1. Introduction

Carbon dioxide (CO

2) is the most problematic greenhouse gas (GHG) and contributes significantly to global warming. The global cement industry is responsible for 27% of total direct CO

2 emissions, making it the second-largest CO

2 producer of the industrial sectors [

1]. The cement industry is expected to grow between 12 and 23% from 2005 to 2050, a disproportionate amount of this growth occurring among non-OECD countries, which could increase total global CO

2 emissions by 4% in that time [

2]. The updated synthesis report of nationally determined contributions reveals a worrying trend of a GHG increase of about 16% as opposed to a 45% reduction by 2030 [

3]. The reduction target of 45% for CO

2 emissions, keeping the global temperature increase below 2 degrees, and net-zero emissions cannot be achieved if a highly energy-intensive sector such as cement does not take measures to reduce CO

2 emissions [

4].

Cement is used as glue in concrete, a building material that is second only to water in the total annual volume of consumption [

5]. The International Energy Agency (IEA) has predicted annual cement production to be 4.4 billion tonnes in 2050. In reality, however, global cement production was already 4.1 billion tonnes in 2020 [

6]. The cement production and processing industry is the second-largest energy-intensive sector after heating and cooling, and thus contributes significantly to GHG emissions. In the cement sector, the direct emissions from energy and other sources account for 20% of total emissions, while the indirect emissions from the production of electricity and heat together with the fuels purchased and used account for 40–50% of total emissions [

4]. Moreover, the calcination of limestone in cement production also triggers large amounts of CO

2 emissions [

7]. It is therefore of utmost importance that the cement industry adopts decarbonisation strategies and reduces CO

2 emissions in their production processes.

Carbon emissions in cement production can be reduced in several ways, including increasing the use of renewable energies to reduce energy-related emissions, improving clinker production efficiency to reduce process emissions, and developing carbon capture–utilisation–storage mechanisms [

8,

9]. Another effective path to CO

2-emissions reductions is to replace cement with alternative materials, such as geopolymer, which uses waste materials and by-products and contributes less to global warming [

7]. However, the actual practice of carbon reduction in cement production is limited due to the reluctance of the industry to compromise on clinker quality and the performance characteristics of cement [

8].

Although China is the biggest producer and user of cement, the high growth of other developing countries means that they are also consuming large quantities of cement to build infrastructure [

10]. Increasing cement consumption is also referred to as a development indicator [

11,

12]. Consequently, Bildirici [

13] purports that cement production has a critical impact on CO

2 emissions and economic growth. Comparatively, CO

2 emissions from cement production are greater in developing countries than in developed countries because of greater reliance on nonrenewable energy sources (e.g., oil, coal, gas) [

2]. For instance, China’s CO

2 emissions have decelerated due to the country’s commitment towards low-carbon transitions [

14]. While CO

2 emissions in advanced economies are projected to decline steadily by about one-third between 2020 and 2050, CO

2 emissions are expected to grow in emerging economies by almost 20% by the mid-2040s. This is because of increased population, economic growth, rapid urbanisation, and infrastructure expansion [

4]. Consequently, there is a need to learn about CO

2-emission-reduction potentials in emerging economies.

This paper answers the following research questions (RQs) to address the aforementioned issues:

RQ1: What are the CO2 emission factors of the cement manufacturing process in the context of an emerging economy?

RQ2: What are the most important factors that influence the CO2 emissions in the cement manufacturing industries in an emerging economy?

To answer RQ1, an extensive literature review is conducted using the Scopus and Web of Science databases. RQ2 is answered using the Bangladesh cement industry as a case study. This study considers the Bangladeshi cement industry for several reasons. To begin, cement manufacturing in Bangladesh constitutes a noteworthy source of the country’s total carbon emissions. In recent years, there has been significant expansion in both the local and international cement markets [

15]. The compound annual growth rate for the past seven years has reached approximately 11.5%, indicating promising prospects for potential investments and business expansion in the future [

16]. In 2018, the per capita cement usage stood at 184 kg, almost twice the per capita consumption recorded in 2011 [

17]. Sunny et al. [

18] found that within the Dhaka division in Bangladesh, the cement sector was a primary source of soil pollution due to the release of dust particles containing heavy metals and air pollution. Additionally, according to Rasul et al. [

19], cement industries in Bangladesh were ranked as the second-largest contributor to air pollution and ninth in terms of chemical pollution. As a result, the cement industry is now compelled to explore sustainable approaches to mitigate its adverse effects on the environment in Bangladesh. Furthermore, the Bangladeshi cement manufacturing sector is under significant international scrutiny to achieve economic, social, and environmental sustainability in alignment with the United Nations’ Sustainable Development Goals [

20]. Therefore, the determination of CO

2 emission factors can play a crucial role in this endeavour.

