Abstract

Promotion of durable materials and products is a common approach to enhance sustainability. However, the effectiveness of such efforts lies on shifts in user behavior and consumption patterns, and these patterns are influenced not only by material aspects but also by social and experiential dimensions. It has been observed that the consumers’ consumption pattern, i.e., post-consumption behavior, is as harmful as production. However, this area remains largely unexplored. The primary purpose of this study is to explore sustainable garment design strategies to enhance emotional durability of garments and reduce pre-consumer and most importantly, the post-consumer waste. For this purpose, 18 garments were produced using ZWPC for pre-consumption waste reduction and DFD for post-consumption waste minimization. Three hypotheses were developed. Quantitative and qualitative data were collected through questionnaires and wear trials on the practicality of DFD implementation in garments. The results demonstrated that the combination of these strategies has the potential to curb both pre-consumer and post-consumer waste by designing garments that can enter the biological as well as technical cycle of circular fashion (CF). Furthermore, DFD is a success in increasing the use-life of a garment.

1. Introduction

The textile and fashion industry is the leading potential polluter in the world. This industry generates about 92 million tons of waste annually and consumes nine trillion liters of water [1]. Fast fashion has acquired a lot of success in the international market [2], providing demand-driven style, quality fashion, and a swift time-to-market strategy [3]. Its production is derived from the market’s demand in the shortest possible time [4]. These values of a fast business model automatically speed up the buying and consumption rate leading to overconsumption and tons of waste in the landfill [5]. This waste comprises both pre-consumption and post-consumption waste [6]. The overconsumption of fast fashion and continued improper disposal methods are growing environmental concerns because our landfills are piled up with billions of pounds of post-consumer waste. Sustainable consumption occurs when consumers reduce consumption and opt for products that support environmental integrity and ecological integrity [7]. The fourth industrial revolution and digitalization are known as Industry 4.0 [8]. A study conducted by Beltrami et al. reported current interrelations between Industry 4.0 technologies and sustainability theory. Four focal areas, i.e., Industry 4.0 and sustainability performance; Industry 4.0 and sustainability practices; Industry 4.0, sustainability practices, and sustainability performance; and moderating factors, were noted [9]. I4.0 technologies must be used to encourage transformation for multinational corporate purposes and as a system to distribute it across various subsidiaries and stakeholders [10]. In a study, [11] acknowledged the sustainability functions of I4.0.

Circular fashion is a new concept [12]: it mainly refers to fashion items that are designed by considering factors such as product life longevity, good ethics, non-toxicity, recyclability, resource efficiency, and biodegradability [13]. It is about keeping the material in circulation and advocates energy efficiency, repairability, reusability, and recyclability of textile products. Furthermore, it focuses on taking initiatives along the entire life cycle of a product from its design to its usability [14]. Product life extension outlines maintenance and the ability to be repaired, upgradability, compatibility, and disassembly and reassembly [15]. This strategy is about extending the use period of the product through the availability of a service loop [6]. “Designing for Circularity” has become a global goal as a counterpart to the global trend of fast fashion [16]. Research conducted by [17] reported a holistic framework by utilizing novel technologies such as artificial intelligence and blockchain to address the problem of packaging waste. Thus, the circular economy was linked with using advanced technologies and adding a resource value loop to product life cycle theory. From previous literature, it was noted that when the circular economy was applied in the textiles and apparel industry, four themes, i.e., drivers, barriers, practices, and indicators, were identified for the sustainable performance of the manufacturing industry [18]. The circular business model keeps the raw material in the loop [19]. It allows to continually reuse materials and goods, using viable renewable resources [20]. According to [12], circular fashion (CF) research emerged in 2017, with only 13 (22.0%) CF-published articles. Although CF was introduced in the 1990s, academic research in a circular fashion is still far from saturation. Zero-waste fashion advocates designs to minimize/prevent waste [21]. Almost 85% of the fabric spread in a garment is used in conventional garment-making methods. This result produces 15% to 20% and sometimes 25% cutting wastage. However, the amount of fabric wasted during the production of a single garment can vary depending on several factors such as production processes used, design complexity, pattern layout, and the skill of the pattern maker. The higher the garment yield, the lower the interlaced waste [8]. McQuillan [22] in a study ran field tests in order to efficiently improve garment yield and minimize interlaced waste, without changing the critical details of the garments. In one case, it was found that the addition of an extra seam reduced the yield by 26%, and not just that—the savings on fabric yield outweighed the additional seam cost.

Chen [23] investigated the impact of a social, environmental, and economic assessment as a triple bottom line on the performance of the manufacturing industry and its supply chain. It was noted that acknowledging interrelationships between these above-mentioned assessments provided convenience to the manufacturing companies of Sweden to incorporate sustainability into manufacturing operation strategies. Thus, these companies can maintain their manufacturing operations for extended periods. In research conducted by [24], the impact of sustainable business development on manufacturing operations was studied. The prime focus was given to environmental factors instead of other factors of sustainability, i.e., social and economic longevity of the manufacturing industry. Materials recycling, prevention of pollution, minimizing wastage, and industrial performance were evaluated in terms of the four competitive capabilities, i.e., cost, quality, flexibility, and delivery.

Design for disassembly (DFD) initially emerged from design for assembly (DFA) and design for manufacture (DFM), and these concepts were established in 1970 [25]. Design for disassembly optimizes remanufacturing, recycling, and reuse of materials and components. This strategy overlaps and contributes to the design of technological and biological cycles [20]. Design for the disassembly and reassembly strategy demonstrates that products and parts can be disassembled or separated easily and conveniently assembled again [20]. This strategy helps increase the reuse rate of materials and components and proves vital for material separation that will enter different cycles, i.e., technological or biological. Thus, DFD products are made considering the disassembly aspect, and here the designer stands as a leading player in integrating such design elements into the product. In a case study led by [26], the effectiveness of incorporating demanufacturing along with disassembly operations at the initial stages was reaffirmed. The study urges that instead of using recycling methods at the end of the life of a product, manufacturers should focus on recycling initially as it appears more beneficial and reduces CO2 emissions. Moreover, demanufacturing of EoL products through a systematic disassembly plan and operations holds promise in effectively cutting down on the amount of waste being produced. However, it has been observed that sustainability practices, such as reuse and repurposing, are becoming more pronounced, particularly in the Global North; however, the Global South is predominantly aligned with livelihoods and employment [27]. This study further investigated the challenges and enablers of sustainable fashion manufacturing and found funding as a driving factor and inadequate remanufacturing education a notable hindrance.

Rissanen [28], claimed that the most favorable strategy was to eliminate waste in the design process. All the critical points in the fashion industry’s value chain were highlighted where the waste is being produced. The textile and fashion industry has an extensive supply chain, beginning with fiber production and ending with manufacturing and retailing [1]. It was suggested that hybrid zero-waste design strategies were required for a holistic approach toward production waste, as the current fashion production process was claimed to be unsustainable [29]. For instance, the intersection between fashion and textile design is to reduce or eliminate waste at the design level and to reveal new expressions. ZWFD strategies can be implemented in the designing stage for waste elimination. In a study that solved the issue of prototype waste, ref. [22] explored the possible level of 3D software such as CLO in augmenting zero waste design into garment making by conducting case studies in the context of research, industry, and education. The application of design to a disassemble strategy was investigated in the making of men’s jackets [30]. Afterward, a new design with a disassembly property was constructed, and the assembly time was also noted. It was pointed out that a reduction in material diversity, specific stitch selection, and minimizing minor details led to a jacket that could easily be disassembled within 1.5 min [31].

The literature review concluded that the post-consumption area is still untapped despite alarming conditions of landfill textile waste. Until now, there was no evidence of a research study being able to use both ZWFD and DFD strategies to achieve a circular fashion model. Moreover, much work is required to explore DFD as an aid to ZWFD.

The main objectives of this study are:

To reduce pre-consumer waste using zero-waste pattern cutting for the development of 2D/3D samples with the help of CAD software (Adobe Illustrator 2020).

To determine seam strength before and after disassembly and to conduct wear trials for aesthetic evaluation and for measuring time for the disassembly and reassembly of garments.

To reduce post-consumer waste using Design for Disassembly (DFD) to ensure product longevity.

