Abstract

The effects of wastewater step-feeding (SF) on the performance of horizontal subsurface flow constructed wetlands (HSF CWs) are numerically investigated. The purpose is to check if this alternative feeding technique increases the ability of HSF CWs to remove pollutants. Two methodologies are used: Initially, the tanks-in-series (TIS) methodology, based on the finite volume method (FVM), is analyzed using the volumetric degradation coefficient λ. In this case, the operation of a CW is similar to a series of continuous stirred-tank reactors (CSTRs) operating under steady conditions. Then, the step-feeding (SF) procedure is presented, in which the CW is operated like a plug flow reactor (PFR). For the numerical investigation, the available experimental data for five existing HSF CWs are used. The results show that SF does not improve the performance of HSF CWs in removing biochemical oxygen demand (BOD) operating under Mediterranean conditions. When the HSF CWs operate without the SF procedure, the performance is between 55 and 81% for the TIS method and 60 and 89% for the PFR method, while the ability of the CW tank to remove the BOD decreases and varies from 48 to 79% (TIS) and from 54 to 86% (PFR), respectively.

1. Introduction

Wastewater treatment is one of the main problems that should be solved in order to ensure the protection of the environment and public health, especially in small cities and settlements where the construction and operation of modern wastewater treatment units are difficult to carry out. An effective, economic and ecological solution for this problem is the construction and operation of constructed wetlands (CWs) [,,]. As these systems have become increasingly popular over the last 25 years, especially in developing countries, it is important to investigate if the use of alternative feeding techniques could have positive or negative effects on their performance. One of these techniques is the step-feeding of the wastewater [,,].

“Step-feeding” (SF) describes the case when wastewater is not entirely introduced at the inlet of the CW, but it is split at several points along the flow path in a gradational way. Most of the studies that have been realized concern the SF procedure in vertical flow (VF) CWs [,,,,,,]. Fewer studies are available about the implementation of the SF technique in horizontal subsurface flow (HSF) CWs [,] with experiments [] or computer codes [].

The economic cost for the construction and operation of a CW facility could be useless and have a negative impact if the results do not provide a sustainable solution. This means that the inlet’s contaminated wastewater must have a zero (or almost zero) concentration at the outlet after its “treatment” inside the CW. The operation could also be sustainable when the outlet concentration is significantly smaller in comparison with the inlet concentration. Usually, the CW operation provides positive results, as the outlet wastewater is cleaner than the inlet quantity [,].

Alternative feeding techniques, like wastewater step-feeding or effluent recirculation, are used in praxis in order to yield a better result []. But, as presented in detail in the present study, sometimes, SF does not improve the performance of a CW in pollutant removal, and in this case, the procedure should not be selected [,]. The key factors are usually operation characteristics, like environmental parameters, the type of pollutant and the dimensions of the CW.

In the present study, we numerically investigated if SF could increase the ability of HSF CWs to remove the biochemical oxygen demand (BOD), which is one of the main pollutants monitored in municipal wastewater. This investigation is realized for pilot-scale HSF CWs, which were constructed and operated under Mediterranean conditions. In this case, it is interesting to check the effectiveness of HSF CWs in BOD removal, as the Mediterranean climate is usually characterized by hot, dry summers and cool, wet winters. The term “Mediterranean” is usually used for locations between about 30° and 45° latitude north and south of the Equator and on the western sides of the continents.

Two different methodologies, TIS and PFR, are used. The first method has been used in CWs, but recently, PFR has been preferred. Grismer et al. [] initially used the TIS method for the analysis of residence time distributions (RTDs) to determine the detention times, water velocities and dispersion coefficients. Data from an HSF CW were used for the treatment of winery effluent when the wetlands were planted initially with cattails while remaining unplanted in the second stage. The porous material was pea gravel. The TIS model can also be applied in VF CWs for the prediction of the effects feeding (continuous and batch) and hydraulic loading rate (HLR) on hydraulic behavior [] and for assessing pesticide reduction within a Bayesian framework [].

