Role of Design for Disassembly in Educating Consumers for Circular Behavior

Abstract

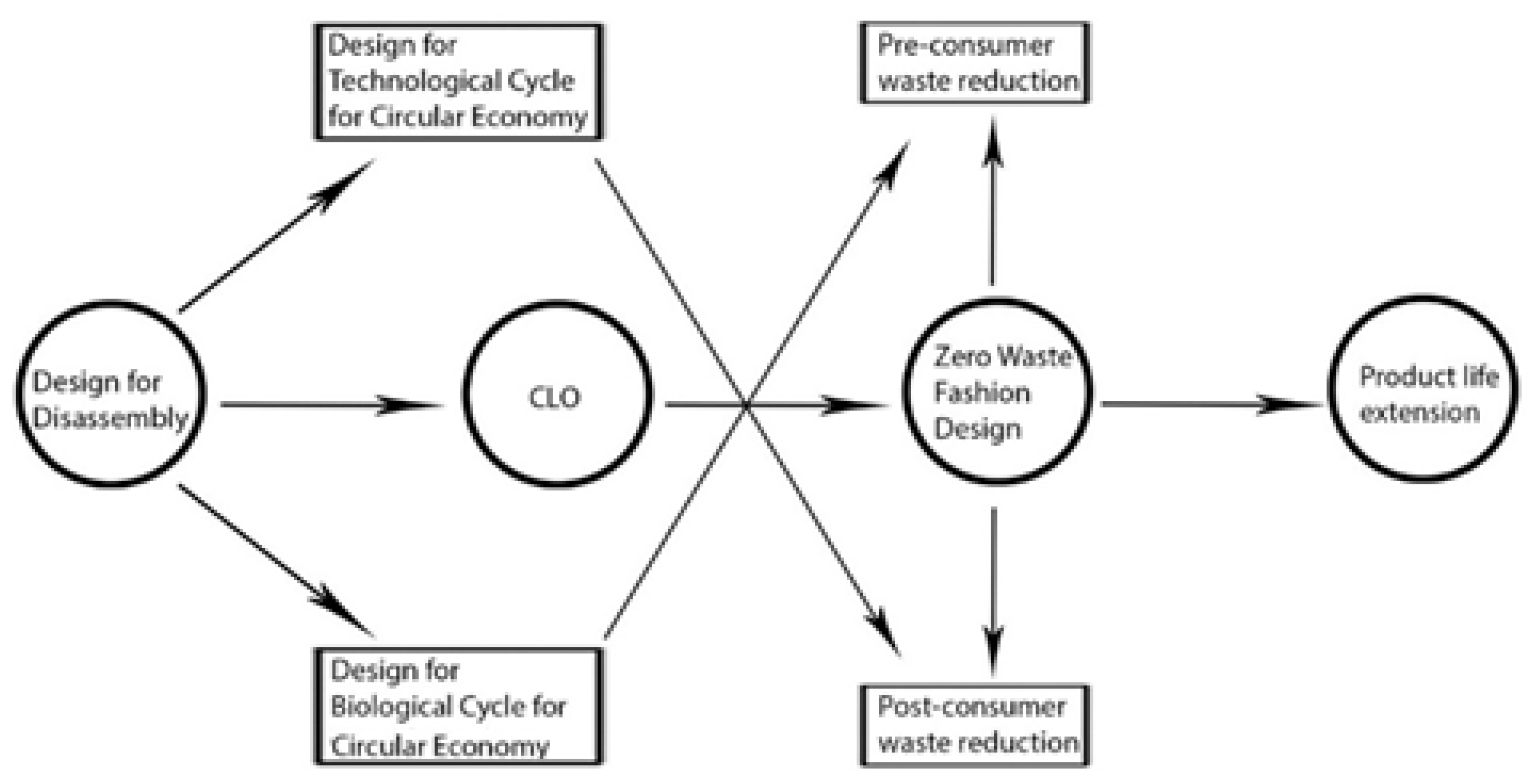

:1. Introduction

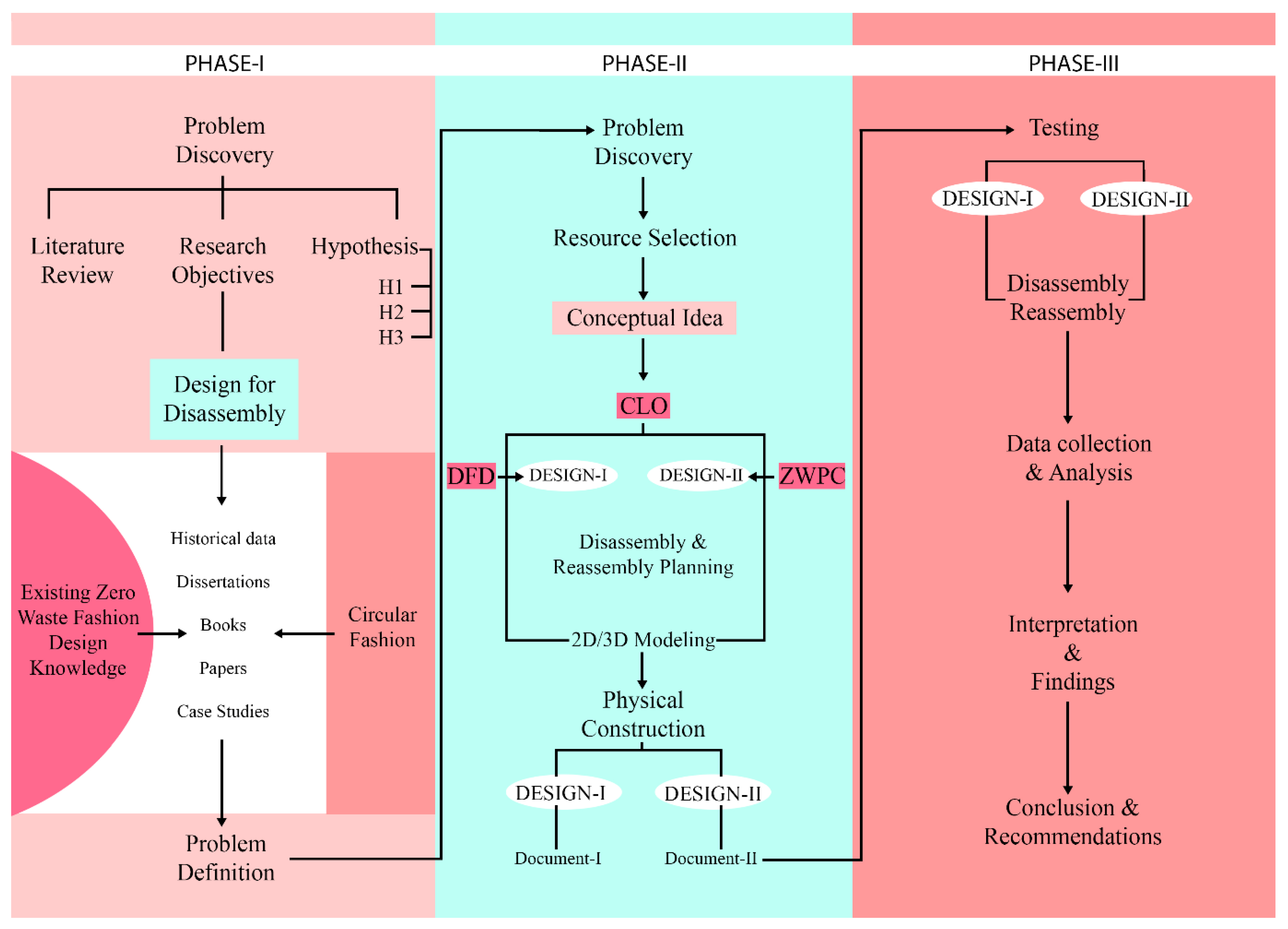

