Exploring Lean Six Sigma as Dynamic Capability to Enable Sustainable Performance Optimisation in Times of Uncertainty

Abstract

:1. Introduction

2. Literature Review

2.1. Lean Six Sigma (LSS)

2.2. Dynamic Capabilities

2.3. The Integration of the LSS as DCs

3. Methodology

3.1. Phase 1: Identifying the Central Research Question

3.2. Phase 2: Defining Search Strategy and Keywords

3.3. Phase 3: Analysis and Synthesis

- o

- Triangulation: This involves using multiple sources of data or different methods to examine the same phenomenon. By converging data from various angles, authors have established the consistency and reliability of their findings.

- o

- Credibility Checks: Authors have discussed their findings and interpretations with colleagues, mentors, and advisors to receive feedback and ensure that their interpretations are grounded in the data.

- o

- Longitudinal Studies: Conducting research over an extended period allows for the observation of changes, patterns, and trends, increasing the reliability of conclusions drawn from the data.

3.4. Phase 4: Discussion and Future Research

4. Key Findings

4.1. The Role of DCs in Performance Optimisation

4.2. Dynamic Capabilities, Lean Six Sigma and Performance Optimisation

5. Discussion

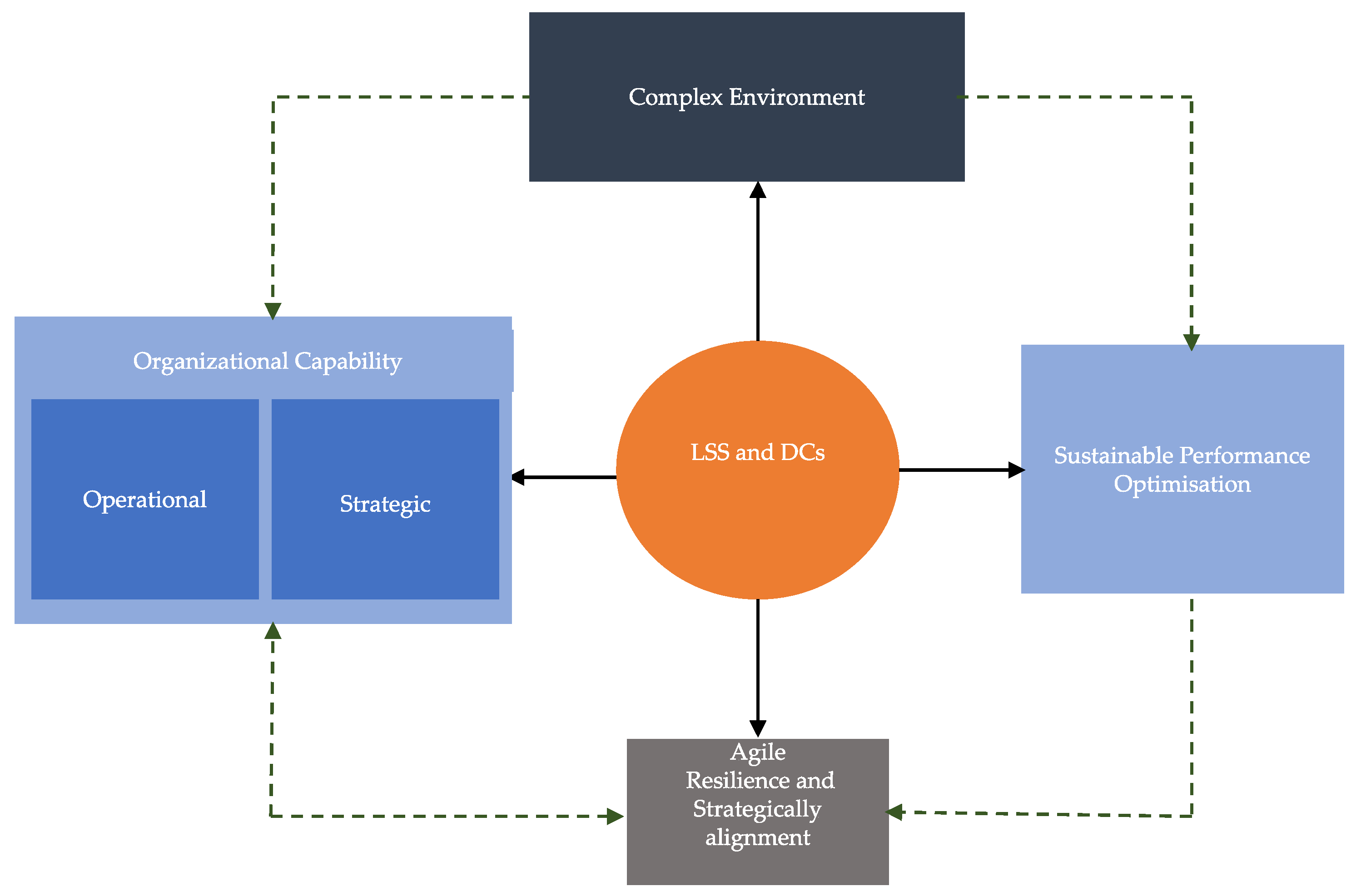

How Does the Integration of LSS as DCs Contribute to Sustainable Performance Optimisation in Times of Uncertainty?

6. Conclusions and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Lean Six Sigma | DCs |

|---|---|

| Journal of High Technology Management, International Journal of Quality & Reliability Management, Journal of Operations Management, International Journal of Quality & Reliability Management, Journal of the Operational Research Society, International Journal of Lean Six Sigma, Journal of Industrial Engineering and Management, Journal of Manufacturing Technology Management, Journal of Production & Manufacturing, Research Cleaner Production, International Journal of Production Economics. | Academy of Management Journal, Academy of Management Review, Administrative Science Quarterly, British Journal of Management, Journal of Management, Journal of Management Studies, Management Science, Organisation Science, Strategic Management Journal, Industrial and Corporate Change, Strategic Organisation and Academy of Management Perspective, Productive & Management Review, Journal of Change Management, Research and Theory, International Journal of Operations & Production Management, Journal of Operations Management, (Peer Reviewed Journal) Strategic Change, Journal of Strategic Change, International Business Review, and Strategic Management Journal. |

