Analysis of Key Injury-Causing Factors of Object Strike Incident in Construction Industry Based on Data Mining Method

Abstract

:1. Introduction

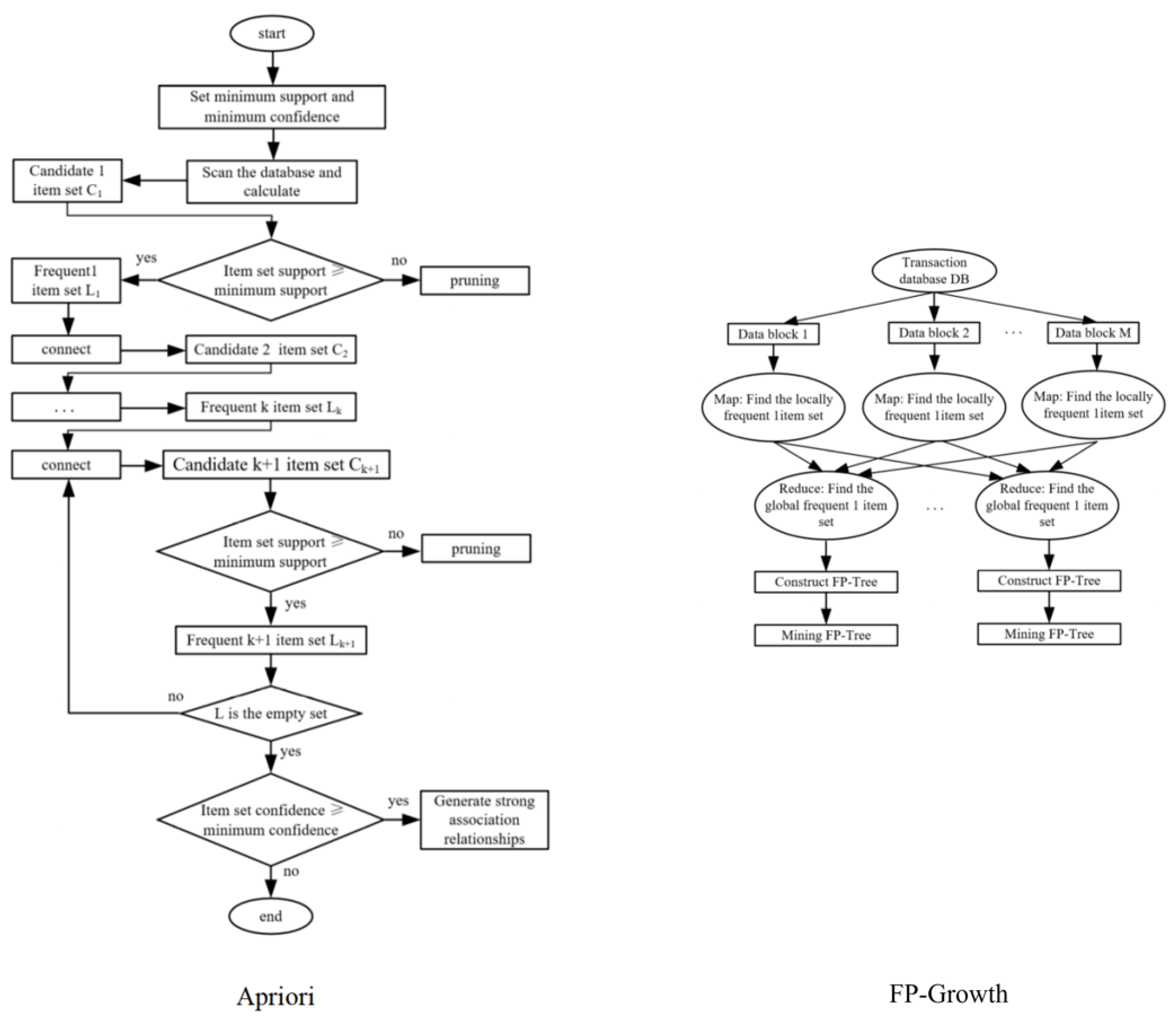

2. Data Mining Algorithm

2.1. Apriori Algorithm

2.2. FP-Growth Algorithm

2.2.1. Constructing FP Tree

