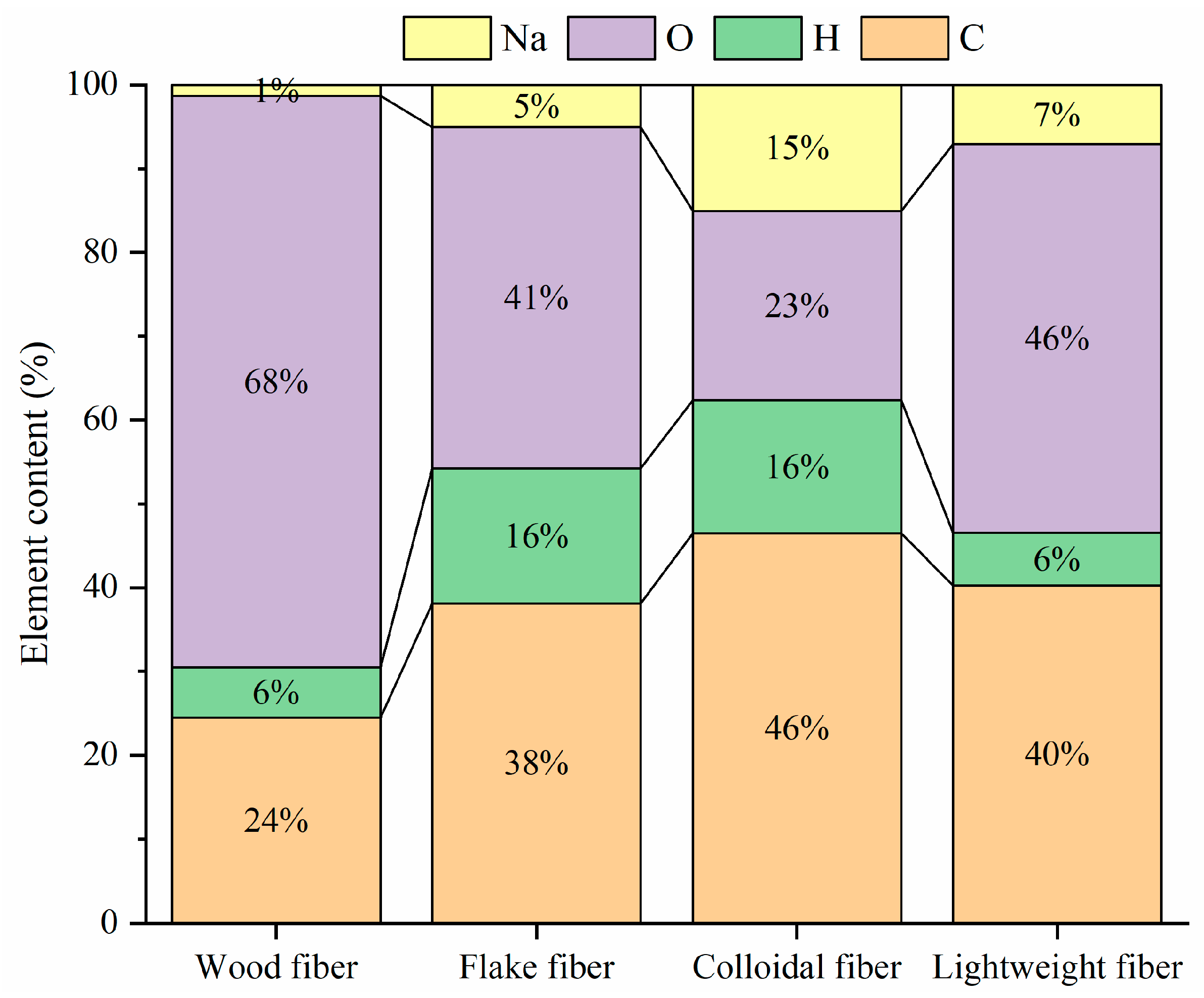

2.1. Development of Improved Materials

2.2. Testing the Self-Sustainability of a Mud Film of the Weathered Soil of Red Beds Based on Improved Materials

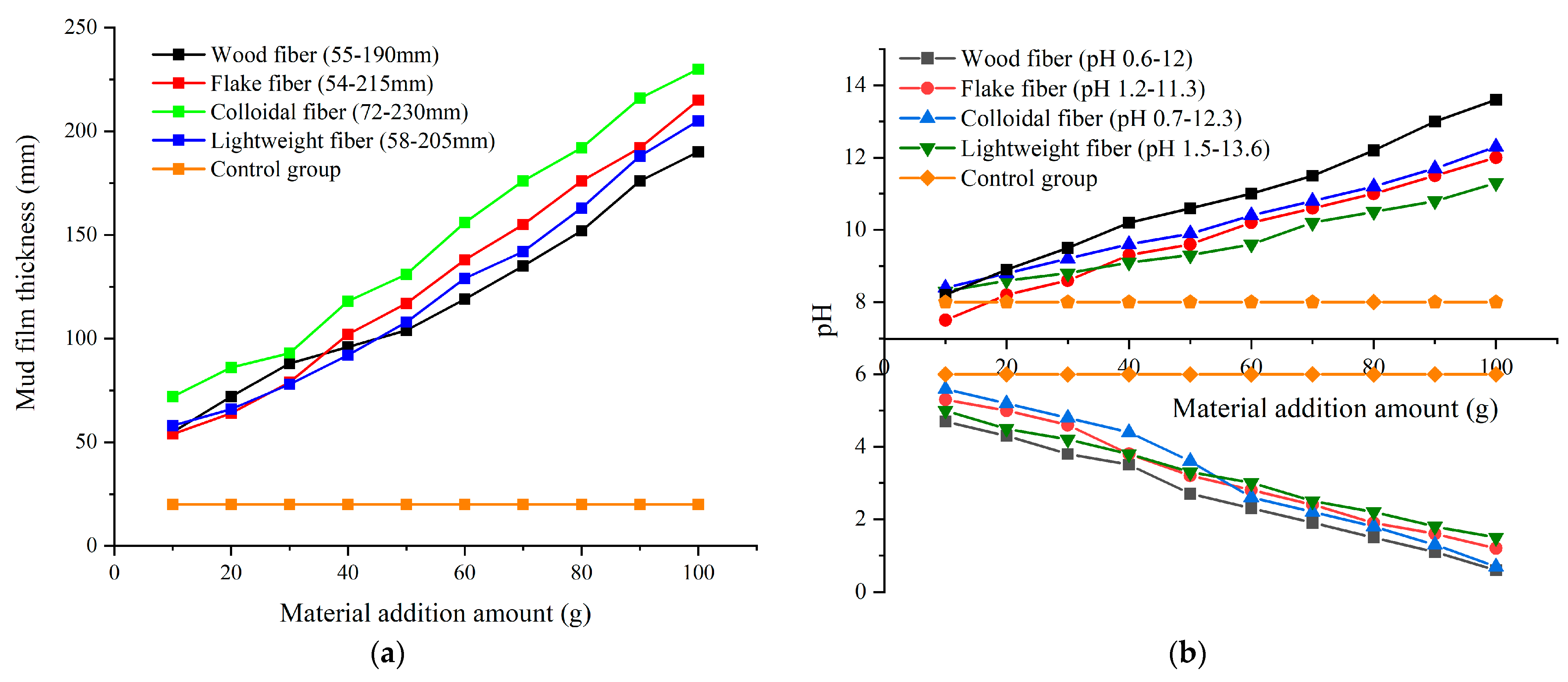

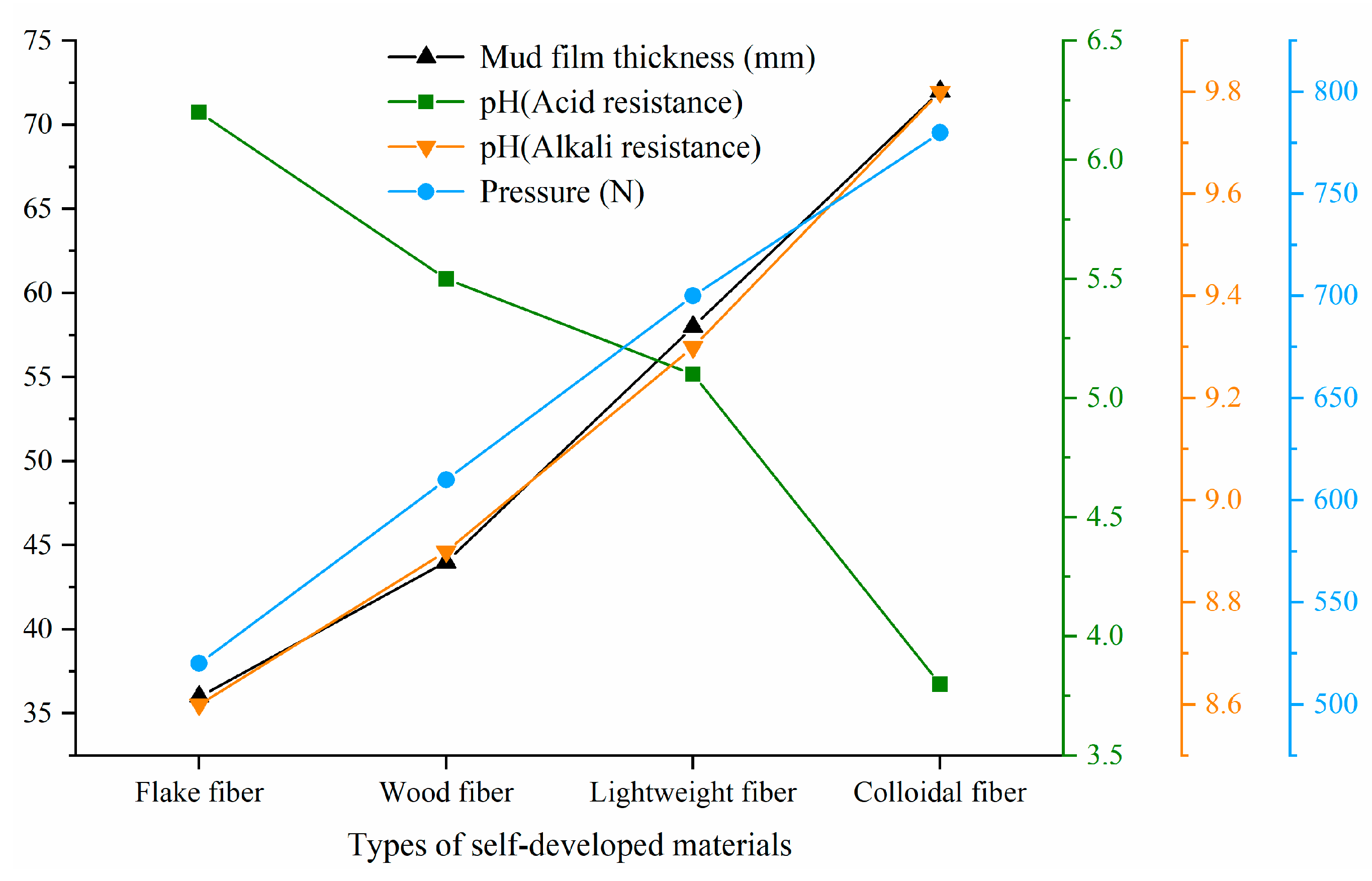

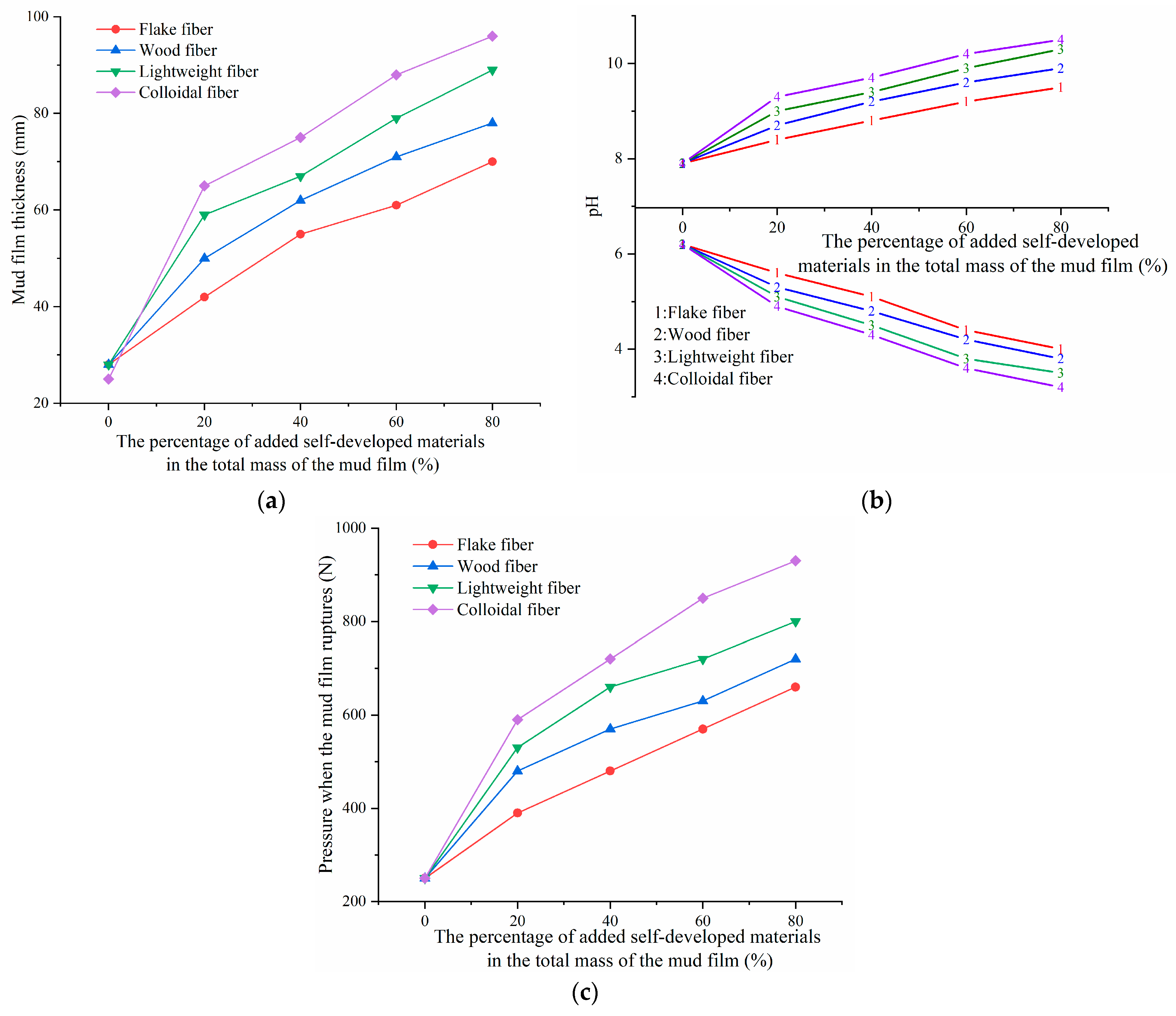

- Thin-layer property (overall anti-skid): The thickness of the mud film of the naturally weathered soil of red beds in each group is measured. The thicker the mud film of the natural weathered soil of red beds, the stronger the self-developed new composite material improves the thin-layer properties of the weathered soil of red beds.

- Corrosion resistance: A dropper is used to continuously add hydrochloric acid solution and sodium hydroxide solution to the mud film of the weathered soil of red beds of different groups. The concentrations of hydrochloric acid solution and sodium hydroxide solution are 0.01, 0.1, and 1 mol/L. They are dripped once every 5 s until the mud film of the weathered soil of red beds ruptures. The pH value is then recorded at this time to obtain the corrosion resistance of the mud film.

- Flexibility (local compression resistance): Pressure is applied to different groups of the mud film of the weathered soil of red beds, starting from 100 N and increasing by 10 N each time, until the mud film of the weathered soil of red beds ruptures. The pressure value is recorded at this time to obtain the flexibility of the mud film.

