1. Introduction

The International Maritime Organization’s greenhouse gas strategy (IMO, GHG 2018) seeks to reduce the shipping industry’s carbon emissions by 40% by 2030 and 50% by 2050, relative to those of 2008. Due to the expansion of container vessel fleets and to attain the aforementioned goals, their decarbonization is crucial, as the industry was responsible for 2.8% of the global CO

2 emissions in 2020 [

1,

2].

On the other hand, about 70% of the value of international trade is carried by maritime transportation, and two-thirds of this trade is carried by containers, mainly because most valued commercial cargo is containerized. This issue implies an average value of the trade of about USD 54,500 per twenty equivalent units (TEUs) or USD 109,000 per forty equivalent units (FEUs) [

2].

Moreover, by accounting for over 60% of marine trade, container shipping contributes significantly to global trade and transportation. Since 2019, container ships have produced 277 million tons, or 2.8%, of the total CO

2 emissions worldwide. This implies that container ships substantially impact GHG emissions [

2,

3].

Therefore, container ship owners and operators play a crucial role in developing a sustainable maritime industry. Indeed, to decarbonize their fleet, they must make technical and operational efforts [

1]. However, transport companies may need help to apply carbon reduction methods. Challenges include low investment incentives among first adopters, lack of infrastructure to generate alternative fuels, limited availability, and the high cost of deploying new technology. Thus, marine firms’ perspectives, their efforts to minimize carbon emissions, particularly those of container ships, and technical and operational obstacles must be recognized [

4].

The main objective of this study is to combine analytical, practical, and theoretical approaches to identify the most effective decarbonization strategies for container shipping transportation. A multi-criteria decision-making (MCDM) analysis is used in this research to evaluate the decarbonization possibilities and obstacles and to determine the optimal functional and technical choices to meet IMO GHG reduction objectives.

The study’s novelty is the proposal of its breakthrough maritime decarbonization technique. A MCDM analysis is applied to container transportation, for which carbon mitigation solutions are rarely examined. This research addresses a knowledge gap and considers sustainable practices that benefit marine sustainability academic and industry partners.

Limited studies have been conducted on the best ways to reduce emissions from container shipping, and many have focused on specialized technology or broad GHG mitigation methods rather than technical solutions or the perspectives of marine professionals. This research gap is filled by using an MCDM framework to analyze and compare carbon reduction strategies particular to container transportation in this research work.

This study’s target audience comprises container shipping businesses, regulators, and environmentalists who want to practice sustainable container transportation. This study targets maritime studies, environmental science, and MCDM academics and researchers as an innovative and multidisciplinary technique for reducing the maritime sector’s carbon emissions.

The Materials and Methods section describes the literature and data collection and provides an overview of MCDM analysis. The Literature Review critically evaluates shipping and container transport decarbonization studies to identify information gaps for this inquiry. In the Findings and Analysis section, this study presents the MCDM analysis results on container shipping carbon reduction methods. The Discussion section discusses industrial dynamics and sustainability goals. Finally, the Conclusion emphasizes the research’s relevance to attaining IMO GHG objectives and leading to container shipping’s sustainable future.

2. Materials and Methods

This research consisted of many methodological steps, including a scoping review of the pertinent literature, selecting the essential criteria, an expert survey, data analysis, and ranking GHG emission reduction technology. This section is divided into two distinct sections. The first section focuses on the materials, including the selection and screening process for the research study.

2.1. Step 1: Materials

This study uses the PRISMA-ScR critical scoping review process, frequently used in academia and research, to create a shared language and enhance scope review uniformity.

