A Novel Photovoltaic Panel Cleaning and Cooling Approach through Air Conditioner Condensate Water

Abstract

:1. Introduction

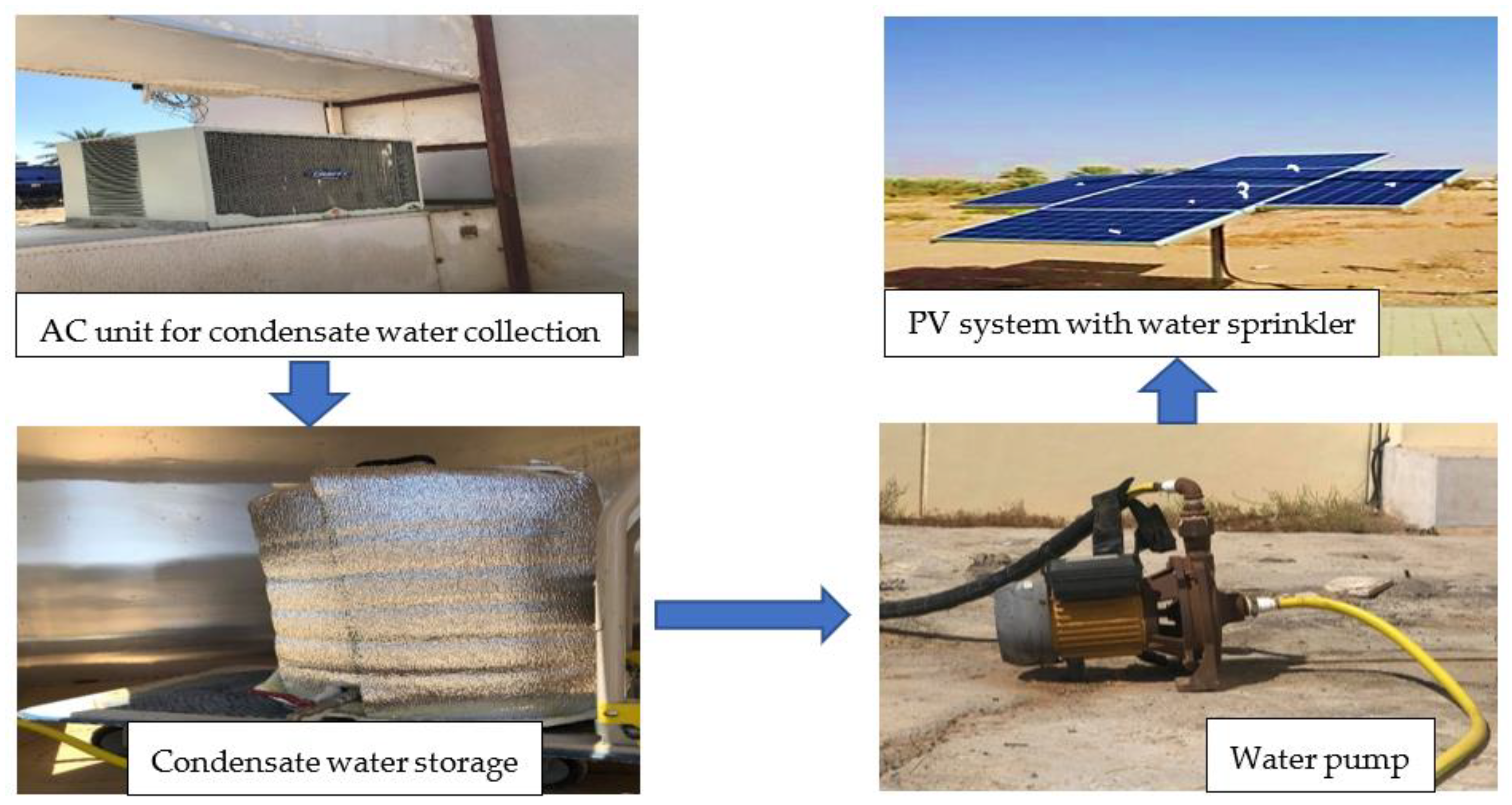

2. Materials and Methods

2.1. Methodology and Setup

2.2. Experimental Design

- ▪

- To determine the appropriate time to flow water in a single run on one panel for effective cleaning.

- ▪

- To determine the time required for one cooling run to ensure keeping the temperature below the reference temperature.

- ▪

- To evaluate the effectiveness of cooling and cleaning one panel compared to cooling four panels (to represent array design) while flowing the same amount of water over panels.

- ▪

- To assess the added benefit from the proposed configuration of cooling and cleaning setups compared to cleaning only.

