Risk Assessment in Sustainable Production: Utilizing a Hybrid Evaluation Model to Identify the Waste Factors in Steel Plate Manufacturing

Abstract

:1. Introduction

- The waste factors in the steel-plate-cutting process have been effectively identified.

- The Decision-Making Trial and Evaluation Laboratory (DEMATEL) method is utilized to determine the weights of the four risk factors pertaining to the issue.

- PCIM-MADM (Performance Calculation technique of the Integrated Multiple Multi-Attribute Decision Making) is applied to integrate the computational outcomes of SAW (Simple Additive Weight), VIKOR (VlseKriterijuska Optimizacija I Komoromisno Resenje), GRA (Grey Relational Analysis), and COPRAS (COmplex PRoportional ASsessment), thereby yielding a more reliable final risk score for the fault modes.

- Improvement strategies are devised for the fault modes with the highest risk scores in order to diminish waste during the steel-plate-cutting process.

- The research concept and methodology proposed offer replicability, serving as a foundation for waste factor evaluations in other industries.

- Systematically identify the waste factors in the steel-plate-cutting process by using an integrated approach that combines FMEA with advanced Multi-Criteria Decision-Making (MCDM) methods.

- Apply the DEMATEL method to quantitatively assess the interdependencies among the identified risk factors, thereby enhancing the accuracy of risk prioritization.

- Utilize the Performance Calculation technique of Integrated Multiple Multi-Attribute Decision Making (PCIM-MADM) to amalgamate various analytical outcomes, thereby deriving a robust and reliable final risk score for each identified fault mode.

- Develop and propose targeted improvement strategies for the most critical waste factors, aiming to significantly reduce waste and enhance the efficiency of the steel plate manufacturing process.

- Demonstrate the replicability and applicability of the proposed model across different industrial sectors, thereby broadening its utility in addressing similar challenges in waste management and sustainable manufacturing practices.

2. Literature Review

3. Methods

3.1. Theory of FMEA

- i.

- Different risk factors might yield the same RPN value, but their underlying risks may not be identical. For instance, two failure modes with S, O, and D values of 1, 3, and 6, and 2, 3, and 3, respectively, both yield an RPN value of 18. Therefore, these two failure modes might be perceived as being equally significant by decision makers, although one may pose a higher risk. This failure mode may lead to the malfunction of other components, affecting the safety and reliability of the product and process.

- ii.

- The formula for RPN is contentious, as it only considers three risk factors, overlooking the interrelationship among them and other factors influencing risk. Additionally, the traditional RPN computation often oversimplifies the interrelationship among these risk factors and their influence on overall risk [36]. Risk is a complex and multifaceted concept involving various factors, including technical, operational, and economic considerations. The traditional approach treats these factors in isolation, which can lead to an incomplete understanding of the true risk landscape. Furthermore, using a single numerical value like RPN can create a false sense of precision and may not capture the full spectrum of risks associated with a system or process. This limitation becomes particularly evident when comparing different failure modes with varying economic implications [37].

- iii.

- When calculating the RPN, the relative importance of the three risks is not considered. All three factors bear the same weight, and the ambiguity and subjectivity involved in the process are often overlooked. Practically, each risk holds a different level of importance.

- iv.

- The formula for RPN is overly simplistic, lacking a robust mathematical foundation. It is susceptible to changes in risk factors; moreover, a slight variation could significantly impact the final RPN value, which is not conducive to determining rankings.

3.2. FMEA-Based MADM

- i.

- Adjustment of risk factor weights.

- ii.

- Calculation of the RPN formula.

- iii.

- Information uncertainty.

- Previous studies need to address or discuss the risks inherent in the cutting process of steel-plate-cutting factories. This research, therefore, centers on this niche, targeting the reduction in raw material wastage and operational costs of enterprises. It delves into the major failure modes in the operations of steel-plate-cutting factories, identifying the modes requiring priority consideration and improvement, making the findings applicable in practice.

- The PCIM-MADM method is utilized for ranking, diverging from traditional FMEA risk assessment studies. Following the suggestions of Lo et al. [46], the incorporation of anticipated cost (E) significantly enhances the reliability of risk assessment. By amalgamating various MADM techniques, failure modes are ranked, thus offering a fresh perspective on prioritizing and addressing operational risks in steel-plate-cutting factories.

3.3. Determining the Influential Weights Using DEMATEL

3.4. Using the SAW, VIKOR, GRA, and COPRAS Methods to Obtain the Rankings of the Failure Modes

3.5. PCIM-MADM

4. Results

4.1. Algorithm Execution and Analysis

- What is the severity level post-occurrence of the failure mode?

- What is the probability of occurrence for this failure mode?

- How feasible is it to detect this failure mode prior to its occurrence?

- What are the costs associated with repair or loss when this failure mode occurs?

4.2. SAW

4.3. VIKOR

4.4. GRA

4.5. COPRAS

4.6. PCIM

4.7. Comparison of Research Method

- SAW Ranking: FM2 > FM3 > FM7 > FM6 > FM4.

- VIKOR Ranking: FM2 > FM7 > FM3 > FM6 > FM4.

- GRA Ranking: FM2 > FM3 > FM7 > FM6 > FM4.

- COPRAS Ranking: FM2 > FM3 > FM7 > FM6 > FM4.

4.8. Sensitivity Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statements

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Belova, I.N.; Chusmakaev, R.M.; Belov, F.D.; Egorycheva, E.A. Impact of the COVID-19 Pandemic on the World Steel Market. In Geo-Economy of the Future: Sustainable Agriculture and Alternative Energy; Springer: Berlin/Heidelberg, Germany, 2022; pp. 75–84. [Google Scholar]

- Maher, R.A.; Melhem, N.N.; Almutlaq, M. Developing a control and management system for reinforcement steel-leftover in industrial factories. IFAC-PapersOnLine 2019, 52, 625–629. [Google Scholar] [CrossRef]

- Cao, X.; Deng, Y. A new geometric mean FMEA method based on information quality. IEEE Access 2019, 7, 95547–95554. [Google Scholar] [CrossRef]

- Mabkhot, M.M.; Ferreira, P.; Maffei, A.; Podržaj, P.; Mądziel, M.; Antonelli, D.; Lanzetta, M.; Barata, J.; Boffa, E.; Finžgar, M. Mapping industry 4.0 enabling technologies into united nations sustainability development goals. Sustainability 2021, 13, 2560. [Google Scholar] [CrossRef]

- Moldavska, A.; Welo, T. A Holistic approach to corporate sustainability assessment: Incorporating sustainable development goals into sustainable manufacturing performance evaluation. J. Manuf. Syst. 2019, 50, 53–68. [Google Scholar] [CrossRef]

- Davim, J.P. Green Manufacturing Processes and Systems; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Rissman, J.; Bataille, C.; Masanet, E.; Aden, N.; Morrow III, W.R.; Zhou, N.; Elliott, N.; Dell, R.; Heeren, N.; Huckestein, B. Technologies and policies to decarbonize global industry: Review and assessment of mitigation drivers through 2070. Appl. Energy 2020, 266, 114848. [Google Scholar] [CrossRef]

- Wang, W.; Liu, X.; Chen, X.; Qin, Y. Risk assessment based on hybrid FMEA framework by considering decision maker’s psychological behavior character. Comput. Ind. Eng. 2019, 136, 516–527. [Google Scholar] [CrossRef]

- Nidheesh, P.; Kumar, M.S. An overview of environmental sustainability in cement and steel production. J. Clean. Prod. 2019, 231, 856–871. [Google Scholar] [CrossRef]

- Branca, T.A.; Colla, V.; Algermissen, D.; Granbom, H.; Martini, U.; Morillon, A.; Pietruck, R.; Rosendahl, S. Reuse and recycling of by-products in the steel sector: Recent achievements paving the way to circular economy and industrial symbiosis in Europe. Metals 2020, 10, 345. [Google Scholar] [CrossRef]