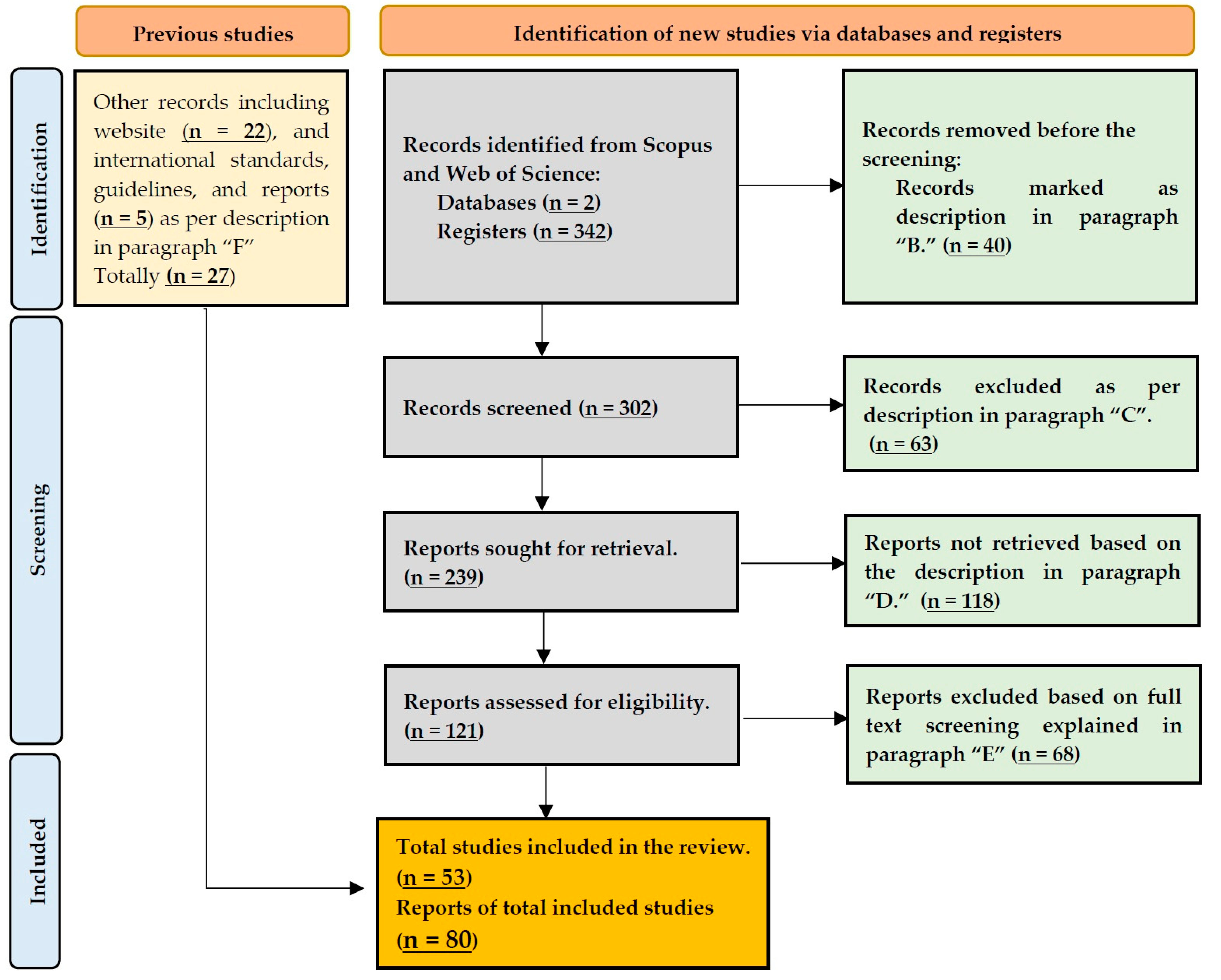

Figure 1 demonstrates the approach and procedure (identification, screening, and inclusion of relevant works) and the selection process, with a number refined at each step. The processes below identify and filter the literature and references in this research endeavor.

- A.

Databases searched Scopus and Web of Science using keywords such as “decarbonization” OR “GHG” OR “Greenhouse gas” OR “Carbon dioxide” OR “CO2” OR “carbon footprint” OR “Emission” AND “Shipping” OR “Marine” OR “Maritime”. This research study’s focus was “container shipping”, but the authors focused on maritime transportation in the refinement because the database did not have enough resources when “container shipping” was necessary. The first identification criteria included duplicate, ineligible, and unavailable records deleted before screening. From 2008–2023, all topic disciplines were evaluated.

- B.

Results were adjusted based on English language use, the type of publications (conference papers, articles, reports, and reviews), and the access method (open access due to availability).

- C.

The next phase involved reducing the whole results by focusing on “container shipping” components in the title, abstract, and keywords and phrases of “carbon dioxide”, “greenhouse gas”, “gas emission”, “carbon footprint”, and “CO2emission”, “air pollution”, and “carbon dioxide emission” to address this study’s main issue.

- D.

Following a detailed abstract and keyword screening, eligibility is refined to focus on “mitigation carbon footprint” in “container shipping” and “IMO GHG strategy.” This eligibility criteria and refinement stage involves deep reading of abstracts to narrow the results to the focus of this research, which is reducing container shipping emissions using technical solutions and from the perspective of ship owners and maritime professionals.

- E.

Final selection and the inclusive and exclusive systematic process produced 53 results by deep reading the 121 papers filtered in the previous phase. The eligibility criteria for this research solely assess a record’s contribution to emission reduction in container maritime transportation, theory, and practice during this in-depth reading and analysis. Only the record was picked if it solved the key concerns faced by writers using approaches and inventions.

- F.

In addition, considering the nature of this work study, initiatives by shipbuilders, international entities (as significant game players in the maritime industry), and professional studies are also reviewed. These initiatives included 22 websites and 5 guidelines and standards, bringing the total number of references to 80. The PRISMA-ScR diagram in

Figure 1 describes the procedure for searching and selecting the literature.

2.2. Step 2: Method

This research examines decarbonization by concentrating on ship owners and maritime professionals as critical stakeholders. A careful literature review revealed that ship owners and shipping businesses, the ultimate decision-makers in GHG emission reduction projects, should have been more frequently addressed.

The MCDM approach criteria and alternatives were chosen following comprehensive literature research based on shipping business issues, limitations, and potential repercussions. Ship owners and professional experts pick one or more technical and operational options based on criteria and emission reduction percentages.

The MCDM approach evaluated the most likely container ship GHG emission reduction options. The analytic hierarchy process (AHP) and technique for order of preference by similarity to ideal solution (TOPSIS) are frequently used to analyze possibilities and weigh and rank options.

