Navigating Environmental Challenges through Supply Chain Quality Management 4.0 in Circular Economy: A Comprehensive Review

Abstract

1. Introduction

2. Materials and Methods

2.1. Planning

2.2. Conducting

2.3. Reporting

3. Results Analysis of the SLR

3.1. Descriptive Statistics

3.2. Thematic Synthesis and Analysis

“Supply Chain Quality Management 4.0 is a holistic approach in which companies leverage advanced Industry 4.0 technologies within their industry network to streamline processes, elevate product quality, cultivate resilient supply chain relationships, and proactively minimize their environmental and social footprint, with the ultimate goal of achieving stakeholder satisfaction and sustainable operations.”

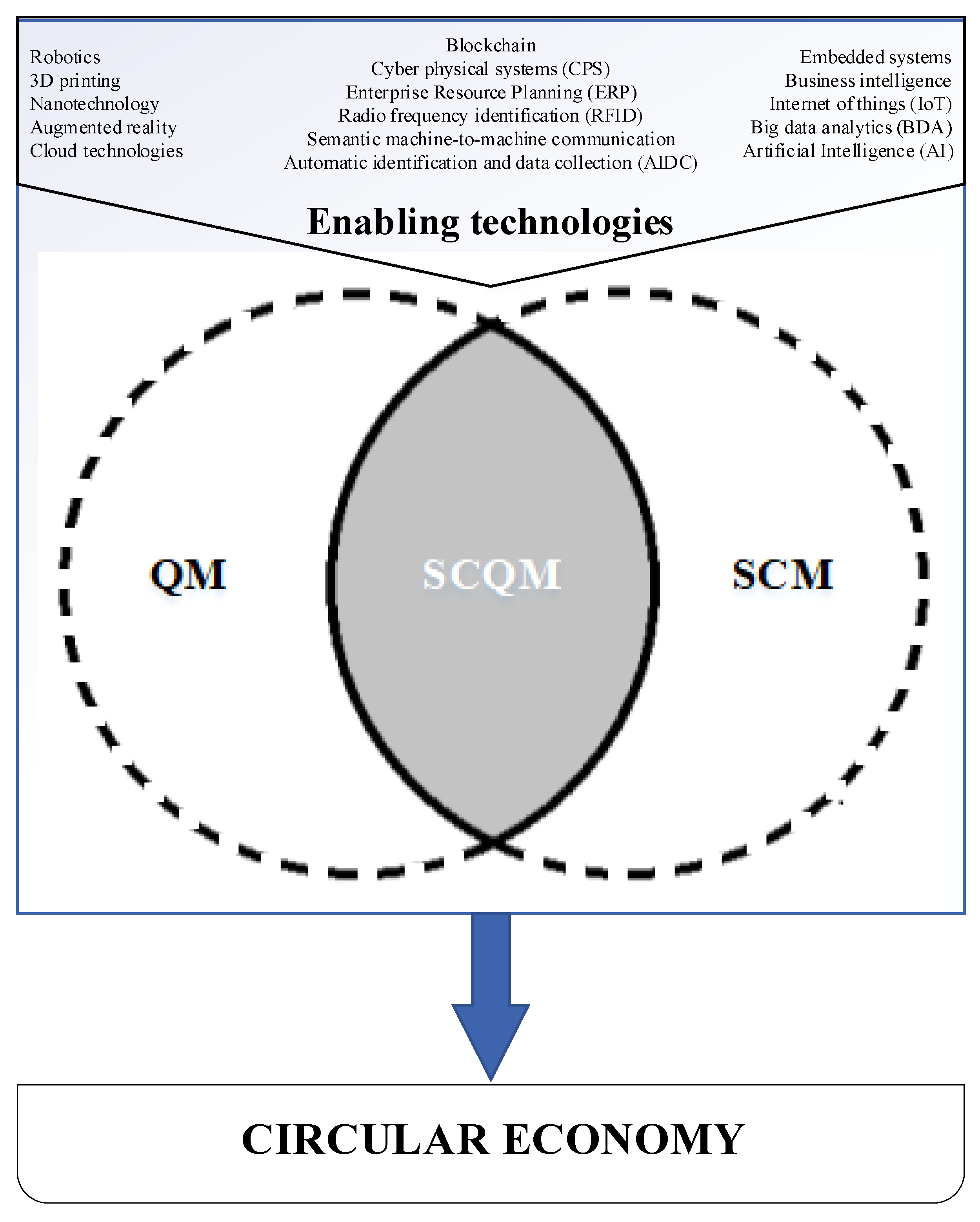

4. Conceptual Framework for SCQM 4.0

4.1. Disruptive Technologies in SCQM 4.0

4.2. Supply Chain Operations

4.3. Environmental Performance in SCQM 4.0 towards a CE

4.3.1. Input Management

- Resource Efficiency: Sustainable businesses prioritize efficient utilization of resources, such as energy, water, and raw materials. By reducing resource consumption, optimizing production processes, and minimizing waste, companies can attain substantial environmental benefits and cost savings [165].

- Sustainable Sourcing: Adopting sustainable sourcing practices involves selecting suppliers who adhere to responsible environmental standards. This ensures that the inputs and materials used in the production process are obtained in a manner that minimizes negative ecological impacts, such as deforestation or habitat destruction [163].

- Life Cycle Assessment: Businesses can perform life cycle assessments to assess the environmental effect and impact of their products/services across the entire life cycle, from raw material mining to disposal. This approach enables companies to recognize areas for improvement and make informed-decisions aimed at minimizing their overall environmental footprint [166].

4.3.2. Waste Handling

- Waste Reduction: Sustainable businesses implement strategies to minimize waste generation through process optimization, product redesign, and material substitution. By reducing waste at its source, companies can decrease their environmental impact and save on waste management costs [85].

- Recycling and Reuse: Encouraging recycling and reuse initiatives helps divert waste from landfills and conserve valuable resources. By implementing efficient recycling programs and exploring innovative ways to reuse materials, companies contribute to a more sustainable and CE [168].

- Hazardous Waste Management: Environmentally respectful sustainable performance involves proper handling and disposal of hazardous materials to prevent pollution and protect ecosystems and human health. Compliance with regulations, implementing appropriate storage and treatment procedures, and promoting responsible waste management practices are essential in this regard [167].

4.3.3. Preservation

- Biodiversity Conservation: Sustainable businesses prioritize the protection and restoration of biodiversity by minimizing habitat destruction, supporting conservation efforts, and implementing sustainable land management practices. Preserving biodiversity is essential for maintaining ecosystem resilience and ensuring the long-term health of the planet [170].

- Environmental Stewardship: Engaging in environmental stewardship involves actively monitoring and mitigating negative environmental impacts caused by business activities. This includes reducing emissions, minimizing water and air pollution, and promoting sustainable land use practices [171].

- Climate Change Mitigation: Sustainable performance requires businesses to actively contribute to global efforts to mitigate climate change [138]. This entails implementing measures to curtail greenhouse gas emissions, transitioning to renewable energy sources, and implementing carbon offset strategies.

