Experimental Investigation for Shear Wave Velocity and Dynamic Characteristics of Unsaturated Sand–Clay Liners

Abstract

:1. Introduction

2. Materials Used and Characterization

3. Experimental Work

3.1. Mixture Preparation and Compaction Characteristics

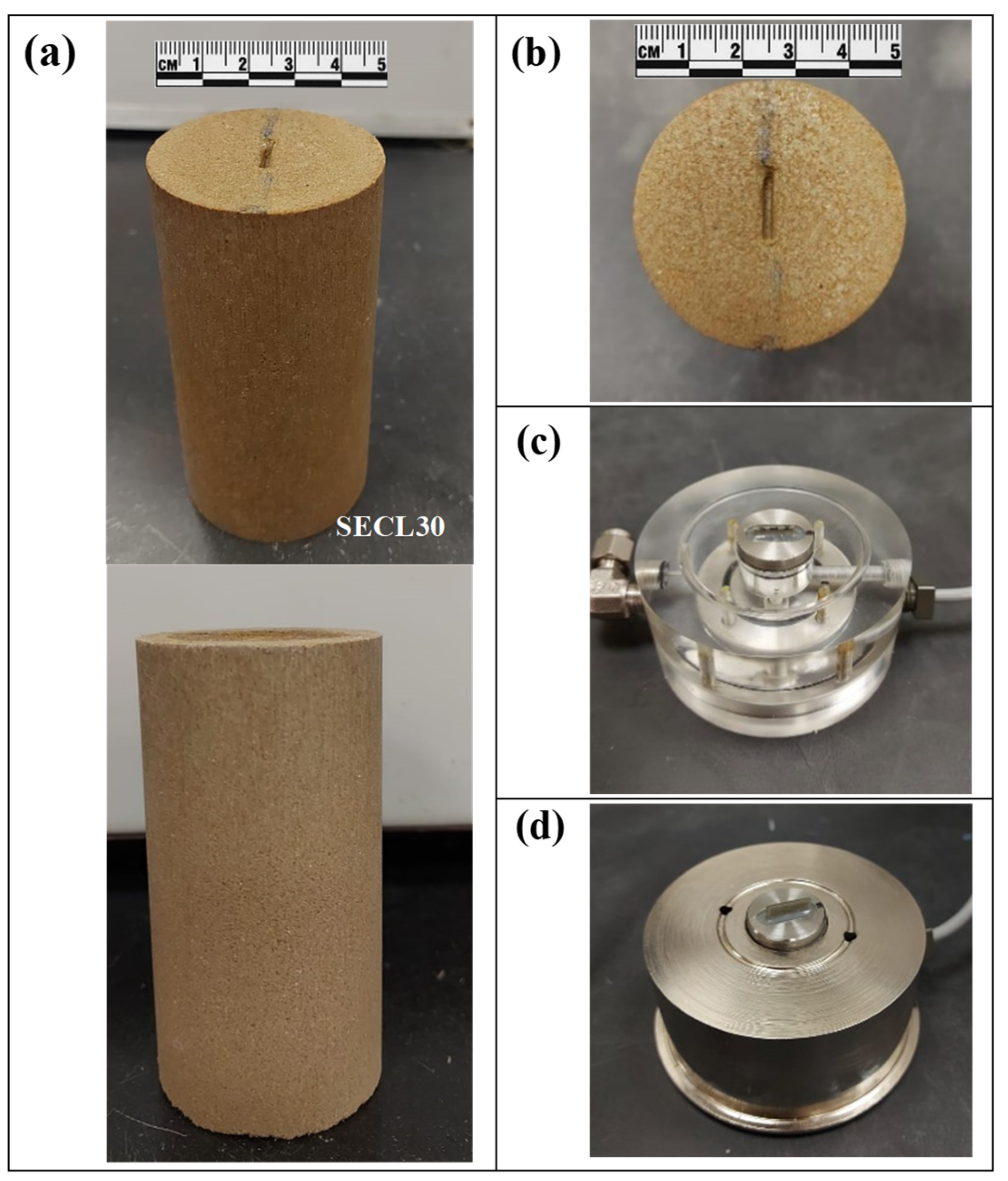

3.2. Specimen Preparation and Suction Equalization

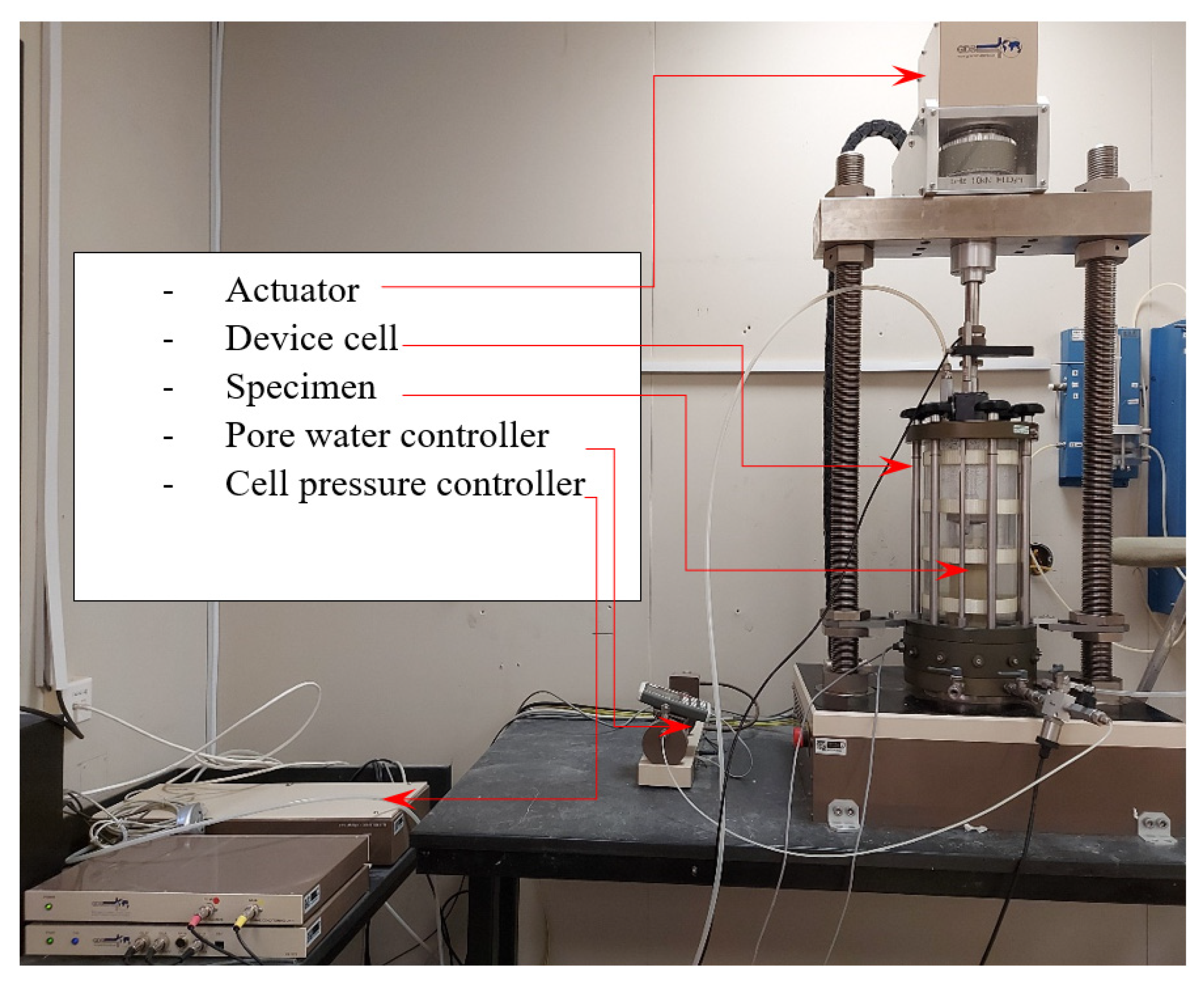

3.3. Testing Procedures

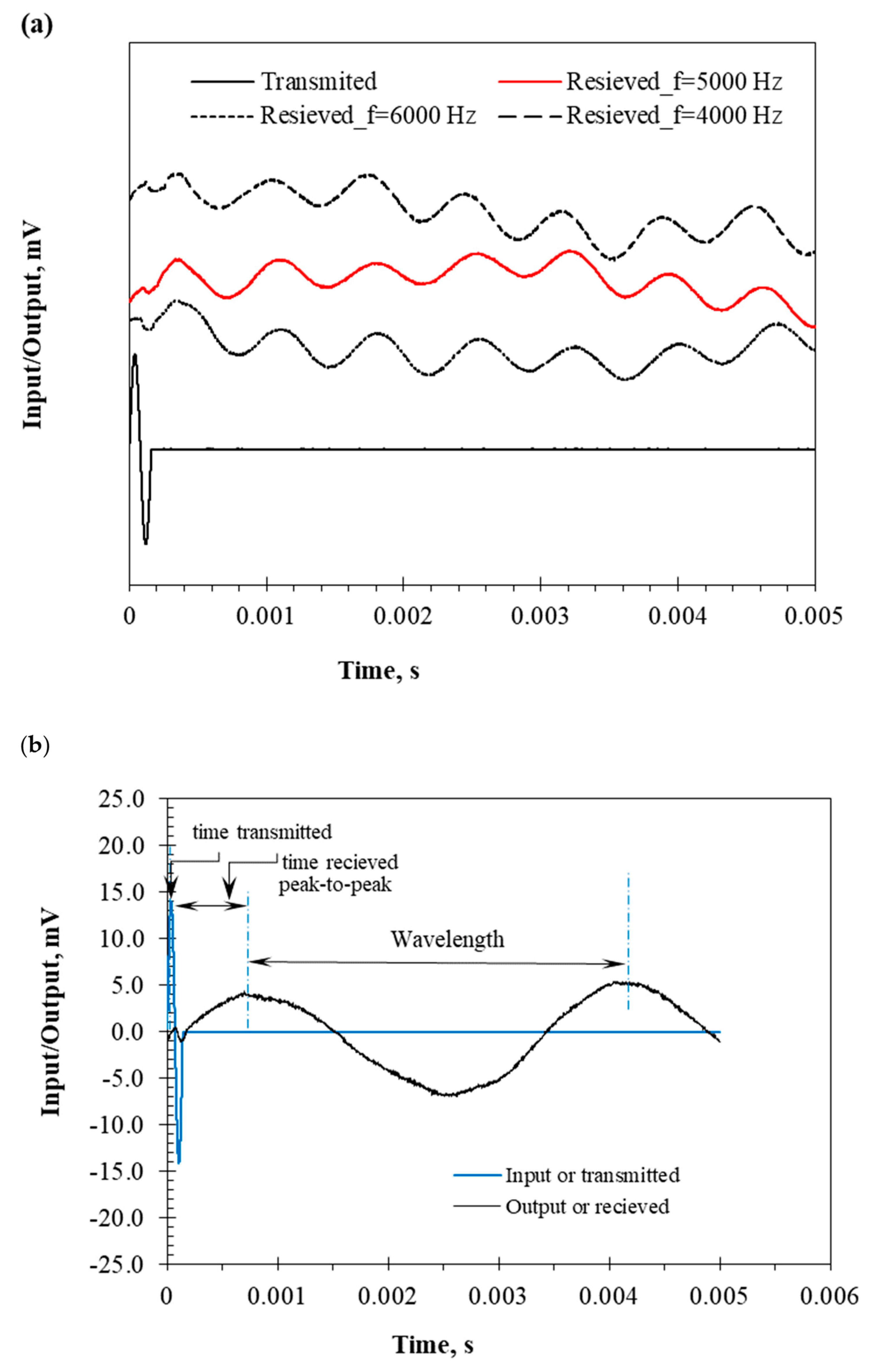

3.3.1. Shear Wave Velocity Test

3.3.2. Dynamic Cyclic Loading

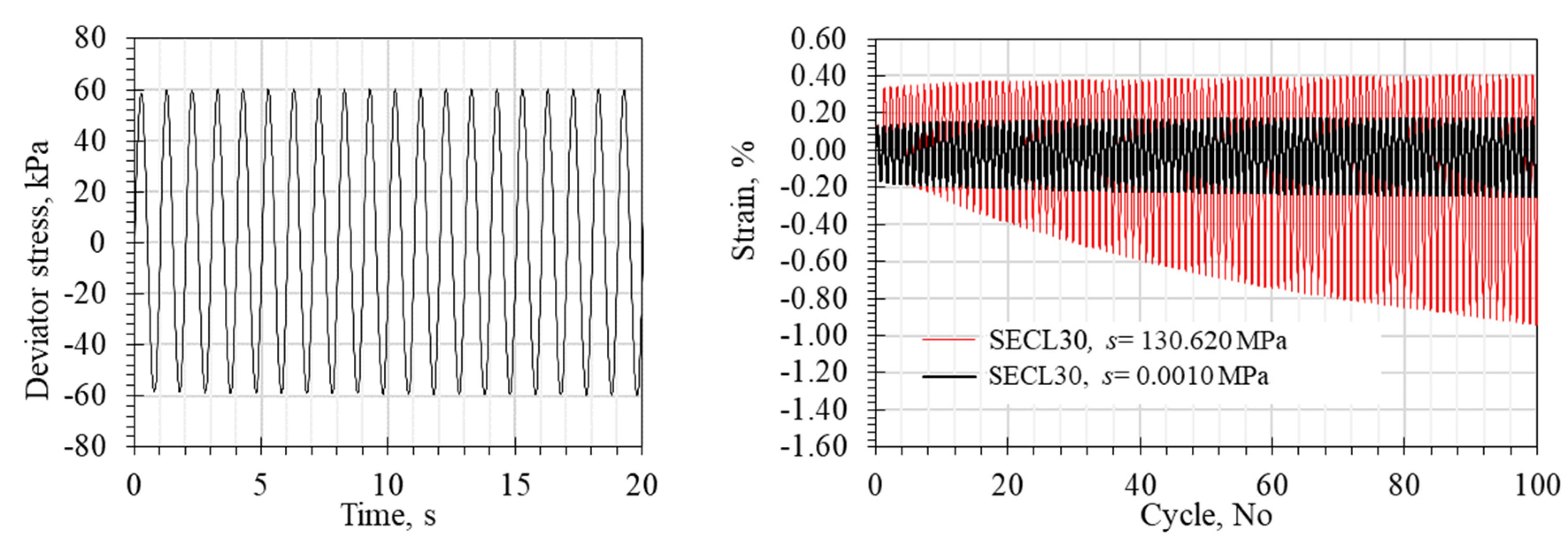

4. Results and Discussion

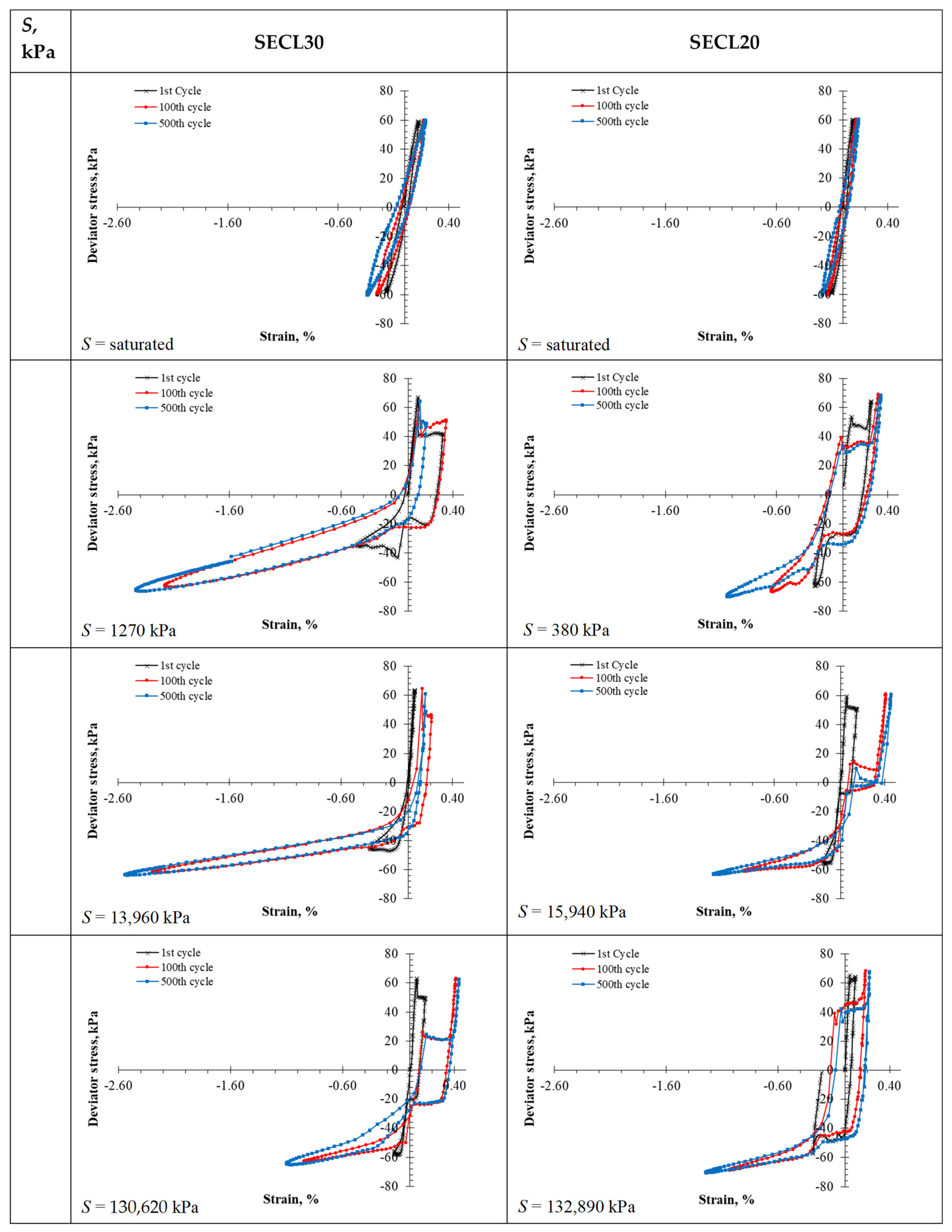

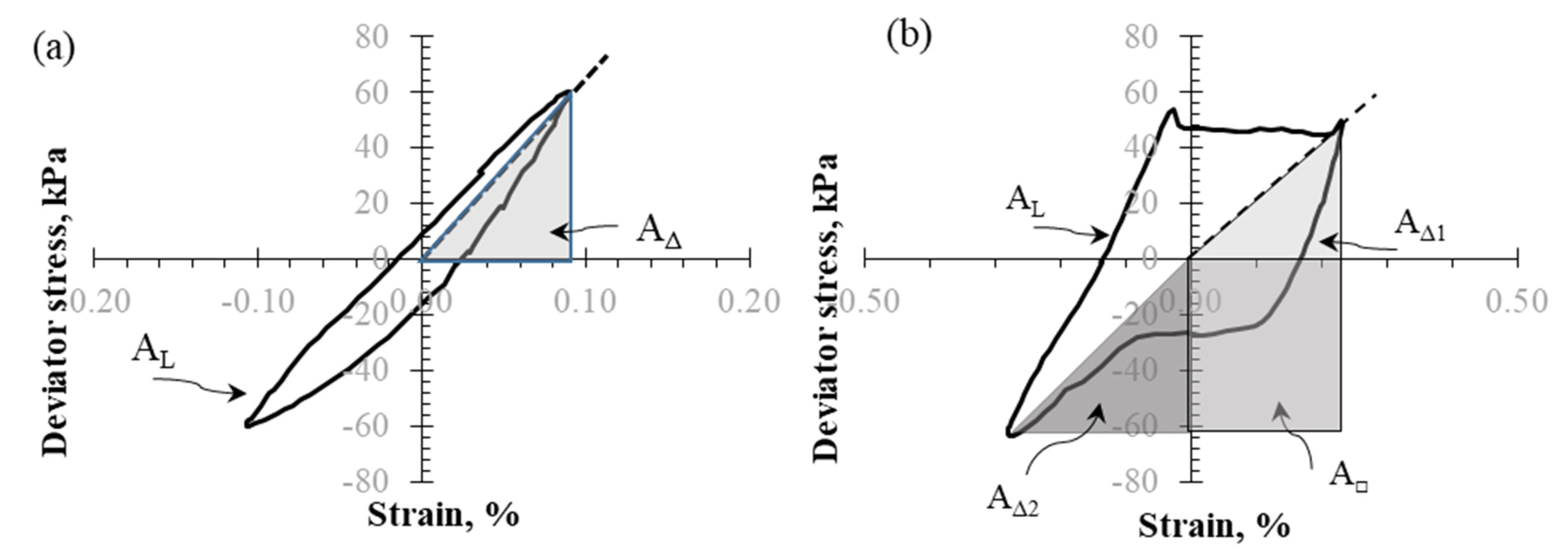

4.1. Stiffness and Stress–Strain Behavior

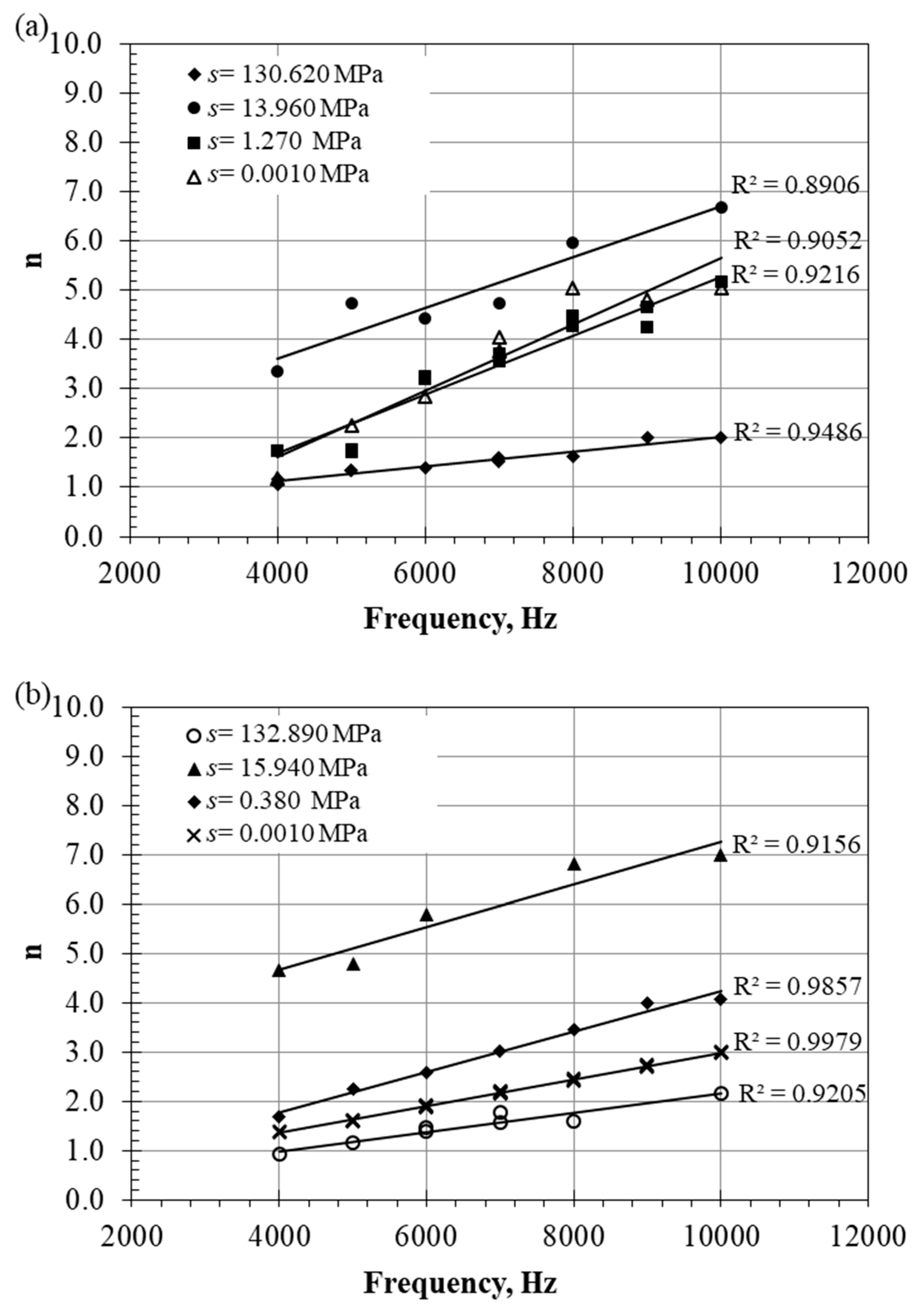

4.2. Shear Wave Velocity

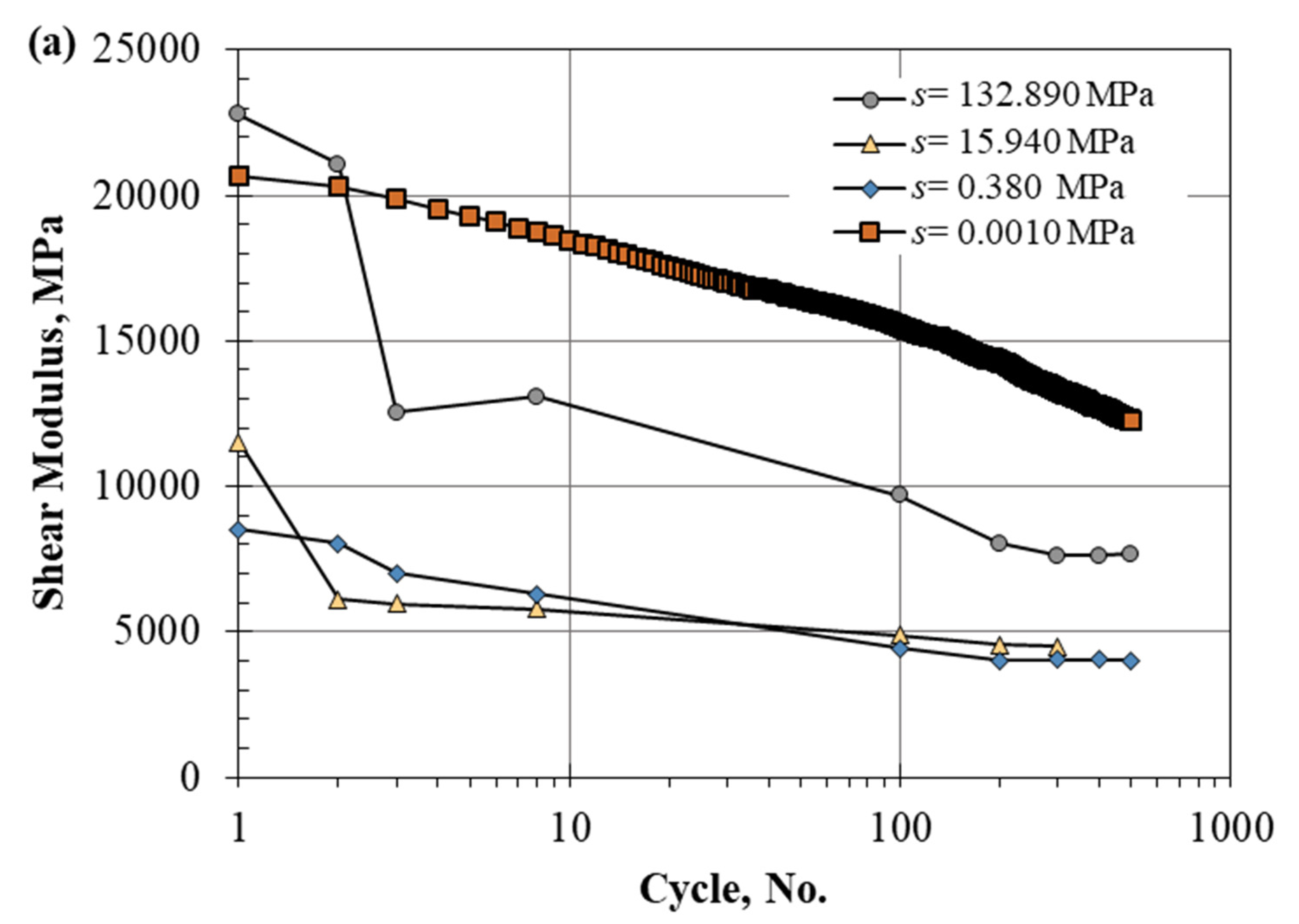