2. Materials and Methodology

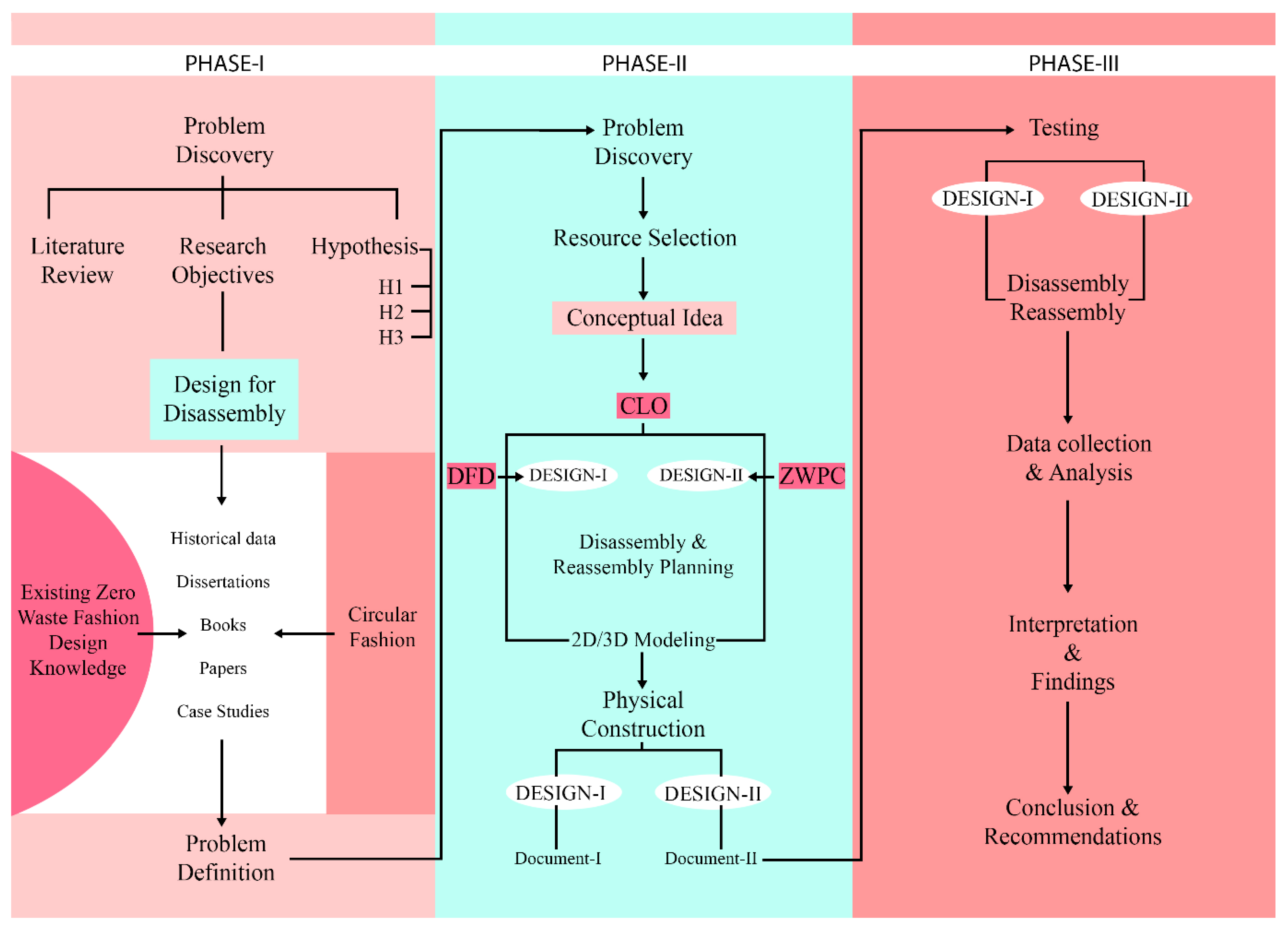

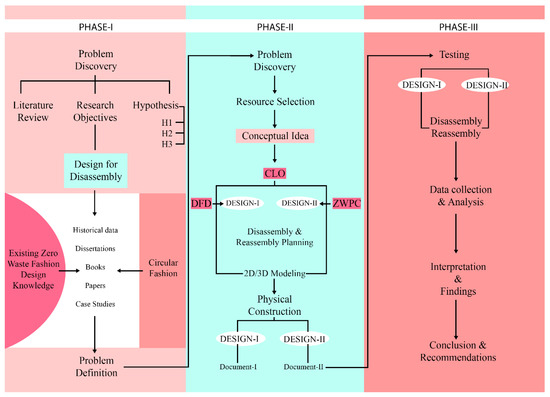

This study is divided into three phases. The first phase is acknowledged as the zero-waste design thinking stage. Afterward, the hypotheses were formulated, and the research problem was defined according to the objectives identified, as shown in Figure 1.

Figure 1.

Process flow chart.

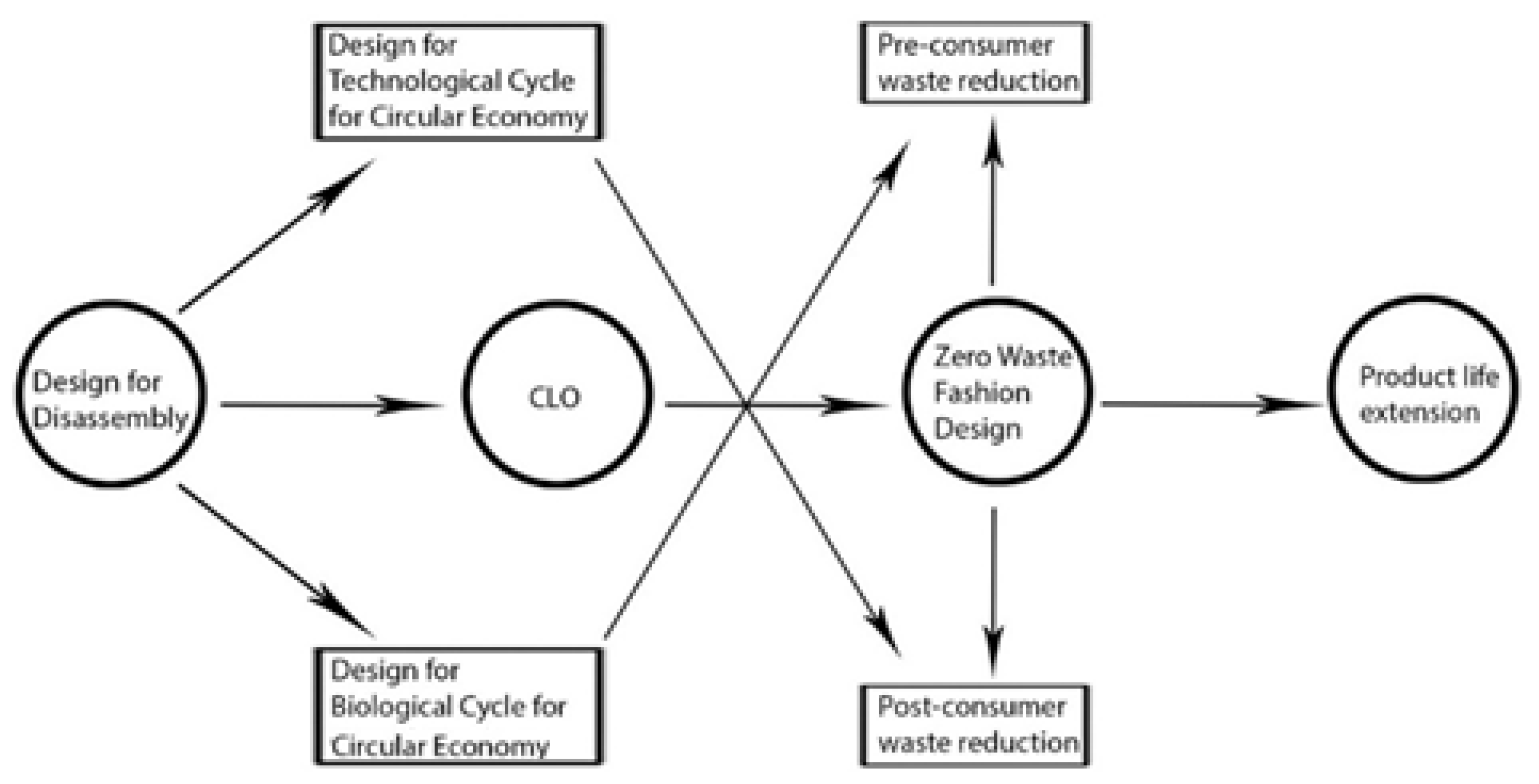

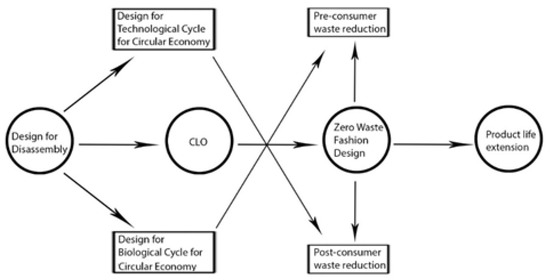

In Figure 2 the frame of the study presents 3 hypotheses that will be tested in this research.

Figure 2.

Conceptual framework for product life extension.

H1.

Design for disassembly strategy can reduce pre-consumer waste by designing garments that can enter the biological cycle for circular fashion.

H2.

Design for disassembly strategy can reduce post-consumer waste by designing garments that can enter the technical cycle for circular fashion.

H3.

Design for disassembly strategy can enhance the life of a garment.

The input variables include three subjects for objective and subjective evaluation of the outputs. Further, they had two garment categories to test the DFD strategy success or failure and three different stitch types for garment assembly to find the best suitable stitch type for DFD garments, as mentioned in Table 1.

Table 1.

Design of experiment.

Subjects (S): Three subjects will try eighteen garments, and one subject will try six garments each.

Garments (G): Two garment categories will be used for experimentation; tunic and kaftan dress. The material 100% cotton fabric was decided to be used to produce both garments as it allows for recycling.

Stitch types (N): Three types of stitches will be used; class 200 Hand stitch (insertion stitch), class 300 lock stitch, and class 500 Overlock stitch.

Fabric (F) is a fixed variable expected not to affect the output. The subjective analysis includes a questionnaire that will be filled out by the users in the trial session for the aesthetic preferences of the users. Objective observations will be taken for the success and failure analysis of DFD. Output variables are:

- Seam Strength (before disassembly);

- Disassembly time evaluation concerning stitch type;

- Reassembly time evaluation;

- Seam strength (after reassembly).

Phase II recontextualizes the constraints of the product, complying with zero waste design methodology. The selected research method was the collection of both quantitative and qualitative data. It includes seam strength before disassembly and after reassembly, disassembly time evaluation concerning stitch types, and reassembly time evaluation concerning stitch types, while qualitative data or subjective analysis includes a questionnaire that will be filled out by the users in the trial session for the aesthetic preferences of the users. The selected participants were three corporate women aged between 25 to 35 years. This phase is divided into the following steps:

- Development of 2D zero waste pattern of kaftan and tunic dress from Adobe Illustrator and comparison with conventional patterns followed by virtual simulation of the garment on 3D Fashion Software CLO (CLO 6.0) for precise virtual prototyping. Four designs were developed on CLO software, two designs for each category. Utilization of CLO addressed the possibility of reducing fabric waste by eliminating the need for physical sample development. Furthermore, it adjusts avatar body measurements according to the required sizes and provides accurate simulation. For this study, the default avatar main measurements in CLO were already compatible with the volunteered participants, thus negating any need for adjustments.