4.3.4. SCQM 4.0 Practice Route towards a CE

5. Implications and Future Research

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chau, K.-Y.; Tang, Y.M.; Liu, X.; Ip, Y.-K.; Tao, Y. Investigation of critical success factors for improving supply chain quality management in manufacturing. Enterp. Inf. Syst. 2021, 15, 1418–1437. [Google Scholar] [CrossRef]

- Bui, L.T.C.; Carvalho, M.; Pham, H.T.; Nguyen, T.T.B.; Duong, A.T.B.; Quang, H.T. Supply chain quality management 4.0: Conceptual and maturity frameworks. Int. J. Qual. Reliab. Manag. 2022. ahead of print. [Google Scholar] [CrossRef]

- Fernandes, A.C.; Sampaio, P.; Sameiro, M.; Truong, H.Q. Supply chain management and quality management integration: A conceptual model proposal. Int. J. Qual. Reliab. Manag. 2017, 34, 53–67. [Google Scholar] [CrossRef]

- Quang, H.T.; Sampaio, P.; Carvalho, M.S.; Fernandes, A.C.; Binh An, D.T.; Vilhenac, E. An extensive structural model of supply chain quality management and firm performance. Int. J. Qual. Reliab. Manag. 2016, 33, 444–464. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Zengin, Y.; Naktiyok, S.; Kaygın, E.; Kavak, O.; Topçuoğlu, E. An investigation upon industry 4.0 and society 5.0 within the context of sustainable development goals. Sustainability 2021, 13, 2682. [Google Scholar] [CrossRef]

- Hoang, T.-H.; Nguyen, N.P.P.; Hoang, N.-Y.N.; Akbari, M.; Quang, H.T.; Binh, A.D.T. Application of social media in supply chain 4.0 practices: A bibliometric analysis and research trends. Oper. Manag. Res. 2023, 16, 1162–1184. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Akbari, M. Data-driven review of additive manufacturing on supply chains: Regionalization, key research themes and future directions. Comput. Ind. Eng. 2023, 184, 109600. [Google Scholar] [CrossRef]

- Akbari, M.; Kok, S.K.; Hopkins, J.; Frederico, G.F.; Nguyen, H.; Alonso, A.D. The changing landscape of digital transformation in supply chains: Impacts of industry 4.0 in Vietnam. Int. J. Logist. Manag. 2023. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z.; Banimfreg, B.H. The role of internet of things in food supply chain quality management: A review. Qual. Manag. J. 2020, 28, 17–40. [Google Scholar] [CrossRef]

- Ngo, V.M.; Quang, H.T.; Hoang, T.G.; Binh, A.D.T. Sustainability-related supply chain risks and supply chain performances: The moderating effects of dynamic supply chain management practices. Bus. Strategy Environ. 2023, 1–19. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, S.P. Connecting circular economy and industry 4.0. Int. J. Inf. Manag. 2019, 49, 98–113. [Google Scholar] [CrossRef]

- Akbari, M. Revolutionizing supply chain and circular economy with edge computing: Systematic review, research themes and future directions. Manag. Decis. 2023. ahead of print. [Google Scholar] [CrossRef]

- Akbari, M.; Hopkins, J.L. Digital technologies as enablers of supply chain sustainability in an emerging economy. Oper. Manag. Res. 2022, 15, 689–710. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2020, 58, 1662–1687. [Google Scholar] [CrossRef]

- Dev, N.K.; Shankar, R.; Qaiser, F.H. Industry 4.0 and circular economy: Operational excellence for sustainable reverse supply chain performance. Resour. Conserv. Recycl. 2020, 153, 104583. [Google Scholar] [CrossRef]

- Haupt, M.; Hellweg, S. Measuring the environmental sustainability of a circular economy. Environ. Sustain. Indic. 2019, 1, 100005. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, M.; Huo, B. The impact of supply chain quality integration on green supply chain management and environmental performance. Total Qual. Manag. Bus. Excell. 2019, 30, 1110–1125. [Google Scholar] [CrossRef]

- Masurel, E. Why SMEs invest in environmental measures: Sustainability evidence from small and medium-sized printing firms. Bus. Strategy Environ. 2007, 16, 190–201. [Google Scholar] [CrossRef]

- Barnett-Page, E.; Thomas, J. Methods for the synthesis of qualitative research: A critical review. BMC Med. Res. Methodol. 2009, 9, 59. [Google Scholar] [CrossRef]

- Le, Q.H.; Phan Tan, L.; Hoang, T.H. Customer brand co-creation on social media: A systematic review. Mark. Intell. Plan. 2022, 40, 1038–1053. [Google Scholar] [CrossRef]

- Briner, R.B.; Denyer, D. Systematic review and evidence synthesis as a practice and scholarship tool. In Handbook of Evidence-Based Management: Companies, Classrooms and Research; Oxford University Press: Oxford, UK, 2012; pp. 112–129. [Google Scholar]

- Webster, J.; Watson, R.T. Analyzing the past to prepare for the future: Writing a literature review. MIS Q. 2002, 26, xiii–xxiii. [Google Scholar]

- Ferrari, R. Writing narrative style literature reviews. Med. Writ. 2015, 24, 230–235. [Google Scholar] [CrossRef]

- Kitchenham, B. Procedures for performing systematic reviews. Keele UK Keele Univ. 2004, 33, 1–26. [Google Scholar]

- Robertson, G.R.; Field, J.; Goodwin, B.; Bierach, S.; Tran, M.; Lehnert, A.; Liddle, C. Transgenic mouse models of human CYP3A4 gene regulation. Mol. Pharmacol. 2003, 64, 42–50. [Google Scholar] [CrossRef] [PubMed]

- Thomas, J.; Harden, A. Methods for the thematic synthesis of qualitative research in systematic reviews. BMC Med. Res. Methodol. 2008, 8, 45. [Google Scholar] [CrossRef]

- Sayama, H. Introduction to the Modeling and Analysis of Complex Systems; Open SUNY Textbooks: Geneseo, NY, USA, 2015. [Google Scholar]

- Persson, O.; Danell, R.; Schneider, J.W. How to use Bibexcel for various types of bibliometric analysis. In Celebrating Scholarly Communication Studies: A Festschrift for Olle Persson at His 60th Birthday; International Society for Scientometrics and Informetrics, Lund University: Lund, Sweden, 2009; Volume 5, pp. 9–24. [Google Scholar]

- Frederico, G.F.; Garza-Reyes, J.A.; Anosike, A.; Kumar, V. Supply Chain 4.0: Concepts, maturity and research agenda. Supply Chain Manag. Int. J. 2020, 25, 262–282. [Google Scholar] [CrossRef]

- Sony, M.; Antony, J.; Douglas, J.A. Essential ingredients for the implementation of Quality 4.0: A narrative review of literature and future directions for research. TQM J. 2020, 34, 779–793. [Google Scholar] [CrossRef]

- Carranza, E.J.M. Geochemical Anomaly and Mineral Prospectivity Mapping in GIS; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Treiblmaier, H.; Garaus, M. Using blockchain to signal quality in the food supply chain: The impact on consumer purchase intentions and the moderating effect of brand familiarity. Int. J. Inf. Manag. 2023, 68, 102514. [Google Scholar] [CrossRef]

- Wang, Y.; Han, J.H.; Beynon-Davies, P. Understanding blockchain technology for future supply chains: A systematic literature review and research agenda. Supply Chain Manag. Int. J. 2019, 24, 62–84. [Google Scholar] [CrossRef]

- Hoang, L.C.; Do, M.H.T.; Quang, H.T.; Hoang, T.H. Blockchain technology applications in retail branding: Insights from retailers in the developing world. Thunderbird Int. Bus. Rev. 2023. [Google Scholar] [CrossRef]