This research identifies ten CO

2 emission factors from the literature and ranks them by applying the Bayesian best–worst method (BWM). The Bayesian BWM is a new benchmarking and multicriteria decision-making (MCDM) method based on various performance indicators [

21]. Compared to widely used MCDM procedures, such as the analytic hierarchy process, the BWM offers fewer pairwise evaluations but more consistent calculations of subcriteria and main criteria [

22,

23].

The rest of the paper is structured as follows.

Section 2 reviews and identifies CO

2 emission factors in the cement industry. The following section presents the methodology and model implementation.

Section 4 presents the results and discusses the findings.

Section 5 highlights the theoretical, managerial, and policy implications of the study. The final section summarises the study, highlights limitations, and provides direction for future research.

2. Literature Review

This section summarises the CO

2 emission factors and studies in the cement industry. Cement production comprises three main steps: kiln feed preparation, clinker production, and cement manufacturing [

24].

Figure 1 shows the cement production process along with sources of CO

2 emissions.

During cement production, CO

2 is released from four different sources: emissions from the calcination of calcium carbonate, combustion of fossil fuel, electricity usage for transporting raw materials, and operation of electrical motors and facilities [

26,

27]. The calcification of calcium carbonate and combustion of fossil fuels are considered direct emissions and account for 90% of total emissions. A large part of the emissions (nearly 50–60%) result from the breakdown of limestone (CaCO

3), which yields lime (CaO) as the vital element in cement formulations [

28]. Burning fossil fuels in high-temperature processing units (preheaters, calciners, furnaces) accounts for 30–40% of the overall CO

2 [

28]. Electricity-related emissions are referred to as indirect emissions and represent 10% of total emissions [

29,

30]. Emissions from the calcification of calcium carbonate are also considered process emissions and consist of raw-material drying and pyroprocessing, whereas combustion-related emissions include the burning of coal, coke, petroleum, and solid and liquid waste fuels. In contrast, electricity-related emissions are generated by the operation of motors, blowers, and fans for rotating kilns, heating, drying, and the grinding of materials and clinkers [

31].

Several mechanical inadequacies in the traditional cement manufacturing process led to additional CO

2 emissions. Such inadequacies reduce plant performance, result in additional fuel and power consumptions, produce more waste heat, and increase CO

2 emission levels. According to Benhelal et al. [

28], the leading reasons for excess CO

2 emissions from the cement industry are (a) using inefficient systems, (b) losing heat through the exhaust streams, (c) utilising poor quality raw materials and carbon-extensive fossil fuels, (d) producing cement with a high percentage of clinker, and (e) using inefficient and outdated types of machinery.

Multiple factors contribute to the carbon emissions in the cement industry. The importance and priority of these factors may vary according to the manufacturing process of the particular cement industry. Based on the literature, ten carbon emission factors for the cement industry are identified and summarised in

Table 1.

3. Methodology

This paper adopts a mix-method methodology to identify and rank the most significant carbon emission factors in the cement industry.

Figure 2 explains the step-by-step procedure adopted in the article. Ten CO

2 emission factors were initially identified, scrutinising the literature and followed by feedback from the industry experts. Ten factors were then extracted and classified into direct and indirect emission factors, and the Bayesian BWM was utilised to specify the position of the emission factors and rank them according to importance. The BWM allows decision-makers to determine the best (i.e., the most essential and desirable), and worst (i.e., the least necessary and desirable factors). The BWM also requires the performance of a pairwise evaluation between best–worst factors and other factors. The rationale for using the BWM is its superior performance when prioritising strategies with incomplete and ambiguous information [

22,

23].