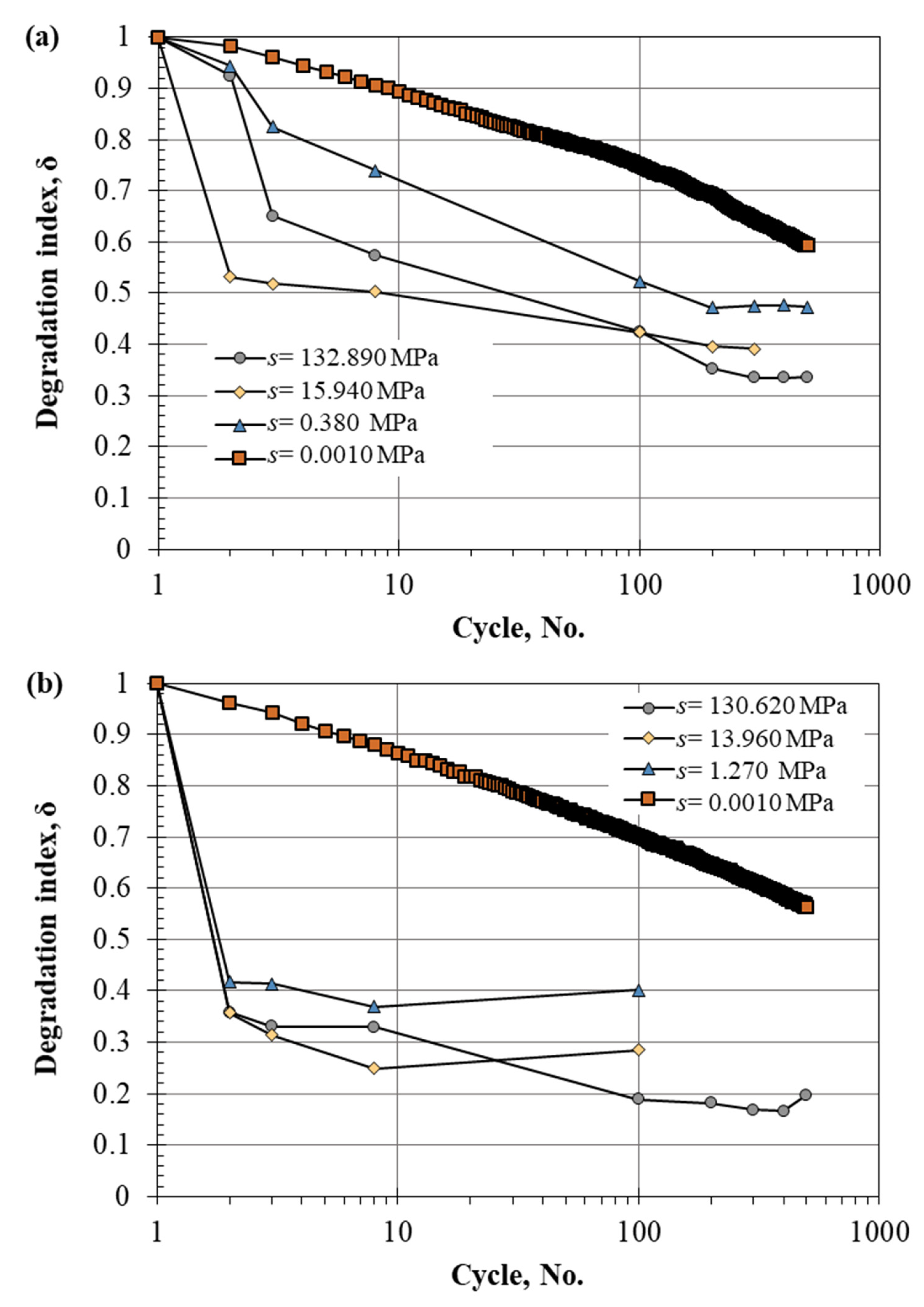

4.3. Shear Modulus and Degradation Index

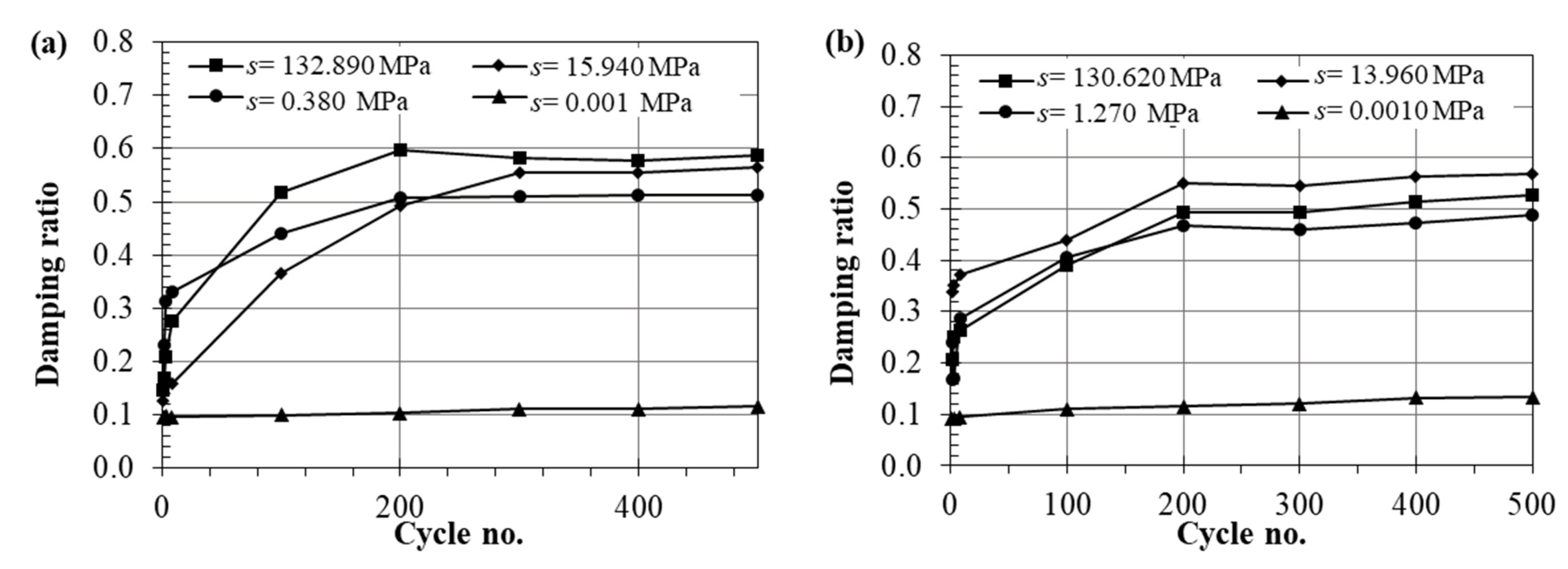

4.4. Damping Ratio

5. Summary and Conclusions

- The study findings demonstrate the variability of unsaturated soil stiffness within the range of applied suction, with the hysteric loop showing a nonlinear and asymmetric behavior. The stress–strain behavior is a key characteristic, and accounting for this variation under expected dynamic loads ensures an accurate and adequate design.

- The shear wave velocities of both liners exhibit a nonlinear relation with suction. A minor change was observed at the earliest stage of low suction (boundary effect zone). This change has been significant with an increase in suction up to the residual stage.