2. Materials and Methodology

- Seam Strength (before disassembly);

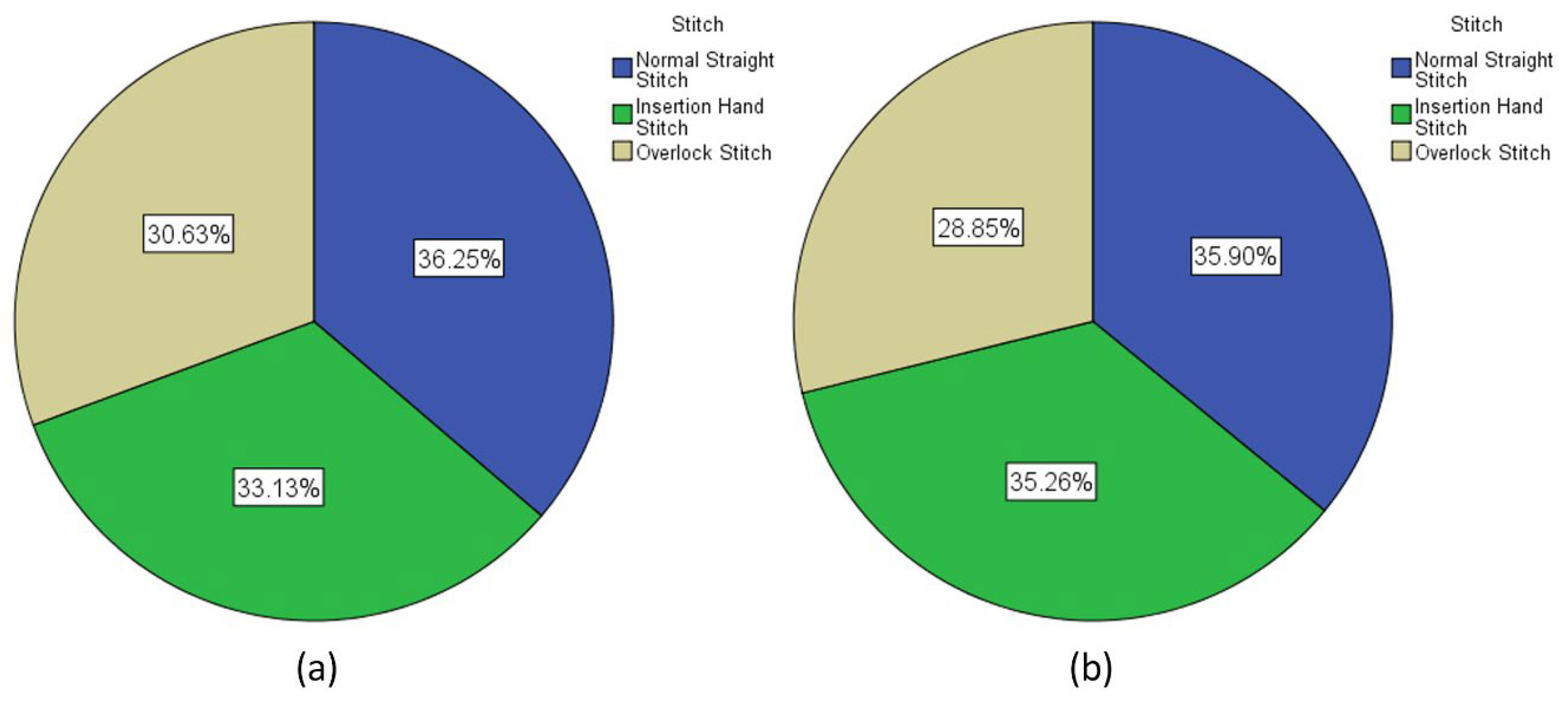

- Disassembly time evaluation concerning stitch type;