References

- Muthuveloo, R.; Ping, A.T. Heart Count: Optimizing Performance for Business Sustainability in Digital Era. In Proceedings of the 8th International Conference of Entrepreneurship and Business Management (ICEBM), Kuala Lumpur, Malaysia, 7–8 November 2019. [Google Scholar]

- Freitas, J.G.; Costa, H.G. Impacts of Lean Six Sigma over organizational sustainability: A systematic literature review on Scopus base. Int. J. Lean Six Sigma 2017, 8, 89–108. [Google Scholar] [CrossRef]

- Anand, G.; Ward, P.T.; Tatikonda, M.V.; Schilling, D.A. Dynamic capabilities through continuous improvement infrastructure. J. Oper. Manag. 2009, 27, 444–461. [Google Scholar] [CrossRef]

- Gutierrez, L.; Antony, J. Continuous improvement initiatives for dynamic capabilities development: A systematic literature review. Int. J. Lean Six Sigma 2020, 11, 125–149. [Google Scholar] [CrossRef]

- Sunder, M.V.; Ganesh, L.S. Lean Six Sigma in Banking Services; Springer: Singapore, 2020. [Google Scholar]

- Roth, N.; Franchetti, M. Process improvement for printing operations through the DMAIC Lean Six Sigma approach: A case study from Northwest Ohio, USA. Int. J. Lean Six Sigma 2010, 1, 119–133. [Google Scholar] [CrossRef]

- Rajenthirakumar, D.; Mohanram, P.V.; Harikaarthik, S.G. Process Cycle Efficiency Improvement through Lean: A case study. Int. J. Lean Think. 2011, 2, 46–58. [Google Scholar]

- Knowles, G. Six Sigma, 1st ed.; Graeme Knowles & Ventus Publishing Aps.: Erie, CO, USA, 2011. [Google Scholar]

- Rodgers, A.B.; Antony, J.; He, H.; Cundney, A.E.; Laux, C. A directed content analysis of viewpoints on the changing patterns of Lean Six Sigma research. TQM J. 2019, 31, 641–654. [Google Scholar] [CrossRef]

- Laureani, A.; Antony, J. Leadership—A critical success factors for the effective implementation of Lean Six Sigma. Total. Qual. Manag. Bus. Excel. 2018, 29, 502–523. [Google Scholar] [CrossRef]

- Juliani, F.; de Oliveira, J.O. Lean Six Sigma principles and practices under the management perspective. Prod. Plan. Control 2019, 31, 1223–1244. [Google Scholar] [CrossRef]

- Lee, K.L.; Wei, C.C. Reducing Mould changing time by implementing Lean Six Sigma. Qual. Reliab. Eng. Int. 2009, 26, 387–395. [Google Scholar] [CrossRef]

- Laureani, A.; Antony, J. Critical success factors for the effective implementation of Lean Sigma: Results from an empirical study and agenda for future research. Int. J. Lean Six Sigma 2012, 23, 274–283. [Google Scholar] [CrossRef]

- Antony, J.; Scheumann, T.; Sunder, M.V.; Cudney, E.; Rodgers, B.; Grigg, P.N. Using Six Sigma DMAIC for Lean project management in education: A case study in a German kindergarten. Total Qual. Manag. Bus. Excell. 2022, 33. [Google Scholar] [CrossRef]

- Ruben, R.B.; Vinodh, S.; Asokan, P. Lean Six Sigma with environmental focus: Review and framework. Int. J. Adv. Manuf. Technol. 2018, 94, 4023–4037. [Google Scholar] [CrossRef]

- Sunder, M.V.; Antony, J.A. conceptual Lean Six Sigma framework for quality excellence in higher education institutions. Int. J. Qual. Reliab. Manag. 2018, 35, 857–874. [Google Scholar] [CrossRef]

- Gutierrez, L.; Barrales-Molina, V.; Fernandez-Giordano, M.; Lopez-Morales, B. Six Sigma for dynamic capabilities development: Becoming more flexible organizations. Int. J. Lean Six Sigma 2020, 11, 35–56. [Google Scholar] [CrossRef]

- Hilton, R.J.; Sohal, A. A conceptual model for the successful deployment of Lean Six Sigma. Int. J. Qual. Reliab. Manag. 2012, 29, 54–70. [Google Scholar] [CrossRef]

- Teece, J.D. The evolution of the Dynamic Capabilities Framework. In Artificiality and Sustainability in Entrepreneurship; Springer: Cham, Switzerland, 2023; Available online: https://link.springer.com/chapter/10.1007/978-3-031-11371-0_6 (accessed on 8 November 2023).

- Breznik, L.; Lahovnik, M. Dynamic capabilities and increasing competition in the market: Findings from case studies. Management 2016, 21, 167–185. [Google Scholar]

- Mu, J. Dynamic capability and firm performance: The role of marketing capability and operations capability. IEEE Trans. Eng. Manag. 2017, 64, 554–565. [Google Scholar] [CrossRef]

- Teece, J.D. Dynamic capabilities as (workable) management systems theory. J. Manag. Organ. 2018, 24, 359–368. [Google Scholar] [CrossRef]

- Teece, J.D. China and the Reshaping of the Auto Industry: A Dynamic Capabilities Perspective. Manag. Organ. Rev. 2019, 15, 177–199. [Google Scholar] [CrossRef]

- Collins, J.D.; Anand, N.B. The Limitations of Dynamic Capabilities; Working Paper; Harvard Business School: Cambridge, MA, USA, 2019. [Google Scholar]

- Mukhtar, M.A.; Baloch, N.A.; Khattak, S.R. Dynamic Capability & Firm Performance: Mediating Role of Learning Orientation, Organizational Culture & Corporate Entrepreneurship: A Case Study of SME’s of Pakistan. J. Manag. Stud. 2019, 13, 119–128. [Google Scholar]

- Sainsbury, D. Toward a dynamic capability theory of economic growth. Ind. Corp. Chang. 2019, 29, 1047–1065. [Google Scholar] [CrossRef]

- Teece, J.D.; Pisano, G. Dynamic Capabilities of Firms: An Introduction. 1994. Available online: http://pure.iiasa.ac.at/4109/1/WP-94-103.pdf (accessed on 2 January 2022).

