Abstract

Among the construction products manufactured with Portland cement (PC) are (in addition to hydraulic concrete) construction blocks. These elements are used as masonry materials for the elaboration of walls in all types of construction. For the elaboration of these elements, large amounts of geomaterials such as sand are utilized. The aim of this investigation was to reduce the consumption of geomaterials using block manufacturing that incorporates construction and demolition waste as a substitute for gravel and tire flakes as a substitute for sand. These blocks were characterized by their resistance in a compression test, flexion, modulus of elasticity, electrical resistivity, moisture absorption, and MEB microscopy, as well as an analysis of the unit price for different mixtures. The results show that the addition of tire flakes severely decreased the blocks’ physical-mechanical performance and increased the production costs, while the incorporation of 50% construction and demolition waste achieved a performance very close to that of the control blocks and presented improvements in the modulus of elasticity, although the costs could be higher than those for the control blocks.

1. Introduction

The urgent need for affordable and durable housing means that many people self-build. The first way to establish an intimate or private space is to erect masonry walls, which may or may not later have a roof attached to protect people from the environment. On the other hand, the accelerated growth of cities and the urbanization of spaces has led to the demolition of numerous buildings to create spaces for new buildings [1,2].

The demand for buildings is increasing day by day. According to statistics, in 2018, the total investment in the construction industry (public and private) was USD 11.4 billion, and it is estimated that by 2025, it will be USD 14 billion, which translates into a greater need for materials such as cement, aggregates, steel, and wood [3], in the case of natural aggregates (gravels and sands), which could be replaced with residues, such as those from concrete demolition. These usually come from nonrenewable natural resources. This industry has significant impacts on the use of water (50%) and energy (45–50%) and the loss of agricultural land (80%), among others [3,4]. In addition, there are challenges such as avoiding the generation of greenhouse gases, reusing materials, recycling materials to avoid the exploitation of geomaterials from nearby material banks, avoiding the accumulation of solid waste, aiding the circular economy, and supporting communities in their need for housing.

It has been observed that the use of fine aggregates directly impacts the environment, mainly in the case of extraction sources such as rivers and banks formed of materials of volcanic origin. In some countries, the use of these materials has begun to be banned due to the impact on ecosystems and the environment [5]. In addition, demolition waste is placed in cleared areas where aquifers could be recharged; this has not only led to problems, including a lack of space to store large amounts of materials, but also to environmental and social problems since most of this waste is deposited in rural or unpopulated areas, which makes it difficult to reuse [6,7].

The use of demolition materials has begun to boom due to the increasing quantities of materials resulting from the demolition of old buildings, in which geomaterials that are currently scarcer were used [8,9]. In the elaboration of concrete or mortars, aggregates represent more than 70% of their volume; therefore, the use of recycled materials may have a significant impact [10].

Demolition waste can be classified into three categories: (1) difficult to use or recycle; (2) not possible to use directly (requiring some treatment or process); and (3) easy to reuse or recycle, including asphalt, tiles, concrete, blocks, stones and materials used in floors [11,12]. In order to make use of these materials, it is important to know their properties and whether they can be used in accordance with international construction standards. Knowing the capabilities of these materials, in terms of their volumes and generation locations, in relation to the improvements in the physical and mechanical properties of the composites into which they could be incorporated, can help to define their appropriate use. The use of waste from construction and demolition opens up new prospects in the development of new and better materials [13]. Although a decrease in properties has been reported [14], there is a study reporting the feasibility of using construction and demolition waste as aggregates for the manufacture of concrete blocks, replacing 80% of the natural aggregates with recycled ones, which generates a reduction in compressive strength.

One way to compensate for these decreases in resistance is the use of alkaline activators. Zubair and Mahmood studied the effect of adding ground granulated blast furnace slag, fly ash, and a NaOH activator on recycled aggregate concrete mixes to construct blocks achieving mechanical improvements [15]. Liu et al. reported the influence of the recycled aggregate–sand ratio, active activator content, and fly ash on the compressive strength of insulating concrete blocks, achieving the highest strength with 45% sand [16]. Rojas-Valencia et al. compared concrete blocks composed of different proportions of waste, such as construction and demolition waste (CDW), PET flakes, tire dust, and cane bagasse ash [17]. The results indicate that concrete blocks with PET and CDW meet the Mexican compression standards for these types of elements.

Another locally abundant residue is tires. Michoacan, Mexico, has a large vehicle fleet, with 21.95% concentrated in the capital, Morelia. The vehicle fleet in 2002 was around 800 thousand vehicles. It doubled in a decade, and by 2012, it was 1,750,000. Of these vehicles, 49.4% were cars, 44.1% were trucks and cargo vans, 5.9% were motorcycles, and the remaining 0.7% were passenger buses [18,19]. In 2021, there were 2,631,755 motor vehicles in Michoacán [20].

Tire residues have been studied by various researchers. Fraile-Garcia et al. analyzed the acoustic performance of blocks, lattice joists, and hollow concrete blocks doped with rubber in proportions of 0–20% [21]. They found that as rubber doping increases, so does the isolation of low-frequency sounds such as those emitted by heavy trucks and dogs, among other sources, while intermediate doping (10%) presents better isolation for medium and high frequencies. Gerges et al., Sambucci, and Valente studied the feasibility of using ground rubber powder and granules as aggregates in concrete pavers [22,23]. They reported a decrease in compressive strength, but it was possible to maintain flexural strength and improved its toughness, deformation capacity, acoustic insulation, and ductile plastic failure.

Rocha et al. incorporated 0.75% and 1.5% of steel fibers from ground tires to concrete blocks, reporting an increase of 20% for the mixture with 1.5% steel fibers added, complying with the minimum standards of Colombian, Spanish, French, and New Zealand regulations [24].

Several investigations have used different substitutions in the manufacture of blocks, cobblestone, or block, thereby contributing to sustainable construction, and they have used a wide variety of residues and incorporation methods. Tarek et al. reported thermal improvements in blocks that incorporate ferrosilicon and aluminum slag [25]. Gao et al. used super-thin-layer mortar smeared on both sides of sintered blocks, achieving 84% and 89% of a high-cost commercial mortar [26]. Different substitutions have also been studied in the manufacture of pavers such as low-calcium and granulated blast furnace slag [27], steel slag powder [28], rice husk ash [29], processed waste tea ash [30], steel fibers [31,32], crushed glass and granulated blast furnace slag [33], shredded plastic waste, powdered ceramic waste [34], olive wood waste [35], and fly ash and microsilica [36].

This research focuses on the study of the behavior of building blocks composed of CDW and tire flakes. The work was carried out in the city of Morelia, Michoacán, Mexico. The CDW from a closed state prison “Francisco J. Múgica Social Readaptation Center” was taken as the sampling material and sent for characterization and study. The CDW added to the mixes has a life of more than 60 years. The materials were analyzed with the intention of determining their feasibility of incorporation in the production of partition walls as a substitute for natural aggregates and thus achieve multiple benefits, including environmental, economic, and social benefits.

2. Materials and Methods

2.1. Stone Materials

In this study, the stone materials used were silt as a fine aggregate, with a fineness module of 2.25, and volcanic gravel with a nominal maximum size of 3/8 inch; see Figure 1. These materials are commonly used in the production of cement-based blocks.

Figure 1.

Stone aggregates: silt (left) and gravel (right).

Silt: This material comes from the “Mr. Enrique” material bank located in the region of Zinapécuaro, Michoacán (coordinates: 9°52′41.8″ N 100°52′52.4″ W).

Gravel: This granular material was obtained from the “Cerritos” bank of material located on the Morelia–Guadalajara highway, Michoacán (coordinates: latitude 19°41′41″ N and longitude 101°16′43″ W).

Both materials (silt and gravel) were characterized according to current standards with the following tests:

- -

- Absorption humidity (ASTM C127-15 [37]);

- -

- Specific gravity or saturated relative density (ASTM C127-15 [37]);

- -

- Dry and loose volumetric mass (MVSS) (ASTM C29/C29M-07 [38]);

- -

- Compacted dry volumetric mass (MVSC) (ASTM C29/C29M-07 [38]);

- -

- Granulometry or particle size analysis (ASTM C 136/C 136M-19 [39]).

2.2. Cement

The PC was obtained from a national distributor; it is a fast CPC 40R cement, according to the NMX-C-414-2017 standard [40].

2.3. Water

The water used in this study was obtained from a well in the place where the facilities of the company specialized in the manufacture and sale of partitions are located, in Morelia, Michoacán.

2.4. Construction and Demolition Waste (CDW)

The origin of construction and demolition waste (CDW) comes from the demolition of buildings and infrastructure, rehabilitation and restoration of existing buildings and structures, and residues from the production of building materials. However, its composition varies in terms of quantity and recovery potential, since construction waste (originating from new construction) is less mixed and less contaminated, and its recovery potential is higher than that of waste originating from demolition and rehabilitation [41].

The CDW materials were characterized according to current standards for aggregates in concrete processing with the following tests:

- -

- Absorption humidity (ASTM C127-15 [37]);

- -

- Specific gravity or saturated relative density (ASTM C127-15 [37]);

- -

- Dry and loose volumetric mass (MVSS) (ASTM C29/C29M-07 [38]);

- -

- Compacted dry volumetric mass (MVSC) (ASTM C29/C29M-07 [38]);

- -

- Granulometry or particle size analysis (ASTM C 136/C 136M-19 [39]).

2.5. Tire Flakes

This material was obtained from a local company located on the Morelia–Salamanca highway, in Tarímbaro, Michoacán; it produces the shredding of tires out of use in the city of Morelia.

2.6. Mix Design

The coarse aggregate (gravel) was progressively substituted with recycled construction and demolition waste (CDW) at levels of 15%, 30%, 50%, and 100%. This step aimed to explore the feasibility of replacing coarse aggregates with CDW, starting with lower percentages and gradually reaching full replacement.

In the third stage, three additional preliminary mixtures were developed, focusing on the replacement of fine aggregate (ballast) with tire flakes at levels of 5%, 10%, and 20%. These replacements were applied while maintaining the original proportions of the control mixture. The selection of these percentages was informed by research documented in an article titled “Influence of rubber particles on the compressive strength of concrete blocks” [42].

Ten mixtures were designed with variations in the proportions and type of material used. Therefore, the design of the mixtures was subdivided into four stages. In the first stage, the mixture was designed for the control blocks. Since there are no standardized design methods for Portland cement-based blocks, and each manufacturer usually has its own particular proportions depending on the quality of the materials used and, of course, their experience, we decided to use the proportions of the company where the blocks were manufactured. The intention was that the results obtained would be easily accepted by and appropriate for the manufacturers. In the second stage, four preliminary mixtures were prepared, replacing 15, 30, 50, and 100% of the CDW using the same proportions as the control mixture (Table 1), only replacing the coarse aggregate (gravel) in each percentage. In the third stage, 3 more preliminary mixtures were formed, replacing 5, 10, and 20% of the tire flakes with fine aggregate (silt), using the same proportion (Table 1). Once the results of the mixtures of stages two and three were obtained, we proceeded with the fourth and final stage of this section, where two final mixtures were prepared, the first by replacing only the coarse aggregate with 50% CDW and 5% tire flakes (Table 1) and the second by replacing 50% CDW and 10% tire flakes with coarse aggregate. A total of 42 pieces were manufactured for each mixture, due to the number of parts needed for the tests that were subsequently carried out.

Table 1.

Design and nomenclature of mixtures.

