An Innovative Approach to Organizational Changes for Sustainable Processes: A Case Study on Waste Minimization

Abstract

:1. Introduction

1.1. Project Initialization: Definition of Requirements and Boundary Conditions

1.2. Project Conception: Definition of the Organizational Change Content

1.3. Organizational Change Project Planning

- Preparation for improvement;

- Process mapping/process modeling (if we do not have an up-to-date business repository);

- Process analysis;

- Key process improvement through selected measures;

- Solution implementation/system adaptation (the adaptation of an organizational structure, IT system, and HR system to the improved process);

- Process monitoring and control.

- Demonstrating the usefulness and benefits of process improvement methods and techniques through their impact on performance indicators (Section 3.1);

- A case study of waste minimization in the development process (Section 3.2).

2. Research Procedure

- An overview of the theoretical background (Section 1);

- A verification of the suitability of the innovative approach through considering evidence of the usefulness and benefits of the methods and techniques (the determination of a representative sample, Section 2.1, and a survey questionnaire, Section 2.2);

- A verification of the effectiveness of the innovative approach through a case study of waste minimization in the development process (Section 2.3).

2.1. Determination of the Representative Sample

2.2. Survey Questionnaire

- It covers the scientific and professional needs in the research field;

- It covers the purpose of this research;

- It covers performance indicators and relevant process improvement methods and techniques (based on a review of the available literature);

- It enables a comparison of results according to the enterprise classification criteria.

2.3. Case Study on Waste Minimization in the Development of New Products in the Coatings Industry

- Waste minimization [74]:

- ○

- Data on the number of necessary laboratory test repetitions for a successful realization of coating development;

- ○

- Data on the amount of waste generated during laboratory tests.

- Throughput time reduction, where the time for each process activity was monitored [68]:

- ○

- Waiting time;

- ○

- Orientation time (preparation–finishing time);

- ○

- Processing time.

- Cost reduction where this was observed [75]:

- ○

- The cost of each process activity (the activity-based costing method)—the difference between the average cost of the process before and after digital transformation. The calculation considered the following savings: fewer laboratory tests, lower material consumption, and less labor (due to shorter activity times).

3. Results

- Descriptive statistics (averages; contingency tables);

- Conducting a proportion test;

- Conducting a population mean test.

3.1. Analysis of the Usefulness and Benefits of Process Improvement Methods and Techniques

- Medium (55.9%) and large enterprises (41.8%);

- Material (60.6%) and non-material enterprises (36.6%);

- Enterprises from Slovenia (60.6%) and Croatia (28.6%).

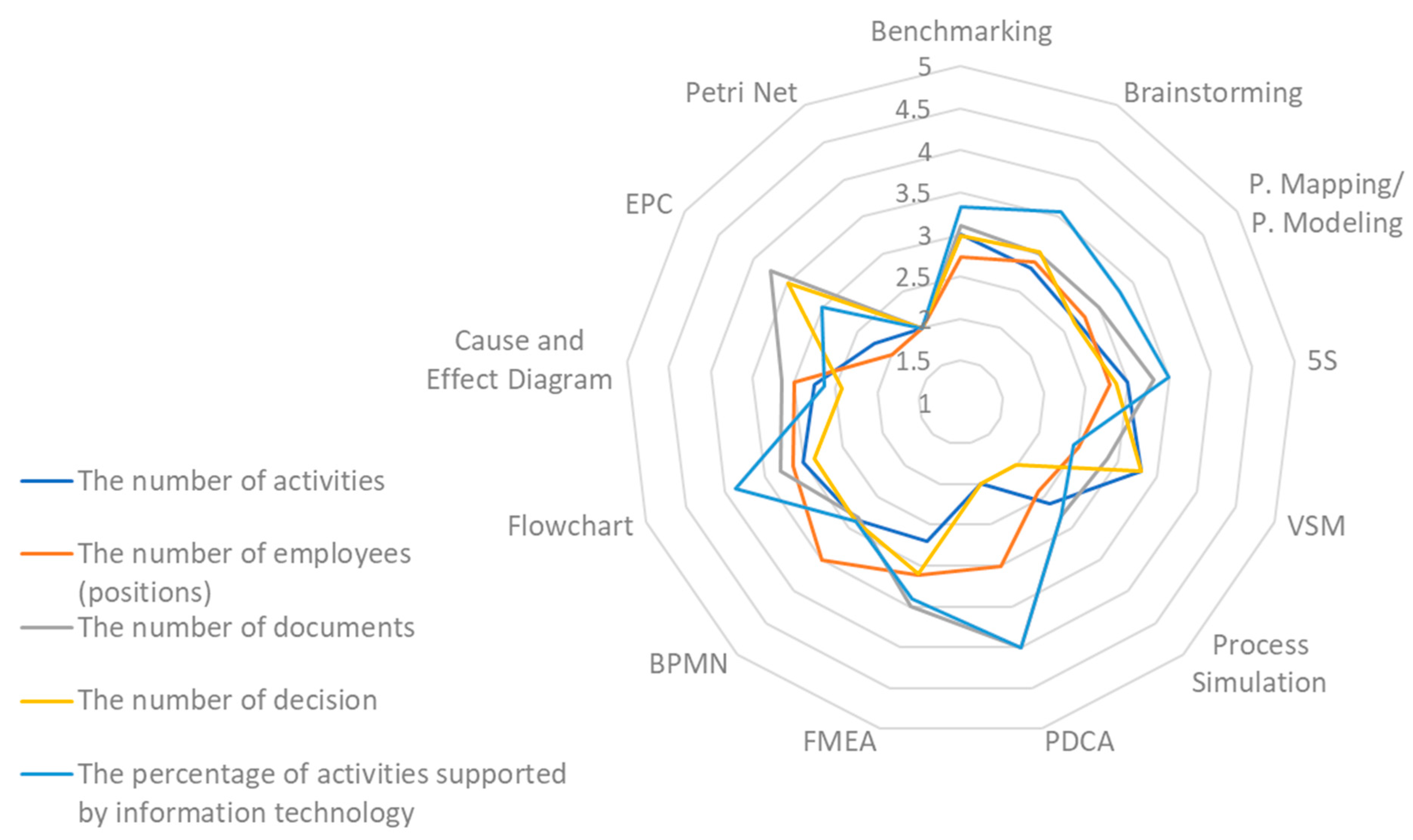

- Benchmarking, with an impact of reducing the number of activities, documents, and decisions, and of increasing the percentage of activities supported by information technology;

- Brainstorming, with an impact of reducing the number of activities, documents, and decisions;

- P. napping/P. modeling, with an impact of reducing the number of activities and decisions, and of increasing the percentage of activities supported by information technology;

- Finally, 5S, with an impact of reducing the number of activities, employees (positions), and decisions, and of increasing the percentage of activities supported by information technology.

