Biomethane and Compost Production by Anaerobic Digestion of Organic Waste: Suggestions for Rural Communities in Southern Italy

Abstract

:1. Introduction

2. Research Context

2.1. Study Area

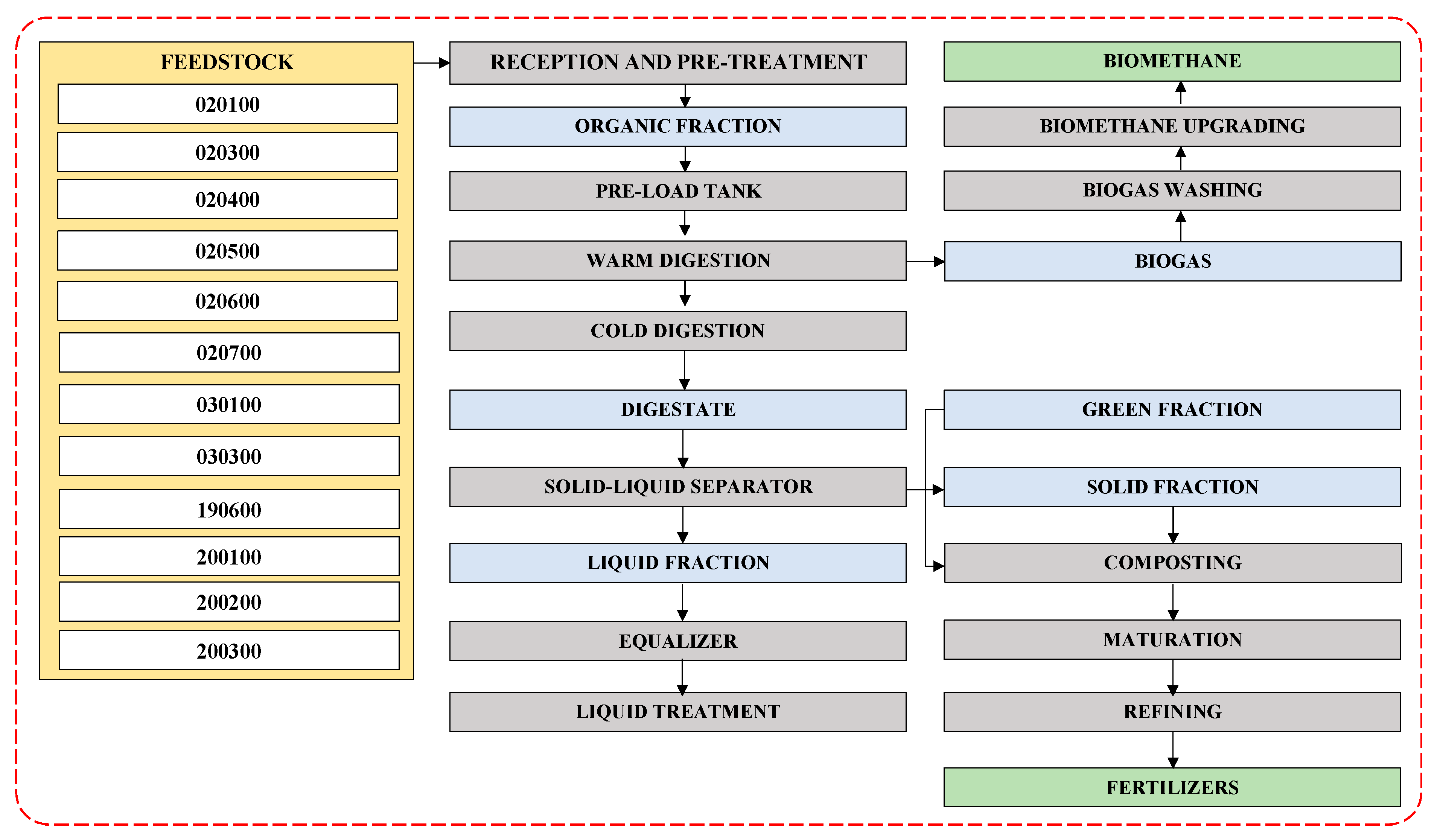

2.2. Characteristics of the Anaerobic Digestion and Composting Plant

3. Materials and Methods

3.1. Research Strategy

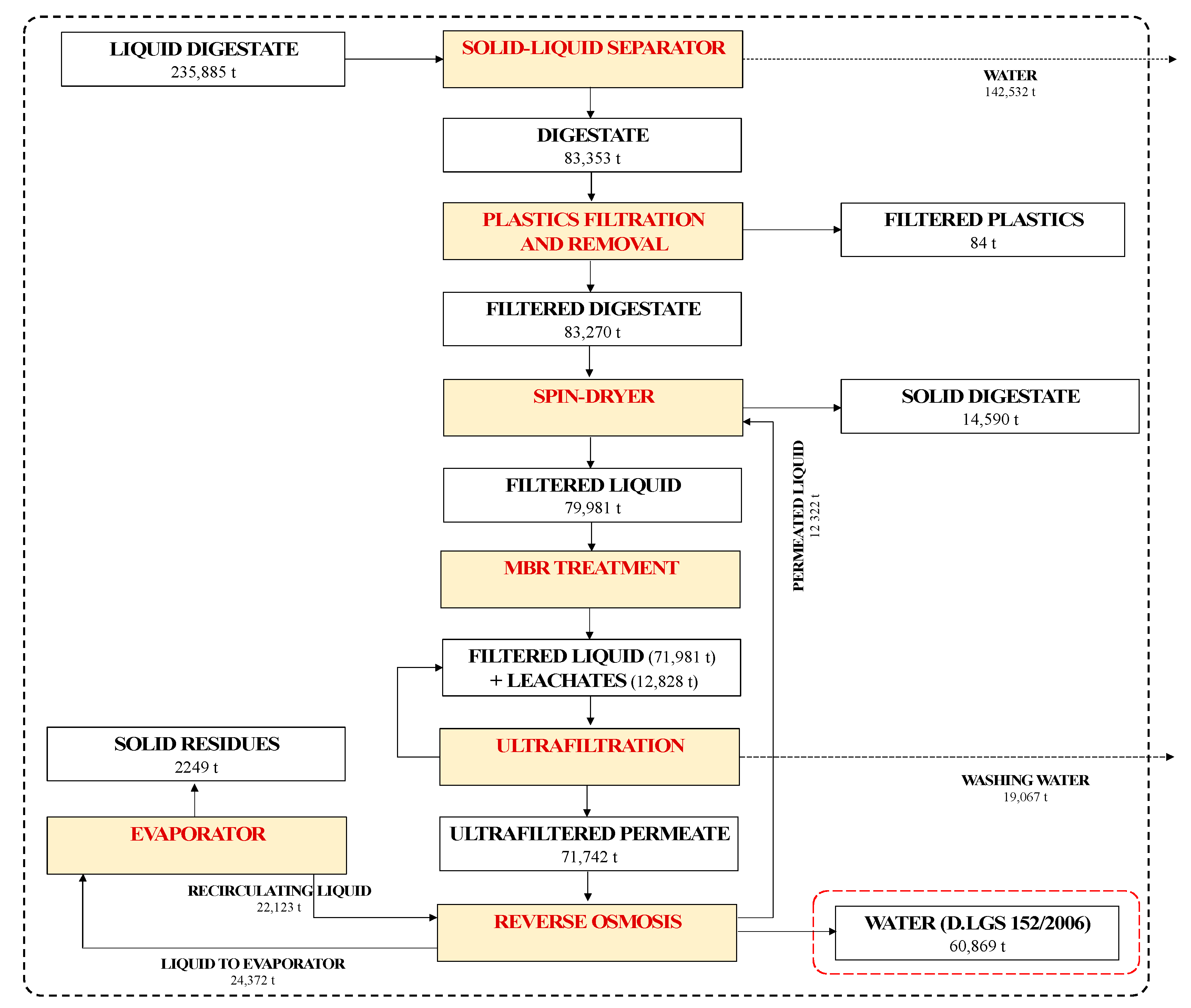

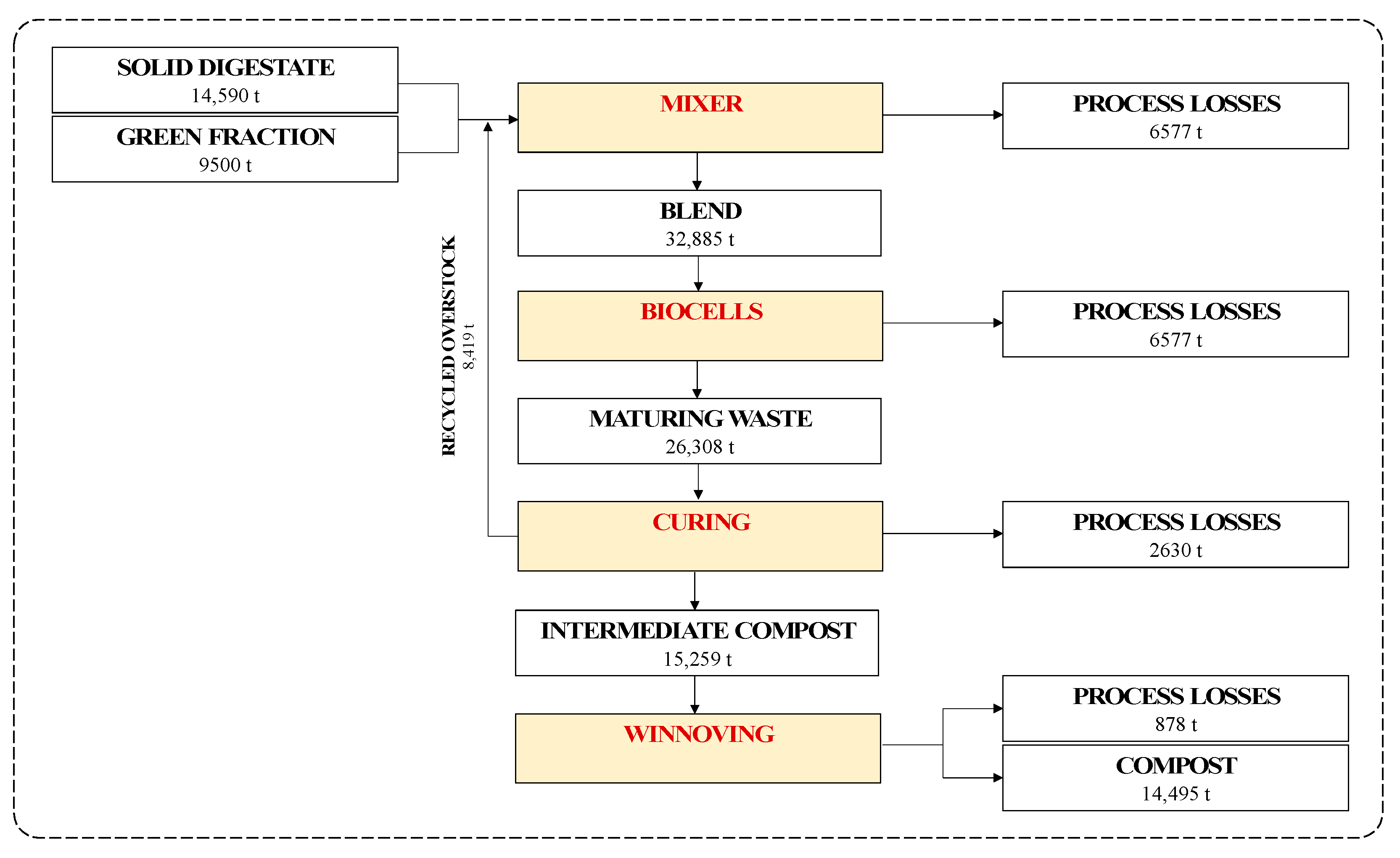

3.2. Material Flow Analysis of the Anaerobic Digestion and Composting Plant

3.3. Data Collection

4. Results

4.1. Material Flow Analysis for the Biogas Production