2.7. Specimen Processing

The manufacturing process was carried out at a micro-company in semi-industrialized conditions. The elaboration stages are as follows:

- -

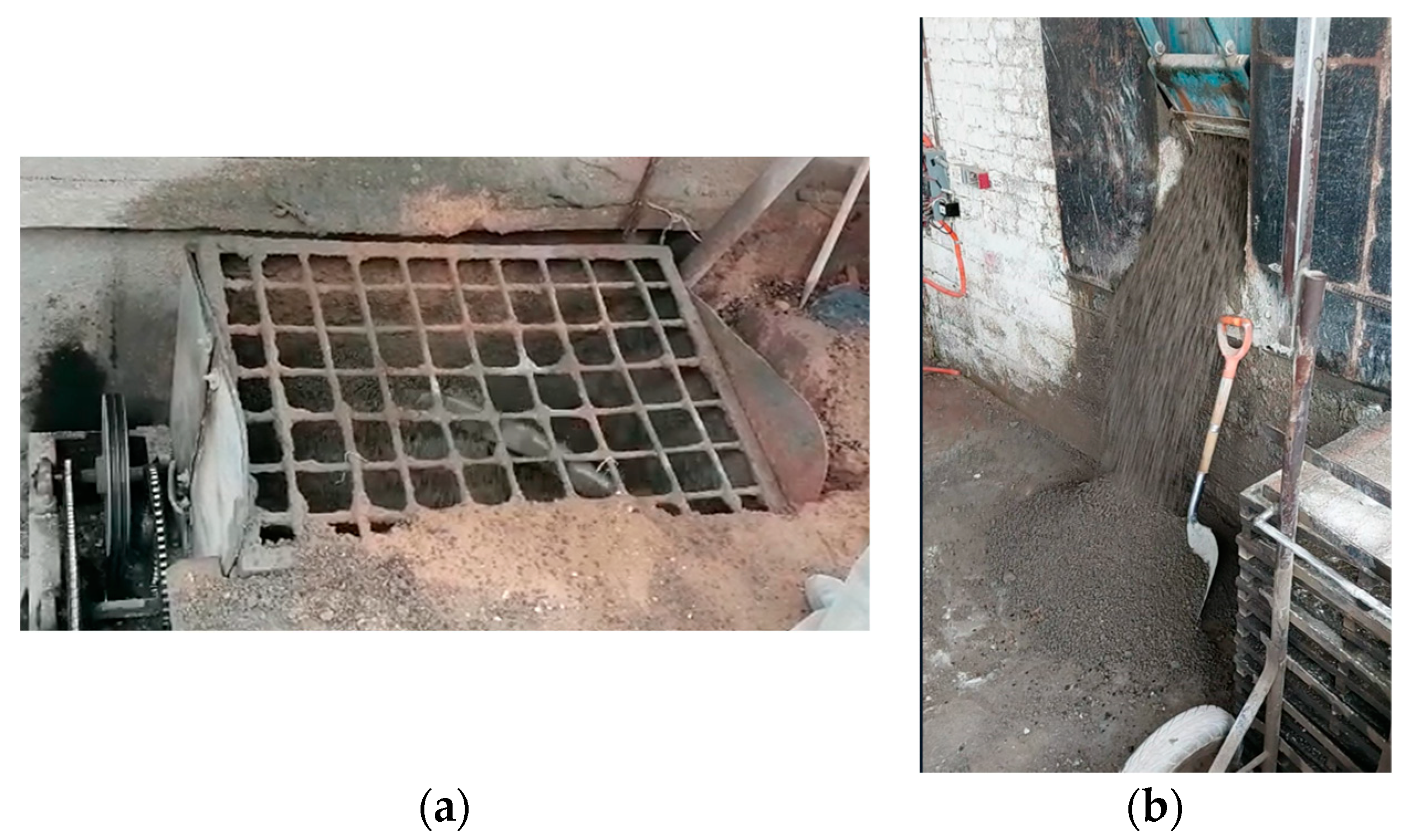

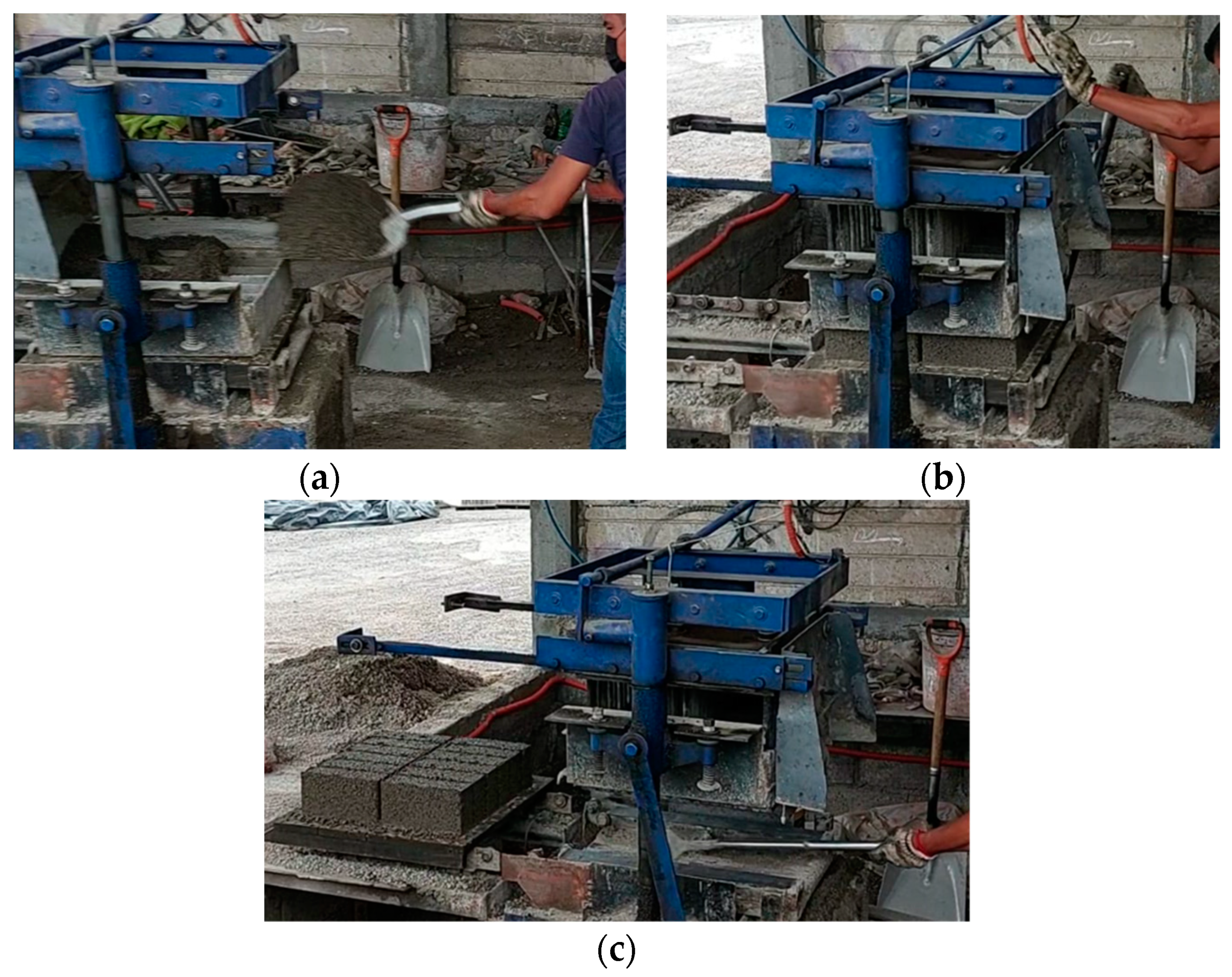

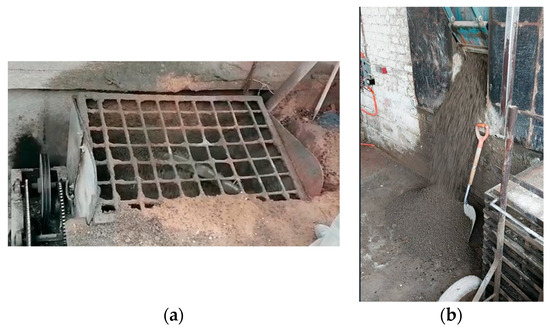

- Mixing: A motorized blade mixer was used for mixing (Figure 2a,b). The coarse aggregates (gravel and CDW) were added first, followed by fine aggregates (silt and tire flakes); then, the cement was added, and they were dry-mixed until a homogeneous mixture was achieved. Then, the water was incorporated in partial quantities until reaching the total for each mixture and achieving again a homogeneous mixture.

Figure 2. Material mixer (a) and mixed material pouring gate (b).

Figure 2. Material mixer (a) and mixed material pouring gate (b).

- -

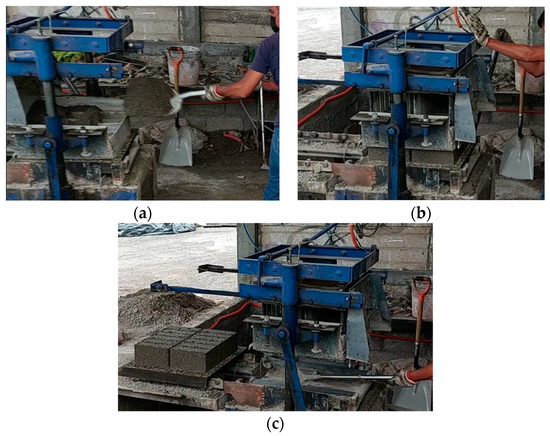

- Filling of molds: Once the adequate consistency of the mixture was obtained, the gate was opened (Figure 2b), and the manufacture of the blocks continued. We placed the mixture inside the molds, and the specimens were manufactured through vibro-compacting (semi-industrial manual equipment of national elaboration, with a single-phase motor at 110 V with 2 HP, including a mold for a block of any model and size; model CK-7571) (Figure 3a–c).

Figure 3. Filling and compacting molds: (a) mold filling, (b) vibro-compacting, and (c) demolding and specimen removal.

Figure 3. Filling and compacting molds: (a) mold filling, (b) vibro-compacting, and (c) demolding and specimen removal.

- -

- Storage and curing of specimens: Finally, the specimens were left to dry for three days, outdoors, covered with plastic in order to not lose moisture too quickly. Subsequently, they were taken to cure in the wet sand beds of the materials laboratory “Luis Silva Ruelas” at the UMSNH.

For the curing process, we decided to follow the procedure used by the local company where the specimens were manufactured in order not to alter their internal processes and to follow the actual manufacturing conditions so that when trying to implement the results obtained here, the company would not have to modify its installations.

2.8. Tests Performed on the Blocks

Compressive and flexural strength tests of the mortars were performed using the Tinius Olsen Universal Testing Machine with a capacity of up to 50 tons and approximations of 1 kg. The beams were tested with a three-load bearing, using the simply supported method, and fracture occurred in the middle third in all cases. Table 2 summarizes the tests performed, the dimensions of the samples, and the standards followed to carry out this study.

Table 2.

Tests performed on the building blocks.

2.9. Microscopic Evaluation of Mortars

After the rupture test under the load stress, chips of material were collected, subjected to vacuum, metalized with copper, and observed in a scanning electron microscope (SEM) to observe their matrix and morphology. EDS (energy-dispersive X-ray spectroscopy) analysis is a punctual characterization using an X-ray detector that can obtain data from the X-ray photon with a characteristic value from each element. The quantitative data obtained from EDS analysis are the atomic and element percentages, indicating the elements present in the sample.

3. Results and Discussion

3.1. Characterization of Aggregates and CDW

The physical characterization of aggregate substitutes (CDW) is important for estimating their impact on the mechanical behavior of mixtures in a hardened state. The results of this characterization are presented in Table 3. Two important indicators of the quality of the materials are the percentage of water absorption and the density since they indicate how porous the aggregate is. In this case, it is evident that the three materials have a high absorption, greater than 10% in all three cases, and therefore a low density, which has a null mechanical contribution to the mixture; by contrast, it can absorb water from the mixture and affect its setting and final resistance.

Table 3.

Characterization results of coarse and fine aggregates.

The results for the dry material and loose and compacted volumetric masses (Table 3) also show low densities, especially for gravel. These results could be considered negative for the elaboration of concrete, but this study focuses on the elaboration of blocks, and in these pieces of masonry, the aim is to reduce their weight as much as possible to be competitive with extruded clay blocks.