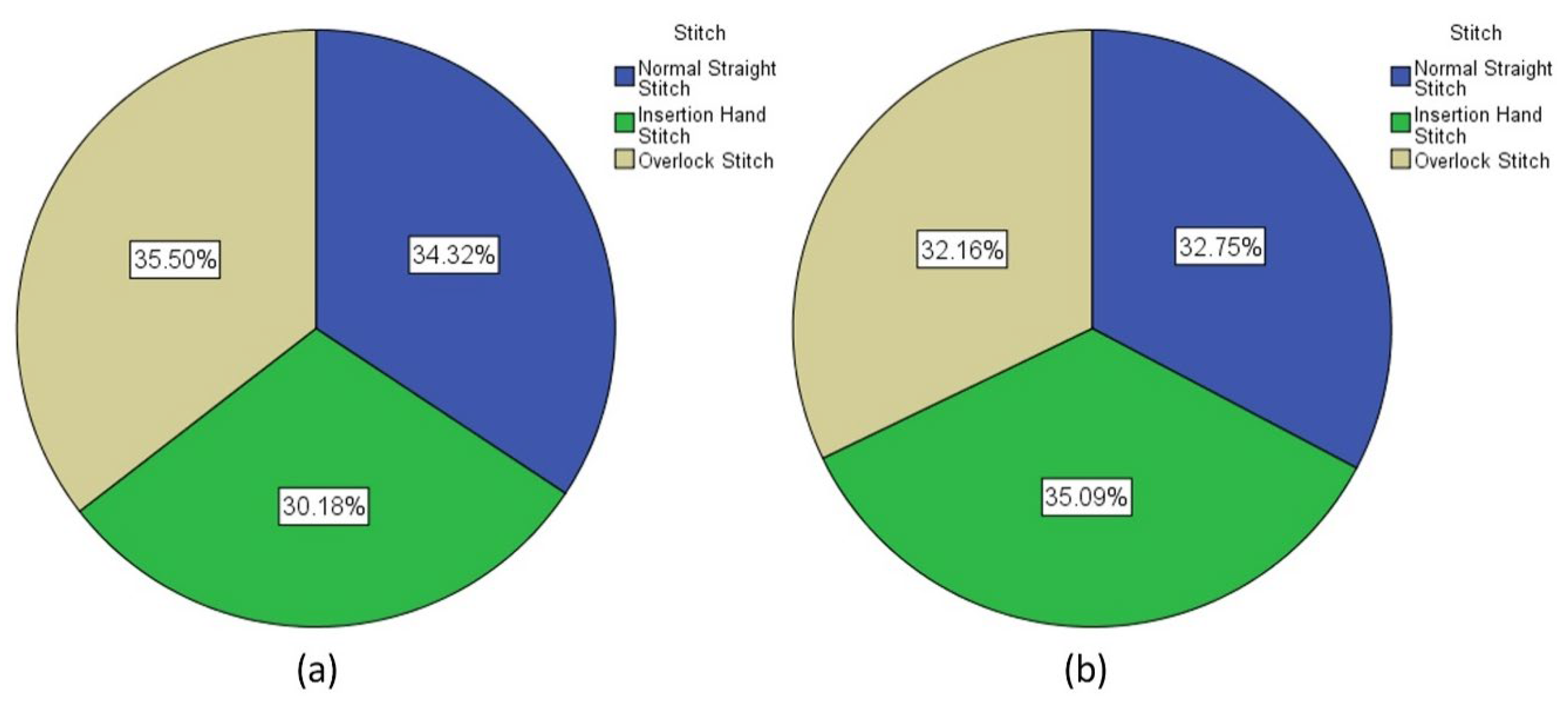

- Reassembly time evaluation;

- Seam strength (after reassembly).