- The results revealed a dual trend of shear modulus over the entire range of suction. The degradation index of the shear modulus reached approximately 60% at the first fifth cycles, and the change is marginal beyond the 100th cycle.

- The application of suction resulted in a significant increase in the damping ratio, with the increment reaching approximately five and four times for SECL_20 and SECL_30, respectively. Implementing the new procedures to estimate the damping ratio, taking into account the asymmetric conditions of the hysteresis loop, resulted in a reduction in the damping values varying from 10% at the first cycle to 80% after 500 cycles.

- The achievements of this study will guide practitioner engineers to conduct a sustainable and stable design for clay–sand layers under expected dynamic loads.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, M.; Zhang, H.; Cui, S.; Jia, L.; Zhou, L.; Chen, H. Engineering properties of GMZ bentonite-sand as buffer/backfilling material for high-level waste disposal. Eur. J. Environ. Civ. Eng. 2012, 16, 1216–1237. [Google Scholar] [CrossRef]

- Nowamooz, H.; Jahangir, E.; Masrouri, F.; Tisot, J.P. Effective stress in swelling soils during wetting drying cycles. Eng. Geol. 2016, 210, 33–44. [Google Scholar] [CrossRef]

- Vilarrasa, V.; Rutqvist, J.; Martin, L.; Birkholzer, J. Use of a dual-structure constitutive model for predicting the long-term behavior of an expansive clay buffer in a nuclear waste repository. Int. J. GeoMech. 2016, 16, D4015005. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Dafalla, M.; Shaker, A.; Al-Shamrani, M.A. Sustainable and Stable Clay Sand Liners over Time. Sustainability 2021, 13, 7840. [Google Scholar] [CrossRef]