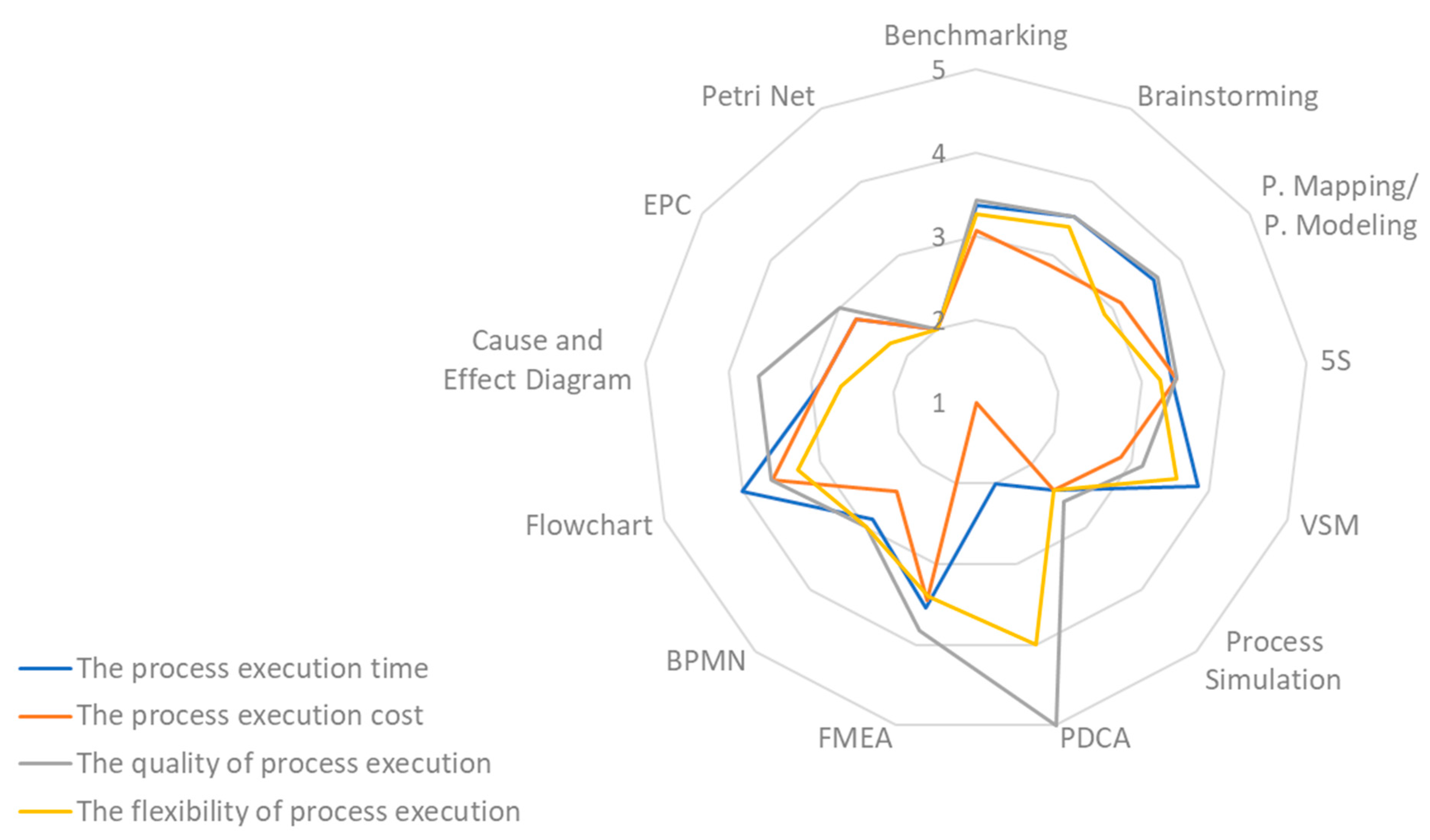

- Benchmarking, brainstorming, and P. mapping/P. modeling, with the impact of shortening the process time, reducing the process costs, and achieving quality and flexibility improvements in the process;

- The method of 5S, with the impact of shortening the process time and achieving quality improvement in the process;

- FMEA, with an impact of shortening the process time, reducing the process costs, and achieving quality improvements in the process.

- Therefore, based on the tests conducted, we can confirm the following:

- The use of individual process improvement methods has a positive impact on operational efficiency indicators (14 out of 16 tests conducted);

- The use of individual process improvement methods has a positive impact on structural efficiency indicators (14 out of 20 tests conducted);

- The use of process improvement methods has a positive impact on operational efficiency indicators (four out of four tests conducted);

- The use of process improvement methods has a positive impact on structural efficiency indicators (five out of five tests conducted);

- The use of FMEA has a positive impact on operational efficiency indicators (three out of four tests conducted);

- The use of FMEA has no positive impact on structural efficiency indicators (zero out of five tests conducted);

- The use of process improvement techniques has a positive impact on operational efficiency indicators (four out of four tests conducted);

- The use of process improvement techniques has a positive impact on structural efficiency indicators (three out of five tests conducted).

- Benchmarking and FMEA have an average improvement of above 2.5 for reducing the number of employees (positions), documents, and decisions, and for increasing the percentage of activities supported by information technology;

- Brainstorming has an average improvement of above 2.5 for reducing the number of activities, documents, and decisions, and for increasing the percentage of activities supported by information technology;

- P. mapping/P. modeling has an average improvement of above 2.5 for increasing the percentage of activities supported by information technology;

- The method of 5S has an average improvement of above 2.5 for reducing the number of activities and documents, and for increasing the percentage of activities supported by information technology.

- Benchmarking, brainstorming, 5S, and FMEA have an average improvement of above 2.5 for shortening the process time, reducing the process costs, and achieving quality and flexibility improvements in the process;

- P. mapping/P. modeling has an average improvement of above 2.5 for shortening the process time, reducing the process costs, and achieving quality improvements in the process.

- A range of methods:

- ○

- Moderate average improvement for the five structural indicators;

- ○

- Moderate average improvement for the four operational indicators.