- Davim, J.P. Sustainable and Intelligent Manufacturing: Perceptions in line with 2030 Agenda of Sustainable Development. BioResources 2024, 19, 4–5. [Google Scholar] [CrossRef]

- Miśkiewicz, R.; Wolniak, R. Practical application of the Industry 4.0 concept in a steel company. Sustainability 2020, 12, 5776. [Google Scholar] [CrossRef]

- Gu, X.; Lin, C.; Wang, B.; Wang, J.; Ouyang, W. A comprehensive assessment of anthropogenic impacts, contamination, and ecological risks of toxic elements in sediments of urban rivers: A case study in Qingdao, East China. Environ. Adv. 2022, 7, 100143. [Google Scholar] [CrossRef]

- Davim, J.P. Sustainable Manufacturing; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Pantazopoulos, G.; Tsinopoulos, G. Process failure modes and effects analysis (PFMEA): A structured approach for quality improvement in the metal forming industry. J. Fail. Anal. Prev. 2005, 5, 5–10. [Google Scholar] [CrossRef]

- Ahmed, U.; Carpitella, S.; Certa, A. An integrated methodological approach for optimising complex systems subjected to predictive maintenance. Reliab. Eng. Syst. Saf. 2021, 216, 108022. [Google Scholar] [CrossRef]

- Papadopoulou, S.; Vazdirvanidis, A.; Toulfatzis, A.; Rikos, A.; Pantazopoulos, G. Failure investigation of products and components in metal forming industry: Root cause analysis and process-based approach. J. Fail. Anal. Prev. 2020, 20, 106–114. [Google Scholar] [CrossRef]

- Gajdzik, B.; Sitko, J. Steel mill products analysis using qualities methods. Metalurgija 2016, 55, 807–810. [Google Scholar]

- Zhang, J.; Zhang, S.; Liang, Z.; Lang, X.; Shi, M.; Qiao, J.; Wei, J.; Dai, H.; Kang, J. A risk assessment method based on DEMATEL-STPA and its application in safety risk evaluation of hydrogen refueling stations. Int. J. Hydrogen Energy, 2023; in press. [Google Scholar] [CrossRef]

- Mzougui, I.; Carpitella, S.; Certa, A.; El Felsoufi, Z.; Izquierdo, J. Assessing supply chain risks in the automotive industry through a modified MCDM-based FMECA. Processes 2020, 8, 579. [Google Scholar] [CrossRef]

- Liu, Z.; Bi, Y.; Liu, P. An evidence theory-based large group FMEA framework incorporating bounded confidence and its application in supercritical water gasification system. Appl. Soft Comput. 2022, 129, 109580. [Google Scholar] [CrossRef]

- Ervural, B.; Ayaz, H.I. A fully data-driven FMEA framework for risk assessment on manufacturing processes using a hybrid approach. Eng. Fail. Anal. 2023, 152, 107525. [Google Scholar] [CrossRef]

- Carli, R.; Cavone, G.; Dotoli, M.; Epicoco, N.; Manganiello, C.; Tricarico, L. ICT-based methodologies for sheet metal forming design: A survey on simulation approaches. In Proceedings of the 2019 IEEE International Conference on Systems, Man and Cybernetics (SMC), Bari, Italy, 6–9 October 2019; pp. 128–133. [Google Scholar]

- Cavone, G.; Bozza, A.; Carli, R.; Dotoli, M. MPC-based process control of deep drawing: An industry 4.0 case study in automotive. IEEE Trans. Autom. Sci. Eng. 2022, 19, 1586–1598. [Google Scholar] [CrossRef]

- Gajdzik, B.; Sitko, J. An analysis of the causes of complaintsabout steel sheets in metallurgical product quality management systems. Metalurgija 2014, 53, 135–138. [Google Scholar]

- Trzepieciński, T. Recent developments and trends in sheet metal forming. Metals 2020, 10, 779. [Google Scholar] [CrossRef]

- Liu, H.-C.; Chen, X.-Q.; Duan, C.-Y.; Wang, Y.-M. Failure mode and effect analysis using multi-criteria decision making methods: A systematic literature review. Comput. Ind. Eng. 2019, 135, 881–897. [Google Scholar] [CrossRef]

- Lo, H.-W.; Liou, J.J. A novel multiple-criteria decision-making-based FMEA model for risk assessment. Appl. Soft Comput. 2018, 73, 684–696. [Google Scholar] [CrossRef]

- Lin, S.-W.; Lo, H.-W. An FMEA model for risk assessment of university sustainability: Using a combined ITARA with TOPSIS-AL approach based neutrosophic sets. Ann. Oper. Res. 2023, 1–27. [Google Scholar] [CrossRef]

- Chang, T.-W.; Lo, H.-W.; Chen, K.-Y.; Liou, J.J. A novel FMEA model based on rough BWM and rough TOPSIS-AL for risk assessment. Mathematics 2019, 7, 874. [Google Scholar] [CrossRef]

- Yazdi, M.; Daneshvar, S.; Setareh, H. An extension to fuzzy developed failure mode and effects analysis (FDFMEA) application for aircraft landing system. Saf. Sci. 2017, 98, 113–123. [Google Scholar] [CrossRef]

- Chi, C.-F.; Sigmund, D.; Astardi, M.O. Classification scheme for root cause and failure modes and effects analysis (FMEA) of passenger vehicle recalls. Reliab. Eng. Syst. Saf. 2020, 200, 106929. [Google Scholar] [CrossRef]

- Başhan, V.; Demirel, H.; Gul, M. An FMEA-based TOPSIS approach under single valued neutrosophic sets for maritime risk evaluation: The case of ship navigation safety. Soft Comput. 2020, 24, 18749–18764. [Google Scholar] [CrossRef]

- Chiozza, M.L.; Ponzetti, C. FMEA: A model for reducing medical errors. Clin. Chim. Acta 2009, 404, 75–78. [Google Scholar] [CrossRef]

- Huang, J.; You, J.-X.; Liu, H.-C.; Song, M.-S. Failure mode and effect analysis improvement: A systematic literature review and future research agenda. Reliab. Eng. Syst. Saf. 2020, 199, 106885. [Google Scholar] [CrossRef]

- Xu, N.; Di, K.; Liu, F.; Zhao, W.; Zhang, B. Risk Assessment of Lift-Jacking Accidents Using FFTA-FMEA. Appl. Sci. 2023, 13, 7312. [Google Scholar] [CrossRef]

- Ribas, J.R.; Severo, J.C.R.; Guimaraes, L.F.; Perpetuo, K.P.C. A fuzzy FMEA assessment of hydroelectric earth dam failure modes: A case study in Central Brazil. Energy Rep. 2021, 7, 4412–4424. [Google Scholar] [CrossRef]

- Ouyang, L.; Che, Y.; Yan, L.; Park, C. Multiple perspectives on analyzing risk factors in FMEA. Comput. Ind. 2022, 141, 103712. [Google Scholar] [CrossRef]

- Mohsen, O.; Fereshteh, N. An extended VIKOR method based on entropy measure for the failure modes risk assessment–A case study of the geothermal power plant (GPP). Saf. Sci. 2017, 92, 160–172. [Google Scholar] [CrossRef]

- Dhalmahapatra, K.; Garg, A.; Singh, K.; Xavier, N.F.; Maiti, J. An integrated RFUCOM–RTOPSIS approach for failure modes and effects analysis: A case of manufacturing industry. Reliab. Eng. Syst. Saf. 2022, 221, 108333. [Google Scholar] [CrossRef]

- Wang, L.; Yan, F.; Wang, F.; Li, Z. FMEA-CM based quantitative risk assessment for process industries—A case study of coal-to-methanol plant in China. Process Saf. Environ. Prot. 2021, 149, 299–311. [Google Scholar] [CrossRef]

- Moslem, S.; Gul, M.; Farooq, D.; Celik, E.; Ghorbanzadeh, O.; Blaschke, T. An integrated approach of best-worst method (BWM) and triangular fuzzy sets for evaluating driver behavior factors related to road safety. Mathematics 2020, 8, 414. [Google Scholar] [CrossRef]