- Daniel, D.E. Clay liners. In Geotechnical Practice for Waste Disposal; Springer: Boston, MA, USA, 1993; pp. 137–163. [Google Scholar]

- Likos, W.J.; Wayllace, A.W.; Godt, J.G.; Lu, N. Modified Direct Shear Apparatus for Unsaturated Sands at Low Suction and Stress. ASTM Geotech. Test. J. 2010, 33, 286–298. [Google Scholar]

- Goh, S.G.; Rahardjo, H.; Leong, E.C. Shear strength of unsaturated soils under multiple drying-wetting cycles. J. Geotech. Geoenviron. Eng. 2014, 140, 06013001. [Google Scholar] [CrossRef]

- Elkady, T.Y.; Shaker, A.A.; Dhowain, A.W. Shear strengths and volume changes of sand–attapulgite clay mixtures. Bull. Eng. Geol. Environ. 2015, 74, 595–609. [Google Scholar] [CrossRef]

- Elkady, T.Y.; Dafalla, M.A.; Al-Mahbashi, A.M.; Al-Shamrani, M. Effect of Compaction State on the Soil Water Characteristic Curves of Sand–Natural Expansive Clay Mixtures. Eur. J. Environ. Civ. Eng. 2017, 21, 289–302. [Google Scholar] [CrossRef]

- Seiphoori, A.; Laloui, L.; Ferrari, A.; Hassan, M.; Khushefati, W.H. Water retention and swelling behaviour of granular bentonites for application in Geosynthetic Clay Liner (GCL) systems. Soils Found. 2016, 56, 449–459. [Google Scholar] [CrossRef]

- Abdolahzadeh, A.M.; Lacroix Vachon, B.; Cabral, A.R. Evaluation of the effectiveness of a cover with capillary barrier effect to control percolation into a waste disposal facility. Can. Geotech. J. 2011, 48, 996–1009. [Google Scholar] [CrossRef]

- Sobti, J.; Singh, S.K. Techno-economic analysis for barrier materials in landfills. Int. J. Geotech. Eng. 2017, 11, 467–478. [Google Scholar] [CrossRef]