- A range of techniques:

- ○

- Moderate average improvement for the four structural indicators;

- ○

- Moderate average improvement for the four operational indicators.

- Individual methods:

- ○

- Moderate average improvement for structural indicators (12 out of 20 tests);

- ○

- Moderate average improvement for operational indicators (15 out of 16 tests).

- Individual techniques:

- ○

- Moderate average improvement for the four structural indicators;

- ○

- Moderate average improvement for the four operational indicators.

- To improve the percentage of activities supported by information technology (structural efficiency indicator), using 5S, P. mapping/P. modeling and benchmarking is most appropriate;

- To improve the quality of process execution (an operational efficiency indicator), using FMEA, P. mapping/P. modeling and benchmarking is most appropriate.

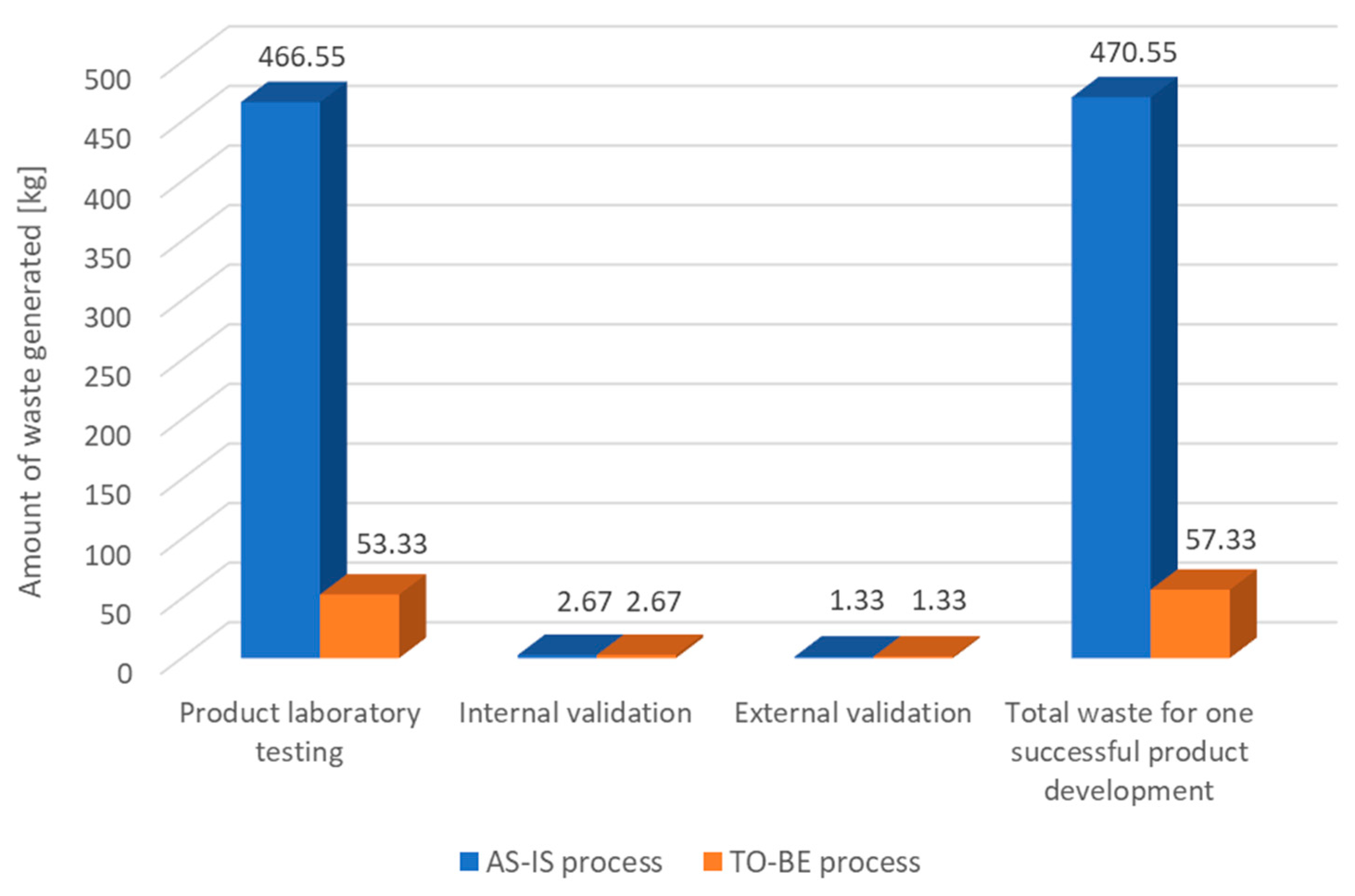

3.2. Case Study on Waste Minimization in the Development of New Products in the Coatings Industry

- The development of a new product without information communication technology (ICT) support (classic process);

- The development of a new product with ICT support and a local database.

4. Discussion and Conclusions

- The purpose of organizational changes—operational efficiency indicators;

- Necessary organizational (process) changes—structural efficiency indicators;

- Essential process change measures—process improvement methods and techniques.

- The positive impact of process improvement methods and techniques on structural and operational efficiency indicators is confirmed. The results obtained are confirmed by Bait et al. [70] and also by Griesberger et al. [80], who theoretically evaluate the impact of methods and techniques on efficiency indicators. They estimate that, e.g., the cause and effect diagram technique impacts individual elements, such as the resources and process inputs involved.

- The concurrent positive impact of process improvement methods and techniques on structural and operational efficiency indicators is confirmed. The concurrent positive impact is supported by Djordevic et al. [81] and by the finding [80] that no technique can improve structural efficiency indicators without impacting the improvement of at least one operational efficiency indicator.

- The enterprise plans and implements organizational changes to improve performance through more efficient processes;

- The enterprise has a system of operational indicators to measure the efficiency of processes. Operational indicators must be measured across all dimensions of competitive advantage for each process and the business system as a whole.