In contrast to TIS, the PFR method in CWs has been used more recently. Brito-Espiso et al. [] developed a mathematical model for primary treatment using HSF CWs for ammonia (NH3) removal. This model was based on the finite element method (FEM) and provided useful design information. Similarly, the PFR model has been used in order to show the importance of vetiver grass for secondary wastewater treatment in HSF CWs for the removal of antibiotics and nutrients []. Finally, the impact of HLR on VF CW performance when a combination of the PFR and CSTR models is chosen for the removal of various pollutants (BOD, NH4, NO3) has been investigated [].

The above analysis shows that there are no available studies that evaluate SF techniques in CWs using the TIS or PFR methodology. This is applied in the present study, where a numerical investigation is followed, and the results are compared with other studies, which conduct experiments or use computer codes. The advantage of numerical analysis is that it is an economical form of research that does not need to construct a whole facility (experimental part) or to buy/develop a computer code (computational procedure). The results of the present study could be an important and economical tool in order to predict the sustainability of these systems when they operate under Mediterranean conditions. They also provide the possibility to avoid the (construction and operation) costs if the conclusion is that the SF procedure does not really improve the performance of CWs.

2. Methods and Materials

2.1. The Numerical Formulation of Step-Feeding

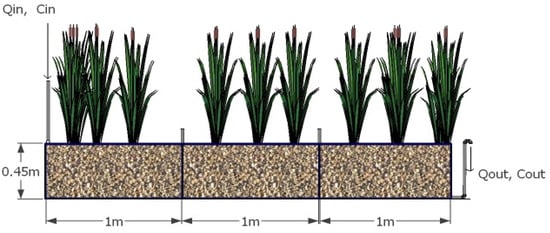

The problem of SF is formulated for the case of a pilot-scale HSF CW, which is presented in Figure 1.

Figure 1.

Schematic diagram of the HSF CW tank.

Five similar HSF CWs were constructed in total and are still in operation, in the facilities of the Laboratory of Ecological Engineering and Technology, Department of Environmental Engineering, Democritus University of Thrace, Xanthi, Greece. The dimensions of each CW tank are 3 m in length, 0.75 m in width and 1 m in depth, while the thickness of the porous media is 0.45 m.

A different combination of vegetation and porous medium appears in each tank. The types of porous materials were medium gravel (MG), fine gravel (FG) and cobbles (CO). The tanks were planted with common reeds (Phragmites australis—R) or cattails (Typha latifolia—C), while one tank was kept unplanted (Z). Therefore, the symbols for the five tanks were MG-R, MG-C, MG-Z, FG-R and CO-R. The units were equipped with vertical perforated plastic pipes (50 mm diameter each), which could be used in praxis during the SF procedure for the introduction of the wastewater at several points along the length (each pipe per 1 m), as shown in Figure 1.

The main operational characteristics are presented in Table 1, for a total operation period of two years. For each CW tank and for the used values of hydraulic residence time HRT (6, 8, 14 and 20 days), the experimental values of porosity ε, hydraulic conductivity K, volume of porous material Vp, average temperature Tav, inlet and outlet concentrations of the pollutant (BOD) Cin and Cout, respectively, and first-order decay coefficient λ are presented. A more detailed description of the calculation and explanation for each one of these parameters is given by []. The impact of the size of porous materials is obvious in the values of hydraulic conductivity, especially between the FG-R and CO-R tanks.

Table 1.

Operation characteristics of HSF CWs.

The total inflowing wastewater flow rate Q = Qin, in L/day, is distributed in three inflowing points along the CW tank: x0 = 0, x1 = 1 m and x2 = 2 m. The following equations give the inflowing wastewater flow rates for each one of these points:

where x, y and z are the corresponding percentages of Q in each position; therefore, they fulfill the following condition:

When the SF procedure is present during the operation of the wetlands, i.e., x#0, y#0 and z#0, the aim is to determine the optimal values of these percentages in order to minimize the concentration of the pollutant at the outlet Cout, in mg/L. Then, this value should be compared with the corresponding outlet concentration for the case that CW is operated without SF, i.e., x = 1 and y = z = 0. The results of this comparison give the answer to whether the performance of the tank was increased or decreased by using the SF procedure. The performance R, in %, is given by the following equation:

