Mechanical and Thermal Properties of Sustainable Low-Heat High-Performance Concrete

Abstract

:1. Introduction

2. Experimental Program

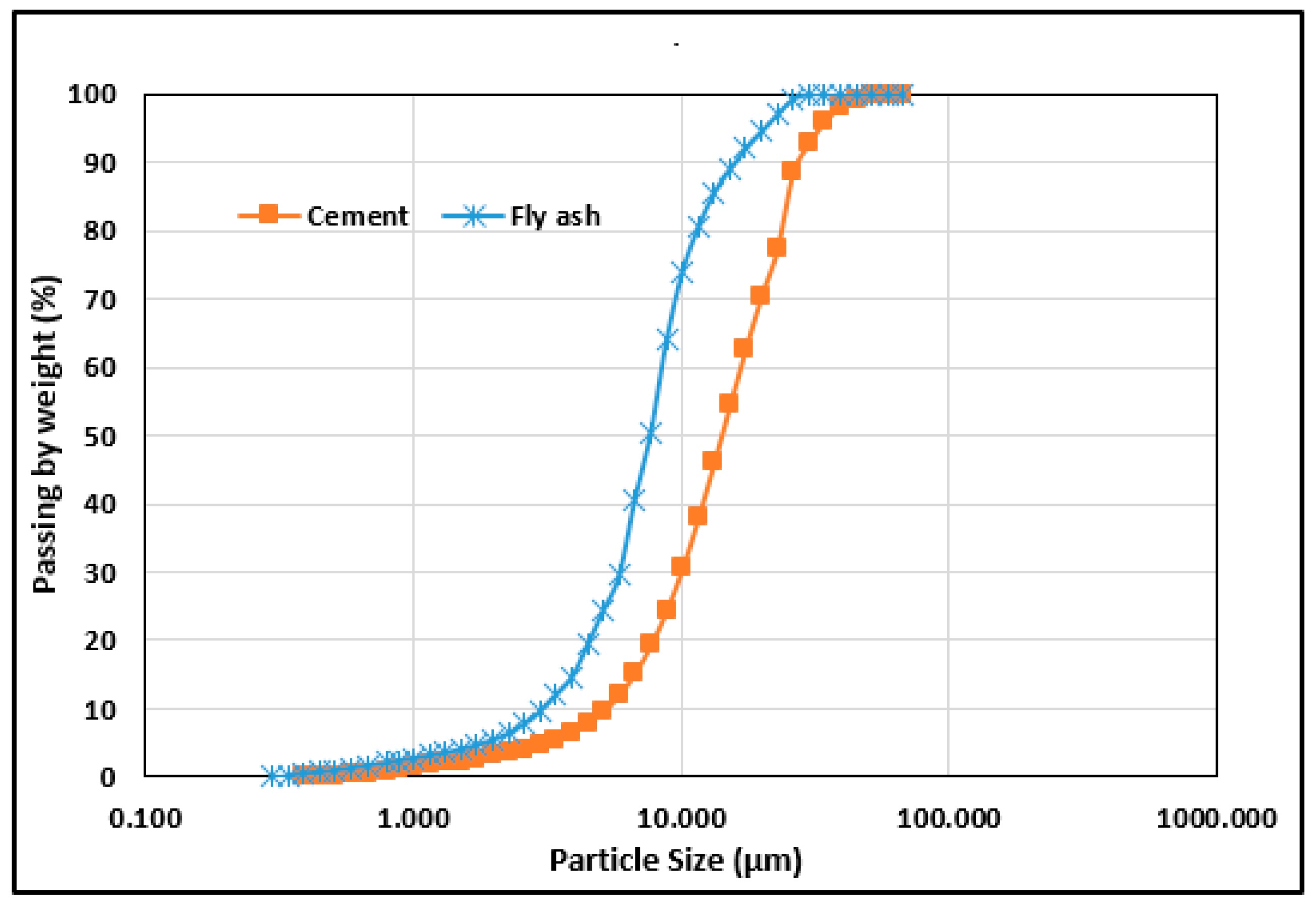

2.1. Materials

2.2. Mix Proportions

2.3. Casting and Curing of Concrete Specimens

2.4. Methodology

3. Results and Discussion

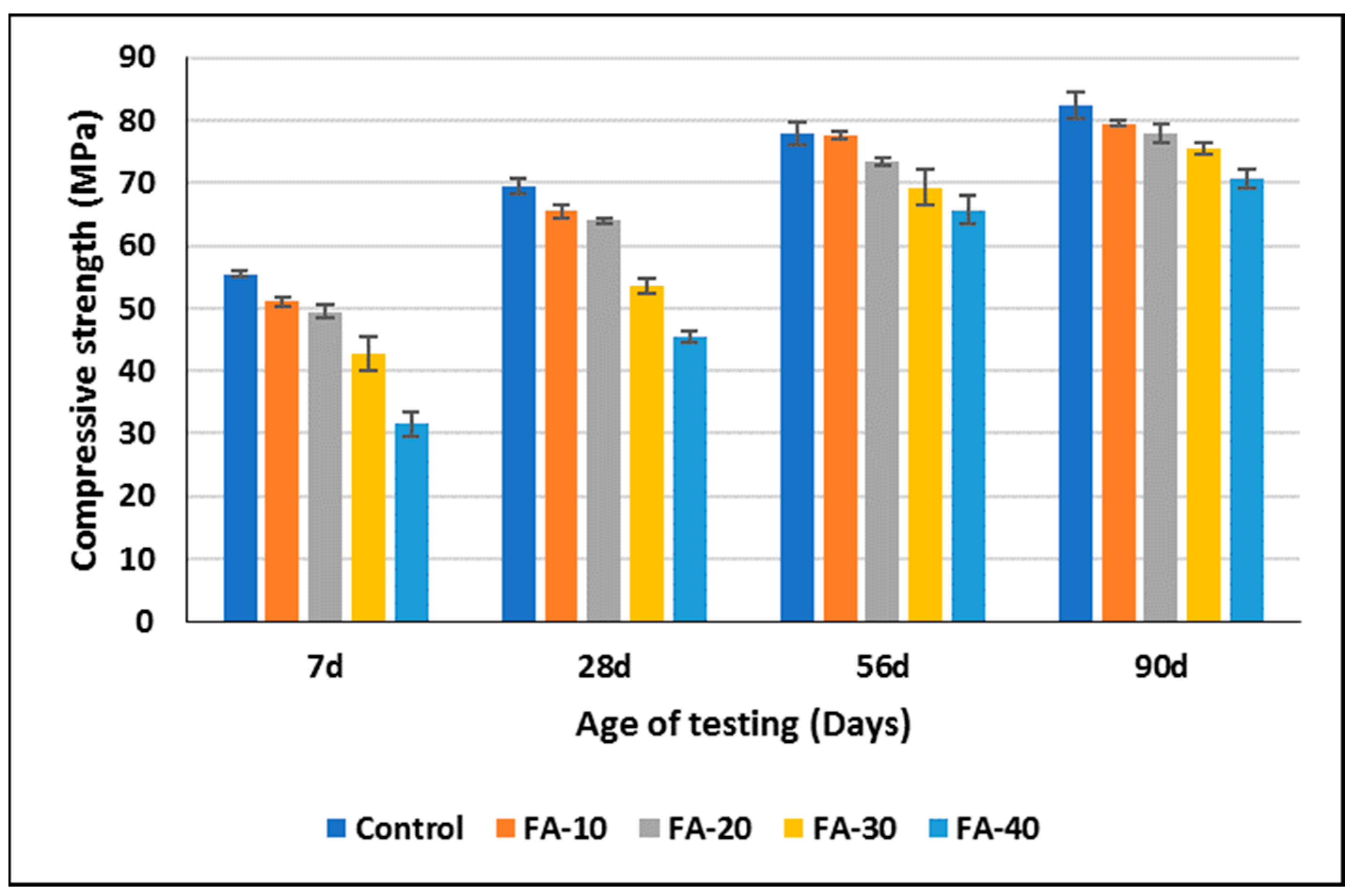

3.1. Compressive Strength

3.2. Tensile Strength

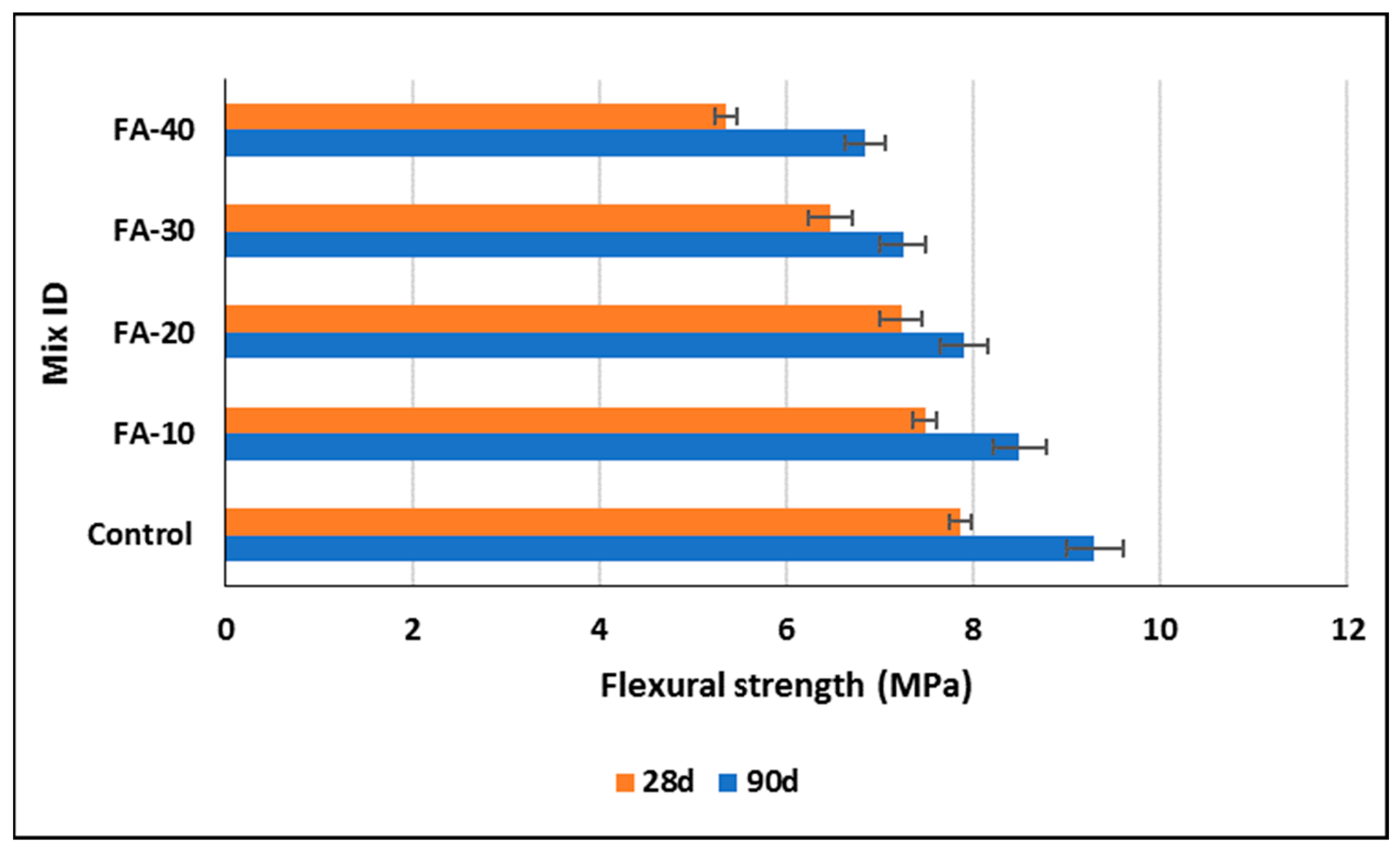

3.3. Flexural Strength

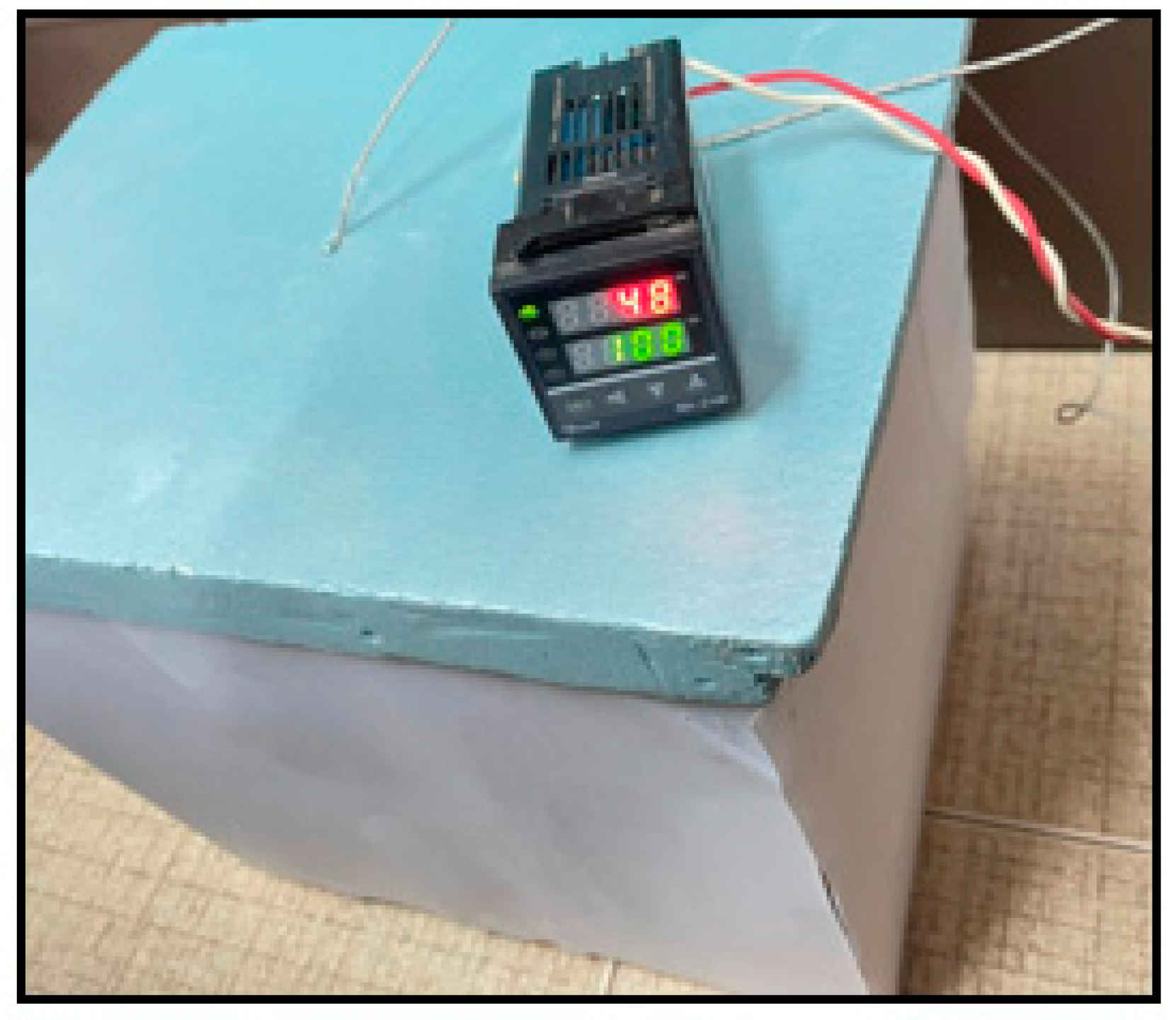