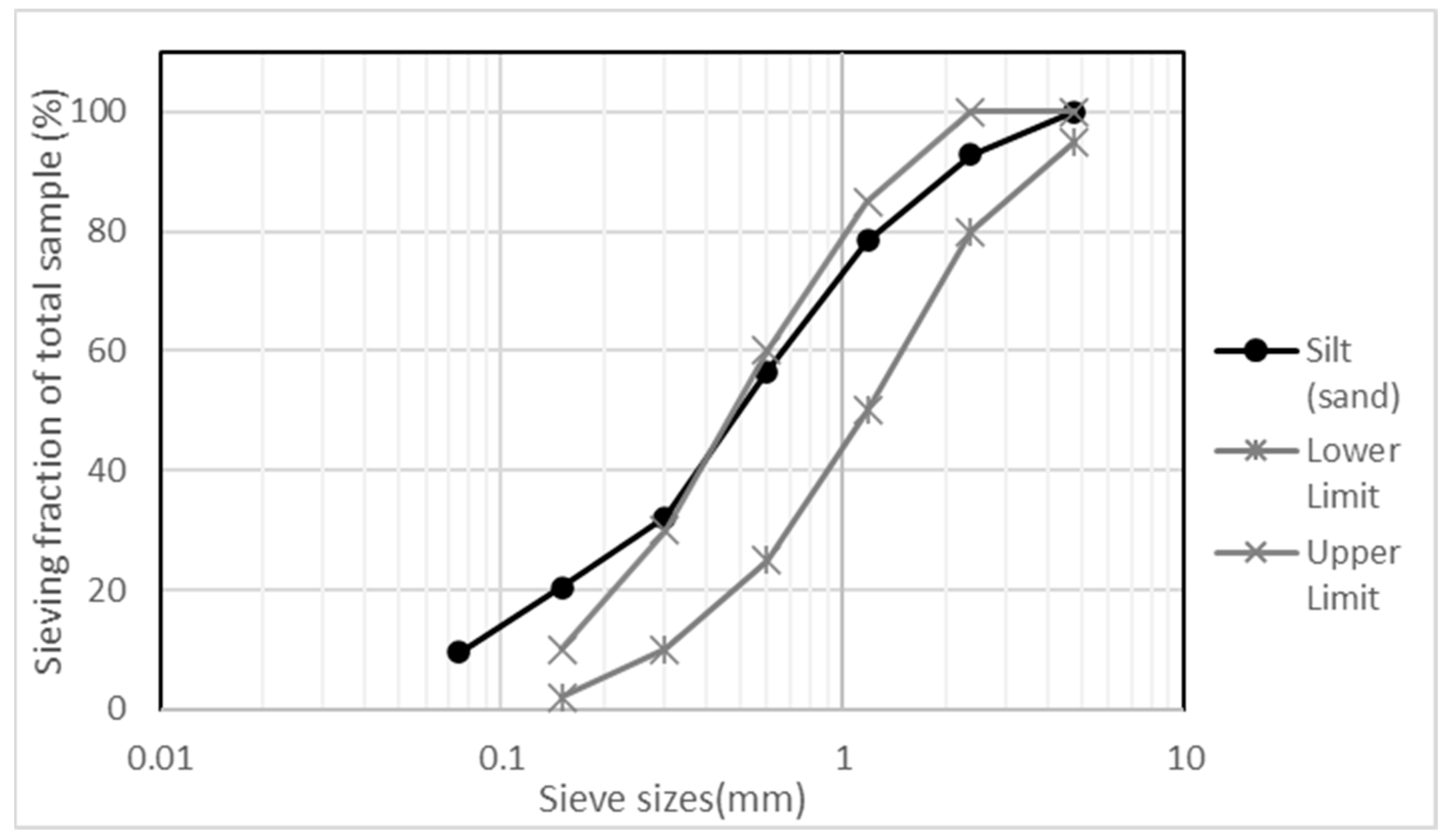

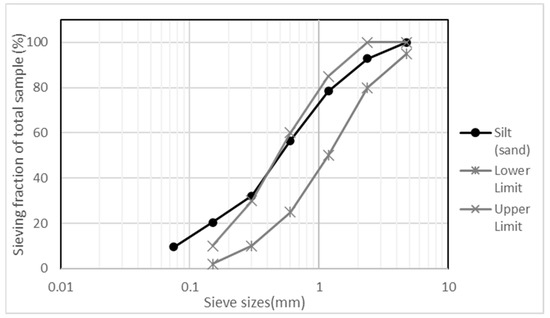

In the case of the granulometry of fine aggregate (silt), an excess of fine particles can be observed (Figure 4) compared with the permissible limits for the production of concrete. This excess of fine aggregates impacts the fineness module close to 2.0 (Table 3) so that the silt used can be classified as fine sand.

Figure 4.

Granulometry of the fine aggregate (silt) with acceptance limits for concrete manufacturing.

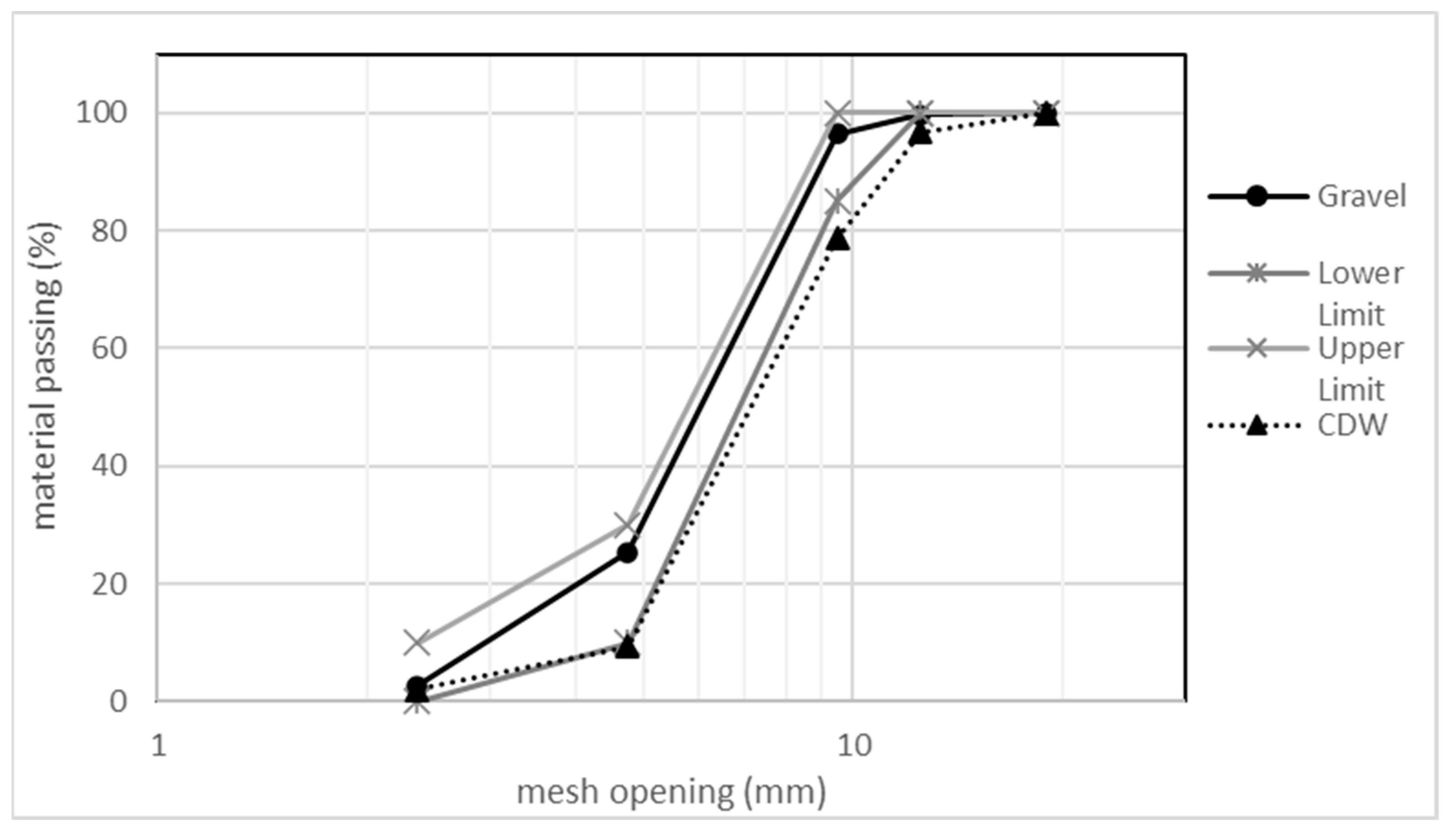

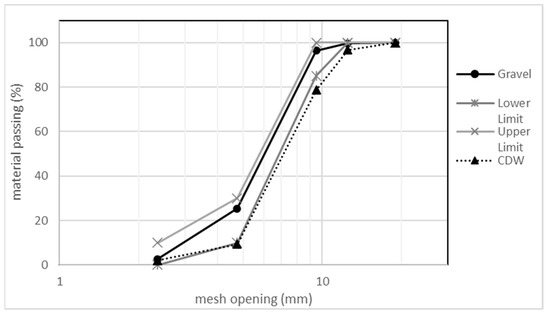

The granulometry studies of the coarse gravel and the CDW aggregates (Figure 5) show that gravel is within the permissible limits for concrete, so this aggregate would have little impact on the mechanical performance of the samples, and the arrangement of its particles during the elaboration of the partitions is adequate. The opposite occurs with CDW materials, since they have excess coarse particles, although this is not significant.

Figure 5.

Granulometry of coarse aggregate (gravel) and CDW with acceptance limits for concrete manufacturing.

3.2. Mechanical Tests on the Blocks

3.2.1. Compressive Strength

These tests were performed at 7, 14, 28, and 180 days for both control mixtures and CDW substitutions, while for mixtures with tire flake substitutions, the times were 7, 14, 28, 90, and 120 days. From each sample, five pieces of blocks were tested. Prior to carrying out the compressive strength tests, it was necessary to submit the pieces to a pitching process so that the load applied to the element was uniform. For pitching, a mixture of gypsum–cement was prepared at a mass ratio of 4:1, respectively, with the addition of water until adequate workability was achieved. The preliminary results showed that decreasing the amount of fine aggregate silt considerably decreased the compressive strength.

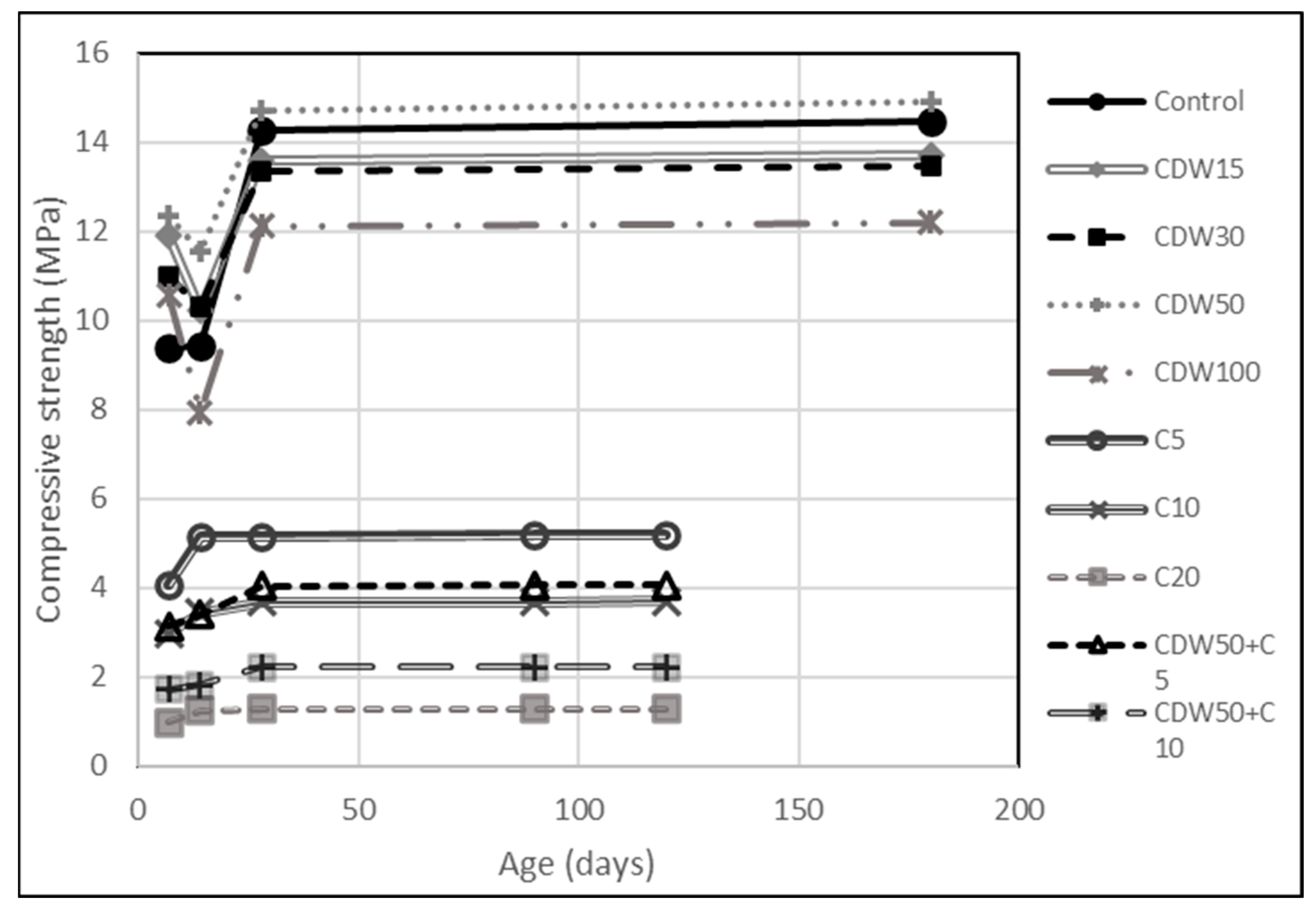

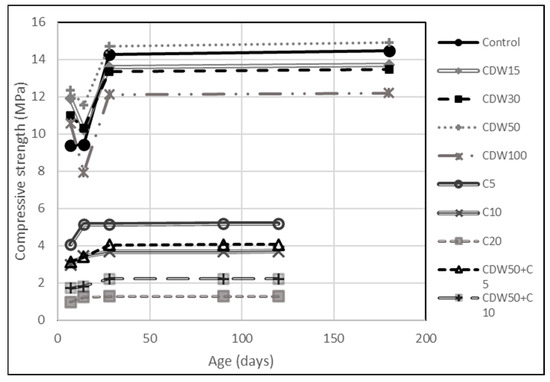

The simple compression test (Figure 6) shows the strong impact of the incorporation of tire flakes, as it reduces the resistance from 14.2 MPa of the control mixture to 1.3 MPa of the incorporation of 20% tire flakes. This can be attributed to the method of incorporating the tire flakes since fragments of approximately 2 cm (diameter of the larger side) could cause preferential accommodation of the same in the mixture, which at the time of vibro-compacting give rise to areas of low rigidity in the blocks.

Figure 6.

Compressive strength of study mixtures.

The incorporation of CDW shows a slight improvement in the compressive strength of the mixture that incorporates 50% of them (Figure 6), as the only mixture that managed to overcome the control in all test ages. For this reason, we decided to combine 50% of the RCD with tire flakes, although again extremely unfavorable results were obtained.