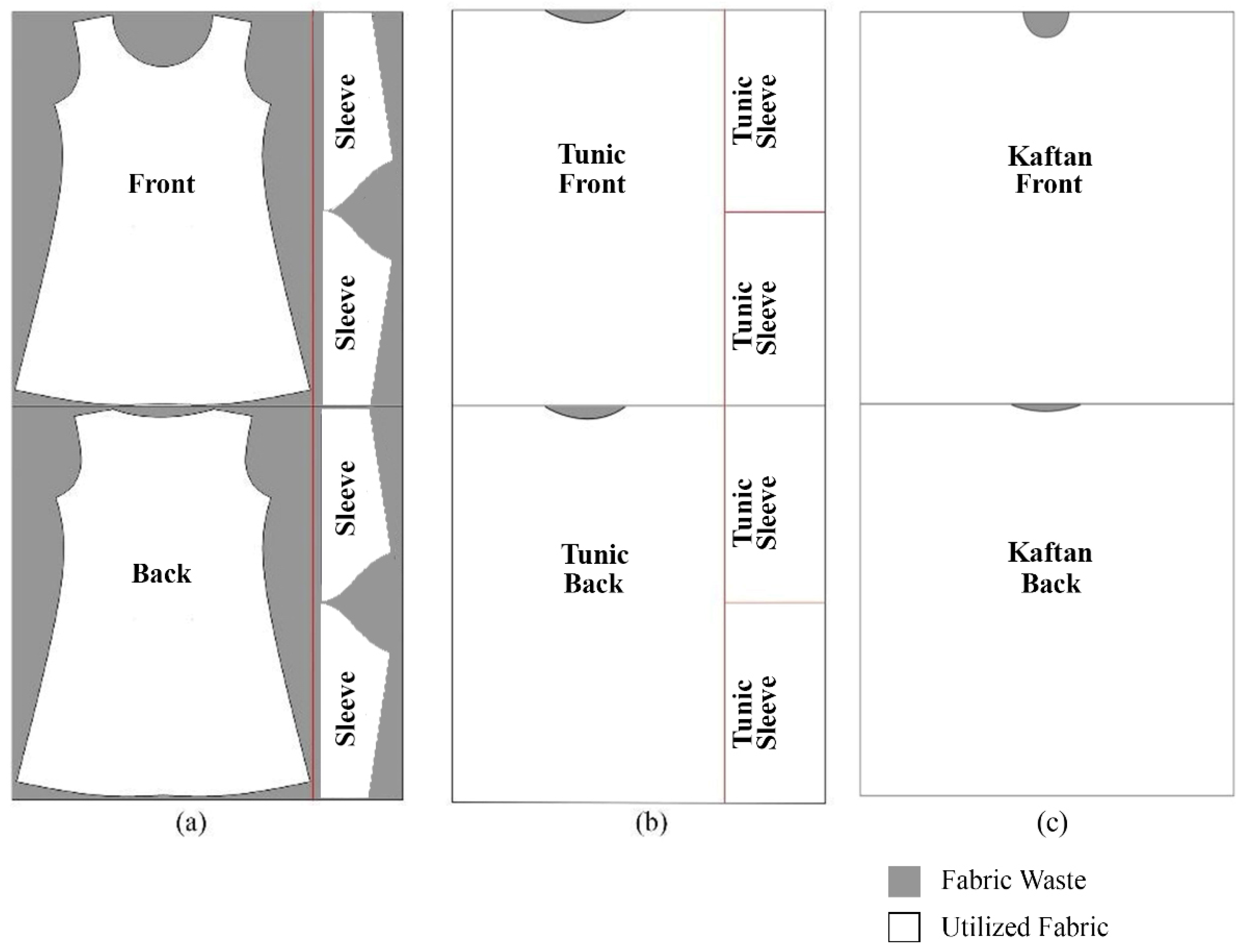

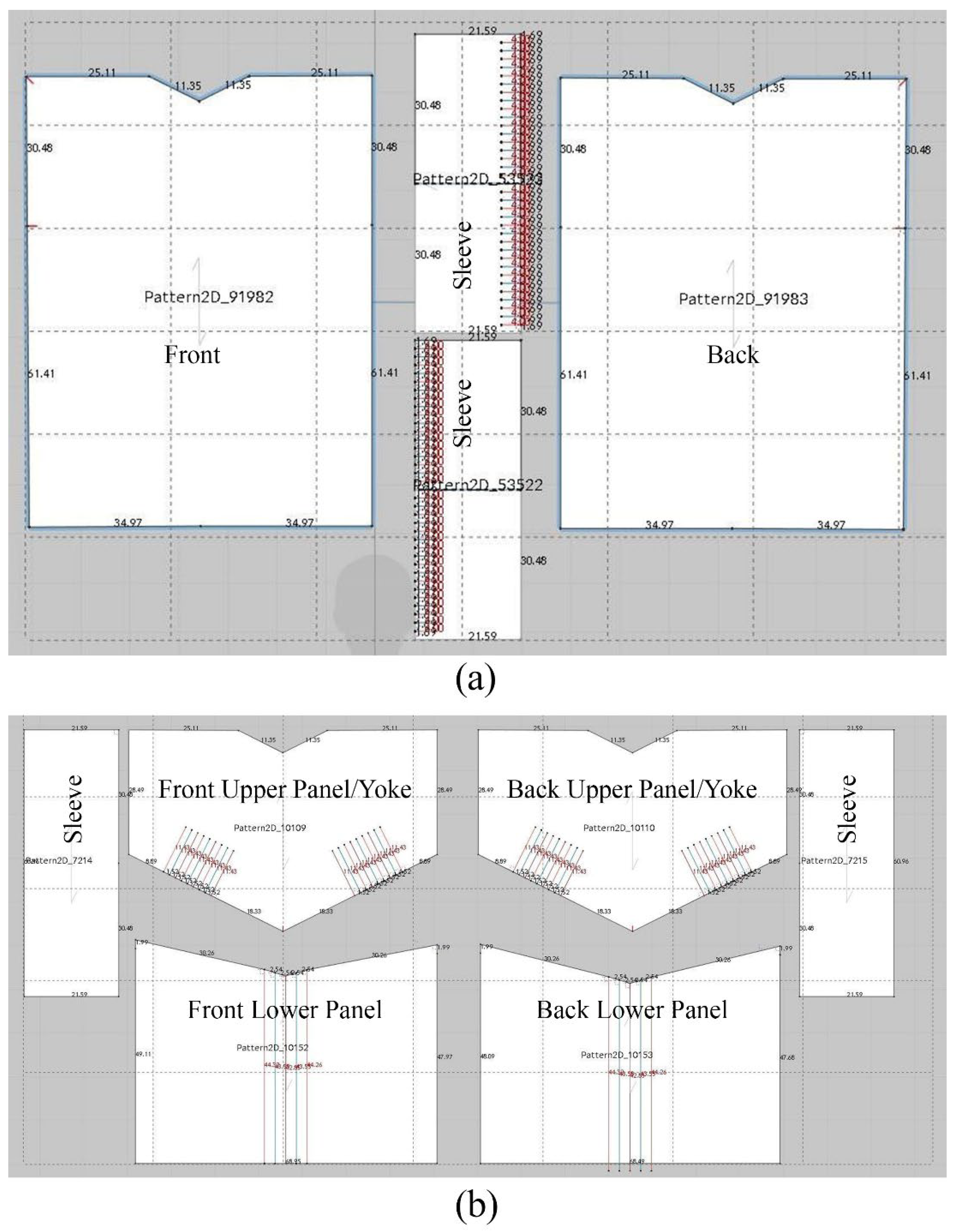

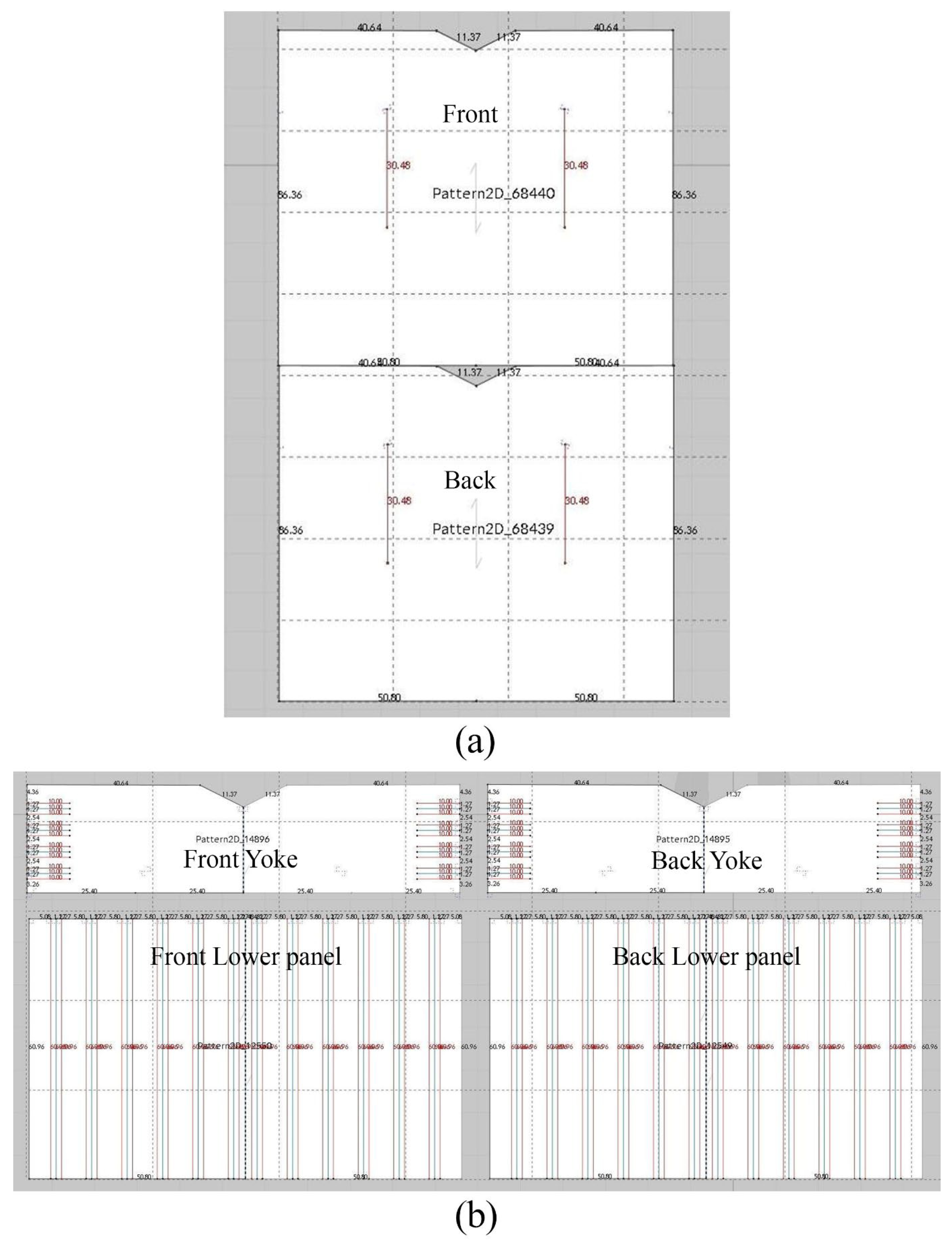

- Development of 2D zero waste pattern of kaftan and tunic dress from Adobe Illustrator and comparison with conventional patterns followed by virtual simulation of the garment on 3D Fashion Software CLO (CLO 6.0) for precise virtual prototyping. Four designs were developed on CLO software, two designs for each category. Utilization of CLO addressed the possibility of reducing fabric waste by eliminating the need for physical sample development. Furthermore, it adjusts avatar body measurements according to the required sizes and provides accurate simulation. For this study, the default avatar main measurements in CLO were already compatible with the volunteered participants, thus negating any need for adjustments.

- Preparation of user guide document for each garment. This document comprised directions on disassembling and reassembling the garment into its second design. This document bearing information on the second designs was to be given to the subjects along with the garments after the wear trial of the first designs to assess how much subjects comprehend and easily interpret it.

- For the physical construction of the garment, three different types of stitches were selected.

- To test the seam strength/durability, the samples were tested according to the ASTM-D5035 [32].