- FAO; ICTSD. Emerging Opportunities for the Application of Blockchain in the Agri-Food Industry, Revised version; Food and Agriculture Organization of the United Nations (FAO): Rome, Italy; International Centre for Trade and Sustainable Development (ICTSD): Geneva, Switzerland, 2020. [Google Scholar]

- Vadgama, N.; Tasca, P. An Analysis of Blockchain Adoption in Supply Chains Between 2010 and 2020. Front. Blockchain 2021, 4, 610476. [Google Scholar] [CrossRef]

- Saurabh, S.; Dey, K. Blockchain technology adoption, architecture, and sustainable agri-food supply chains. J. Clean. Prod. 2021, 284, 124731. [Google Scholar] [CrossRef]

- Wong, L.-W.; Leong, L.-Y.; Hew, J.-J.; Tan, G.W.-H.; Ooi, K.-B. Time to seize the digital evolution: Adoption of blockchain in operations and supply chain management among Malaysian SMEs. Int. J. Inf. Manag. 2020, 52, 101997. [Google Scholar] [CrossRef]

- Xu, J.; Guo, S.; Xie, D.; Yan, Y. Blockchain: A new safeguard for agri-foods. Artif. Intell. Agric. 2020, 4, 153–161. [Google Scholar] [CrossRef]

- Qian, W. Environmental Management Accounting and Supply Chain Management. J. Clean. Prod. 2012, 20, 186–187. [Google Scholar] [CrossRef]

- Tian, F. An agri-food supply chain traceability system for China based on RFID & blockchain technology. In Proceedings of the 2016 13th International Conference on Service Systems and Service Management (ICSSSM), IEEE, Kunming, China, 24–26 June 2016; pp. 1–6. [Google Scholar]

- Mainetti, L.; Mele, F.; Patrono, L.; Simone, F.; Stefanizzi, M.L.; Vergallo, R. An RFID-Based Tracing and Tracking System for the Fresh Vegetables Supply Chain. Int. J. Antennas Propag. 2013, 2013, 531364. [Google Scholar] [CrossRef]

- Barge, P.; Gay, P.; Merlino, V.; Tortia, C. Item-level Radio-Frequency IDentification for the traceability of food products: Application on a dairy product. J. Food Eng. 2014, 125, 119–130. [Google Scholar] [CrossRef]

- Chen, S.; Shi, R.; Ren, Z.; Yan, J.; Shi, Y.; Zhang, J. A blockchain-based supply chain quality management framework. In Proceedings of the 2017 IEEE 14th International Conference on e-Business Engineering (ICEBE), IEEE, Shanghai, China, 4–6 November 2017; pp. 172–176. [Google Scholar]

- Óskarsdóttir, K.; Oddsson, G.V. Towards a decision support framework for technologies used in cold supply chain traceability. J. Food Eng. 2019, 240, 153–159. [Google Scholar] [CrossRef]

- Bhatt, T.; Cusack, C.; Dent, B.; Gooch, M.; Jones, D.; Newsome, R.; Stitzinger, J.; Sylvia, G.; Zhang, J. Project to Develop an Interoperable Seafood Traceability Technology Architecture: Issues Brief. Compr. Rev. Food Sci. Food Saf. 2016, 15, 392–429. [Google Scholar] [CrossRef]

- Olsen, P.; Borit, M. The components of a food traceability system. Trends Food Sci. Technol. 2018, 77, 143–149. [Google Scholar] [CrossRef]

- Wang, J.; Yue, H.; Zhou, Z. An improved traceability system for food quality assurance and evaluation based on fuzzy classification and neural network. Food Control 2017, 79, 363–370. [Google Scholar] [CrossRef]

- Xiao, X.; Fu, Z.; Zhang, Y.; Peng, Z.; Zhang, X. SMS-CQ: A quality and safety traceability system for aquatic products in cold-chain integrated WSN and QR code. J. Food Process Eng. 2017, 40, e12303. [Google Scholar] [CrossRef]

- Wang, X.; Fu, D.; Fruk, G.; Chen, E.; Zhang, X. Improving quality control and transparency in honey peach export chain by a multi-sensors-managed traceability system. Food Control 2018, 88, 169–180. [Google Scholar] [CrossRef]

- Zhang, H.; Deng, Y.; Chan, F.T.S.; Zhang, X. A modified multi-criterion optimization genetic algorithm for order distribution in collaborative supply chain. Appl. Math. Model. 2013, 37, 7855–7864. [Google Scholar] [CrossRef]

- Liu, L.; Liu, P.; Wen, F.; Zhang, C.; Zhao, R.; Yan, M.; Yu, X. Information collection system of duck products based on IoT. EURASIP J. Wirel. Commun. Netw. 2018, 2018, 124. [Google Scholar] [CrossRef]

- Jin, S.; Zhang, Y.; Xu, Y. Amount of information and the willingness of consumers to pay for food traceability in China. Food Control 2017, 77, 163–170. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Traceability in a food supply chain: Safety and quality perspectives. Food Control 2014, 39, 172–184. [Google Scholar] [CrossRef]

- Cuinas, I.; Newman, R.; Trebar, M.; Catarinucci, L.; Melcon, A.A. Rfid-based traceability along the food-production chain. IEEE Antennas Propag. Mag. 2014, 56, 196–207. [Google Scholar] [CrossRef]

- Chen, K.; Xiao, T. Outsourcing strategy and production disruption of supply chain with demand and capacity allocation uncertainties. Int. J. Prod. Econ. 2015, 170, 243–257. [Google Scholar] [CrossRef]

- Alfian, G.; Syafrudin, M.; Rhee, J. Real-time monitoring system using smartphone-based sensors and nosql database for perishable supply chain. Sustainability 2017, 9, 2073. [Google Scholar] [CrossRef]

- Bai, H.; Zhou, G.; Hu, Y.; Sun, A.; Xu, X.; Liu, X.; Lu, C. Traceability technologies for farm animals and their products in China. Food Control 2017, 79, 35–43. [Google Scholar] [CrossRef]

- Giagnocavo, C.; Bienvenido, F.; Ming, L.; Yurong, Z.; Antonio Sanchez-Molina, J.; Xinting, Y. Agricultural cooperatives and the role of organisational models in new intelligent traceability systems and big data analysis. Int. J. Agric. Biol. Eng. 2017, 10, 115–125. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Mc Carthy, U.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Robla Villalba, J.I. New trends in cold chain monitoring applications—A review. Food Control 2018, 86, 170–182. [Google Scholar] [CrossRef]

- Tian, F. A supply chain traceability system for food safety based on HACCP, blockchain & Internet of things. In Proceedings of the 2017 IEEE-International Conference on Service Systems and Service Management, Dalian, China 16–18 June 2017; pp. 1–6. [Google Scholar]

- Lin, J.; Shen, Z.; Miao, C. Using Blockchain Technology to Build Trust in Sharing LoRaWAN IoT. In Proceedings of the 2nd International Conference on Crowd Science and Engineering, Beijing, China, 6–9 July 2017; pp. 38–43. [Google Scholar]

- Caro, M.P.; Ali, M.S.; Vecchio, M.; Giaffreda, R. Blockchain-based traceability in Agri-Food supply chain management: A practical implementation. In Proceedings of the 2018 IEEE-IoT Vertical and Topical Summit on Agriculture-Tuscany (IOT Tuscany), Tuscany, Italy, 8–9 May 2018; pp. 1–4. [Google Scholar]