4.2. Material Flow Analysis for the Digestate Production

4.3. Material Flow Analysis for the Compost Production

4.4. Biomethane, Digestate and Compost Potential through Anaerobic Digestion in Southern Italy

5. Discussion

5.1. Policy Implications

5.2. Environmental Implications

5.3. Economic Implications

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, Y.; Wang, P.; Zhang, D. Challenges and Prospects of Solid Waste Management in Rural Tourism Areas in China. E3S Web Conf. 2021, 251, 020802. [Google Scholar] [CrossRef]

- Almeida-García, F.; Peláez-Fernández, M.Á.; Balbuena-Vázquez, A.; Cortés-Macias, R. Residents’ Perceptions of Tourism Development in Benalmádena (Spain). Tour. Manag. 2016, 54, 259–274. [Google Scholar] [CrossRef]

- An, W.; Alarcón, S. How Can Rural Tourism Be Sustainable? A Systematic Review. Sustainability 2020, 12, 7758. [Google Scholar] [CrossRef]

- Li, Y.; Jin, Y.; Borrion, A.; Li, H. Current status of food waste generation and management in China. Bioresour. Technol. 2019, 273, 654–665. [Google Scholar] [CrossRef]

- Dumitrescu, G.C.; Poladian, S.M.; Aluculesei, A.C. Repositioning of Romanian Seaside Tourism as an Effect of Climate Change. Information 2021, 12, 108. [Google Scholar] [CrossRef]