2.2. Analysis by Using the TIS Methodology

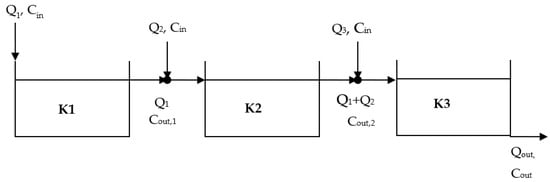

For the numerical investigation of the problem, first the tanks-in-series (TIS) methodology is used [], which is based on finite volume method [,]. It is considered that the wetlands are operated as continuous stirred-tank reactors (CSTRs), under steady conditions, and the volumetric degradation coefficient λ is used. According to the experimental procedure [], the tank is divided into three equal cells (Figure 2), with corresponding volumetric degradation coefficients λ1, λ2 and λ3.

Figure 2.

TIS system of constructed wetlands.

The above cells have equal volume, which is

where Vp = εLWd; L is the length of the CW, in m; W is the width of the CW, in m; and d is the depth of the porous material, in m.

As shown in Figure 2, the operation of the above system begins with the entering flow rate Q1 at the inlet of the first cell. The outlet flow rate of the first cell Q1 is mixed with the entering flow rate of the second cell Q2. Similarly, the outlet flow rate of the second cell Q1 + Q2 is mixed with the entering flow rate of the third cell Q3. Finally, at the end of the operation, the concentration Cout,3 is the outlet concentration of the system Cout which should be minimized.

The numerical formulation of the whole procedure is the following: For the first cell K1, the outlet concentration Cout,1 and the hydraulic residence time HRT1 are

The pollutant mass balance between the first and the second cell is used in order to determine the inlet concentration Cin,2:

Thus, it is

Equations (7) and (10) show

Similarly, for the second cell K2, the outlet concentration Cout,2 and the hydraulic residence time HRT2 are

The pollutant mass balance between the second and the third cell is used:

Thus, the inlet concentration in the third cell Cin,3 is

Equations (12) and (15) show

Finally, for the third cell K3, the outlet concentration Cout,3 (which is the outlet concentration for the whole system Cout) and the hydraulic residence time HRT3 are

The main problem could be expressed numerically as follows: Which are the optimal values of x, y and z in order to minimize the function Cout = f (x, y, z)?

2.3. Analysis by Using the PFR Methodology

The pilot-scale HSF CWs could be considered to operate like plug flow reactors (PFRs). This means that the contribution of the dispersion during the operation of the tanks is negligible. By following the same steps as in the previous paragraph, the inlet and outlet concentrations are determined.

Thus, for the first cell K1,

Similarly, for the cell K2,

Finally, for the last cell K3,

3. Results and Discussion

3.1. Numerical Investigation

The numerical investigation is presented below in order to examine whether the SF procedure increases or decreases the performance in BOD removal of the five HSF CWs (MG-R, MG-C, MG-Z, FG-R and CO-R) which were described previously. For the main parameters (Cin, Vp, λ), average values from the available experimental data presented in Table 1 are used and presented in Table 2 (Cin,av, Vp,av, λav). The range of the values’ first-order decay coefficient was determined in [], in which the dependence of λ on HRT and temperature T for the same CW tanks of the present study was analyzed and relative empirical relations were developed. The selected average values of λav for the numerical investigation of the present study are based, for each HSF CW, on these results [].

Table 2.

Impact of SF on HSF CW performance in BOD removal.

Four scenarios are investigated, and the outlet concentration (Cout) for each one of these scenarios is compared with the corresponding outlet concentration when the wetlands are operating without SF. Apart from scenario (A), in which the CWs are operated without SF (x = 1 and y = z = 0), four more scenarios are investigated: (B) The wastewater is introduced at two inflowing points along the HSF CW length: 80% at x0 = 0 and 20% at x1 = 1 m, i.e., x = 0.80, y = 0.20 and z = 0. (C) The wastewater is introduced at two inflowing points along the HSF CW length: 60% at x0 = 0 and 40% at x1 = 1 m, i.e., x = 0.60, y = 0.40 and z = 0. (D) The wastewater is introduced at three inflowing points along the HSF CW length: 60% at x0 = 0, 25% at x1 = 1 m and 15% at x2 = 2 m, i.e., x = 0.60, y = 0.25 and z = 0.15. (E) The wastewater is introduced at three inflowing points along the HSF CW length: 33.33% at x0 = 0, 33.33% at x1 = 1 m and 33.33% at x2 = 2 m, i.e., x = y = z = 0.333.