- We used only the most relevant business process improvement methods and techniques. We imposed this limitation due to the extensive literature in the studied field;

- We limited the sample of enterprises according to specific criteria for their classification. This limitation was imposed due to the scope of the research and to meet the requirements of statistical methods (e.g., several countries were not included in the sample; enterprises were not divided by business area);

- Our research did not aim to examine differences between countries. Therefore, the uneven rate of responses by enterprises to the survey by country is irrelevant;

- In selecting the statistical methods, we considered the limitations imposed by the sample size. We also considered the assumptions of the statistical methods, such as the normal distribution and homogeneity of variances, which depend on the distribution of respondents’ answers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Methods/ Techniques | Reducing the Number of Activities | Reducing the Number of Employees (Positions) | Reducing the Number of Documents | Reducing the Number of Decisions | Increasing the Percentage of Activities Supported by Information Technology | Shortening the Process Time | Reducing the Process Cost | Quality Improvement of the Process | Flexibility Improvement of the Process |

|---|---|---|---|---|---|---|---|---|---|

| Brainstorming (47) | 3.00 1 | 2.74 | 3.10 | 2.98 | 3.33 | 3.37 | 3.07 | 3.43 | 3.26 |

| Benchmarking (32) | 2.81 | 2.89 | 3.00 | 3.03 | 3.57 | 3.53 | 2.87 | 3.53 | 3.39 |

| P. Mapping/ P. Modeling (17) | 2.69 | 2.80 | 3.00 | 2.65 | 3.31 | 3.59 | 3.12 | 3.65 | 2.88 |

| 5S (14) | 3.00 | 2.79 | 3.31 | 2.86 | 3.50 | 3.36 | 3.42 | 3.43 | 3.23 |

| VSM (7) | 3.29 | 2.50 | 2.86 | 3.29 | 2.43 | 3.86 | 2.86 | 3.14 | 3.57 |

| Process Simulation (5) | 2.60 | 2.40 | 2.80 | 2.00 | 2.80 | 2.40 | 2.40 | 2.60 | 2.40 |

| PDCA (1) | 2.00 | 3.00 | 4.00 | 2.00 | 4.00 | 2.00 | 1.00 | 5.00 | 4.00 |

| Average rating of the impact on the indicator | 2.90 | 2.77 | 3.06 | 2.90 | 3.34 | 3.42 | 3.00 | 3.45 | 3.22 |

| Average impact rating per indicator group | 2.99 | 3.27 | |||||||

| Methods/ Techniques | Reducing the Number of Activities | Reducing the Number of Employees (Positions) | Reducing the Number of Documents | Reducing the Number of Decisions | Increasing the Percentage of Activities Supported by Information Technology | Shortening the Process time | Reducing the Process Cost | Quality Improvement of the Process | Flexibility Improvement of the Process |

|---|---|---|---|---|---|---|---|---|---|

| FMEA (11) | 2.70 | 3.11 | 3.50 | 3.10 | 3.40 | 3.55 | 3.45 | 3.82 | 3.40 |

| BPMN (9) | 2.86 1 | 3.50 | 2.83 | 2.88 | 2.88 | 2.88 | 2.43 | 3.00 | 3.00 |

| Flowchart (8) | 3.00 | 3.13 | 3.29 | 2.86 | 3.87 | 4.00 | 3.62 | 3.63 | 3.29 |

| Cause and Effect Diagram (8) | 2.75 | 3.00 | 3.14 | 2.43 | 2.63 | 2.88 | 2.88 | 3.63 | 2.63 |

| EPC (4) | 2.25 | 2.00 | 3.75 | 3.50 | 3.00 | 2.75 | 2.75 | 3.00 | 2.25 |

| Petri Nets (1) | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 |

| Average rating of the impact on the indicator | 2.74 | 2.97 | 3.24 | 2.89 | 3.15 | 3.25 | 3.08 | 3.44 | 2.97 |

| Average impact rating per indicator group | 3.00 | 3.19 | |||||||

References

- Žužek, T.; Gosar, Ž.; Kušar, J.; Berlec, T. A new product development model for SMEs: Introducing agility to the plan-driven concurrent product development approach. Sustainability 2021, 13, 12159. [Google Scholar] [CrossRef]

- Rezaee, Z. Supply chain management and business sustainability synergy: A theoretical and integrated perspective. Sustainability 2018, 10, 275. [Google Scholar] [CrossRef]

- van der Aalst, W.M.P.; La Rosa, M.; Santoro, F.M. Business process management: Don’t forget to improve the process! Bus. Inf. Syst. Eng. 2016, 58, 1–6. [Google Scholar] [CrossRef]

- Vos, L.; Chalmers, S.E.; Dückers, M.L.; Groenewegen, P.P.; Wagner, C.; van Merode, G.G. Towards an organisation-wide process-oriented organisation of care: A literature review. Implement. Sci. 2011, 6, 8. [Google Scholar] [CrossRef]

- Pettersen, J. Defining lean production: Some conceptual and practical issues. TQM J. 2009, 21, 127–142. [Google Scholar] [CrossRef]

- Dumas, M.; La Rosa, M.; Mendling, J.; Reijers, H.A. Fundamentals of Business Process Management, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 253–287. [Google Scholar] [CrossRef]

- van der Aalst, W. Process Mining: Data Science in Action, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 25–52. [Google Scholar] [CrossRef]

- Shiralkar, K. Just-in-Time manufacturing using cloud computing. Int. J. Eng. Technol. 2017, 3, 405–408. [Google Scholar]

- Rosário, A.T.; Dias, J.C. Sustainability and the digital transition: A literature review. Sustainability 2022, 14, 4072. [Google Scholar] [CrossRef]

- Krhač Andrašec, E. Business Process Improvement Methods and Techniques and their Impact on the Efficiency of Organizational Systems. Ph.D. Thesis, University of Maribor, Maribor, Slovenia, 1 March 2023. [Google Scholar]

- Gazi, F.; Atan, T.; Kılıç, M. The assessment of internal indicators on the balanced scorecard measures of sustainability. Sustainability 2022, 14, 8595. [Google Scholar] [CrossRef]

- Kern, T.; Urh, B.; Krhač Andrašec, E. The profitability threshold of organizational changes. In Research Trends and Sustainable Solutions in Enterprise Engineering, 1st ed.; Urh, B., Maletič, M., Eds.; University of Maribor, University Press: Maribor, Slovenia, accepted.