These techniques are appropriate for this research study due to their capacity to incorporate expert opinion, objective ranking, flexibility and adaptability, openness and replicability, and full support for decision making.

Figure 2 depicts the phases of the MCDM technique chosen for this study.

Figure 2 illustrates the initial phase of the MCDM analysis, which involved establishing the contextual framework for the primary issue. Subsequently, the objectives were identified, and appropriate criteria were selected, drawing upon the hypotheses derived from the literature review, which will be elaborated upon in subsequent sections. Finally, the alternatives were addressed.

The subsequent procedure involves the measurement of the external validity of the criteria to ascertain their respective significance for this section. Subsequently, the values are computed by normalizing the weighting criteria consistency ratio, utilizing the AHP. The positive and negative ideal solutions and the separation measures comprehensively elucidated in this research are then calculated. Lastly, the relative closeness and ranking are determined by employing the alter method.

Following the above explanations, assessment questions about technical concerns like fuel consumption, technical feasibility, and scalability are created in the subsequent stage based on the decarbonization scheme evaluation criteria established by the scoping research. By this method, the strategy performance ratings objectively analyze the efficacy of emission reduction.

3. Review the Maritime Practices on Carbon Emissions Reduction in Container Shipping

The marine industry has been at the forefront of sustainability initiatives to minimize emissions. This section categorizes significant industry actors’ activities and their effects on the shipping sector.

3.1. Industry Collaborations and Initiatives

The marine sector, which accounts for 3% of world emissions, is attempting to cut emissions by 2050, and some critical multinational firms are spearheading this project, which might influence the global maritime industry.

One of these businesses was established by the Copenhagen-based Maersk McKinney Moller Center for zero-carbon shipping. Another is the Arnold Peter (A.P.) Moller Foundation, which generously finances this non-profit research facility. It connects academia, the marine sector, and regulators [

5].

This center develops comprehensive decarbonization policies, accelerates the development and use of sustainable fuels and new technologies, and builds legal and financial institutions to facilitate this significant transformation. With these primary partners, the center hopes to work with more stakeholders shortly. The maritime sector needs new fuels and operational changes to go carbon free [

5].

3.2. Individual Company Efforts

While several container shipping firms operate globally, just a few companies substantially influence the container shipping industry worldwide. This subsection provides a concise overview of the emission reduction strategies undertaken by prominent international container transport corporations.

Maersk: By 2023, this company launched the first carbon-neutral liner vessel using dual-fuel technology to run on e-methanol or bio-methanol. This concept relies on the Maersk McKinney Moller Center for zero-carbon shipping [

6].

However, Maersk will deploy dual-fuel technology on all future ships to run carbon neutrally or with very low sulfur fuel oil (VLSFO). According to their new target, the fleet should be carbon neutral by 2050. All their new medium-sized container ships must first use carbon-neutral e-methanol or sustainable bio-methanol. To achieve their carbon-neutral methanol goal, fuel producers, technological partners, and innovators must collaborate [

6].

Mediterranean Shipping Company (MSC): This company studies hydrogen and oxygen fuels and uses biofuels in its fleet to reduce its carbon footprint. It also studies biofuels, bio-methane, and liquefied natural gas (LNG) [

7].

MSC wants to work with manufacturers to accelerate container shipping hydrogen fuel cell technology. LNG is the best alternative; however, MSC encourages its research and development (R&D) to identify cleaner, greener fuels to reduce shipping fleet CO

2 and GHG emissions. MSC assesses wind, solar, and storage. It funded a USD 5 billion environmental research fund to accelerate zero-emission vessel development [

8].

Compagnie Maritime d’Affrètement and Compagnie Générale Maritime (CMA CGM): As the fourth-largest container shipping company, CMA CGM wants to investigate LNG and biofuels and become carbon neutral by 2050. CMA CGM’s LNG-powered green energy will transport 40,000 TEUs of household appliances with Electrolux.

Electrolux plans to reduce its carbon impact by 25% with bio-methane and CMA CGM’s dual-fuel LNG ships. The two companies collaborate, demonstrating their dedication to sustainable energy and transport. Companies purchase dual-fuel LNG vessels. By 2023, CMA CGM hopes to employ 10% alternative fuels [

9].

Hapag-Lloyd: Hapag-Lloyd, the world’s fifth-largest container shipping company, is researching LNG and ammonia as alternative fuels to reach net zero emissions by 2045. In a long-term contract, Shell (a global group of energy and petrochemical companies) and Hapag-Lloyd provide LNG to their dual-fuel ultra-large container ships. Shell and Hapag-Lloyd’s strategic partnership will advance alternative naval fuel decarbonization. This partnership boosts bio- and e-methane production and use [

10].

3.3. Industry Perspectives and Recommendations

The inclusion of industry opinions and proposals in policy formulation and decision-making processes, as well as the provision of encouragement, can significantly influence the decarbonization of marine container transportation. One of them is the “financing and reward” initiative from the “International Chamber of Shipping (ICS)”, which encourages shipping companies to utilize low- or net-zero-emission fuels. In addition, developing countries are receiving “International Maritime Sustainability Fund” funds to create bunkering facilities and innovative marine fuels to reduce the cost gap between high-carbon fuels and alternatives [

11].