First, the TIS methodology is followed. According to Equation (6), V1 = V2 = V3 = V = Vp/3. By using Equations (1)–(4) and (7)–(18), the values of inlet concentrations, outlet concentrations and hydraulic residence time are as follows:

Cell K1:

Cell K2:

Cell K3:

Thus, by following the limitations of Equation (4), the purpose is to determine the optimal values of x, y and z which minimize the function Cout = f(x, y, z) of the above Equation (34).

Similarly, the PFR methodology is used. For the same values of VP, HRT and λav, Equations (1)–(4) and (19)–(26) give the following results:

Cell K1:

Cell K2:

Cell K3:

Similarly, the optimal values x, y and z which minimize the function Cout = f(x, y, z) of Equation (42) should be determined, when the limitations of Equation (4) are followed.

The results of the numerical investigation for each one of the two methodologies (TIS and PFR) and for each SF scenario are presented in Table 2. Apart from the performances of CW tanks in BOD removal, the relationships between the inlet Cin and the outlet Cout concentrations are shown.

3.2. Discussion and Comparison with Other Studies

For both methodologies (TIS and PFR) and for all the HSF CWs, the results show that the minimum values of outlet concentration Cout (therefore, the maximum performance in BOD removal) were found for the scenario according to which the CWs are operating without SF. This confirms that this procedure does not increase the performance of the HSF CWs, at least for wetlands operating in similar Mediterranean conditions to those in the present study. On the contrary, when the number of inlet points of the wastewater among the CW tanks is increased to more than one inlet point, see scenarios (D) and (E) of the previous paragraph, the ability of the wetlands to remove BOD becomes lower. The main explanation for this is that the parts of the effluent entering at the points x1 = 1 m and x2 = 2 m have lower HRT; thus, the total time of the operation of the HSF CW is shorter.

The fact that this conclusion remains the same for different combinations of plants and porous materials is also interesting. The real time of the operation of the HSF CWs, which gave us the experimental data used, was 2 years and included all the seasons of the year. This means that all the climate and meteorological conditions were taken into account; thus, the SF procedure was examined for high and low temperatures (and corresponding plant growth, which increases the BOD removal). Therefore, in the present study, the SF procedure fails to increase the ability of the CW to remove pollutants, irrespective of the growth of the plants and the size of the porous medium. The reliability of the present study is confirmed by the fact that the conclusions are the same when (for the same CW tanks) the SF procedure is followed by using experiments and computer codes.

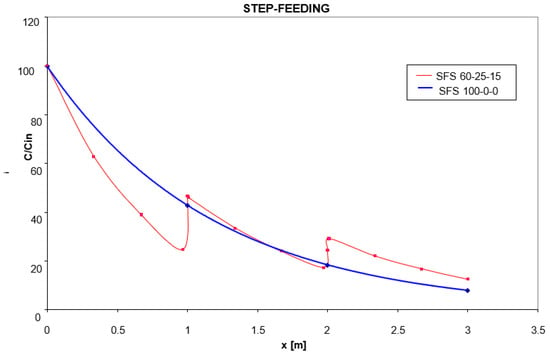

The conclusion of the present work confirms the results of a relevant computational study []: For the same pilot-scale HSF CWs, and by using the computer code Visual MODFLOW, it was proven that SF acts negatively on the performance of these tanks in removing BOD. Schematically, a part of the results from this computational study is shown in Figure 3. This diagram concerns the HSF CW tank which contains medium gravel as porous material and is planted with common reed (Phragmites australis). The values of the main parameters are HRT = 14 days, Cin = 360 mg BOD/L, λ = 0.06 day−1 and ε = 0.38. For the SF procedure, scenario (D) is investigated, i.e., x = 0.60, y = 0.25 and z = 0.15.

Figure 3.