- Project Management Institute. A Guide to the Project Management Body of Knowledge (PMBOK®® Guide), 7th ed.; Project Management Institute: Newtown Square, PA, USA, 2021. [Google Scholar]

- Kern, T.; Urh, B. Digital transformation of multi project environment in companies and institutions. In Modern Approaches to Enterprise System Engineering, 1st. ed.; Maletič, M., Urh, B., Eds.; University of Maribor, University Press: Maribor, Slovenia, 2022; pp. 7–36. [Google Scholar] [CrossRef]

- Van Looy, A.; Shafagatova, A. Business process performance measurement: A structured literature review of indicators, measures and metrics. SpringerPlus 2016, 5, 1797. [Google Scholar] [CrossRef]

- Dumas, M.; La Rosa, M.; Mendling, J.; Reijers, H.A. Fundamentals of Business Process Management, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 297–341. [Google Scholar] [CrossRef]

- Chimhamhiwa, D.; van der Molen, P.; Mutanga, O.; Rugege, D. Towards a framework for measuring end to end performance of land administration business processes—A case study. Comput. Environ. Urban Syst. 2009, 33, 293–301. [Google Scholar] [CrossRef]

- Longo, A.; Motta, G. Design processes for sustainable performances: A model and a method. In BPM 2005: Business Process Management Workshops: Lecture Notes in Computer Science, 1st ed.; Bussler, C.J., Haller, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2006; Volume 3812, pp. 399–407. [Google Scholar] [CrossRef]

- Vernadat, F.; Shah, L.; Etienne, A.; Siadat, A. VR-PMS: A new approach for performance measurement and management of industrial systems. Int. J. Prod. Res. 2013, 51, 7420–7438. [Google Scholar] [CrossRef]

- Bhagwat, R.; Sharma, M.K. Performance measurement of supply chain management: A balanced scorecard approach. Comput. Ind. Eng. 2007, 53, 43–62. [Google Scholar] [CrossRef]

- Pourshahid, A.; Amyot, D.; Peyton, L.; Ghanavati, S.; Chen, P.; Weiss, M.; Forster, A.J. Business process management with the user requirements notation. Electron. Commer. Res. 2009, 9, 269–316. [Google Scholar] [CrossRef]

- Walsh, P. Finding key performance drivers: Some new tools. Total Qual. Manag. 1996, 7, 509–520. [Google Scholar] [CrossRef]

- Korherr, B.; List, B. Extending the EPC with Performance Measures. In Proceedings of the ‘07 ACM Symposium on Applied Computing, Seoul, Republic of Korea, 11–15 March 2007. [Google Scholar] [CrossRef]

- Kutucuoglu, K.Y.; Hamali, J.; Sharp, J.M.; Irani, Z. Enabling BPR in maintenance through a performance measurement system framework. Int. J. Flex. Manuf. Syst. 2002, 14, 33–52. [Google Scholar] [CrossRef]

- Bosilj-Vuksic, V.; Milanovic, L.; Skrinjar, R.; Indihar-Stemberger, M. Organizational Performance Measures for Business Process Management: A Performance Measurement Guideline. In Proceedings of the Tenth International Conference on Computer Modeling and Simulation, Cambridge, UK, 1–3 April 2008. [Google Scholar] [CrossRef]

- Glavan, L.M. Understanding process performance measurement systems. Bus. Syst. Res. J. 2012, 2, 25–38. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Kobu, B. Performance measures and metrics in logistics and supply chain management: A review of recent literature (1995–2004) for research and applications. Int. J. Prod. Res. 2007, 45, 2819–2840. [Google Scholar] [CrossRef]

- Mirsu, D.B. Monitoring help desk process using KPI. In Soft Computing Applications: Advances in Intelligent Systems and Computing, 1st ed.; Balas, V., Fodor, J., Várkonyi-Kóczy, A., Dombi, J., Jain, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 195, pp. 637–647. [Google Scholar] [CrossRef]

- Wu, H.Y. Constructing a strategy map for banking institutions with key performance indicators of the balanced scorecard. Eval. Program Plan. 2012, 35, 303–320. [Google Scholar] [CrossRef]

- Herzog, N.V.; Polajnar, A.; Pizmoht, P. Performance measurement in business process reengineering. Stroj. Vestn. J. Mech. Eng. 2006, 52, 210–224. [Google Scholar]

- Martinsons, M.; Davison, R.; Tse, D. The balanced scorecard: A foundation for the strategic management of information systems. Decis. Support Syst. 1999, 25, 71–88. [Google Scholar] [CrossRef]

- Urh, B.; Zajec, M.; Kern, T.; Krhač Andrašec, E. Structural indicators for business process redesign efficiency assessment. In Advances in Manufacturing II: Vol 3—Quality Engineering and Management, 1st ed.; Hamrol, A., Grabowska, M., Maletič, D., Woll, R., Eds.; Springer: Cham, Switzerland, 2019; Volume 3, pp. 16–32. [Google Scholar] [CrossRef]

- Rolón, E.; Ruiz, F.; García, F.; Piatiini, M. Applying software metrics to evaluate business process models. CLEI Electron. J. 2006, 9, 5. [Google Scholar] [CrossRef]

- Cardoso, J.; Mendling, J.; Neumann, G.; Reijers, H.A. A discourse on complexity of process models. In BPM 2006: Business Process Management Workshops: Lecture Notes in Computer Science, 1st ed.; Eder, J., Dustdar, S., Eds.; Springer: Berlin/Heidelberg, Germany, 2006; Volume 4103, pp. 117–128. [Google Scholar] [CrossRef]

- Cardoso, J. Business process control-flow complexity: Metric, evaluation, and validation. Int. J. Web Serv. Res. 2008, 5, 49–76. [Google Scholar] [CrossRef]

- Reijers, H.A.; Mendling, J. A study into the factors that influence the understandability of business process models. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 2011, 41, 449–462. [Google Scholar] [CrossRef]

- Sun, H.; Hou, H. Study on complexity metrics of business process. In Proceedings of the 3rd International Conference on Computer Science and Service System: Advances in Intelligent System Research, Bangkok, Thailand, 13–15 June 2014; Luo, X., Ed.; Atlantis Press: Dordrecht, The Netherlands, 2014; Volume 109, pp. 289–292. [Google Scholar] [CrossRef]

- Figl, K. Comprehension of procedural visual business process models—A literature review. Bus. Inf. Syst. Eng. 2017, 59, 41–67. [Google Scholar] [CrossRef]

- Urh, B. Predicting the Effectiveness of Business System from the Point of View of Managing Business Process Efficiency. Ph.D. Thesis, University of Maribor, Maribor, Slovenia, 6 March 2012. [Google Scholar]

- Davis, R. ARIS Design Platform: Advanced Process Modelling and Administration, 1st ed.; Springer: London, UK, 2008; pp. 155–186. [Google Scholar] [CrossRef]