2.3. Application Test of Engineering Ecological Protection Based on Improved Materials

3. Research Results and Discussion

3.1. Analysis of Self-Sustaining Improvement Effect of Red Layer Weathered Soil Mud Films

3.1.1. The Effect of Self-Developed New Composite Materials on the Self-Sustainability of Mud Films of the Weathered Soil of Red Beds

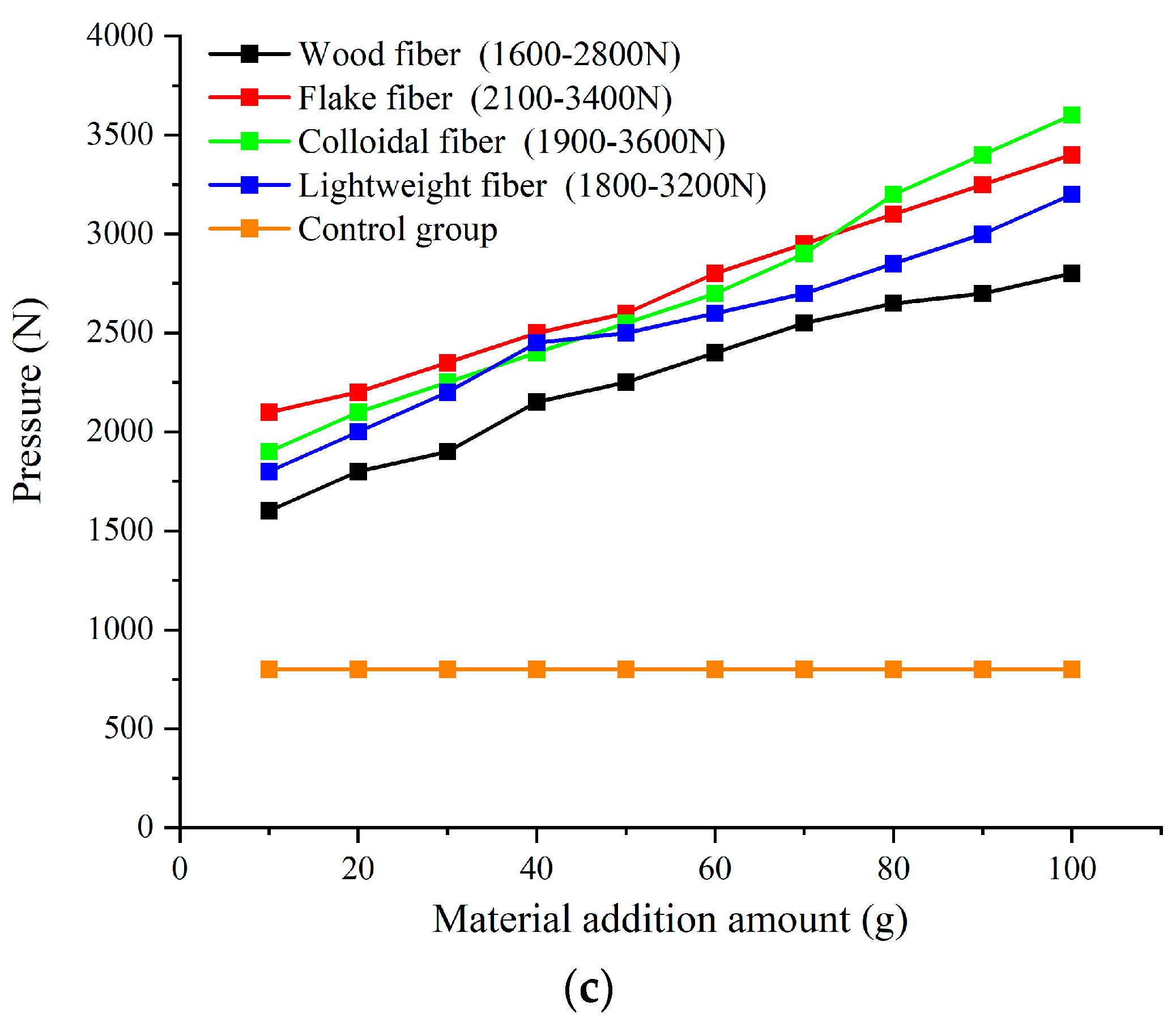

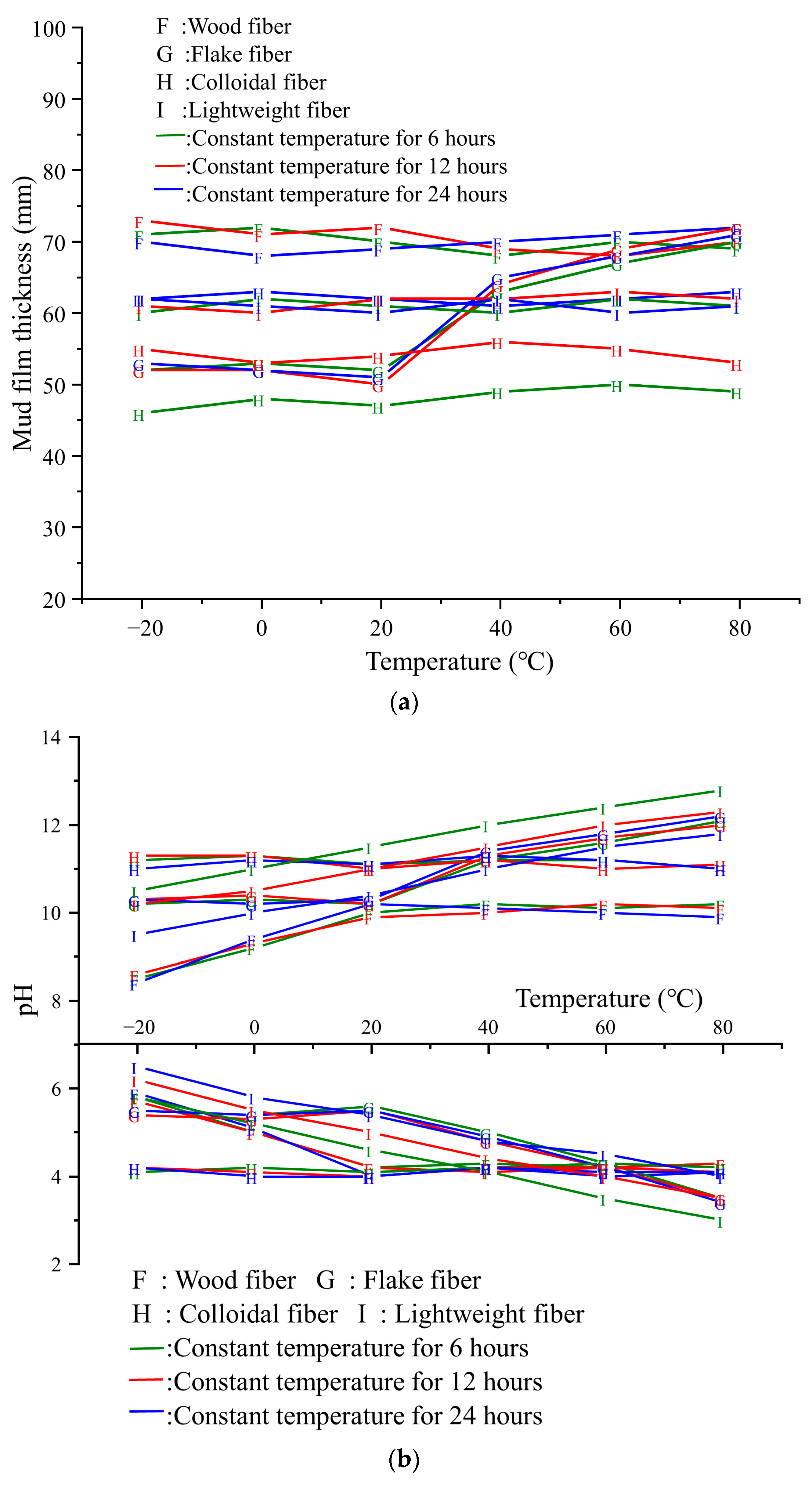

3.1.2. The Effect of Self-Developed New Composite Materials after Constant Temperature Tests on the Self-Sustainability of Mud Films of the Weathered Soil of Red Beds