- Teece, J.D.; Pisano, G.; Shuen, A. Dynamic capabilities and strategic management. Strat. J. Manag. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Plenert, G. Reinventing Lean: Introducing Lean Management into the Supply Chain; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Pepper, M.P.J.; Spedding, T.A. The evolution of lean Six Sigma. Int. J. Qual. Reliab. Manag. 2010, 27, 138–155. [Google Scholar] [CrossRef]

- Alhuraish, I.; Robledo, C.; Kobi, A. A comparative exploration of Lean Manufacturing and Six Sigma in terms of their critical success factors. J. Clean. Prod. 2017, 164, 325–337. [Google Scholar] [CrossRef]

- Gleeson, F.; Coughlan, P.; Goodman, L.; Newell, A.; Hargaden, V. Improving manufacturing productivity by combining cognitive engineering and lean-six sigma methods. Procedia CIRP 2019, 81, 641–646. [Google Scholar] [CrossRef]

- Balzer, W.K.; Brodke, M.H.; Kluse, C.; Zickar, M.J. Revolution or 30-year fad? A role for I-O psychology in Lean management. Ind. Organ. Psychol. 2019, 12, 215–233. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in the Corporation; Simon & Schuster: New York, NY, USA, 1996. [Google Scholar]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine that Changed the World; Rawson Associates: New York, NY, USA, 1990. [Google Scholar]

- Shan, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 129–149. [Google Scholar]

- Cox, J.F.; Blackstone, J.H. APICS Dictionary, 9th ed.; APICS-The Education Society for Resource Management: Falls Church, VA, USA, 1998. [Google Scholar]

- Storch, R.L.; Lim, S. Improving flow to achieve lean manufacturing in shipbuilding. Prod. Plan. Control 1999, 10, 127–137. [Google Scholar] [CrossRef]

- Naylor, B.; Naim, M.M.; Berry, D. Legality: Integrating the lean and agile manufacturing paradigm in the total supply chain. Int. J. Prod. Econ. 1999, 62, 107–118. [Google Scholar] [CrossRef]

- Bicheno, J. The Lean Toolbox, 3rd ed.; PICSIE Books: Buckingham, UK, 2004. [Google Scholar]

- Senapati, N.R. Six Sigma: Myths and realities. Int. J. Qual. Reliab. Manag. 2004, 21, 683–690. [Google Scholar] [CrossRef]

- Manville, G.; Greatbanks, R.; Krishnasamy, R.; Parker, D. Critical success factors for Lean Six Sigma programmes: A view from middle management. Int. J. Qual. Reliab. Manag. 2012, 29, 7–20. [Google Scholar] [CrossRef]

- Eckes, G. Six Sigma for Everyone; John Wiley & Son: Hoboken, NJ, USA, 2003. [Google Scholar]

- Dasgupta, T. Using the six-sigma metric to measure and improve the performance of a supply chain. Total. Qual. Manag. Bus. Excel. 2003, 14, 355–366. [Google Scholar] [CrossRef]

- Antony, J.; McDermott, O.; Powell, D.; Sony, M. The evolution of future of Lean Six Sigma 4.0. Total Qual. Manag. J. 2022, 35, 1030–1045. [Google Scholar] [CrossRef]

- Snee, R.D. Digging the holistic approach: Rethinking business improvement to improve the bottom line. Qual. Prog. 2009, 4–52. [Google Scholar]

- Orji, J.I.; Liu, C.S. A dynamic perspective on the key drivers of innovation-led lean approaches to achieve sustainability in the manufacturing supply chain. Int. J. Prod. Econ. 2018, 219, 481–496. [Google Scholar] [CrossRef]

- Antony, J.; Snee, R.; Hoerl, R. Lean Six Sigma: Yesterday, today, and tomorrow. Int. J. Qual. Reliab. Manag. 2017, 34, 1073–1093. [Google Scholar] [CrossRef]

- Byrne, G. Ensuring optimal success with Six Sigma Implementations. J. Organ. Excel. 2003, 22, 43–50. [Google Scholar] [CrossRef]

- George, M.L. Lean Six Sigma for Service: How to Use Lean Speed and Six Sigma Quality to Improve Services and Transactions; McGraw-Hill: New York, NY, USA; London, UK, 2003. [Google Scholar]

- George, M.L. Lean Six Sigma: Combining Six Sigma Quality with Lean Speed; McGraw-Hill: New York, NY, USA, 2002. [Google Scholar]

- Hill, J.; Thomas, R.K.; Mason-Jones, R.; El-Kateb, S. The implementation of a Lean Six Sigma framework to enhance operational performance in an MRO facility. Prod. Manuf. Res. 2018, 6, 26–48. [Google Scholar] [CrossRef]

- Antony, J.; Setijono, D.; Dahlgaard, J.J. Lean Six Sigma and Innovation—An exploratory study among UK organisations. Total. Qual. Manag. Bus. Excell. 2016, 27, 124–140. [Google Scholar] [CrossRef]

- Albliwi, S.; Antony, J.; Lim, S. A systematic review of Lean Six Sigma for the manufacturing industry. Bus. Process. Manag. J. 2015, 21, 665–691. [Google Scholar] [CrossRef]

- Harris, L.; Fitzsimmons, M. Your Taxes: Taking Start-Ups to the Next Level. 2019. Available online: https://www.jpost.com/Jpost-Tech/Business-and-Innovation/Your-taxes-Taking-start-ups-to-the-next-level-588566 (accessed on 23 December 2019).