2.2.2. Mining Frequent Itemsets from the FP Tree

3. Extraction of Cause of Construction Object Strike Incident

3.1. Data Preprocessing

3.2. Algorithm Model

4. Correlation Result Analysis

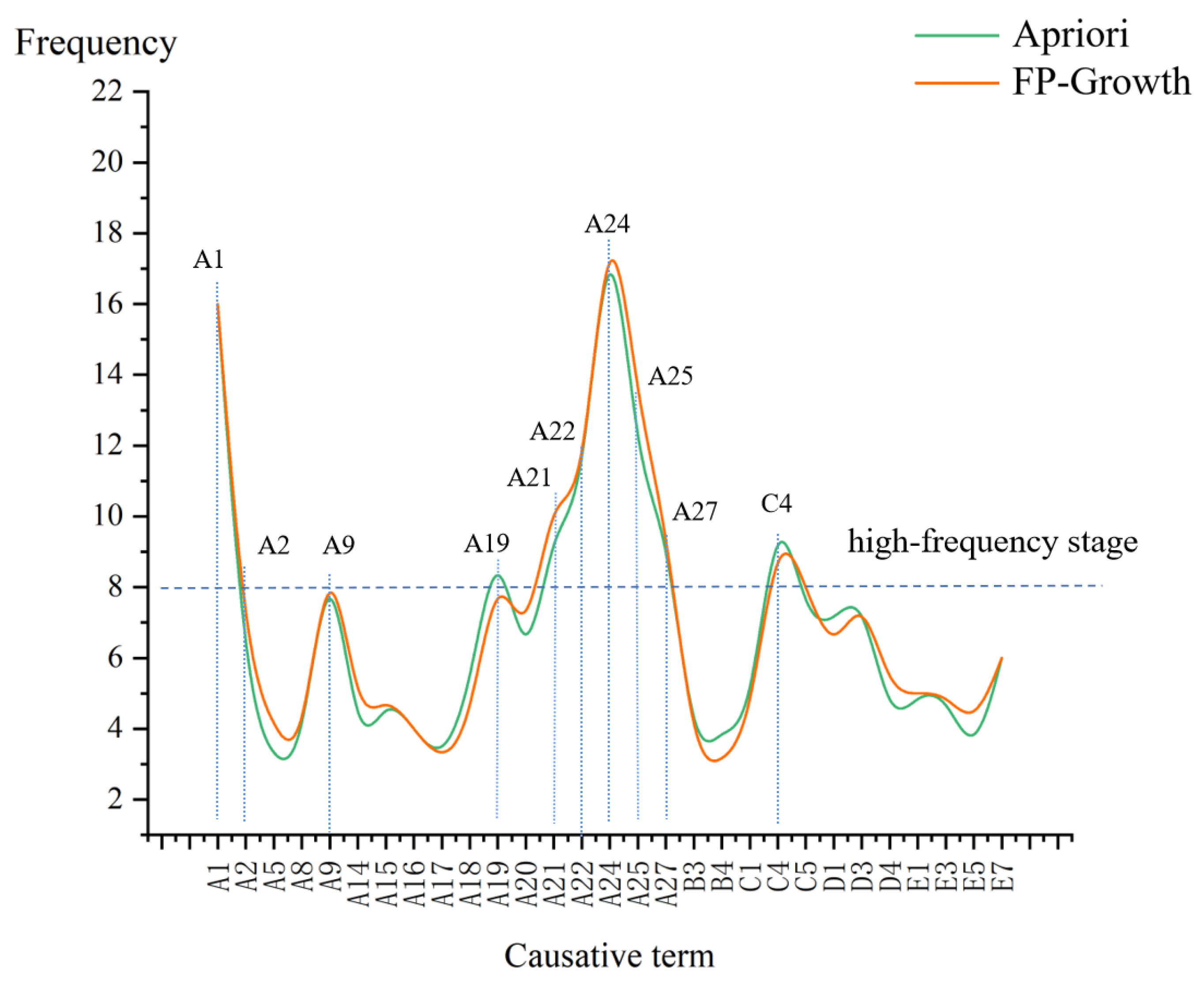

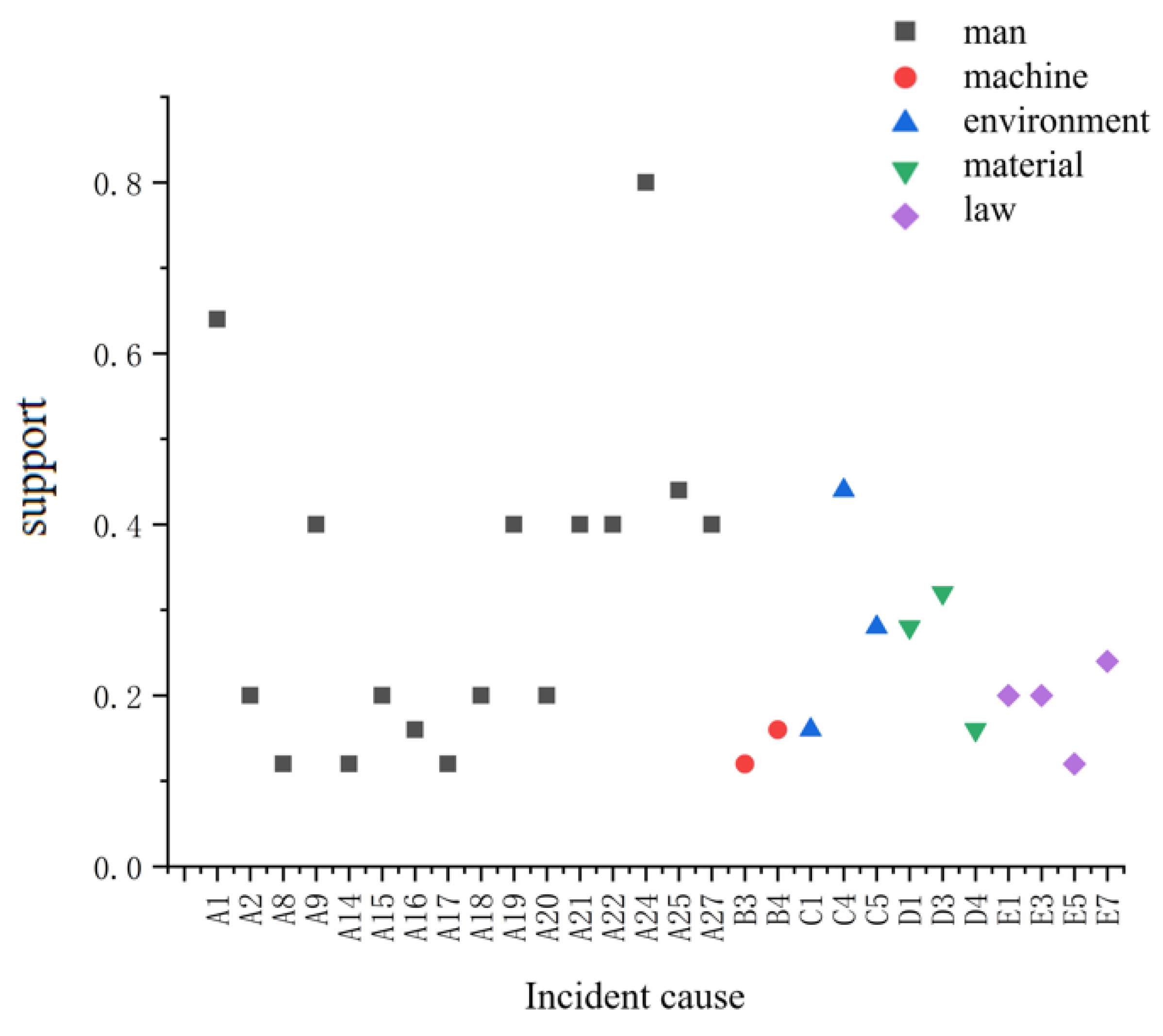

4.1. Analysis of Major Incident Causes