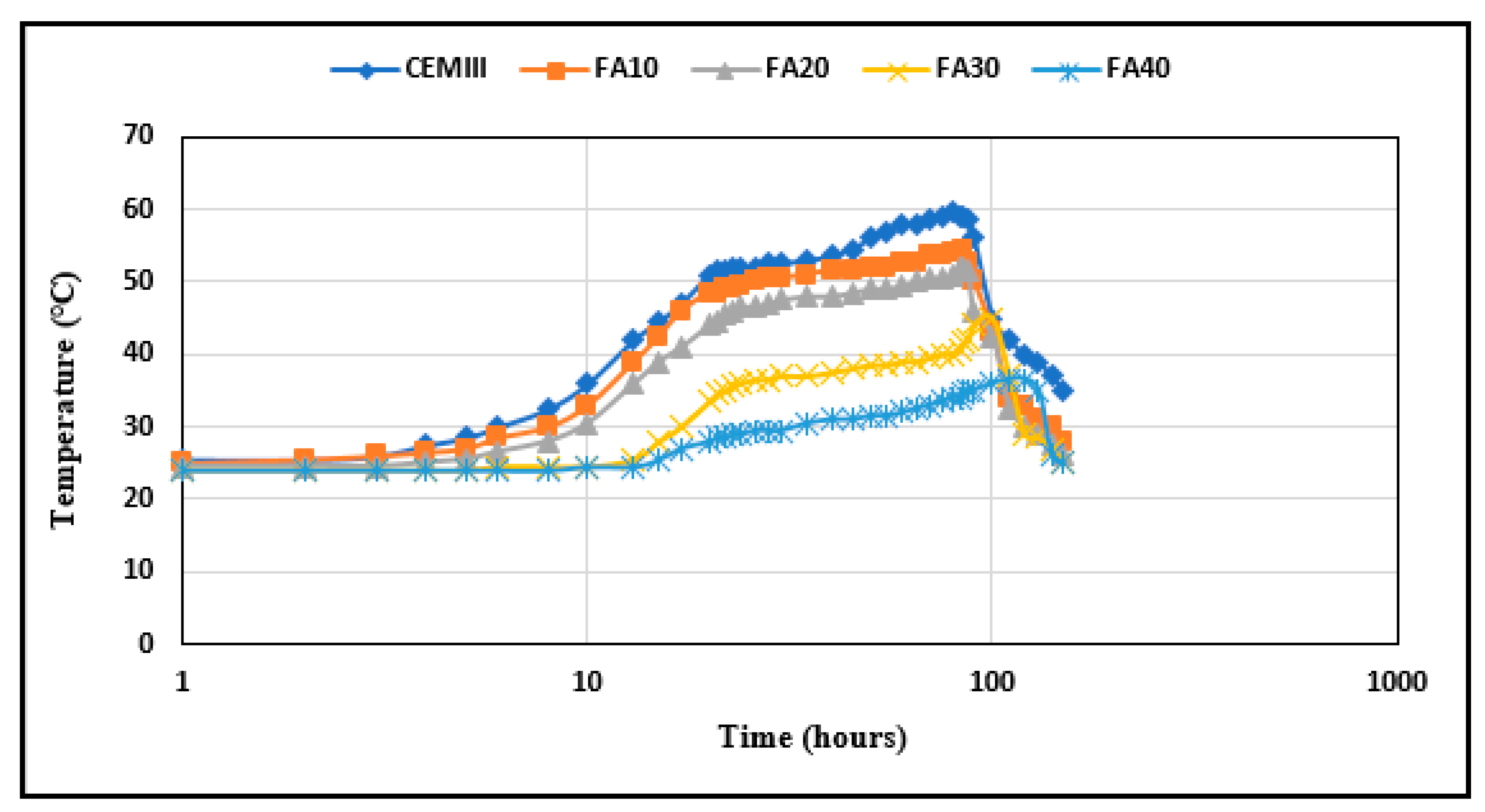

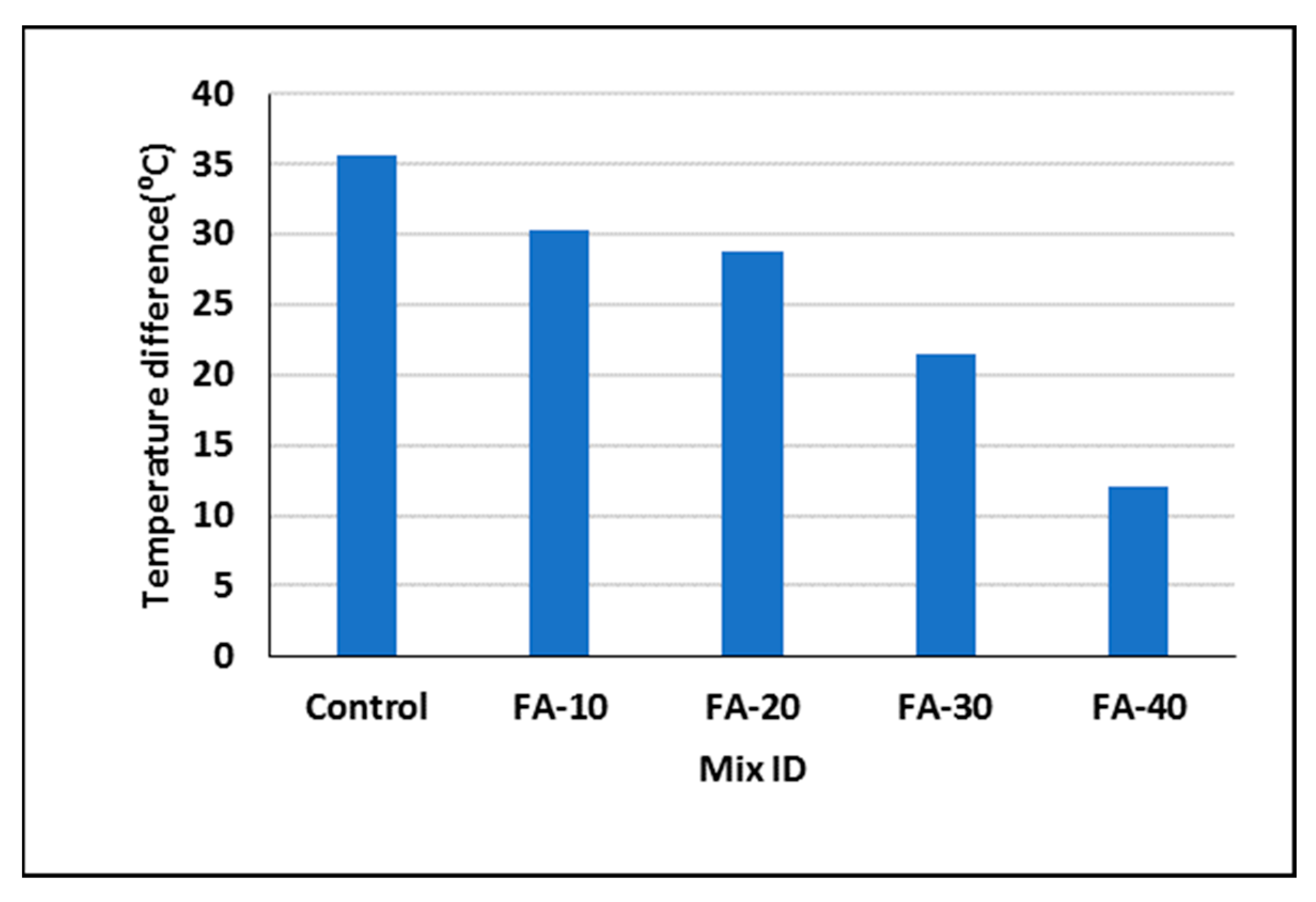

3.4. Hydration Heat

3.5. Thermal Conductivity and Specific Heat

3.6. Microstructural Analyses

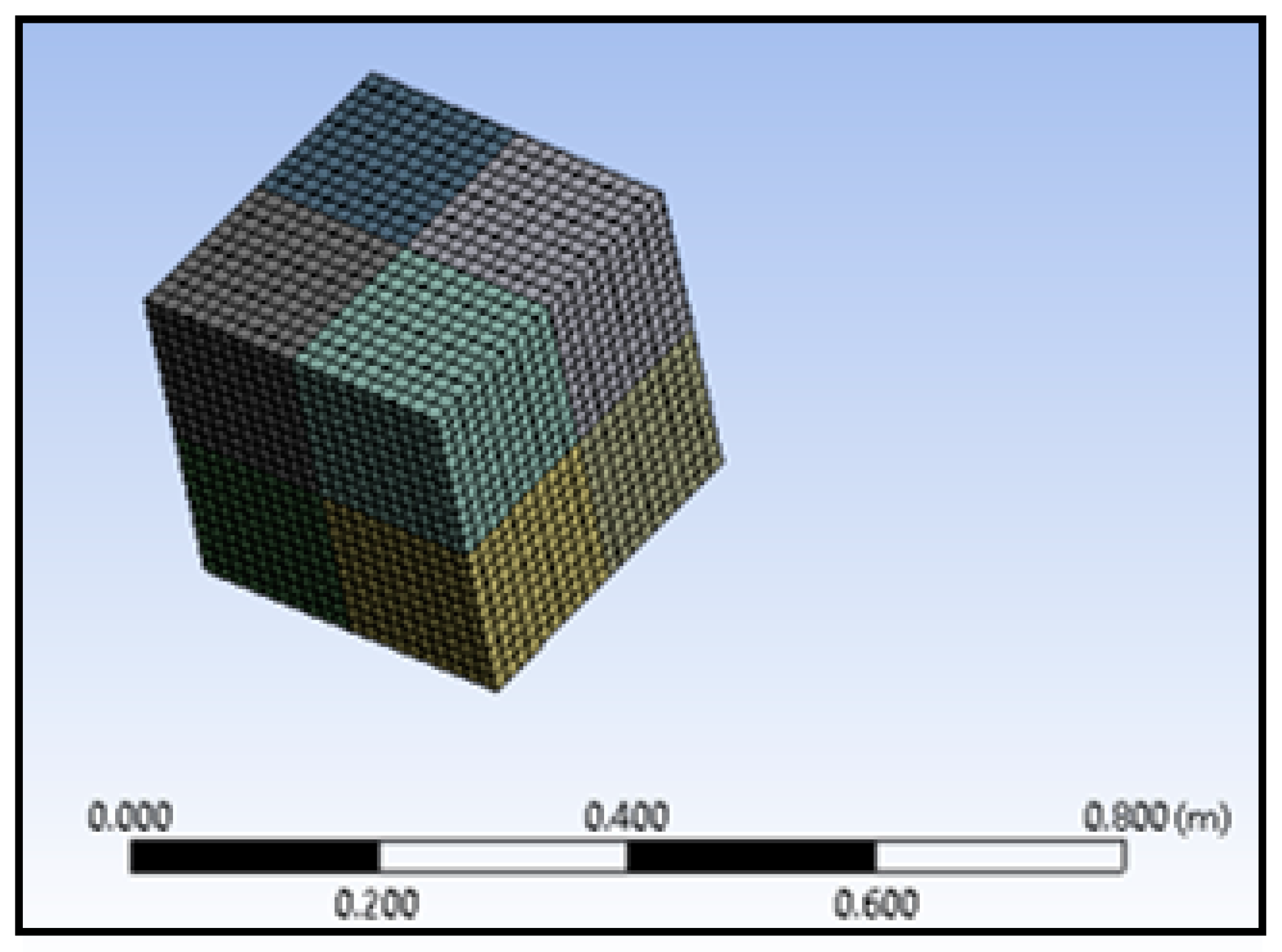

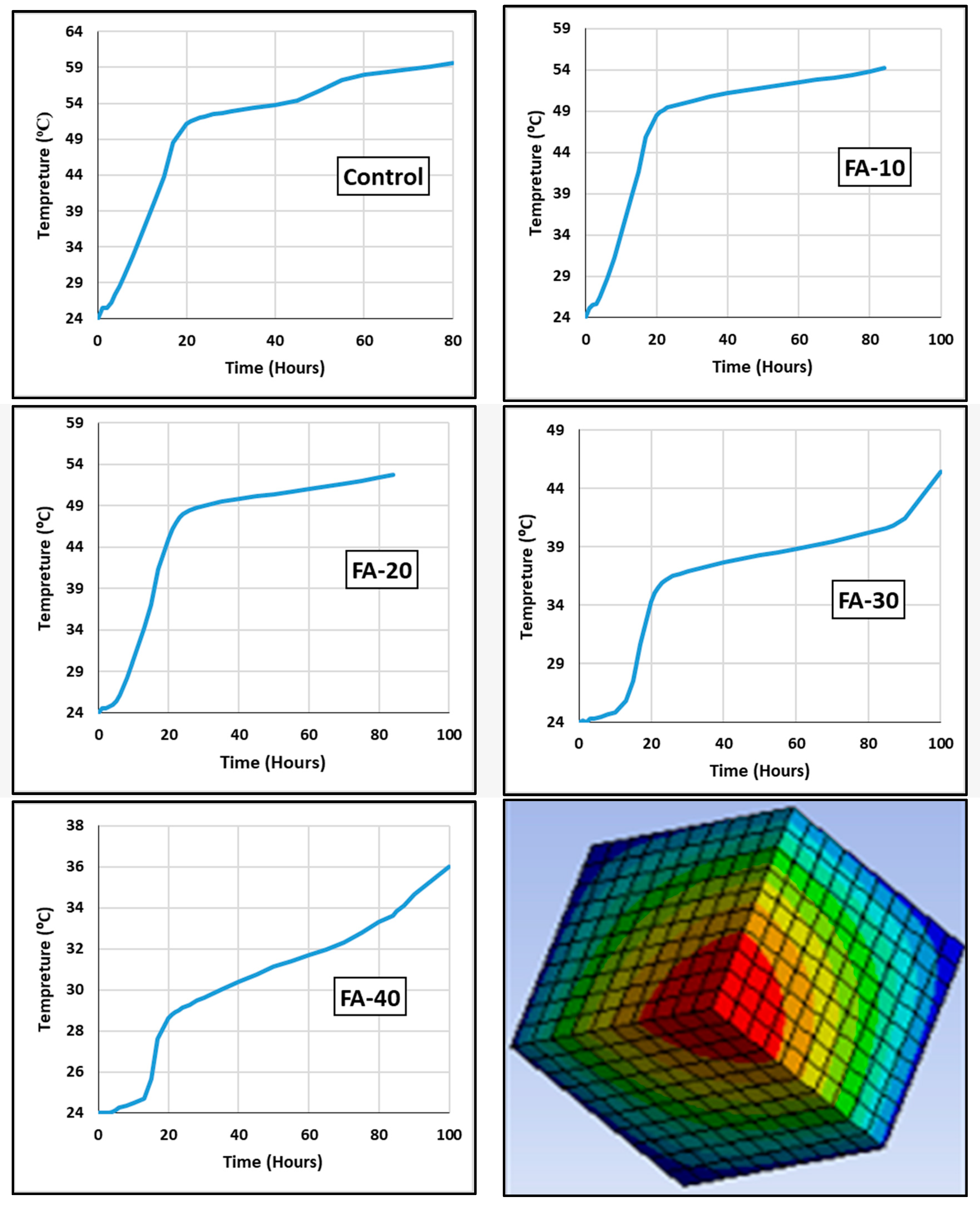

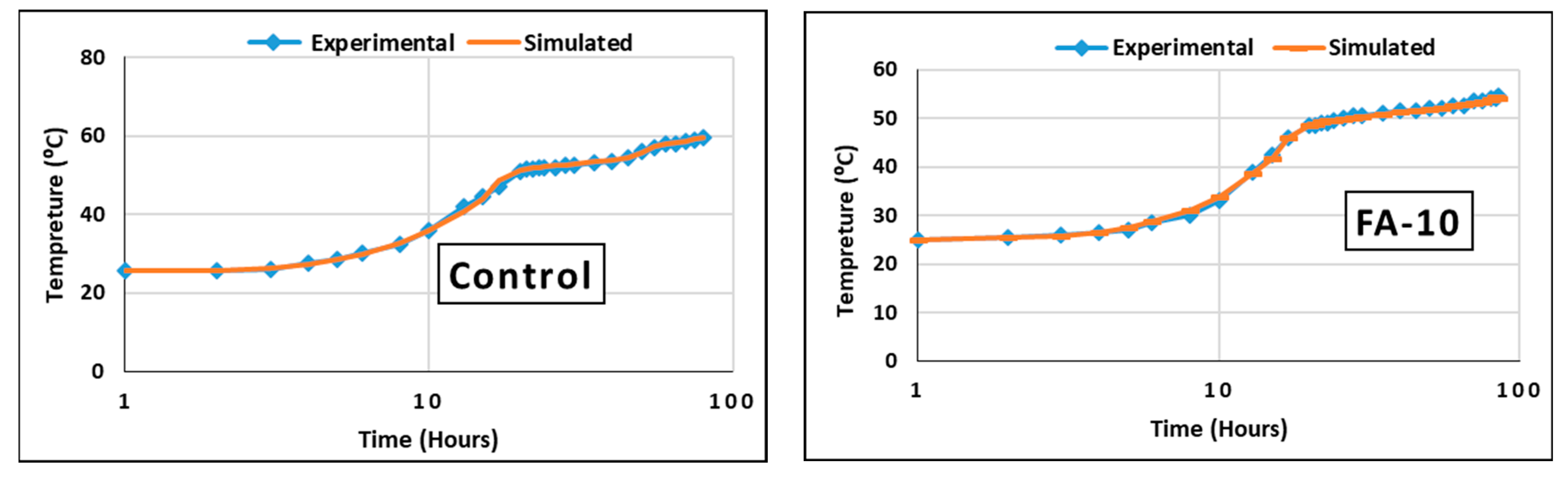

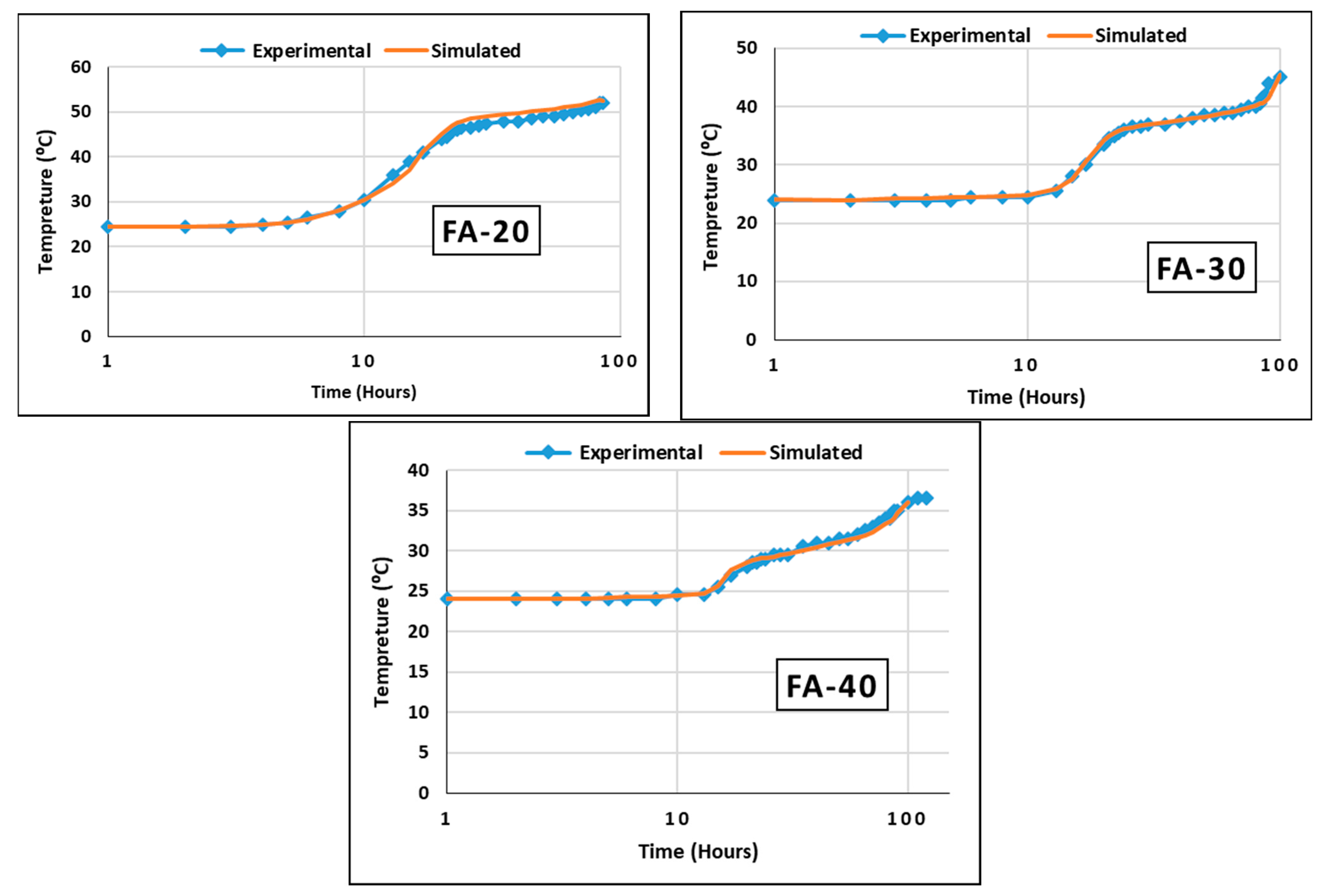

3.7. Results of the Numerical Study

4. Conclusions

- The concrete’s sustainability was enhanced when 40% of the cement weight was replaced by FA. The improvement of