3.1.3. The Effect of Self-Developed New Composite Materials after Cyclic Testing on the Self-Sustainability of Mud Films of the Weathered Soil of Red Beds

3.1.4. Comparison of Self-Developed New Composite Materials and Conventional Materials for Improving the Self-Sustainability of Mud Films of the Naturally Weathered Soil of Red Beds

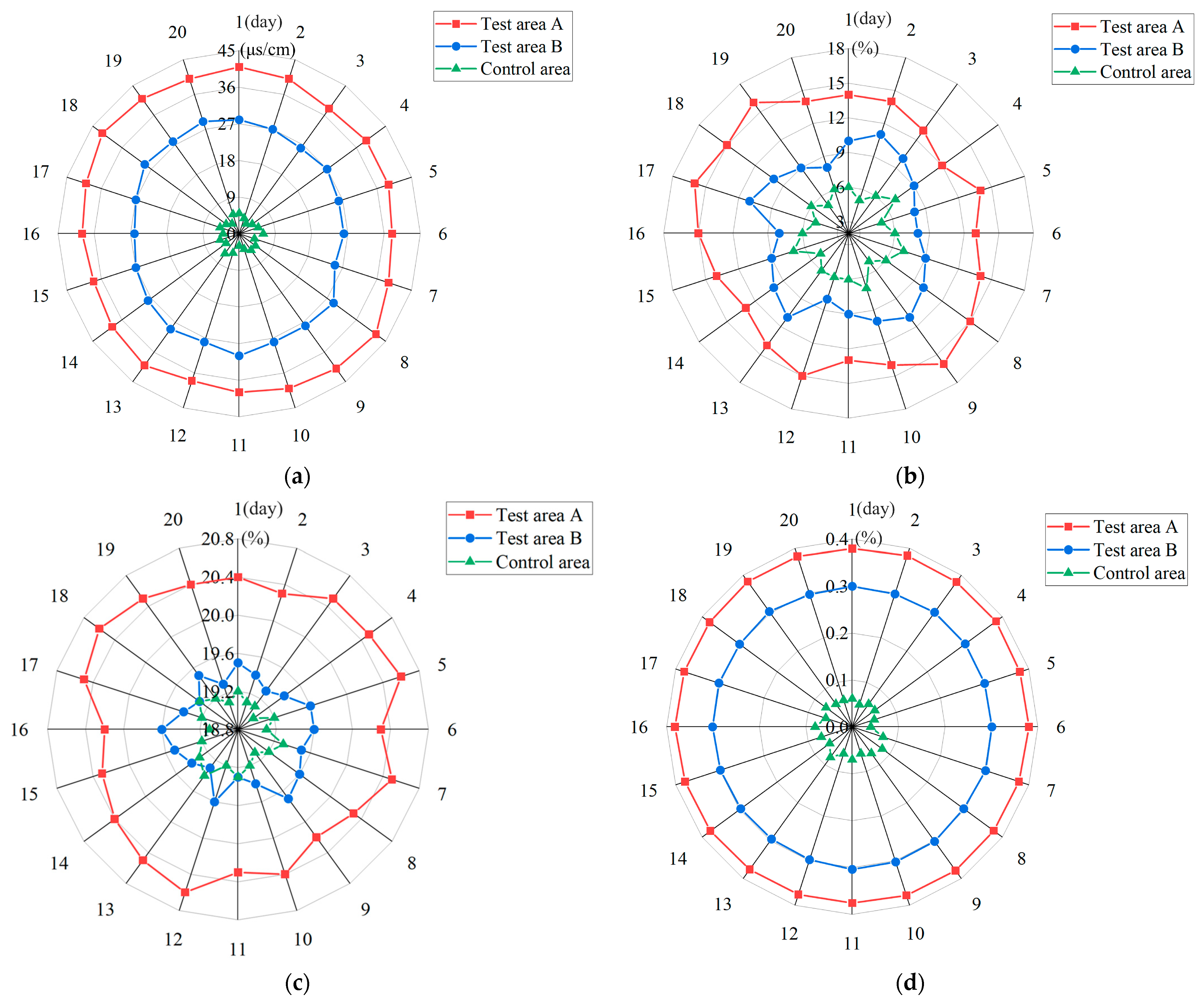

3.2. Analysis and Evaluation of Engineering Ecological Protection in Mud Films of the Naturally Weathered Soil of Red Beds