3.2.2. Flexural Strength

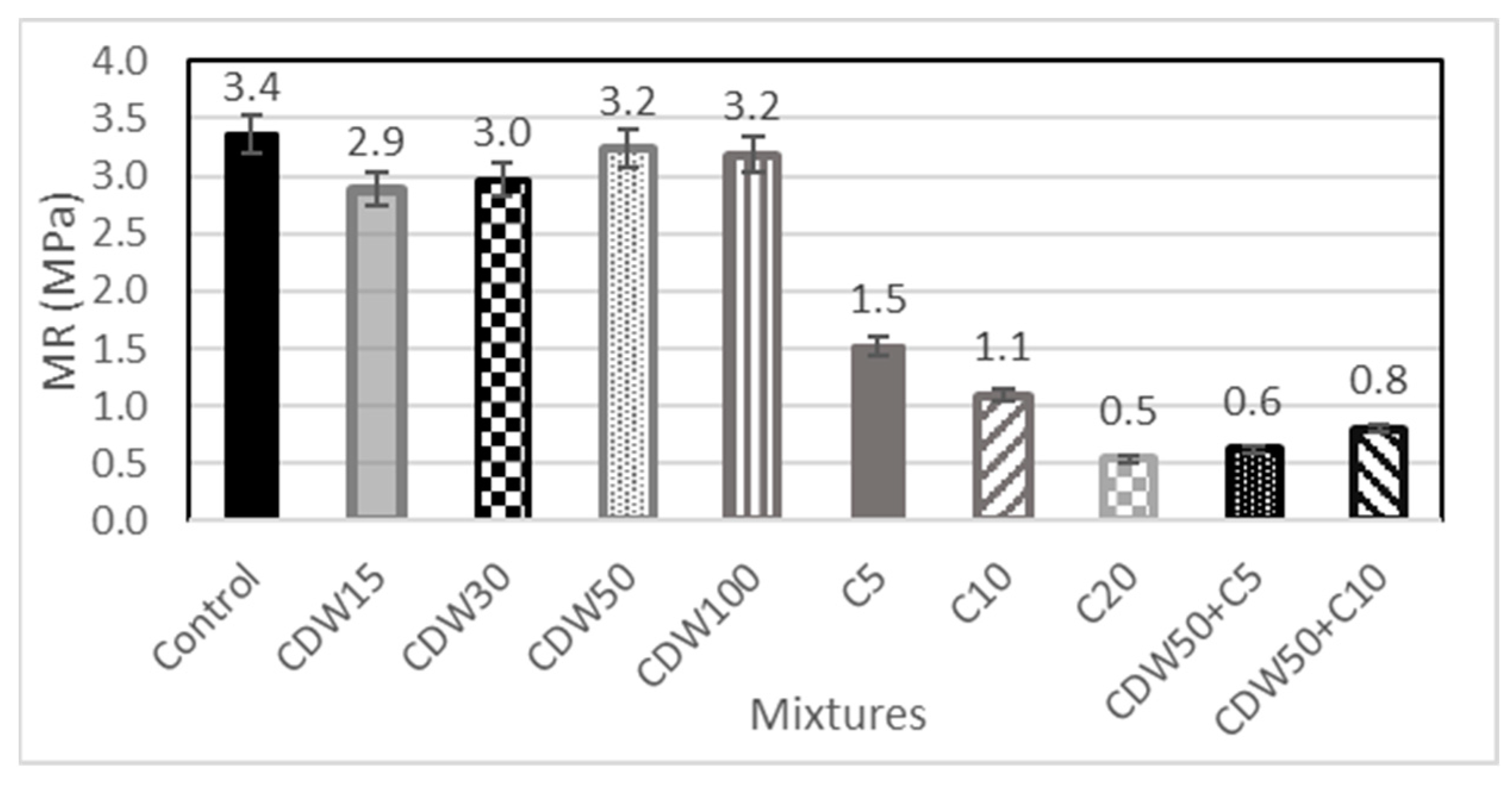

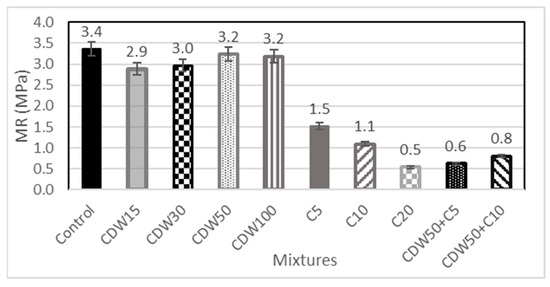

The static bending (MR) tests were performed when the specimens were 28 days old since this is the age at which 100% of the design strength of the mixtures is reached; this is also the value considered for structural and constructive calculations in civil works. The results of this test (Figure 7) again show that the incorporation of CDW by 50% manages to maintain a flexural strength very similar to that of the control, with a difference of only 5.9%. Another mixture that presents similar results is that which incorporates 100% CDW, which reaffirms the fact that CDW can be a substitute for natural stone materials in high percentages.

Figure 7.

Block breaking module.

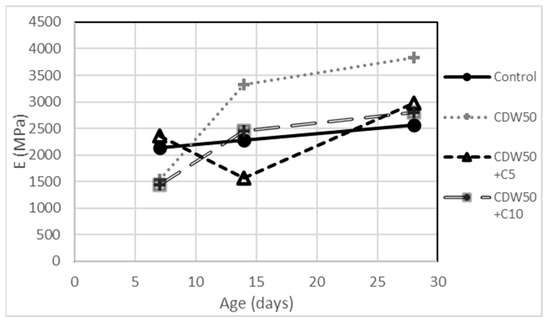

In the case of the incorporation of tire flakes, the results again show that the values are well below those of the control mixture and the same as those of the mixtures that incorporate both residues. Flexural strength is directly related to the stiffness of the material and compressive strength; therefore, if these properties decrease, so will the flexural strength. The incorporation of tire residue flakes decreases the compressive strength (Figure 6) as well as the modulus of elasticity (Figure 8); therefore, the flexural performance is also affected. Recent research has reported that the use of tire residue as a substitute for stone aggregates decreases the mechanical properties of concrete [48,49]. Even though in this research, tire residues are used as flakes instead of dust or fragments, they present the same effect.

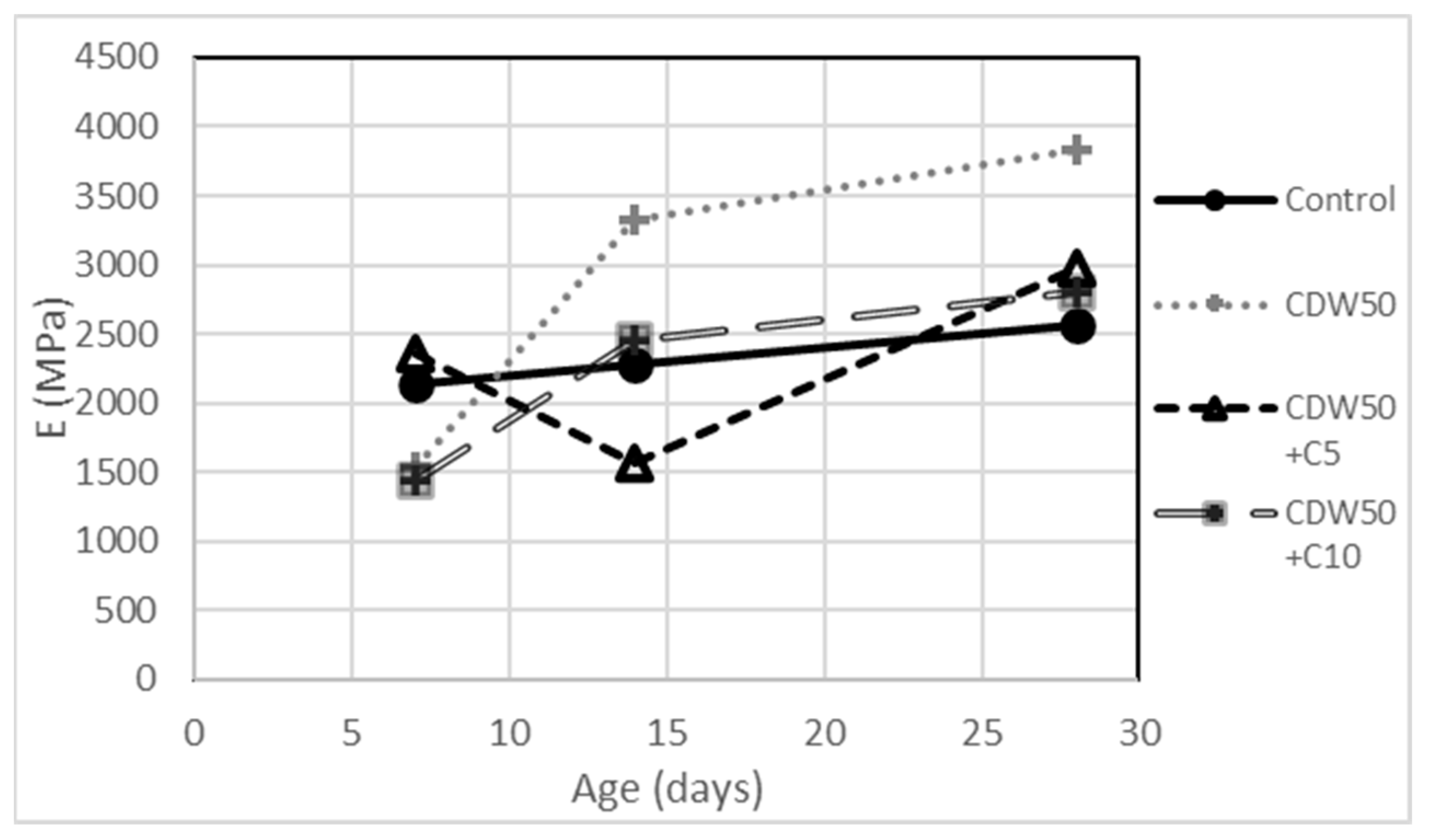

Figure 8.

Static module of elasticity.

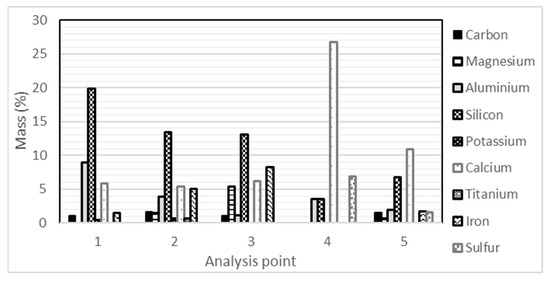

3.2.3. Static Module of Elasticity

For this test, cylinders of 10 cm in diameter by 20 cm in height were manufactured, with the mixtures that had better results or were representative of the combinations of residues used. The specimens tested were the control mixture, mixtures with 50% replacement of CDW, mixtures with 50% replacement of CDW plus 5% tire flakes, and mixtures with 50% replacement of CDW plus 10% tire waste. The test ages for all mixtures were 7, 14, and 28 days.