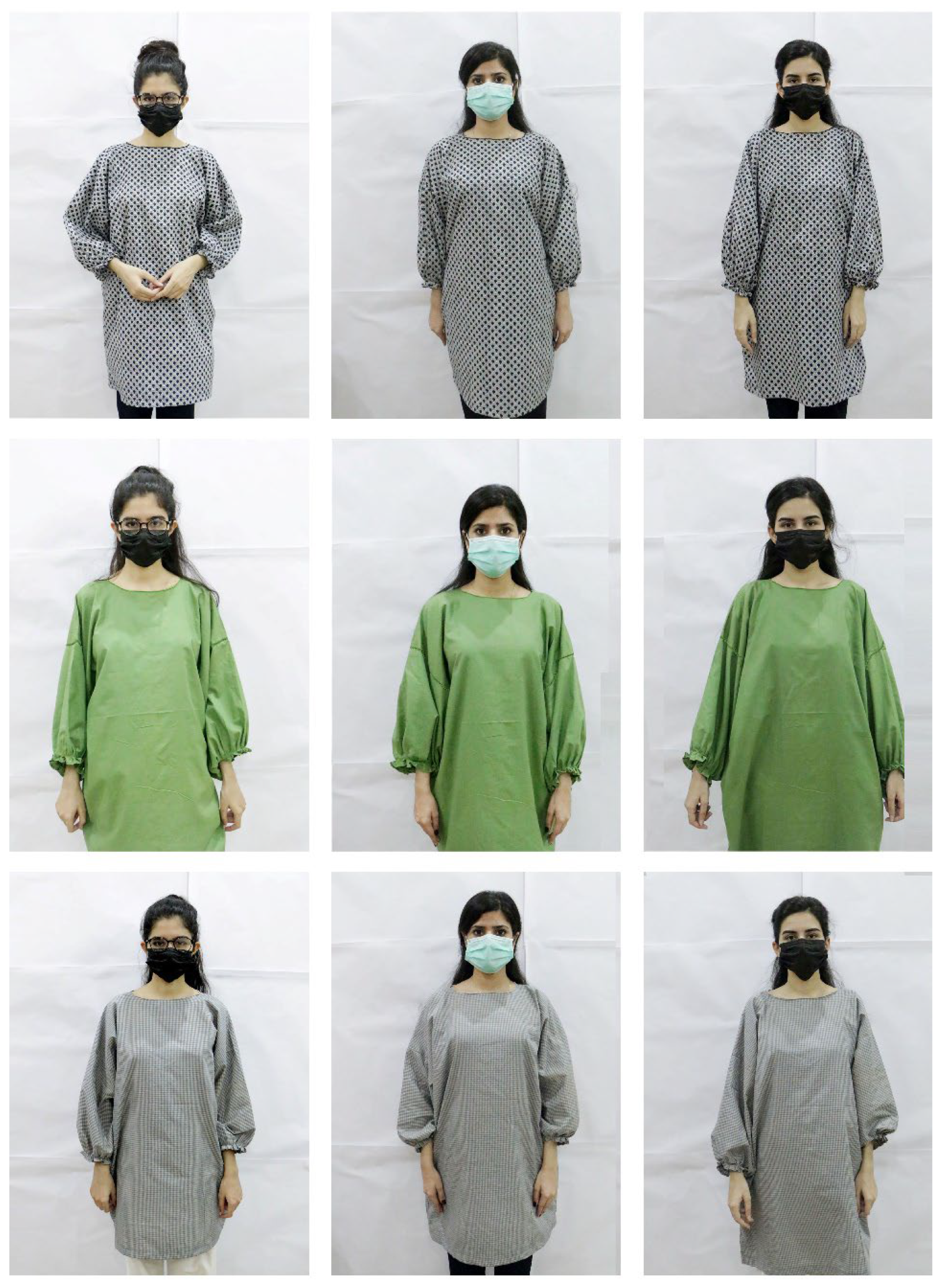

- Development of 18 garments. Nine tunic dresses were sewn in 3 different stitch types. In short, three sets of tunic dresses were manufactured for three selected subjects, and each set comprised three tunics sewn with three types of stitches and in three different colors and patterns. Similarly, nine kaftan dresses were also manufactured using three different stitch types. The fabric type remained constant except for colors or print/pattern.

- Development of a questionnaire.

3. Results and Discussions

3.1. Digital Procedures

3.2. Physical Construction

3.2.1. Seam Strength Testing

3.2.2. First Wear Trial Assessment

3.2.3. Second Wear Trial Assessment

3.2.4. Quantitative and Qualitative Data

3.3. Descriptive Statistics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Niinimäki, K.; Peters, G.; Dahlbo, H.; Perry, P.; Rissanen, T.; Gwilt, A. The environmental price of fast fashion. Nat. Rev. Earth Environ. 2020, 1, 189–200. [Google Scholar] [CrossRef]

- Jung, S.; Jin, B. From quantity to quality: Understanding slow fashion consumers for sustainability and consumer education. Int. J. Consum. Stud. 2016, 40, 410–421. [Google Scholar] [CrossRef]

- Anguelov, N. The Dirty Side of the Garment Industry: Fast Fashion and Its Negative Impact on Environment and Society; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar] [CrossRef]

- Caro, F.; Martìnez-De-Albèniz, V. Fast fashion: Business model overview and research opportunities. In Retail Supply Chain Management; International Series in Operations Research and Management Science; Springer: Boston, MA, USA, 2015. [Google Scholar] [CrossRef]

- Johansson, E. Slow Fashion: The Answer for a Sustainable Fashion Industry? Master’s Thesis, University of Borås, Borås, Sweden, 2010. [Google Scholar]

- Kanan, M.; Habib, M.S.; Habib, T.; Zahoor, S.; Gulzar, A.; Raza, H.; Abusaq, Z. A Flexible Robust Possibilistic Programming Approach for Sustainable Second-Generation Biogas Supply Chain Design under Multiple Uncertainties. Sustainability 2022, 14, 11597. [Google Scholar] [CrossRef]

- Marchand, A.; Walker, S. Product development and responsible consumption: Designing alternatives for sustainable lifestyles. J. Clean. Prod. 2008, 16, 1163–1169. [Google Scholar] [CrossRef]

- Munir, M.A.; Habib, M.S.; Hussain, A.; Shahbaz, M.A.; Qamar, A.; Masood, T.; Sultan, M.; Mujtaba, M.A.; Imran, S.; Hasan, M.; et al. Blockchain Adoption for Sustainable Supply Chain Management: Economic, Environmental, and Social Perspectives. Front. Energy Res. 2022, 10, 899632. [Google Scholar] [CrossRef]

- Beltrami, M.; Orzes, G.; Sarkis, J.; Sartor, M. Industry 4.0 and sustainability: Towards conceptualization and theory. J. Clean. Prod. 2021, 312, 127733. [Google Scholar] [CrossRef]