- Kamath, R. Food Traceability on Blockchain: Walmart’s Pork and Mango Pilots with IBM. J. Br. Blockchain Assoc. 2018, 1, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Galvez, J.F.; Mejuto, J.C.; Simal-Gandara, J. Future challenges on the use of blockchain for food traceability analysis. TrAC Trends Anal. Chem. 2018, 107, 222–232. [Google Scholar] [CrossRef]

- Tripoli, M.; Schmidhuber, J. Emerging Opportunities for the Application of Blockchain in the Agri-Food Industry; FAO: Rome, Italy; ICTSD: Geneva, Switzerland, 2018; Volume 3. [Google Scholar]

- Gupta, S.; Modgil, S.; Choi, T.-M.; Kumar, A.; Antony, J. Influences of artificial intelligence and blockchain technology on financial resilience of supply chains. Int. J. Prod. Econ. 2023, 261, 108868. [Google Scholar] [CrossRef]

- Biswas, D.; Jalali, H.; Ansaripoor, A.H.; De Giovanni, P. Traceability vs. sustainability in supply chains: The implications of blockchain. Eur. J. Oper. Res. 2023, 305, 128–147. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, L.; Battino, M.; Farag, M.A.; Xiao, J.; Simal-Gandara, J.; Gao, H.; Jiang, W. Blockchain: An emerging novel technology to upgrade the current fresh fruit supply chain. Trends Food Sci. Technol. 2022, 124, 1–12. [Google Scholar] [CrossRef]

- Ellis, S.; Morris, H.D.; Santagate, J. IoT-Enabled Analytic Applications Revolutionize Supply Chain Planning and Execution; White Paper; International Data Corporation (IDC): Needham, MA, USA, 2015; p. 259697. [Google Scholar]

- Makhdoom, I.; Abolhasan, M.; Abbas, H.; Ni, W. Blockchain’s adoption in IoT: The challenges, and a way forward. J. Netw. Comput. Appl. 2019, 125, 251–279. [Google Scholar] [CrossRef]

- Lu, Y. The blockchain: State-of-the-art and research challenges. J. Ind. Inf. Integr. 2019, 15, 80–90. [Google Scholar] [CrossRef]

- Arfi, W.B.; Nasr, I.B.; Khvatova, T.; Ben Zaied, Y. Understanding acceptance of eHealthcare by IoT natives and IoT immigrants: An integrated model of UTAUT, perceived risk, and financial cost. Technol. Forecast. Soc. Chang. 2021, 163, 120437. [Google Scholar] [CrossRef]

- Puligundla, P.; Jung, J.; Ko, S. Carbon dioxide sensors for intelligent food packaging applications. Food Control 2012, 25, 328–333. [Google Scholar] [CrossRef]

- Brizio, A.P.; Prentice, C. Use of smart photochromic indicator for dynamic monitoring of the shelf life of chilled chicken based products. Meat Sci. 2014, 96, 1219–1226. [Google Scholar] [CrossRef]

- Tsironi, T.; Giannoglou, M.; Platakou, E.; Taoukis, P. Evaluation of Time Temperature Integrators for shelf-life monitoring of frozen seafood under real cold chain conditions. Food Packag. Shelf Life 2016, 10, 46–53. [Google Scholar] [CrossRef]

- Zhang, X.; Van Donk, D.P.; van der Vaart, T. The different impact of inter-organizational and intra-organizational ICT on supply chain performance. Int. J. Oper. Prod. Manag. 2016, 36, 803–824. [Google Scholar] [CrossRef]

- Lorite, G.S.; Selkälä, T.; Sipola, T.; Palenzuela, J.; Jubete, E.; Viñuales, A.; Cabañero, G.; Grande, H.J.; Tuominen, J.; Uusitalo, S. Novel, smart and RFID assisted critical temperature indicator for supply chain monitoring. J. Food Eng. 2017, 193, 20–28. [Google Scholar] [CrossRef]

- Brizio, A.P.; Prentice, C. Development of Aa New Time Temperature Indicator for Enzymatic Validation of Pasteurization of Meat Products. J. Food Sci. 2015, 80, M1271–M1276. [Google Scholar] [CrossRef]

- Maksimović, M.; Vujović, V.; Periśić, B. A custom Internet of Things healthcare system. In Proceedings of the 2015 IEEE-10th Iberian Conference on Information Systems and Technologies (CISTI), Aveiro, Portugal, 17–20 June 2015; pp. 1–6. [Google Scholar]

- Tsang, Y.P.; Choy, K.L.; Wu, C.-H.; Ho, G.T.; Lam, C.H.; Koo, P. An Internet of Things (IoT)-based risk monitoring system for managing cold supply chain risks. Ind. Manag. Data Syst. 2018, 118, 1432–1462. [Google Scholar] [CrossRef]

- Haass, R.; Dittmer, P.; Veigt, M.; Lütjen, M. Reducing food losses and carbon emission by using autonomous control—A simulation study of the intelligent container. Int. J. Prod. Econ. 2015, 164, 400–408. [Google Scholar] [CrossRef]

- Fang, B.; Guo, J.; Li, F.; Giesy, J.P.; Wang, L.; Shi, W. Bioassay directed identification of toxicants in sludge and related reused materials from industrial wastewater treatment plants in the Yangtze River Delta. Chemosphere 2017, 168, 191–198. [Google Scholar] [CrossRef] [PubMed]

- Heising, J.K.; Claassen, G.D.H.; Dekker, M. Options for reducing food waste by quality-controlled logistics using intelligent packaging along the supply chain. Food Addit. Contam. Part A 2017, 34, 1672–1680. [Google Scholar] [CrossRef]

- Liu, C.; Yang, C.; Zhang, X.; Chen, J. External integrity verification for outsourced big data in cloud and IoT: A big picture. Future Gener. Comput. Syst. 2015, 49, 58–67. [Google Scholar] [CrossRef]

- Barmpounakis, S.; Kaloxylos, A.; Groumas, A.; Katsikas, L.; Sarris, V.; Dimtsa, K.; Fournier, F.; Antoniou, E.; Alonistioti, N.; Wolfert, S. Management and control applications in Agriculture domain via a Future Internet Business-to-Business platform. Inf. Process. Agric. 2015, 2, 51–63. [Google Scholar] [CrossRef][Green Version]

- Yan, B.; Yan, C.; Ke, C.; Tan, X. Information sharing in supply chain of agricultural products based on the Internet of Things. Ind. Manag. Data Syst. 2016, 116, 1397–1416. [Google Scholar] [CrossRef]

- Balamurugan, S.; Divyabharathi, N.; Jayashruthi, K.; Bowiya, M.; Shermy, R.; Shanker, R. Internet of agriculture: Applying IoT to improve food and farming technology. Int. Res. J. Eng. Technol. 2016, 3, 713–719. [Google Scholar]

- Witjaksono, G.; Saeed Rabih, A.A.; Yahya, N.B.; Alva, S. IOT for agriculture: Food quality and safety. IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 343, p. 012023. [Google Scholar]

- Wen, Z.; Hu, S.; De Clercq, D.; Beck, M.B.; Zhang, H.; Zhang, H.; Fei, F.; Liu, J. Design, implementation, and evaluation of an Internet of Things (IoT) network system for restaurant food waste management. Waste Manag. 2018, 73, 26–38. [Google Scholar] [CrossRef]

- Tsang, Y.; Choy, K.; Wu, C.-H.; Ho, G.; Lam, H.; Koo, P. An IoT-based cargo monitoring system for enhancing operational effectiveness under a cold chain environment. Int. J. Eng. Bus. Manag. 2017, 9, 1847979017749063. [Google Scholar] [CrossRef]