- Preparation of user guide document for each garment. This document comprised directions on disassembling and reassembling the garment into its second design. This document bearing information on the second designs was to be given to the subjects along with the garments after the wear trial of the first designs to assess how much subjects comprehend and easily interpret it.

- For the physical construction of the garment, three different types of stitches were selected.

- To test the seam strength/durability, the samples were tested according to the ASTM-D5035 [32].

- Development of 18 garments. Nine tunic dresses were sewn in 3 different stitch types. In short, three sets of tunic dresses were manufactured for three selected subjects, and each set comprised three tunics sewn with three types of stitches and in three different colors and patterns. Similarly, nine kaftan dresses were also manufactured using three different stitch types. The fabric type remained constant except for colors or print/pattern.

- Development of a questionnaire.

Phase III includes user testing of garments through a wear trial and quantitative and qualitative data collection.

3. Results and Discussions

Following the methodology described in the previous section, results are collected and summarized to validate the hypotheses. This section is divided into three parts under the heading of digital procedures, physical construction, and descriptive statistics. The physical construction is subdivided into seam strength testing, first wear trial assessment, second wear trial assessment, and quantitative and qualitative data.

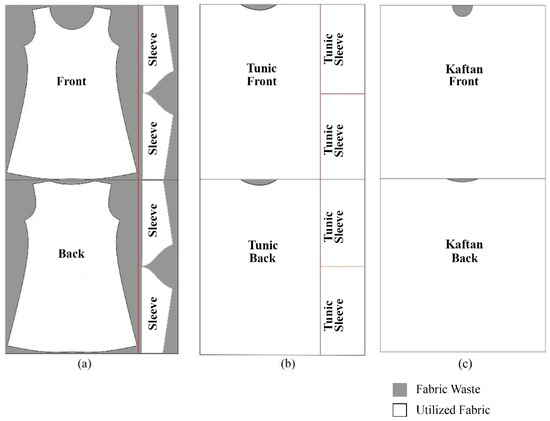

3.1. Digital Procedures

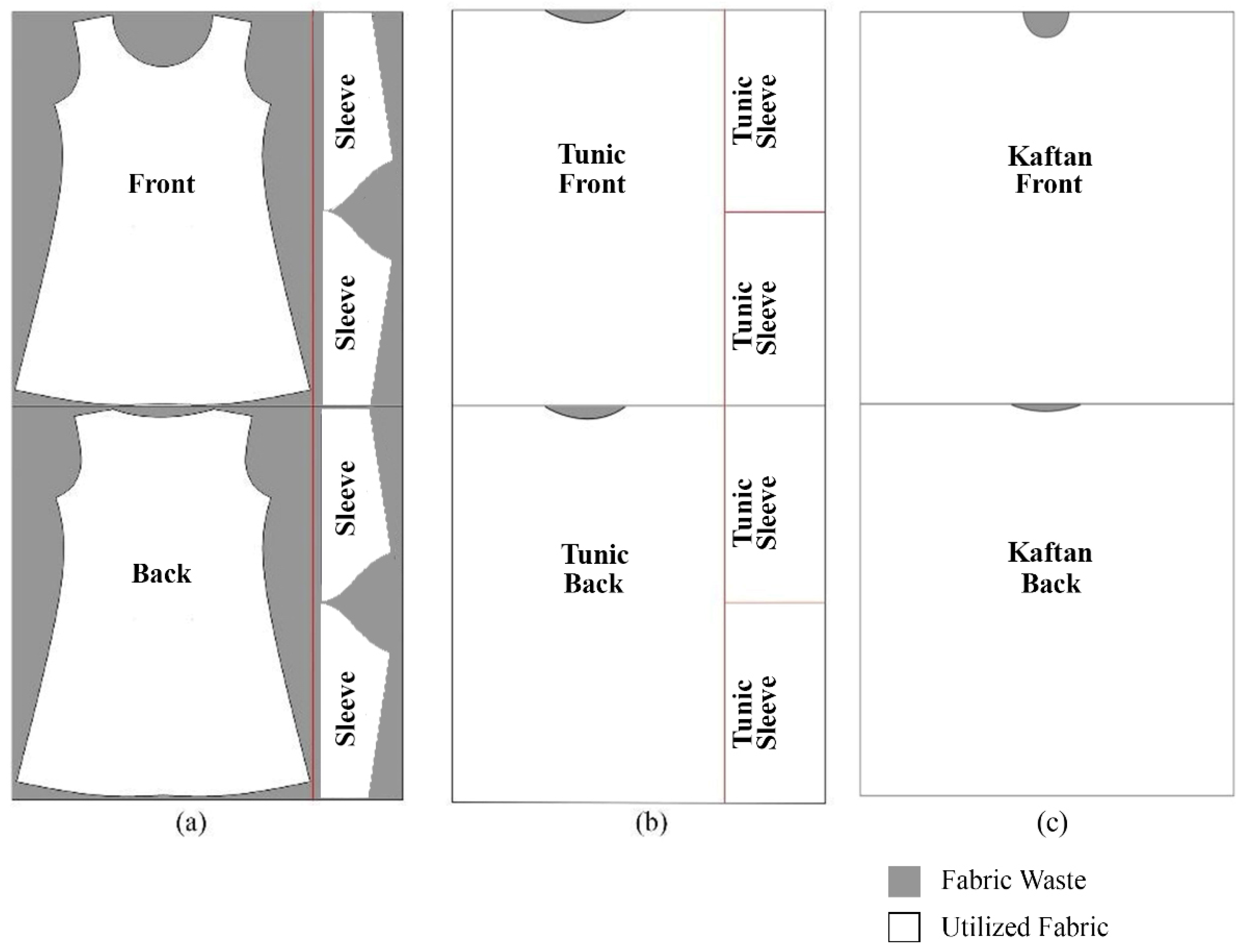

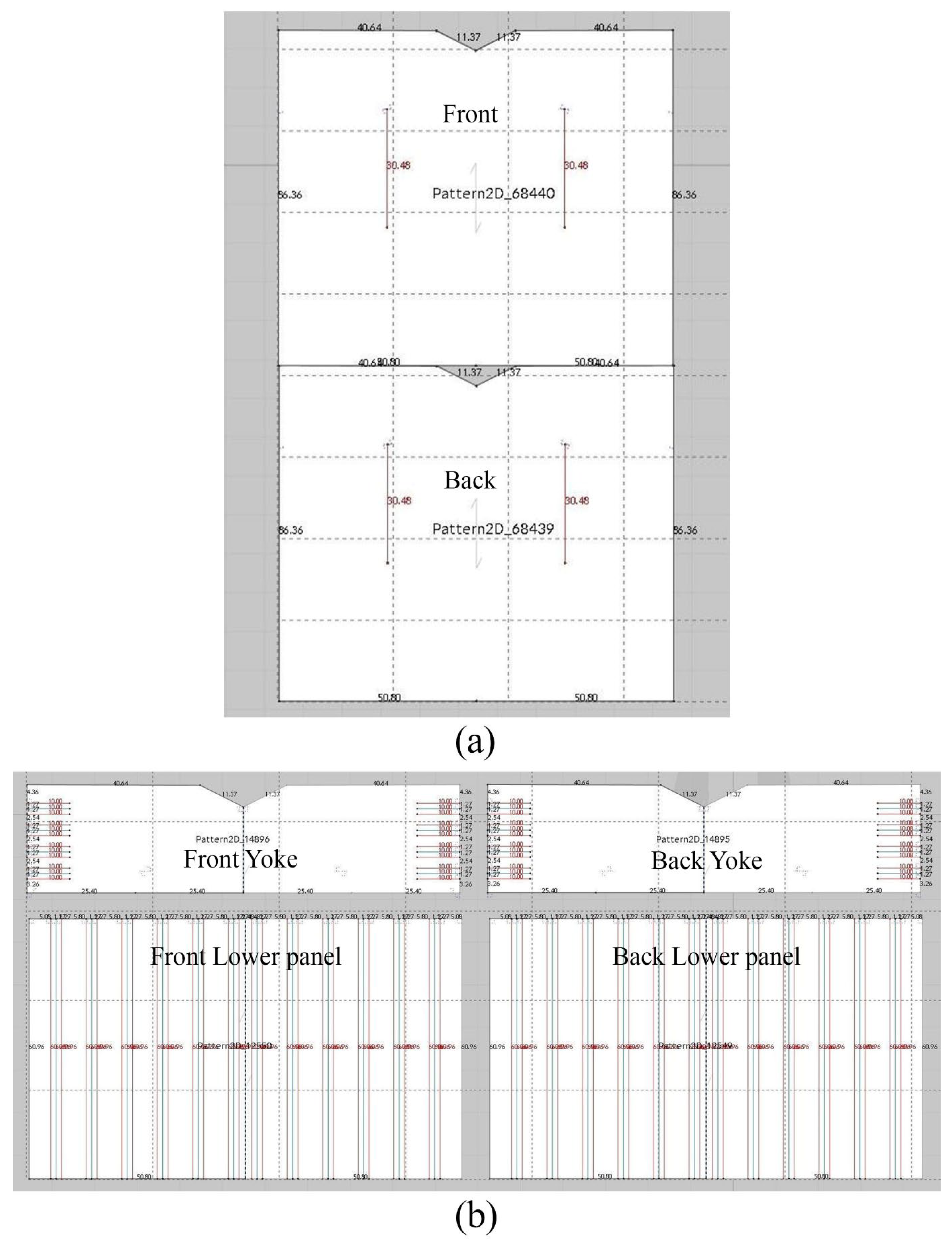

Testing of hypothesis-1 was accomplished by developing 2D patterns utilizing Adobe Illustrator (Adobe Illustrator 2020). The ZWPC strategy was implemented for tunics (traditional garments) to eliminate solid waste at the design stage and augment upcycling. However, the kaftan was a zero-waste garment itself unquestionably. The zero-waste pattern of the Tunic was established during the pre-planning design for disassembly execution. Figure 3 depicted that the conventional pattern of a tunic dress had 15% of wastage (in grey color), which was mainly because of curves in the pattern. A tunic made from two yards of fabric with a traditional pattern does not permit one-piece sleeves but two-piece sleeves with a seam in the center. To achieve one-piece sleeves without a seam requires an extra half-yard. This traditional pattern generates waste on the neckline, side seams, and sleeves mainly. While the zero-waste pattern of a tunic dress shows only 1% of waste production (in grey color), that too can be further reduced to 0%. Furthermore, it allows one-piece sleeves with gathers/pleats/ruffles detailing, but it is generated in a shorter length. Unlike zero-waste patterns, the conventional patterns of tunic dresses do not allow any detailing such as gathers or pleats in two yards. For the kaftan dress—the second garment type—there was no need to develop a zero-waste pattern as it is a zero-waste garment itself.