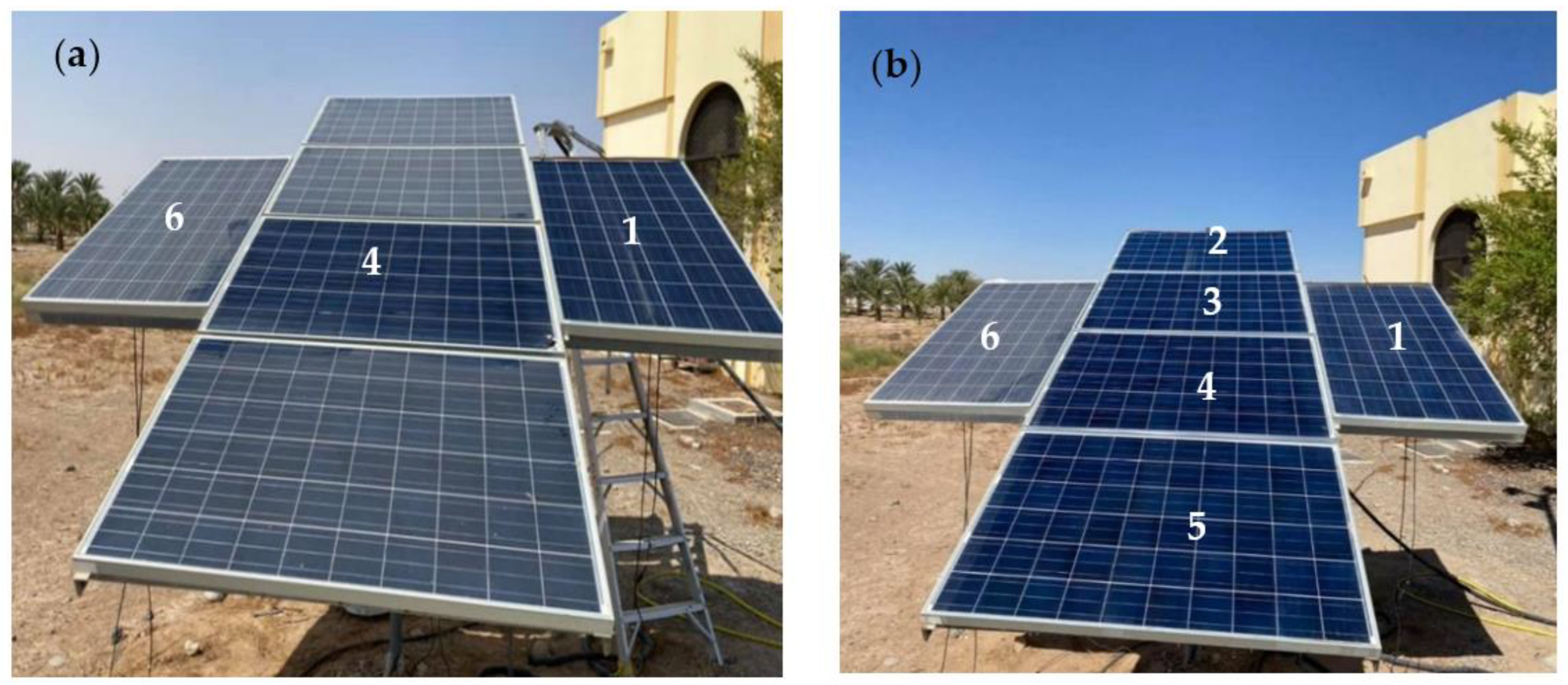

2.2.1. Configuration 1 (Single Panel Cooling and Cleaning)

- ▪

- In the first run, water was flown over panel 1’s front surface for five minutes to cool and clean the panel. The temperature as well as the electrical performance were recorded during water flow and afterwards until the cooled panel got back to (or was near) the original steady-state temperature before cooling. This measure provided the minimum temperature achieved by the panel when cooled with water and the duration for which the cooled panel got back to the initial temperature after stopping the flow.

- ▪

- In the second experimental run, the water flow duration was reduced to one minute in order to compare the cleaning achieved in the 1 min run to that in the 5 min run, as represented by the panel’s electrical performance. The objective was to determine whether comparable panels’ performance could be maintained while reducing water consumption by a factor of five by reducing the flow duration while keeping the constant flow rate.

2.2.2. Configuration 2 (4 PV Panels Array Cooling and Cleaning)

- ▪

- Water was flushed over the four PV panels for one minute and stopped. The temperature and electrical performance, measured by open circuit voltage and short circuit current, of these panels were recorded to quantify the cooling and cleaning achieved by the proposed system.

2.3. Air Conditioner Condensate Water Prediction

- W: The rate of water generation is in liters per hour.

- k: The coefficient represents the efficiency and cooling capacity of the air conditioner.

- T: The ambient temperature is measured in degrees Celsius.

- Td: Dew point temperature in Degree Celsius.

- A: Surface area of the air conditioner’s evaporator coil in meters squared.

- A constant cooling capacity and efficiency for the air conditioner.

- Neglect other factors, such as the air conditioner’s insulation and specific design.