- Lu, S.; Wang, X. Toward an intelligent solution for perishable food cold chain management. In Proceedings of the 2016 7th IEEE International Conference on Software Engineering and Service Science (ICSESS), IEEE, Beijing, China, 26–28 August 2016; pp. 852–856. [Google Scholar]

- Luo, H.; Zhu, M.; Ye, S.; Hou, H.; Chen, Y.; Bulysheva, L. An intelligent tracking system based on internet of things for the cold chain. Internet Res. 2016, 26, 435–445. [Google Scholar] [CrossRef]

- Ruiz-Garcia, L.; Lunadei, L. Monitoring cold chain logistics by means of RFID. Sustain. Radio Freq. Identif. Solut. 2010, 2, 37–50. [Google Scholar]

- Yan, R. Optimization approach for increasing revenue of perishable product supply chain with the Internet of Things. Ind. Manag. Data Syst. 2017, 117, 729–741. [Google Scholar] [CrossRef]

- Pang, Z.; Chen, Q.; Han, W.; Zheng, L. Value-centric design of the internet-of-things solution for food supply chain: Value creation, sensor portfolio and information fusion. Inf. Syst. Front. 2015, 17, 289–319. [Google Scholar] [CrossRef]

- Verdouw, C.; Robbemond, R.M.; Verwaart, T.; Wolfert, J.; Beulens, A.J. A reference architecture for IoT-based logistic information systems in agri-food supply chains. Enterp. Inf. Syst. 2018, 12, 755–779. [Google Scholar] [CrossRef]

- Accorsi, R.; Bortolini, M.; Baruffaldi, G.; Pilati, F.; Ferrari, E. Internet-of-things paradigm in food supply chains control and management. Procedia Manuf. 2017, 11, 889–895. [Google Scholar] [CrossRef]

- Verdouw, C.N.; Beulens, A.J.M.; van der Vorst, J.G.A.J. Virtualisation of floricultural supply chains: A review from an Internet of Things perspective. Comput. Electron. Agric. 2013, 99, 160–175. [Google Scholar] [CrossRef]

- Verdouw, C.N.; Wolfert, J.; Beulens, A.; Rialland, A. Virtualization of food supply chains with the internet of things. J. Food Eng. 2016, 176, 128–136. [Google Scholar] [CrossRef]

- Accorsi, R.; Cholette, S.; Manzini, R.; Tufano, A. A hierarchical data architecture for sustainable food supply chain management and planning. J. Clean. Prod. 2018, 203, 1039–1054. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, X.D. Research on the construction of green evaluation model based on IOT of agricultural products. Appl. Mech. Mater. 2014, 687, 4631–4637. [Google Scholar] [CrossRef]

- Pereira, A.C.; Romero, F. A review of the meanings and the implications of the Industry 4.0 concept. Procedia Manuf. 2017, 13, 1206–1214. [Google Scholar] [CrossRef]

- Bienhaus, F.; Haddud, A. Procurement 4.0: Factors influencing the digitisation of procurement and supply chains. Bus. Process Manag. J. 2018, 24, 965–984. [Google Scholar] [CrossRef]

- Barata, J.; Da Cunha, P.R.; Stal, J. Mobile supply chain management in the Industry 4.0 era: An annotated bibliography and guide for future research. J. Enterp. Inf. Manag. 2018, 31, 173–192. [Google Scholar] [CrossRef]

- Huang, W.; Wang, X.; Xia, J.; Li, Y.; Zhang, L.; Feng, H.; Zhang, X. Flexible sensing enabled agri-food cold chain quality control: A review of mechanism analysis, emerging applications, and system integration. Trends Food Sci. Technol. 2023, 133, 189–204. [Google Scholar] [CrossRef]

- Tjahjono, B.; Esplugues, C.; Ares, E.; Pelaez, G. What does Industry 4.0 mean to Supply Chain? Procedia Manuf. 2017, 13, 1175–1182. [Google Scholar] [CrossRef]

- Van Nguyen, T.; Pham, H.T.; Ha, H.M.; Tran, T.T.T. An integrated model of supply chain quality management, Industry 3.5 and innovation to improve manufacturers’ performance—A case study of Vietnam. Int. J. Logist. Res. Appl. 2022, 1–23. [Google Scholar] [CrossRef]

- Ardito, L.; Scuotto, V.; Del Giudice, M.; Petruzzelli, A.M. A bibliometric analysis of research on Big Data analytics for business and management. Manag. Decis. 2019, 57, 1993–2009. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 implications in logistics: An overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Significance of Quality 4.0 towards comprehensive enhancement in manufacturing sector. Sens. Int. 2021, 2, 100109. [Google Scholar] [CrossRef]

- Kache, F.; Seuring, S. Challenges and opportunities of digital information at the intersection of Big Data Analytics and supply chain management. Int. J. Oper. Prod. Manag. 2017, 37, 10–36. [Google Scholar] [CrossRef]

- Lim, A.-F.; Ooi, K.-B.; Tan, G.W.-H.; Cham, T.-H.; Alryalat, M.A.; Dwivedi, Y.K. Adapt or die: A competitive digital supply chain quality management strategy. J. Enterp. Inf. Manag. 2022. ahead of print. [Google Scholar] [CrossRef]

- Muthusami, S.; Srinivsan, M. Supply chain 4.0: Digital transformation, disruptions and strategies. Rev. Bus. Technol. Res. 2018, 14, 32–35. [Google Scholar]

- Tu, M. An exploratory study of Internet of Things (IoT) adoption intention in logistics and supply chain management: A mixed research approach. Int. J. Logist. Manag. 2018, 29, 131–151. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. Digital Supply Chain: Literature review and a proposed framework for future research. Comput. Ind. 2018, 97, 157–177. [Google Scholar] [CrossRef]

- Iddris, F. Digital supply chain: Survey of the literature. Int. J. Bus. Res. Manag. 2018, 9, 47–61. [Google Scholar]

- Ju, Y.; Hou, H.; Yang, J. Integration quality, value co-creation and resilience in logistics service supply chains: Moderating role of digital technology. Ind. Manag. Data Syst. 2021, 121, 364–380. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, R.K.; Modgil, S. Influence of data-driven supply chain quality management on organizational performance: Evidences from retail industry. TQM J. 2023, 35, 24–50. [Google Scholar] [CrossRef]

- Zhou, X.; Zhu, Q.; Xu, Z. The mediating role of supply chain quality management for traceability and performance improvement: Evidence among Chinese food firms. Int. J. Prod. Econ. 2022, 254, 108630. [Google Scholar] [CrossRef]

- Shabani-Naeeni, F.; Ghasemy Yaghin, R. Incorporating data quality into a multi-product procurement planning under risk. J. Bus. Ind. Mark. 2021, 36, 1176–1190. [Google Scholar] [CrossRef]

- Silbernagel, R.; Wagner, C.; Albers, A.; Trapp, T.-U.; Lanza, G. Data-Based Supply Chain Collaboration–Improving Product Quality in Global Production Networks by Sharing Information. Procedia CIRP 2021, 104, 470–475. [Google Scholar] [CrossRef]

- Zimon, D.; Urbaniak, M.; Madzík, P.; Prokopiuk, I. Supply Chain Quality Management (Scqm) Literature Review And Model Proposal In The Era Of Industry 4.0. Int. J. Qual. Res. 2022, 16, 1283–1296. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Mondal, S.; Samaddar, K. Reinforcing the significance of human factor in achieving quality performance in data-driven supply chain management. TQM J. 2023, 35, 183–209. [Google Scholar] [CrossRef]