- Franz, P.H.; Kirchmer, M.; Rosemann, M. Value-Driven Business Process Management—Which Values Matter for BPM, 1st ed.; Accenture, Queensland University of Technology (QUT): London, UK; Philadelphia, PA, USA; Brisbane, QLD, Australia, 2011. [Google Scholar]

- Schweikhart, S.A.; Dembe, A.E. The applicability of Lean and Six Sigma techniques to clinical and translational research. J. Investig. Med. 2009, 57, 748–755. [Google Scholar] [CrossRef]

- Botha, G.J.; Kruger, P.S.; De Vries, M. Enhancing customer experience through business process improvement: An application of the Enhanced Customer Experience Framework (ECEF). S. Afr. J. Ind. Eng. 2012, 23, 39–56. [Google Scholar] [CrossRef]

- Boutros, T.; Cardella, J. The Basics of Process Improvement, 1st ed.; CRC Press: New York, NY, USA, 2016; pp. 132–141. [Google Scholar] [CrossRef]

- Stoiljković, V.; Trajković, J.; Stoiljković, B. Lean Six Sigma sample analysis process in a microbiology laboratory. J. Med. Biochem. 2011, 30, 346–353. [Google Scholar] [CrossRef]

- Pinney, S.J.; Page, A.E.; Jevsevar, D.S.; Bozic, K.J. Current concept review: Quality and process improvement in orthopedics. Orthop. Res. Rev. 2015, 8, 1–11. [Google Scholar] [CrossRef]

- Schuller, B.W.; Burns, A.; Ceilley, E.A.; King, A.; LeTourneau, J.; Markovic, A.; Sterkel, L.; Taplin, B.; Wanner, J.; Albert, J.M. Failure mode and effects analysis: A community practice perspective. J. Appl. Clin. Med. Phys. 2017, 18, 258–267. [Google Scholar] [CrossRef]

- Amjad, A.; Azam, F.; Anwar, M.W.; Butt, W.H.; Rashid, M. Event-driven process chain for modeling and verification of business requirements—A systematic literature review. IEEE Access 2018, 6, 9027–9048. [Google Scholar] [CrossRef]

- Valiris, G.; Glykas, M. Business analysis metrics for business process redesign. Bus. Process Manag. J. 2004, 10, 445–480. [Google Scholar] [CrossRef]

- Structural Business Statistics Overview. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Structural_business_statistics_overview#Size_class_analysis (accessed on 12 January 2021).

- Sectoral Share of the Number of Enterprises within the Non-Financial Business Economy, EU. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=File:Sectoral_share_of_the_number_of_enterprises_within_the_non-financial_business_economy,_EU,_2018.png (accessed on 12 January 2021).

- Analysis of Non-Financial Business Economy Value Added and Employment, EU. 2018. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=File:Analysis_of_non-financial_business_economy_value_added_and_employment,_EU,_2018_FP18.png (accessed on 12 January 2021).

- Value Added, 2017 (Billion EUR). Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=File:T1_Value_added,_2017_(billion_EUR)_FP18.png#file (accessed on 12 January 2021).

- Annual Enterprise Statistics for Special Aggregates of Activities (NACE Rev. 2). Available online: https://ec.europa.eu/eurostat/databrowser/view/SBS_NA_SCA_R2__custom_1524839/default/table?lang=en (accessed on 12 January 2021).

- Jové-Llopis, E.; Segarra-Blasco, A. Eco-efficiency actions and firm growth in European SMEs. Sustainability 2018, 10, 281. [Google Scholar] [CrossRef]

- 1ka. Available online: https://www.1ka.si/ (accessed on 9 February 2021).

- Sivo, S.A.; Saunders, C.; Chang, Q.; Jiang, J.J. How low should you go? Low response rates and the validity of inference in IS questionnaire research. J. Assoc. Inf. Syst. 2006, 7, 351–414. [Google Scholar] [CrossRef]

- Baruch, Y.; Holtom, B.C. Survey response rate levels and trends in organizational research. Hum. Relat. 2008, 61, 1139–1160. [Google Scholar] [CrossRef]

- Morton, S.M.B.; Bandara, D.K.; Robinson, E.M.; Atatoa Carr, P.E. In the 21st century, what is an acceptable response rate? Aust. N. Z. J. Public Health 2012, 36, 106–108. [Google Scholar] [CrossRef]

- Sample Size Calculator. Available online: http://www.raosoft.com/samplesize.html (accessed on 18 August 2021).

- Sekaran, U. Research Methods for Business: A Skill-Building Approach, 4th ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Bohorquez, S.J.; Van den Berg, P.; Akkerman, J.; Mestach, D.; Van Loon, S.; Repp, J. High-throughput paint optimization by use of a pigment-dispersing polymer. Surf. Coat. Int. 2015, 98, 85–89. [Google Scholar]

- Langille, M.; Izmitli, A.; Lan, T.; Agrawal, A.; Liu, C.; Henderson, K.; Lu, Y. Balancing performance of slip/mar additives using a high throughput approach. Coatingstech 2018, 15, 52–56. [Google Scholar]

- Judson, R.; Richard, A.; Dix, D.J.; Houck, K.; Martin, M.; Kavlock, R.; Dellarco, V.; Henry, T.; Holderman, T.; Sayre, P.; et al. The toxicity data landscape for environmental chemicals. Environ. Health Perspect. 2009, 117, 685–695. [Google Scholar] [CrossRef]

- Dionisio, K.L.; Frame, A.M.; Goldsmith, M.R.; Wambaugh, J.F.; Liddell, A.; Cathey, T.; Smith, D.; Vail, J.; Ernstoff, A.S.; Fantke, P.; et al. Exploring consumer exposure pathways and patterns of use for chemicals in the environment. Toxicol. Rep. 2015, 2, 228–237. [Google Scholar] [CrossRef]

- Dionisio, K.L.; Phillips, K.; Price, P.S.; Grulke, C.M.; Williams, A.; Biryol, D.; Hong, T.; Isaacs, K.K. The chemical and products database, a resource for exposure-relevant data on chemicals in consumer products. Sci. Data 2018, 5, 180125. [Google Scholar] [CrossRef]

- Askham, C.; Gade, A.L.; Hanssen, O.J. Linking chemical risk information with life cycle assessment in product development. J. Clean. Prod. 2013, 51, 196–204. [Google Scholar] [CrossRef]

- Kern, T.; Krhač Andrašec, E.; Senegačnik, M.; Urh, B. Digitalizing the paints and coatings development process. Processes 2019, 7, 539. [Google Scholar] [CrossRef]