- Liu, P.; Li, Y. An improved failure mode and effect analysis method for multi-criteria group decision-making in green logistics risk assessment. Reliab. Eng. Syst. Saf. 2021, 215, 107826. [Google Scholar] [CrossRef]

- Liu, Y.; Alcantud, J.C.R.; Rodríguez, R.M.; Qin, K.; Martínez, L. Intertemporal hesitant fuzzy soft sets: Application to group decision making. Int. J. Fuzzy Syst. 2020, 22, 619–635. [Google Scholar] [CrossRef]

- Boral, S.; Howard, I.; Chaturvedi, S.K.; McKee, K.; Naikan, V.N.A. An integrated approach for fuzzy failure modes and effects analysis using fuzzy AHP and fuzzy MAIRCA. Eng. Fail. Anal. 2020, 108, 104195. [Google Scholar] [CrossRef]

- Lo, H.-W.; Liou, J.J.; Huang, C.-N.; Chuang, Y.-C. A novel failure mode and effect analysis model for machine tool risk analysis. Reliab. Eng. Syst. Saf. 2019, 183, 173–183. [Google Scholar] [CrossRef]

- Fontela, E.; Gabus, A. The DEMATEL Observer: Battelle Institute; Geneva Research Center: Geneva, Switzerland, 1976; pp. 56–61. [Google Scholar]

- Lo, H.-W.; Liou, J.J.; Yang, J.-J.; Huang, C.-N.; Lu, Y.-H. An extended FMEA model for exploring the potential failure modes: A case study of a steam turbine for a nuclear power plant. Complexity 2021, 2021, 5766855. [Google Scholar] [CrossRef]

- Zayat, W.; Kilic, H.S.; Yalcin, A.S.; Zaim, S.; Delen, D. Application of MADM methods in Industry 4.0: A literature review. Comput. Ind. Eng. 2023, 177, 109075. [Google Scholar] [CrossRef]

| Risk Factor | Description | References |

|---|---|---|

| Severity (S) | Severity evaluates the extent of damage and impact caused by a failure mode on the overall system. It assesses the level of influence that a failure mode exerts on the entire system, product, equipment, or process when it occurs. | [27,29,33] |

| Occurrence (O) | Occurrence measures the likelihood or probability of a failure mode manifesting. The frequency of failure mode occurrences can be estimated by examining past related failure records. A higher value indicates a higher probability of the failure mode occurring. Typically, the frequency of a failure mode over a specific period determines the level. | [28,29,33] |

| Detectability (D) | Detectability refers to the possibility of or difficulty in identifying a failure mode when it occurs in the system, product, equipment, or process. If a failure mode can be effectively and timely predicted before its occurrence, the generation of the failure mode can be reduced. High detectability implies a lower risk of failure, while low detectability suggests a higher probability of risk emergence. | [27,31,32] |