Furthermore, ammonia, biofuels, hydrogen, and methanol are promising low- and zero-carbon fuels, according to “Energy and Environmental Research Associates (EERA)”, an energy and environmental consultant [

12]. However, “Wärtsilä” helps ship owners reduce pollutants and boost fuel economy. The company claims that combining ship propellers, air lubrication, and wind technologies would cut fuel and pollution [

13,

14].

3.4. Broader Implications

The literature review also examined economic considerations that arose after the 2020 pandemic. These considerations profoundly influenced the worldwide economy and the efforts made by players in the marine sector to address decarbonization. The coronavirus epidemic impeded global economic growth in 2020, according to 2022 research by the World Bank. Based on this analysis, it is projected that advanced economies are expected to recover their financial circumstances to the level of 2019. The growth of developing economies had an increase from 2021 to 2022; nonetheless, it remained lower than the levels observed in 2019 [

15]. This matter highlights the necessity for authors in the work-study field to research cost-effective and viable approaches to decarbonization.

3.5. Technical and Operational Solutions for Reducing Ship Emissions

Another subsection of the literature focused on examining the effects of practical and operational solutions implemented by significant stakeholders in the container shipping industry to mitigate ship emissions. Wärtsilä and Silverstream Technologies, a leading marine clean technology firm, are testing the Silverstream Air Lubrication System on board an A.P. Moller-Maersk container ship. They use air lubrication to minimize hull-to-water friction. According to research, this method reduces emissions and fuel consumption by 5–10% [

16].

Another study found that ship hull coating reduced CO

2 emissions by 1.97%. Hull coatings reduce carbon emissions by 1.5 to 5% under normal operating conditions, depending on quality and type [

17]. Hydrogel coatings enhance hull smoothness, marine fouling, friction, and efficiency [

18].

According to Farkas et al. (2022), 10–40% slow steaming can reduce fuel usage and GHG emissions by 40%. Avoiding port timing issues by sailing slower may improve service. It may meet the Energy Efficiency Existing Ship Index (EEXI) for cargo ships built up to 2016. The research calculated the speed drop for non-EEXI ships [

19].

Furthermore, a ship’s trim (the numerical difference between its forward and aft drafts at its extreme ends) adjustment may significantly affect ship propulsion energy, according to various studies [

20,

21,

22]. The trim modification lowered Hapag-Lloyd’s container fleet’s fuel and emissions [

20].

In another study, according to Halim et al. (2018), optimizing ship size for cargo volume might reduce CO

2 emissions by 30%. However, the study should describe the vessel and define size optimization [

23].

Utilizing engine combustion waste heat reduces ship fossil fuel usage. According to studies, this method cuts ship fuel use. Fuel utilization is related to GHG emissions, reducing the ship’s carbon footprint. Shippers have implemented waste heat recovery systems to cut emissions. Official sources report that Mitsubishi Heavy Industries Marine Machinery & Engine Co., Ltd. (Nagasaki, Japan) (MHI-MME) has received orders for WHRS installations on several ships [

24].

In addition, optimizing ship sailing routes reduces GHG emissions. Several studies have indicated that route optimization can significantly reduce fuel use. Optimizing ship routes and reducing port anchoring wait times have the potential to save fuel [

25,

26,

27].

Furthermore, reducing fuel consumption may be achieved by optimizing the ship’s hull architecture by implementing a bulbous bow design [

23]. A European joint effort is at the forefront of the maritime industry’s enormous advancement in incorporating cutting-edge lightweight materials into shipbuilding. This initiative substantially reduces emissions and enhances overall ship efficiency [

28].

According to Roh et al. (2019), fuel-cell hybrid power sources decreased fuel use and CO

2 emissions. Electric load values for container, bulk, LNG, and crude oil tankers were evaluated. Testing indicated that the hybrid system cut emissions more than the diesel generator. This research suggests that diversified power sources may reduce shipping sector emissions [

29].

3.6. Alternative Fuels for Carbon Reduction

One of the most often cited lines in the literature on decarbonization in maritime transportation pertains to using alternative fuels to reduce carbon emissions. Alternative fuels, such as LNG, emit less CO

2 than heavy fuel oil (HFO) because they contain less carbon and are more efficient [

30,

31]. The literature on alternative fuels may be divided into four categories: research on alternative fuels, electric and hybrid solutions, challenges and opportunities with alternative fuels, and technical and infrastructural challenges.

In a study published in 2022, Mastorakos et al. assessed shipping fuel substitutes for HFO. The findings could help interested parties implement a decarbonization strategy [

32]. Alcohol, ammonia, and biomethane could power ships, according to a different Lloyds Register-Maersk study [

33]. However, the study also notes ammonia toxicity and the environmental impact of biomethane. According to the survey, batteries and fuel cells might not be the most environmentally benign ship propulsion option [

33].