- Schroeder, R.G.; Linderman, K.; Liedtke, C.; Choo, A.S. Six Sigma: Definition and underlying theory. J. Oper. Manag. 2008, 26, 536–554. [Google Scholar] [CrossRef]

- Thomerson, L.D. Journey for excellence: Kentucky’s Commonwealth Health Corporation adopts Six Sigma approach. Annu. Qual. Congr. Proc. 2001, 55, 152–158. [Google Scholar]

- Kumar, M.; Antony, J.; Singh, R.K.; Tiwari, M.K.; Perry, D. Implementing the Lean Sigma framework in an Indian SME: A case study. Prod. Plan. Control 2006, 17, 407–423. [Google Scholar] [CrossRef]

- Bicheno, J.; Holweg, M. The Lean Toolbox, 4th ed.; PICSIE Books: Buckingham, UK, 2009. [Google Scholar]

- Singh, B.; Garg, S.K.; Sharma, S.K.; Grewal, C. Lean implementation and its benefits to the production industry. Int. J. Lean Six Sigma 2010, 1, 157–168. [Google Scholar] [CrossRef]

- Goriwondo, W.M.; Mhlanga, S.; and Marecha, A. Use of value stream mapping tool for waste reduction in manufacturing: Case study of Bread manufacturing in Zimbabwe. In Proceedings of the 2011 International Conference on Industrial Engineering and Operations Management, Kuala Lumpur, Malaysia, 3–5 September 2011; pp. 239–241. [Google Scholar]

- Gnanaraj, S.M.; Devadasan, S.R.; Murugesh, R.; Sreenivasa, C.G. Sensitisation of SMEs towards the implementation of Lean Six Sigma—An initialisation in a cylinder frame manufacturing Indian SME. Prod. Plan. Control 2012, 23, 599–608. [Google Scholar] [CrossRef]

- Karunakaran, S. Innovative application of LSS in aircraft maintenance environments. Int. J. Lean Six Sigma 2016, 7, 85–108. [Google Scholar] [CrossRef]

- Rahman, M.M.; Ogunleye, J.A. Lean, Green and Six Sigma (LG6σ) for SMEs in the leather industry in Bangladesh. Int. J. Entrepreneurship Innov. 2019, 7, 42–66. [Google Scholar]

- Antony, J.; Kumar, M.; Madu, C.N. Six Sigma in small- and medium-sized UK manufacturing enterprises: Some empirical observations. Int. J. Qual. Reliab. Manag. 2005, 22, 860–874. [Google Scholar] [CrossRef]

- Antony, J.; Banuelas, R. Key ingredients for the effective implementation of Six Sigma program. Meas. Bus. Excell. 2002, 6, 20–27. [Google Scholar] [CrossRef]

- Uluskan, M. A comprehensive insight into the Six Sigma DMAIC toolbox. Int. J. Lean Six Sigma 2016, 7, 406–429. [Google Scholar] [CrossRef]

- Radnor, Z.J.; Bucci, G. Evaluation of Pacesetter: Lean Senior Leadership and Operational Management within HMRC Processing; HM Revenue & Customs: London, UK, 2007; Volume 86. [Google Scholar]

- Bogers, M.; Chesbrough, H.; Heaton, S.; Teece, J.D. Strategic Management of Open Innovation: A Dynamic Capabilities Perspective. Calif. Manag. Rev. 2019, 62, 77–94. [Google Scholar] [CrossRef]

- Hopp, J.W.; Spearman, L.M. Factory Physics, 3rd ed.; Waveland Press: Long Grove, IL, USA, 2011. [Google Scholar]

- Teece, J.D. Dynamic Capabilities: Routines versus Entrepreneurial Action. J. Manag. Stud. 2012, 49, 1395–1401. [Google Scholar] [CrossRef]

- Teece, J.D. Hand in Glove: Open Innovation and the Dynamic Capabilities. 2019. Available online: https://www.strategicmanagementreview.net/assets/articles/Teece%20OI.pdf (accessed on 24 August 2023).

- Teece, J.D. Strategies for Managing Knowledge Assets: The role of firm structure and industry context. Long Range Plan. 2000, 33, 35–54. [Google Scholar] [CrossRef]

- Teece, J.D. The foundations of enterprise performance: Dynamic and ordinary capabilities in an (economic) theory of firms. Acad. Manag. Perspect. 2014, 28, 328–352. [Google Scholar] [CrossRef]

- Teece, D.J. Business models and dynamic capabilities. Long Range Plan. 2018, 51, 40–49. [Google Scholar] [CrossRef]

- Teece, D.J. Explicating dynamic capabilities: The nature and micro-foundations of (sustainable) enterprise performance. Strat. J. Manag. 2007, 28, 1319–1350. [Google Scholar] [CrossRef]

- Teece, J.D. A dynamic capability based entrepreneurial theory of the multinational enterprise. J. Int. Bus. Stud. 2014, 45, 8–37. [Google Scholar] [CrossRef]

- Winter, S.G. Understanding Dynamic Capabilities. Strateg. Manag. J. 2003, 24, 991–995. [Google Scholar] [CrossRef]

- Ambrosini, V.; Bowman, C. What are dynamic capabilities and are they useful constructs in strategic management? Indian J. Med. Res. 2009, 11, 29–49. [Google Scholar] [CrossRef]

- Chien, Y.S.; Tsai, H.C. Dynamic Capabilities, Knowledge, learning and firm’s performance. J. Organ. Chang. Manag. 2012, 25, 434–444. [Google Scholar] [CrossRef]

- Feiler, F.P.; Teece, J.D. Case study, dynamic capabilities and upstream strategy: Supermajor EXP. Energy Strategy Rev. 2014, 3, 14–20. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Martin, J. Dynamic Capabilities: What are they? Strateg. Manag. J. 2000, 21, 1105–1121. [Google Scholar] [CrossRef]

- Helfat, C.E.; Petraf, M.A. Understanding Dynamic Capabilities: Progress along a development path. Strateg. Organ. 2009, 7, 91–102. [Google Scholar] [CrossRef]

- Helfat, C.E.; Raubitschek, R.S. Product sequencing: Co-evolution of knowledge, capabilities and products. Strateg. Manag. J. 2000, 21, 961–980. [Google Scholar] [CrossRef]

- Helfat, C.E.; Peteref, M.A. Managerial Cognitive capabilities and microfoundation of dynamic capabilities. Strateg. Manag. J. 2014, 36, 831–850. [Google Scholar] [CrossRef]

- Barreto, I. Dynamic Capabilities: A Review of Past Research and an Agenda for the Future. J. Manag. 2010, 36, 256–280. [Google Scholar] [CrossRef]

- Zahra, S.A.; George, G. Absorptive Capacity: A Review, Reconceptualization, and Extension. Acad. Manag. Res. 2002, 27, 185–203. [Google Scholar] [CrossRef]

- Zahra, S.A.; Petricevic, O.; Luo, Y. Toward an action-based view of dynamic capabilities for international business. J. Int. Bus. Stud. 2022, 53, 583–600. [Google Scholar] [CrossRef]