- Mihai, F.C. Rural plastic emissions into the largest mountain lake of the Eastern Carpathians. R. Soc. Open Sci. 2018, 5, 172396. [Google Scholar] [CrossRef]

- Otles, S.; Despoudi, S.; Bucatariu, C.; Kartal, C. Chapter 1-Food waste management, valorization, and sustainability in the food industry. In Food Waste Recovery; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2015; pp. 3–23. [Google Scholar] [CrossRef]

- Omolayo, Y.; Feingold, B.J.; Neff, R.A.; Romeiko, X.X. Life cycle assessment of food loss and waste in the food supply chain. Resour. Conserv. Recycl. 2021, 164, 105119. [Google Scholar] [CrossRef]

- Mehariya, S.; Patel, A.K.; Obulisamy, P.K.; Punniyakotti, E.; Wong, J.W.C. Co-digestion of food waste and sewage sludge for methane production: Current status and perspective. Bioresour. Technol. 2018, 265, 519–531. [Google Scholar] [CrossRef]

- European Commission. Member State Page: Italy. 2023. Available online: https://ec.europa.eu/food/safety/food_waste/eu-food-loss-waste-prevention-hub/eu-member-state-page/show/IT (accessed on 6 April 2023).

- Regione Puglia. Osservatorio Regionale dei Rifiuti Puglia. 2023. Available online: https://pugliacon.regione.puglia.it/orp/public/servizi/rsu-per-comune (accessed on 13 April 2023).

- De Boni, A.; Melucci, F.M.; Acciani, C.; Roma, R. Community composting: A multidisciplinary evaluation of an inclusive, participative, and eco-friendly approach to biowaste management. Clean. Environ. Syst. 2022, 6, 100092. [Google Scholar] [CrossRef]

- Zeller, V.; Lavigne, C.; D’Ans, P.; Towa, E.; Achten, V.M.J. Assessing the environmental performance for more local and more circular biowaste management options at city-region level. Sci. Total Environ. 2020, 745, 140690. [Google Scholar] [CrossRef]

- Poponi, S.; Ruggieri, A.; Pacchera, F.; Arcese, G. The circular potential of a Bio-District: Indicators for waste management. Br. Food J. 2023. [Google Scholar] [CrossRef]

- Syafrudin, S.; Masjhoer, J.M.; Maryono, M. Characterization and quantification of solid waste in rural regions. Glob. J. Environ. Sci. Manag. 2023, 9, 337–352. [Google Scholar]

- Han, Z.; Dan, Z.; Shi, G.; Shen, L.; Xu, W.; Xie, Y. Characteristics and management of domestic waste in a rural area of the Tibetan Plateau. J. Air Waste Manag. Assoc. 2015, 65, 1365–1375. [Google Scholar] [CrossRef] [PubMed]

- Darban Astane, A.R.; Hajilo, M. Factors affecting the rural domestic waste generation. Glob. J. Environ. Sci. Manag. 2017, 3, 417–426. [Google Scholar]

- Taghipour, H.; Amjad, Z.; Aslani, H.; Armanfar, F.; Dehghanzadeh, R. Characterizing and quantifying solid waste of rural communities. J. Mater. Cycles Waste Manag. 2016, 18, 790–797. [Google Scholar] [CrossRef]

- Suma, Y.; Pasukphun, N.; Hongtong, A.; Keawdunglek, V.; Laor, P.; Apidechkul, T. Waste composition evaluation for solid waste management guideline in highland rural tourist area in Thailand. Appl. Environ. Res. 2019, 41, 13–26. [Google Scholar]

- Anwar, S.; Elagroudy, S.; Abdel Razik, M.; Gaber, A.; Bong, C.P.C.; Ho, W.S. Optimization of solid waste management in rural villages of developing countries. Clean Technol. Environ. Policy 2018, 20, 489–502. [Google Scholar] [CrossRef]

- Chereji, A.-I.; Chiurciu, I.-A.; Popa, A.; Chereji, I.; Iorga, A.-M. Consumer Behaviour Regarding Food Waste in Romania, Rural versus Urban. Agronomy 2023, 13, 571. [Google Scholar] [CrossRef]

- Hanssen, O.J.; Syversen, F.; Sto, E. Edible food waste from Norwegian households—Detailed food waste composition analysis among households in two different regions in Norway. Resour. Conserv. Recycl. 2016, 109, 146–154. [Google Scholar] [CrossRef]

- Hoang, M.G.; Fujiwara, T.; Pham Phu, S.T.; Nguyen Thi, K.T. Predicting waste generation using Bayesian model averaging. Glob. J. Environ. Sci. Manag. 2017, 3, 385–402. [Google Scholar]

- OJEU (Official Journal of European Union) Directive 2008/98/EC of the European Parliament and the Council of 19 November 2008 on Waste and Repealing Certain Directives. 2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02008L0098-20180705 (accessed on 3 April 2023).