- Bokolo, A.J.; Mazlina, A.M.; Awanis, R. A proposed model for green practice adoption and implementation in information technology based organizations. Probl. Sustain. Dev. 2018, 13, 95–112. [Google Scholar]

- Bait, S.; Di Pietro, A.; Schiraldi, M.M. Waste reduction in production processes through simulation and VSM. Sustainability 2020, 12, 3291. [Google Scholar] [CrossRef]

- Camodeca, R.; Almici, A. Digital Transformation and Convergence toward the 2030 Agenda’s Sustainability Development Goals: Evidence from Italian Listed Firms. Sustainability 2021, 13, 11831. [Google Scholar] [CrossRef]

- Elektronik Informationstechnik in DIN und VDE, German Standardization Roadmap, Industrie 4.0. Available online: https://www.din.de/blob/65354/57218767bd6da1927b181b9f2a0d5b39/roadmap-i4-0-e-data.pdf (accessed on 30 November 2018).

- ALLCHEMIST®. Available online: https://www.allchemist.net/ (accessed on 7 November 2019).

- Urh, B.; Senegačnik, M.; Kern, T.; Krhač Andrašec, E. Reducing laboratory test waste in the coating development process. Pol. J. Environ. Stud. 2020, 29, 3841–3851. [Google Scholar] [CrossRef]

- Kern, T.; Krhač Andrašec, E.; Urh, B.; Senegačnik, M. Digital transformation reduces costs of the paints and coatings development process. Coatings 2020, 10, 703. [Google Scholar] [CrossRef]

- Binomial Test—Simple Tutorial. Available online: https://www.spss-tutorials.com/binomial-test/ (accessed on 10 September 2021).

- Jesenko, J. Statistika v Organizaciji in Managementu, 1st ed.; Moderna Organizacija: Kranj, Slovenia, 2001. [Google Scholar]

- Binomial Test and 95% Confidence Interval (CI) Using SPSS Statistics. Available online: https://statistics.laerd.com/spss-tutorials/binomial-test-using-spss-statistics.php (accessed on 10 September 2021).

- Hoffman, K.A.; Green, C.A.; Ford, J.H., II; Wisdom, J.P.; Gustafson, D.H.; McCarty, D. Improving quality of care in substance abuse treatment using five key process improvement principles. J. Behav. Health Serv. Res. 2012, 39, 234–244. [Google Scholar] [CrossRef]

- Griesberger, P.; Leist, S.; Zellner, G. Analysis of Techniques for Business Process Improvement. In Proceedings of the 19th European Conference on Information Systems (ECIS 2011), Helsinki, Finland, 9–11 June 2011; Available online: https://aisel.aisnet.org/ecis2011/20 (accessed on 17 December 2020).

- Zahar Djordjevic, M.; Djordjevic, A.; Klochkova, E.; Misic, M. Application of modern digital systems and approaches to business process management. Sustainability 2022, 14, 1697. [Google Scholar] [CrossRef]

- Urh, B.; Zajec, M. Connectedness of structural and operational business processes efficiency. Uporab. Inform. 2016, 24, 178–190. [Google Scholar]

- Micheli, G.J.L.; Cagno, E.; Tappia, E. Improving eco-efficiency through waste reduction beyond the boundaries of a firm: Evidence from a multiplant case in the ceramic industry. Sustainability 2018, 10, 167. [Google Scholar] [CrossRef]

- Novak, R.; Janeš, A. Merjenje Zrelosti Procesne Usmerjenosti, 1st ed.; University of Primorska Press: Koper, Slovenia, 2007. [Google Scholar]

- Digital Business Maturity Model: 9 Essential Competencies to Assess Digital Business Maturity. Available online: www.gartner.com/en/documents/3983264 (accessed on 8 March 2023).

- Paullada, A.; Raji, I.D.; Bender, E.M.; Denton, E.; Hanna, A. Data and its (dis)contents: A survey of dataset development and use in machine learning research. Patterns 2021, 2, 100336. [Google Scholar] [CrossRef]

| Country | Six Business Areas (Medium Enterprises) | Six Business Areas (Large Enterprises) | Medium Enterprises | Large Enterprises | Percentage Covered Medium Enterprises | Percentage Covered Large Enterprises |

|---|---|---|---|---|---|---|

| Slovenia | 1001 | 188 | 1182 | 233 | 84.69% | 80.69% |

| Croatia | 1525 | 329 | 1861 | 416 | 81.95% | 79.09% |

| Germany | 46,031 | 8715 | 61,634 | 12,139 | 74.68% | 71.79% |

| Sweden | 4466 | 779 | 5527 | 1031 | 80.80% | 75.56% |

| Country | Medium Enterprises | Large Enterprises | Material Enterprises | Non-Material Enterprises |

|---|---|---|---|---|

| Slovenia | 24 | 6 | 16 | 14 |

| Croatia | 24 | 6 | 13 | 17 |

| Germany | 25 | 5 | 12 | 18 |

| Sweden | 27 | 3 | 9 | 21 |

| Country | Total Number of Enterprises | Response Rate |

|---|---|---|

| Slovenia | 879 | 14.7% |

| Croatia | 503 | 12.1% |

| Germany | 797 | 2.3% |

| Sweden | 633 | 0.8% |

| Total | 2812 | 7.6% |

| Methods/ Techniques | The Number of Activities | The Number of Employees (Positions) | The Number of Documents | The Number of Decision | The Percentage of Activities Supported by Information Technology |

|---|---|---|---|---|---|

| Methods (123) 1 | <0.001 | 0.007 | <0.001 | <0.001 | <0.001 |

| Techniques (41) | 0.004 | 0.270 | 0.270 | 0.013 | <0.001 |

| Benchmarking (32) | <0.001 | 0.070 | 0.025 | 0.025 | 0.007 |

| Brainstorming (47) | 0.012 | 0.478 | 0.012 | 0.012 | 0.135 |

| P. Mapping/ P. Modeling (17) | 0.050 | 0.164 | 0.164 | 0.008 | 0.050 |

| 5S (14) | 0.018 | 0.018 | 0.101 | 0.018 | 0.018 |

| FMEA (11) | 0.197 | 0.455 | 0.455 | 0.197 | 0.197 |

| Methods/ Techniques | The Process Execution Time | The Process Execution Cost | The Quality of Process Execution | The Flexibility of Process Execution |