Furthermore, Heaslip analysis from 2019 shows marine companies favoring hybrid and electric choices. Almost 320 hybrid ships were in operation or ordered in the same year. LNG can reduce CO

2 and other pollutants by 20% to 30%. The maritime sector must spend on R&D to identify the most sustainable and cost-effective way to reduce emissions [

34].

On the other hand, alternative fuels have safety, storage, and transportation concerns, notwithstanding their potential. Ammonia, a carbon-free alternative fuel, is poisonous and corrosive and needs stainless steel and Teflon fuel storage and transfer systems [

34].

In another study, Prussi et al. (2021) emphasize alternative fuel challenges due to technological, safety, and infrastructure limits. Demand for these fuels must be addressed as most choices need good infrastructure. This study revealed that cost and GHG emission reductions are essential, but technology improvements, accessibility, and emission reduction potential must also be addressed [

35].

There are other instances; however, due to the nature of this research study, only the sources indicated are used. The following section will first discuss the technique of analyzing and selecting criteria, then use MCDM in container ship decarbonization, and finally uncover suitable options in detail.

4. Analysis and Findings

This section will employ the MCDM methodology, based on the process described in

Section 2.2. The MCDM approach is based on the AHP. Subsequently, a thorough analysis will be conducted using the TOPSIS technique. This analysis aims to identify the most effective choices for addressing the core issue of this study. The initial subsection entails the identification of criteria and alternatives, which will be further discussed in subsequent paragraphs.

4.1. Identify Criteria and Alternatives

The study’s criteria and alternatives were developed after thoroughly evaluating the current literature. Each criterion and option was set based on critical difficulties, recommendations, and technological breakthroughs described in many container shipping carbon emissions reduction publications. The selected criteria are as follows:

- I.

Ability and willingness of ship owners to implement the method (AWOI): The efficacy of decarbonization endeavors is contingent upon the actions undertaken by ship owners and corporations. The individuals’ dedication and proficiency ensure the adoption and durability of these strategies. Organizations may also embrace novel technology depending on their perceived advantages, financial capabilities, and prevailing corporate culture [

36,

37,

38,

39,

40,

41].

- II.

Scalability and adaptability (SA): Scalable and adaptable carbon mitigating solutions for different vessel types, sizes, and operating routes are necessary to maximize emissions reduction. When evaluating feasible options, shipping companies should consider flexibility and adoption potential [

42,

43,

44,

45,

46,

47].

- III.

Adverse effects on transportation time (NETT): Decarbonization may lengthen freight transportation time due to decreased speeds or port delays for refueling or maintenance. Shipping companies may assess how these indicators impact service quality and client satisfaction [

48,

49,

50,

51].

- IV.

Costs of implementation, installation, and operation (CIIO): Many carbon-reduction methods require significant upfront and ongoing costs. Shipping companies should consider financial implications carefully, such as return on capital and efficiency savings [

52,

53,

54,

55].

- V.

Regulatory compliance and incentives (RCI): Shipping companies must comply with international, regional, and national GHG emission limits. Under this rule, they may be urged to decarbonize. Financial assistance and favorable port treatment may be required [

56,

57,

58,

59].

- VI.

Life-cycle environmental impact (LCEI): The environmental impact of carbon mitigation technologies throughout their life cycle must be evaluated in addition to emissions reduction during operation. Resources and emissions from the production, installation, maintenance, and disposal of equipment or technology are considered [

60,

61,

62,

63].

- VII.

Compatibility with Existing Infrastructure and Operational and Technical Limitations (CEIOTL): Some carbon-free options require compatible port infrastructure and vessel designs. Operating and technical constraints, such as vessel size or operational zones, may have an impact on the measure’s viability [

64,

65,

66,

67,

68].

- VIII.

Training and proficiency requirements for implementing the method (TPRI): Decarbonization demands knowledge and skills. Shipping companies should investigate the training and skills required to operate and maintain these systems and their implications for crew workload and safety [

69,

70,

71,

72,

73].

- IX.

Effectiveness and potential capacity of the method in reducing emissions (EPCRE): Shipping companies must select a coherent and appropriate GHG emission reduction strategy. The method’s prospective capacity is critical for developing a road map and planning to achieve this goal [

52,

74,

75,

76].

Table 1 shows an overview of the criteria that were taken into consideration.

On the other hand, 12 different measures or alternatives were analyzed for each criterion. These alternatives included both technological and operational solutions and are as follows:

Alt 1 (alternative fuels): Using unconventional fuels like LNG or biofuels;

Alt 2 (main and auxiliary machinery efficiency optimization): Improving main and auxiliary engine and other equipment performance to increase operational output;

Alt 3 (light material container): The utilization of lightweight materials in the fabrication of containers to reduce the overall weight of the vessel;

Alt 4 (ship’s trim optimization): Modifying the ship’s trim condition for optimum performance;

Alt 5 (ship’s hull design optimization by light material): Using more lightweight materials to construct the ship’s hull enhances buoyancy and reduces propulsion load, resulting in lower emissions;

Alt 6 (marine route and schedule optimization): Identifying the quickest and most efficient marine routes and, as a result, improving sailing schedules;