- Zahra, S.A.; Sapienza, H.J.; Davidson, P. Entrepreneurship and Dynamic Capabilities: A Review, Model, and Research Agenda. J. Manag. Stud. 2006, 43, 917–955. [Google Scholar] [CrossRef]

- Zollo, M.; Winter, S.G. Deliberate Learning and the Evolution of Dynamic Capabilities. Organ. Sci. 2002, 13, 339–351. [Google Scholar] [CrossRef]

- Meyer-Doyle, P.; Lee, S.; Helfat, E.C. Disentangling the microfoundations of acquisition behaviour and performance. Strateg. Manag. J. 2019, 40, 1733–1756. [Google Scholar] [CrossRef]

- Leemann, N.; Kanbach, K.D. Toward a taxonomy of dynamic capabilities—A systematic literature review. Manag. Res. Rev. 2021, 45, 486–501. [Google Scholar] [CrossRef]

- Teece, J.D. Fundamental Issues in Strategy: Time to Reassess? Int. Strateg. Manag. Rev. 2020, 1, 103–144. [Google Scholar] [CrossRef]

- Vashishth, A.; Lameijer, B.A.; Chakraborty, A.; Antony, J.; Moormann, J. Implementing Lean Six Sigma in financial services: The effect of motivations, selected methods and challenges on LSS program- and organizational performance. Int. J. Qual. Reliab. Manag. 2023. [Google Scholar] [CrossRef]

- Chiarini, A.; Vagnoni, E. Can IATF 16949 certificate and foster Lean Six Sigma Implementation? Research form Italy. Total. Qual. Manag. Bus. Excel. 2018, 31, 1478–3371. [Google Scholar] [CrossRef]

- Wang, C.L.; Ahmed, P.K. Dynamic Capabilities: A review and research agenda. Indian J. Med. Res. 2007, 9, 31–51. [Google Scholar] [CrossRef]

- Kohlbacher, M. The impact of dynamic capabilities through continuous improvement on innovation: The role of business process orientation. Knowl. Process. Manag. 2013, 20, 71–76. [Google Scholar] [CrossRef]

- Martelo-Landroguez, S.; Castro, B.C.; Cepeda-Carrion, G. Creating dynamic capabilities to increase customer value. Manag. Decis. 2011, 49, 1141–1159. [Google Scholar] [CrossRef]

- Wilden, R.; Gudergan, S.; Akaka, M.A.; Averdung, A.; Teichert, T. The role of cocreation and dynamic capabilities in service provision and performance: A configurational study. Ind. Mark. Manag. 2019, 78, 43–57. [Google Scholar] [CrossRef]

- Cepeda, G.; Vera, D. Dynamic Capabilities and Operational Capabilities: Aknowledge Management Perspective. J. Bus. Res. 2007, 60, 426–437. [Google Scholar] [CrossRef]

- Worren, N.A.M. Creating Dynamic Capabilities: The Role of Modular Product and Process Architectures. Ph.D. Thesis, Oxford University, Oxford, UK, 2002. [Google Scholar]

- Zott, C. Dynamic Capabilities and the Emergence of Interindustry Differential Firm Performance: Insights from a Simulation Study. Strat. Manag. J. 2003, 24, 97–125. [Google Scholar] [CrossRef]

- Pisano, P.G. Towards a perspective theory of dynamic capabilities: Connecting strategic choice, learning, and competition. Ind. Corp. Chang. 2017, 26, 747–762. [Google Scholar] [CrossRef]

- Rothaemel, T.F.; Hess, M.A. Building Dynamic Capabilities: Innovation Driven by Individual-, Firm-, and Network-Level Effects. Organ. Sci. 2007, 8, 898–921. [Google Scholar] [CrossRef]

- Vogel, R.; Güttel, W.H. The dynamic capability view in strategic management: A bibliometric review. Indian J. Med. Res. 2013, 15, 426–446. [Google Scholar] [CrossRef]

- Warner, K.S.; Wäger, M. Building dynamic capabilities for digital transformation: An ongoing process of strategic renewal. Long Range Plan. 2019, 52, 326–349. [Google Scholar] [CrossRef]

- Kornfeld, B.; Kara, S. Selection of Lean and Six Sigma projects in industry. Int. J. Lean Six Sigma 2013, 4, 4–16. [Google Scholar] [CrossRef]

- Lertwattanapongchai, S.; William Swierczek, F. Assessing the change process of Lean Six Sigma: A case analysis. Int. J. Lean Six Sigma 2014, 5, 423–443. [Google Scholar] [CrossRef]

- Salah, S.; Rahim, A.; Carretero, J.A. The integration of Six Sigma and lean management. Int. J. Lean Six Sigma 2010, 1, 249–274. [Google Scholar] [CrossRef]

- Sreedharan, V.R.; Sunder, M.V.; Gurumurthy, A. Development of Lean Six Sigma training module: Evidence from an emerging economy. Int. J. Qual. Reliab. Manag. 2020, 30, 689–710. [Google Scholar] [CrossRef]

- Sunder, M.V.; Ganesh, L.S.; Marathe, R.R. A morphological analysis of research literature on Lean Six Sigma for service. Int. J. Oper. Prod. Manag. 2018, 38, 149–182. [Google Scholar] [CrossRef]

- Hu, Q.; Mason, R.; Willams, S.J.; and Found, P. Lean implementation within SMEs: A literature review. J. Manuf. Technol. Manag. 2015, 26, 980–1012. [Google Scholar] [CrossRef]

- Verma, R.; Dewan, R.M. Lean Six Sigma sustainability framework. J. Clean. Prod. 2014, 85, 115–132. [Google Scholar]

- Antony, J. Some pros and cons of Six Sigma: An academic perspective. TQM Mag. 2004, 16, 303–306. [Google Scholar] [CrossRef]

- Arnheiter, E.D.; Maleyeff, J. The integration of lean management and six sigma. TQM Mag. 2005, 17, 5–18. [Google Scholar] [CrossRef]

- Timans, W.; Antony, J.; Ahaus, K.; van Solingen, R. Implementation of Lean Six Sigma in small-and medium-sized manufacturing enterprises in the Netherlands. J. Oper. Res. Soc. 2012, 63, 339–353. [Google Scholar] [CrossRef]