3.1. Expert Selection

This section evaluates the CO

2 emission factors for Bangladesh cement manufacturing with the proposed methodology. Data for the model were collected from seven experts working for seven local and multinational cement companies in Bangladesh. The names of the companies are not disclosed to protect privacy and maintain confidentiality. The criteria for selecting an expert encompassed familiarity with the cement industry, possession of a minimum of a bachelor’s degree, proficiency in carbon-emission matters, and a minimum of five years experience in the pertinent field. A seven-respondent sample is deemed sufficient for three reasons [

43]. First, MCDM research is not based on statistical inferences. Consequently, it is not necessary to have many respondents. Second, the quality of the information is more important than is the quantity, and it is ensured by selecting respondents with more than ten years of experience and university education. Third, data saturation in the MCDM study is typically achieved using a small number of interviewees.

Table 2 reports the demographic profile of the seven respondents.

3.2. Model Development

In this study, the Bayesian BWM is utilised to determine the most important direct and indirect CO

2 emission factors. The Bayesian BWM is applied in the following six stages [

21,

44]:

Step 1: Understanding the specific decision factors

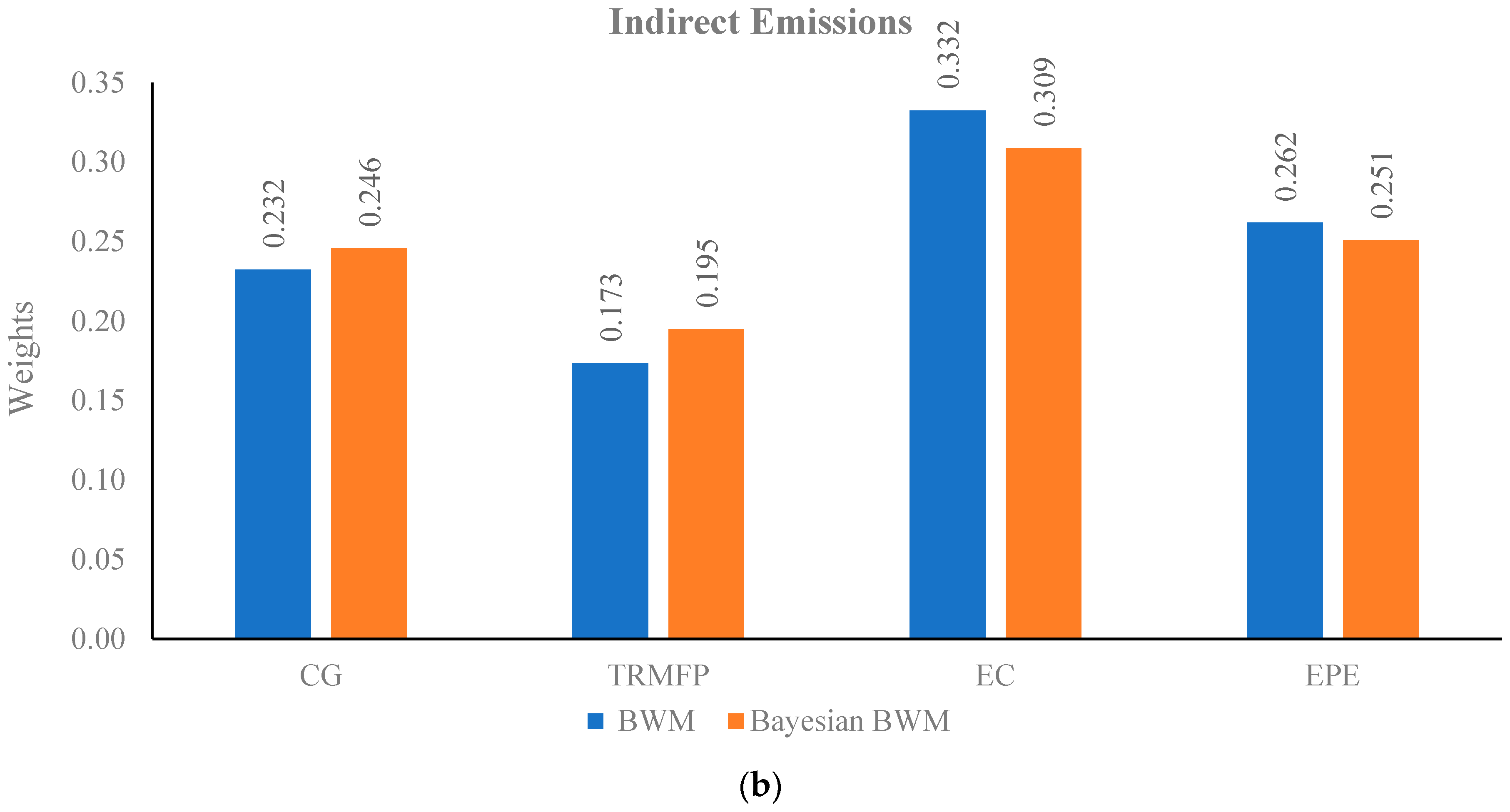

In this step, based on the existing literature and interviews with numerous experts, the 10 most significant sources of cement industry carbon emissions are identified. These factors are divided into direct and indirect CO2 emission factors: raw materials (RM), clinker reaction (CR), clinker quality (CQ), heating the raw ingredients (HTRI), organic and inorganic carbon in the fuel (OICITF), fuel burning (FB), cement grinding (CG), transport of raw materials and finished products (TRMFP), electricity consumption (EC), and external production of electricity (EPE).

Step 2: Identifying the worst (W) and best (B) decision factors and sub-factors

In this step, the best (

B) and worst (

W) direct and indirect CO

2 emission factors are identified based on feedback from the experts or respondents [

21].

Step 3: Evaluating the best factor (B) with other factors (j)

Once the best direct and indirect CO

2 emission factors (

B) are identified, the respondents compare them (

B) with the remaining factors on a nine-point scale presented in

Table 3. One on a nine-point scale means a factor is as essential as the other, whereas nine means a factor is more important than the other. The outcome of this step is the best vector (

BO) or

AB = (

aB1,

aB2,

aB3, ….…,

aBn), where

aBJ illustrates the favourite of the best factor

B over factor

j, and

aBB = 1. A similar approach was applied for both direct and indirect CO

2 emission factors [

21].

Step 4. Evaluation of worst factor (W) with other factors (j)