| Failure Mode | Description | Possible Causes | Figure Reference |

|---|---|---|---|

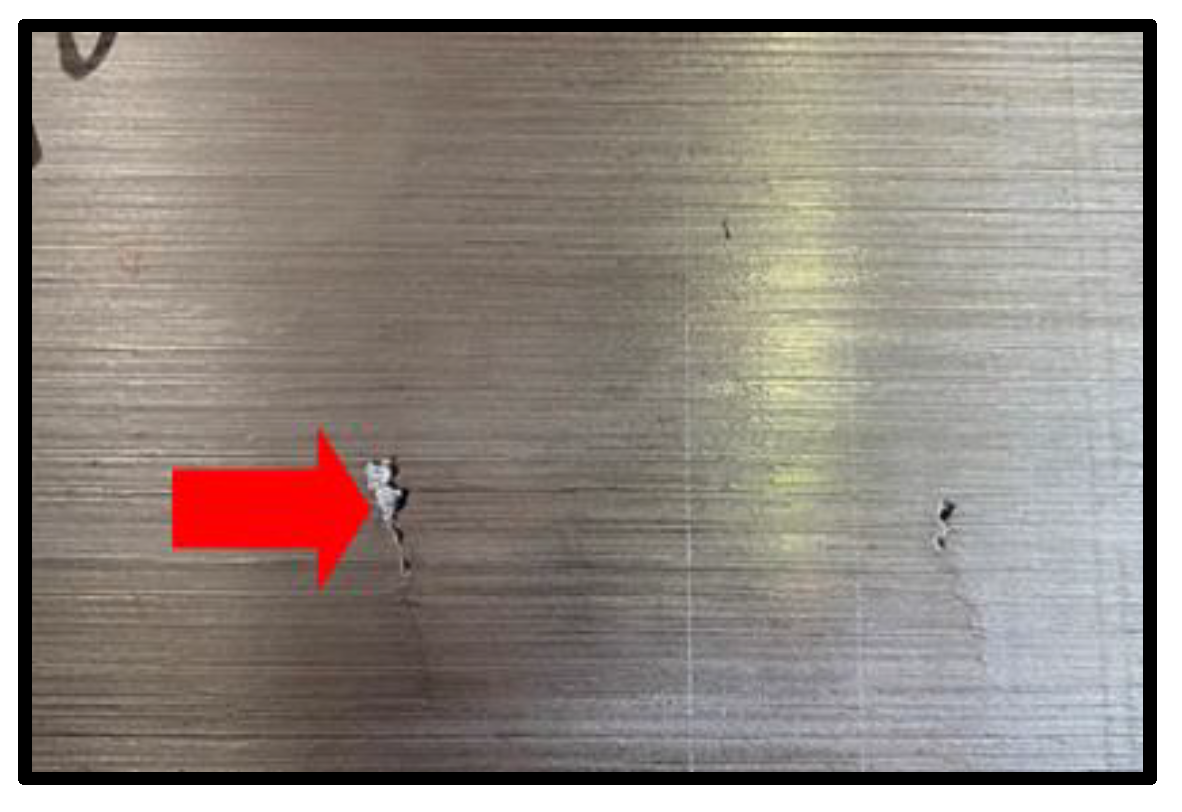

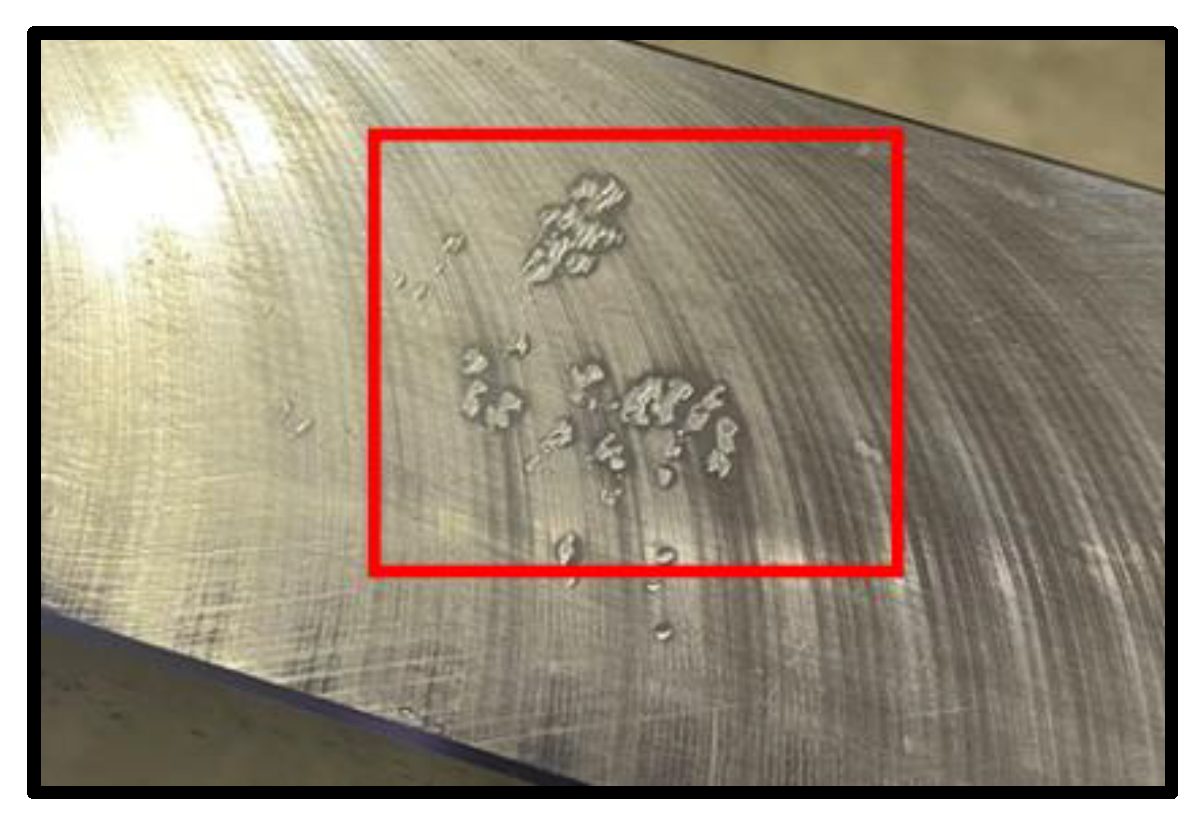

| FM1 | Surface Deformation of Steel Plate | Excessive clamp pressure, leading to extrusion and uneven steel plate surface | Figure 1 |

| FM2 | Excessive Internal Holes in Steel Plate | Upstream material factors and insufficient rolling ratio during raw material production, leading to the formation of air or sand holes internally | Figure 2 |

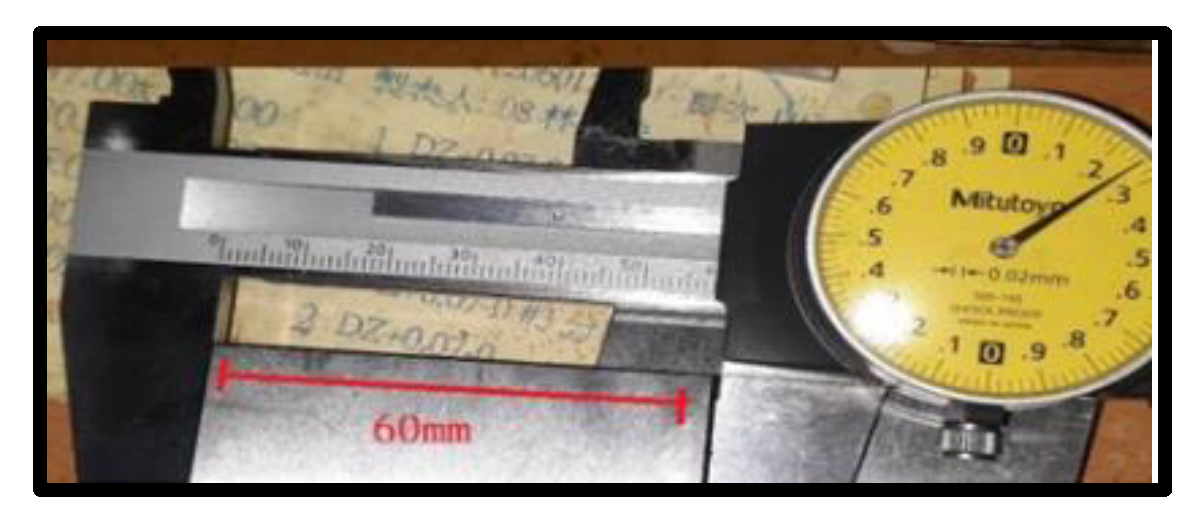

| FM3 | Incorrect Dimensioning in Exterior Processing, Non-conformity in Workpiece Dimensions | Misinterpretation of order dimensions by on-site operators, leading to non-conformity in processing dimensions | Figure 3 |

| FM4 | Workpiece Precision Deviation, Flatness/Perpendicularity exceeding tolerances | Machines not calibrated for an extended period, leading to cutting position displacement | Figure 4 |

| FM5 | Automatic Feeding Equipment Malfunction, Abnormal Cutting Position, Inaccurate Calibration/Positioning | Linear rail/screw rail failure | Figure 5 |

| FM6 | Mismatch in Workpiece Dimensions with Production Control Handover and Business Information | Communication lapse among production control, business, and on-site workers, leading to misinformation during handover | N/A |

| FM7 | Client/Order-taking Window Oversight, Non-conformity in Workpiece Dimensions | Client/order-taking window oversight without re-confirming order details, leading to erroneous order content | N/A |

| FM8 | Hydraulic Oil Pipeline Abnormality, Elevated Cutting Rate | Oil pipe leakage, leading to increased cutting rate, possibly resulting in insufficient workpiece dimensions | Figure 6 |

| FM9 | Saw Blade Breakage | Wear and tear or aging of the saw blade or usage of incorrect saw blade | Figure 7 |

| FM10 | Saw Blade Teeth Damage | Wear and tear or aging of the saw blade or usage of incorrect saw blade | Figure 8 |

| FM11 | Inadequate Packaging and Delivery, leading to Workpiece Wear or Damage | Absence of standard SOP or staff education, resulting in drivers or shipping personnel not packaging the workpieces adequately | Figure 9 |

| FM12 | Excessive Residual Material Production | Lack of detailed optimal cutting plan setting | Figure 10 |