Alt 7 (waste heat recovery, advanced and innovative methods): This method uses waste heat generated during ship operations to enhance the performance of the ship’s engine;

Alt 8 (ship size and economy of scale optimization): Selecting the optimal ship size for transportation involves balancing capacity and operational costs;

Alt 9 (speed optimization: slow steaming): Lowering ship speed to optimize fuel expenses and lower pollutants;

Alt 10 (ship’s bulbous bow design optimization (hull optimizing)): Designing the ship’s bulbous bow to optimize fuel consumption by lowering hydrodynamic drag;

Alt 11 (advanced ship’s hull coating (optimizing hull)): Modern protective coatings may be applied to a ship’s hull to minimize friction between the hull and the seawater, which will lower the operating load of the ship’s main engine, cut fuel consumption, and reduce emissions;

Alt 12 (air lubrication technique (optimizing hull)): Fixing devices or materials on the ship’s hull to reduce water resistance by adding a layer of air bubbles on the hull.

Table 2 provides a quick summary of the alternatives and references considered and the reasons for selecting them.

4.2. Implementation of the Questionnaire and Analysis

The surveys aimed to rank alternatives for each criterion and evaluate each criterion’s relevance to the others. Maritime experts received the questionnaires and were asked to assess each criterion’s value and score alternate criteria. Their responses determined how the findings were arranged. Throughout the questionnaire evaluation process,

Table 3 was used to determine the relative importance of each criterion.

After addressing the literature review-based possibilities in

Table 2, questionnaire preparation and execution are the next steps. This study distributed questionnaires to maritime specialists in marine science and sustainability to collect their perspectives. Nine experts from a varied range of backgrounds responded to the questionnaires, including:

A master mariner with twenty years of experience in the marine sector, a Ph.D. in maritime and logistics, and a university lecturer;

A master mariner, an MSc in maritime transport, 25 years in the marine industry, and university teaching;

A doctorate in marine engineering and naval architecture, 15 years in the maritime industry, and university teaching;

A master mariner, a Ph.D. student in marine energy, MSc in marine (almost 15 years in the maritime industry and university teaching);

A marine ecosystem scientist with 18 years of research and university experience;

An environmental policy Ph.D. marine policy specialist with a decade of maritime regulations and sustainability experience;

A twelve-year industry and academic practitioner in marine logistics and supply chain management;

A Ph.D.-trained marine renewable energy specialist;

A naval engineer with twenty years of expertise who has designed ships and reduced emissions.

The response sheets were required to be authenticated when they were received. Answers were to be examined and filtered by analyzing the relative importance of the criteria based on respondents’ perspectives. Calculations considered questionnaire errors, and the response requested that any differences be corrected and resubmitted. Then, make a comparison matrix and compare the criteria pairwise to determine their weight. This calculation phase necessitated the creation of a decision matrix for the many alternatives.

A geometric interpretation of the information from each part of the answer sheets was used to figure out the parts of the criteria comparison matrix [

78]. In the pairwise comparison matrix,

Table 4 illustrates the relative importance of each criterion.

The data in this study need to be scaled and organized in a narrow range to lessen the impact of high numerical values on tiny ones. Normalize the comparison matrix so that there are only 0 or 1 values in each row and column. During the normalization process, the value of each cell must be divided by the numerical sum of the values in the column in which the cell is located [

78].

In this respect, the criterion’s weight is calculated by dividing its total value by the number of cells in each row. The normalized results for the criterion and their weights in the comparison matrix are shown in

Table 5.

The numerical results show that EPCRE, with a weightage of 0.325, has the most significant weight. In addition, the CIIO and RCI criteria, with weights of 0.224 and 0.133, respectively, are ranked second and third. TPRI and NETT, on the other hand, are ranked lowest in the criterion weight list, with respective weights of 0.016 and 0.025.

The subsequent stage involves generating and verifying the weighted value consistency matrix to ascertain the reliability and accuracy of the obtained outcomes.

Table 6 presents the consistency matrix and λ max, which represent the average of all criterion weights, whereas “Ā” represents the normalized criteria value, which is the weighted sum of values to the criterion weight [

78].

Equations (1) and (2) were utilized to obtain the consistency index (CI) and consistency ratio (CR), yielding values of 0.1205 and 0.0831, respectively.

In this equation, the total number of criteria is represented by “

N”.

Table 7 displays the random index values for different numbers of criteria, ranging from 1 to 10. For the specific case of this study, which considers nine criteria, the random index value is 1.45. It calculates the consistency ratio (CR), which assesses the preferences’ reliability in the decision matrix. For the decision matrix to be considered consistent and reliable, the consistency ratio should ideally be less than 0.10 (or 10%). The values in

Table 7 are standard benchmarks used to determine the acceptable level of consistency in the decision-making process.

After determining the criterion weights, each option can be examined concerning each criterion to establish its position and value. Professionals are asked to assess the value of each option concerning each criterion using the scale of alternative ratings indicated in

Table 8. The choice matrix, shown in

Table 9, represents the outcome of the assessment.

The values inside the decision matrix (

Table 9) are derived by calculating the geometric mean based on the responses obtained from the surveys.