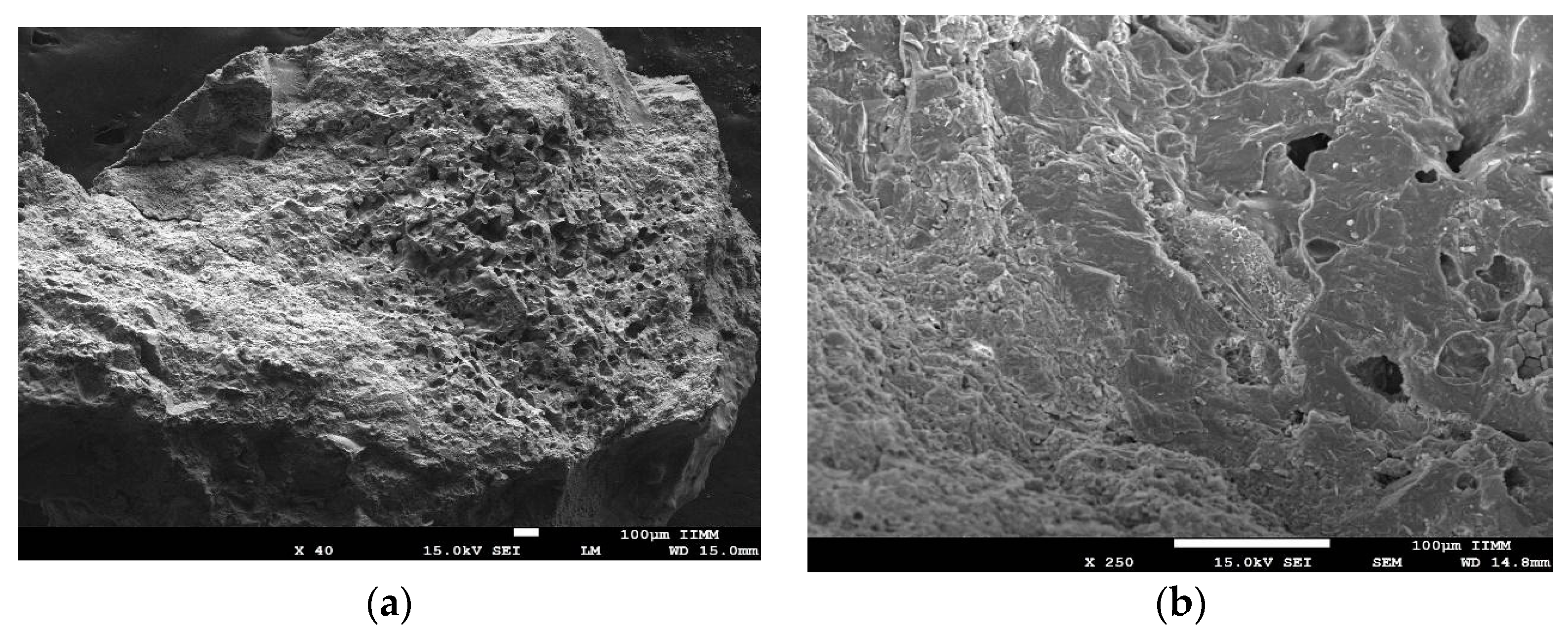

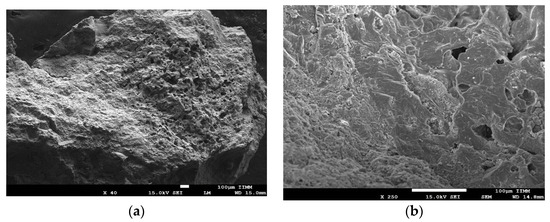

Figure 8 shows the different rigidities of the mixtures analyzed and their behavior at different times of study. The effect generated by the incorporation of CDW and tire flakes in the mixtures is evident, since 50% CDW increases the modulus of stiffness by 50% compared with the control at the age of 28 days. This can be attributed to the texture of CDW (Figure 9), which is much rougher than the texture of the natural gravels used in this work. This allows for a greater adhesion between the cement–water grout and the aggregates, achieving greater cohesion of the resulting matrix.

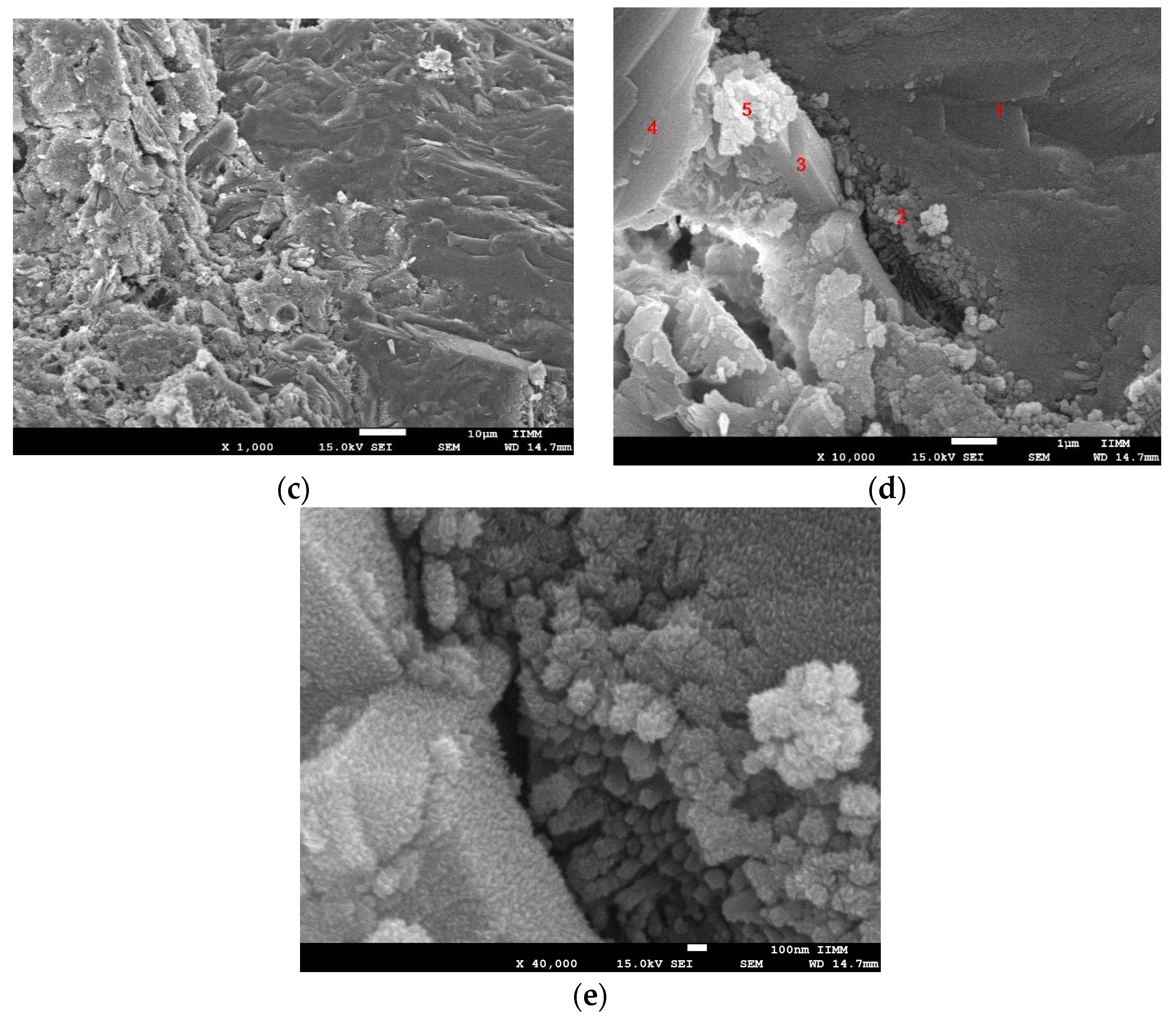

Figure 9.

MEB images of the interface between CDW aggregate (right side of the images) and new cementitious matrix (left side of the images): (a) 40× magnification; (b) 250× magnification; (c) 1000× magnification; (d) 10,000× magnification, and numbers in red indicate the EDS sampling points; (e) 40,000× magnification.

In the case of mixtures incorporating both residues, there is a drop in stiffness with respect to the mixture with 50% CDW, and this may be due to the presence of tire flakes as already observed in the previous tests, although in this case, the decrease in stiffness slightly exceeds the control at 28 days. This could imply improvements in the dynamic behavior of the mixtures; since they do not present the same resistance as the control, but the same modulus of elasticity, it could be inferred that other properties related to stiffness could be improved, such as impact resistance [49] and resilient modulus [50].

3.3. Physical Tests in the Blocks

3.3.1. MEB Images

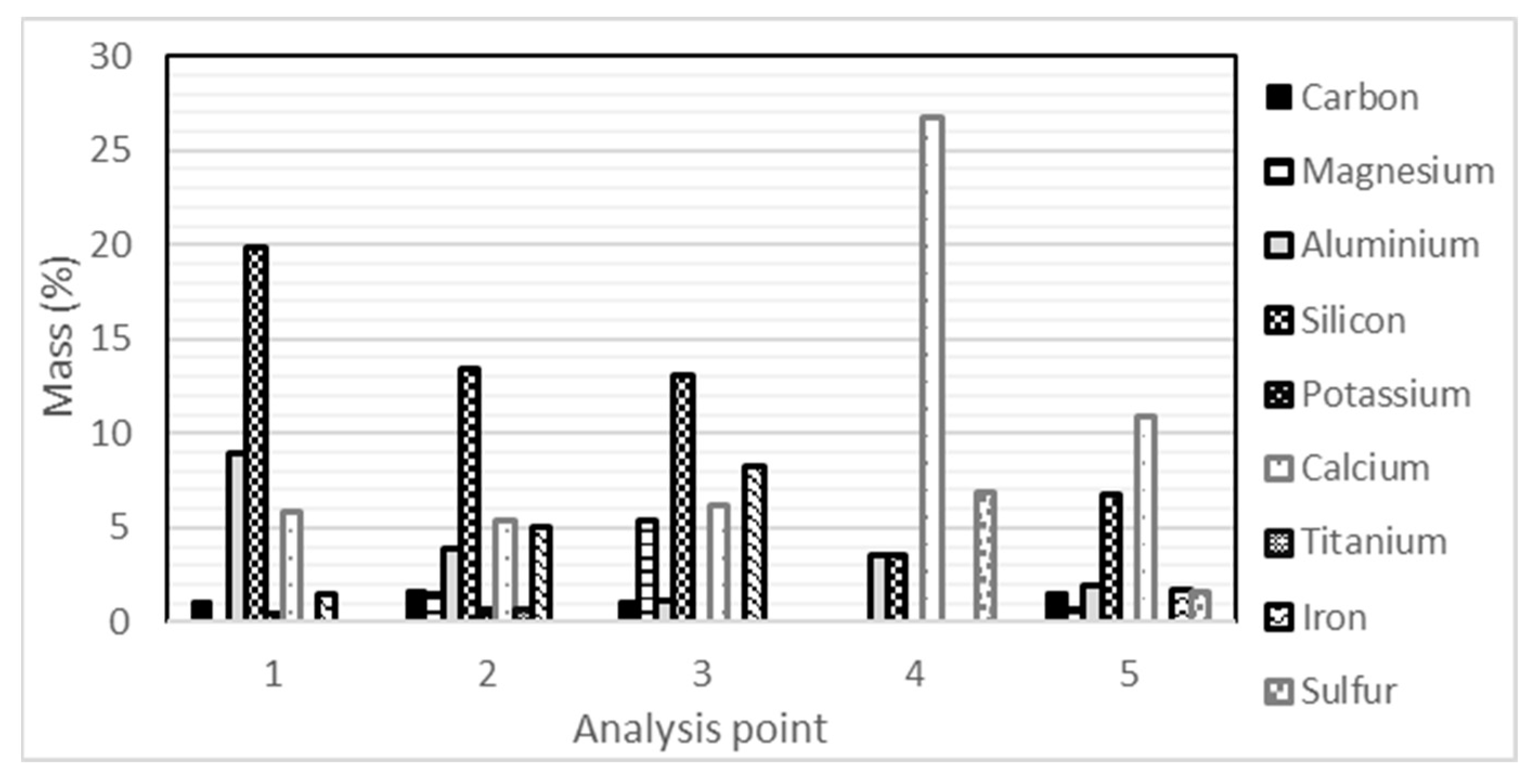

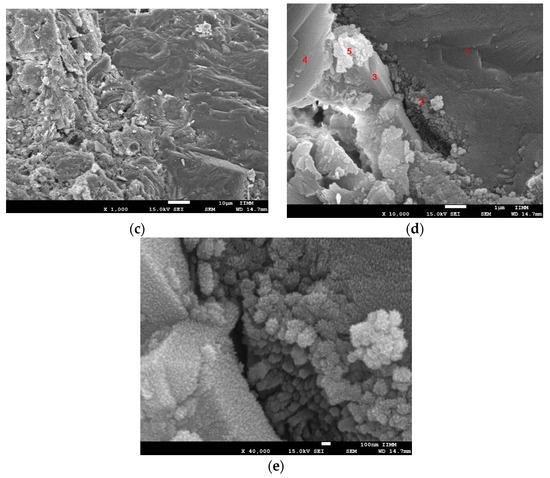

This analysis focused on the interface between the CDW aggregate and the new cementitious matrix formed with Portland cement. In Figure 9a, we can observe a difference in the morphology of the surface. The union between the new cementitious matrix and CDW is observed; the CDW shows greater porosity and the presence of more pronounced irregularities (Figure 9b) than the new cementitious matrix, where a more compact surface with less presence of pores can be observed. Figure 9c more clearly shows the difference in the surface morphology of the two materials; the CDW material shows a more compact surface with small variations in height, always showing it as a whole. On the other hand, the surface of the new matrix shows changes in morphology with a variety of shapes and heights and the presence of gaps or separations between the parts that constitute it. Figure 9d shows a difference in the tonality of the surfaces, in addition to the presence of crystalline morphologies in the new cementitious matrix. The union between the two materials is clearly appreciated, as is how the new material forms the bond—by means of small agglomerations on the CDW material. Figure 9e shows a closer view with 40,000× magnification; the gap union of CDW and the new cementitious matrix can be seen. As for the differences in morphology, the CDW shows the agglomeration of prism particles with small sizes, producing a rougher surface, unlike the surface of the new cementitious matrix, which shows a smoother surface with larger particles. In this image (Figure 9c), the sampling points for the EDS analysis are labeled; the values of the % of mass are shown in the graph of Figure 10. A greater presence of silica and aluminum can also be observed in the CDW sample; this may be due to the fact that the CDW was derived from structural concrete, in which elaboration and curing processes were carried out according to standard regulations, while the samples taken from the new cementitious matrix show the presence of a higher percentage of calcium and sulfides, which may be due to a poor curing process, since the samples, once elaborated, were left to dry for the standard time. In the case of analysis point 4, a high calcium content is observed, which is due to the fact that it is a portlandite crystal given the morphology of the crystal; since it is a byproduct of the hydration of Portland cement, its dicalcium and tricalcium silicate phases are belite and alite. The composition matches the morphology.