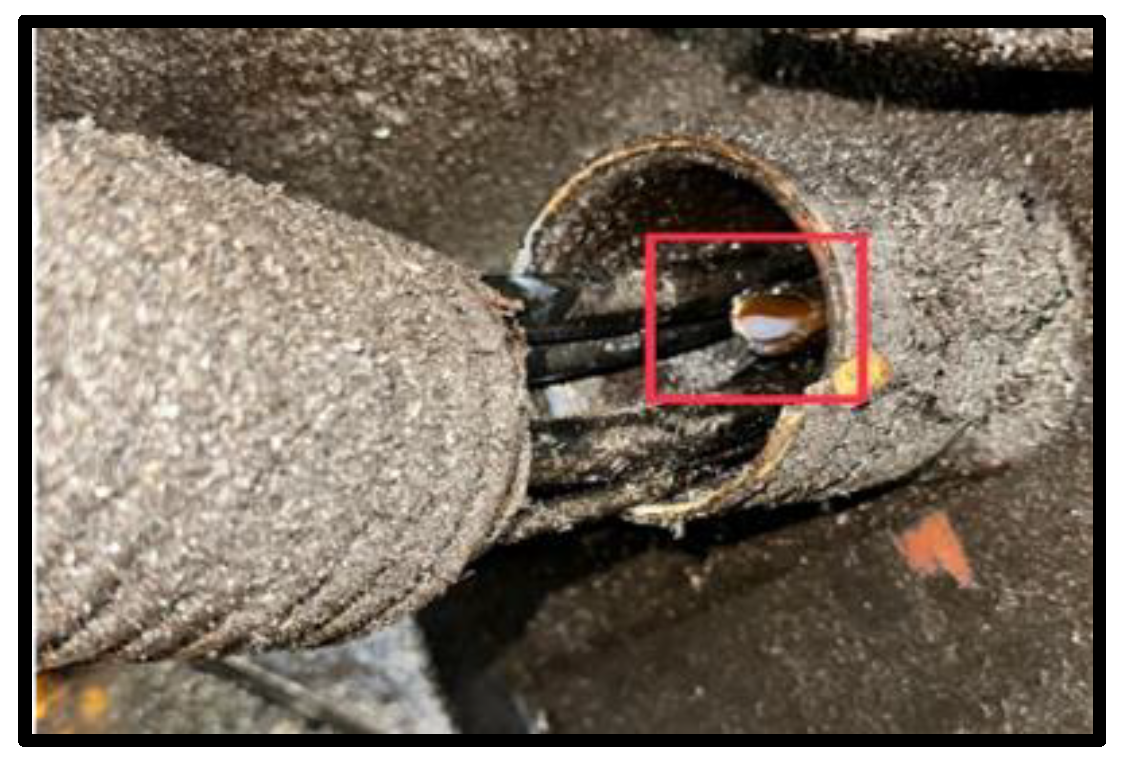

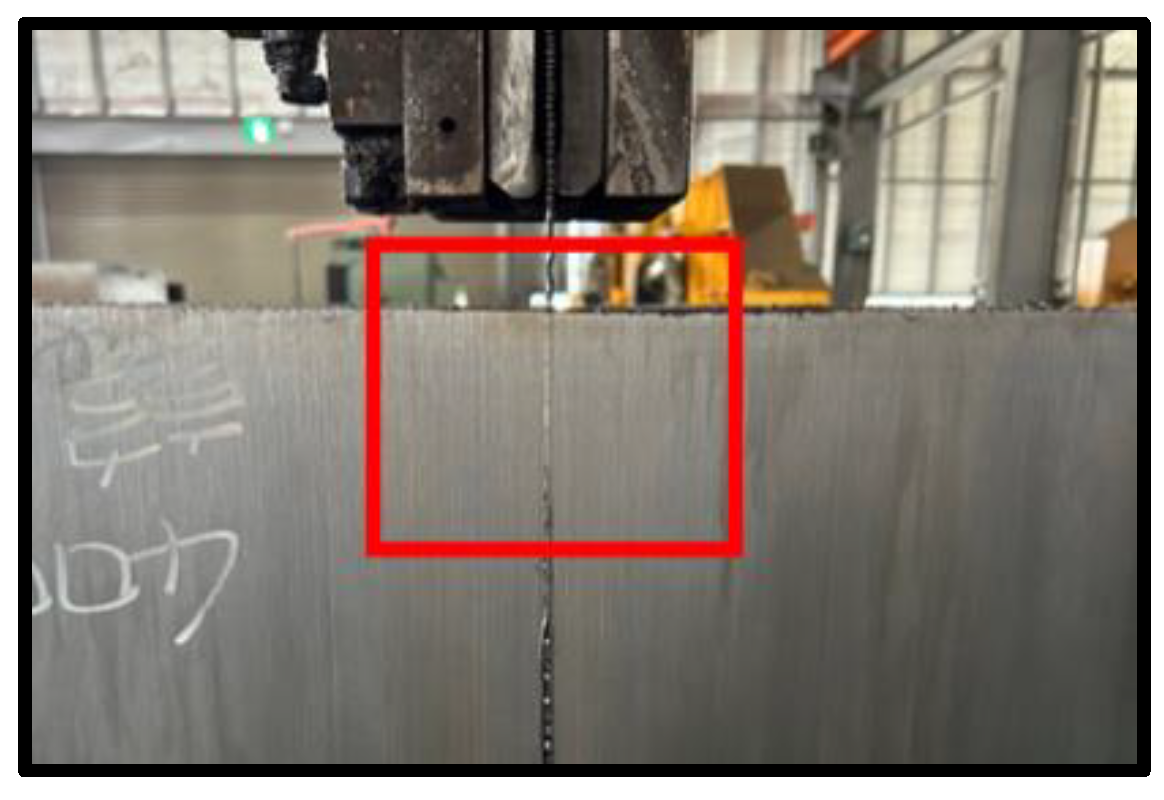

| FM13 | Steel Plate Clamping onto the Tool during Cutting Process | Machine bed unevenness with height differences | Figure 11 and Figure 12 |

| FM14 | Tool Arm Malfunction | 1. Long-term operation at machine limits, leading to tool arm offset 2. Unaddressed human-induced collisions | Figure 13 |