sustainability while attaining the appropriate strength and low hydration temperature remained the primary objective.

- The mechanical properties of LHHPC containing 40% FA at 90 days were similar to those of the control mix at 28 days.

- At 90 days, the LHHPC mix containing 40% FA showed fewer pores and thermal cracks than that of the control mix, as was evidenced by the microstructure investigations (SEM and XRD).

- By using LHHPC with the optimum thermal characteristics, concrete with low heat, high thermal conductivity, and low thermal expansion was produced. This lowers the ensuing stresses and the risk of cracking occurrence.

- The proposed 3D FEM provided good predictions of temperature distribution compared with the experimental results.

- The results of this research introduce the ideal FA content that can ensure durable and sustainable LHHPC for mass concrete production.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lyu, X.; Elchalakani, M.; Ahmed, T.; Sadakkathulla, M.A.; Youssf, O. Residual strength of steel fibre reinforced rubberised UHPC under elevated temperatures. J. Build. Eng. 2023, 76, 107173. [Google Scholar] [CrossRef]

- Chakraborty, D.; Awolusi, I.; Gutierrez, L. An explainable machine learning model to predict and elucidate the compressive behavior of high-performance concrete. Results Eng. 2021, 11, 100245. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Ellatief, M.A.; Heneigel, A.M.; Abd Elrahman, M. Characteristics of eco-friendly ultra-high-performance geopolymer concrete incorporating waste materials. Ceram. Int. 2022, 48, 19662–19674. [Google Scholar] [CrossRef]

- Korolev, A.S.; Kopp, A.; Odnoburcev, D.; Loskov, V.; Shimanovsky, P.; Koroleva, Y.; Vatin, N.I. Compressive and Tensile Elastic Properties of Concrete: Empirical Factors in Span Reinforced Structures Design. Materials 2021, 14, 7578. [Google Scholar] [CrossRef]

- American Concrete Institute. AACI 207.1R-05 “Guide to Mass Concrete”; ACI Committee 207; American Concrete Institute: Farmington Hills, MI, USA, 2005. [Google Scholar]