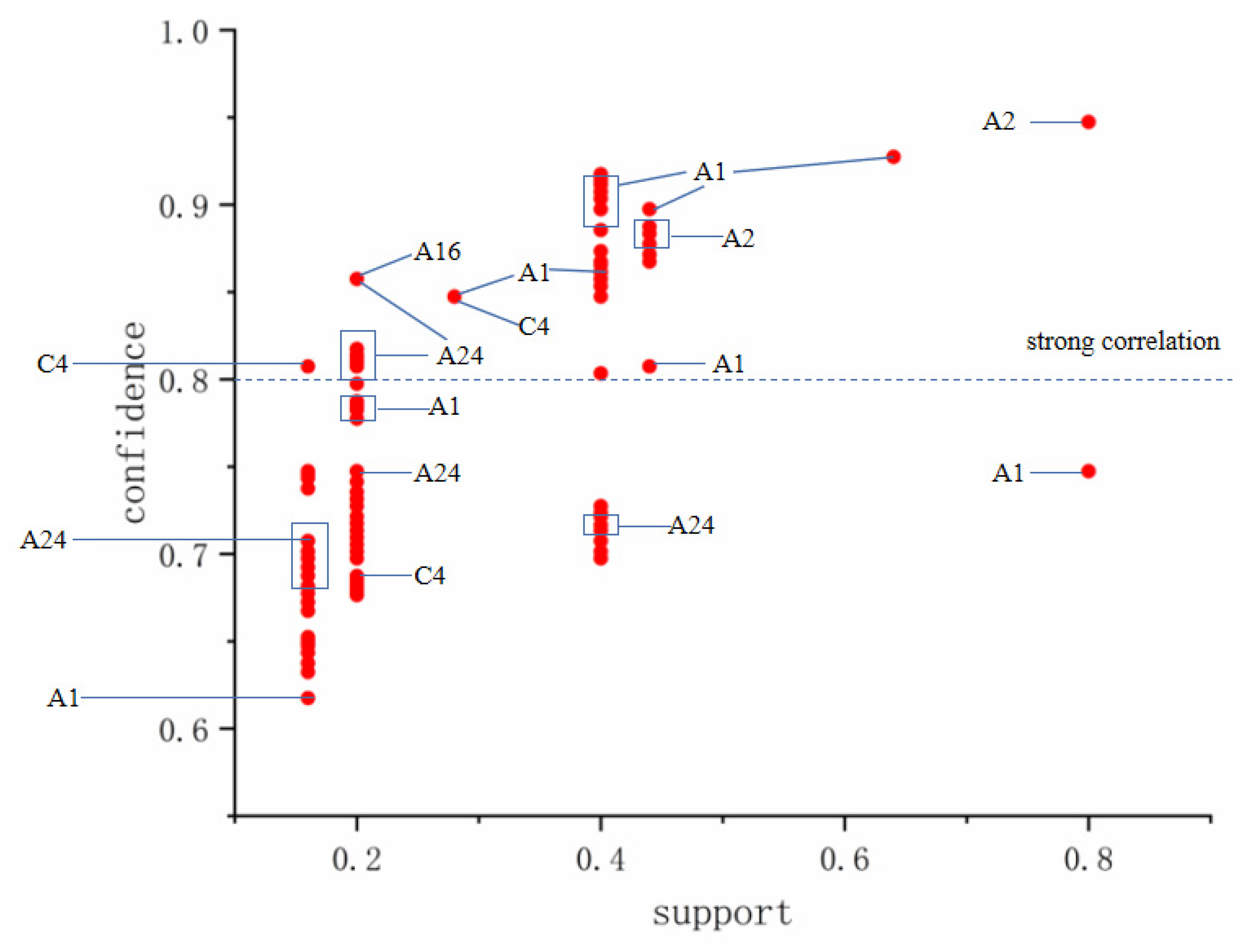

4.2. Association Rule Result

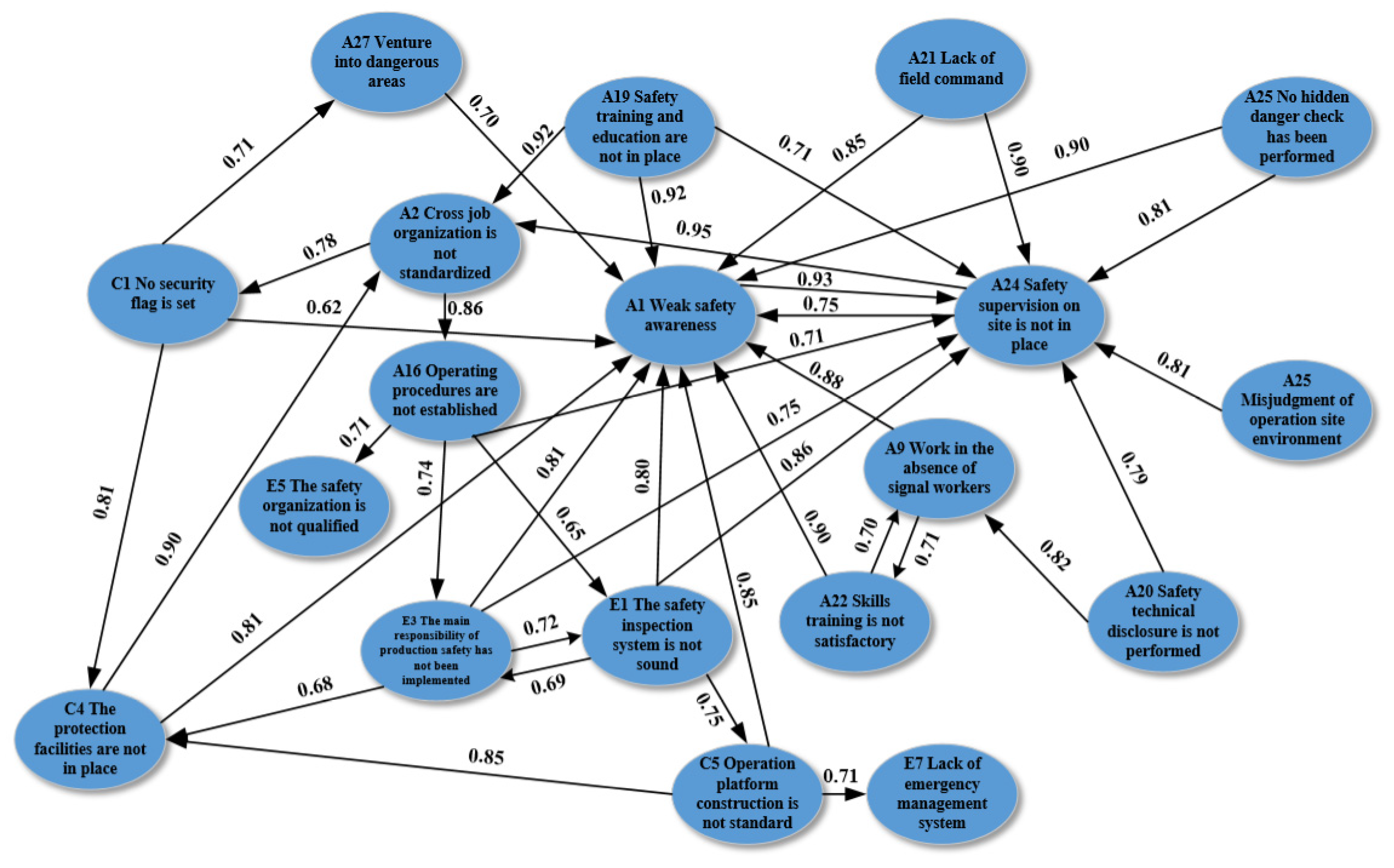

4.3. Incident Cause Prediction Based on Bayesian Network

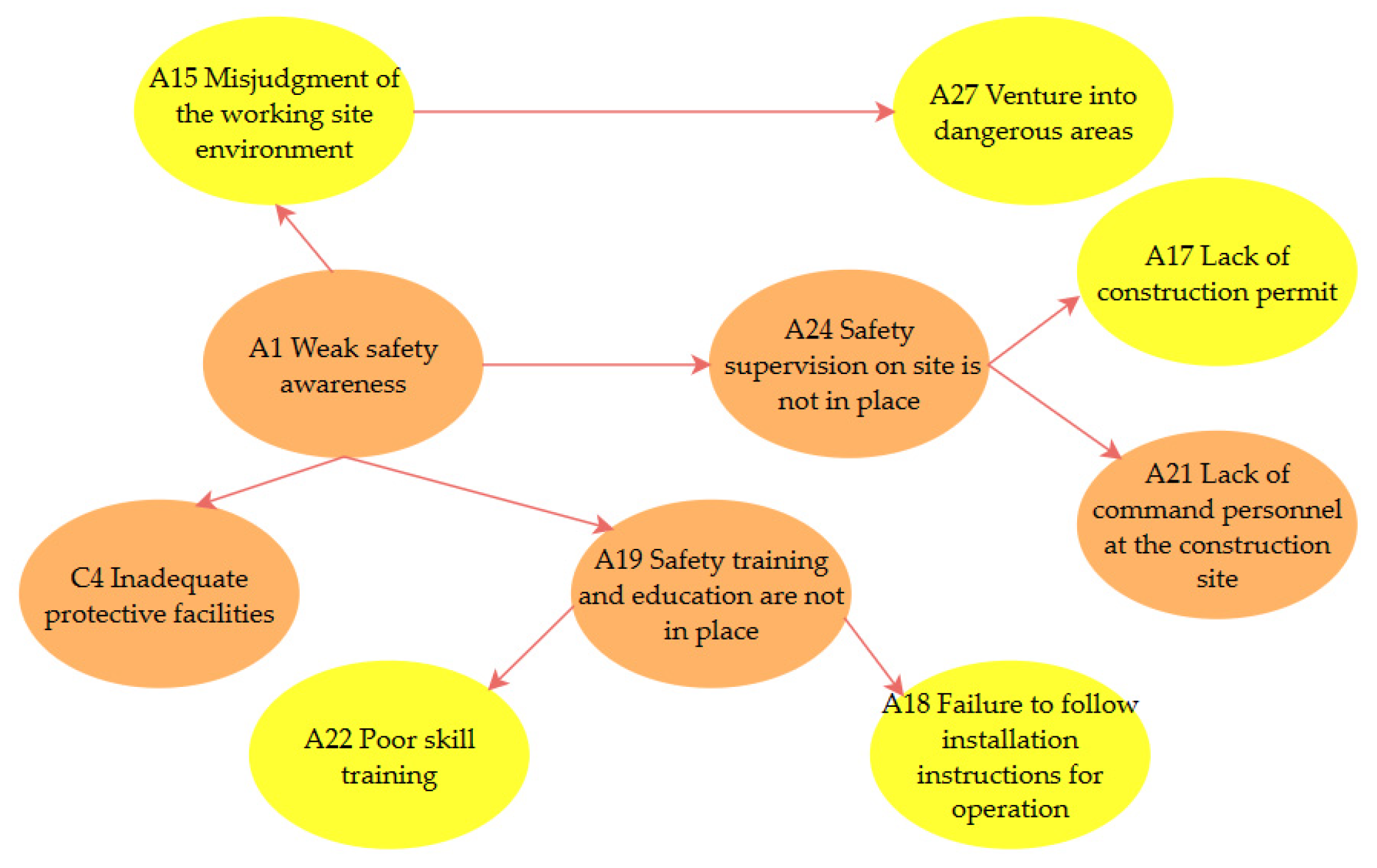

4.4. Incident Causative Association Rule Analysis

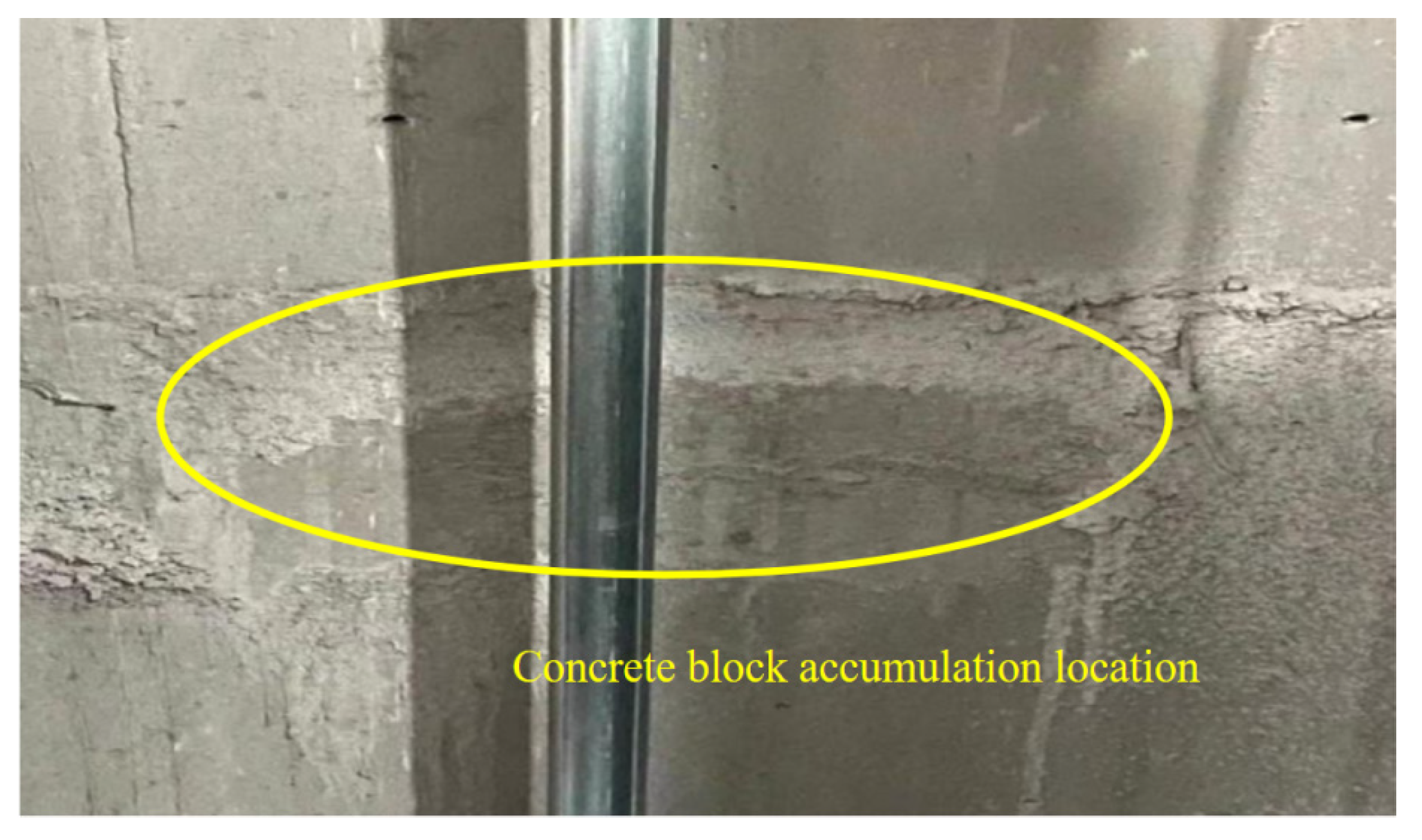

4.5. Case Study

- Strengthening the safety awareness of construction workers can reduce the occurrence of most striking incidents. The operation cannot take a chance; it must set up the correct concept of work, and develop the habit of construction in accordance with the norms, to fundamentally avoid the occurrence of incidents;