Figure 10.

EDS analysis of points marked in Figure 9d.

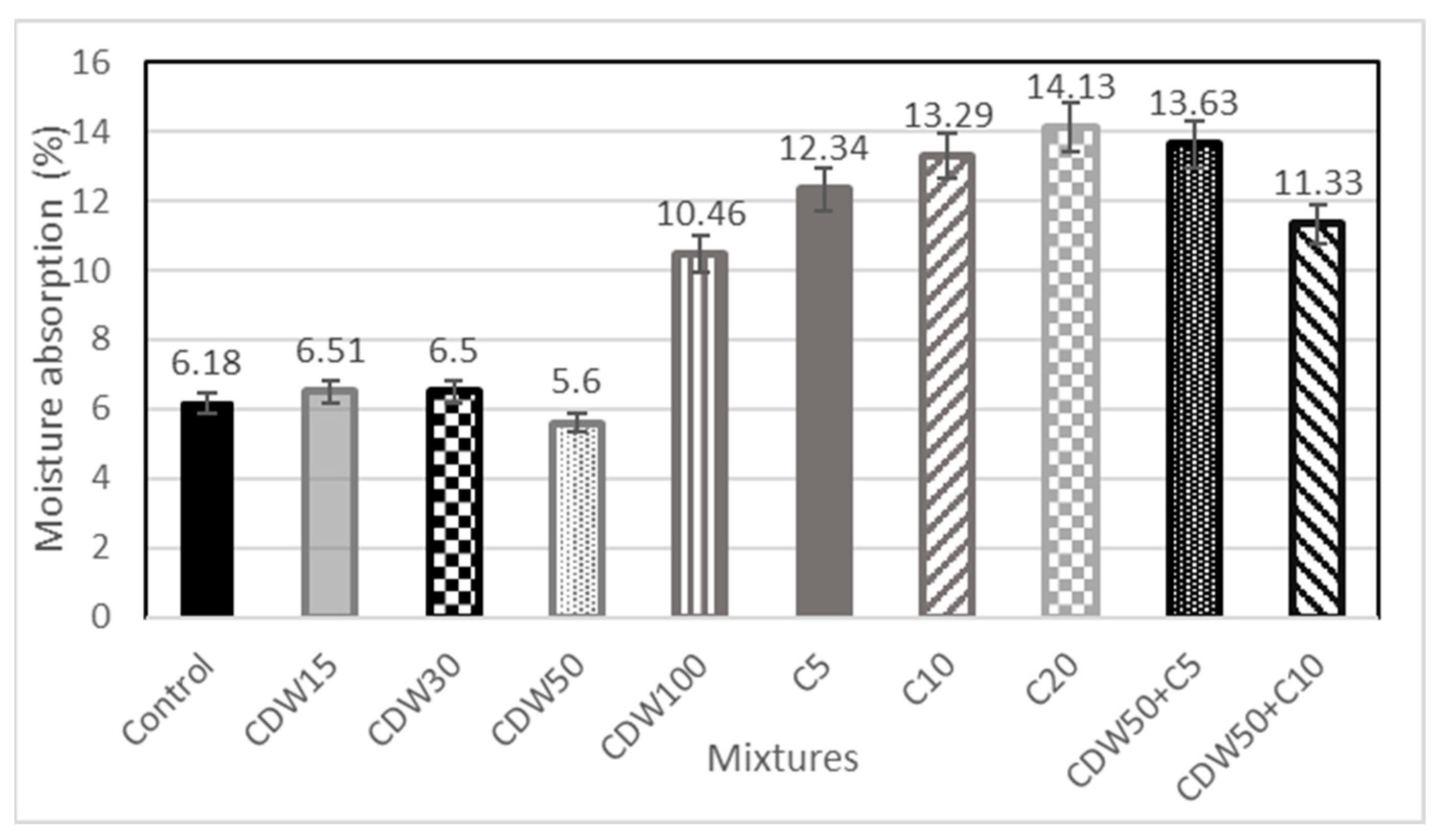

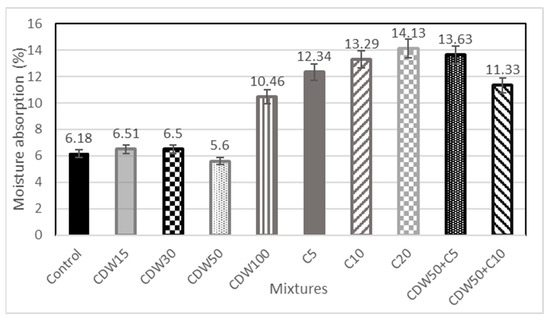

3.3.2. Absorption Humidity

Like static bending, absorption moisture tests were performed at 28 days of age of the specimens, since this is the age at which 100% of the design strength of the mixtures is reached. It is also the age at which they are used in civil works.

Figure 11 shows the results of this test. It can be seen how the mixtures with the highest recorded absorption correspond to those that incorporate tire flakes. The lowest percentages of absorption correspond to the mixtures that incorporate CDW, with the 50% CDW mixture being the one that presents the lowest result (in fact, lower than that of the control mixture).

Figure 11.

Absorption humidity in study blocks.

Absorption is directly related to the porosity of the matrix, mainly to the interconnected porosity or effective porosity. When comparing the absorption results with the compressive strength (Figure 6), it is found that the mixtures with lower mechanical strength have the highest moisture absorption, which confirms that samples with more porosity have lower strength and higher absorption. Figure 9 shows the microstructure of the study specimens. In this figure, it is observed that the new cementitious matrix presents high porosity due to deficient curing of the specimens; at the same time, the incorporated CDW granules present high porosity, so the incorporation of 100% CDW also presents high absorption and low mechanical strength.

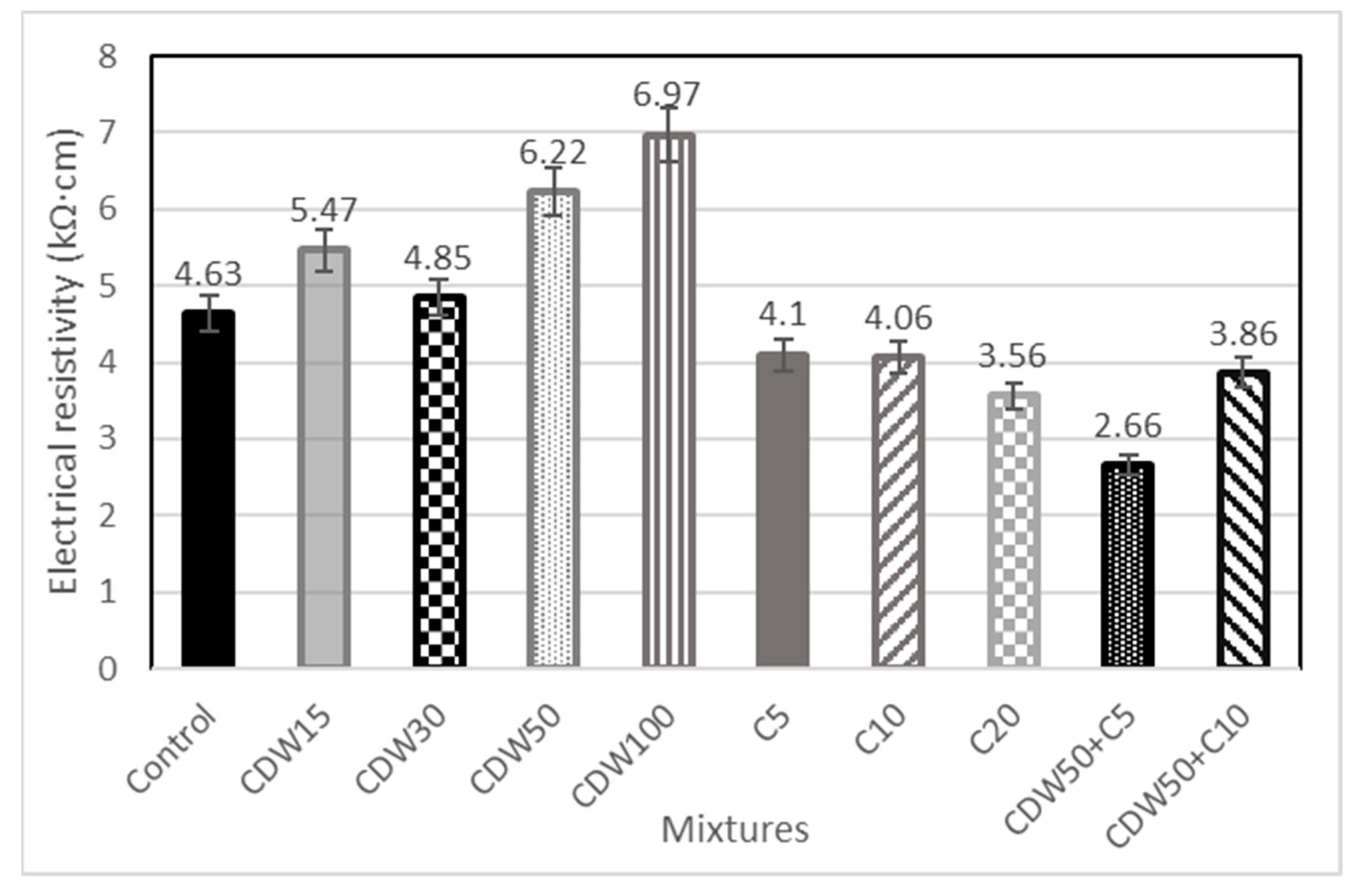

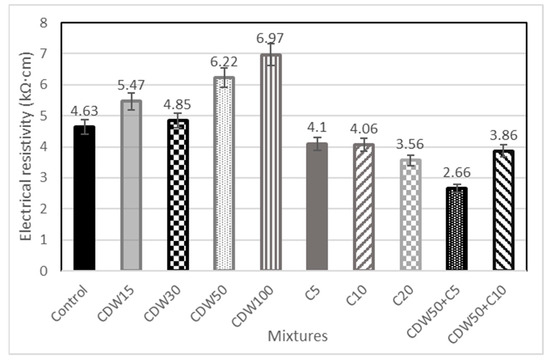

3.3.3. Electrical Resistivity (ER)

The electrical resistivity was determined using the direct method and the same specimens with which the static module of elasticity was determined at 28 days. The test was executed following the ASTM C1876 [47] standard and the DURAR network manual [51], as seen in Figure 12. In the case of the electrical resistivity test (Figure 12), it is observed that the lowest results correspond to mixtures with tire flakes, which is consistent with the absorption results (Figure 11), since the higher the absorption, the greater the presence of pores and therefore the lower the electrical resistivity. Similarly, the lowest performances correspond to the mixtures that incorporate CDW and tire flakes; the 50% and 100% mixtures present the highest results. Comparing this test with the results of absorption, the mixture with 100% CDW exhibits a strangely high level of electrical resistivity, not in agreement with its percentage of moisture absorption. Figure 9 shows the microstructure of the interface between a CDW aggregate and the new Portland cement matrix. In this figure, the high porosity of the CDW can be seen (Figure 9a,b), so in the specimens in which 100% of the CDW is replaced with gravel, there is a significant effect of this porosity. As the ER test is very sensitive to the moisture content of the sample, this strange behavior may be due to the rapid drying of the samples composed of 100% CDW and therefore could impact the obtained results.

Figure 12.

Electrical resistivity in study blocks.