- Cui, Y.J.; Tang, A.M.; Loiseau, C.; Delage, P. Determining the unsaturated hydraulic conductivity of a compacted sand-bentonite mixture under constant-volume and free-swell conditions. Phys. Chem. Earth A/B/C 2008, 33 (Suppl. S1), 462–471. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Dafalla, M. Impact of placement and field conditions on hydraulic conductivity and lifetime of liners. J. King Saud Univ. Sci. 2021, 33, 101410. [Google Scholar] [CrossRef]

- Li, D.; Selig, E.T. Cumulative Plastic Deformation for Fine-Grained Subgrade Soils. J. Geotech. Eng. 1996, 122, 1006–1013. [Google Scholar] [CrossRef]

- Abdelkrim, M.; Bonnet, G.; de Buhan, P. A computational procedure for predicting the long term residual settlement of a platform induced by repeated traffic loading. Comput. Geotech. 2003, 30, 463–476. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Alnuaim, A. Effect of Dynamic Loads on the Long-Term Efficiency of Liner Layers. Buildings 2023, 13, 688. [Google Scholar] [CrossRef]

- Yan, K.; Wang, Y.; Yang, Z.; Lai, X.; Chen, C. Experimental study on small-strain shear modulus of unsaturated silty-fine sand. Appl. Sci. 2022, 12, 8743. [Google Scholar] [CrossRef]

- Głuchowski, A.; Skutnik, Z.; Biliniak, M.; Sas, W.; Lo Presti, D. Laboratory characterization of a compacted-unsaturated silty sand with special attention to dynamic behavior. Appl. Sci. 2020, 10, 2559. [Google Scholar] [CrossRef]

- Lu, Z.; Sabatier, J.M. Effects of soil water potential and moisture content on the sound speed. Soil Sci. Soc. Am. J. 2009, 73, 1614–1625. [Google Scholar] [CrossRef]

- Whalley, W.R.; Jenkins, M.; Attenborough, K. The velocity of shear waves in unsaturated soil. Soil Tillage Res. 2012, 125, 30–37. [Google Scholar] [CrossRef]

- Indraratna, B.; Heitor, A.; Rujikiatkamjorn, C. Effect of compaction energy on shear wave velocity of dynamically compacted silty sand soil. In 5th Asia-Pacific Conference on Unsaturated Soils; Jotisankasa, A., Sawangsuriya, A., Soralump, S., Mairaing, W., Eds.; Kasetsart University: Pattaya, Thailand, 2012; Volume 2, pp. 538–543. [Google Scholar]

- Leng, W.; Xiao, Y.; Nie, R.; Zhou, W.; Liu, W. Investigating Strength and Deformation Characteristics of Heavy-Haul Railway Embankment Materials Using Large-Scale Undrained Cyclic Triaxial Tests. Int. J. Geomech. 2017, 17, 04017074. [Google Scholar] [CrossRef]

- Dafalla, M.A. Efficiency of Sand Clay Liners in Controlling Subsurface Water Flow. In Engineering Geology for Society and Territory—Volume 3: River Basins, Reservoir Sedimentation and Water Resources; Springer: Cham, Switzerland, 2014; pp. 497–499. [Google Scholar]

- ASTM D2487; Standard Practice for Classification of Soils for Engineering Purpose (United Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D854-14; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D6913-09; Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis. ASTM Standard International: West Conshohocken, PA, USA, 2009.

- ASTM D 4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils, Vol. 4.08. D-18 Committee on Soils and Rocks: West Conshohocken, PA, USA, 2000.

- ASTM D 4546; Standard Test Methods for One-Dimensional Swell or Collapse of Cohesive Soils, Vol. 4.08. D-18 Committee on Soils and Rocks: West Conshohocken, PA, USA, 2003.

- ASTM D 2435; Standard Test Methods for One-Dimensional Consolidation Properties of Soils Using Incremental Loading, Vol. 4.08. D-18 Committee on Soils and Rocks: West Conshohocken, PA, USA, 2003.

- ASTM D 422; Standard Test Method for Particle-Size Analysis of Soils, Vol. 4.08. D-18 Committee on Soils and Rocks: West Conshohocken, PA, USA, 2002.

- Slater, D.E. Potential Expansive Soils in Arabian Peninsula. J. Geotech. Eng. 1983, 109, 744–746. [Google Scholar] [CrossRef]

- Abduljauwad, S.N.; Azam, S.; Al-Shayea, N.A.; Al-Amoudi, O.S.B. The behaviour of geological formations containing expansive clay and calcium sulphate phases. In Proceedings of the 8th International Congress of the International Association of Engineering Geology, Vancouver, BC, Canada, 21–25 September 1998; Moore, D., Hungr, O., Eds.; A.A. Balkema: Rotterdam, The Netherlands, 1998; Volume 1, pp. 169–175. [Google Scholar]

- Azam, S. Influence of mineralogy on swelling and consolidation of soils in eastern Saudi Arabia. Can. Geotech. J. 2003, 40, 964–975. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Al-Shamrani, M.A.; Abbas, M.F. Hydromechanical behavior of unsaturated expansive clay under repetitive loading. J. Rock Mech. Geotech. Eng. 2021, 13, 1136–1146. [Google Scholar] [CrossRef]

- Al-Mahbashi, A.M.; Dafalla, M. The distribution and mineralogy of expansive clay in a semi-arid region. Arab. J. Geosci. 2023, 16, 283. [Google Scholar] [CrossRef]

- Rafi, A. Engineering Properties and Mineralogical Composition of Expansive Clays in Al-Qatif Area. Ph.D. Thesis, King Fahd University of Petroleum and Minerals, Dhahran, Saudi Arabia, 1988. Available online: https://core.ac.uk/download/pdf/242408217.pdf (accessed on 10 August 2019).

- Chittoori, B.C.S.; Moghal, A.A.B.; Pedarla, A.; Al-Mahbashi, A.M. Effect of unit weight on porosity and consolidation characteristics of expansive clays. J. Test. Eval. 2017, 45, 94–104. [Google Scholar] [CrossRef]

- ASTMD698-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM International: West Conshohocken, PA, USA, 2012.

- BS EN 13286-53; Unbound and Hydraulically Bound Mixtures. Methods for the Manufacture of Test Specimens of Hydraulically Boundmixtures Using Axial Compression. British Standard Institute: London, UK, 2004.

- ASTM E 104; Standard Practice for Maintaining Constant Relative Humidity by Means of Aqueous Solutions. ASTM Standards: West Conshohocken, PA, USA, 2007.

- ASTM D 6836; Standard Test Methods for Determination of the Soil Water Characteristic Curve for Desorption Using a Hanging Column, Pressure Extractor, Chilled Mirror Hygrometer, and/or Centrifuge (Vol. 15.09). ASTM Standards: West Conshohocken, PA, USA, 2002.