In the subsequent phase, the decision matrix vector performed normalization by dividing each element or value by the corresponding denominator value of each column [

79].

Table 10 presents the decision matrix with the normalized vectors.

However, the study by Patsariya et al. (2019) indicates that the criterion’s optimal value might be either a maximum or a minimum. In this regard, the term “

” represents the highest possible value for that column. For example, the optimal value is the highest when considering the potential reduction in ship emissions. However, the optimal value is the minimum when considering the time required to implement the approach [

80].

According to the criterion, the smallest possible value (

) might be considered the optimal value, either the lowest or highest, depending on the specific context. Additionally, the variable “

” represents the assigned value for the (

jth) criteria of the (

ith) alternative. In other terms, it represents the numerical assessment or value given to the (

ith) option about the (

jth) criterion [

80].

The standard deviation between the optimal best and worst scenarios is calculated using Equations (3) and (4), as described in reference [

80].

Equation (5) then determines the performance score as a last step. The options shown in

Table 11 are ranked using performance scores [

80].

“

Pi” in the formula represents the performance score of each alternative, as indicated by its presence in

Table 11.

As a result,

Table 11 displays the decision matrix for result values, accompanied by normalized weights. The matrix values are obtained by multiplying the normalized value with the criterion’s weight. A calculation is performed to determine a range of values for each criterion, ranging from the smallest possible value, indicated as “

”, to the highest potential value, marked as “

” [

80].

According to the MCDM technique analysis results, rank 1 is first, and rank 12 is last; hence, “speed optimization”, “marine route and schedule optimization”, and “ship’s trim optimization” are rated in the top three places, respectively. The following, however, are ranked between ten and twelve: “light material container”, “ship’s hull design optimization by light material”, and “main and auxiliary equipment efficiency optimization.”

Table 12 displays all possibilities, along with their ranks.

This study’s objective was to explore the current operational and technical alternatives that can be utilized to mitigate emissions from container ships. The researchers solicited the participation of specialists involved in the study, asking them to respond to the questions based on their expertise and knowledge. The following section entails a discussion of the findings of this analysis and the potential for their use.

5. Discussion

The study outlined in this article attempts to ascertain the optimal operational and technological strategies for container shipping by employing a comprehensive assessment and prioritization methodology. The findings of this study demonstrate the significance of these solutions in facilitating the maritime transportation sector’s attainment of its emission reduction objectives. This conversation aims to analyze and explain the significant difficulties associated with decarbonization in container shipping to enhance the understanding of shipping firms and stakeholders.

Based on the results of this study, after using the matrix and normalizing it in the MCDM analysis, the most common alternatives for decarbonizing container ships, in order of their respective scores, include “speed optimization: slow steaming”, “marine route and schedule optimization”, “ship’s trim optimization”, “advanced ship’s hull coating”, “alternative fuels”, “air lubrication technique”, “waste heat recovery advanced and innovative methods”, “ship’s bulbous bow design optimization”, “ship size and economy of scale optimization”, “light material container”, “ship’s hull design optimization by light material” and “main and auxiliary machinery efficiency optimization.” The alternative performance scores and ranks are displayed in

Figure 3.

On the other hand, it is feasible to classify alternatives into two major categories: operation alternatives and technical alternatives. The last group can be divided into three subcategories: ship design alternatives, ship machinery modifying alternatives, and other alternatives, as depicted in

Figure 4.

Implementing operational alternatives 1, 2, 3, and 9 necessitates establishing a well-suited framework, proper training, and suitable legislation. In contrast, the technical alternatives are options 4, 5, 6, 7, 8, 10, 11, and 12. The optimization of material and machinery efficiency in primary and secondary technical alternatives necessitates concurrent asset investment and long-term improvements to methods and manufacture. This procedure is both expensive and time consuming. However, marine stakeholders, the subject of this survey, value spending less money and obtaining faster emission reduction targets.

Operational alternatives, such as speed optimization, marine route and schedule optimization, ship trim optimization, and ship size and economy of scale optimization, require a suitable framework, appropriate training, and proper regulations. On the other hand, technical alternatives encompass alternative fuels, advanced ship’s hull coating, air lubrication technique, waste heat recovery advanced and innovative methods, ship’s bulbous bow design optimization, light material container, and ship’s hull design optimization using lightweight materials.

The optimization of material and machinery efficiency in technical alternatives, both main and auxiliary, requires simultaneous investment in assets and long-term adjustments to procedures and manufacturing. This process is costly and time consuming. However, it is evident that maritime stakeholders, who were the focus of this survey, prioritize spending less money and achieving a quicker reduction in emissions.

Implementing operational alternatives aimed at reducing fuel consumption and, therefore, GHG emissions, such as optimizing the ship’s hull and improving the efficiency of main and auxiliary machinery, has been identified as having a limited impact on emission reduction.

Nevertheless, according to the results of this survey, the first three alternatives may be argued without incurring additional expenditures with a well-designed crew training program and adequate rules.

Furthermore, energy-efficient port procedures such as cold ironing (CI) or shore power may reduce emissions while vessels are docked, but they were not included in the present research study.