3. Results

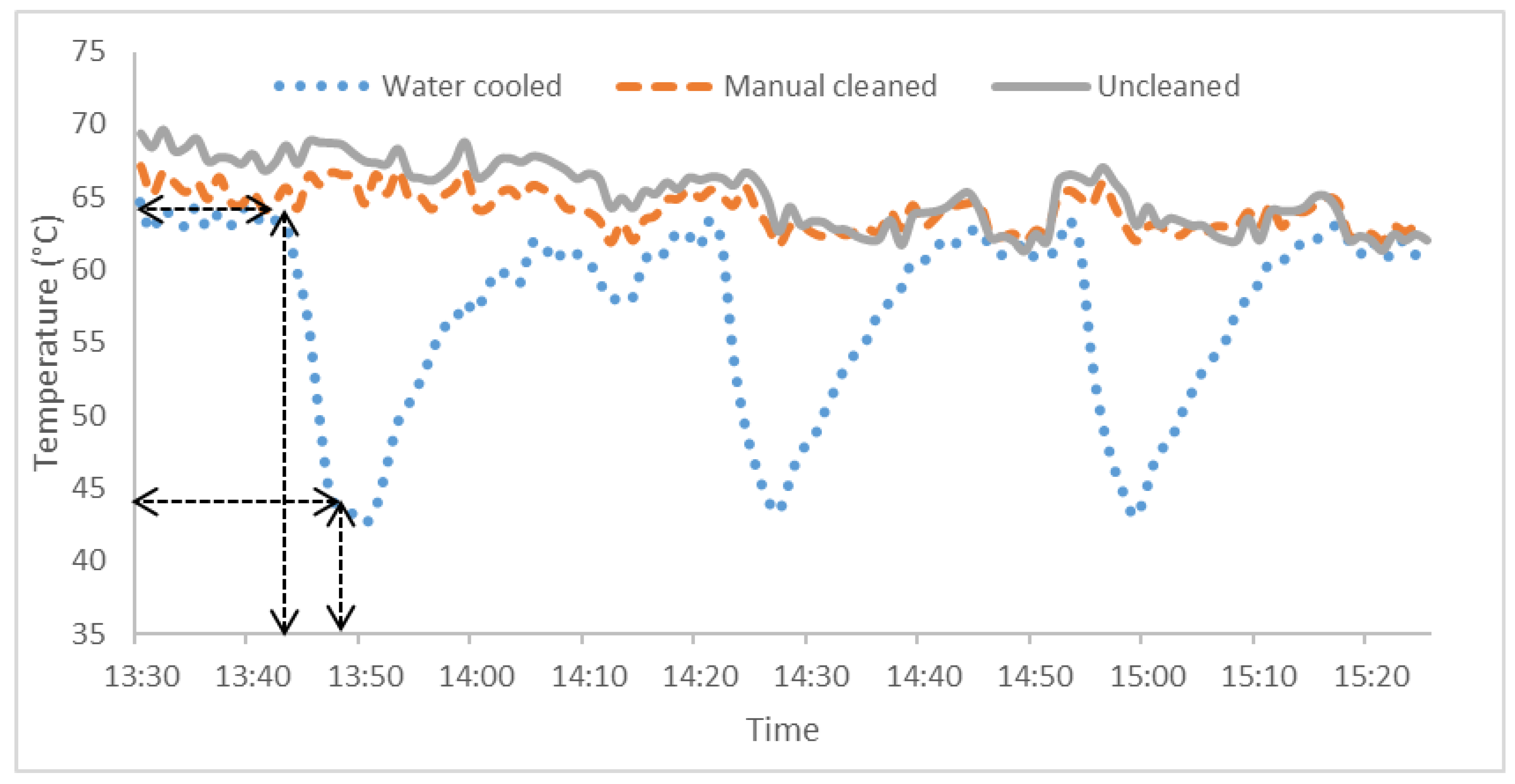

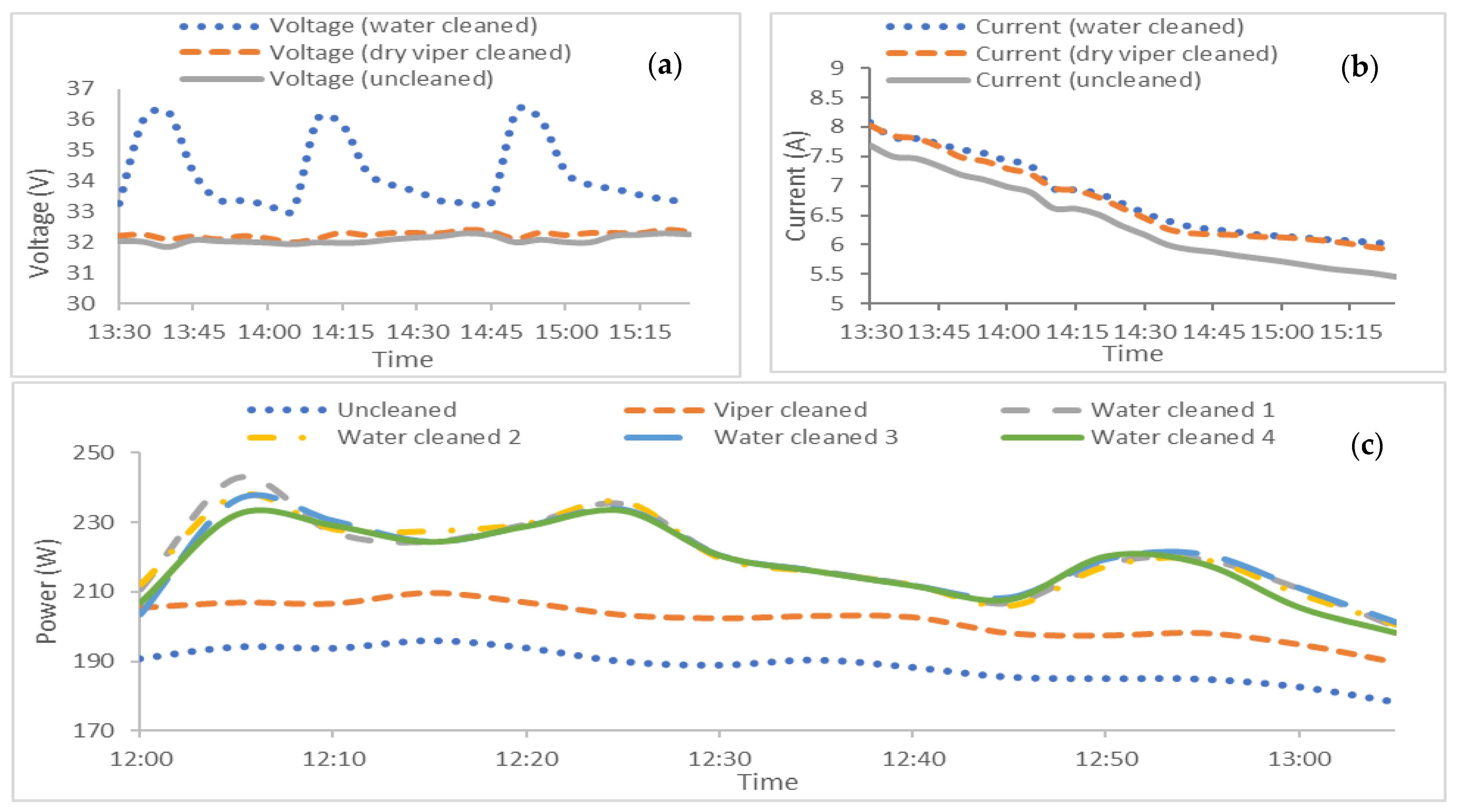

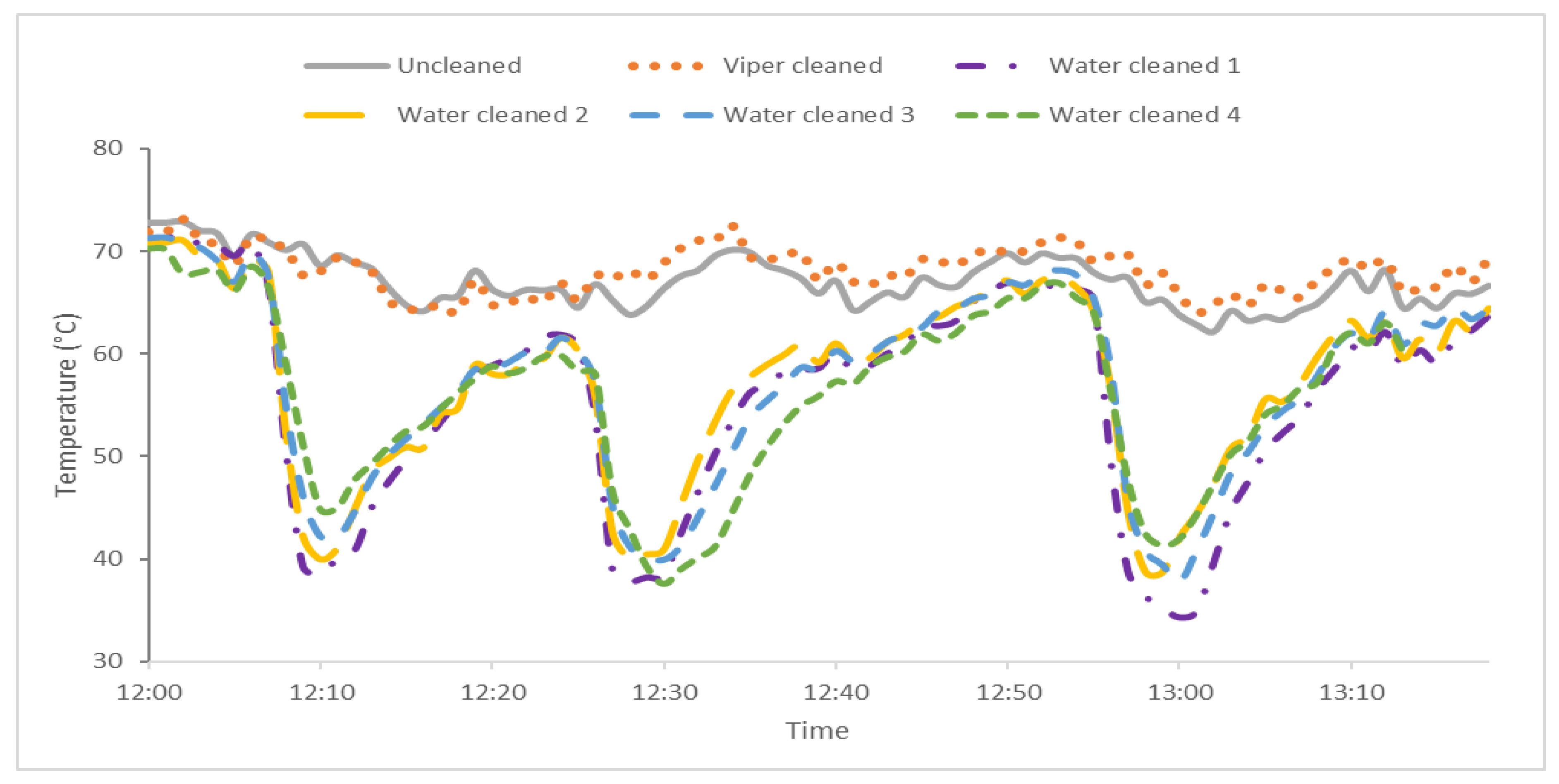

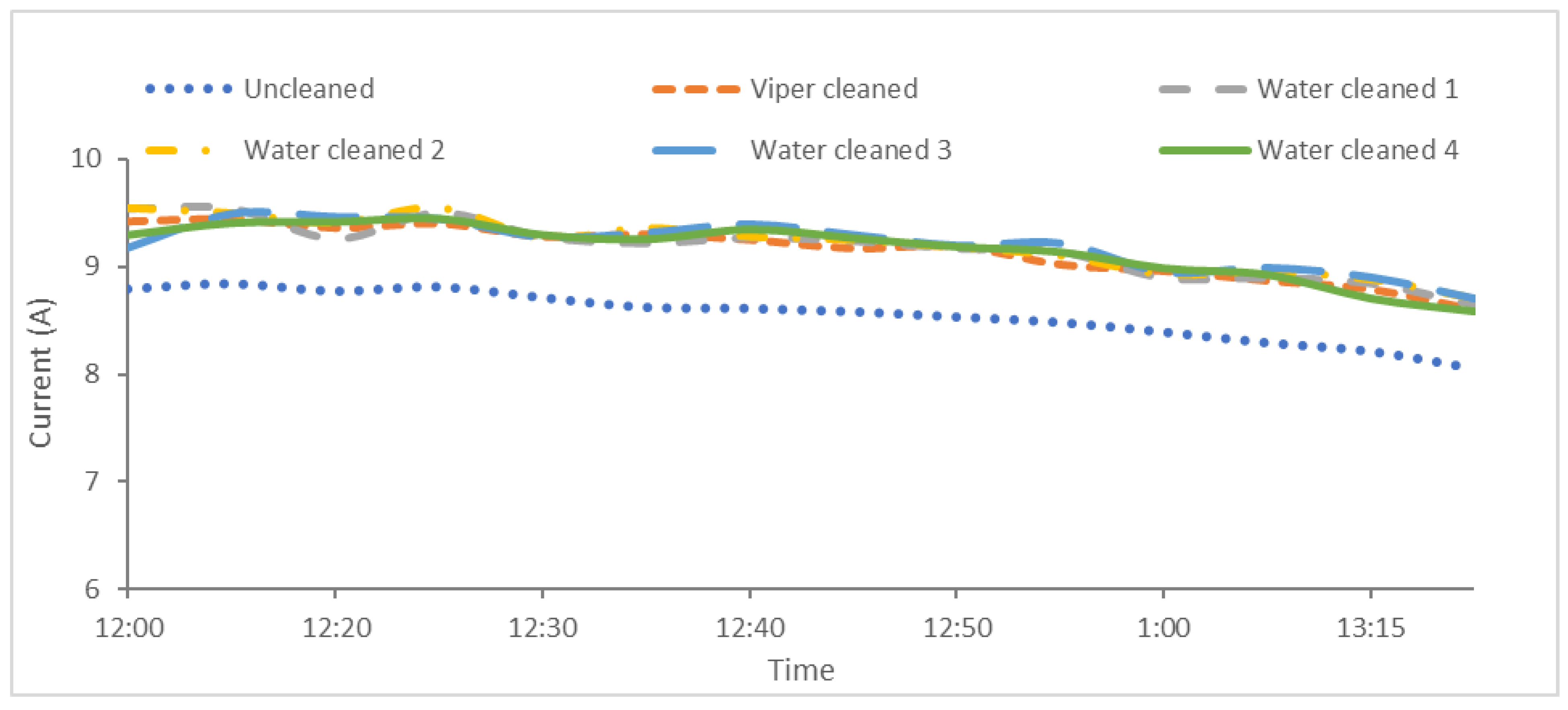

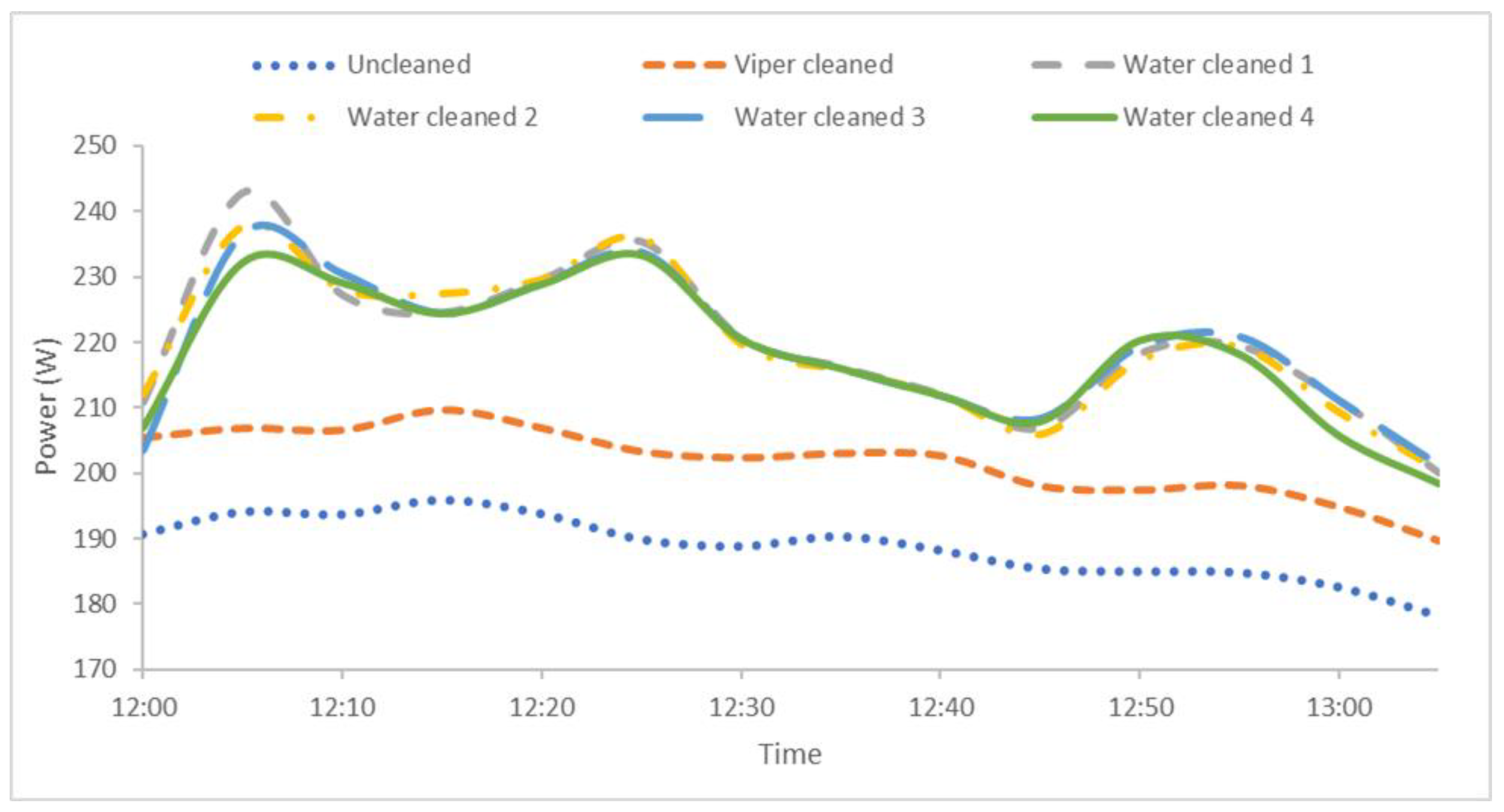

3.1. Configuration 1

3.2. Configuration 2

3.3. Prediction of Generated A/C Condensate Water

4. Discussion

- Data acquisition: Proceed with the acquisition of relevant information from the air conditioning system. This includes the collection of various inputs, such as ambient temperature, humidity levels, and cooling capacity, alongside the corresponding measurements of water generation.

- Preprocess the data: The second step in the research process involves the preprocessing of the data. This includes the rigorous cleaning and preprocessing of the data set to eliminate any potential outliers or missing values that may adversely impact the accuracy and reliability of the subsequent analyses. To ensure consistency and comparability among the numerical features, it may be necessary to normalize them to a common scale.