- Wu, L.; Yue, X.; Jin, A.; Yen, D.C. Smart supply chain management: A review and implications for future research. Int. J. Logist. Manag. 2016, 27, 395–417. [Google Scholar] [CrossRef]

- Li, J.; Zhu, S.; Zhang, W.; Yu, L. Blockchain-driven supply chain finance solution for small and medium enterprises. Front. Eng. Manag. 2020, 7, 500–511. [Google Scholar] [CrossRef]

- Sharma, M.; Joshi, S. Digital supplier selection reinforcing supply chain quality management systems to enhance firm’s performance. TQM J. 2023, 35, 102–130. [Google Scholar] [CrossRef]

- Saihi, A.; Awad, M.; Ben-Daya, M. Quality 4.0: Leveraging Industry 4.0 technologies to improve quality management practices–a systematic review. Int. J. Qual. Reliab. Manag. 2023, 40, 628–650. [Google Scholar] [CrossRef]

- Zaid, A.; Sleimi, M.; Saleh, M.W.; Othman, M. The mediating roles of knowledge transfer and supply chain quality management capabilities on organisational performance. VINE J. Inf. Knowl. Manag. Syst. 2021. ahead of print. [Google Scholar] [CrossRef]

- Brinch, M. Understanding the value of big data in supply chain management and its business processes: Towards a conceptual framework. Int. J. Oper. Prod. Manag. 2018, 38, 1589–1614. [Google Scholar] [CrossRef]

- Bruque, S.; Moyano, J. Organisational determinants of information technology adoption and implementation in SMEs: The case of family and cooperative firms. Technovation 2007, 27, 241–253. [Google Scholar] [CrossRef]

- Patterson, K.A.; Grimm, C.M.; Corsi, T.M. Adopting new technologies for supply chain management. Transp. Res. Part E Logist. Transp. Rev. 2003, 39, 95–121. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Joshi, S. Modeling the internet of things adoption barriers in food retail supply chains. J. Retail. Consum. Serv. 2019, 48, 154–168. [Google Scholar] [CrossRef]

- Arzu Akyuz, G.; Erman Erkan, T. Supply chain performance measurement: A literature review. Int. J. Prod. Res. 2010, 48, 5137–5155. [Google Scholar] [CrossRef]

- Sriram, R.; Vinodh, S. Analysis of readiness factors for Industry 4.0 implementation in SMEs using COPRAS. Int. J. Qual. Reliab. Manag. 2021, 38, 1178–1192. [Google Scholar] [CrossRef]

- Stentoft, J.; Jensen, K.W.; Philipsen, K.; Haug, A. Drivers and barriers for Industry 4.0 readiness and practice: A SME perspective with empirical evidence. In Proceedings of the 52nd Hawaii International Conference on System Sciences, Maui, HI, USA, 8–11 January 2019. [Google Scholar]

- Nair, L.; Adetayo, O.A. Cultural competence and ethnic diversity in healthcare. Plast. Reconstr. Surg. Glob. Open 2019, 7, e2219. [Google Scholar] [CrossRef]

- Blatz, F.; Bulander, R.; Dietel, M. Maturity model of digitization for SMEs. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), IEEE, Stuttgart, Germany, 17–20 June 2018; pp. 1–9. [Google Scholar]

- Moharana, H.S.; Murty, J.; Senapati, S.; Khuntia, K. Coordination, collaboration and integration for supply chain management. Int. J. Intersci. Manag. Rev. 2012, 2, 46–50. [Google Scholar] [CrossRef]

- Asha, A.A.; Dulal, M.; Habib, A. The influence of sustainable supply chain management, technology orientation, and organizational culture on the delivery product quality-customer satisfaction nexus. Clean. Logist. Supply Chain 2023, 7, 100107. [Google Scholar] [CrossRef]

- Alamsjah, F.; Yunus, E.N. Achieving supply chain 4.0 and the importance of agility, ambidexterity, and organizational culture: A Case of Indonesia. J. Open Innov. Technol. Mark. Complex. 2022, 8, 83. [Google Scholar] [CrossRef]

- Fan, Z.-P.; Wu, X.-Y.; Cao, B.-B. Considering the traceability awareness of consumers: Should the supply chain adopt the blockchain technology? Ann. Oper. Res. 2022, 390, 837–860. [Google Scholar] [CrossRef]

- Dhamija, P.; Chiarini, A.; Shapla, S. Technology and leadership styles: A review of trends between 2003 and 2021. TQM J. 2023, 35, 210–233. [Google Scholar] [CrossRef]

- Luo, L.; Liu, X.; Zhao, X.; Flynn, B.B. The impact of supply chain quality leadership on supply chain quality integration and quality performance. Supply Chain Manag. Int. J. 2023, 28, 508–521. [Google Scholar] [CrossRef]

- Dutta, P.; Choi, T.-M.; Somani, S.; Butala, R. Blockchain technology in supply chain operations: Applications, challenges and research opportunities. Transp. Res. Part E Logist. Transp. Rev. 2020, 142, 102067. [Google Scholar] [CrossRef] [PubMed]

- Bautista-Santos, H.; Martínez-Flores, J.L.; Fernández-Lambert, G.; Bernabé-Loranca, M.B.; Sánchez-Galván, F.; Sablón-Cossío, N. Integration model of collaborative supply chain. Dyna 2015, 82, 145–154. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Montoya-Torres, J.R.; Ortiz-Vargas, D.A. Collaboration and information sharing in dyadic supply chains: A literature review over the period 2000–2012. Estud. Gerenciales 2014, 30, 343–354. [Google Scholar] [CrossRef]

- Montoya-Torres, J.; Ortiz-Vargas, D. Analysis of the collaboration concept in supply chain: A scientific literature review. In Proceedings of the Ninth Latin American and Caribbean Conference, Medellín, Colombia, 3–5 August 2011; pp. 1–10. [Google Scholar]

- Faller, C.; Feldmüller, D. Industry 4.0 learning factory for regional SMEs. Procedia Cirp 2015, 32, 88–91. [Google Scholar] [CrossRef]

- Ganzarain, J.; Errasti, N. Three stage maturity model in SME’s toward industry 4.0. J. Ind. Eng. Manag. 2016, 9, 1119–1128. [Google Scholar] [CrossRef]

- Basheer, M.; Siam, M.; Awn, A.; Hassan, S. Exploring the role of TQM and supply chain practices for firm supply performance in the presence of information technology capabilities and supply chain technology adoption: A case of textile firms in Pakistan. Uncertain Supply Chain Manag. 2019, 7, 275–288. [Google Scholar] [CrossRef]

- Lin, C.; Chow, W.S.; Madu, C.N.; Kuei, C.-H.; Yu, P.P. A structural equation model of supply chain quality management and organizational performance. Int. J. Prod. Econ. 2005, 96, 355–365. [Google Scholar] [CrossRef]

- Kuei, C.H.; Madu, C.N.; Lin, C.; Chow, W.S. Developing supply chain strategies based on the survey of supply chain quality and technology management. Int. J. Qual. Reliab. Manag. 2002, 19, 889–901. [Google Scholar] [CrossRef]

- Duclos, L.K.; Vokurka, R.J.; Lummus, R.R. A conceptual model of supply chain flexibility. Ind. Manag. Data Syst. 2003, 103, 446–456. [Google Scholar] [CrossRef]