This research assesses the feasibility of operational and technological solutions by utilizing expert views, criterion weights, and performance evaluations. These methodologies aid in objectively evaluating a given strategy’s advantages and disadvantages, enabling informed decision making. Including expert opinions is crucial to enhance the efficacy of each alternative. However, it is vital to consider the feasibility, legislation, and infrastructure frameworks for container shipping for every proposed solution.

Even so, it is imperative to remember that the execution and augmentation of these decarbonization tactics pose substantial challenges. First, executing operational solutions requires excellent coordination and collaboration across several stakeholders, such as shipping businesses, port authorities, and government agencies. The practical implementation of technological solutions necessitates investments in novel technology and infrastructure, which may entail a substantial initial expenditure.

In addition, successfully mitigating pertinent challenges and attaining optimal carbon-neutral approaches in container shipping would necessitate implementing a comprehensive and diverse strategy. The participation of stakeholders is necessary to establish a well-defined plan for decarbonization and ascertain the most efficient methodologies. These stakeholders encompass shipping companies, regulatory bodies, and technology suppliers.

According to the study’s results, the transition of container shipping towards a low-carbon future is driven by business considerations and aligns with the global objective of sustainability. The maritime sector substantially generates global GHG emissions, necessitating collaborative endeavors to mitigate its ecological footprint. Achieving global emission reduction goals, such as those outlined in the International Maritime Organization’s GHG rules, requires a collaborative effort, including all stakeholders.

Consequently, this study provides significant insights into the underlying issues, potential opportunities, and obstacles associated with successfully decarbonizing container shipping. Analyzing and rating different operational and technological solutions is crucial for making informed decisions since it incorporates expert opinions, criterion weights, and performance scores. Transportation entities and relevant parties have the potential to make significant contributions towards global sustainability objectives through the implementation of strategies aimed at reducing GHG emissions. Eventually, it can be asserted that the integration of operational and technical measures has the potential to effectively mitigate the carbon emissions linked to container shipping.

6. Conclusions

The current study examined feasible and potential technological and operational strategies to reduce emissions in the context of container ships as the main finding and contribution. The viewpoint used was that of shipping corporations, which might be regarded as ship owners. On the other hand, it needs to be considered that technology to reduce emissions in existing ships requires substantial initial capital investment. However, shipowners are expected to switch to operational solutions with lower initial capital due to economic slowdowns and rising inflation, especially after COVID-19 inflationary pressures.

Hence, the primary outcome of this study analysis emphasizes that slow steaming has been identified as the most efficient operational approach for mitigating emissions and enhancing overall fuel consumption optimization.

Additionally, the utilization of alternative fuels has considerable potential for mitigating emissions; nonetheless, it encounters obstacles to fuel accessibility, expenses associated with modifications, and technical compatibility with current engine systems. Furthermore, aligning with the International Maritime Organization’s GHG emission reduction objectives demands a comprehensive approach combining operational and technological techniques.

While this study offers significant contributions regarding emission reduction techniques for container transportation, it promptly acknowledges certain inherent limitations. The research utilized a restricted range of criteria to assess various emission reduction options. Subsequent investigations may extend the existing criteria or incorporate supplementary possibilities to enhance the precision of the analysis.

Additionally, this research mainly concentrated on established strategies for reducing emissions. It did not extensively explore emerging technologies or innovative alternatives that could significantly reduce emissions. Lastly, this study did not examine the impact of national and international regulations and incentives on facilitating the adoption of emission reduction techniques.

Future studies should prioritize exploring several routes to enhance comprehension of solutions aimed at reducing emissions in container transportation. Subsequent investigations might explore various economic, environmental, and societal factors to comprehensively evaluate different strategies for mitigating emissions. On the other hand, future studies can analyze the policy consequences of the subject matter.

This analysis would aim to assess the impact of government policies, incentives, and regulations on reducing emissions and decarbonizing the container shipping sector. However, the authors strongly believe the successful implementation of these methods necessitates the establishment of regulatory frameworks and the introduction of supporting laws and regulations.

It is important to emphasize that implementing alternatives, which require significant time and initial investment, depends on the sustainability of the trading and shipping markets. Any unexpected threats can significantly impact and alter emission reduction plans.

Nevertheless, the authors hold the firm belief that the adoption of these tactics necessitates the establishment of regulatory frameworks and the implementation of corresponding laws and regulations. The sustainability of trade and shipping markets significantly influences the determination of the time and financial resources required to develop alternatives. The emergence of new challenges can substantially alter emission reduction objectives.

By considering several variables, this analysis provides a holistic understanding of emission reduction in maritime and container transportation, becoming an essential tool in addressing the issue of climate change. The mitigation of climate change necessitates collective action from communities, and implementing these pragmatic techniques represents a crucial stride towards establishing a sustainable framework for container shipping, warranting further investigation in future research endeavors.

The adoption and implementation of this proposal could facilitate the development of a more sustainable maritime transport system. It would create a better world for future generations, enabling professionals, entities, societies, and practitioners to assume accountability for their actions and actively preserve a cleaner and more environmentally friendly ecosystem.