- Blewett, J.; Blewett, I.J.; Woodward, P.K. Phase and amplitude responses associated with the measurement of shear-wave velocity in sand by bender elements. Can. Geotech. J. 2000, 37, 1348–1357. [Google Scholar] [CrossRef]

- Da Fonseca, A.V.; Ferreira, C.; Fahey, M. A framework interpreting bender element tests, combining time-domain and frequencydomain methods. Geotech. Test. J. 2009, 32, 91–107. [Google Scholar]

- Alonso, E.E.; Gens, A.; Josa, A. A constitutive model for partially saturated soils. Geotechnique 1990, 40, 405–430. [Google Scholar] [CrossRef]

- Alonso, E.E.; Romero, E.; Hoffmann, C.; García-Escudero, E. Expansive bentonite–sand mixtures in cyclic controlled-suction drying and wetting. Eng. Geol. 2005, 81, 213–226. [Google Scholar] [CrossRef]

- Zhong, Z.; Zou, H.; Hu, X.; Liu, X. Experimental study on stiffness softening of soil-rock mixture backfill under metro train cyclic load. Adv. Mater. Sci. Eng. 2021, 2021, 3024490. [Google Scholar] [CrossRef]

- Han, Z.; Vanapalli, S.K. Stiffness and shear strength of unsaturated soils in relation to soil-water characteristic curve. Géotechnique 2016, 66, 627–647. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Zheng, G.; Ni, J.; Zhou, C. Use of unsaturated small-strain soil stiffness to the design of wall deflection and ground movement adjacent to deep excavation. Comput. Geotech. 2020, 119, 103375. [Google Scholar] [CrossRef]

- Greening, P.D.; Nash, D.F.T. Frequency Domain Determination of G0 Using Bender Elements. Geotech. Test. J. 2004, 27, 288–294. [Google Scholar]

- Yang, S.R.; Lin, H.D.; Kung, J.H.S.; Liao, J.Y. Shear wave velocity and suction of unsaturated soil using bender element and filter paper method. J. GeoEng. 2008, 3, 67–74. [Google Scholar]

- Yang, S.R.; Lin, H.D. Influence of soil suction on small-strain stiffness of compacted residual subgrade soil. Transp. Res. Rec. 2009, 2101, 63–71. [Google Scholar] [CrossRef]

- Lu, Z. A Review of the High-Frequency Multi-Channel Analysis of Surface Wave Method for Proximal Soil Sensing. Int. J. Earth Environ. Sci. 2021, 6, 180. [Google Scholar]

- Das, B.M. Fundamentals of Soil Dynamics; Elsevier: New York, NY, USA, 1983. [Google Scholar]

- Albers, B. Linear elastic wave propagation in unsaturated sands, silts, loams and clays. Transp. Porous Media 2011, 86, 537–557. [Google Scholar] [CrossRef]

- Vucetic, M.; Dobry, R. Effect of soil plasticity on cyclic response. J. Geotech. Eng. 1991, 117, 89–107. [Google Scholar] [CrossRef]

- ASTM D3999/D3999M-13; Standard Test Methods for the Determination of the Modulus and Damping Properties of Soils Using the Cyclic Triaxial Apparatus. ASTM: West Conshohocken, PA, USA, 2013.

- Kokusho, T. Cyclic triaxial test of dynamic soil properties for wide strain range. Soils Found. 1980, 20, 45–60. [Google Scholar] [CrossRef]

- Kumar, S.S.; Krishna, A.M.; Dey, A. Evaluation of dynamic properties of sandy soil at high cyclic strains. Soil Dyn. Earthq. Eng. 2017, 99, 157–167. [Google Scholar] [CrossRef]

- Hussain, M.; Sachan, A. Effect of loading conditions and stress history on cyclic behavior of Kutch soil. Geomech. Geoeng. 2020, 15, 233–251. [Google Scholar] [CrossRef]

- Vassallo, R.; Mancuso, C.; Vinale, F. Modelling the influence of stress–strain history on the initial shear stiffness of an unsaturated compacted silt. Can. Geotech. J. 2007, 44, 463–472. [Google Scholar] [CrossRef]

- Biglari, M.; Jafari, M.K.; Shafiee, A.; Mancuso, C.; d’Onofrio, A. Shear Modulus and Damping Ratio of Unsaturated Kaolin Measured by New Suction-Controlled Cyclic Triaxial Device. Geotech. Test. J. 2011, 34, 525–536. [Google Scholar]

- Biglari, M.; Ashayeri, I. An empirical model for shear modulus and damping ratio of unsaturated soils. In Proceedings of the 5th Asia-Pacific Conference on Unsaturated Soils; Kasetsart University: Pattaya, Thailand, 2012; pp. 591–596. [Google Scholar]

| Title | Specification | Value |

|---|---|---|

| Sand | ||

| Specific Gravity, Gs | ASTM D854 [26] | 2.67 |

| Uniformity Coefficient, Cu | ASTM D6913 [27] | 1.75 |

| Coefficient of Concavity, Cc | ASTM D6913 [27] | 0.95 |

| Classification | ASTM D2487 [25] | SP |

| Expansive soil | ||

| Specific Gravity, Gs | ASTM D854 [26] | 2.71–2.77 |

| Liquid Limit, wL (%) | ASTM D4318 [28] | 160–170 |

| Plastic Limit, wP (%) | 60 | |

| Shrinkage Limit (%) | 11–15 | |

| Plasticity Index (%) | 100–110 | |

| Unified Soil Classification | ASTM D2487 [25] | CH |

| Swelling Potential (%) | ASTM D 4546 [29] | 26 |

| Swelling Pressure (kPa) | ASTM D 2435 [30] | 450 |

| Passing #200 (%) | ASTM D 422 [31] | 95 |

| Clay Percentage (%) | 74 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alnuaim, A.; Al-Mahbashi, A.M. Experimental Investigation for Shear Wave Velocity and Dynamic Characteristics of Unsaturated Sand–Clay Liners. Sustainability 2023, 15, 15681. https://doi.org/10.3390/su152215681

Alnuaim A, Al-Mahbashi AM. Experimental Investigation for Shear Wave Velocity and Dynamic Characteristics of Unsaturated Sand–Clay Liners. Sustainability. 2023; 15(22):15681. https://doi.org/10.3390/su152215681

Chicago/Turabian StyleAlnuaim, Ahmed, and Ahmed M. Al-Mahbashi. 2023. "Experimental Investigation for Shear Wave Velocity and Dynamic Characteristics of Unsaturated Sand–Clay Liners" Sustainability 15, no. 22: 15681. https://doi.org/10.3390/su152215681