- Bowen, R.; Dowell, D.; Morris, W. Hospitality SMEs and the circular economy: Strategies and practice post-COVID. Br. Food J. 2023. [Google Scholar] [CrossRef]

- Papargyropoulou, E.; Lozano, R.; Steinberger, J.K.; Wright, N.; bin Ujang, Z. The food waste hierarchy as a framework for the management of food surplus and food waste. J. Clean. Prod. 2014, 76, 106–115. [Google Scholar] [CrossRef]

- Mirmohamadsadeghi, S.; Karimi, K.; Tabatabaei, M.; Aghbashlo, M. Biogas production from food wastes: A review on recent developments and future perspectives. Bioresour. Technol. Rep. 2019, 7, 100202. [Google Scholar] [CrossRef]

- Molino, A.; Nanna, F.; Ding, Y.; Bikson, B.; Braccio, G. Biomethane production by anaerobic digestion of organic waste. Fuel 2013, 103, 1003–1009. [Google Scholar] [CrossRef]

- Zhu, T.; Curtis, J.; Clancy, M. Promoting agricultural biogas and biomethane production: Lessons from cross-country studies. Renew. Sustain. Energy Rev. 2019, 114, 109332. [Google Scholar] [CrossRef]

- Xiang Keng, Z.; Chong, S.; Guan Ng, C.; Ridzuan, N.I.; Hanson, S.; Pan, G.T.; Li Lau, P.; Vimala Supramaniam, C.; Singh, A.; Chin, C.F.; et al. Community-scale composting for food waste: A life-cycle assessment-supported case study. J. Clean. Prod. 2020, 261, 121220. [Google Scholar] [CrossRef]

- Vieira, V.H.A.d.M.; Matheus, D.R. Environmental assessments of biological treatments of biowaste in life cycle perspective: A critical review. Waste Manag. Res. 2019, 37, 1183–1198. [Google Scholar] [CrossRef]

- Murphy, J.D.; Power, N.M. A technical, economic and environmental comparison of composting and anaerobic digestion of biodegradable municipal waste. J. Environ. Sci. Health 2006, 41 Pt A, 865–879. [Google Scholar] [CrossRef]

- Tricase, C.; Lombardi, M. State of the art and prospects of Italian biogas production from animal sewage: Technical-economic considerations. Renew. Energy 2009, 34, 477–485. [Google Scholar] [CrossRef]

- Tricase, C.; Lombardi, M. Environmental analysis of biogas production systems. Biofuels 2012, 3, 749–760. [Google Scholar] [CrossRef]

- Rana, R.L.; Lombardi, M.; Giungato, P.; Tricase, C. Trends in Scientific Literature on Energy Return Ratio of Renewable Energy Sources for Supporting Policymakers. Adm. Sci. 2020, 10, 21. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee for the Regions. A long-Term Vision for the EU’s Rural Areas–Towards Stronger, Connected, Resilient and Prosperous Rural Areas by 2040; European Union: Brussels, Belgium, 2021. [Google Scholar]

- European Biogas Association. Integrating Biogas in the Sustainable Future of Rural Areas. 2020. Available online: https://www.europeanbiogas.eu/wp-content/uploads/2020/12/EBA-Long-term-vision-for-rural-areas.pdf (accessed on 25 October 2023).

- European Biogas Association. EBA Statistical Report 2018. Available online: https://www.europeanbiogas.eu/wp-content/uploads/2019/05/EBA_Statistical-Report-2018_AbrigedPublic_web.pdf (accessed on 25 October 2023).