- Linderman, K.; Schroeder, R.G.; Zaheer, S.; Choo, A.S. Six Sigma: A goal-theoretic perspective. J. Oper. Manag. 2003, 21, 193–203. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Govindan, K.; Garza-Reyes, J.A.; Benhida, K.; Mokhlis, A. A framework for the integration of Green and Lean Six Sigma for superior sustainability performance. Int. J. Prod. Res. 2017, 55, 4481–4515. [Google Scholar] [CrossRef]

- Easterby-Smith, M.; Thorpe, R.; Jackson, R.P. Management and Business Research, 5th ed.; SAGE Publication Ltd.: Thousand Oaks, CA, USA, 2015. [Google Scholar]

- Saunders, M.; Lewis, P.; Thornhill, A. Research Methods for Business Students, 8th ed.; Pearson Professional Ltd.: London, UK, 2019. [Google Scholar]

- Gray, E.D. Doing Research in the Real World, 3rd ed.; SAGE Publication Ltd.: London, UK, 2014. [Google Scholar]

- Easterby-Smith, M.; Jaspersen, J.L.; Thorpe, R.; Valizade, D. Management and Business Research, 7th ed.; SAGE Publication Ltd.: Thousand Oaks, CA, USA, 2020. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Randolph, J.J. A guide to Writing the Dissertation Literature Review, Practical Assessment. Pract. Assess. Res. Eval. 2009, 14, 13. [Google Scholar]

- di Stefano, G.; Peteraf, M.A.; Verona, G. Dynamic capabilities deconstructed: A bibliographic investigation into the origins, development, and future directions of the research domain. Ind. Corp. Chang. 2010, 19, 1187–1204. [Google Scholar] [CrossRef]

- Rowe, F. What literature review is not: Diversity, boundaries and recommendations. Eur. J. Inf. Syst. 2014, 23, 241–255. [Google Scholar] [CrossRef]

- Klein, G.P.; Mahoney, T.J.; McGahan, M.A.; Pitelis, N.C. Resources, Capabilities, and Routines in Public Organizations (9 February 2010). Rotman School of Management Working Paper No. 1550028, Atlanta Competitive Advantage Conference 2010 Paper. Available online: https://ssrn.com/abstract=1550028 (accessed on 19 September 2014).

- Peteraf, M.; Di Stefano, G.; Verona, G. The Elephant in the Room of Dynamic Capabilities: Bringing Two Diverging Conversations Together. Strat. Manag. J. 2013, 34, 1389–1410. [Google Scholar] [CrossRef]

- Piening, E.P. Dynamic Capabilities in Public Organisations. Public Manag. Rev. 2013, 15, 209–245. [Google Scholar] [CrossRef]

- Christoffersen, J.A. Review of Antecedents of International Strategic Alliance Performance: Synthesized Evidence and New Directions for Core Constructs. Int. J. Manag. Rev. 2013, 15, 66–85. [Google Scholar] [CrossRef]

- Dumay, J.; Cai, L. A review and critique of content analysis as a methodology for inquiring into IC disclosure. J. Intellect. Cap. 2014, 15, 264–290. [Google Scholar] [CrossRef]

- Massaro, M.; Dumay, J.; Garlatti, A. Public sector knowledge management: A structured literature review. J. Knowl. Manag. 2015, 16, 530–558. [Google Scholar] [CrossRef]

- Petticrew, M.; Roberts, H. Systematic Review in the Social Sciences: A Practical Guidance; Blackwell Publishing: Malden, MA, USA, 2008. [Google Scholar]

- Bailey, S.J.; Burch, R.M. Research Methods in Applied Behavior Analysis, 2nd ed.; Routledge: New York, NY, USA, 2018. [Google Scholar]

- Nguyen, T.; Graham, I.D.; Mrklas, K.J.; Bowen, S.; Cargo, M.; Estabrooks, C.A.; Kothari, A.; Lavis, J.; Macaulay, A.C.; MacLeod, M.; et al. How does integrated knowledge translation (IKT) compare to other collaborative research approaches to generating and translating knowledge? Learning from experts in the field. Health Res. Policy Syst. 2020, 18, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Salvato, C. Capabilities Unveiled: The Role of Ordinary Activities in the Evolution of Product Development. Organ. Sci. 2009, 20, 384–409. [Google Scholar] [CrossRef]

- Salvato, C.; Rerup, C. Beyond Collective Entities: Multilevel Research on Organisational Routines and Capabilities. J. Manag. 2011, 37, 468–490. [Google Scholar] [CrossRef]

- Maritan, A.C. Capital Investment as Investing in Organisational Capabilities: An Empirically Grounded Process Model. Acad. Manag. J. 2001, 44, 513–531. [Google Scholar] [CrossRef]

- Zollo, J.; Reuer, J.J.; Singh, H. Inter Organisational Routines and Performance in Strategic Alliances. Organ. Sci. 2002, 13, 701–713. [Google Scholar] [CrossRef]

- Pavlou, P.A.; El Sawy, O.A. Understanding the elusive black box of dynamic capabilities. Decis. Sci. 2011, 42, 239–273. [Google Scholar] [CrossRef]

- Bitencourt, C.C.; Santini, O.F.; Ladeira, J.W.; Santos, C.A.; Teixeira, K.E. The extended dynamic capabilities model: A meta-analysis. Eur. Manag. J. 2020, 38, 108–120. [Google Scholar] [CrossRef]

- Prieto, M.I.; Revilla, E.; Rodriguez-Prado, B. Building dynamic capabilities in product development: How do contextual antecedent matters? Strat. J. Manag. 2009, 25, 313–326. [Google Scholar] [CrossRef]

- Heaton, S.; Lewin, D.; Teece, J.D. Managing campus entrepreneurship: Dynamic capabilities and university leadership. Manag. Decis. Econ. 2020, 41, 1126–1140. [Google Scholar] [CrossRef]

- Collis, D.J. Research note: How valuable are organisational capabilities? Strateg. Manag. J. 1994, 15, 143–152. [Google Scholar] [CrossRef]