- Nguyen, C.T.; Luu, X.B. Reducing temperature difference in mass concrete by surface insulation. Mag. Civ. Eng. 2019, 4, 70–79. [Google Scholar]

- Jebli, M.; Jamin, F.; Pelissou, C.; Lhopital, E.; El Youssoufi, M.S. Characterization of the expansion due to the delayed ettringite formation at the cement paste-aggregate interface. Constr. Build. Mater. 2021, 289, 122979. [Google Scholar] [CrossRef]

- Luo, F.; Jin, Y. Comparison of the Properties of Coal Gasification Fly Ash and Pulverized Coal Fly Ash as Supplementary Cementitious Materials. Sustainability 2023, 15, 14960. [Google Scholar] [CrossRef]

- Bushmanova, A.V.; Semenov, K.V.; Struchkova, A.Y.; Manovitsky, S.S. Thermal cracking resistance in massive foundation slabs in the building period. Mag. Civ. Eng. 2017, 76, 193–200. [Google Scholar]

- Bushmanova, A.V.; Videnkov, N.V.; Semenov, K.V.; Dernakova, A.V.; Korovina, V.K. The thermo-stressed state in massive concrete structures. Mag. Civ. Eng. 2017, 28, 51–60. [Google Scholar]

- Grey, D.M. Presentation Low Heat High Performance Concrete; NRC Research Press: Ottawa, ON, Canada, 1996. [Google Scholar]

- Breton, D. Low-Heat High-Performance Concrete. U.S. Patent 5,531,823, 6 February 1995. [Google Scholar]

- Jawara, A. Low Heat High Performance Concrete for Glass Fiber Reinforced Polymer Reinforcement. Master’s Thesis, Department of Civil Engineering, University of Manitoba, Winnipeg, MB, Canada, 1999. [Google Scholar]

- Kigha, F.; Sadeeq, J.A.; Abejide, O.S. Effects of temperature levels and concrete cover thickness on residual strength characteristics of fire exposed reinforced concrete beams. Niger. J. Technol. 2015, 34, 429–437. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Fouda, R.M.; Elrahman, M.A.; Youssf, O. Long-Term Performance of Concrete Made with Different Types of Cement under Severe Sulfate Exposure. Materials 2022, 16, 240. [Google Scholar] [CrossRef] [PubMed]

- Bonnet, J.; Mosser-Ruck, R.; Sterpenich, J.; Bourdelle, F.; Verron, H.; Michau, N.; Bourbon, X.; Linard, Y. Chemical and mineralogical characterizations of a low-pH cementitious material designed for the disposal cell of the high-level radioactive waste (HLW). Cem. Concr. Res. 2022, 162, 107013. [Google Scholar] [CrossRef]

- Cuesta, A.; Ayuela, A.; Aranda, M.A.G. Belite cements and their activation. Cem. Concr. Res. 2021, 140, 106319. [Google Scholar] [CrossRef]

- Zongshou, L.; Weihong, X.; Wei, C. Cementitious Materials Science: Theories and Applications; Walter de Gruyter GmbH & Co. KG: Berlin, Germany, 2019. [Google Scholar]

- Mohammed, S.; Safiullah, O. Optimization of the SO3 content of an Algerian Portland cement: Study on the effect of various amounts of gypsum on cement properties. Constr. Build. Mater. 2018, 164, 362–370. [Google Scholar] [CrossRef]

- Horkoss, S.; Escadeillas, G.; Rizk, T.; Lteif, R. The effect of the source of cement SO3 on the expansion of mortars. Case Stud. Constr. Mater. 2016, 4, 62–72. [Google Scholar]

- Helmy, S.H.; Tahwia, A.M.; Mahdy, M.G.; Elrahman, M.A.; Abed, M.A.; Youssf, O. The Use of Recycled Tire Rubber, Crushed Glass, and Crushed Clay Brick in Lightweight Concrete Production: A Review. Sustainability 2023, 15, 10060. [Google Scholar] [CrossRef]

- El-Mir, A.; Nehme, S.G.; Assaad, J.J. Effect of binder content and sand type on mechanical characteristics of ultra-high performance concrete. Arab. J. Sci. Eng. 2022, 47, 13021–13034. [Google Scholar] [CrossRef]

- Arshad, S.; Sharif, M.B.; Irfan-ul-Hassan, M.; Khan, M.; Zhang, J.-L. Efficiency of supplementary cementitious materials and natural fiber on mechanical performance of concrete. Arab. J. Sci. Eng. 2020, 45, 8577–8589. [Google Scholar] [CrossRef]

- Saridemir, M.; Severcan, M.H.; Ciflikli, M.; Celikten, S.; Ozcan, F.; Atis, C.D. The influence of elevated temperature on strength and microstructure of high strength concrete containing ground pumice and metakaolin. Constr. Build. Mater. 2016, 124, 244–257. [Google Scholar] [CrossRef]

- Arrigoni, A.; Panesar, D.K.; Duhamel, M.; Opher, T.; Saxe, S.; Posen, I.D.; MacLean, H.L. Life cycle greenhouse gas emissions of concrete containing supplementary cementitious materials: Cut-off vs. substitution. J. Clean. Prod. 2020, 263, 121465. [Google Scholar] [CrossRef]

- Alanazi, H.; Hu, J.; Kim, Y.-R. Effect of slag, silica fume, and metakaolin on properties and performance of alkali-activated fly ash cured at ambient temperature. Constr. Build. Mater. 2018, 197, 747–756. [Google Scholar] [CrossRef]

- Sherwani, A.F.H.; Younis, K.H.; Arndt, R.W.; Pilakoutas, K. Performance of Self-Compacted Geopolymer Concrete Containing Fly Ash and Slag as Binders. Sustainability 2022, 14, 15063. [Google Scholar] [CrossRef]

- Kang, S.-H.; Kang, H.; Lee, N.; Kwon, Y.-H.; Moon, J. Development of cementless ultra-high performance fly ash composite (UHPFC) using nucleated pozzolanic reaction of low Ca fly ash. Cem. Concr. Compos. 2022, 132, 104650. [Google Scholar] [CrossRef]

- Wang, T.; Ishida, T. Multiphase pozzolanic reaction model of low-calcium fly ash in cement systems. Cem. Concr. Res. 2019, 122, 274–287. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Lee, H.-S. Modeling the hydration of concrete incorporating fly ash or slag. Cem. Concr. Res. 2010, 40, 984–996. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, J.; Ma, H.; Wang, L.; Qian, X.; Qiao, P. Performance enhancement of silica fume blended mortars using bio-functionalized nano-silica. Constr. Build. Mater. 2021, 312, 125467. [Google Scholar] [CrossRef]