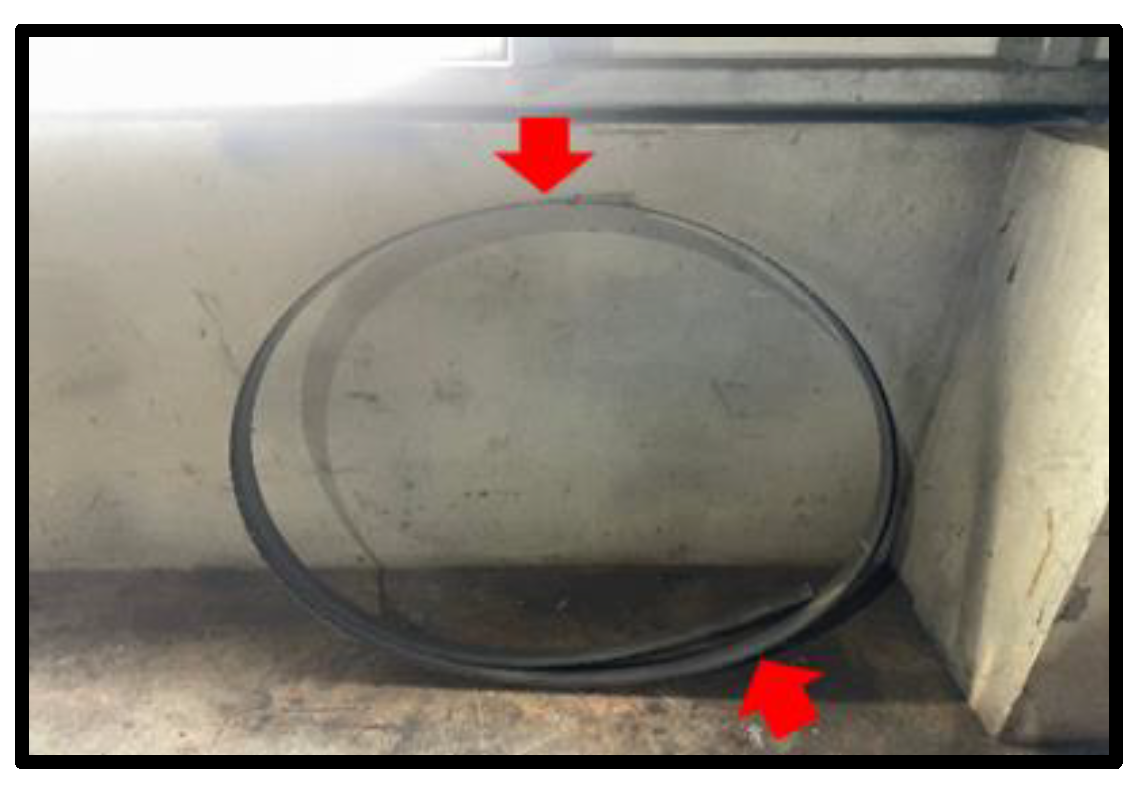

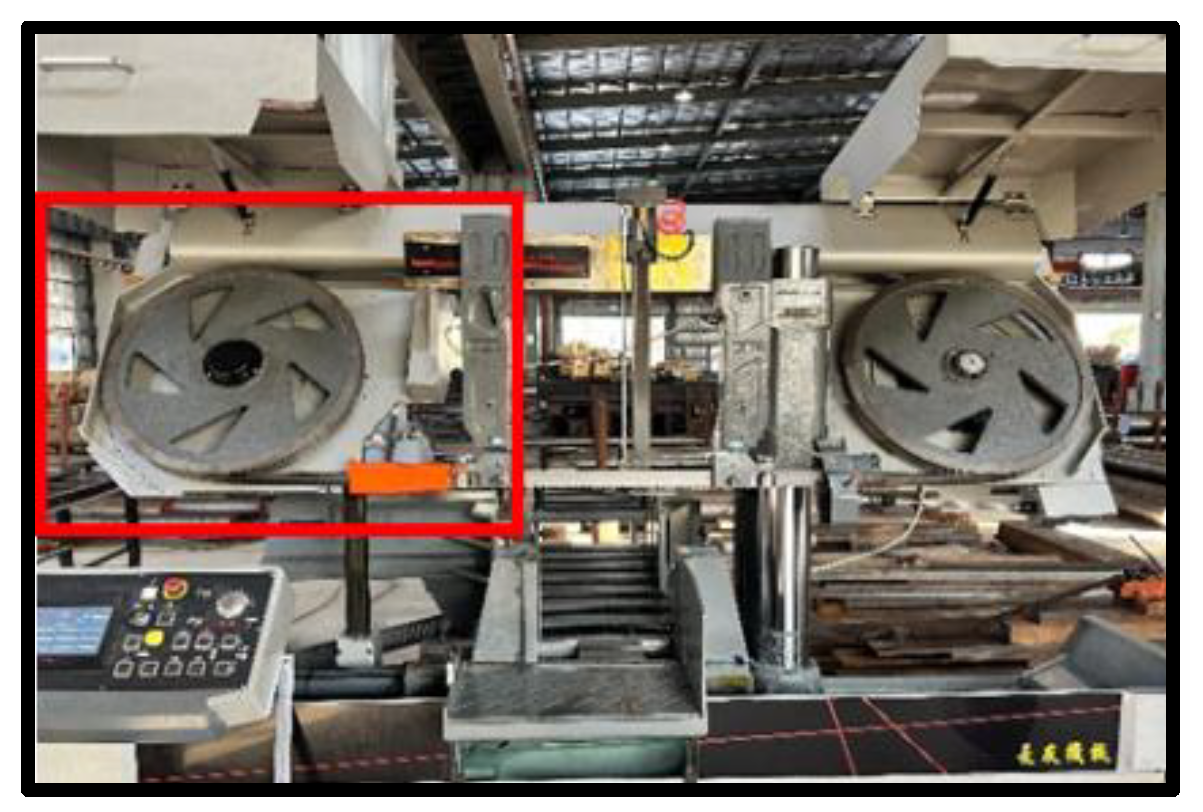

| FM15 | Saw Blade Wheel/Wheel Shaft Eccentricity | Improper operation and long-term usage without wheel replacement, leading to wheel eccentricity or even wheel shaft displacement | Figure 14 |

| FM16 | Tungsten Steel Seat Clamp too Loose/Tight | 1. Consumables not replaced in time 2. Hydraulic inaccuracy 3. On-site operator procedural errors | Figure 15 |

| Expert No. | Department | Position | Years of Experience |

|---|---|---|---|

| 1 | Management | Chairman | 30 |

| 2 | Management | Manager | 22 |

| 3 | Management | Plant Manager | 25 |

| 4 | Management | Assistant Plant Manager | 17 |

| 5 | Sales | Sales Manager | 23 |

| 6 | Sales | Senior Sales | 13 |

| 7 | Sales | Senior Sales | 15 |

| 8 | Cutting | Team Leader | 11 |

| 9 | Cutting | Team Leader | 19 |

| 10 | Cutting | Senior Technician | 24 |

| Failure Mode | S | O | D | E |

|---|---|---|---|---|

| FM1 | (5, 3, 6, 7, 6, 6, 6, 4, 5, 5) | (6, 2, 6, 2, 3, 2, 4, 4, 3, 4) | (6, 2, 3, 2, 3, 2, 4, 3, 4, 4) | (4, 3, 4, 6, 4, 4, 3, 3, 4, 3) |

| FM2 | (7, 5, 9, 9, 9, 8, 5, 8, 9, 7) | (3, 1, 2, 1, 1, 2, 2, 2, 3, 3) | (5, 9, 7, 9, 8, 5, 8, 8, 9, 7) | (5, 9, 6, 6, 6, 8, 6, 8, 7, 7) |

| FM3 | (6, 7, 9, 10, 10, 6, 8, 6, 7, 6) | (6, 3, 3, 3, 6, 4, 6, 6, 6, 5) | (5, 6, 3, 7, 5, 3, 4, 4, 4, 3) | (4, 6, 7, 5, 5, 5, 4, 3, 5, 5) |

| FM4 | (7, 7, 7, 4, 7, 7, 7, 5, 7, 4) | (6, 3, 3, 5, 5, 4, 3, 6, 4, 5) | (4, 6, 3, 3, 2, 4, 5, 4, 3, 3) | (4, 7, 4, 5, 4, 7, 3, 3, 5, 4) |

| FM5 | (5, 3, 4, 5, 2, 6, 2, 3, 5, 3) | (3, 2, 1, 3, 2, 2, 2, 4, 3, 2) | (7, 3, 3, 3, 7, 3, 7, 7, 3, 4) | (4, 3, 6, 2, 2, 3, 3, 4, 2, 4) |

| FM6 | (4, 5, 8, 8, 8, 5, 6, 4, 6, 6) | (6, 3, 4, 2, 2, 4, 4, 4, 6, 3) | (7, 3, 3, 3, 3, 3, 7, 7, 5, 4) | (4, 7, 4, 4, 7, 7, 5, 7, 6, 5) |

| FM7 | (4, 4, 9, 9, 9, 5, 6, 4, 6, 6) | (6, 5, 4, 4, 2, 4, 4, 3, 6, 3) | (7, 3, 3, 3, 3, 4, 6, 7, 5, 4) | (4, 4, 6, 4, 8, 7, 5, 8, 4, 5) |

| FM8 | (4, 2, 5, 5, 2, 2, 4, 2, 3, 4) | (4, 2, 2, 1, 2, 2, 3, 4, 2, 2) | (7, 9, 9, 3, 8, 3, 7, 9, 4, 6) | (4, 3, 7, 4, 3, 3, 6, 5, 5, 4) |

| FM9 | (3, 2, 5, 4, 2, 2, 6, 2, 3, 2) | (2, 2, 1, 3, 4, 1, 2, 4, 3, 2) | (7, 3, 8, 3, 8, 3, 8, 8, 3, 4) | (3, 4, 4, 5, 4, 3, 5, 2, 5, 4) |

| FM10 | (3, 2, 3, 4, 3, 1, 5, 2, 3, 2) | (6, 2, 3, 3, 5, 2, 2, 4, 3, 3) | (5, 3, 7, 3, 7, 2, 5, 3, 3, 3) | (3, 2, 5, 5, 3, 2, 4, 2, 4, 3) |

| FM11 | (6, 2, 6, 5, 6, 2, 3, 5, 2, 4) | (5, 3, 3, 3, 6, 3, 4, 4, 4, 3) | (6, 3, 2, 2, 6, 2, 6, 3, 2, 2) | (3, 3, 7, 5, 4, 6, 5, 3, 6, 5) |

| FM12 | (6, 4, 7, 7, 3, 4, 3, 6, 5, 4) | (8, 4, 6, 4, 8, 4, 8, 5, 7, 5) | (3, 3, 2, 2, 2, 3, 6, 5, 2, 2) | (6, 2, 6, 5, 4, 5, 2, 3, 3, 3) |

| FM13 | (4, 2, 6, 4, 2, 3, 6, 2, 4, 3) | (5, 2, 2, 4, 3, 2, 6, 3, 4, 3) | (6, 3, 6, 3, 8, 3, 4, 8, 3, 5) | (4, 2, 6, 5, 2, 3, 3, 2, 2, 3) |

| FM14 | (4, 2, 6, 4, 2, 2, 6, 2, 4, 4) | (6, 2, 2, 4, 2, 2, 6, 3, 4, 3) | (7, 3, 7, 3, 8, 3, 3, 8, 3, 5) | (3, 2, 6, 5, 2, 2, 4, 3, 3, 4) |

| FM15 | (3, 3, 6, 4, 2, 2, 6, 2, 6, 4) | (5, 2, 2, 3, 1, 1, 5, 3, 2, 2) | (6, 3, 7, 3, 8, 3, 4, 8, 4, 5) | (3, 3, 7, 5, 4, 2, 3, 3, 5, 3) |

| FM16 | (4, 2, 6, 4, 5, 2, 6, 2, 6, 2) | (5, 2, 2, 3, 3, 1, 5, 2, 2, 3) | (6, 3, 7, 3, 3, 3, 4, 7, 4, 4) | (4, 3, 7, 5, 3, 3, 4, 3, 3, 3) |