|---|---|---|---|---|

| Methods (123) | <0.001 | <0.001 | <0.001 | <0.001 |

| Techniques (41) | <0.001 | <0.001 | <0.001 | 0.004 |

| Benchmarking (32) | <0.001 | 0.001 | <0.001 | 0.001 |

| Brainstorming (47) | 0.004 | 0.032 | <0.001 | 0.004 |

| P. Mapping/ P. Modeling (17) | 0.008 | 0.008 | 0.008 | 0.008 |

| 5S (14) | 0.018 | 0.281 | 0.018 | 0.101 |

| FMEA (11) | 0.042 | 0.042 | 0.042 | 0.197 |

| Methods/ Techniques | The Number of Activities | The Number of Employees (Positions) | The Number of Documents | The Number of Decision | The Percentage of Activities Supported by Information Technology |

|---|---|---|---|---|---|

| Methods | <0.001 (117) | 0.003 (104) | <0.001 (112) | <0.001 (115) | <0.001 (112) |

| Techniques | 0.077 (38) | 0.006 (33) | <0.001 (33) | 0.015 (37) | <0.001 (39) |

| Benchmarking | 0.080 (32) | 0.031 (28) | 0.012 (29) | 0.004 (29) | <0.001 (30) |

| Brainstorming | <0.001 (42) | 0.076 (35) | <0.001 (42) | 0.005 (42) | <0.001 (39) |

| P. Mapping/ P. Modeling | 0.180 (16) | 0.136 (15) | 0.064 (15) | 0.276 (17) | 0.002 (16) |

| 5S | 0.037 (14) | 0.146 (14) | 0.003 (13) | 0.108 (14) | 0.002 (14) |

| FMEA | 0.283 (10) | 0.008 (9) | 0.004 (8) | 0.015 (10) | 0.013 (10) |

| Methods/ Techniques | The Process Execution Time | The Process Execution Cost | The Quality of Process Execution | The Flexibility of Process Execution |

|---|---|---|---|---|

| Methods | <0.001 (119) | <0.001 (114) | <0.001 (120) | <0.001 (117) |

| Techniques | <0.001 (40) | 0.001 (39) | <0.001 (41) | 0.007 (38) |

| Benchmarking | <0.001 (32) | 0.045 (31) | <0.001 (32) | <0.001 (31) |

| Brainstorming | <0.001 (43) | <0.001 (41) | <0.001 (44) | <0.001 (43) |

| P. Mapping/ P. Modeling | <0.001 (17) | 0.010 (17) | <0.001 (17) | 0.054 (17) |

| 5S | 0.002 (14) | 0.007 (12) | 0.005 (14) | 0.016 (13) |

| FMEA | 0.012 (11) | 0.003 (11) | <0.001 (11) | 0.019 (10) |

| New Product Development Process (Without ICT Support or with ICT Support and a Local Database) | |

|---|---|

| ## | Process Activity |

| 10 | Creating a new product idea |

| 20 | Market analysis of existing products |

| 30 | Searching for suitable binders |

| 40 | Study of binders’ properties |

| 50 | Searching for pigments |

| 60 | Searching for additives |

| 70 | Searching for solvents |

| 80 | Searching for fillers |

| 90 | Formulation of (modified) formulations |

| 100 | Ordering samples |

| 110 | Product laboratory testing |

| 120 | Product parameter measurement |

| 130 | Product hazard identification |

| 140 | Product price calculating |

| 150 | Internal validation |

| 160 | External validation |

| 170 | Preparation of documentation draft |

| 180 | Creating documentation |

| New Product Development Process (with ICT Support and a Cloud-Based Database) | |||

|---|---|---|---|

| ## | Process Activity | ## 2 | ICT |

| 10 | Creating a new product idea | 10 | ✓ 4 |

| 20 | Market analysis of existing products | 20 | |

| 30 | Searching for suitable binders | 30 | ✓ |

| 40 | Study of binders’ properties | ✕ 3 | |

| 50 | Searching for pigments | 50⇨40 | ✓ |

| 0 | Searching for additives | 60⇨50 | ✓ |

| 70 | Searching for solvents | 70⇨60 | ✓ |

| 80 | Searching for fillers | 80⇨70 | ✓ |

| 90 | Formulation of (modified) formulations | 90⇨80 | ✓ |

| 100 | Ordering samples | 100⇨130 | ✓ |

| 110 | Product laboratory testing | 110⇨140 | |

| 120 | Product parameter measurement (calculation) 1 | 120⇨90 | ✓ |

| 130 | Product hazard identification | 130⇨100 | ✓ |

| 140 | Product price calculating | 140⇨110 | ✓ |

| 150 | Internal validation | 150 | |

| 160 | External validation | 160 | |

| 170 | Preparation of documentation draft | ✕ 3 | |

| 180 | Creating documentation | 180⇨120 | ✓ |

| Dimensions of Competitive Advantage | Total for One Successful Product Development | Process | Waste (kg) | Process Throughput Time (h) | Process Execution Cost (EUR ) | Number of Process Variants |

|---|---|---|---|---|---|---|

| AS-IS | 470.55 | 3853.46 | 50,326.83 | 2 | ||

| TO-BE | 57.33 | 2018.82 | 25,716.45 | 1 | ||

| Quality | Waste reduction (%) | 87.82% | ||||

| Time | Throughput time reduction (%): | 47.61% | ||||

| Cost | Cost reduction (%) | 48% | ||||

| Flexibility | Reduction in number of process variants (%) | −50% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krhač Andrašec, E.; Kern, T.; Urh, B. An Innovative Approach to Organizational Changes for Sustainable Processes: A Case Study on Waste Minimization. Sustainability 2023, 15, 15706. https://doi.org/10.3390/su152215706

Krhač Andrašec E, Kern T, Urh B. An Innovative Approach to Organizational Changes for Sustainable Processes: A Case Study on Waste Minimization. Sustainability. 2023; 15(22):15706. https://doi.org/10.3390/su152215706

Chicago/Turabian StyleKrhač Andrašec, Eva, Tomaž Kern, and Benjamin Urh. 2023. "An Innovative Approach to Organizational Changes for Sustainable Processes: A Case Study on Waste Minimization" Sustainability 15, no. 22: 15706. https://doi.org/10.3390/su152215706

APA StyleKrhač Andrašec, E., Kern, T., & Urh, B. (2023). An Innovative Approach to Organizational Changes for Sustainable Processes: A Case Study on Waste Minimization. Sustainability, 15(22), 15706. https://doi.org/10.3390/su152215706