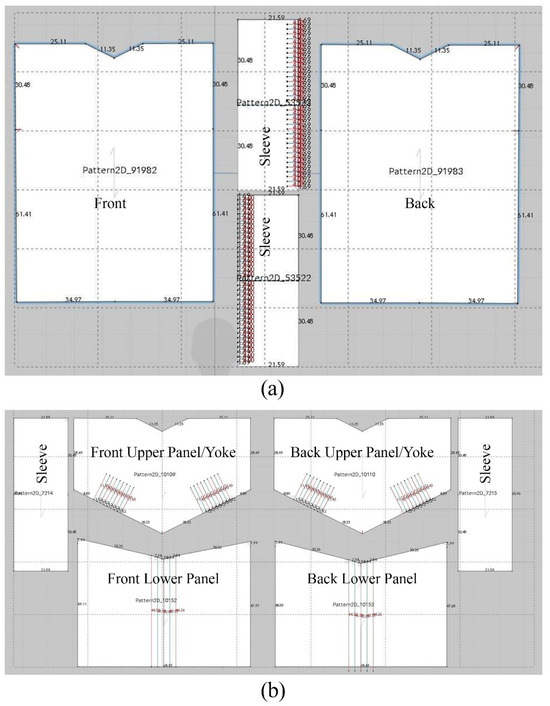

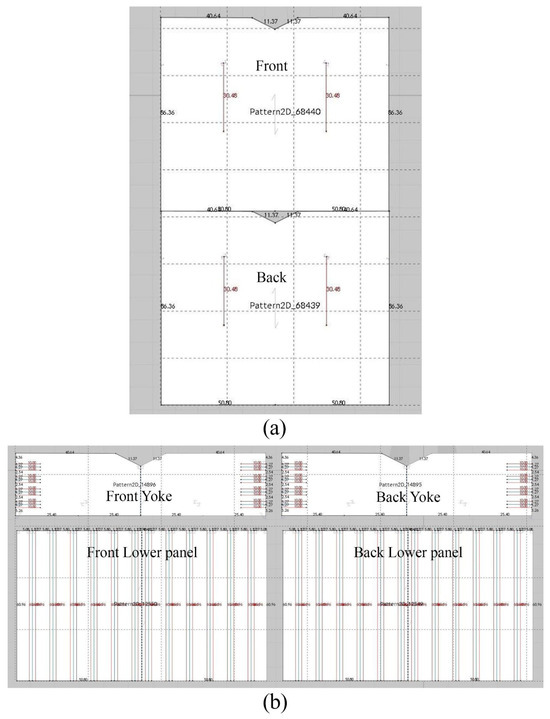

Figure 3.

(a) Comparison between conventional tunic pattern, (b) zero-waste tunic pattern, and (c) a pattern of a kaftan dress.

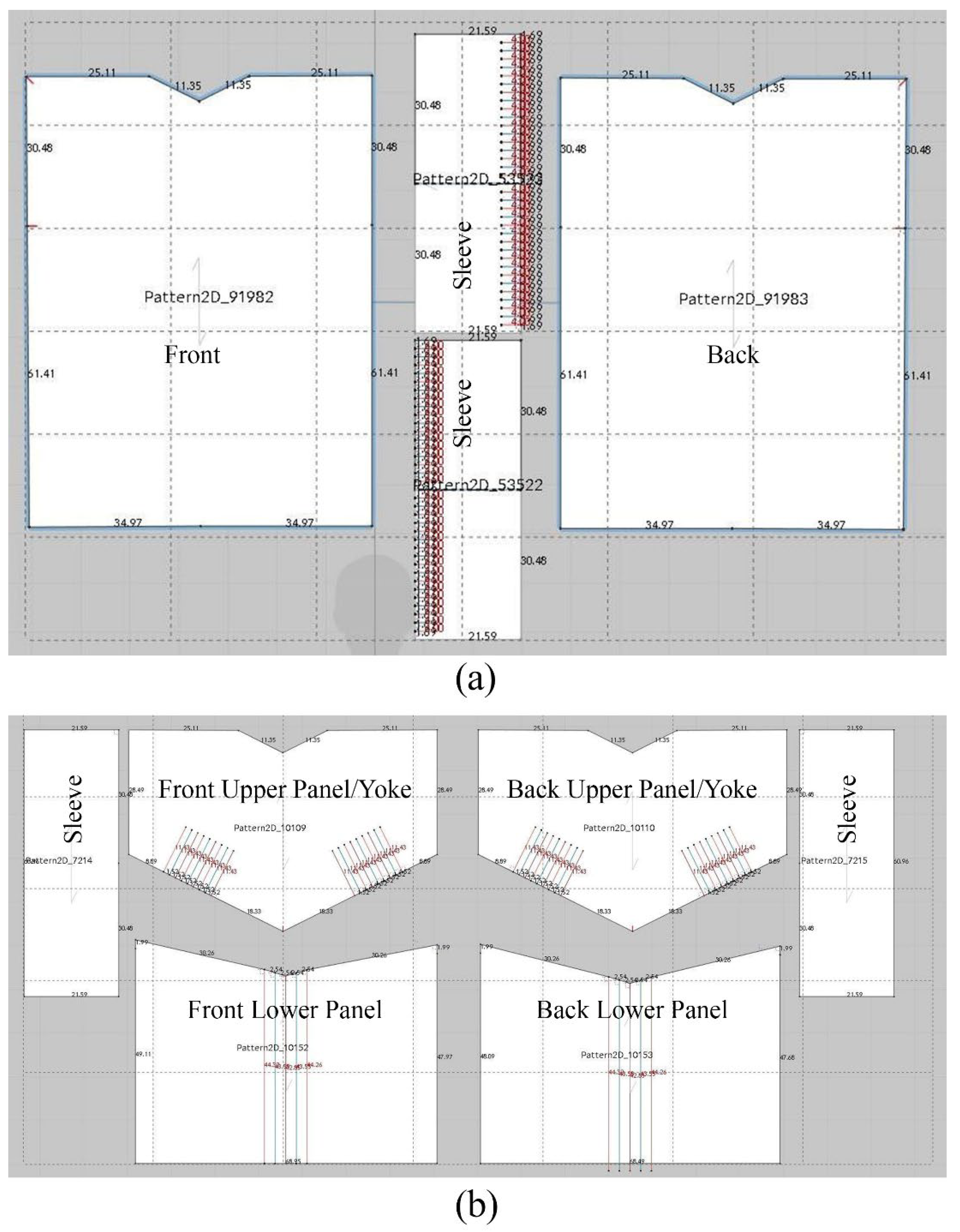

Waste minimization in the designing phase was stimulated using CLO software. No greige fabric or any kind of same-nature fabric was required to create the first samples, and it was noted that this method does not comply with the conventional ways of garment manufacturing. Using CLO addressed the possibility of reducing fabric waste by eliminating the need for physical sample development. Figure 4 displays the 2D patterns (design-I (a) and design-II (b)) of a tunic dress, made in two yards of 100% cotton fabric, which comprises a front, a back, and two sleeve pieces with all the required measurements and design element details. It was seen that the only waste generated was the neckline cutting from front and back, which makes up about 1% of the waste or less. Completing the first look/design-I led to translating this virtual design into the physical and final product. It was noted that design-II was virtually generated simultaneously out of the first look without adding or subtracting fabric. However, this second design was not to be developed physically; a document was prepared for user guidance. After various tries and a long process of virtual sampling, the second design was also finalized. Kaftan is already a zero-waste garment; thus, it requires no pattern engineering. Figure 5 depicts a simulation of its first design, the finalization of which led to the virtual sampling of its second look. The pattern represents zero waste generation; thus, design-II was successfully achieved without any addition or subtraction of fabric.

Figure 4.

(a) A 2D pattern of zero-waste tunic design-I, (b) design-II.

Figure 5.

A 2D Pattern of zero-waste kaftan dress (a) design-I and (b) design-II.