- Do a good job of performing security risk investigations and rectifications. The existence of hidden dangers should be rectified in a timely manner and registered. The temporary inability to rectify such dangers must involve practical monitoring and protection measures until they are resolved;

- The operation of a variety of machinery personnel must involve professional training; personnel must be able to master the basic knowledge of the performance of the equipment and be qualified by examination. On-duty operations must be carefully operated, involving the strict implementation of the relevant rules and regulations. The correct use of labor-protective equipment is mandatory, with workers being strictly prohibited to work without a license to use the mechanical equipment;

- Do a good job of construction site management. On-site safety inspection is an important part of the safety management process. Every safety issue in the construction process should be effectively controlled. Safety inspections must cover the range of expectations and qualifications, including the implementation of safety rules and regulations, safety and technical delivery, the operation and maintenance of machinery and equipment, electrical safety use, safety protection facility setup, the wearing of safety labor protection products, the proper management of the site operating environment, and so on.

5. Conclusions

- The association rule results for incident causation reflect the fact that most incidents occur as a function of the common outcome of multiple causative factors and that incident causation can be controlled by strong association results;

- Nine key incident causative factors were extracted by combining the results of the incident causative factors’ support values and association rules, as well as confirming the reasonableness of the results with Bayesian inference. In particular, the factors Weak safety awareness and Safety supervision on site is not in place had the highest frequencies of occurrence, followed by Cross-operations are not standardized, Operating procedures are not established, Poor skill training, Lack of command personnel at the construction site, Safety training and education are not in place, No hidden danger check has been performed, and Inadequate protective facilities. The results of the analysis reduced the interference of human factors, and the results are more scientific, objective, and reasonable. The results are more scientific, objective, and reasonable so as to provide a reference for construction safety research;

- In addition, the limitation of this study is that the extraction of the incident causes within the sample of incident investigation reports may be misunderstood semantically, which may result in the omission of certain incident causative factors, and a new methodology can be found for the extraction of incident causes from the incident investigation reports via a subsequent study to enhance the scientific validity of the data.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Incident Number | Cause Number |