- Battista, F.; Frison, N.; Bolzonella, D. Energy and Nutrients’ Recovery in Anaerobic Digestion of Agricultural Biomass: An Italian Perspective for Future Applications. Energies 2019, 12, 3287. [Google Scholar] [CrossRef]

- Wang, J.; Chen, X.; Zhang, S.; Wang, Y.; Shao, X.; Wu, D. Analysis of raw materials and products characteristics from composting and anaerobic digestion in rural areas. J. Clean. Prod. 2022, 338, 130455. [Google Scholar] [CrossRef]

- De Marco, O.; Lagioia, G.; Amicarelli, V.; Sgaramella, A. Constructing Physical Input-Output Tables with Material Flow Analysis (MFA) Data: Bottom-Up Case Studies. In Handbook of Input-Output Economics in Industrial Ecology; Eco-Efficiency in Industry and Science; Suh, S., Ed.; Springer: Dordrecht, The Netherlands, 2009; Volume 23. [Google Scholar] [CrossRef]

- Mattioli, A.; Gatti, G.B.; Mattuzzi, G.P.; Cecchi, F.; Bolzonella, D. Co-digestion of the organic fraction of municipal solid waste and sludge improves the energy balance of wastewater treatment plants: Rovereto case study. Renew. Energy 2017, 113, 980–988. [Google Scholar] [CrossRef]

- Nguyen, L.N.; Kumar, J.; Vu, M.T.; Mohammed, J.A.H.; Pathak, N.; Commault, A.S.; Sutherland, D.; Zdarta, J.; Kumar Tyagi, V.; Nghiem, L.D. Biomethane production from anaerobic co-digestion at wastewater treatment plants: A critical review on development and innovations in biogas upgrading techniques. Sci. Total Environ. 2021, 765, 142753. [Google Scholar] [CrossRef]

- Pantaleo, A.; De Gennaro, B.; Shah, N. Assessment of optimal size of anaerobic co-digestion plants: An application to cattle farms in the province of Bari (Italy). Renew. Sustain. Energy Rev. 2013, 20, 57–70. [Google Scholar] [CrossRef]

- L’Associazione de I Borghi Più Belli D’Italia. Homepage. 2023. Available online: https://borghipiubelliditalia.it (accessed on 6 April 2023).

- Istat. Classificazione dei Comuni in Base Alla Densità Turistica. Tavole di Classificazione dei Comuni Italiani per Densità Turistica. 2022. Available online: https://www.istat.it/it/archivio/247191 (accessed on 6 April 2023).

- National Geographic. Resource. Encyclopedic Entry. Rural Area. 2022. Available online: https://education.nationalgeographic.org/resource/rural-area/ (accessed on 12 April 2023).

- OECD. Chapter 3. Understanding Rural Economies. OECD Regional Outlook 2016; OECD: Paris, France, 2016. [Google Scholar] [CrossRef]

- Gestore Servizi Energetici. Allegato A–Precisazioni Sulle Materie Prime. Procedure Applicative DM 2 Marzo 2018. 2021. Available online: https://www.consorziobiogas.it/wp-content/uploads/2021/10/allegato_a_materie_prime.pdf (accessed on 3 April 2023).

- GU (Gazzetta Ufficiale). Legge 29 Luglio 2021 n. 108. Conversione in Legge, Con Modificazioni, del Decreto-Legge 31 Maggio 2021, n. 77, Recante Governance del Piano Nazionale di Ripresa e Resilienza e Prime Misure di Rafforzamento Delle Strutture Amministrative e di Accelerazione e Snellimento Delle Procedure. 2021. Available online: https://www.gazzettaufficiale.it/eli/id/2021/07/30/21G00118/sg (accessed on 13 April 2023).

- Brunner, P.H.; Rechberger, H. Handbook of Material Flow Analysis. for Environmental, Resource and Waste Engineers, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Schuch, D.; Lederer, J.; Fellner, J.; Scharff, C. Separate collection rates for plastic packaging in Austria–A regional analysis taking collection systems and urbanization into account. Waste Manag. 2023, 155, 211–219. [Google Scholar] [CrossRef]

- Chazirakis, P.; Giannis, A.; Gidarakos, E. Material flow and environmental performance of the source segregated biowaste composting system. Waste Manag. 2023, 160, 23–34. [Google Scholar] [CrossRef]

- Lombardi, M.; Rana, R.; Fellner, J. Material flow analysis and sustainability of the Italian plastic packaging management. J. Clean. Prod. 2021, 287, 125573. [Google Scholar] [CrossRef]

- Rubinstein, R.Y.; Kroese, D.P. Simulation and the Monte Carlo Method; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Amicarelli, V.; Lombardi, M.; Varese, E.; Bux, C. Material flow and economic cost analysis of the Italian artisan bread production before and during the Russia-Ukraine conflict. Environ. Impact Assess. Rev. 2023, 101, 107101. [Google Scholar] [CrossRef]

- Rashid, M.I.; Shahzad, K. Food waste recycling for compost production and its economic and environmental assessment as circular economy indicators of solid waste management. J. Clean. Prod. 2021, 317, 128467. [Google Scholar] [CrossRef]

- GU (Gazzetta Ufficiale). Decreto Legislativo 3 Aprile 2006, n. 152, 2006. Available online: https://faolex.fao.org/docs/pdf/ita64213.pdf (accessed on 12 April 2023).