3.3. Improvement Principles and Control Elements of Mud Films of the Weathered Soil of Red Beds

3.3.1. The Film-Forming Principle of Mud Films of the Naturally Weathered Soil of Red Beds

3.3.2. Control Elements of Mud Films of the Natural Weathered Soil of Red Beds Based on Self-Developed New Composite Materials

4. Conclusions

- (1)

- The self-developed new composite material has a good improvement effect on the self-sustainability of mud films of the natural weathered soil of red beds. After undergoing constant temperature and cyclic tests on self-made new composite materials, mud films of the naturally weathered soil of red beds with the addition of wood fibres have the best high-temperature resistance effect, while mud films of the naturally weathered soil of red beds with the addition of thin fibres have the weakest high-temperature resistance effect. Mud films of the natural weathered soil of red beds with the addition of thin fibres have the best low-temperature resistance effect, while mud films of the natural weathered soil of red beds with the addition of colloidal fibres have the weakest low-temperature resistance effect. Research has shown that self-developed new composite materials have good improvement effects on mud films of the naturally weathered soil of red beds, promoting research on the self-sustaining green environmental improvement methods of mud films of the natural weathered soil of red beds.

- (2)

- Through on-site testing, the addition of self-developed new composite materials to mud films of the naturally weathered soil of red beds and the absence of materials to mud films of the naturally weathered soil of red beds promote vegetation growth. The addition of self-developed new composite materials to mud films of the naturally weathered soil of red beds has a better effect, verifying the ecological protection effect of mud films of the naturally weathered soil of red beds based on the new composite material.

- (3)

- The control factors for the self-sustainability of mud films of the naturally weathered soil of red beds based on self-developed new composite materials are the type and quality proportion of materials, which can be promoted and applied to ecological protection projects, such as slopes and mines.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, C.; Liu, Z.; Xue, Y.; Li, Y.; Fan, X.; Chen, W.; Sun, P. Some thoughts on basic research of red beds disaster. J. Eng. Geol. 2023, 31, 689–705. (In Chinese) [Google Scholar] [CrossRef]

- Yan, P.; Lin, K.R.; Wang, Y.R.; Tu, X.J.; Bai, C.M.; Yan, L.B. Assessment of Influencing Factors on the Spatial Variability of SOM in the Red Beds of the Nanxiong Basin of China, Using GIS and Geo-Statistical Methods. ISPRS Int. J. Geo-Inf. 2021, 10, 366. [Google Scholar] [CrossRef]

- Zhou, C.Y.; Liu, C.H.; Liang, Y.H.; Liu, Z.; Wei, P.C.; Wang, X.D. Application of natural weathered red-bed soil for effective wall protection filter-cake formation. Mater. Lett. 2020, 258, 4. [Google Scholar] [CrossRef]

- McFarlane, D. Soil Conservation Research in New South Wales and Its Significance to Research on Water Erosion in Western Australia Recommended Citation; Department of Primary Industries and Regional Development: Perth, Australia, 1984.

- Sui, B.Y.; Dang, X.H.; Fan, L.X.; Guo, B.; Bi, W.; Liu, G.B. Interactions between soil conservation and dryland farming of heterogeneously eroding areas in Loess Hills, China. Int. Soil Water Conserv. Res. 2022, 10, 574–585. [Google Scholar] [CrossRef]

- Hefner, M.; Labouriau, R.; Norremark, M.; Kristensen, H.L. Controlled traffic farming increased crop yield, root growth, and nitrogen supply at two organic vegetable farms. Soil Tillage Res. 2019, 191, 117–130. [Google Scholar] [CrossRef]

- Kim, S.H.; Tonon, F. Face stability and required support pressure for TBM driven tunnels with ideal face membrane—Drained case. Tunn. Undergr. Space Technol. 2010, 25, 526–542. [Google Scholar] [CrossRef]

- Cheruiyot, W.K.; Wang, W.; Zhu, S.G.; Kavagi, L.; Zhang, X.C.; Mburu, D.M.; Ma, M.S.; Munyasya, A.N.; Koskei, K.; Indoshi, S.N.; et al. Environmental and Economic Impacts of Biodegradable Plastic Film Mulching on Rainfed Maize: Evaluations on Sustainability and Productivity. ACS Agric. Sci. Technol. 2022, 2, 908–918. [Google Scholar] [CrossRef]

- Zhang, X.L.; Zhao, Y.Y.; Zhang, X.T.; Shi, X.P.; Shi, X.Y.; Li, F.M. Re-used mulching of plastic film is more profitable and environmentally friendly than new mulching. Soil Tillage Res. 2022, 216, 11. [Google Scholar] [CrossRef]

- Wang, J.M.; Liu, H.; Wu, X.H.; Li, C.S.; Wang, X.L. Effects of different types of mulches and legumes for the restoration of urban abandoned land in semi-arid northern China. Ecol. Eng. 2017, 102, 55–63. [Google Scholar] [CrossRef]

- Rajasekaran, G.; Rao, S.N. Compressibility behaviour of lime-treated marine clay. Ocean Eng. 2002, 29, 545–559. [Google Scholar] [CrossRef]