|---|---|

| T1 | A1, A28, A25, A22, A21, A24, E3 |

| T2 | A1, A27, A5, A14, A15, A17, A19, A24, C3, B5 |

| T3 | A1, A2, A15, A21, A22, A24, A25, A27, C5, A8, E8, A6, A9, A20 |

| T4 | C4, C5, A19, A21, A24, E7, E1, E2 |

| T5 | A1, C4, A19, A27 |

| T6 | A1, A18, A22, A27 |

| T7 | A1, A27, A9, A18, C1, A25 |

| T8 | A9, A27, A24, A21 |

| T9 | A1, A15, A27, A1, C1, C4 |

| T10 | A22, A27, A24 |

| T11 | B2, B6, A15, A24, A25 |

| T12 | B4, A1, A2, A24, A25, D4 |

| T13 | B3, A24 |

| T14 | A5, A2, A10, A18, A21, A24, A1 |

| T15 | A22, A28, C5, C4, A19, A24, E7, EA9 |

| T16 | A24, A22, A21, A18, A9 |

| T17 | A11, A14, A19, A1, A21, A25 |

| T18 | A1, A8, A9, A19, A24, A27, B2 |

| T19 | A1, A2, A9, A22, A24, E7, A19, A20, A25, A6 |

| T20 | A1, A15, A24, C4, C5, A21, A24, E8, A19, A20, C1, E7 |

| T21 | A9, A18, A22, C4, A24, A21, A16, D4, A25 |

| T22 | A2, A14, A22, A1, C4, E1, A20, E3, E5, A5, C4, A9, A16, A17 |

| T23 | A27, C5, C1, C4, E6, E7, E1, E3, A24, A25 |

| T24 | A1, A9, A16, A17, A19, A20, A24, C4, C5, A19, A25, A22, E1, E3, E5 |

| T25 | A9, C5, C4, A24, A8, A21, A16, A25, E1, E3, E5, E6, E7 |

| T26 | B3, A24 |

| T27 | A25, B2, B6, A15, A24 |

| T28 | A1, A15, A24, C4, C5, A21, A24, E8, A19, A20, C1, E7 |

| T29 | A15, C3, A1, A27, A5, A14, A17, A19, A24, B5 |

| T30 | A2, A14, A22, A1, C4, E1, A20, E3, E5, A5, C4, A9, A16, A17 |

| T31 | A19, A1, C4, A27 |

| T32 | A24, A25, B2, B6, A15, |

| T33 | C4, C5, A19, A21, A24, E7, E1, E2 |

| T34 | A1, A8, A9, A19, A24, A27, B2 |

| T35 | A1, A27, C4, A19, |

| T36 | A24, A22, A27, |

| T37 | A5, A2, A10, A18, A21, A24, A1 |

| T38 | A24, E3, A1, A28, A25, A22, A21 |

| T39 | A22, A28, C5, C4, A19, A24, E7, EA9 |

| T40 | A24, A27, A9, A21 |

| T41 | A15, A24, A25, B2, B6, |

| T42 | A2, A14, A22, A1, C4, E1, A20, E3, E5, A5, C4, A9, A16, A17 |

| T43 | A6, A20, E8, A9, A1, A2, A15, A21, A22, A24, A25, A27, C5, A8 |

| T44 | A22, A28, C5, C4, A19, A24, E7, EA9 |

| T45 | A5, A2, A10, A18, A21, A24, A1 |

| T46 | A22, A21, A1, A28, A25, A24, E3 |

| T47 | B2, B6, A15, A24, A25 |

| T48 | B4, A1, A2, A24, A25, D4 |

| T49 | C4, C5, A19, A21, A24, E7, E1, E2 |

| T50 | B3, A24 |

| T51 | A17, A24, A1, A27, A5, A14, A15, A19, C3, B5 |

| T52 | A1, A2, A9, A22, A24, E7, A19, A20, A25, A6 |

| T53 | A19, A27A1, C4, |

| T54 | B4, A1, A2, A24, A25, D4 |

| T55 | A1, A15, A24, C4, C5, A21, A24, E8, A19, A20, C1, E7 |

| T56 | A8, A6, A1, A2, A15, A21, A22, A24, A25, A27, C5, E8, A9, A20 |

| T57 | A22, A27, A24 |

| T58 | A19, A25, A22, E1, A1, A9, A16, A17, A19, A20, A24, C4, C5, E3, E5 |

| T59 | A1, C4, A19, A27 |

| T60 | A24, A22, A21, A18, A9 |

| T61 | A1, A27, B5, A5, A14, A15, A17, A19, A24, C3 |

| T62 | A9, C5, C4, A24, A8, A21, A16, A25, E1, E3, E5, E6, E7 |

| T63 | C4, C5, A19, A21, A24, E7, E1, E2 |

| T64 | A9, A18, A22, C4, A24, A21, A16, D4, A25 |

| T65 | A19, A1, A27, A5, A14, A15, A17, A24, C3, B5 |

| T66 | A22, A28, C5, C4, A19, A24, E7, EA9 |

| T67 | A1, A2, A9, A22, A24, E7, A19, A20, A25, A6 |

| T68 | A24, A27, A8, E8, A6, A9, A20, A25, C5, A1, A2, A15, A21, A22 |

| T69 | A2, A14, A22, A1, C4, E1, A20, E3, E5, A5, C4, A9, A16, A17 |

| T70 | C1, A1, A27, A18, A25A9, |

| T71 | A1, A15, A27, A1, C1, C4 |

| T72 | A11, A14, A19, A1, A21, A25 |

| T73 | A9, A18, A22, C4, A24, A21, A16, D4, A25 |

| T74 | A28, A25, A1, A22, A21, A24, E3 |

| T75 | A27, C5, C1, C4, E6, E7, E1, E3, A24, A25 |

| T76 | B3, A24 |

| T77 | A22, A28, C5, C4, A19, A24, E7, EA9 |

| T78 | A17, A19, A20, A24, C4, C5, A19, A25, A22, E1, E3, E5, A1, A9, A16 |

| T79 | A27, A24, A1, A2, A15, A21, A22, A25, C5, A8, E8, A6, A9, A20 |

| T80 | A9, C5, C4, A24, A8, A21, A16, A25, E1, E3, E5, E6, E7 |

| T81 | A1, A8, A9, A19, A24, A27, B2 |

| T82 | A1, A8, A9, A19, A24, A27, B2 |

| T83 | A1, A22, A18, A27 |

| T84 | A22, A27, A24 |

| T85 | A1, A15, A24, C4, C5, A21, A24, E8, A19, A20, C1, E7 |

| T86 | A18, A1, A27, A9, C1, A25 |

| T87 | B3, A24 |

| T88 | A1, A15, A27, A1, C1, C4 |

| T89 | B4, A1, A2, A24, A25, D4 |

| T90 | A11, A14, A19, A1, A21, A25 |

| T91 | A1, A2, A15, A21, A22, A24, A25, A27, C5, A8, E8, A6, A9, A20 |

| T92 | A9, C5, C4, A24, A8, A21, A16, A25, E1, E3, E5, E6, E7 |

| T93 | A1, A2, A9, A22, A24, E7, A19, A20, A25, A6 |

| T94 | A9, A27, A24, A21 |

| T95 | A9, A18, A22, C4, A24, A21, A16, D4, A25 |

| T96 | A22, A28, C5, C4, A19, A24, E7, EA9 |

| T97 | A27, C5, C1, C4, E6, E7, E1, E3, A24, A25 |

| T98 | A1, A22, A27, A18 |

| T99 | A1, A9, A16, A17, A19, A20, A24, C4, C5, A19, A25, A22, E1, E3, E5 |

| T100 | A24, A22, A21, A18, A9 |

| T101 | A1, A15, A24, C4, C5, A21, A24, E8, A19, A20, C1, E7 |

| T102 | A1, A15, A27, A1, C1, C4 |

| T103 | A24, A22, A21, A18, A9 |

| T104 | A9, C5, C4, A24, A8, A21, A16, A25, E1, E3, E5, E6, E7 |

| T105 | A28, A25, A22, A21, A1, A24, E3 |

| T106 | A5, A2, A10, A18, A21, A24, A1 |

| T107 | A11, A14, A19, A1, A21, A25 |

| T108 | A9, A18, A22, C4, A24, A21, A16, D4, A25 |

| T109 | A9, A18, A1, A27, C1, A25 |

| T110 | A2, A14, A22, A1, C4, E1, A20, E3, E5, A5, C4, A9, A16, A17 |

| T111 | A22, A27, A24 |

| T112 | B4, A1, A2, A24, A25, D4 |

| T113 | A18, A22, A27, A1 |

| T114 | A27, C5, C1, C4, E6, E7, E1, E3, A24, A25 |

| T115 | A9, A27, A24, A21 |

| T116 | A1, A2, A9, A22, A24, E7, A19, A20, A25, A6 |

| T117 | A1, A27, A9, A18, C1, A25 |

| T118 | A9, A27, A24, A21 |

| T119 | A1, A15, A27, A1, C1, C4 |

| T120 | A9, A18, A22, C4, A24, A21, A16, D4, A25 |

| T121 | E1, C4, A21, C5, A19, A24, E7, E2 |

| T122 | A24, A22, A21, A18, A9 |

| T123 | A11, A14, A19, A1, A21, A25 |

| T124 | A1, A18, A22, A27 |

| T125 | A27, C5, C1, C4, E6, E7, E1, E3, A24, A25 |

| T126 | A5, A2, A10, A18, A21, A24, A1 |

References

- Hu, L.; Peng, S.; Wei, Q.; Huang, Y.; Wang, X. Hotel safety management model based on causal chain theory of incident. Safety 2019, 40, 35–39. [Google Scholar]

- Kuang, Y. Case Study of Tower Crane Incident Based on Data Mining; Huazhong University of Science and Technology: Wuhan, China, 2021. [Google Scholar]

- Huang, Q. Safety Management of high work in building construction project. Ind. Build. 2021, 51, 209. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Available online: http://www.mohurd.goc.cn/ (accessed on 27 July 2023).