- Richey, R.G.; Adams, F.G.; Dalela, V. Technology and flexibility: Enablers of collaboration and time-based logistics quality. J. Bus. Logist. 2012, 33, 34–49. [Google Scholar] [CrossRef]

- Xu, L.D. Information architecture for supply chain quality management. Int. J. Prod. Res. 2011, 49, 183–198. [Google Scholar] [CrossRef]

- Fish, L.A. Supply chain quality management. Supply Chain Manag. Pathw. Res. Pract. 2011, 25, 225–234. [Google Scholar]

- Gualandris, J.; Golini, R.; Kalchschmidt, M. Do supply management and global sourcing matter for firm sustainability performance?: An international study. Supply Chain Manag. Int. J. 2014, 19, 258–274. [Google Scholar] [CrossRef]

- Gomiero, T.; Paoletti, M.G.; Pimentel, D. Energy and Environmental Issues in Organic and Conventional Agriculture. Crit. Rev. Plant Sci. 2008, 27, 239–254. [Google Scholar] [CrossRef]

- Chee Tahir, A.; Darton, R.C. The Process Analysis Method of selecting indicators to quantify the sustainability performance of a business operation. J. Clean. Prod. 2010, 18, 1598–1607. [Google Scholar] [CrossRef]

- Kostakis, V.; Roos, A.; Bauwens, M. Towards a political ecology of the digital economy: Socio-environmental implications of two competing value models. Environ. Innov. Soc. Transit. 2016, 18, 82–100. [Google Scholar] [CrossRef]

- Ada, N.; Kazancoglu, Y.; Sezer, M.D.; Ede-Senturk, C.; Ozer, I.; Ram, M. Analyzing barriers of circular food supply chains and proposing industry 4.0 solutions. Sustainability 2021, 13, 6812. [Google Scholar] [CrossRef]

- Shen, B.; Chen, C. Quality management in outsourced global fashion supply chains: An exploratory case study. Prod. Plan. Control 2020, 31, 757–769. [Google Scholar] [CrossRef]

- Ding, G.K.C. Developing a multicriteria approach for the measurement of sustainable performance. Build. Res. Inf. 2005, 33, 3–16. [Google Scholar] [CrossRef]

- Addison, P.F.E.; Stephenson, P.J.; Bull, J.W.; Carbone, G.; Burgman, M.; Burgass, M.J.; Gerber, L.R.; Howard, P.; McCormick, N.; McRae, L.; et al. Bringing sustainability to life: A framework to guide biodiversity indicator development for business performance management. Bus. Strategy Environ. 2020, 29, 3303–3313. [Google Scholar] [CrossRef]

- Hoang, T.G.; Bui, M.L. Business intelligence and analytic (BIA) stage-of-practice in micro-, small-and medium-sized enterprises (MSMEs). J. Enterp. Inf. Manag. 2023, 36, 1080–1104. [Google Scholar] [CrossRef]

- Lahane, S.; Kant, R.; Shankar, R. Circular supply chain management: A state-of-art review and future opportunities. J. Clean. Prod. 2020, 258, 120859. [Google Scholar] [CrossRef]

- Yadav, G.; Luthra, S.; Jakhar, S.K.; Mangla, S.K.; Rai, D.P. A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. J. Clean. Prod. 2020, 254, 120112. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S.S. Ten lessons for managers while implementing Industry 4.0. IEEE Eng. Manag. Rev. 2019, 47, 45–52. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

| Phase 1: | |

| Planning | Search Strings |

| SCQM: Supply Chain Quality Management, Supply Chain Management and Quality Management SCQM4.0: Industry 4.0 AND supply AND chain AND quality, Digitization AND supply AND chain AND quality, Fourth Industrial revolution AND supply AND chain AND quality, Smart Manufacturing AND supply AND chain AND quality, Smart factory AND supply AND chain AND quality, Cyber-Physical System AND supply AND chain AND quality, Internet of things AND supply AND chain AND quality, Industrial Internet AND supply AND chain AND quality, Big data AND supply AND chain AND quality, Blockchain AND supply AND chain AND quality. | |

| Search Period | |

| 1998 to October 2023 | |

| Phase 2: | |

| Conducting | Searching Conducting searches in accordance with predetermined criteria |

| Screening Identification: Confirm identity across the database and abstract Eligibility: Assess the introduction and conclusion for eligibility Included: Scrutinize the full text for inclusion | |

| Analysis Comprehensive examination through descriptive analysis and thematic synthesis | |

| Phase 3: | |

| Reporting | Establishing Constructs for SCQM 4.0 Concept Building Conceptual Frameworks in the Context of CE |

| Traceability Research Issue | References |

|---|---|

| Traceability Systems Applications: | |

| RFIDs | Qian [42] |

| RFIDs with PDA and barcodes | Tian [43] |

| “Gapless” traceability with RFIDs | Mainetti et al. [44] |

| RFIDs | Barge et al. [45] |

| IoT, EPCglobal | Chen et al. [46] |

| Cold supply chain | Óskarsdóttir and Oddsson [47] |

| General tools | Bhatt et al. [48]; Olsen and Borit [49] |

| Traceability for quality | Wang et al. [50]; Xiao et al. [51]; Wang et al. [52] |

| Traceability for safety and security | Zhang et al. [53]; Xiao, Fu, Zhang, Peng and Zhang [51]; Liu et al. [54] |

| Value of traceability to consumers | Jin, et al. [55] |

| RFID technology management: Traceability in logistics and Traceability for anti-counterfeit operations | Aung and Chang [56]; Cuinas et al. [57]; Chen and Xiao [58]; Alfian et al. [59]; Bai et al. [60] |

| Implementation requirements, consistency, data security and big data expertise | Giagnocavo et al. [61] |

| Challenges in dealing with the heterogeneous nature of the supply chain from a technological perspective | Badia-Melis et al. [62] |

| Research Topics | References |

|---|---|

| Framework for intelligent Blockchain-based SCQM | Chen, Shi, Ren, Yan, Shi and Zhang [46] |

| Supply chain traceability system based on Blockchain and IoT technology | Tian [63]; Lin et al. [64]; Caro et al. [65] |

| Supply chain traceability system based on HACCP (Hazard Analysis and Critical Control Points), Blockchain and the IoT | Tian [63] |

| Blockchain pilot implementation | Kamath [66] |

| Blockchain and smart contracts implementation challenges | Galvez et al. [67]; Tripoli and Schmidhuber [68] |

| Pilot implementations | Kamath [66] |

| Research Issues in the Domain of Smart Packaging | References |

|---|---|

| Various types of carbon dioxide sensors | Puligundla et al. [76] |

| Implementation of photochromic time-temperature indicators (TTI) to monitor the time-temperature history | Brizio and Prentice [77]; Tsironi et al. [78]; Zhang et al. [79] |

| Smart time-temperature indicator | Lorite et al. [80]; Brizio and Prentice [81] |

| Product tracking using IoT technology | Maksimović et al. [82]; Tsang et al. [83] |

| Implementation of intelligent packaging for waste reduction | Haass et al. [84]; Fang et al. [85]; Heising et al. [86] |

| IoT Systems Applications and Frameworks | References |

|---|---|

| IoT systems application | |

| Quality and safety monitoring of agricultural products. | Liu et al. [87]; Barmpounakis et al. [88]; Yan et al. [89]; Balamurugan et al. [90]; Witjaksono et al. [91]; Wen et al. [92] |