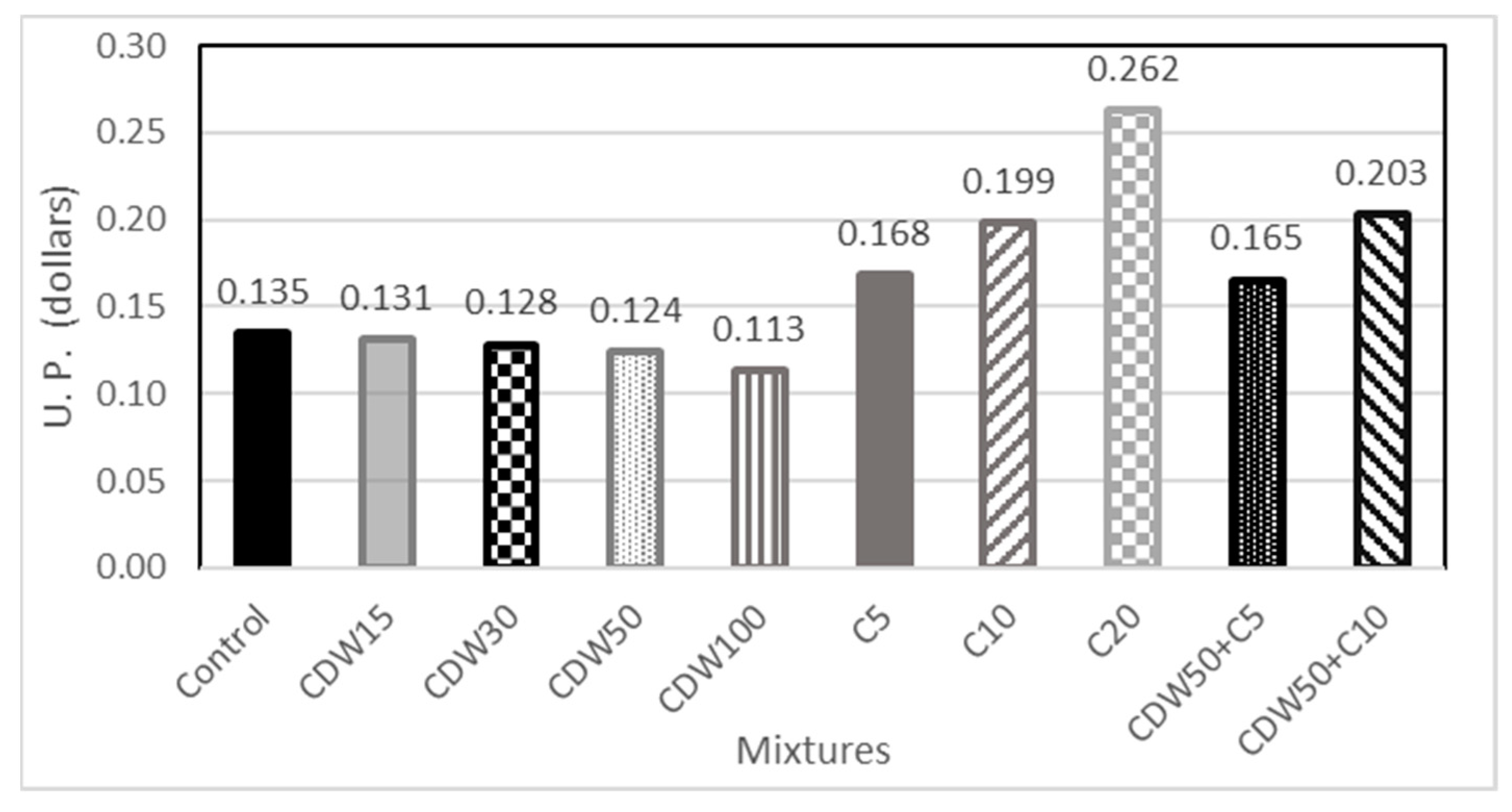

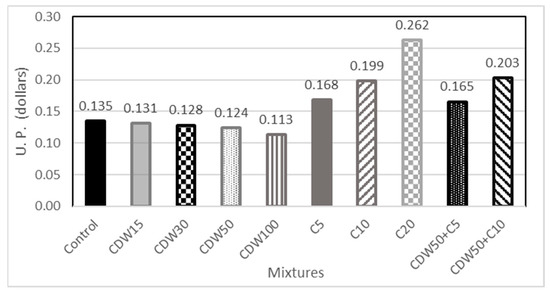

3.3.4. Unit Cost Analysis of Specimen Manufacturing

A direct economic cost analysis was prepared based on the material combinations mentioned in the mixture design. For this analysis, current prices as of November 2022 were corroborated. This analysis is important as it provides us with a slightly broader picture of the possible economic savings based on the use of these types of waste as raw materials. It should be noted that this study was carried out assuming that the CDW is provided by a recycled concrete plant, which facilitated the price of the material per m3 as MXN 130.00 for the CDW and MXN 8.00 per kg of tire flakes.

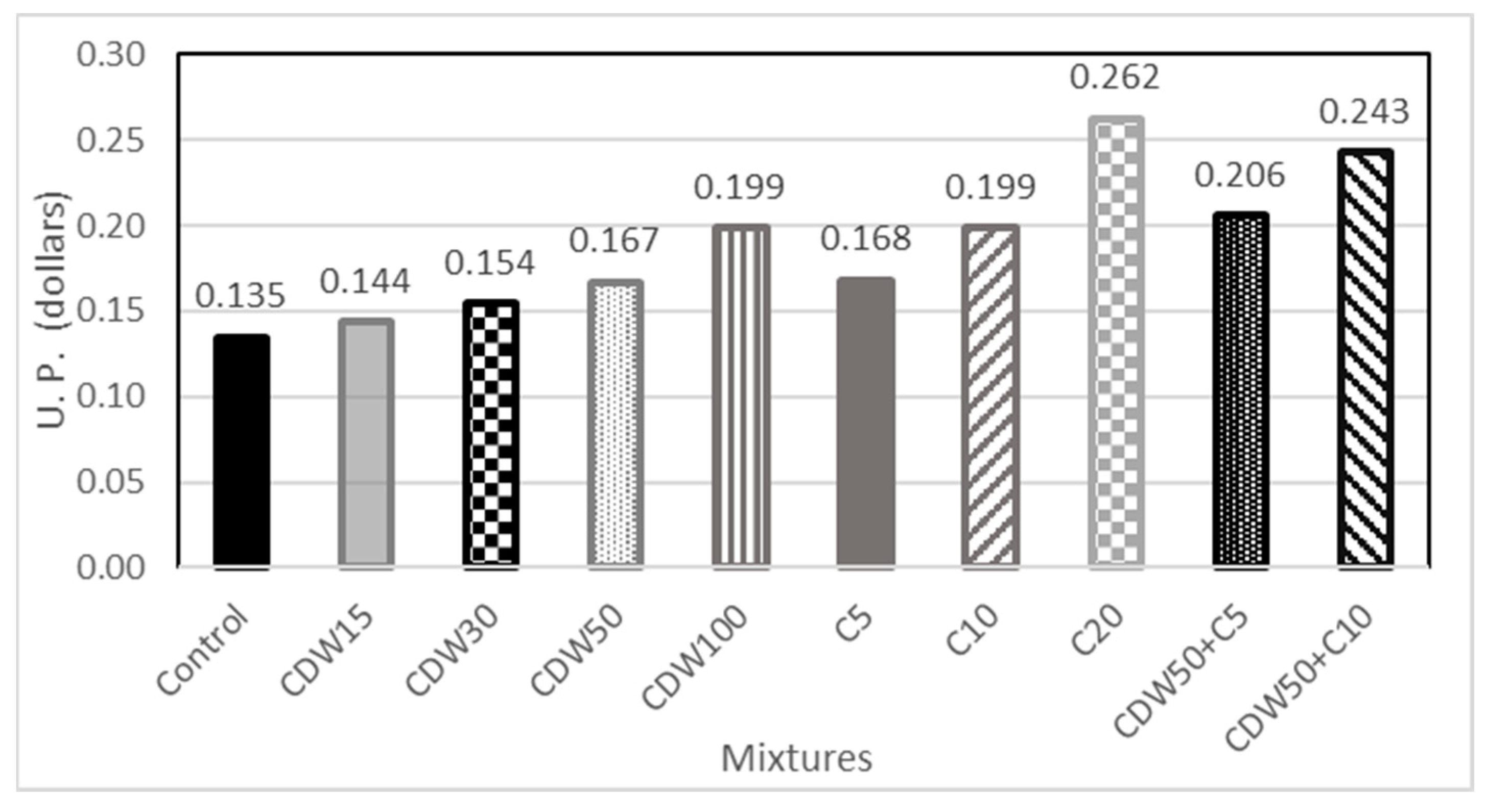

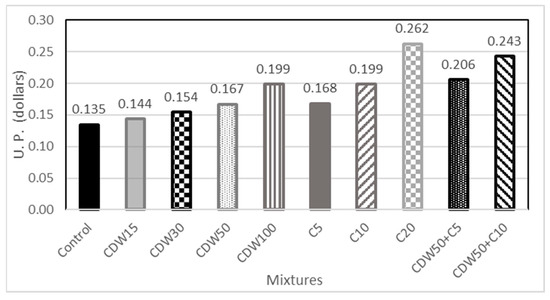

It is important to mention that the price of CDW was obtained from a CDW marketing company in Mexico City, and they do not ship outside the city; therefore, these unit cost conditions were met for a maximum of approximately 30 km, which is the maximum shipping distance of the plant. In the case of exceeding this transfer distance, an extra cost per shipment would have to be considered, so we decided to carry out a second study considering a price for a transfer of 14 m3 MXN 10,000.00.

The analysis of the direct cost per piece took into account materials, labor (two laborers), machinery, and equipment, considering an exchange rate of the national currency (MXN) to USD of MXN 17.0672 for USD 1 as of 14 August 2023. The first step in the analysis was to determine the volume of the aggregates required for each concrete mix. Subsequently, for each mix, the volume of each component within the concrete was calculated, accounting for the gravel, silt, and water. This volume determination was based on the mass per unit and the respective density of each component. Following this, the unit price of each material per part was analyzed, including the unit price of Portland cement per unit mass. This analysis provided the cost of materials per unit. The labor cost was then evaluated, considering a team of two general helpers. Finally, the expenses associated with machinery and equipment were accounted for.

Figure 13 shows the first comparison of the unit costs of the blocks analyzed with different additions and combinations of tire and CDW. It can be seen that CDW achieves a slight improvement in the unit cost of the block, while the tire flakes significantly increase this cost, even in combination with CDW. Evidently, the greater the replacement of CDW with natural aggregate in the mixture, the greater the reduction in the unit cost of the partition; therefore, the mixture with the lowest unit cost is the one that incorporates 100% CDW.

Figure 13.

Unit price comparison of study mixtures without considering CDW transfer costs.

Looking at the results in Figure 14, it can be seen that reductions in unit prices for mixtures with CDW can easily be reversed and even increased above the control if a carry-through cost is to be added to the base cost of the CDW. Since relocation costs are very common and necessary in the construction industry, this variable can make the process more complex or hinder its acceptance by builders and/or block manufacturers.

Figure 14.

Comparison of unit price of study mixtures considering transfer costs of the CDW.

4. Conclusions

The reuse of solid waste in different industrial processes has been extensively researched worldwide, particularly the reuse of waste that is generated in large quantities. One of the industries that demand a large number of raw materials is construction manufacturing. For this reason, the recovery of solid waste as raw materials is a viable option for incorporation into this industry’s value and production chains, which in turn would benefit the environment.

This study proves that the incorporation of CDW as a substitute for coarse aggregate (gravel) up to 50% in the elaboration of blocks is viable from a physical–mechanical point of view, without diminishing the resistance to compression and bending and increasing the stiffness. From an economic point of view, it is demonstrated (with a simple analysis of unit price) that acceptable economic savings can be achieved with the use of CDW as a raw material, although it is also evident that this economic improvement is easily reversible at greater transport distances.

In this context, it can be concluded that, although it is technically feasible to incorporate CDW in the development of blocks (without significantly altering their physical–mechanical properties and even improving some of their properties such as stiffness), it is necessary to develop waste management mechanisms since the technical advantages do not necessarily translate into economic advantages, and this can severely affect the acceptance of these new raw materials by the producers and consumers of building blocks. These management mechanisms should incorporate strategies to raise public awareness of the revaluation of these waste materials, the provision of local collection centers, and the correct regulation of these waste materials by decision makers. In this way, the technical and economic advantages of the use of these waste products in the construction industry can be fully exploited so that they are no longer considered waste.

In the case of tire flakes, although they have highly elastic characteristics and chemical stability, no improvements were achieved with their incorporation. In fact, they seriously affect the physical–mechanical behavior of the blocks and at the same time increase their production costs. Even though no benefits were achieved through this incorporation, this research provides results that increase the technoscientific knowledge of this waste. This will serve as a starting point for other researchers and/or future research projects investigating the appropriate way to incorporate this waste in some type of compost for construction. They can be used for up to 5% of nonstructural partitions in combination with CDW. Additionally, on their own, they can be effective for up to 10% incorporation. The benefits are difficult to calculate in terms of greenhouse gases, for example, but the geomaterials that are replaced are nonrenewable resources. Not exploiting stone quarries also implies the conservation of endemic flora and fauna. Tire flakes are very, very difficult to recycle. In this case, further research is required to address different shapes and sizes of incorporation of tire flake particles in order to achieve results similar to those of CDW. In the same way, further studies could assess the effects of CDW variability on properties using multi-source demolition waste.