After identifying the worst direct and indirect CO

2 emission factors (

W), the respondents may be asked to compare other factors (

j) with the worst factor (

W) using the same 1–9 scale. Similarly, 1 indicates equal priority over the worst, while 9 indicates that another factor has the greatest importance over the worst [

21].

The result was the other-to-worst (OW) vector, as given below:

Aw = (a1W, a2W, …, anW)T, where ajW illustrates the priority of j over the worst factor W, and aWW = 1.

The same approach was applied for both direct and indirect CO2 emission factors.

Step 5. Calculate weights based on optimal group

The optimal weight for each respondent or expert (

wk) is dependent on the two sets of vectors:

and

The group optimal weight

w∗ is also dependent on the optimal weight for each respondent or expert (

wk) [

21].

The calculation of the optimal weights for each respondent

wk,

k = 1,2, ….,

K and the aggregated weights for all respondents

are performed using the Bayesian BWM, as follows [

21]:

where multinomial and Dir denotes a multinomial and Dirichlet distribution, respectively. Gamma (0.1, 0.1) indicates a gamma distribution with the shape parameters of 0.1. Markov-chain Monte Carlo (MCMC) sampling is required to estimate the solution of the probabilistic model.

Step 6. Credal ranking

In this step, the credal ranking is determined to indicate the level to which one CO

2 emission factor is superior to another factor [

46]. The distribution of weights can guide us to assess the reliance on different factors. The confidence of these relationships among different factors can be analysed using the subsequent distribution in the weights (i.e., the Dirichlet distribution of

w*) [

44].

For example, there is a set of factor

ci and

cj being measured. It is essential to understand whether the ranking outcomes of the group weights are consistent with the evaluation of all respondents or experts. To analyse the confidence of this assessment, the concept of credal ranking is used. The probability of

ci being better than

cj can then be expressed as [

21]:

where

is the posterior probability of

and

I is a conditional parameter, which can be measured if

; otherwise, it is 0. The number of samples

Q obtained by MCMC sampling is used to calculate the confidence and the posterior distribution [

21,

44].

where

w* represents

q w*’s from MCMC samples. When

, it implies that factor

i is valued higher than factor

j, and the confidence is represented by the probability. Moreover, the total probability

5. Implication of This Study

One-third of the global CO

2 emissions result from energy usage in the industrial sector [

39]. Evaluating carbon emission factors in the cement industry is a fundamental tool to identify the CO

2 reduction efforts and establish prospective CO

2 reduction targets for the cement industry [

34]. Hence, several implications can be drawn from this study.