- Feature engineering: The relevant characteristics within the data set that could potentially impact water generation shall be identified and extracted. The dew point temperature, also known as the temperature of saturation, refers to the specific temperature at which the air becomes fully saturated with water vapor, leading to the onset of condensation.

- Split the data: The data set should be divided into two distinct subsets, namely a training set and a test set. The training set will be utilized for the purpose of training the model, whereas the test set will be employed to assess and evaluate the performance of the model.

- Select a regression model: To accurately capture the relationship between the input features and the target variable, it is important to select an appropriate regression model. Linear regression, decision trees, and random forests are widely employed methodologies for addressing prediction tasks of this kind.

- Train the model: The chosen regression model should be applied to the training data in order to assess its performance and predictive capabilities. The proposed model aims to acquire the ability to establish a functional relationship between the input features and the target variable.

- Evaluate the model: The evaluation of the trained model’s performance can be conducted using the test set. In order to assess the accuracy of predictions, it is common practice to employ metrics such as mean squared error (MSE) or root mean squared error (RMSE). These metrics provide quantitative measures that allow researchers to evaluate the quality of predictions made by a given model. By calculating the MSE or RMSE, one can gain insights into the average squared difference between predicted values and actual values. This information aids in determining the level of accuracy achieved by the predictive model under consideration.

- Fine-tune the model: In case the performance of the model does not meet expectations, researchers may explore alternative models, fine-tune hyperparameters, or consider including additional features as possible approaches to enhance the accuracy of predictions.

- Predict water generation: Upon successfully training and validating a model, it becomes feasible to employ an addressed model for the purpose of predicting water generation based on novel input data. To estimate water generation, the model requires input features such as ambient temperature, humidity levels, and other relevant factors.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| A | Area |

| AWG | Atmospheric water generation |

| BHK | Bedroom, hall kitchen |

| CC | Cooling capacity |

| DAQ | Data acquisition system |

| HWAC | Heating ventilation air conditioning |

| Isc | Short circuit current |

| k | The coefficient represents the efficiency and cooling capacity of an air conditioner |

| ML | Machine Learning |

| MSE | Mean square error |

| P | Power |

| PV | Photovoltaic |

| RH | Relative humidity |

| RMSE | Route mean square error |

| T | The ambient temperature in Degrees Celsius |

| Td | Dew point temperature in Degree Celsius |

| Voc | Open circuit voltage |

| W | Water |

| A/C | Air Conditioner |

References

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Radziemska, E. The effect of temperature on the power drop in crystalline silicon solar cells. Renew. Energy 2003, 28, 1–12. [Google Scholar] [CrossRef]

- Moharram, K.A.; Abd-Elhady, M.S.; Kandil, H.A.; El-Sherif, H. Enhancing the performance of photovoltaic panels by water cooling. Ain Shams Eng. J. 2013, 4, 869–877. [Google Scholar] [CrossRef]

- Liu, X.; Yue, S.; Lu, L.; Li, J. Investigation of the dust scaling behaviour on solar photovoltaic panels. J. Clean. Prod. 2021, 295, 126391. [Google Scholar] [CrossRef]

- Shenouda, R.; Abd-Elhady, M.S.; Kandil, H.A. A review of dust accumulation on PV panels in the MENA and the Far East regions. J. Eng. Appl. Sci. 2022, 69, 8. [Google Scholar] [CrossRef]

- Pradhan, A.; Parashar, S.K.S.; Ali, S.M.; Paikray, P. Water cooling method to improve efficiency of photovoltaic module. In Proceedings of the 2016 International Conference on Signal Processing, Communication, Power and Embedded System (SCOPES), Paralakhemundi, India, 3–5 October 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1044–1047. [Google Scholar]

- Younis, A.; Onsa, M. A brief summary of cleaning operations and their effect on the photovoltaic performance in Africa and the Middle East. Energy Rep. 2022, 8, 2334–2347. [Google Scholar] [CrossRef]

- AlMallahi, M.N.; El Haj Assad, M.; AlShihabi, S.; Alayi, R. Multi-criteria decision-making approach for the selection of cleaning method of solar PV panels in United Arab Emirates based on sustainability perspective. Int. J. Low-Carbon Technol. 2022, 17, 380–393. [Google Scholar] [CrossRef]

- Salamah, T.; Ramahi, A.; Alamara, K.; Juaidi, A.; Abdallah, R.; Abdelkareem, M.A.; Amer, E.-C.; Olabi, A.G. Effect of dust and methods of cleaning on the performance of solar PV module for different climate regions: Comprehensive review. Sci. Total Environ. 2022, 827, 154050. [Google Scholar] [CrossRef]

- Zhou, X.; Lu, H.; Zhao, F.; Yu, G. Atmospheric water harvesting: A review of material and structural designs. ACS Mater. Lett. 2020, 2, 671–684. [Google Scholar] [CrossRef]

- Chen, K.; Tao, Y.; Shi, W. Recent Advances in Water Harvesting: A Review of Materials, Devices and Applications. Sustainability 2022, 14, 6244. [Google Scholar] [CrossRef]