| Failure Mode | S | O | D | E |

|---|---|---|---|---|

| Wi | 0.213 | 0.215 | 0.258 | 0.313 |

| FM1 | 5.300 | 3.600 | 3.300 | 3.800 |

| FM2 | 7.700 | 3.500 | 7.500 | 6.800 |

| FM3 | 7.500 | 4.800 | 4.400 | 4.900 |

| FM4 | 6.200 | 4.400 | 3.700 | 4.600 |

| FM5 | 3.800 | 2.400 | 4.700 | 3.300 |

| FM6 | 6.000 | 3.800 | 4.500 | 5.600 |

| FM7 | 6.200 | 4.100 | 4.500 | 5.500 |

| FM8 | 3.300 | 2.400 | 6.500 | 4.400 |

| FM9 | 3.100 | 2.400 | 5.500 | 3.900 |

| FM10 | 2.800 | 3.300 | 4.100 | 3.300 |

| FM11 | 4.100 | 3.800 | 3.400 | 4.700 |

| FM12 | 4.900 | 5.900 | 3.000 | 3.900 |

| FM13 | 3.600 | 3.400 | 4.900 | 3.200 |

| FM14 | 3.600 | 3.400 | 5.000 | 3.400 |

| FM15 | 3.800 | 2.600 | 5.100 | 3.800 |

| FM16 | 3.900 | 2.800 | 4.400 | 3.800 |

| Failure Mode | S | O | D | E | SAWh |

|---|---|---|---|---|---|

| FM1 | 0.149 | 0.102 | 0.112 | 0.157 | 0.519 |

| FM2 | 0.213 | 0.057 | 0.255 | 0.280 | 0.805 |

| FM3 | 0.210 | 0.136 | 0.149 | 0.202 | 0.698 |

| FM4 | 0.174 | 0.125 | 0.126 | 0.190 | 0.614 |

| FM5 | 0.107 | 0.068 | 0.160 | 0.136 | 0.470 |

| FM6 | 0.168 | 0.108 | 0.153 | 0.231 | 0.660 |

| FM7 | 0.174 | 0.116 | 0.153 | 0.227 | 0.670 |

| FM8 | 0.093 | 0.068 | 0.221 | 0.181 | 0.563 |

| FM9 | 0.087 | 0.068 | 0.187 | 0.161 | 0.503 |

| FM10 | 0.079 | 0.094 | 0.139 | 0.136 | 0.447 |

| FM11 | 0.115 | 0.108 | 0.115 | 0.194 | 0.532 |

| FM12 | 0.138 | 0.167 | 0.102 | 0.161 | 0.567 |

| FM13 | 0.101 | 0.096 | 0.166 | 0.132 | 0.496 |

| FM14 | 0.101 | 0.096 | 0.170 | 0.140 | 0.507 |

| FM15 | 0.107 | 0.074 | 0.173 | 0.157 | 0.510 |

| FM16 | 0.109 | 0.079 | 0.149 | 0.157 | 0.495 |

| Failure Mode | S | O | D | E | Sj | Rj |

|---|---|---|---|---|---|---|

| FM1 | 0.088 | 0.154 | 0.198 | 0.212 | 0.652 | 0.212 |

| FM2 | 0.000 | 0.215 | 0.005 | 0.045 | 0.265 | 0.215 |

| FM3 | 0.004 | 0.108 | 0.147 | 0.151 | 0.410 | 0.151 |

| FM4 | 0.053 | 0.123 | 0.180 | 0.168 | 0.524 | 0.180 |

| FM5 | 0.145 | 0.200 | 0.134 | 0.240 | 0.719 | 0.240 |

| FM6 | 0.061 | 0.146 | 0.143 | 0.112 | 0.462 | 0.146 |

| FM7 | 0.053 | 0.135 | 0.143 | 0.117 | 0.448 | 0.143 |

| FM8 | 0.164 | 0.200 | 0.051 | 0.179 | 0.593 | 0.200 |

| FM9 | 0.171 | 0.200 | 0.097 | 0.207 | 0.675 | 0.207 |

| FM10 | 0.183 | 0.165 | 0.161 | 0.240 | 0.750 | 0.240 |

| FM11 | 0.133 | 0.146 | 0.194 | 0.162 | 0.635 | 0.194 |

| FM12 | 0.103 | 0.065 | 0.212 | 0.207 | 0.587 | 0.212 |

| FM13 | 0.152 | 0.162 | 0.124 | 0.246 | 0.684 | 0.246 |

| FM14 | 0.152 | 0.162 | 0.120 | 0.235 | 0.669 | 0.235 |

| FM15 | 0.145 | 0.192 | 0.115 | 0.212 | 0.665 | 0.212 |

| FM16 | 0.141 | 0.185 | 0.147 | 0.212 | 0.686 | 0.212 |

| Failure Mode | Si | R | V × S | (1 − V) × R | Qj(Qh) |

|---|---|---|---|---|---|

| FM1 | 0.652 | 0.212 | 0.399 | 0.337 | 0.737 |

| FM2 | 0.265 | 0.215 | 0.000 | 0.352 | 0.352 |

| FM3 | 0.410 | 0.151 | 0.150 | 0.039 | 0.189 |

| FM4 | 0.524 | 0.180 | 0.267 | 0.179 | 0.446 |

| FM5 | 0.719 | 0.240 | 0.468 | 0.473 | 0.941 |

| FM6 | 0.462 | 0.146 | 0.203 | 0.016 | 0.219 |

| FM7 | 0.448 | 0.143 | 0.189 | 0.000 | 0.189 |

| FM8 | 0.593 | 0.200 | 0.339 | 0.277 | 0.616 |

| FM9 | 0.675 | 0.207 | 0.423 | 0.310 | 0.733 |

| FM10 | 0.750 | 0.240 | 0.500 | 0.473 | 0.973 |

| FM11 | 0.635 | 0.194 | 0.382 | 0.246 | 0.628 |

| FM12 | 0.587 | 0.212 | 0.332 | 0.335 | 0.667 |

| FM13 | 0.684 | 0.246 | 0.432 | 0.500 | 0.932 |

| FM14 | 0.669 | 0.235 | 0.416 | 0.446 | 0.862 |

| FM15 | 0.665 | 0.212 | 0.412 | 0.337 | 0.750 |

| FM16 | 0.686 | 0.212 | 0.434 | 0.337 | 0.771 |

| Failure Mode | S | O | D | E |

|---|---|---|---|---|

| FM1 | 0.411 | 0.714 | 0.768 | 0.679 |

| FM2 | 0.000 | 1.000 | 0.018 | 0.143 |

| FM3 | 0.018 | 0.500 | 0.571 | 0.482 |

| FM4 | 0.250 | 0.571 | 0.696 | 0.536 |

| FM5 | 0.679 | 0.929 | 0.518 | 0.768 |

| FM6 | 0.286 | 0.679 | 0.554 | 0.357 |

| FM7 | 0.250 | 0.625 | 0.554 | 0.375 |

| FM8 | 0.768 | 0.929 | 0.196 | 0.571 |

| FM9 | 0.804 | 0.929 | 0.375 | 0.661 |

| FM10 | 0.857 | 0.768 | 0.625 | 0.768 |

| FM11 | 0.625 | 0.679 | 0.750 | 0.518 |

| FM12 | 0.482 | 0.304 | 0.821 | 0.661 |

| FM13 | 0.714 | 0.750 | 0.482 | 0.786 |

| FM14 | 0.714 | 0.750 | 0.464 | 0.750 |

| FM15 | 0.679 | 0.893 | 0.446 | 0.679 |

| FM16 | 0.661 | 0.857 | 0.571 | 0.679 |

| Failure Mode | S | O | D | E | GRAh |

|---|---|---|---|---|---|

| FM1 | 0.117 | 0.089 | 0.102 | 0.133 | 0.440 |

| FM2 | 0.213 | 0.072 | 0.249 | 0.244 | 0.778 |

| FM3 | 0.206 | 0.108 | 0.120 | 0.159 | 0.594 |

| FM4 | 0.142 | 0.101 | 0.108 | 0.151 | 0.502 |

| FM5 | 0.090 | 0.075 | 0.127 | 0.123 | 0.416 |