3.2. Physical Construction

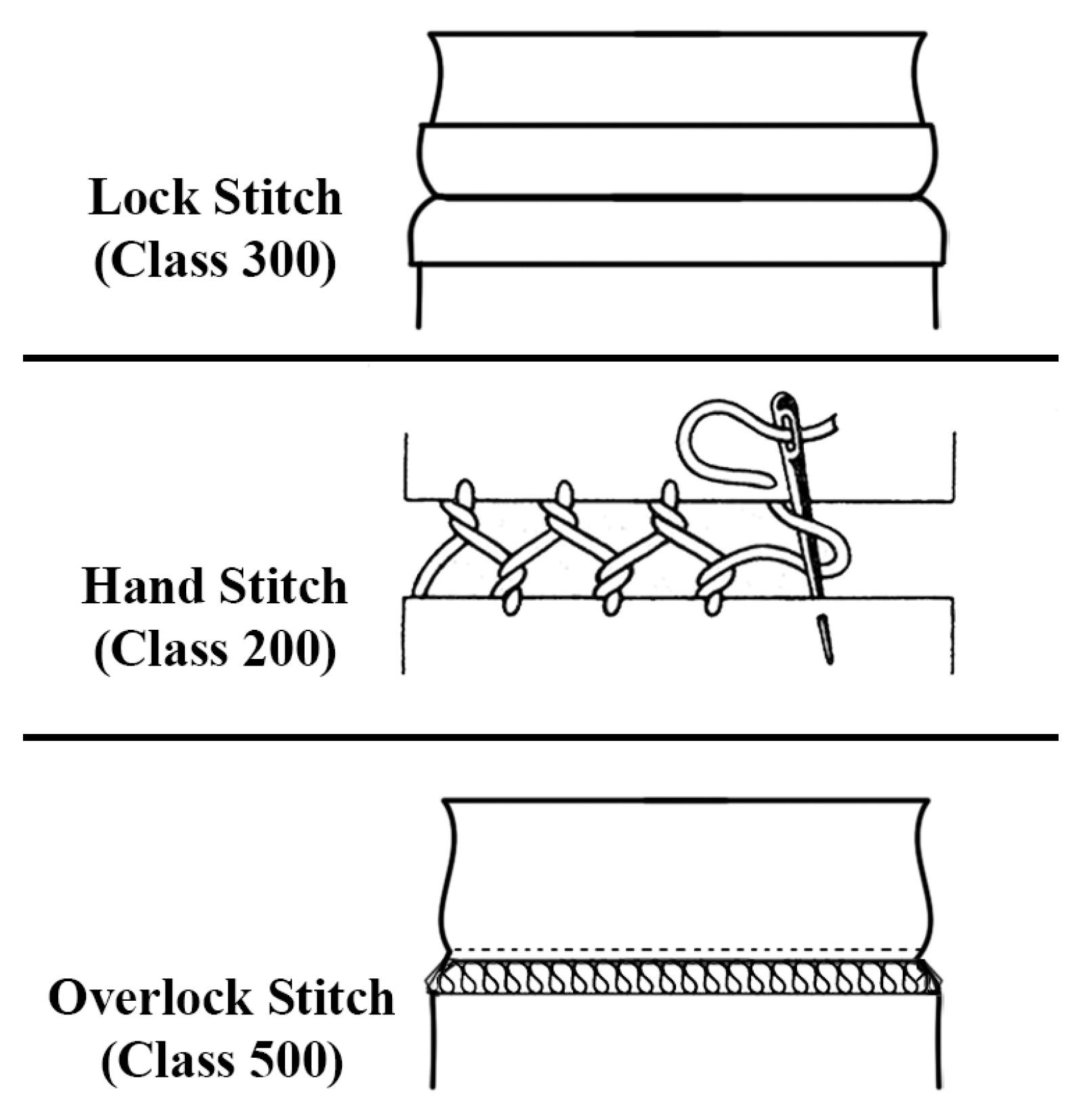

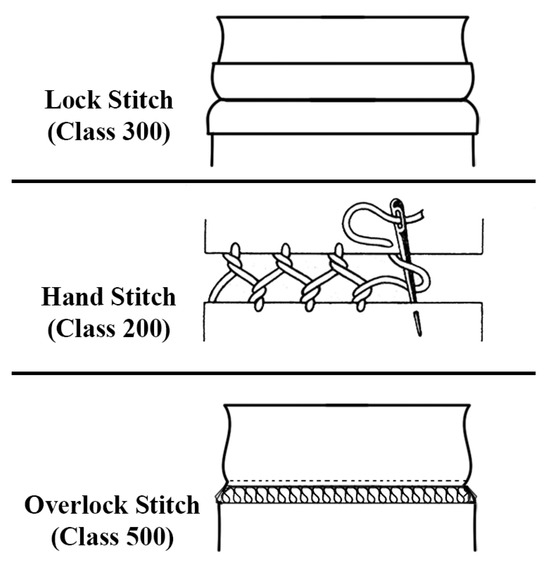

The very aim of the study was to test the viability of DFD in the field of fashion; following that, three types of stitches were used, i.e., hand stitch, lock stitch, and overlock stitch with an SPI of six, as shown in Figure 6 and Figure 7.

Figure 6.

Samples for seam strength testing.

Figure 7.

Flat drawings for seam strength testing.

3.2.1. Seam Strength Testing

ASTM D5035—Textile Strip Method was used in order to test tensile strengths of seams. The samples used were 50 mm wide and 200 mm long. Seam strength was tested using a superimposed seam for samples. According to the results of seam strength measured for all three stitch types, the regular straight stitch of the lock stitch machine was observed as the strongest stitch, as shown in Table 2. In comparison, the overlock stitch came second in strength, and the hand stitch was weakest.

Table 2.

Seam strength testing observations.