Longitudinal concentration distribution profile of concentration C/Cin within the HSF CW for the scenarios “SFS 100-0-0” and “SFS 60-25-15”.

In Figure 3, the outlet BOD concentration without SF is Cout,A = 8.42 mg/L, while that with SF is noticeably higher, Cout,D = 17.47 mg/L. The inequalities (11) and (16) could explain the occurrence of the “leaps” in the longitudinal concentration distribution profile at the feeding positions x1 = 1 m and x2 = 2 m.

Stefanakis et al. [] also presented an experimental procedure for the same tanks, and they investigated the above SF scenarios (D) and (E), for the pollutants BOD, chemical oxygen demand (COD) and total Kjeldahl nitrogen (TKN). While an agreement has been observed between these experimental results and the numerical results of the present work concerning scenario (E), i.e., x = y = z = 0.333, a small difference appears for scenario (D), i.e., x = 0.60, y = 0.25 and z = 0.15. Stefanakis et al. [] concluded that the SF slightly increases the performance of the HSF CWs in BOD removal, for this scenario. This can be explained by the fact that the experiments were realized during the summer months, when the ability of CWs to remove pollutants is always greater, due to high temperatures and the growth of the plants.

Li et al. [] experimentally investigated the removal of COD, total nitrogen (TN) and ammonium nitrogen (NH4+-N). As the results show, the HRT could influence the effectiveness of the SF procedure. Especially for COD and NH4+-N removal, the SF procedure acted negatively on CW performances for a low HRT, HRT = 5 days; however, it increased the performance of the wetlands for a higher HRT, HRT = 8.4 days. Concerning the TN, SF seems to increase the performance of HSF CWs significantly, but the removal of nitrogen requires special investigation as it is governed by the phenomenon of adsorption.

In contrast with HSF CWs, more studies have been realized concerning SF in VF CWs. Fan et al. [] investigated an SF scenario where half of the wastewater is introduced at the inlet and the other half is introduced in the middle of a VF CW. The results showed that the COD removal was increased slightly, while the increase in the performance in TN removal was remarkable. Hu et al. [] succeeded in showing higher performance in nitrogen removal in VF CWs for the SF scenario (B), i.e., x = 0.80, y = 0.20 and z = 0.

Moreover, Khajah et al. [] investigated the effects of SF concerning COD and TN removal in a VF CW, for scenarios (B) and (C). The performance was increased concerning COD but remained stable for TN removal. Similarly, positive effects on the ability of VF CWs to remove pollutants were recorded by Saeed et al. [], concerning BOD and total phosphorus (TP) removal for the SF scenario (F).

Wang et al. [] did not find an important effect of SF on organics removal for scenarios (E) and (F), as the performance with and without the SF procedure remained almost stable. Finally, Torrijos et al. [] investigated the effects of SF on the performance of a hybrid system, which included both an HSF and a VF CW. The removal of COD was increased from 96% to 99% for the SF scenario (F).

The following table (Table 3) presents the results of all these studies. The performance of the HSF and VF CWs for various pollutants and for all the different SF scenarios described in the previous paragraphs are shown. These results show that the SF procedure generally increases the ability of VF CWs to remove pollutants, whereas it has a negative effect on the performance of HSF CWs. The results indicate that the flow of the inlet wastewater is a key factor for the implementation of this alternative feeding technique in full-scale CW facilities. In any case, the environmental operation parameters (like temperature, rainfall and growth of plants) could give non-stable results, especially in a comparison between experimental studies. Especially for the present study, the negative effect of the SF technique on the HSF CW operation could be explained by the fact that the part of the wastewater that is introduced among the tanks decreases the total hydraulic residence time (HRT) of the pollutant, in comparison with the case when the wastewater is introduced entirely at the inlet. Therefore, a part of the wastewater does not remain inside the CW facility long enough in order to be “cleaned”, and the outlet pollutant concentration is higher than that in the case where SF is not applied.

Table 3.

Performance (%) of HSF and VF CWs for various pollutants and SF scenarios.