| FM6 | 0.136 | 0.091 | 0.122 | 0.183 | 0.532 |

| FM7 | 0.142 | 0.096 | 0.122 | 0.179 | 0.539 |

| FM8 | 0.084 | 0.075 | 0.185 | 0.146 | 0.491 |

| FM9 | 0.082 | 0.075 | 0.147 | 0.135 | 0.440 |

| FM10 | 0.079 | 0.085 | 0.115 | 0.123 | 0.402 |

| FM11 | 0.095 | 0.091 | 0.103 | 0.154 | 0.443 |

| FM12 | 0.109 | 0.134 | 0.098 | 0.135 | 0.475 |

| Failure Mode | S | O | D | E | S+ | S− | Ch |

|---|---|---|---|---|---|---|---|

| FM1 | 0.015 | 0.014 | 0.011 | 0.017 | 0.058 | 0 | 0.058 |

| FM2 | 0.021 | 0.008 | 0.026 | 0.031 | 0.086 | 0 | 0.086 |

| FM3 | 0.021 | 0.019 | 0.015 | 0.022 | 0.077 | 0 | 0.077 |

| FM4 | 0.017 | 0.017 | 0.013 | 0.021 | 0.068 | 0 | 0.068 |

| FM5 | 0.011 | 0.009 | 0.016 | 0.015 | 0.051 | 0 | 0.051 |

| FM6 | 0.017 | 0.015 | 0.016 | 0.025 | 0.073 | 0 | 0.073 |

| FM7 | 0.017 | 0.016 | 0.016 | 0.025 | 0.074 | 0 | 0.074 |

| FM8 | 0.009 | 0.009 | 0.023 | 0.020 | 0.061 | 0 | 0.061 |

| FM9 | 0.009 | 0.009 | 0.019 | 0.018 | 0.055 | 0 | 0.055 |

| FM10 | 0.008 | 0.013 | 0.014 | 0.015 | 0.050 | 0 | 0.050 |

| FM11 | 0.012 | 0.015 | 0.012 | 0.021 | 0.060 | 0 | 0.060 |

| FM12 | 0.014 | 0.023 | 0.010 | 0.018 | 0.065 | 0 | 0.065 |

| FM13 | 0.010 | 0.013 | 0.017 | 0.015 | 0.055 | 0 | 0.055 |

| FM14 | 0.010 | 0.013 | 0.017 | 0.015 | 0.056 | 0 | 0.056 |

| FM15 | 0.011 | 0.010 | 0.018 | 0.017 | 0.056 | 0 | 0.056 |

| FM16 | 0.011 | 0.011 | 0.015 | 0.017 | 0.054 | 0 | 0.054 |

| Method | SAW | VIKOR | GRA | COPRAS | ||||

|---|---|---|---|---|---|---|---|---|

| Failure Mode | SAWh | Rank | 1 − Qh | Rank | GRAh | Rank | Ch | Rank |

| FM1 | 0.202 | 9 | 0.301 | 10 | 0.103 | 9 | 0.214 | 9 |

| FM2 | 1.000 | 1 | 0.792 | 4 | 1.000 | 1 | 1.000 | 1 |

| FM3 | 0.701 | 2 | 1.000 | 1 | 0.510 | 2 | 0.759 | 2 |

| FM4 | 0.466 | 5 | 0.672 | 5 | 0.266 | 5 | 0.509 | 5 |

| FM5 | 0.064 | 15 | 0.041 | 15 | 0.038 | 15 | 0.038 | 15 |

| FM6 | 0.594 | 4 | 0.961 | 3 | 0.347 | 4 | 0.631 | 4 |

| FM7 | 0.622 | 3 | 1.000 | 2 | 0.366 | 3 | 0.667 | 3 |

| FM8 | 0.323 | 7 | 0.455 | 6 | 0.237 | 6 | 0.310 | 7 |

| FM9 | 0.154 | 12 | 0.306 | 9 | 0.101 | 10 | 0.136 | 13 |

| FM10 | 0.000 | 16 | 0.000 | 16 | 0.000 | 16 | 0.000 | 16 |

| FM11 | 0.237 | 8 | 0.440 | 7 | 0.110 | 8 | 0.265 | 8 |

| FM12 | 0.336 | 6 | 0.390 | 8 | 0.195 | 7 | 0.415 | 6 |

| FM13 | 0.135 | 13 | 0.052 | 14 | 0.068 | 13 | 0.137 | 12 |

| FM14 | 0.168 | 11 | 0.142 | 13 | 0.083 | 12 | 0.172 | 10 |

| FM15 | 0.176 | 10 | 0.285 | 11 | 0.094 | 11 | 0.161 | 11 |

| FM16 | 0.133 | 14 | 0.258 | 12 | 0.061 | 14 | 0.123 | 14 |

| Failure Mode | Normalized αh+ | Normalized αh− | FRIh | Rank |

|---|---|---|---|---|

| FM1 | 0.073 | 0.039 | −0.035 | 9 |

| FM2 | 0.010 | 0.170 | 0.160 | 1 |

| FM3 | 0.029 | 0.136 | 0.107 | 2 |

| FM4 | 0.050 | 0.089 | 0.039 | 5 |

| FM5 | 0.088 | 0.008 | −0.079 | 15 |

| FM6 | 0.039 | 0.119 | 0.080 | 4 |

| FM7 | 0.037 | 0.125 | 0.088 | 3 |

| FM8 | 0.062 | 0.061 | −0.001 | 7 |

| FM9 | 0.076 | 0.034 | −0.042 | 11 |

| FM10 | 0.092 | 0.000 | −0.092 | 16 |

| FM11 | 0.068 | 0.051 | −0.017 | 8 |

| FM12 | 0.062 | 0.061 | 0.000 | 6 |

| FM13 | 0.083 | 0.019 | −0.064 | 14 |

| FM14 | 0.079 | 0.026 | −0.053 | 13 |

| FM15 | 0.076 | 0.034 | −0.041 | 10 |

| FM16 | 0.079 | 0.029 | −0.050 | 12 |

| S | O | D | E | |

|---|---|---|---|---|

| Initial results | 0.213 | 0.215 | 0.258 | 0.313 |

| RUN1 | 0.279 | 0.282 | 0.338 | 0.1 |

| RUN2 | 0.248 | 0.251 | 0.301 | 0.2 |

| RUN3 | 0.217 | 0.22 | 0.263 | 0.3 |

| RUN4 | 0.186 | 0.188 | 0.225 | 0.4 |

| RUN5 | 0.155 | 0.157 | 0.188 | 0.5 |

| RUN6 | 0.124 | 0.125 | 0.15 | 0.6 |

| RUN7 | 0.093 | 0.094 | 0.113 | 0.7 |

| RUN8 | 0.062 | 0.063 | 0.075 | 0.8 |

| RUN9 | 0.031 | 0.031 | 0.038 | 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, K.-K.; Lin, S.-W.; Lo, H.-W.; Hsiao, C.-Y.; Lai, P.-J. Risk Assessment in Sustainable Production: Utilizing a Hybrid Evaluation Model to Identify the Waste Factors in Steel Plate Manufacturing. Sustainability 2023, 15, 16583. https://doi.org/10.3390/su152416583

Lai K-K, Lin S-W, Lo H-W, Hsiao C-Y, Lai P-J. Risk Assessment in Sustainable Production: Utilizing a Hybrid Evaluation Model to Identify the Waste Factors in Steel Plate Manufacturing. Sustainability. 2023; 15(24):16583. https://doi.org/10.3390/su152416583

Chicago/Turabian StyleLai, Kuei-Kuei, Sheng-Wei Lin, Huai-Wei Lo, Chia-Ying Hsiao, and Po-Jung Lai. 2023. "Risk Assessment in Sustainable Production: Utilizing a Hybrid Evaluation Model to Identify the Waste Factors in Steel Plate Manufacturing" Sustainability 15, no. 24: 16583. https://doi.org/10.3390/su152416583