- Passaro, P.; Perchinunno, P.; Rotondo, F. Statistical analysis of the circular economy for the intervention policies of the NRRP. Br. Food J. 2023. [Google Scholar] [CrossRef]

- Mondello, G.; Salomone, R.; Ioppolo, G.; Saija, G.; Sparacia, S.; Lucchetti, M.C. Comparative LCA of alternative scenarios for waste treatment: The case of food waste production by the mass-retail sector. Sustainability 2017, 9, 827. [Google Scholar] [CrossRef]

- European Commission. The Common Agricultural Policy at a Glance. 2023. Available online: https://agriculture.ec.europa.eu/common-agricultural-policy/cap-overview/cap-glance_en (accessed on 13 April 2023).

- Prota, F.; Viesti, G. Linking the ‘Recovery and Resilience Plan’ and Smart Specialisation. The Italian Case; JRC Working Papers on Territorial Modelling and Analysis; European Commission: Seville, Spain, 2022; JRC130071.

- Privitera, D.; Nedelcu, A.; Nicula, V. Gastronomic and Food Tourism as an Economic Local Resource: Case Studies from Romania and Italy. GeoJournal Tour. Geosites 2018, 21, 143–157. [Google Scholar]

- Calabro, G.; Vieri, S. Limits and potential of organic farming towards a more sustainable European agri-food system. Br. Food J. 2023. [Google Scholar] [CrossRef]

- Wang, L.; Filimonau, V.; Li, Y. Exploring the patterns of food waste generation by tourists in a popular destination. J. Clean. Prod. 2021, 279, 123890. [Google Scholar] [CrossRef]

- Lagioia, G.; Amicarelli, V.; Strippoli, R.; Bux, C.; Gallucci, T. Sustainable and circular practices in the hotel industry in Southern Italy: Opportunities, barriers and trends in food waste management. Br. Food J. 2023. [Google Scholar] [CrossRef]

- Filimonau, V.; De Coteau, D.A. Food waste management in hospitality operations: A critical review. Tour. Manag. 2019, 71, 234–245. [Google Scholar] [CrossRef]

- Kim, S.H.; Choi, E.H.; Lee, K.E.; Kwak, T.K. Effects of nutrition education on food waste reduction. J. Korean Diet. Assoc. 2007, 13, 357–367. [Google Scholar]

- European Commission. Sustainable Mobility Using Renewable Liquefied Biomethane–Lombardia, Italy. 2020. Available online: https://s3platform.jrc.ec.europa.eu/en/w/sustainable-mobility-using-renewable-liquefied-biomethane-lombardy-italy (accessed on 13 April 2023).

- Czekała, W. Biogas as a Sustainable and Renewable Energy Source. In Clean Fuels for Mobility. Energy, Environment, and Sustainability; Di Blasio, G., Agarwal, A.K., Belgiorno, G., Shukla, P.C., Eds.; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

- Gebrezgabher, S.A.; Meuwissen, M.P.N.; Prins, B.A.M.; Oude Lansink, A.G.J.M. Economic analysis of anaerobic digestion—A case of Green power biogas plant in The Netherlands. NJAS-Wagening. J. Life Sci. 2010, 57, 109–115. [Google Scholar] [CrossRef]

- Slorach, P.C.; Jeswani, H.K.; Cuéllar-Franca, R.; Azapagic, A. Environmental sustainability of anaerobic digestion of household food waste. J. Environ. Manag. 2019, 236, 798–814. [Google Scholar] [CrossRef] [PubMed]

- Al-Rumaihi, A.; McKay, G.; Mackey, H.R.; Al-Ansari, T. Environmental Impact Assessment of Food Waste Management Using Two Composting Techniques. Sustainability 2020, 12, 1595. [Google Scholar] [CrossRef]

- Kraemer, T.; Gamble, S. Integrating anaerobic digestion with composting. BioCycle 2014, 55, 32. [Google Scholar]

- Chowdhury, T.H. Technical-economical analysis of anaerobic digestion process to produce clean energy. Energy Rep. 2021, 7, 247–253. [Google Scholar] [CrossRef]

- D’Adamo, I.; Ribichini, M.; Tsagarakis, K.P. Biomethane as an energy resource for achieving sustainable production: Economic assessments and policy implications. Sustain. Prod. Consum. 2023, 35, 13–27. [Google Scholar] [CrossRef]