- Ahmad, F.F.; Ghenai, C.; Al Bardan, M.; Bourgon, M.; Shanableh, A. Performance analysis of atmospheric water generator under hot and humid climate conditions: Drinkable water production and system energy consumption. Case Stud. Chem. Environ. Eng. 2022, 6, 100270. [Google Scholar] [CrossRef]

- Meng, Y.; Dang, Y.; Suib, S.L. Materials and devices for atmospheric water harvesting. Cell Rep. Phys. Sci. 2022, 3, 100976. [Google Scholar] [CrossRef]

- Liu, X.; Beysens, D.; Bourouina, T. Water harvesting from air: Current passive approaches and outlook. ACS Mater. Lett. 2022, 4, 1003–1024. [Google Scholar] [CrossRef]

- Inbar, O.; Gozlan, I.; Ratner, S.; Aviv, Y.; Sirota, R.; Avisar, D. Producing safe drinking water using an atmospheric water generator (AWG) in an urban environment. Water 2020, 12, 2940. [Google Scholar] [CrossRef]

- Mendoza-Escamilla, J.A.; Hernandez-Rangel, F.J.; Cruz-Alcántar, P.; Saavedra-Leos, M.Z.; Morales-Morales, J.; Figueroa-Diaz, R.A.; Valencia-Castillo, C.M.; Martinez-Lopez, F.J. A feasibility study on the use of an atmospheric water generator (AWG) for the harvesting of fresh water in a semi-arid region affected by mining pollution. Appl. Sci. 2019, 9, 3278. [Google Scholar] [CrossRef]

- Feng, A.; Akther, N.; Duan, X.; Peng, S.; Onggowarsito, C.; Mao, S.; Fu, Q.; Kolev, S.D. Recent Development of Atmospheric Water Harvesting Materials: A Review. ACS Mater. Au 2022, 2, 576–595. [Google Scholar] [CrossRef]

- Magrini, A.; Cattani, L.; Cartesegna, M.; Magnani, L. Water production from air conditioning systems: Some evaluations about a sustainable use of resources. Sustainability 2017, 9, 1309. [Google Scholar] [CrossRef]

- Hosseinkhani, O.; Kargari, A. Production of high-quality drinking water from chillers and air conditioning units’ condensates using UV/GAC/MF/NF hybrid system. J. Clean. Prod. 2022, 368, 133177. [Google Scholar] [CrossRef]

- Moghimi, F.; Ghoddusi, H.; Asiabanpour, B.; Behroozikhah, M. Atmospheric water generation (AWG): Performance model and economic analysis. In Advances in Production Management Systems. Towards Smart Production Management Systems: IFIP WG 5.7 International Conference, APMS 2019, Austin, TX, USA, 1–5 September 2019, Proceedings, Part II; Springer International Publishing: New York, NY, USA, 2019; pp. 151–158. [Google Scholar]

- Ali, M.A.; Saifur, S.; Ali, M.A. Quantification of condensate water generated from air conditioning system. Glob. Sci. Technol. J. 2018, 6, 44–56. [Google Scholar]

- Snyder, R.L.; Shaw, R.H. Converting Humidity Expressions with Computers and Calculators; University of California. Division of Agriculture and Natural Resources: Oakland, CA, USA, 1984. [Google Scholar]

- Chander, S.; Purohit, A.; Sharma, A.; Arvind; Nehra, S.; Dhaka, M. A study on photovoltaic parameters of mono-crystalline silicon solar cell with cell temperature. Energy Rep. 2015, 1, 104–109. [Google Scholar] [CrossRef]

- Banerjee, K.; Bali, V.; Nawaz, N.; Bali, S.; Mathur, S.; Mishra, R.K.; Rani, S. A machine-learning approach for prediction of water contamination using latitude, longitude, and elevation. Water 2022, 14, 728. [Google Scholar] [CrossRef]

- Khoi, D.N.; Quan, N.T.; Linh, D.Q.; Nhi, P.T.T.; Thuy, N.T.D. Using machine learning models for predicting the water quality index in the La Buong River, Vietnam. Water 2022, 14, 1552. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, A.H.; Alraeesi, A.; Hassan, A.; Laghari, M.S. A Novel Photovoltaic Panel Cleaning and Cooling Approach through Air Conditioner Condensate Water. Sustainability 2023, 15, 15431. https://doi.org/10.3390/su152115431

Shah AH, Alraeesi A, Hassan A, Laghari MS. A Novel Photovoltaic Panel Cleaning and Cooling Approach through Air Conditioner Condensate Water. Sustainability. 2023; 15(21):15431. https://doi.org/10.3390/su152115431

Chicago/Turabian StyleShah, Ali Hasan, Abdulrahman Alraeesi, Ahmed Hassan, and Mohammad Shakeel Laghari. 2023. "A Novel Photovoltaic Panel Cleaning and Cooling Approach through Air Conditioner Condensate Water" Sustainability 15, no. 21: 15431. https://doi.org/10.3390/su152115431