- Serdyuk, V.; Rudchenko, D.; Dyuzhilova, N. The use of low clinker binders in the production of autoclaved aerated concrete by cutting technology. East-Eur. J. Enterp. Technol. 2020, 6, 108. [Google Scholar] [CrossRef]

- Machowska, A.; Kledyński, Z.; Wilińska, I.; Pacewska, B. A study of the early hydration processes and properties of fly ash-slag binders. Bull. Mater. Sci. 2019, 42, 213. [Google Scholar] [CrossRef]

- Wagner, D.; Bellmann, F.; Neubauer, J. Influence of aluminium on the hydration of triclinic C3S with addition of KOH solution. Cem. Concr. Res. 2020, 137, 106198. [Google Scholar] [CrossRef]

- Joseph, S.; Cizer, Ö. Hydration of hybrid cements at low temperatures: A study on portland cement-blast furnace slag—Na2SO4. Materials 2022, 15, 1914. [Google Scholar] [CrossRef]

- Yildirim, H.; Ilica, T.; Sengul, O. Effect of cement type on the resistance of concrete against chloride penetration. Constr. Build. Mater. 2011, 25, 1282–1288. [Google Scholar] [CrossRef]

- Sanjuán, M.A.; Argiz, C. The new European standard on common cements specifications EN 197-1: 2011. Mater. Construcción 2012, 62, 425–430. [Google Scholar] [CrossRef]

- BS EN 197-1/2011; Cement Composition, Specifications and Conformity Criteria for Common Cements. European Standard: Brussels, Belgium, 2011.

- ASTM C 109/C 109M; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM C 496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C78-16; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2016.

- Ramos, R.; Aresti, L.; Christodoulides, P.; Vieira, A.; Florides, G. Assessment and comparison of soil thermal characteristics by laboratory measurements. In Energy Geotechnics: SEG-2018; Springer: Cham, Switzerland, 2019; pp. 155–162. [Google Scholar]

- Bendapudi, S.C.K.; Saha, P. Contribution of fly ash to the properties of mortar and concrete. Int. J. Earth Sci. Eng. 2011, 4, 1017–1023. [Google Scholar]

- Klemczak, B.; Batog, M. Heat of hydration of low-clinker cements. J. Therm. Anal. Calorim. 2016, 123, 1351–1360. [Google Scholar] [CrossRef]

- Sarker, P.; McKenzie, L. Strength and hydration heat of concrete using fly ash as a partial replacement of cement. In Proceedings of the 24th Biennial Conference of the Concrete Institute Australia, Luna Park, Sydney, 17–19 September 2009. [Google Scholar]

- Mustapha, F.A.; Sulaiman, A.; Mohamed, R.N.; Umara, S.A. The effect of fly ash and silica fume on self-compacting high-performance concrete. Mater. Today Proc. 2021, 39, 965–969. [Google Scholar] [CrossRef]

- Chouhan, P.; Jamle, S.; Verma, M.P. Effect of Silica Fume on Strength Parameters of Concrete as a Partial Substitution of Cement. IJSART3 2017, 5, 3–7. [Google Scholar]

- Scrivener, K.; Ouzia, A.; Juilland, P.; Mohamed, A.K. Advances in understanding cement hydration mechanisms. Cem. Concr. Res. 2019, 124, 105823. [Google Scholar] [CrossRef]

- Phung, Q.T.; Ferreira, E.; Seetharam, S.; Govaerts, J.; Valcke, E. Understanding hydration heat of mortars containing supplementary cementitious materials with potential to immobilize heavy metal containing waste. Cem. Concr. Compos. 2021, 115, 103859. [Google Scholar] [CrossRef]

- Tang, C.-W. The temperature and pore pressure distribution of lightweight aggregate concrete slabs exposed to elevated temperatures. Appl. Sci. 2022, 12, 10317. [Google Scholar] [CrossRef]

| Component | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | K2O | GGBS |

|---|---|---|---|---|---|---|---|---|---|

| CEM III | 20.6 | 4.9 | 2.8 | 65.14 | 2.2 | 3.5 | 0.56 | 0.3 | 50% |

| Fly ash | 63.77 | 21.6 | 9.6 | 3.2 | 1.2 | 0.1 | 0.53 | 0.45 | - |

| Mix ID | CEM III | Fly Ash | Quartz Powder | Sand | Dolomite | Water | SP | |

|---|---|---|---|---|---|---|---|---|

| Clinker | GGBS | |||||||

| Control | 225 | 225 | 0 | 225 | 540 | 1080 | 165 | 9 |

| FA-10 | 200 | 200 | 50 | 225 | 540 | 1080 | 165 | 9 |

| FA-20 | 180 | 180 | 90 | 225 | 540 | 1080 | 165 | 9 |

| FA-30 | 157.5 | 157.5 | 135 | 225 | 540 | 1080 | 165 | 9 |

| FA-40 | 135 | 135 | 180 | 225 | 540 | 1080 | 165 | 9 |

| Property | Control | FA-10 | FA-20 | FA-30 | FA-40 |

|---|---|---|---|---|---|

| Thermal conductivity λ0 [W/(mK)] | 3.51 | 3.59 | 3.67 | 3.75 | 3.83 |

| Specific heat capacity cb0 [106 J/(kg·K)] | 0.730 | 0.725 | 0.717 | 0.709 | 0.700 |

| Element | Percentage % | |

|---|---|---|

| Control | FA-40 | |

| CaO | 44.63 | 32.83 |

| SiO2 | 53.45 | 65.24 |

| Al2O3 | 0.93 | 1.41 |

| Fe2O3 | 0.99 | 0.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elmahdy, H.; Tahwia, A.M.; Elmasoudi, I.; Youssf, O. Mechanical and Thermal Properties of Sustainable Low-Heat High-Performance Concrete. Sustainability 2023, 15, 16139. https://doi.org/10.3390/su152316139

Elmahdy H, Tahwia AM, Elmasoudi I, Youssf O. Mechanical and Thermal Properties of Sustainable Low-Heat High-Performance Concrete. Sustainability. 2023; 15(23):16139. https://doi.org/10.3390/su152316139

Chicago/Turabian StyleElmahdy, Hager, Ahmed M. Tahwia, Islam Elmasoudi, and Osama Youssf. 2023. "Mechanical and Thermal Properties of Sustainable Low-Heat High-Performance Concrete" Sustainability 15, no. 23: 16139. https://doi.org/10.3390/su152316139

APA StyleElmahdy, H., Tahwia, A. M., Elmasoudi, I., & Youssf, O. (2023). Mechanical and Thermal Properties of Sustainable Low-Heat High-Performance Concrete. Sustainability, 15(23), 16139. https://doi.org/10.3390/su152316139