- Kaniraj, S.R.; Havanagi, V.G. Compressive strength of cement stabilized fly ash-soil mixtures. Cem. Concr. Res. 1999, 29, 673–677. [Google Scholar] [CrossRef]

- Shirazi, H. Field and laboratory evaluation of the use of lime fly ash to replace soil cement as a base course. In Proceedings of the Seventh International Conference on Low-Volume Roads, Baton Rouge, LA, USA, 23–26 May 1999; Planning, Administration, and Environment; Design; Materials, Construction, and Maintenance; Operations and Safety; Louisiana Transportation Research Centre: Baton Rouge, LA, USA, 1999; Volume 1, pp. 270–275. [Google Scholar]

- Miller, G.A.; Azad, S. Influence of soil type on stabilization with cement kiln dust. Constr. Build. Mater. 2000, 14, 89–97. [Google Scholar] [CrossRef]

- Li, Q.B.; Wang, J.Z.; Wang, G.J.; Liu, Q.L.; Yan, C.B. Evaluation of Lithology Variations in Layered Red Beds with Depth: An Example of the Yellow River Guxian Dam, NW China. Lithosphere 2021, 2021, 14. [Google Scholar] [CrossRef]

- Liu, J.; Shi, B.; Lu, Y.; Jiang, H.T.; Huang, H.; Wang, G.H.; Kamai, T. Effectiveness of a new organic polymer sand-fixing agent on sand fixation. Environ. Earth Sci. 2012, 65, 589–595. [Google Scholar] [CrossRef]

- Ma, G.F.; Ran, F.T.; Feng, E.K.; Dong, Z.B.; Lei, Z.Q. Effectiveness of an Eco-friendly Polymer Composite Sand-Fixing Agent on Sand Fixation. Water Air Soil Pollut. 2015, 226, 12. [Google Scholar] [CrossRef]

- Nalbantoglu, Z.; Gucbilmez, E. Improvement of calcareous expansive soils in semi-arid environments. J. Arid. Environ. 2001, 47, 453–463. [Google Scholar] [CrossRef]

- Al-Rawas, A.A.; Hago, A.W.; Al-Sarmi, H. Effect of lime, cement and Sarooj (artificial pozzolan) on the swelling potential of an expansive soil from Oman. Build. Environ. 2005, 40, 681–687. [Google Scholar] [CrossRef]

- Basha, E.A.; Hashim, R.; Mahmud, H.B.; Muntohar, A.S. Stabilization of residual soil with rice husk ash and cement. Constr. Build. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef]

- Kolias, S.; Kasselouri-Rigopoulou, V.; Karahalios, A. Stabilisation of clayey soils with high calcium fly ash and cement. Cem. Concr. Compos. 2005, 27, 301–313. [Google Scholar] [CrossRef]

- Edil, T.B.; Acosta, H.A.; Benson, C.H. Stabilizing soft fine-grained soils with fly ash. J. Mater. Civ. Eng. 2006, 18, 283–294. [Google Scholar] [CrossRef]

- Jauberthie, R.; Rendell, F.; Rangeard, D.; Molez, L. Stabilisation of estuarine silt with lime and/or cement. Appl. Clay Sci. 2010, 50, 395–400. [Google Scholar] [CrossRef]

- Masto, R.E.; Ansari, M.A.; George, J.; Selvi, V.A.; Ram, L.C. Co-application of biochar and lignite fly ash on soil nutrients and biological parameters at different crop growth stages of Zea mays. Ecol. Eng. 2013, 58, 314–322. [Google Scholar] [CrossRef]

- Phetchuay, C.; Horpibulsuk, S.; Arulrajah, A.; Suksiripattanapong, C.; Udomchai, A. Strength development in soft marine clay stabilized by fly ash and calcium carbide residue based geopolymer. Appl. Clay Sci. 2016, 127, 134–142. [Google Scholar] [CrossRef]

- Onyejekwe, S.; Ghataora, G.S. Soil stabilization using proprietary liquid chemical stabilizers: Sulphonated oil and a polymer. Bull. Eng. Geol. Environ. 2015, 74, 651–665. [Google Scholar] [CrossRef]

- Kukal, S.S.; Kaur, M.; Bawa, S.S.; Gupta, N. Water-drop stability of PVA-treated natural soil aggregates from different land uses. Catena 2007, 70, 475–479. [Google Scholar] [CrossRef]

- Liu, J.; Shi, B.; Jiang, H.T.; Bae, S.Y.; Huang, H. Improvement of water-stability of clay aggregates admixed with aqueous polymer soil stabilizers. Catena 2009, 77, 175–179. [Google Scholar] [CrossRef]

- Diacono, M.; Montemurro, F. Long-Term Effects of Organic Amendments on Soil Fertility; Springer: Dordrecht, The Netherlands, 2011; pp. 761–786. [Google Scholar] [CrossRef]

- Liu, J.; Shi, B.; Jiang, H.T.; Huang, H.; Wang, G.H.; Kamai, T. Research on the stabilization treatment of clay slope topsoil by organic polymer soil stabilizer. Eng. Geol. 2011, 117, 114–120. [Google Scholar] [CrossRef]

- Rahmat, M.N.; Ismail, N. Sustainable stabilisation of the Lower Oxford Clay by non-traditional binder. Appl. Clay Sci. 2011, 52, 199–208. [Google Scholar] [CrossRef]

- Sukmak, P.; Horpibulsuk, S.; Shen, S.L. Strength development in clay-fly ash geopolymer. Constr. Build. Mater. 2013, 40, 566–574. [Google Scholar] [CrossRef]

- Marto, A.; Latifi, N.; Eisazadeh, A. Effect of Non-Traditional Additives on Engineering and Microstructural Characteristics of Laterite Soil. Arab. J. Sci. Eng. 2014, 39, 6949–6958. [Google Scholar] [CrossRef]