| IoT-based cold supply chain monitoring. | Tsang, Choy, Wu, Ho, Lam and Koo [83] |

| IoT-based cargo monitoring system for product quality. | Tsang et al. [93] |

| IoT and cloud computing-based solutions for cold supply chain monitoring. | Lu and Wang [94] |

| RFID and critical Temperature Indicators sensors for real-time monitoring of supply chain temperature | Lorite, Selkälä, Sipola, Palenzuela, Jubete, Viñuales, Cabañero, Grande, Tuominen and Uusitalo [80] |

| IoT-based duck product traceability system | Liu, Liu, Wen, Zhang, Zhao, Yan and Yu [54] |

| An intelligent tracking system based on the IoT for the cold chain. | Luo et al. [95] |

| RFID monitoring for cold supply chains. | Ruiz-Garcia and Lunadei [96] |

| An optimization approach for increasing revenue from perishable product supply chain with the IoT | Yan [97] |

| IoT frameworks | |

| Value-centric business-technology design framework. | Pang et al. [98] |

| IoT-based logistic information system architecture for supply chains | Verdouw et al. [99] |

| IoT-based framework for supply chain planning | Accorsi et al. [100] |

| Supply chain virtualization | Verdouw et al. [101]; Verdouw et al. [102] |

| Hierarchical data architecture for sustainable SCM and planning | Accorsi et al. [103] |

| Green evaluation models based on IoT for agricultural products | Wang and Deng [104] |

| Disruptive Technologies | Authors |

|---|---|

| Semantic machine-to-machine communication | [2,106,107,108,109,110] |

| Cyber-physical systems (CPS) | [1,2,106,109,111,112,113,114,115,116,117,118] |

| IoT | [2,106,107,109,111,112,116,117,118,119,120,121,122,123] |

| Cloud technologies | [106,107,109,111,113,123,124,125,126] |

| BDA | [108,109,110,111,113,119,120,122,127,128] |

| Radio frequency identification (RFID) | [106,107,110,118,120,123,126,129] |

| Blockchain | [1,36,46,116,128,130] |

| Robotics | [2,108,109,113,119,121,122] |

| Enterprise Resource Planning (ERP) | [2,107,114,128,131] |

| 3DP | [1,2,119,120,125,132,133] |

| Nanotechnology | [2,109,110,119,124,131] |

| Business intelligence | [2,108,109,134] |

| AI | [2,106,117,123,129,132,133] |

| SCQM 4.0 Practices | Description | Authors |

|---|---|---|

| Infrastructure Practices | ||

| Top management support | The degree to which top management understands the importance of SCMQM 4.0 and the extent of willingness to support disruptive technologies implementation to improve quality in the supply chain. Top management is supposed to shape a proper strategy which ensures the organization’s purposes are aligned with the implementation of new technology. | Sriram and Vinodh [139], Stentoft et al. [140], Nair and Adetayo [141] |

| IT Infrastructure | IT capabilities and resources need to be readily accessible for the initial development, implementation, and continuous management and evolution of disruptive technologies. The capability of the infrastructure enables entities to store and interpret huge volumes of data. | Sriram and Vinodh [139], Blatz et al. [142] |

| Human resource and organizational skills | Management structure, HR strategy, work environment, and skill development are crucial components for the successful implementation of SCWM 4.0, particularly in the context of adopting new technologies. | [2] |

| Coordination | Effective communication across different tiers of the supply chain is paramount, considering the evolutionary implications of SCQM 4.0. Coordination, in this context, involves active and direct cooperation achieved through transmitting accurate signals, sharing relevant information, and aligning policies. It denotes a collaborative interactive process that results in joint decisions and activities [143]. | [143] |

| Organizational culture | A shared set of norms, beliefs, and values among members of the organization is essential for fostering a collective understanding of SCQM 4.0. | Asha et al. [144] Alamsjah and Yunus [145] |

| Awareness | A comprehensive understanding among all entities in the supply chain is crucial regarding the benefits and requirements of SCQM 4.0. | Fan et al. [146] |

| Leadership | A thorough comprehension of the evolutionary nature and strategic implications of SCQM 4.0 is essential for making informed decisions regarding budget and resource allocations. | Dhamija et al. [147] Luo et al. [148] |

| SCOR indicators | ||

| Transparency | The extent of visibility and the dissemination of information, both internally and externally, depends on the desired level of disclosure. This involves the degree to which stakeholders effectively identify and gather data from all linkages in the supply chain. | Dutta et al. [149] Bui, Carvalho, Pham, Nguyen, Duong and Quang [2] |

| Integration | Integration, in this context, refers to the act of “making a whole” and aligning the constituent parts. It involves synchronizing the requirements, concepts, and flows among the chain members, with the ultimate goal of maximizing competitive advantages at strategic, tactical, and operative levels. | Bautista-Santos et al. [150] |

| Interoperability | Refers to the level of information sharing and applications; interoperability of systems and their ability to share and utilize data and features. | Sriram and Vinodh [139] Lu [151] |

| Collaboration | Collaboration entails working together or with someone towards a specific purpose [152]. In collaborative supply chains, all members are obligated to execute the mutually agreed-upon strategies, regardless of their size, function, or position within the chain [153]. | Sriram and Vinodh [139] Faller and Feldmüller [154] Ganzarain and Errasti [155] |

| Performance measurement | Evaluate the efficacy of steps in the SCOR model by assessing the ratio of perfect orders to defect rates. | Basheer et al. [156] Lin et al. [157] |

| Efficiency | The extent to which a company’s procedures optimize the use of available resources. This includes but is not limited to monetary, human, technological, and physical assets. | Lin, Chow, Madu, Kuei and Yu [157] Kuei et al. [158] |

| Flexibility | The business’s capability to adapt to risks and shifts in consumer expectations without incurring substantial financial, temporal, or performance setbacks is known as resilience. This resilience is maintained while preserving positive relationships with critical suppliers and customers. | Duclos et al. [159] Richey et al. [160] |

| Responsiveness | Refers to how quickly and effectively a company’s supply chain can react to new demands from customers or shifts in the marketplace. | Xu [161] Fish [162] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, K.; Akbari, M.; Quang, H.T.; McDonald, S.; Hoang, T.-H.; Yap, T.L.; George, M. Navigating Environmental Challenges through Supply Chain Quality Management 4.0 in Circular Economy: A Comprehensive Review. Sustainability 2023, 15, 16720. https://doi.org/10.3390/su152416720

Nguyen K, Akbari M, Quang HT, McDonald S, Hoang T-H, Yap TL, George M. Navigating Environmental Challenges through Supply Chain Quality Management 4.0 in Circular Economy: A Comprehensive Review. Sustainability. 2023; 15(24):16720. https://doi.org/10.3390/su152416720

Chicago/Turabian StyleNguyen, Kevin, Mohammadreza Akbari, Huy Truong Quang, Scott McDonald, Thu-Hang Hoang, Teck Lee Yap, and Majo George. 2023. "Navigating Environmental Challenges through Supply Chain Quality Management 4.0 in Circular Economy: A Comprehensive Review" Sustainability 15, no. 24: 16720. https://doi.org/10.3390/su152416720

APA StyleNguyen, K., Akbari, M., Quang, H. T., McDonald, S., Hoang, T.-H., Yap, T. L., & George, M. (2023). Navigating Environmental Challenges through Supply Chain Quality Management 4.0 in Circular Economy: A Comprehensive Review. Sustainability, 15(24), 16720. https://doi.org/10.3390/su152416720