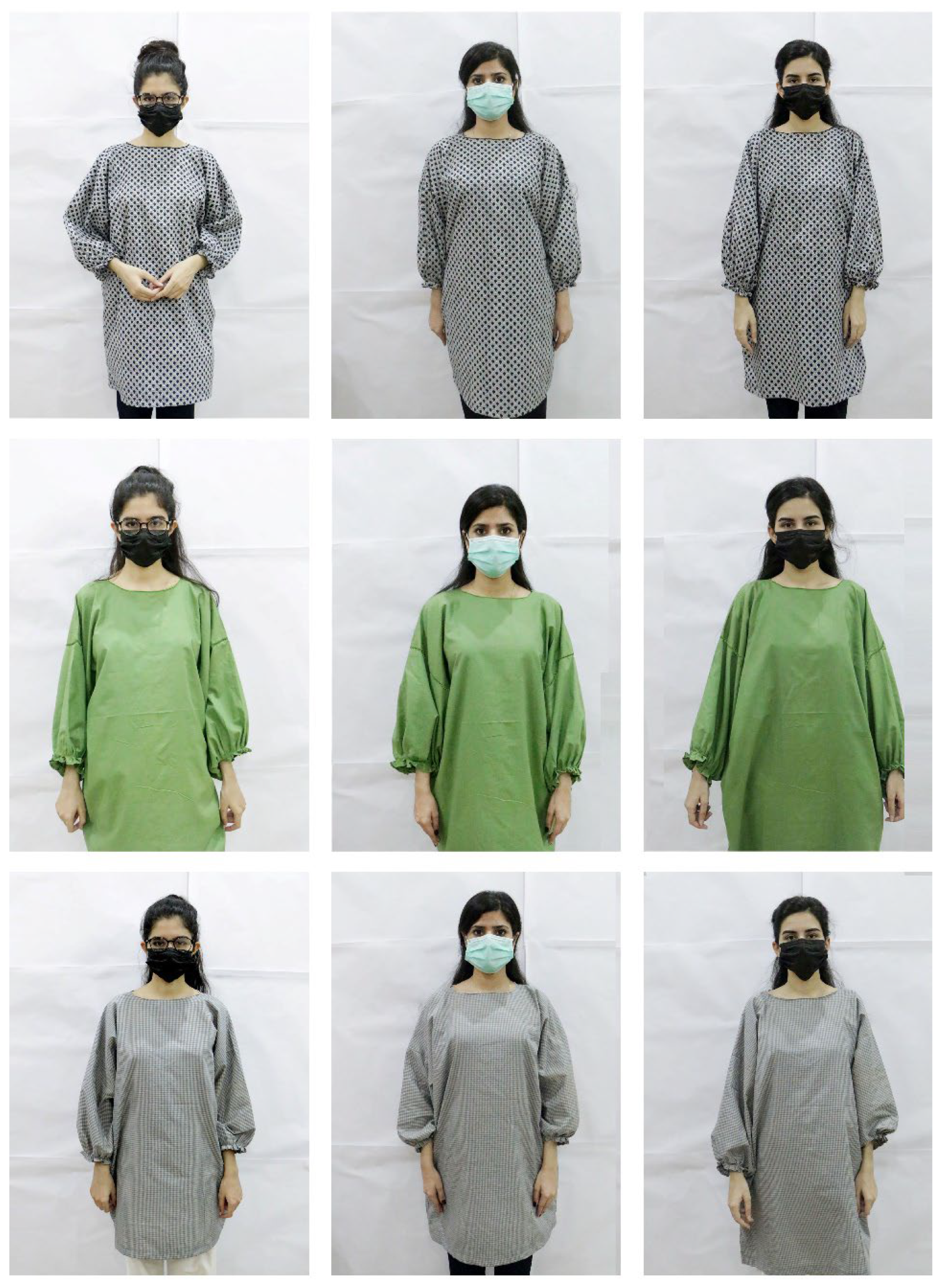

3.2.2. First Wear Trial Assessment

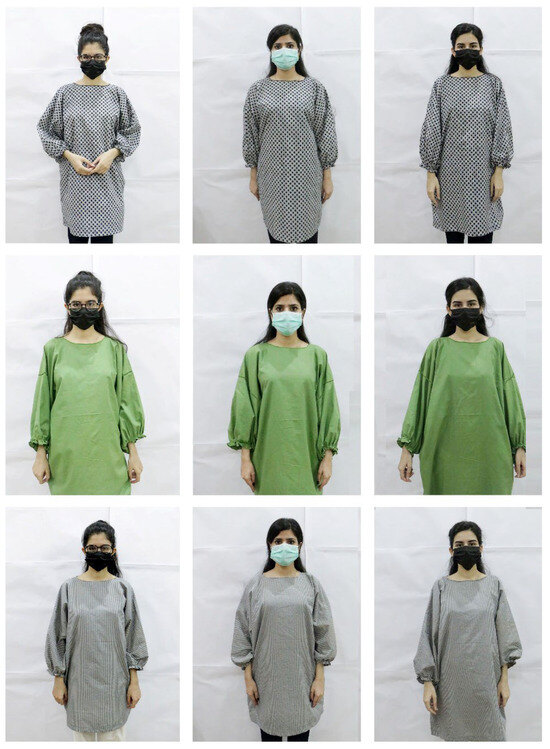

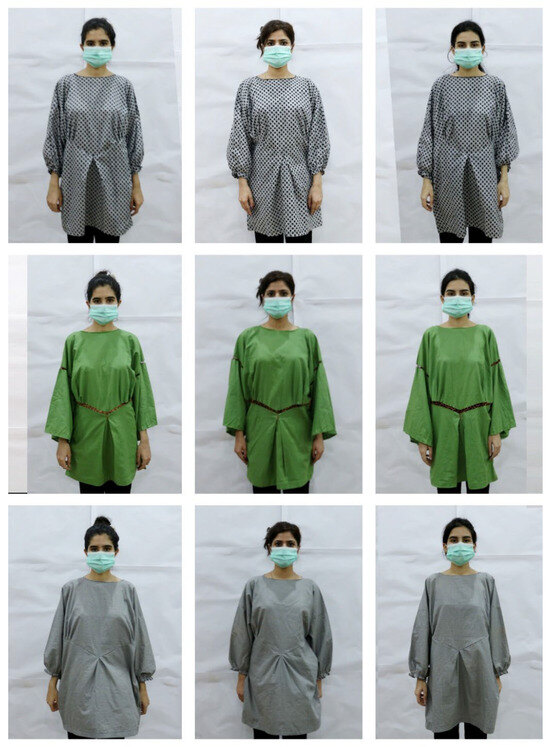

All three participants arrived at the given time at the university as user testing was organized in the university studio. Sufficient time, space, and privacy were provided to experiment in a relaxed environment. Each trial took 15 to 20 min, inclusive of questionnaire filling. Each subject was given one garment at a time. Questions regarding aesthetics were to be answered in the first wear trial, and the rest regarding the user guide document and disassembly and reassembly were to be answered after a month by participants. Each participant tried every garment given and completed its evaluation in the wear trial. See Figure 8 middle row, for a demonstration of the first wear trial by all three subjects.

Figure 8.

Top row shows the front view of tunic (design-I) sewn in lock stitch, middle row demonstrates tunic sewn using a hand stitch, and bottom row shows tunic sewn overlock stitch (subjects: P1, P2, P3 from left to right).

The first dress given for aesthetic assessment was a tunic dress, made using a black and white 100% cotton printed fabric. Afterward, the tunic dress was sewn in the subsequent trial using a hand stitch (Class 200). This tunic was made in a plain 100% cotton fabric in the color green. The third tunic was made using 100% cotton fabric in a blue color. The third tunic was sewn using a safety overlock machine falling in class 500. After trying this dress, users filled out the questionnaire making recommendations to improve the outlook of the garment and rating it aesthetically. The same wear trial procedure was used for the kaftan dress as well.

3.2.3. Second Wear Trial Assessment

User redesign and a second testing session were organized in the university studio with all the required equipment a month after the first session of the wear trial. Now the participants were required to disassemble all garments and sew them using three different sewing techniques. The first step was disassembling all the garments of the participants at the same time in the same studio. All three tunic dresses were sewn using three different sewing techniques so it was to be noted how much time each stitch type required for ripping. The second step was document reading and its implementation and execution. After the participants disassembled, they were given the prepared user guide documents containing guidelines on how to reassemble the garment for a new look/design-II. Participants were asked to rank the understanding level of the document out of five (one being very poor and five being excellent), having read it thoroughly. The attributes redesigned for the tunic dress (design-I) were its main body and sleeves. Figure 9 shows the wear and trial of the tunic dress (design- II).

Figure 9.

Top row shows the front view of tunic (design-II) sewn in lock stitch, middle row demonstrates tunic sewn using a hand stitch, and bottom row shows tunic sewn in overlock stitch (subjects: P1, P2, P3 from left to right).

All three tunic dresses were to be sewn by three different stitch types: those in which they were sewn before disassembly. Time was noted for each garment and each stitch style to compare and assess which stitch style requires less time to reassemble the garment (see Table 3). Time was noted by the researcher separately and the participants themselves on the questionnaire.

Table 3.

Disassembly and reassembly time recorded.

The recorded time for disassembly and reassembly of the tunic and kaftan dress is shown in Table 3.

The same process was repeated for the kaftan dress. The participants were required to disassemble the three garments they were each given and to sew it using three different sewing techniques.

3.2.4. Quantitative and Qualitative Data

Table 4 shows the ANOVA results of the disassembly and reassembly time evaluation of the tunic dress. It was inferred that the hand stitch required more time for reassembly than the lock stitch or overlock stitch, while the shortest time for disassembly was compared to other stitch types.

Table 4.

ANOVA result of disassembly (D) and reassembly (R) time evaluation of tunic.

Table 5 displays the ANOVA results of the disassembly and time evaluation of the kaftan dress. The average reassembly time of the lock stitch is the lowest, while the overlock stitch falls near it with a minute more. Far from them sits the hand stitch, which consumes double the amount of time. It is concluded that the hand stitch required a longer time for reassembly as compared to the lock stitch or overlock stitch.

Table 5.

ANOVA result of disassembly (D) and reassembly (R) time evaluation of kaftan.