- Zhang, J.H.; Soltani, A.; Deng, A.; Jaksa, M.B. Mechanical Performance of Jute Fiber-Reinforced Micaceous Clay Composites Treated with Ground-Granulated Blast-Furnace Slag. Materials 2019, 12, 576. [Google Scholar] [CrossRef] [PubMed]

- Akbarimehr, D.; Rahai, A.; Eslami, A.; Karakouzian, M. Deformation Characteristics of Rubber Waste Powder-Clay Mixtures. Sustainability 2023, 15, 12384. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, Z.; Zhou, C.Y. Study on the properties of mud films derived from naturally weathered red-bed soil under pressureless conditions. PLoS ONE 2022, 17, 26. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Liu, Z.; Zhou, C.Y. Classification and Zoning of Improved Materials of Weathered Redbed Soil in China Based on the Integrity of Mud Skin. Sustainability 2023, 15, 6486. [Google Scholar] [CrossRef]

| Self-Developed New Composite Materials | Viscosity (Pa s) | Density (g/cm3) |

|---|---|---|

| Wood fibre | 70.2 | 1.3 |

| Flake fibre | 65.3 | 1.5 |

| Colloidal fibre | 61.8 | 1.8 |

| Lightweight fibre | 62.6 | 1.1 |

| Material Type | Adhesive | Mineral Materials | Construction Material | Plant Materials | Cellulose | Self-Developed New Composite Materials | |||

|---|---|---|---|---|---|---|---|---|---|

| Maximum improvement in thin-layer properties (%) | No. 1 (780) | Albite (579) | Environmentally friendly adhesive (640) | Wheat straw (495) | HBR cellulose (690) | Wood fibre (850) | Flake fibre (975) | Colloidal fibre (1050) | Lightweight fibre (925) |

| Minimal improvement in thin-layer properties (%) | No. 4 (190) | Feldspar (166) | Air-entraining agents (81.5) | Corn straw (31.5) | HHBR cellulose (150) | Wood fibre (175) | Flake fibre (170) | Colloidal fibre (260) | Lightweight fibre (195) |

| Maximum improvement in corrosion resistance (acid resistance) (%) | No. 2 (91.7) | Feldspar (86.7) | Thickener (91.7) | Wormwood straw (55) | HBR cellulose (68.3) | Wood fibre (90) | Flake fibre (80) | Colloidal fibre (88.3) | Lightweight fibre (75) |

| Minimal improvement in corrosion resistance (acid resistance) (%) | No. 1 (20) | Albite (13.3) | Environmentally friendly adhesive (20) | Rice straw (−13.3) | HHBR cellulose (−3.3) | Wood fibre (21.7) | Flake fibre (11.7) | Colloidal fibre (6.6) | Lightweight fibre (16.7) |

| Maximum improvement in corrosion resistance (alkali resistance) (%) | No. 1 (68.8) | Nano-silica (65) | Drought strengthening agent (45) | Yangmei Tannin Extract (65) | HHR cellulose (52.1) | Wood fibre (50) | Flake fibre (41.25) | Colloidal fibre (53.8) | Lightweight fibre (70) |

| Minimal improvement in corrosion resistance (alkali resistance) (%) | No. 6 (15) | Nano-silica (10) | Putty (9.8) | Potato straw (10) | HHBR cellulose (−2.5) | Wood fibre (−6.2) | Flake fibre (3.75) | Colloidal fibre (5) | Lightweight fibre (2.5) |

| Maximum improvement in flexibility (%) | No. 7 (187.5) | Feldspar (150) | Putty (225) | Sweet potato straw (112.5) | HHR cellulose (187.5) | Wood fibre (250) | Flake fibre (325) | Colloidal fibre (350) | Lightweight fibre (300) |

| Minimal improvement in flexibility (%) | No. 5 (125) | Albite (50) | Water-reducing agent (100) | Pine straw (25) | HBR cellulose (75) | Wood fibre (100) | Flake fibre (162.5) | Colloidal fibre (137.5) | Lightweight fibre (125) |

| Name | The Percentage of the Added Self-Developed New Composite Material in the Total Mass of Mud Films of the Natural Weathered Soil of Red Beds (%) |

|---|---|

| Flake fibre | 0, 20, 40, 60, 80 |

| Wood fibre | 0, 20, 40, 60, 80 |

| Lightweight fibre | 0, 20, 40, 60, 80 |

| Colloidal fibre | 0, 20, 40, 60, 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Wang, J.; Gao, Y.; Liao, J.; Lan, C.; Zhou, C. Development of Self-Sustaining Improvement Material for a Mud Film of the Weathered Soil of Red Beds. Sustainability 2023, 15, 15284. https://doi.org/10.3390/su152115284

Liu Z, Wang J, Gao Y, Liao J, Lan C, Zhou C. Development of Self-Sustaining Improvement Material for a Mud Film of the Weathered Soil of Red Beds. Sustainability. 2023; 15(21):15284. https://doi.org/10.3390/su152115284

Chicago/Turabian StyleLiu, Zhen, Jingqi Wang, Yi Gao, Jin Liao, Chunhui Lan, and Cuiying Zhou. 2023. "Development of Self-Sustaining Improvement Material for a Mud Film of the Weathered Soil of Red Beds" Sustainability 15, no. 21: 15284. https://doi.org/10.3390/su152115284

APA StyleLiu, Z., Wang, J., Gao, Y., Liao, J., Lan, C., & Zhou, C. (2023). Development of Self-Sustaining Improvement Material for a Mud Film of the Weathered Soil of Red Beds. Sustainability, 15(21), 15284. https://doi.org/10.3390/su152115284