Environmental and sustainable issues are major concerns for businesses, governments, and international organisations. Corporate organisations readily strive for sustainable practices as a part of their corporate social responsibility [

48]. CO

2 emission factors increase the adverse environmental impact of industrial activities. Therefore, it is elemental to comprehend the effects of carbon emission factors in the cement industry so that appropriate interventions can be designed to counteract its detrimental impact on the environment. Emerging economies such as Bangladesh are expected to consume large quantities of cement because of their need for infrastructure development during the growth phase.

GHG accumulation in the atmosphere is currently posing a serious environmental threat. CO

2 emissions are the most harmful of the GHGs, and the cement industry is one of the high GHG emitters [

28]. It is therefore of utmost importance that managers working in the cement industry recognise the emission factors and make decisions, taking action accordingly to reduce GHG emissions as much as possible. This research not only identifies the principal emission factors of CO

2 but also ranks the most critical ones. For instance, fuel burning is clearly the highest contributor to the cement industry GHG emissions. Consequently, using high quality fuel can reduce cement industry emissions significantly [

34].

Moreover, using alternative fuels such as biomass and municipal or industrial waste can further reduce CO

2 emissions [

41]. Heating the raw material ingredient is another significant contributor to CO

2 emissions. A massive amount of thermal loss occurs during raw material heating, and such losses can be minimised by improving the cement industry production process [

28]. The use of thermal energy recovery can accomplish much to reduce CO

2 emissions in the cement industry [

39].

In comparison, the transport of the raw materials and finished goods and cement grinding contribute less to CO

2 emissions, meaning that these two factors can be tackled after other critical factors are addressed. Understanding CO

2 emission factors in the cement industry can help policy-makers devise suitable policies for CO

2 reduction, which will help the industry become more climate-friendly [

36].

6. Conclusions

GHG emissions from the cement industry deserve special attention. This paper identifies ten critical carbon emission factors for emerging economies and ranks them using the Bayesian BWM. Fuel burning and heating the raw material ingredients have been found to be the most dominant carbon emission factors among direct emission factors. Among the indirect emission factors, electricity consumption and external production of electricity are the most critical. Emerging economies such as Bangladesh invest heavily in infrastructure, resulting in disproportionate cement consumption. Because of the high energy usage in the cement industry combined with the significant release of CO2 from the raw materials, governments and policy-makers in emerging economies must scrutinise the emission factors. Unless proper policies are implemented, high economic growth accompanied by increased consumption of cement will substantially damage the climate.

The contribution of this study can be summarised as follows:

This research identifies ten carbon emission factors in the cement industry through an extensive literature review.

The study then verifies these carbon emission factors using expert opinions.

It also ranks the factors using the Bayesian BWM.

The research then compares the Bayesian BWM with the BWM and demonstrates how the Bayesian BWM produces superior results.

The study also illustrates the relative importance of the factors using credal diagrams.

Despite the valuable contributions of this study, it does come with certain limitations. Firstly, in the Bayesian BWM approach, the participating experts who provide evaluations are not assigned experience coefficients and are considered equally important. While the inclusion of seven experienced experts is typically sufficient for a multicriteria decision-making model of this kind, future researchers may consider obtaining feedback from a larger pool of experts to enhance the generalisability of the findings. Another limitation is the potential for the results of this research to be specific to the geographical context of this study. However, the methodology employed in this study is generic and can be replicated in other emerging economy settings like China, India, Brazil, and Pakistan. Future research can validate the findings reported here in these contexts.

This research can benefit substantially from future research. For instance, CO

2 emission factors for other energy-intensive industries, such as steel and iron, can be studied. Methodologically, it will be interesting to explore and compare results with those from the fuzzy grey theory. Future research can also examine the CO

2 emission factors for other high-emission sectors, such as the electricity, heat, and transport sectors. In the future, efforts are needed to find alternative materials to cement, such as cementitious tile adhesive [

49], recycled clay-brick waste [

50], circulating fluidised bed combustion ash, and rice-husk ash [

51] to reduce the use of cement in the construction industry. This is because energy consumption is the fundamental cause of greenhouse gas emissions [

52]. Because the cement industry is a high-energy-intensive industry, reducing the use of cement as a construction material will reduce the overall cement production worldwide. Furthermore, in the future, developing countries such as Bangladesh may introduce green tax policies, which are helping countries like China to reduce CO

2 emissions substantially [

53].