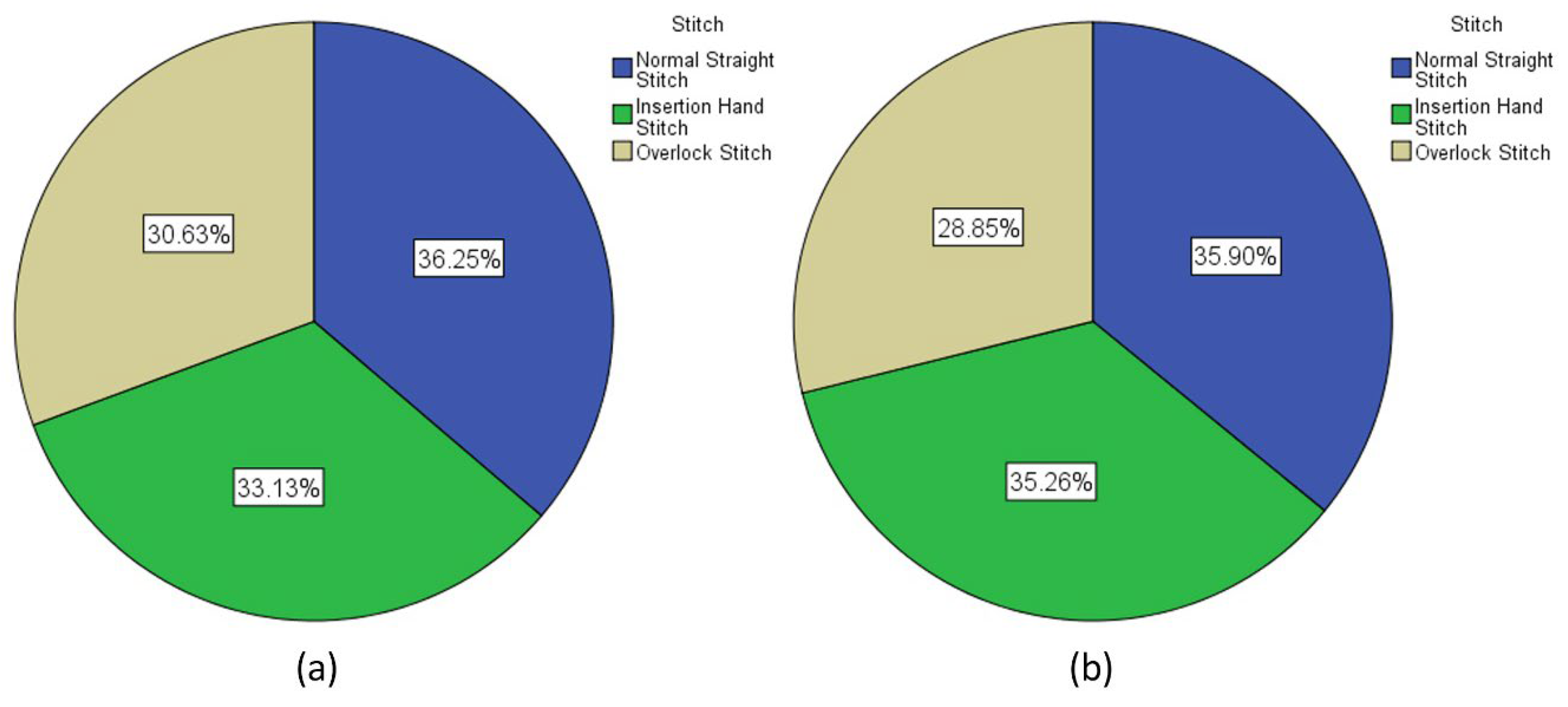

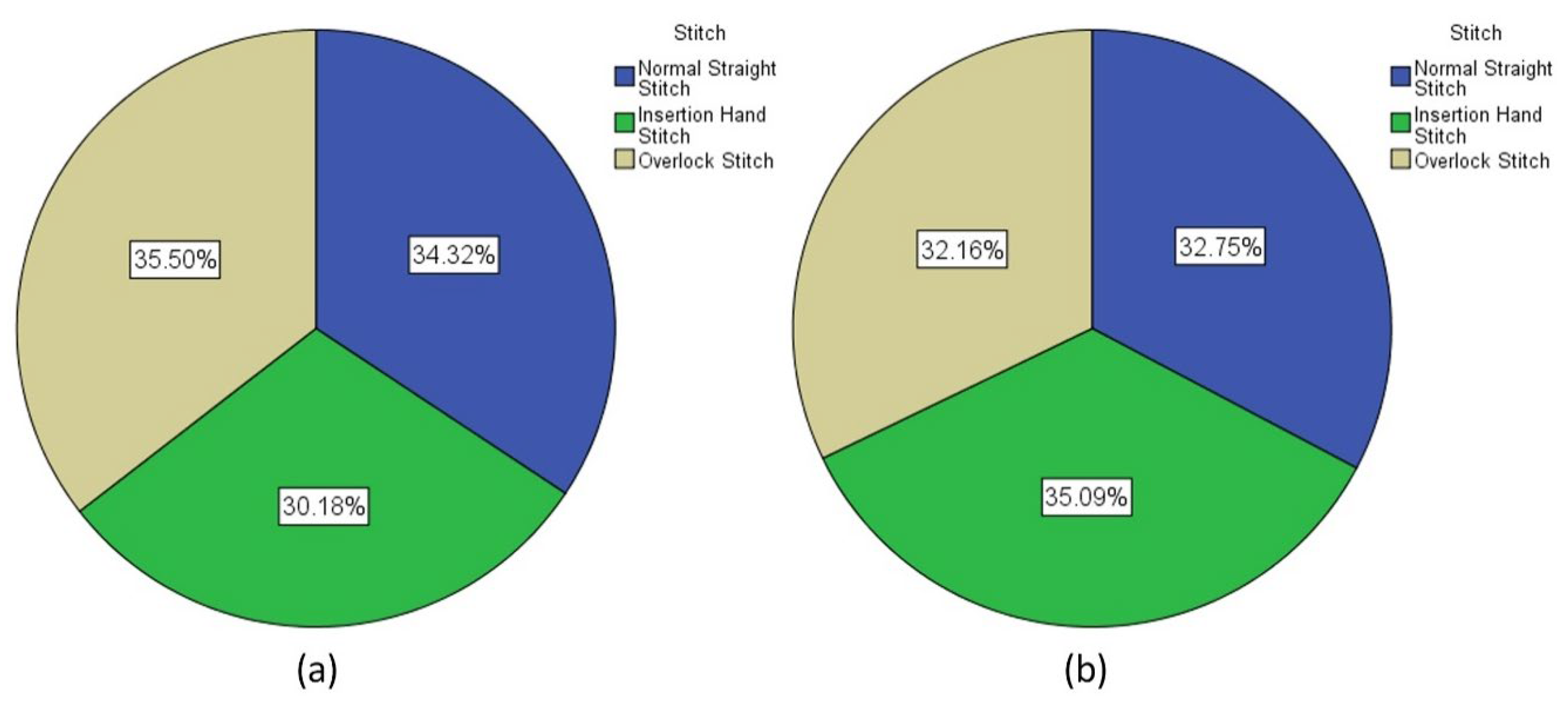

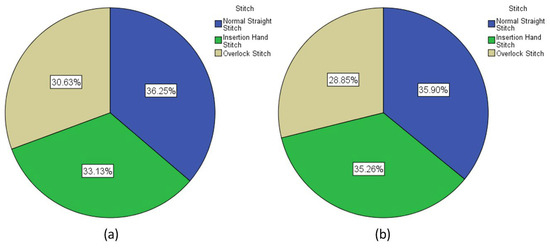

The expected time was very short as it had a very minor ratio of stitches and seams. According to recordings, a minor difference was observed between all three—lock stitch, hand stitch, and overlock stitch disassembly time. As shown in Figure 10, the stance of subjects about the lock stitch tunic remained the same, thus, scoring the same before and after disassembly, while their views of the plain tunic in hand stitch positively and significantly changed after its redesign. The very reason behind this was the use of plain fabric, which allowed room for creativity, and the hand stitch that was used as a garment detail. To them, plain fabric allowed them more creativity with the provision of more room for experimentation and styling options for regular wear.

Figure 10.

(a) Aesthetic evaluation of tunic before disassembly; (b) aesthetic evaluation of tunic after reassembly.

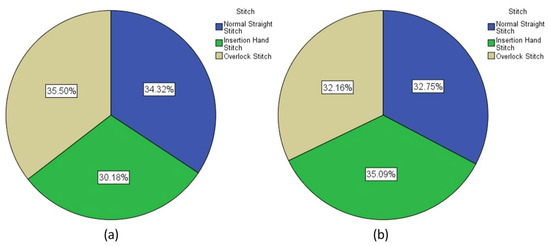

In Figure 11, it was evident in the pie chart percentage values of the hand stitch that its score went up after redesign. While printed fabric, especially floral patterns, scored higher than any other garment before the redesign, its scores went down after the redesign. The very reason found behind this was the participants’ disliking of printed fabric for a busy design such as the kaftans’ redesigned look. The experimental take on kaftan dress-4 in black was much appreciated, which used the wrong side of the fabric as a yoke.

Figure 11.

(a) Aesthetic evaluation of kaftan before disassembly; (b) aesthetic evaluation of tunic after reassembly.

Redesign results of the kaftan concluded that plain fabric was not preferred for a silhouette like a kaftan. To subjects, it appeared bland and simplistic to a negative extent. Figure 9 shows that the pie chart percentage values of the hand stitch score went up after redesign. While printed fabric, especially floral patterns, scored higher than any other garment before the redesign, its scores went down after the redesign.

The very reason found behind this was participants’ disliking of printed fabric for a busy design like that of the kaftans’ redesigned look. The experimental take on kaftan dress-4 in black was much appreciated, which used the wrong side of the fabric as a yoke. Further suggestions were made to improve the look by using surface creation techniques such as installation through layering, smoking, or any other surface pattern designs. Once again, for the kaftan dress too, the hand stitch was liked by the participants. Plain kaftan dress-5 was redesigned using a hand stitch with contrasting threads, which changed the entire look of the garment. Suggestions were made about adding the pattern to the plain fabric such as hand marbling the fabric.

Quantitative data results concluded that the lock stitch was the strongest before disassembly, proving the most durable for the use-life of the garment. In comparison, the overlock stitch came second in strength, and the hand stitch was the weakest. Lock stitch and overlock stitch demanded almost the same amount of time for reassembly, but results varied a bit in disassembly. For reassembly, both the lock stitch and overlock stitch took the least time for reassembly, with no significant difference. The hand stitch, on the other hand, took double the time required for reassembly with a lock stitch or overlock stitch. Furthermore, after redesign and multiple wears, the hand stitch did not remain intact, while the other two showed no signs of ripping.

3.3. Descriptive Statistics

All three participants wore the given 18 dresses on multiple occasions before disassembly and after reassembly as per their liking, in a period of two months total. Regarding the number of wears and satisfaction with each garment, data were collected through a questionnaire. Initially, the normality test was conducted to evaluate the suitability of collected data for further statistical analysis. For this purpose, Skewness and Kurtosis tests were performed within the range of two, as it is acceptable in a normal distribution. Table 6 reported that all the values of Skewness and Kurtosis are in the given range of two. Therefore, the analysis continued, assuming that the data were slightly kurtotic or skewed. Further, sample observations demonstrated consistent satisfaction levels across the items. They also illustrate the mean number of wears for all 18 garments, while the average number recorded for a single garment was 11.

Table 6.

Descriptive statistics.

The collected data supported H1 as the obtained p-value obtained from the t-distribution table (one tail) was smaller than alpha level 0.05, hence, rejecting the null hypothesis (H0) as shown in Table 7.

Table 7.

One-tailed t-test result of hypothesis-1.

Data reported that the number of wears of 18 garments was 198, the average of which is 11, which implies that P1, P2, and P3 wore each garment 11 times on average. As the purpose was to only find out if the average number of wears was greater than 7, the test was performed on Minitab using one sample t-test (one-tailed). According to statistics, the number of wears recorded exceeded the average value of 7, thus, rejecting the null hypothesis. Therefore, hypothesis 3 was also validated.

Results implied that fashion-sensitive consumers were very interested in redesigning and repairing garments. Because fashion trends change rapidly leading to fast product obsolescence, fashion-sensitive consumers display unsustainable clothing consumption. According to research by [33], this hedonic consumption behavior predicts repair for emotionally attached garments. Building on this, value addition to garments can positively change the consumer’s consumption behavior. Hence, proven, physical durability is not the main issue behind rapid disposal but is emotional durability. Therefore, the issue of changing trends and overconsumption can be mitigated by value addition and manufacturing emotionally durable products. Strategies such as Design for Disassembly (DFD) can prove helpful both in the production sector and for consumption, i.e., speeding up the manufacturing process, saving time and cost from a producer perspective, and also it can prove advantageous from the consumer perspective by providing a two in one garment, that will lead to less spending and a lowered purchase rate.

4. Conclusions

This study suggests a shortcut to sustainable consumption in the shape of a user guide document for redesign and workshops for consumer education. CLO software was employed for virtual sampling rather than constructing physical prototypes and execution of zero-waste pattern cutting and design for disassembly strategy to speed up pre-consumer waste minimization to a great level, advocating hypothesis H1. For all the subjects, the disassembly time for hand stitches was lower for all tunic and kaftan dresses. On the other hand, during the reassembly of the garment, less time was consumed for the lockstitch as compared to all other stitches in all tunic and kaftan dresses by all three subjects. Thus, the design for disassembly strategy can reduce post-customer waste by constructing garments that can be disassembled and reassembled, supporting the second hypothesis H2. Data collected on the number of wears of each garment presented a significant figure of 198 times for 18 garments, thus, marking the success of the implementation of DFD in product longevity.