- Schoemaker, H.J.P.; Leih, S.; Teece, J.D. Innovation, Dynamic Capabilities and Leadership. Calif. Manag. Rev. 2018, 61, 15–42. [Google Scholar] [CrossRef]

| Features | Dynamic Capabilities | Lean Six Sigma |

|---|---|---|

| Disciplinary Orientation | Evolutionary economy and strategy [19,83] Organisational sociology [83] Technology [19,83,84] Organisational theories, science, behaviour, information system [82] | LSS—integration of two philosophies namely lean and Six Sigma [16,30,48,53,66] |

| Main Characteristics | [19,74,76] Sensing capability Learning capability Integrating capability Coordinating capability [74,76] Sensing capability Seizing capability Transformational capability [96] Absorptive capability Innovative capability Adaptive capability [79]. Incremental DCs—stable environment Renewal DCs—dynamic environment Regenerative DCs—respond to the need to change DCs themselves (the way firms modify their resource base) | Define scope and purpose. Measure—determine the current situation. Analyses—identification of causes. Improve—remove wastes and opt for optimal solutions. Control—Keep process in control [11,58] Reduce cost, Enhance quality, and employee and customer satisfaction [2,18,32,48,51] Improve communication and information systems [14,61] |

| Customer Orientation | Customer value and relationship management [21,25,97,98,99] | Makes provision for customers [51]. Achieve good customer satisfaction [94,95] |

| Resource Optimisation | Facilitates the deployment of resources to generate new value-creation strategies [23,78,79,82,99] An interaction of cross-functional processes to renew the resource base [82,100,101]. | Eliminates waste and creates an efficient system [6,36,54,62] |

| Organisational Performance | DCs are the mechanisms by which firms achieve competitive advantage [19,23,76,77,78,81,90,102] DCs enhance organisational performance [26,74,75,77,103,104,105,106] | LSS improves the quality, efficiency, and effectiveness of processes while meeting environmental regulations [42,48,53,107,108,109,110,111,112,113,114,115,116,117,118] |

| The Integration of LSS and DCs | Enhances agility and adaptability in uncertain environments. | |

| Enables organisations to effectively manage risks during uncertain times. | ||

| Improve performance measurement and monitoring systems. | ||

| Supports innovation and continuous improvement efforts during uncertain times. | ||

| The role of DCs in Performance Optimisation | Competitive advantage in complex and dynamic environments [19,20,23,27,28]. |

| Innovation—High-level capabilities [47,69,72,97,104,144]. | |

| Long-term CA and wealth creation in a dynamic environment [19,25,27,28,47,75,76]. | |

| Enhance organisational performance by addressing strategic changes [74,80,85,92]. | |

| Reconfigure business model and strategy—Continuous Improvement [97,99,102]. | |

| Innovation and adaptability—flexibility [47,58,69,72,84,97,104,114,144]. | |

| New resource configuration [76,137]. | |

| Redeploy and reconfigure ordinary capabilities [69,71,72,73,74,75,76,77]. | |

| Superior performance and survival in changing environmental conditions [71,72,73,74,75,76,77]. | |

| Indirect links between DCs and performance [82,84]. | |

| Modifies organisational resources and/or routines [82,83,84,85,86,87,88,89,90,100]. | |

| Generate change—an alternative approach to the ‘ad hoc problem solving’ [71,72,73,74,75,76,77]. | |

| Upgrade and reconfigure core capabilities in response to the changing environment and improve market-based performance and financial performance [97,98,102]. | |

| Sense market signals, seize opportunities, and transform their capabilities to adapt to uncertain conditions [115,126]. | |

| Create CA through new resource configuration [34]. | |

| Sensing and seizing capabilities contribute to entrepreneurial behavior and innovation [58,114]. | |

| Respond to strategic changes [124,131,132]. | |

| New product development performance [95]. | |

| Creates ambidexterity and effective management of the business ecosystem [41]. | |

| Determined the speed and degree (and associated cost) of aligned firms’ resources—continuously sense and seize opportunities and periodically transform an aspect of organisation and culture [76,85]. | |

| Support high performance based on new product and process development. Change-orientated organisational culture. Prescient assessment of the business environment and technological opportunities [101,102,103,104,105,106]. | |

| DCs contribute to organisational performance only if the VRIO criteria have been met [25]. |

| Authors | Type of Study | Research Focus | Key Findings |

|---|---|---|---|

| [115] | Qualitative | To eliminate many misconceptions regarding Six Sigma and lean management. | The joint implementation of the programs will result in a lean, Six Sigma (LSS) organisation, overcoming the limitations of each program when implemented in isolation. |

| [109] | Qualitative | Explains how lean compares to the Six Sigma and outline the benefits of integrating them | The paper proposes a new lean Six Sigma (LSS) approach and provides a detailed description of its phases. |

| [42] | Mix method | Evaluates LSS from a middle manager’s perspective. | Findings indicate that developing DCs in middle management along with a learning culture will facilitate participation in strategic formation. |

| [18] | Qualitative | Examines the relationship between the successful deployment of Lean Six Sigma and a number of key explanatory variables. | The study identified several variables that could impact the success of the deployment of the Lean Six Sigma such as leadership, communication, behaviour and awareness, policies, culture, and organisational support and strategy; education, training, and competency of the Six Sigma experts. |

| [116] | Mixed | Aims to present an overview of the implementation of LSS in Dutch manufacturing SMEs and to explore the critical success factors (CSFs) for the implementation of LSS. | The research highlights the importance of leadership and organisational culture. They found that linking to customer, vision and plan statement, communication and management involvement and participation are the highest ranked CSFs. |

| [97] | Quantitative | Examines the interaction effect of continuous improvement and organisational process alignment on innovation. | Findings indicate that firms increase their innovation performance when they implement both DCs and LSS—a process-oriented organisational design and continuous improvement methodologies. |

| [54] | Qualitative | Explores the most common themes within LSS in the manufacturing sector. | Research found that LSS is most popular in large organisation, especially in the US, UK, and the Netherlands, however also becoming popular in developing countries such as India. Most common tools found no statistical significance such as VSM. 5s. |

| [112] | Qualitative | Aim the research gap in regard to lean implementation in SMEs | The study found that SMEs focus on lean implementation very limited to internal operation. It also found the range of lean tools available to adopt in SMEs, however no rationale behind selecting the right tools. Study shows how Lean and Six Sigma can be integrated in SMEs to gain extra benefits and finally the impact and CSF of implementing Lean in the SME sector. |