4. Conclusions

The numerical investigation of the present study confirmed that the step-feeding (SF) technique acts negatively on the performance of HSF CWs, especially when more than two inlet positions along the CW for the wastewater are chosen. Thus, this operation technique does not improve the ability of HSF CWs to remove pollutants, at least when they operate under Mediterranean conditions. Therefore, the operation of (pilot-scale or full-scale) CWs by using the SF technique is not recommended, at least for facilities with similar characteristics to those in the present study. The comparison of these results with other similar studies showed the importance not only of the wastewater direction (HSF or VF CWs) but also of the operational characteristics of the CWs (kind of vegetation and porous material, climatic parameters, hydraulic residence time, type of pollutant). It is important to investigate the effect of these characteristics on SF techniques in future relevant studies. The proposed methodology also provides the possibility for an economic prediction of the effectiveness of CWs, by avoiding the operation and maintenance cost of a real facility. As a general conclusion, the results of the present study could be useful for a better understanding of the use of alternative feeding techniques (like wastewater step-feeding or recirculation of the effluent) in constructed wetlands.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The author declares no conflict of interest.

References

- Vymazal, J.; Zhao, Y.; Mander, U. Recent research challenges in constructed wetlands for wastewater treatment: A review. Ecol. Eng. 2021, 169, 106318. [Google Scholar] [CrossRef]

- Parde, D.; Patwa, A.; Shukla, A.; Vijay, R.; Killedar, D.J.; Kumar, R. A review of constructed wetland on type, treatment and technology of wastewater. Environ. Technol. Innov. 2021, 21, 101261. [Google Scholar] [CrossRef]

- Moshiri, G.A. Constructed Wetlands for Water Quality Improvement; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar] [CrossRef]

- Varma, M.; Gupta, A.K.; Ghosal, P.S.; Majumder, A. A review on performance of constructed wetlands in tropical and cold climate: Insights of mechanism, role of influencing factors, and system modification in low temperature. Sci. Total Environ. 2021, 755, 142540. [Google Scholar] [CrossRef] [PubMed]

- Meng, P.; Pei, H.; Hu, W.; Shao, Y.; Li, Z. How to increase microbial degradation in constructed wetlands: Influencing factors and improvement measures. Bioresour. Technol. 2014, 157, 316–326. [Google Scholar] [CrossRef]

- Saeed, T.; Sun, G. A review on nitrogen and organics removal mechanisms in subsurface flow constructed wetlands: Dependency on environmental parameters, operating conditions and supporting media. J. Environ. Manag. 2012, 112, 429–448. [Google Scholar] [CrossRef] [PubMed]

- Khajah, M.; Bydalek, F.; Babatunde, A.O.; Al-Matouq, A.; Wenk, J.; Webster, G. Nitrogen removal performance and bacterial community analysis of a multistage step-feeding tidal flow constructed wetland. Front. Water 2023, 5, 1128901. [Google Scholar] [CrossRef]

- Saeed, T.; Miah, M.J.; Khan, T.; Ove, A. Pollutant removal employing tidal flow constructed wetlands: Media and feeding strategies. Chem. Eng. J. 2020, 382, 122874. [Google Scholar] [CrossRef]

- Torrijos, V.; Ruiz, I.; Soto, M. Effect of step-feeding on the performance of lab-scale columns simulating vertical flow-horizontal flow constructed wetlands. Environ. Sci. Pollut. Res. 2017, 24, 22649–22662. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, M.; Qi, R.; Fan, S.; Wang, Y.; Fan, T. Enhanced nitrogen removal and associated microbial characteristics in a modified single-stage tidal flow constructed wetland with step-feeding. Chem. Eng. J. 2017, 314, 291–300. [Google Scholar] [CrossRef]

- Shen, L.; Wu, J.; Zhong, F.; Xiang, D.; Cheng, S. Effect of step feeding on the performance of multi-stage vertical flow constructed wetland for municipal wastewater treatment. J. Lake Sci. 2017, 29, 1084–1090. [Google Scholar] [CrossRef][Green Version]

- Fan, J.; Liang, S.; Zhang, B.; Zhang, J. Enhanced organics and nitrogen removal in batch-operated vertical flow constructed wetlands by combination of intermittent aeration and step feeding strategy. Environ. Sci. Pollut. Res. 2013, 20, 2448–2455. [Google Scholar] [CrossRef]