Author Contributions

Conceptualization, M.A.-S. and W.M.-M.; methodology, H.L.C.-G. and M.A.-S.; formal analysis, M.A.N.-S.; investigation, J.A.B.-P.; writing—original draft preparation, J.A.V.-P.; writing—review and editing, A.I.C.-S.; visualization, R.R.-R.; project administration, A.P.-C.; funding acquisition, E.M.A.-G. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to acknowledge sponsorship from CIC Projects at the Universidad Michoacana de San Nicolas de Hidalgo, UMSNH; the National Council of Science and Technology, CONAHCYT; Project 321260: Development of a replicable social production model for housing and habitat.; Project CF-2023-G-985: Concretes and mortars self-degrading biota and polluting compounds present in the atmosphere, for their application in housing of social interest in medium-sized Mexican cities; Project IXM-2313: Solid waste study for improvement and implementation in housing and infrastructure; SEP-Prodep; Laboratory “Ing. Luis Silva Ruelas”, Faculty of Civil Engineering, UMSNH; and the Institute of Science, Technology, and Innovation, ICTI.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Arisha, A.; Gabr, A.; El-Badawy, S.; Shwally, S. Using Blends of Construction & Demolition Waste Materials and Recycled Clay Masonry Brick in Pavement. Procedia Eng. 2016, 143, 1317–1324. [Google Scholar] [CrossRef]

- Desai, M.; Yadav, N.; Desai, N. Application of Recycled Soil and Sand in Brick Production over Conventional Clay Brick: A Sustainable Alternative. Mater. Today Proc. 2023, 77, 879–886. [Google Scholar] [CrossRef]

- Singh, S.; Dalbehera, M.M.; Maiti, S.; Bisht, R.S.; Balam, N.B.; Panigrahi, S.K. Investigation of Agro-Forestry and Construction Demolition Wastes in Alkali-Activated Fly Ash Bricks as Sustainable Building Materials. Waste Manag. 2023, 159, 114–124. [Google Scholar] [CrossRef] [PubMed]

- Hawken, P.; Lovins, A.B.; Lovins, L.H. Natural Capitalism: The Next Industrial Revolution; Gabriel Thoumi Sustainability Collection; Earthscan: London, UK, 2010; ISBN 978-1-84407-170-8. [Google Scholar]

- Chandru, U.; Bahurudeen, A.; Senthilkumar, R. Systematic Comparison of Different Recycled Fine Aggregates from Construction and Demolition Wastes in OPC Concrete and PPC Concrete. J. Build. Eng. 2023, 75, 106768. [Google Scholar] [CrossRef]

- Jike, N.; Xu, C.; Yang, R.; Qi, Y.; Dai, Y.; Peng, Y.; Wang, J.; Zhang, M.; Zeng, Q. Pervious Concrete with Secondarily Recycled Low-Quality Brick-Concrete Demolition Residue: Engineering Performances, Multi-Scale/Phase Structure and Sustainability. J. Clean. Prod. 2022, 341, 130929. [Google Scholar] [CrossRef]

- Yang, D.; Liu, M.; Ma, Z. Properties of the Foam Concrete Containing Waste Brick Powder Derived from Construction and Demolition Waste. J. Build. Eng. 2020, 32, 101509. [Google Scholar] [CrossRef]

- Gu, F.; Xie, J.; Vuye, C.; Wu, Y.; Zhang, J. Synthesis of Geopolymer Using Alkaline Activation of Building-Related Construction and Demolition Wastes. J. Clean. Prod. 2023, 420, 138335. [Google Scholar] [CrossRef]

- Hu, K.; Chen, Y.; Naz, F.; Zeng, C.; Cao, S. Separation Studies of Concrete and Brick from Construction and Demolition Waste. Waste Manag. 2019, 85, 396–404. [Google Scholar] [CrossRef]

- Wichmann, I.; Stephan, D. Mechanical and Physical Properties of Concrete Made of Alkali-Activated Lightweight Aggregates from Construction Demolition Waste. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Chen, B.; Zheng, Y.; Zhao, Y.; Wang, Y.; Zhou, T. Recycled Brick Powder from Construction and Demolition Waste as Waterborne Coating Filler with Robust Scrubbing Resistance. Constr. Build. Mater. 2023, 385, 131494. [Google Scholar] [CrossRef]

- Sharma, A.; Shrivastava, N.; Lohar, J. Construction & Demolition Waste in Geotechnical Applications: A Review. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Dos Reis, G.S.; Cazacliu, B.G.; Cothenet, A.; Poullain, P.; Wilhelm, M.; Sampaio, C.H.; Lima, E.C.; Ambros, W.; Torrenti, J.-M. Fabrication, Microstructure, and Properties of Fired Clay Bricks Using Construction and Demolition Waste Sludge as the Main Additive. J. Clean. Prod. 2020, 258, 120733. [Google Scholar] [CrossRef]

- Ferriz-Papi, J.A.; Thomas, S. Recycled Aggregates from Construction and Demolition Waste in the Production of Concrete Blocks. J. Constr. Mater. 2020, 2, 1–6. [Google Scholar] [CrossRef]

- Zubair, M.; Humayun Mahmood, G.M.S.I. Geopolymer-Based Building Blocks Using Construction and Geopolymer-Based Building Blocks Using Construction. In Proceedings of the 6th International Conference on Advances in Civil Engineering (ICACE-2022), Virtual, 20–22 December 2022. [Google Scholar]

- Liu, D.; Qiao, L.; Li, G. Experimental Performance Measures of Recycled Insulation Concrete Blocks from Construction and Demolition Waste. J. Renew. Mater. 2022, 10, 1675–1691. [Google Scholar] [CrossRef]

- Rojas-Valencia, M.N.; Rivas-Torres, B.I.; Fernández-Rojas, D.Y.; Gómez-Soberón, J.M. Recovery of Mixtures of Construction Waste, PET and Sugarcane Bagasse for the Manufacture of Partition Blocks. Materials 2022, 15, 6836. [Google Scholar] [CrossRef] [PubMed]

- Quadratin. En 10 Años se Duplicó la Cantidad de Vehículos en Michoacán. Available online: https://www.quadratin.com.mx/principal/En-10-anos-se-duplico-la-cantidad-de-vehiculos-en-Michoacan/ (accessed on 8 August 2023).

- La voz de Michoacán. Sin Freno, Crecimiento Vehicular en Morelia; Hay 2 Automóviles por Cada 3 Habitantes. Available online: https://www.lavozdemichoacan.com.mx/michoacan/morelia-appmobil/sin-freno-crecimiento-vehicular-en-morelia-hay-2-automoviles-por-cada-3-habitantes/ (accessed on 8 August 2023).

- INEGI. Available online: https://www.inegi.org.mx/app/cuadroentidad/Mich/2022/22/22_6 (accessed on 8 August 2023).

- Fraile-Garcia, E.; Ferreiro-Cabello, J.; Defez, B.; Peris-Fajanes, G. Acoustic Behavior of Hollow Blocks and Bricks Made of Concrete Doped Withwaste-Tire Rubber. Materials 2016, 9, 962. [Google Scholar] [CrossRef] [PubMed]

- Gerges, N.N.; Issa, C.A.; Fawaz, S.A. Rubber Concrete: Mechanical and Dynamical Properties. Case Stud. Constr. Mater. 2018, 9, e00184. [Google Scholar] [CrossRef]

- Sambucci, M.; Valente, M. Ground Waste Tire Rubber as a Total Replacement of Natural Aggregates in Concrete Mixes: Application for Lightweight Paving Blocks. Materials 2021, 14, 7493. [Google Scholar] [CrossRef] [PubMed]

- Rocha, J.H.A.; Galarza, F.P.; Chileno, N.G.C.; Rosas, M.H.; Peñaranda, S.P.; Diaz, L.L.; Abasto, R.P. Compressive Strength Assessment of Soil–Cement Blocks Incorporated with Waste Tire Steel Fiber. Materials 2022, 15, 1777. [Google Scholar] [CrossRef]

- Tarek, D.; Ahmed, M.M.; Hussein, H.S.; Zeyad, A.M.; Al-Enizi, A.M.; Yousef, A.; Ragab, A. Building Envelope Optimization Using Geopolymer Bricks to Improve the Energy Efficiency of Residential Buildings in Hot Arid Regions. Case Stud. Constr. Mater. 2022, 17, e01657. [Google Scholar] [CrossRef]

- Gao, Q.; Xiao, J.; Shen, J.; Hou, Y.; Guo, J. Properties of Super-Thin Layer Mortar with Recycled Brick Fines for Sintered Perforated Block Masonry. Case Stud. Constr. Mater. 2023, 18, e02015. [Google Scholar] [CrossRef]

- Srividya, T.; Kannan Rajkumar, P.R. Mechanical and Durability Properties of Alkali-Activated Binders Based Paver Blocks Derived from Secondary Sources. Case Stud. Constr. Mater. 2022, 17, e01561. [Google Scholar] [CrossRef]

- Hussain, I.; Ali, B.; Rashid, M.U.; Amir, M.T.; Riaz, S.; Ali, A. Engineering Properties of Factory Manufactured Paving Blocks Utilizing Steel Slag as Cement Replacement. Case Stud. Constr. Mater. 2021, 15, e00755. [Google Scholar] [CrossRef]

- Mahdi, S.N.; Babu, R.D.V.; Hossiney, N.; Abdullah, M.M.A.B. Strength and Durability Properties of Geopolymer Paver Blocks Made with Fly Ash and Brick Kiln Rice Husk Ash. Case Stud. Constr. Mater. 2022, 16, e00800. [Google Scholar] [CrossRef]

- Djamaluddin, A.R.; Caronge, M.A.; Tjaronge, M.W.; Lando, A.T.; Irmawaty, R. Evaluation of Sustainable Concrete Paving Blocks Incorporating Processed Waste Tea Ash. Case Stud. Constr. Mater. 2020, 12, e00325. [Google Scholar] [CrossRef]

- Chaikaew, C.; Sukontasukkul, P.; Chaisakulkiet, U.; Sata, V.; Chindaprasirt, P. Properties of Concrete Pedestrian Blocks Containing Crumb Rubber from Recycle Waste Tyres Reinforced with Steel Fibres. Case Stud. Constr. Mater. 2019, 11, e00304. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Akeed, M.H.; Qaidi, S.; Bakar, B.H.A. Ultra-High-Performance Concrete: Impacts of Steel Fibre Shape and Content on Flowability, Compressive Strength and Modulus of Rupture. Case Stud. Constr. Mater. 2022, 17, e01615. [Google Scholar] [CrossRef]

- Wang, X.; Chin, C.S.; Xia, J. Study on the Properties Variation of Recycled Concrete Paving Block Containing Multiple Waste Materials. Case Stud. Constr. Mater. 2023, 18, e01803. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Olalusi, O.B.; Ibia, S.; Prakash, A.K. Water Absorption, Strength and Microscale Properties of Interlocking Concrete Blocks Made with Plastic Fibre and Ceramic Aggregates. Case Stud. Constr. Mater. 2021, 15, e00677. [Google Scholar] [CrossRef]

- Antoun, M.; Issa, C.A.; Aouad, G.; Gerges, N. Sustainable Masonry Blocks: Olive Wood Waste as Substitute for Fine Aggregates. Case Stud. Constr. Mater. 2021, 15, e00590. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Akeed, M.H.; Qaidi, S.; Bakar, B.H.A. Influence of Sand Grain Size Distribution and Supplementary Cementitious Materials on the Compressive Strength of Ultrahigh-Performance Concrete. Case Stud. Constr. Mater. 2022, 17, e01495. [Google Scholar] [CrossRef]

- ASTM C127-15; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C29/C29M-07; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- Organismo Nacional de Normalización y Certificación de la Construcción y Edificación, S.C. (ONNCCE) NMX-C-414-ONNCCE-2017 Building Industry-Hydraulic Cements-Specifications and Testing Methods 2017. Available online: https://www.onncce.org.mx/es/venta-normas/fichas-tecnicas?view=item&id=1879 (accessed on 8 August 2023).

- Comisión Europea Service Contracton Management of Construction and Demolition waste-SR1. Reporte Final; Paris, 2011. Available online: https://op.europa.eu/en/publication-detail/-/publication/0c9ecefc-d07a-492e-a7e1-6d355b16dde4 (accessed on 8 August 2023).

- Lara Guerrero, E.J.; Guerrero Cuasapaz, D.P.; Altamirano León, B.I. Influencia de Las Partículas de Caucho En La Resistencia a La Compresión de Bloques de Concreto. Rev. Tec. Fac. Ing. Univ. Zulia 2020, 43, 134–141. [Google Scholar] [CrossRef]

- ASTM C140/C140M-21; Standard Test Methods for Sampling and Testing Concrete Masonry Units and Related Units. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C78/C78M-22; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C566-19; Standard Test Method for Total Evaporable Moisture Content of Aggregate by Drying. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C469/C469M-22; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C1876-19; Standard Test Method for Bulk Electrical Resistivity or Bulk Conductivity of Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- Zrar, Y.J.; Younis, K.H.; Sherwani, A.F.H. Properties of Sustainable Self-Compacted Concrete with Recycled Concrete and Waste Tire Crumb Rubber Aggregates. Constr. Build. Mater. 2023, 407, 133524. [Google Scholar] [CrossRef]

- Mei, X.; Sheng, Q.; Cui, Z.; Zhang, M.; Dias, D. Experimental Investigation on the Mechanical and Damping Properties of Rubber-Sand-Concrete Prepared with Recycled Waste Tires for Aseismic Isolation Layer. Soil Dyn. Earthq. Eng. 2023, 165, 107718. [Google Scholar] [CrossRef]

- Juveria, F.; Rajeev, P.; Jegatheesan, P.; Sanjayan, J. Impact of Stabilisation on Mechanical Properties of Recycled Concrete Aggregate Mixed with Waste Tyre Rubber as a Pavement Material. Case Stud. Constr. Mater. 2023, 18, e02001. [Google Scholar] [CrossRef]

- Trocónis, O.; Romero, A.; Andrade, C.; Helene, P.; Díaz, I. Manual de Inspección, Evaluación y Diagnóstico De Corrosión en Estructuras de Hormigón Armado; Red Temática XV. 13, Durabilidad de la Armadura; CYTED: Cambridge, UK, 2006; 208p, ISBN 980-296-541-3. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).