- El Baz, J.; Tiwari, S.; Akenroye, T.; Cherrafi, A.; Derrouiche, R. A framework of sustainability drivers and externalities for Industry 4.0 technologies using the Best-Worst Method. J. Clean. Prod. 2022, 344, 130909. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Ki, C.W.; Chong, S.M.; Ha-Brookshire, J.E. How fashion can achieve sustainable development through a circular economy and stakeholder engagement: A systematic literature review. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 2401–2424. [Google Scholar] [CrossRef]

- Abusaq, Z.; Habib, M.S.; Shehzad, A.; Kanan, M.; Assaf, R. A Flexible Robust Possibilistic Programming Approach toward Wood Pellets Supply Chain Network Design. Mathematics 2022, 10, 3657. [Google Scholar] [CrossRef]

- Keßler, L.; Matlin, S.A.; Kümmerer, K. The contribution of material circularity to sustainability—Recycling and reuse of textiles. Curr. Opin. Green Sustain. Chem. 2021, 32, 100535. [Google Scholar] [CrossRef]

- Linton, J.D.; Jayaraman, V. A framework for identifying differences and similarities in the managerial competencies associated with different modes of product life extension. Int. J. Prod. Res. 2005, 43, 1807–1829. [Google Scholar] [CrossRef]

- Goldsworthy, K. The Speedcycle: A design-led framework for fast and slow circular fashion lifecycles. Des. J. 2017, 20, S1960–S1970. [Google Scholar] [CrossRef]

- Ajwani-Ramchandani, R.; Figueira, S.; de Oliveira, R.T.; Jha, S.; Ramchandani, A.; Schuricht, L. Towards a circular economy for packaging waste by using new technologies: The case of large multinationals in emerging economies. J. Clean. Prod. 2021, 281, 125139. [Google Scholar] [CrossRef]

- Jia, F.; Yin, S.; Chen, L.; Chen, X. The circular economy in the textile and apparel industry: A systematic literature review. J. Clean. Prod. 2020, 259, 120728. [Google Scholar] [CrossRef]

- Ramzan, M.B.; Qureshi, S.M.; Habib, M.S.; Naveed, T.; Awais, M.; Jamshaid, H. Evaluation of human factors on visual inspection skills in textiles and clothing: A statistical approach. J. Eng. Fibers Fabr. 2022, 17, 15589250221128115. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Carrico, M.; Kim, V. Expanding zero-waste design practices: A discussion paper. Int. J. Fash. Des. Technol. Educ. 2014, 7, 58–64. [Google Scholar] [CrossRef]

- McQuillan, H. Digital 3D design as a tool for augmenting zero-waste fashion design practice. Int. J. Fash. Des. Technol. Educ. 2020, 13, 89–100. [Google Scholar] [CrossRef]

- Chen, L. Sustainability and Company Performance: Evidence from the Manufacturing Industry, 1698; Linköping University Electronic Press: Linkoping, Sweden, 2015. [Google Scholar]

- Schoenherr, T. The role of environmental management in sustainable business development: A multi-country investigation. Int. J. Prod. Econ. 2012, 140, 116–128. [Google Scholar] [CrossRef]

- Lowe, G.; Bogue, R. Design for disassembly: A critical twenty-first century discipline. Assem. Autom. 2007, 27, 285–289. [Google Scholar] [CrossRef]

- Kumar, G.A.; Bahubalendruni, M.V.A.R.; Prasad, V.S.S.; Sankaranarayanasamy, K. A multi-layered disassembly sequence planning method to support decision making in de-manufacturing. Sadhana Acad. Proc. Eng. Sci. 2021, 46, 102. [Google Scholar] [CrossRef]

- Monyaki, N.C.; Cilliers, R. Defining Drivers and Barriers of Sustainable Fashion Manufacturing: Perceptions in the Global South. Sustainability 2023, 15, 10715. [Google Scholar] [CrossRef]

- Rissanen, T. From 15% to 0: Investigating the creation of fashion without the creation of fabric waste: Creativity. In Proceedings of the Designer Meets Technology Europe, København, Denmark, 26–27 September 2005. [Google Scholar]

- McQuillan, H. Waste, so What? A reflection on waste and the role of designers in a circular economy. In Proceedings of the Nordes 2019: Who Cares? Espo, Finland, 2–4 June 2019. [Google Scholar] [CrossRef]

- Gam, H.J.; Cao, H.; Bennett, J.; Helmkamp, C.; Farr, C. Application of design for disassembly in men’s jacket: A study on sustainable apparel design. Int. J. Cloth. Sci. Technol. 2011, 23, 83–94. [Google Scholar] [CrossRef]

- Bhatt, D.; Silverman, J.; Dickson, M.A. Consumer interest in upcycling techniques and purchasing upcycled clothing as an approach to reducing textile waste. Int. J. Fash. Des. Technol. Educ. 2019, 12, 118–128. [Google Scholar] [CrossRef]

- ASTM-D5035; Standard Test Method for Breaking Force and Elongation of Textile Fabrics (Strip Method). ASTM: West Conshohocken, PA, USA, 2019.

- McNeill, L.S.; Hamlin, R.P.; McQueen, R.H.; Degenstein, L.; Garrett, T.C.; Dunn, L.; Wakes, S. Fashion sensitive young consumers and fashion garment repair: Emotional connections to garments as a sustainability strategy. Int. J. Consum. Stud. 2020, 44, 361–368. [Google Scholar] [CrossRef]