- Hu, Y.S.; Zhao, Y.Q.; Zhao, X.H.; Kumar, J.L.G. Comprehensive analysis of step-feeding strategy to enhance biological nitrogen removal in alum sludge-based tidal flow constructed wetlands. Bioresour. Technol. 2012, 111, 27–35. [Google Scholar] [CrossRef] [PubMed]

- Patil, S.; Chakraborty, S. Effects of step-feeding and intermittent aeration on organics and nitrogen removal in a horizontal subsurface flow constructed wetland. J. Environ. Sci. Health A 2017, 52, 403–412. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Lu, L.; Zheng, X.; Ngo, H.H.; Liang, S.; Guo, W.; Zhang, X. Enhanced nitrogen removal in constructed wetlands: Effects of dissolved oxygen and step-feeding. Bioresour. Technol. 2014, 169, 395–402. [Google Scholar] [CrossRef] [PubMed]

- Stefanakis, A.I.; Akratos, C.S.; Tsihrintzis, V.A. Effect of wastewater step-feeding on removal efficiency of pilot-scale horizontal subsurface flow constructed wetlands. Ecol. Eng. 2011, 37, 431–443. [Google Scholar] [CrossRef]

- Liolios, K.A.; Moutsopoulos, K.N.; Tsihrintzis, V.A. Modelling alternative feeding techniques in HSF constructed wetlands. Environ. Proces. 2016, 3, 47–63. [Google Scholar] [CrossRef]

- Grismer, M.E.; Tausendschoen, M.; Shepherd, H.L. Hydraulic characteristics of a subsurface flow constructed wetland for winery effluent treatment. Water Environ. Res. 2001, 73, 466–477. [Google Scholar] [CrossRef]

- Panuvatvanich, A.; Koottatep, T.; Kone, D. Hydraulic behaviour of vertical-flow constructed wetland under different operating conditions. Environ. Technol. 2009, 30, 1031–1040. [Google Scholar] [CrossRef]

- Krone-Davis, P.; Watson, F.; Los Huertos, M.; Starner, K. Assessing pesticide reduction in constructed wetlands using a tanks-in-series model within a Bayesian framework. Ecol. Eng. 2013, 57, 342–352. [Google Scholar] [CrossRef]

- Brito-Espino, S.; Ramos-Martin, A.; Perez-Baez, S.O.; Mendieta-Pino, C. Application of a mathematical model to predict simultaneous reactions in anaerobic plug-flow reactors as a primary treatment for constructed wetlands. Sci. Total Environ. 2020, 713, 136244. [Google Scholar] [CrossRef]

- Panja, S.; Sarkar, D.; Zhang, Z.; Datta, R. Removal of antibiotics and nutrients by vetiver grass (Chrysopogon zizanioides) from a plug flow reactor based constructed wetland model. Toxics 2021, 9, 84. [Google Scholar] [CrossRef]

- Weerakoon, G.M.P.R.; Jinadasa, K.B.S.N.; Manatunge, J.; Wijesiri, B.; Goonetilleke, A. Kinetic modelling and performance evaluation of vertical subsurface flow constructed wetlands in tropics. J. Water Proc. Eng. 2020, 38, 101539. [Google Scholar] [CrossRef]

- Liolios, K.A.; Moutsopoulos, K.N.; Tsihrintzis, V.A. Modeling of flow and BOD fate in horizontal subsurface flow constructed wetlands. Chem. Eng. J. 2012, 200–202, 681–693. [Google Scholar] [CrossRef]

- Stephenson, R.; Sheridan, C.; Kappelmeyer, U. A curve-shift technique for the use of non-conservative organic tracers in constructed wetlands. Sci. Total Environ. 2021, 752, 141818. [Google Scholar] [CrossRef] [PubMed]

- Moukalled, F.; Mangani, L.; Darwish, M. The Finite Volume Method in Computational Fluid Mechanics; Springer International Publishing: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Bear, J.; Cheng, A.H.D. Modeling Groundwater Flow and Contaminant Transport; Springer: New York, NY, USA, 2010. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).