- Wang, G.; Li, R.; Shen, J. Statistical Analysis and Countermeasures of Incidents in the National Construction Industry from 2015 to 2018. Sci. Technol. Innov. 2019, 15, 57–58+62. [Google Scholar] [CrossRef]

- Haslam, R.A.; Hide, S.A.; Gibb, A.G.; Gyi, D.E.; Pavitt, T.; Atkinson, S.; Duff, A.R. Contributing factors in construction incidents. Appl. Ergon. 2005, 36, 401–415. [Google Scholar] [CrossRef]

- Mousa, J.; Roghayeh, G. Developing techniques for cause-responsibility analysis of occupational incidents. Incid. Anal. Prev. 2016, 96, 101–107. [Google Scholar]

- Soliman, K. Building Collapse during Construction. Pract. Period. Struct. Des. Constr. 2010, 15, 99–100. [Google Scholar]

- Peng, J.-L.; Ho, C.-M.; Chang, Y.-P.; Chan, S.-L. Study on collapse of steel-reinforced concrete structure caused by self-weight during construction. J. Constr. Steel Res. 2019, 156, 276–286. [Google Scholar] [CrossRef]

- Zhou, D.; Pang, Q. Study on Prevention Measures of Falling Accidents during Construction. Int. Conf. Pipelines Trenchless Technol. 2012, 1494–1501. [Google Scholar] [CrossRef]

- Alizadeh, S.S.; Mortazavi, S.B.; Sepehri, M.M. Building a Model Using Bayesian Network for Assessment of Posterior Probabilities of Falling From Height at Workplaces. Health Promot. Perspect. 2014, 4, 187–194. [Google Scholar]

- Mistikoglu, G.; Gerek, I.H.; Erdis, E.; Usmen, P.M.; Cakan, H.; Kazan, E.E. Decision tree analysis of construction fall incidents involving roofers. Expert Syst. Appl. 2015, 42, 2256–2263. [Google Scholar] [CrossRef]

- Chen, H.; Luo, X. Severity prediction models of falling risk for workers at height. Procedia Eng. 2016, 164, 439–445. [Google Scholar] [CrossRef]

- Sun, S.; Qiu, S.; Geng, X.; Fu, G. Classification and statistical analysis of causes of construction object strike incident based on “2–4” model. Build. Saf. 2019, 35, 55–59. [Google Scholar]

- Cao, J. Object strike incident analysis and preventive measures. Mod. Occup. Saf. 2010, 10, 68. [Google Scholar]

- Jia, W.; Liu, F. Research on Construction Safety Management of prefabricated Buildings based on Incident Analysis. Gansu Sci. Technol. 2017, 37, 99–101. [Google Scholar]

- Duan, H.; Chen, C.; Wang, H.-H.; Liu, H.-R.; Cao, Z.-T. Study on cause analysis and control of striking incidents of construction objects. Value Eng. 2017, 36, 38–41. [Google Scholar]

- Li, T.Z.; You, X. Analysis of influencing factors of prefabricated building quality based on Apriori. J. Tongji Univ. (Nat. Sci.) 2022, 50, 147–152. (In Chinese) [Google Scholar]

- Jiang, D.; He, D.; Zhang, Z. Research on construction safety production management of construction engineering—Based on incident causation theory and data mining technology. J. Shenyang Jianzhu Univ. (Soc. Sci. Ed.) 2021, 23, 605–611. [Google Scholar]

- Ma, R.; Wu, H. Research and application of Association rule Mining based on FP_Growth algorithm. J. Taiyuan Norm. Univ. (Nat. Sci. Ed.) 2021, 20, 19–22. [Google Scholar]

- Fu, Z. Application research of Data mining C4.5 algorithm in municipal engineering cost. Comput. Mod. 2018, 1, 27–31. [Google Scholar]

- Zhang, Q.; Zhang, J.; Zhao, L.; Liu, X.; Ren, G. Classification method of Structural design specifications based on Naive Bayes algorithm. In Proceedings of the 7th National BIM Academic Conference, Chongqing, China, 25–26 December 2021; pp. 60–65. [Google Scholar]

- Singh, A.K.; Kumar, P.; Ali, R.; Al-Ansari, N.; Vishwakarma, D.K.; Kushwaha, K.S.; Panda, K.C.; Sagar, A.; Mirzania, E.; Elbeltagi, A.; et al. An Integrated Statistical-Machine Learning Approach for Runoff Prediction. Sustainability 2022, 14, 8209. [Google Scholar] [CrossRef]

- Zhong, S.; Hua, S.; Chen, C.; Wang, C. Ball K-Means clustering algorithm based on exploration vector. J. Dongguan Univ. Technol. 2022, 29, 78–87. (In Chinese) [Google Scholar]

- Jiang, D.; Zhang, Z.; He, D. Construction of vulnerability assessment index system for injury bearing body of prefabricated building safety incident: Based on Apriori algorithm. J. Shenyang Jianzhu Univ. (Soc. Sci. Ed.) 2020, 22, 259–264. [Google Scholar]

- Hao, T.; Wang, B. Improved FP-growth association rule Mining Algorithm. Comput. Knowl. Technol. 2017, 13, 5–8+14. [Google Scholar]

- Cheng, M.; Mei, A. Research on Evolution network construction of runway landing events based on association rules. China Prod. Saf. Sci. Technol. 2022, 18, 203–208. [Google Scholar]

- Chen, B.; Yu, P.; Zhang, Q. Research on causative association rules Mining of special road incidents based on Apriori algorithm. Road Traffic Manag. 2022, 3, 34–37. [Google Scholar]

- Huang, Y.; Huang, S.; Zhou, Y. Correlation analysis of vehicle traffic characteristics and Traffic incidents based on FP-growth algorithm. Road Traffic Manag. 2022, 1, 30–33. [Google Scholar]

- Yang, C.; Yu, T.S.; Shi, Y.-F.; Xu, M.-M.; Hou, F. Curriculum relevance analysis based on FP-growth algorithm. China Educ. Informatiz. 2019, 17, 35–38. [Google Scholar]

- Guo, A.; Yang, Z.; Du, K.; Zhang, X. Design and application of Coal mine safety information management system based on FP-Growth algorithm. China Min. Ind. 2019, 32, 67–73. [Google Scholar]

- Li, Y.; Zhang, Y.; Chen, X.-J.; Hou, T.; Li, S. Based on unsafe ACTS cause of text mining association network analysis. J. Coal Mine Saf. 2023, 54, 251–256. [Google Scholar] [CrossRef]

- Ruan, J. Landslide Injury Based on Association Rule Data Mining Research; Chongqing Three Gorges College: Chongqing, China, 2023. [Google Scholar]

- Krishankumar, R.; Mishra, A.R.; Rani, P.; Cavallaro, F.; Ravichandran, K.S. A Novel Integrated q-Rung Fuzzy Framework for Biomass Location Selection with No Apriori Weight Choices. Sustainability 2023, 15, 3377. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Zhang, G.; Tian, F.; Ren, F. Application of Improved Apriori Algorithm in Diagnosis of Abnormal Building Energy Consumption. E3S Web Conf. 2021, 257, 02060. [Google Scholar] [CrossRef]

- Chunduri, R.K.; Cherukuri, A.K. Scalable algorithm for generation of attribute implication base using FP-growth and spark. Soft Comput. 2021, 25, 9219–9240. [Google Scholar] [CrossRef]

- Kurniawan, R.; Nazri, M.Z.A.; Abdullah, S.N.H.; Hamzah, J.C.; Yendra, R.; Oktaviana, W. Automatic Rule Generator via FP-Growth for Eye Diseases Diagnosis. Int. J. Adv. Sci. Eng. Inf. Technol. 2019, 9, 960. [Google Scholar] [CrossRef]