| [31] | Quantitative | Examine lean manufacturing versus Six Sigma was conducted, and the success factors relevant to these two methodologies were identified. | CSR for SS was found to be Skills and Expertise, and for Lean, employee involvement and culture change. |

| [118] | Mixed method | Provides framework for Green, Lean, and Six Sigma implementation method | The results showed that the integration of Lean Six Sigma and Green helped organisations to averagely reduce their resource consumption from 20 to 40% and minimise the cost of energy and mass streams by 7–12%. |

| [2] | Qualitative survey and bibliographical research model | Verifies how LSS could influence organisational sustainability. | The study identified the correlation between LSS and organisational sustainability, principally due to impacts that significantly influence the financial pillar of TBL. |

| [14] | Qualitative | Shares the experiences and perspectives of three practitioners from two continents about LSS from both academic and industrial viewpoints | Provided tread of LSS popularity and future direction |

| [52] | Qualitative | Describes the novel implementation of an integrated LSS framework and outlines how it was used to identify the factors that affect supply chain performance in an aerospace Maintenance Repair and Overhaul (MRO) facility | The study outlines the application and measures of the effectiveness of the integrated LSS framework through its ability to achieve new and enhanced performance by simultaneously reducing late material calls and reducing and stabilising Order To Receipt (OTR) times. |

| [15] | Qualitative | Review the literature on Lean Six Sigma from six different perspectives pertaining to manufacturing firms. | A generic framework for the implementation of Lean Six Sigma with environmentally benign tools was developed. The developed framework incorporates environmental aspects while implementing Lean Six Sigma which helps in reducing cost, waste, environmental impacts, and other inefficiencies associated with the manufacturing process |

| [47] | Quantitative | Investigates the dynamics of the key drivers of innovation-led lean approaches and their influence on sustainable performance over a long time in the manufacturing supply chain | The dynamic behaviour of ‘Government regulations’ and ‘Conducive working conditions’ influence sustainable performance exponentially over a long time in the manufacturing supply chain. the study also reported the dynamics of ‘Cash availability’ and ‘Fundamental knowledge’ and indicated that they are not highly influential on sustainable performance over a long time |

| [111] | Qualitative | Reviewing the existing literature review on Lean Six Sigma for services, construct of morphological analysis framework, and identify research gaps to point to future research possibilities and priorities. | The MA framework constructed based on six dimensions, namely, organisational context of applications, desired outcomes, implementation systems, LSS tools and techniques, integration with other management philosophies and evaluation methods, involving 40 focused themes, has revealed 355 distinct research gaps as opportunities for future research. |

| [32] | Qualitative | Describes how human factors and cognitive engineering methods can be combined with LSS to create an enhanced productivity framework for complex manufacturing. | This research showed the successful use of the DMAIC structure as a guide for the deployment of these new methods in conjunction with normal LSS tools |

| [11] | Qualitative | This paper seeks to discover convergences between studies and LSS implementations carried out in organisations comprising various business areas and systematises principles and practices of the Lean Six Sigma (LSS) method to encourage and facilitate its implementation and management in different contexts. | This study suggested that the number of the LSS publication significantly increased between 2008-2018 and the main disciplines related to LSS are business management and accounting (25%), Computer science (6%), Nursing (4%), and social science (3). |

| [9] | Empirical | This paper builds on previous studies that explored the research patterns over 15 years and considers the status of the integration of Lean and Six Sigma. This research specifically, addresses whether Lean and Six Sigma are strong together and explores the reasons why Lean researchers and practitioners may be less likely to integrate Six Sigma in their work. | Findings indicate that LSS has developed over time and will continue to develop and improve as a methodology rather than being replaced with a new methodology. |

| [5] | Qualitative | Chapter 6 of the book focuses on the LSS as a DC in the banking sector exploring the strategic value of the LSS through iterative triangulation offering an evolutionary dynamic perspective of LSS. | Findings indicate that the nature of the LSS as a DC could be established through a cross-case analysis. The presence of input factors shows that LSS as a CI practice could be consciously created as an organisation by focused efforts and does not exist as mere chance. LSS as an organisational capability needs to be nourished for progress, as it gets influenced by both internal and external factors of the organisation. LSS also contributes to the organisational learning process due to its ability to contribute towards first-order (Exploitative/reactive) learning, second order (explorative/proactive) learning, and meta-learning (learning to learn) for creating a culture of CI on an ongoing basis. |

| [14] | A case study of a kindergarten. | The application of the Six Sigma methodology blended and supported by the application of various Lean tools is demonstrated in a case study of a kindergarten | The study suggests that the application of the Six Sigma methodology blended and supported by the application of various Lean tools improve the efficiency and effectiveness of business processes. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ndrecaj, V.; Mohamed Hashim, M.A.; Mason-Jones, R.; Ndou, V.; Tlemsani, I. Exploring Lean Six Sigma as Dynamic Capability to Enable Sustainable Performance Optimisation in Times of Uncertainty. Sustainability 2023, 15, 16542. https://doi.org/10.3390/su152316542

Ndrecaj V, Mohamed Hashim MA, Mason-Jones R, Ndou V, Tlemsani I. Exploring Lean Six Sigma as Dynamic Capability to Enable Sustainable Performance Optimisation in Times of Uncertainty. Sustainability. 2023; 15(23):16542. https://doi.org/10.3390/su152316542

Chicago/Turabian StyleNdrecaj, Vera, Mohamed Ashmel Mohamed Hashim, Rachel Mason-Jones, Valentina Ndou, and Issam Tlemsani. 2023. "Exploring Lean Six Sigma as Dynamic Capability to Enable Sustainable Performance Optimisation in Times of Uncertainty" Sustainability 15, no. 23: 16542. https://doi.org/10.3390/su152316542

APA StyleNdrecaj, V., Mohamed Hashim, M. A., Mason-Jones, R., Ndou, V., & Tlemsani, I. (2023). Exploring Lean Six Sigma as Dynamic Capability to Enable Sustainable Performance Optimisation in Times of Uncertainty. Sustainability, 15(23), 16542. https://doi.org/10.3390/su152316542