Furthermore, it supported the alternate hypothesis that the average number of wears can be more than 7, supporting the H3. Consumer involvement in the design process enhances user connection to the garment, which ultimately increases the lifespan of a garment. Therefore, strategies such as DFD can prove helpful both in the production sector and for consumption, i.e., speeding up the manufacturing process and saving time and cost from a producer perspective. In addition, it can prove advantageous from the consumer perspective by providing two-in-one garments, which will lead to less spending and a low purchase rate.

Contrasting prior research, this study exposes a gap in post-consumer waste reduction, especially in Circular Fashion (CF). Effective strategies are lacking despite landfill textile waste concerns. Findings prompt a rethink of the fashion industry’s conventional system. It is concluded that emotional durability drives disposability more than physical. Enhancing value and creating emotionally resilient products can counter overconsumption.

The study’s uniqueness lies in merging ZWPC and DFD within Circular Fashion, a novel approach with limited evidence. In the face of criticism for unsustainable textile waste, solutions involve DFD, zero-waste pattern cutting (ZWPC), and 3D software. DFD and ZWPC support adaptable designs, fostering reuse and extending garment life. Consumer involvement in design enhances attachment, and workshops reshape consumption patterns. While effective, consumer guides may need supplementary support.

This research has limitations to consider when interpreting results. The small, homogeneous sample size restricts generalization to other groups. Identifying the optimal age group for redesign efforts is challenging due to the limited sample size. Future research should involve a larger, diverse sample to explore varied ethnic backgrounds, qualifications, and pay scales, while also considering underrepresented occupations. Furthermore, time constraints were a factor, limiting the garment sample size to 18 of just two types due to the labor-intensive nature of redesign. Future research could broaden the scope to various garments and categories such as formal wear. Surveys could expand findings, assessing clothing attributes and consumer involvement. Business models, including product take-back schemes with DFD integration, offer potential avenues for exploration.

Author Contributions

Conceptualization, M.B.R.; methodology, M.W.I.; software, A.I.M.; validation, M.S.H.; formal analysis, H.M.; investigation, H.M.; resources, M.W.I.; data curation, H.M.; writing—original draft preparation, H.M.; writing—review and editing, J.N.; visualization, M.O.; supervision, M.B.R.; project administration, J.N.; funding acquisition, A.I.M., M.S.H. and M.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki and approved by the Research Ethics Committee) of National Textile University, Pakistan (NTU/ORIC/REC/2023/ and 13 September 2023).

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The environmental price of fast fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef]

- Jung, S.; Jin, B. From quantity to quality: Understanding slow fashion consumers for sustainability and consumer education. Int. J. Consum. Stud. 2016, 40, 410–421. [Google Scholar] [CrossRef]

- Anguelov, N. The Dirty Side of the Garment Industry: Fast Fashion and Its Negative Impact on Environment and Society; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar] [CrossRef]

- Caro, F.; Martìnez-De-Albèniz, V. Fast fashion: Business model overview and research opportunities. In Retail Supply Chain Management; International Series in Operations Research and Management Science; Springer: Boston, MA, USA, 2015. [Google Scholar] [CrossRef]

- Johansson, E. Slow Fashion: The Answer for a Sustainable Fashion Industry? Master’s Thesis, University of Borås, Borås, Sweden, 2010. [Google Scholar]

- Kanan, M.; Habib, M.S.; Habib, T.; Zahoor, S.; Gulzar, A.; Raza, H.; Abusaq, Z. A Flexible Robust Possibilistic Programming Approach for Sustainable Second-Generation Biogas Supply Chain Design under Multiple Uncertainties. Sustainability 2022, 14, 11597. [Google Scholar] [CrossRef]

- Marchand, A.; Walker, S. Product development and responsible consumption: Designing alternatives for sustainable lifestyles. J. Clean. Prod. 2008, 16, 1163–1169. [Google Scholar] [CrossRef]

- Munir, M.A.; Habib, M.S.; Hussain, A.; Shahbaz, M.A.; Qamar, A.; Masood, T.; Sultan, M.; Mujtaba, M.A.; Imran, S.; Hasan, M.; et al. Blockchain Adoption for Sustainable Supply Chain Management: Economic, Environmental, and Social Perspectives. Front. Energy Res. 2022, 10, 899632. [Google Scholar] [CrossRef]

- Beltrami, M.; Orzes, G.; Sarkis, J.; Sartor, M. Industry 4.0 and sustainability: Towards conceptualization and theory. J. Clean. Prod. 2021, 312, 127733. [Google Scholar] [CrossRef]

- El Baz, J.; Tiwari, S.; Akenroye, T.; Cherrafi, A.; Derrouiche, R. A framework of sustainability drivers and externalities for Industry 4.0 technologies using the Best-Worst Method. J. Clean. Prod. 2022, 344, 130909. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Ki, C.W.; Chong, S.M.; Ha-Brookshire, J.E. How fashion can achieve sustainable development through a circular economy and stakeholder engagement: A systematic literature review. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 2401–2424. [Google Scholar] [CrossRef]

- Abusaq, Z.; Habib, M.S.; Shehzad, A.; Kanan, M.; Assaf, R. A Flexible Robust Possibilistic Programming Approach toward Wood Pellets Supply Chain Network Design. Mathematics 2022, 10, 3657. [Google Scholar] [CrossRef]

- Keßler, L.; Matlin, S.A.; Kümmerer, K. The contribution of material circularity to sustainability—Recycling and reuse of textiles. Curr. Opin. Green Sustain. Chem. 2021, 32, 100535. [Google Scholar] [CrossRef]

- Linton, J.D.; Jayaraman, V. A framework for identifying differences and similarities in the managerial competencies associated with different modes of product life extension. Int. J. Prod. Res. 2005, 43, 1807–1829. [Google Scholar] [CrossRef]

- Goldsworthy, K. The Speedcycle: A design-led framework for fast and slow circular fashion lifecycles. Des. J. 2017, 20, S1960–S1970. [Google Scholar] [CrossRef]

- Ajwani-Ramchandani, R.; Figueira, S.; de Oliveira, R.T.; Jha, S.; Ramchandani, A.; Schuricht, L. Towards a circular economy for packaging waste by using new technologies: The case of large multinationals in emerging economies. J. Clean. Prod. 2021, 281, 125139. [Google Scholar] [CrossRef]

- Jia, F.; Yin, S.; Chen, L.; Chen, X. The circular economy in the textile and apparel industry: A systematic literature review. J. Clean. Prod. 2020, 259, 120728. [Google Scholar] [CrossRef]

- Ramzan, M.B.; Qureshi, S.M.; Habib, M.S.; Naveed, T.; Awais, M.; Jamshaid, H. Evaluation of human factors on visual inspection skills in textiles and clothing: A statistical approach. J. Eng. Fibers Fabr. 2022, 17, 15589250221128115. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Carrico, M.; Kim, V. Expanding zero-waste design practices: A discussion paper. Int. J. Fash. Des. Technol. Educ. 2014, 7, 58–64. [Google Scholar] [CrossRef]

- McQuillan, H. Digital 3D design as a tool for augmenting zero-waste fashion design practice. Int. J. Fash. Des. Technol. Educ. 2020, 13, 89–100. [Google Scholar] [CrossRef]

- Chen, L. Sustainability and Company Performance: Evidence from the Manufacturing Industry, 1698; Linköping University Electronic Press: Linkoping, Sweden, 2015. [Google Scholar]

- Schoenherr, T. The role of environmental management in sustainable business development: A multi-country investigation. Int. J. Prod. Econ. 2012, 140, 116–128. [Google Scholar] [CrossRef]

- Lowe, G.; Bogue, R. Design for disassembly: A critical twenty-first century discipline. Assem. Autom. 2007, 27, 285–289. [Google Scholar] [CrossRef]

- Kumar, G.A.; Bahubalendruni, M.V.A.R.; Prasad, V.S.S.; Sankaranarayanasamy, K. A multi-layered disassembly sequence planning method to support decision making in de-manufacturing. Sadhana Acad. Proc. Eng. Sci. 2021, 46, 102. [Google Scholar] [CrossRef]

- Monyaki, N.C.; Cilliers, R. Defining Drivers and Barriers of Sustainable Fashion Manufacturing: Perceptions in the Global South. Sustainability 2023, 15, 10715. [Google Scholar] [CrossRef]

- Rissanen, T. From 15% to 0: Investigating the creation of fashion without the creation of fabric waste: Creativity. In Proceedings of the Designer Meets Technology Europe, København, Denmark, 26–27 September 2005. [Google Scholar]

- McQuillan, H. Waste, so What? A reflection on waste and the role of designers in a circular economy. In Proceedings of the Nordes 2019: Who Cares? Espo, Finland, 2–4 June 2019. [Google Scholar] [CrossRef]

- Gam, H.J.; Cao, H.; Bennett, J.; Helmkamp, C.; Farr, C. Application of design for disassembly in men’s jacket: A study on sustainable apparel design. Int. J. Cloth. Sci. Technol. 2011, 23, 83–94. [Google Scholar] [CrossRef]

- Bhatt, D.; Silverman, J.; Dickson, M.A. Consumer interest in upcycling techniques and purchasing upcycled clothing as an approach to reducing textile waste. Int. J. Fash. Des. Technol. Educ. 2019, 12, 118–128. [Google Scholar] [CrossRef]

- ASTM-D5035; Standard Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method). ASTM: West Conshohocken, PA, USA, 2019.

- McNeill, L.S.; Hamlin, R.P.; McQueen, R.H.; Degenstein, L.; Garrett, T.C.; Dunn, L.; Wakes, S. Fashion sensitive young consumers and fashion garment repair: Emotional connections to garments as a sustainability strategy. Int. J. Consum. Stud. 2020, 44, 361–368. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).