- Ning, H.; Yu, Y.; Bai, L. Unsafe Behaviors Analysis of Sideswipe Collision on Urban Expressways Based on Bayesian Network. Sustainability 2022, 14, 8142. [Google Scholar] [CrossRef]

- Crema, R.E.; Kobayashi, K. A multi-proxy inference of Jōmon population dynamics using bayesian phase models, residential data, and summed probability distribution of 14 C dates. J. Archaeol. Sci. 2020, 117, 105136. [Google Scholar] [CrossRef]

- Neil, B. Olson’s Gap or Olson’s Extinction? A Bayesian tip-dating approach to resolving stratigraphic uncertainty. Proc. Biol. Sci. 2020, 287, 20200154. [Google Scholar]

- Pearl, J. Fusion, propagation, and structuring in belief networks. Artif. Intell. 1986, 29, 241–288. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, M.; Yu, S.; Wang, J. A Bayesian Network for the Transportation Incidents of Hazardous Materials Handling Time Assessment. Procedia Eng. 2018, 211, 63–69. [Google Scholar] [CrossRef]

- GB 50310-2002; Code for Acceptance of Installation Quality of Lifts, Escalators and Passenger Conveyors. The Standardization Administration of the People’s Republic of China: Beijing, China, 1 April 2002.

| Serial Number | Causative Term | Serial Number | Causative Term | Serial Number | Causative Term | |

|---|---|---|---|---|---|---|

| Man | A1 | Weak safety awareness | A11 | Edge protection failure | A21 | Lack of command personnel at the construction site |

| A2 | Crossoperations are not standardized | A12 | Unauthorized removal of edge protection | A22 | Poor skill training | |

| A3 | The builder throws tools and materials | A13 | Not according to the construction plan | A23 | illegal subcontracting | |

| A4 | Work at height without a tool bag | A14 | Not wearing safety equipment | A24 | Safety supervision on site is not in place | |

| A5 | Helmet wearing is not standard, or workers forget to wear a helmet | A15 | Misjudgment of the working site environment | A25 | No hidden danger check has been performed | |

| A6 | No special operation qualification | A16 | Operating procedures are not established | A26 | Weak government supervision | |

| A7 | No project management qualification | A17 | Lack of construction permits | A27 | Venture into dangerous areas | |

| A8 | Signal worker’s incorrect command | A18 | Failure to follow installation instructions for operation | A28 | Failure to evacuate dangerous areas in time | |

| A9 | The signal worker was not on site during construction | A19 | Safety training and education are not in place | |||

| A10 | No edge protection | A20 | Safety technical disclosure is not performed | |||

| Machine | B1 | The steel wire of the winch is worn and broken | B3 | Pump trucks have maintenance deficiencies | B5 | Damaged dense mesh |

| B2 | Equipment screws loose | B4 | Lifting equipment has hidden dangers | B6 | Pile machine bottom frame is damaged | |

| Environment | C1 | No security flag is set | C3 | Stacked disorderly on the work platform | C5 | The construction of the work platform is not standardized |

| C2 | Big storm, rain, bad weather | C4 | Inadequate protective facilities | |||

| Material | D1 | Safety helmet quality is not up to standard | D3 | Defective quality of materials such as guardrails | ||

| D2 | The high-altitude work tool bag has been damaged | D4 | Failure to maintain equipment according to regulations | |||

| Law | E1 | The safety inspection system is not sound | E4 | No production safety management agreement has been signed | E7 | Lack of emergency management system |

| E2 | Incomplete coordination system for cross operation | E5 | Unqualified safety organization | E8 | Illegal contracting | |

| E3 | The main responsibility of production safety has not been implemented | E6 | Lack of safety technical disclosure |

| Incident Number | Cause Number |

|---|---|

| T1 | A1, A28, A25, A22, A21, A24, E3 |

| T2 | A1, A27, A5, A14, A15, A17, A19, A24, C3, B5 |

| T3 | A1, A2, A15, A21, A22, A24, A25, A27, C5, A8, E8, A6, A9, A20 |

| T4 | C4, C5, A19, A21, A24, E7, E1, E2 |

| …… | …… |

| T126 | A2, A14, A22, A1, C4, E1, A20, E3, E5, A5, C4, A9, A16, A17 |

| Influence Factor | Connected Factors | Confidence Coefficient |

|---|---|---|

| A1 | A24 | 0.93 |

| A2 | A16 | 0.86 |

| C1 | 0.78 | |

| A9 | A22 | 0.71 |

| A1 | 0.88 | |

| A15 | A24 | 0.81 |

| A16 | E1 | 0.65 |

| E3 | 0.74 | |

| E5 | 0.71 | |

| A24 | 0.71 | |

| A19 | A1 | 0.92 |

| A2 | 0.92 | |

| A24 | 0.71 | |

| A20 | A9 | 0.82 |

| A24 | 0.79 | |

| A21 | A1 | 0.85 |

| A24 | 0.9 | |

| A22 | A9 | 0.7 |

| A1 | 0.9 | |

| A24 | A1 | 0.75 |

| A2 | 0.95 | |

| A25 | A24 | 0.81 |

| A1 | 0.90 | |

| A27 | A1 | 0.7 |

| C1 | A1 | 0.62 |

| A27 | 0.75 | |

| C4 | 0.81 | |

| C4 | A2 | 0.90 |

| A1 | 0.81 | |

| C5 | A1 | 0.85 |

| C4 | 0.85 | |

| E7 | 0.71 | |

| E1 | A1 | 0.8 |

| A24 | 0.86 | |

| C5 | 0.75 | |

| E3 | 0.69 | |

| E3 | E1 | 0.72 |

| A1 | 0.81 | |

| C4 | 0.68 | |

| A24 | 0.75 |

| Serial Number | Causative Term | Serial Number | Causative Term | Serial Number | Causative Term |

|---|---|---|---|---|---|

| A1 | Weak safety awareness | A16 | Operating procedures are not established | A22 | Poor skill training |

| A24 | Safety supervision on site is not in place | A19 | Safety training and education are not in place | A25 | No hidden danger check has been performed |

| A2 | Crossoperations are not standardized | A21 | Lack of command personnel at the construction site | C4 | Inadequate protective facilities |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Lu, Z. Analysis of Key Injury-Causing Factors of Object Strike Incident in Construction Industry Based on Data Mining Method. Sustainability 2023, 15, 15609. https://doi.org/10.3390/su152115609

Yang W, Lu Z. Analysis of Key Injury-Causing Factors of Object Strike Incident in Construction Industry Based on Data Mining Method. Sustainability. 2023; 15(21):15609. https://doi.org/10.3390/su152115609

Chicago/Turabian StyleYang, Wei, and Zheng Lu. 2023. "Analysis of Key Injury-Causing Factors of Object Strike Incident in Construction Industry Based on Data Mining Method" Sustainability 15, no. 21: 15609. https://doi.org/10.3390/su152115609