| Sr. No. | Subjects | Garment | Stitch Type | Samples |

|---|---|---|---|---|

| 1 | S1 | G1 | N1 | S1 G1 N1 |

| 2 | N2 | S1 G1 N2 | ||

| 3 | N3 | S1 G1 N3 | ||

| 4 | G2 | N1 | S1 G2 N1 | |

| 5 | N2 | S1 G2 N2 | ||

| 6 | N3 | S1 G2 N3 | ||

| 7 | S2 | G1 | N1 | S2 G1 N1 |

| 8 | N2 | S2 G1 N2 | ||

| 9 | N3 | S2 G1 N3 | ||

| 10 | G2 | N1 | S2 G2 N1 | |

| 11 | N2 | S2 G2 N2 | ||

| 12 | N3 | S2 G2 N3 | ||

| 13 | S3 | G1 | N1 | S3 G1 N1 |

| 14 | N2 | S3 G1 N2 | ||

| 15 | N3 | S3 G1 N3 | ||

| 16 | G2 | N1 | S3 G2 N1 | |

| 17 | N2 | S3 G2 N2 | ||

| 18 | N3 | S3 G2 N3 |

| Stitch Type | N | N | N | N | N | Average | σ |

|---|---|---|---|---|---|---|---|

| Lock stitch (class 300) | 274.5 | 274.5 | 264.7 | 274.5 | 274.5 | 274.5 | 0.447 |

| Hand stitch (class 200) | 107.8 | 117.6 | 117.6 | 107.8 | 107.8 | 107.8 | 0.547 |

| Overlock stitch (class 500) | 205.9 | 196 | 215.7 | 205.9 | 205.9 | 215.7 | 0.707 |

| Subject | Category | Fabric | Disassembly Time Recorded | Reassembly Time Recorded | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lock stitch SPI-6 | Hand stitch SPI-6 | Overlock stitch SPI-6 | Lock stitch SPI-6 | Hand stitch SPI-6 | Overlock stitch SPI-6 | |||||||

| P1 | Tunic | Cotton | 1 min 47 s | 23 min 11 s | ||||||||

| 1 min 13 s | 51 s | min | 10 | |||||||||

| 2 min 12 s | 25 min 45 s | |||||||||||

| Kaftan Dress | 39 s | 38 min 56 s | ||||||||||

| 20 s | 43 s | min | 53 | |||||||||

| 44 s | 39 min 16 s | |||||||||||

| P2 | Tunic | Cotton | 2 min 1 s | 20 min 20 s | ||||||||

| 1 min 5 s | 50 s | min | 23 | |||||||||

| 2 min 7 s | 29 min 12 s | |||||||||||

| Kaftan Dress | 40 s | 40 min 3 s | ||||||||||

| 17 s | 52 s | min | 24 | |||||||||

| 42 s | 36 s | min | 1 | |||||||||

| P3 | Tunic | Cotton | 1 min 33 s | 21 min 15 s | ||||||||

| 1 min 26 s | 47 s | min | 13 | |||||||||

| 2 min 16 s | 28 s | min | 1 | |||||||||

| Kaftan Dress | 36 s | 38 min 2 s | ||||||||||

| 18 s | 49 min 1 s | |||||||||||

| 47 s | 40 s | min | 23 | |||||||||

| Stitch Type | DF | ‘R’ Mean (s) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hand stitch | 3 | 2 | 44.67 | 7.23 | 59.83 | 0.000 | 2975.3 | 125.5 | 209.3 | 0.000 |

| Overlock stitch | 3 | 2 | 145.6 | 11.93 | 1663.3 | 106.6 | ||||

| Lock stitch | 3 | 2 | 107.0 | 14.00 | 1302.0 | 79.0 |

| Stitch Type | DF | ‘R’ Mean (s) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hand stitch | 3 | 2 | 18.333 | 1.528 | 80.54 | 0.000 | 2906 | 257 | 10.29 | 0.011 |

| Overlock stitch | 3 | 2 | 35.33 | 2.52 | 2293.3 | 169.9 | ||||

| Normal straight stitch | 3 | 2 | 38.33 | 2.08 | 2273.3 | 134.2 |

| Scale Items | Means | Std. Error | Std. Deviation | Skewness | Std. Error of Skewness | Kurtosis | Std. Error of Kurtosis |

|---|---|---|---|---|---|---|---|

| Visually Comfortable | 12.6667 | 1.49815 | 3.66970 | −1.423 | 0.845 | 2.081 | 1.741 |

| Is functional | 12.5000 | 0.84656 | 2.07364 | 0.404 | 0.845 | −1.617 | 1.741 |

| Seam Integrity is fine | 13.1667 | 1.16667 | 2.85774 | −1.021 | 0.845 | −1.557 | 1.741 |

| Has a nice feeling | 13.1667 | 0.70317 | 1.72240 | 1.435 | 0.845 | 2.723 | 1.741 |

| Number of wears | 33.0000 | 1.59164 | 3.89872 | 0.547 | 0.845 | −0.103 | 1.741 |

| μ | α | p | ||||

|---|---|---|---|---|---|---|

| 11 | 7 | 9.92 | 0.05 | 17 | 1.74 | 0.0000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramzan, M.B.; Habib, M.S.; Omair, M.; Naeem, J.; Mustafa, H.; Iqbal, M.W.; Malik, A.I. Role of Design for Disassembly in Educating Consumers for Circular Behavior. Sustainability 2023, 15, 15505. https://doi.org/10.3390/su152115505

Ramzan MB, Habib MS, Omair M, Naeem J, Mustafa H, Iqbal MW, Malik AI. Role of Design for Disassembly in Educating Consumers for Circular Behavior. Sustainability. 2023; 15(21):15505. https://doi.org/10.3390/su152115505

Chicago/Turabian StyleRamzan, Muhammad Babar, Muhammad Salman Habib, Muhammad Omair, Jawad Naeem, Hajra Mustafa, Muhammad Waqas Iqbal, and Asif Iqbal Malik. 2023. "Role of Design for Disassembly in Educating Consumers for Circular Behavior" Sustainability 15, no. 21: 15505. https://doi.org/10.3390/su152115505

APA StyleRamzan, M. B., Habib, M. S., Omair, M., Naeem, J., Mustafa, H., Iqbal, M. W., & Malik, A. I. (2023). Role of Design for Disassembly in Educating Consumers for Circular Behavior. Sustainability, 15(21), 15505. https://doi.org/10.3390/su152115505