- Bong, C.P.C.; Goh, R.K.Y.; Lim, J.S.; Ho, W.S.; Lee, C.T.; Hashim, H.; Mansor, N.N.A.; Ho, C.S.; Ramli, A.R.; Takeshi, F. Towards low carbon society in Iskandar Malaysia: Implementation and feasibility of community organic waste composting. J. Environ. Manag. 2017, 201, 679–687. [Google Scholar] [CrossRef]

| Village | Sorted w. | Unsorted w. | Total w. | Procapite w. | Organic Fract. |

|---|---|---|---|---|---|

| Alberobello | 3,524,957 | 1,551,460 | 5,076,417 | 476 | 775,491 |

| Alberona | - | - | - | - | - |

| Bovino | 543,830 | 494,560 | 1,038,390 | 324 | 119,643 |

| Cisternino | 4,366,101 | 1,211,500 | 5,577,601 | 484 | 960,542 |

| Locorotondo | 3,967,259 | 1,396,910 | 5,364,169 | 378 | 872,797 |

| Maruggio | 3,277,640 | 1,281,480 | 4,559,120 | 871 | 721,081 |

| Monte Sant’Angelo | 2,511,265 | 2,261,320 | 4,772,585 | 392 | 552,478 |

| Otranto | 14,832,58 | 3,858,360 | 5,341,618 | 906 | 326,317 |

| Pietramontecorvino | 587,360 | 252,120 | 839,480 | 318 | 129,219 |

| Presicce–Acquarica | 2,631,333 | 1,330,060 | 3,961,393 | 759 | 578,893 |

| Roseto Valfortore | 224,153 | 70,680 | 294,833 | 277 | 49,314 |

| Sammichele di Bari | 2,011,558 | 695,580 | 2,707,138 | 427 | 442,543 |

| Specchia | 545,085 | 1,159,950 | 1,705,035 | 359 | 119,919 |

| Vico del Gargano | 2,167,345 | 1,237,160 | 3,404,505 | 284 | 476,816 |

| Total | 27,841,144 | 16,801,140 | 44,642,284 | 488 | 6,125,052 |

| Village | Organic Fraction | Biogas | Biomethane | Digestate | Compost |

|---|---|---|---|---|---|

| Alberobello | 775,491 | 127,801 | 53,664 | 120,899 | 119,271 |

| Alberona | - | - | - | - | - |

| Pietramontecorvino | 129,219 | 21,295 | 8942 | 20,145 | 19,874 |

| Vico del Gargano | 476,816 | 78,579 | 32,996 | 74,336 | 73,334 |

| Roseto Valfortore | 49,314 | 8127 | 3413 | 7688 | 7584 |

| Bovino | 119,643 | 19,717 | 8279 | 18,652 | 18,401 |

| Sammichele di Bari | 442,543 | 72,931 | 30,624 | 68,992 | 68,063 |

| Cisternino | 960,542 | 158,297 | 66,470 | 149,748 | 147,731 |

| Locorotondo | 872,797 | 143,837 | 60,398 | 136,069 | 134,236 |

| Maruggio | 721,081 | 118,834 | 49,899 | 112,417 | 110,902 |

| Otranto | 326,317 | 53,777 | 22,581 | 50,873 | 50,188 |

| Presicce–Acquarica | 578,893 | 95,402 | 40,059 | 90,249 | 89,034 |

| Specchia | 119,919 | 19,763 | 8298 | 18,695 | 18,444 |

| Monte Sant’Angelo | 552,478 | 91,048 | 38,231 | 86,131 | 84,971 |

| Total | 6,125,052 | 1,009,409 | 423,854 | 954,896 | 942,033 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bux, C.; Cangialosi, F.; Amicarelli, V. Biomethane and Compost Production by Anaerobic Digestion of Organic Waste: Suggestions for Rural Communities in Southern Italy. Sustainability 2023, 15, 15644. https://doi.org/10.3390/su152115644

Bux C, Cangialosi F, Amicarelli V. Biomethane and Compost Production by Anaerobic Digestion of Organic Waste: Suggestions for Rural Communities in Southern Italy. Sustainability. 2023; 15(21):15644. https://doi.org/10.3390/su152115644

Chicago/Turabian StyleBux, Christian, Federico Cangialosi, and Vera Amicarelli. 2023. "Biomethane and Compost Production by Anaerobic Digestion of Organic Waste: Suggestions for Rural Communities in Southern Italy" Sustainability 15, no. 21: 15644. https://doi.org/10.3390/su152115644