Bamboo Construction Inspired by Vernacular Techniques for Reducing Carbon Footprint: A Life Cycle Assessment (LCA)

Abstract

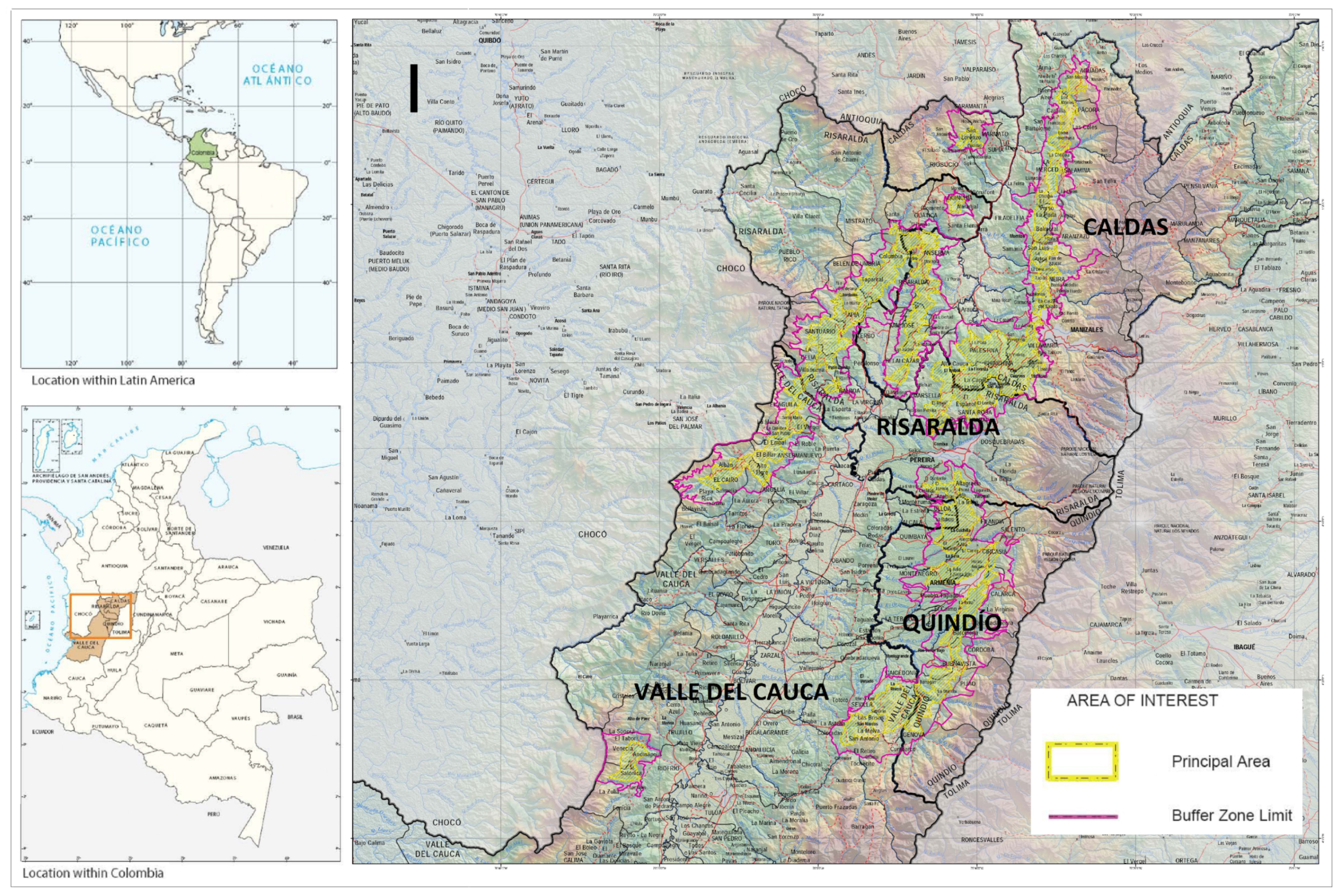

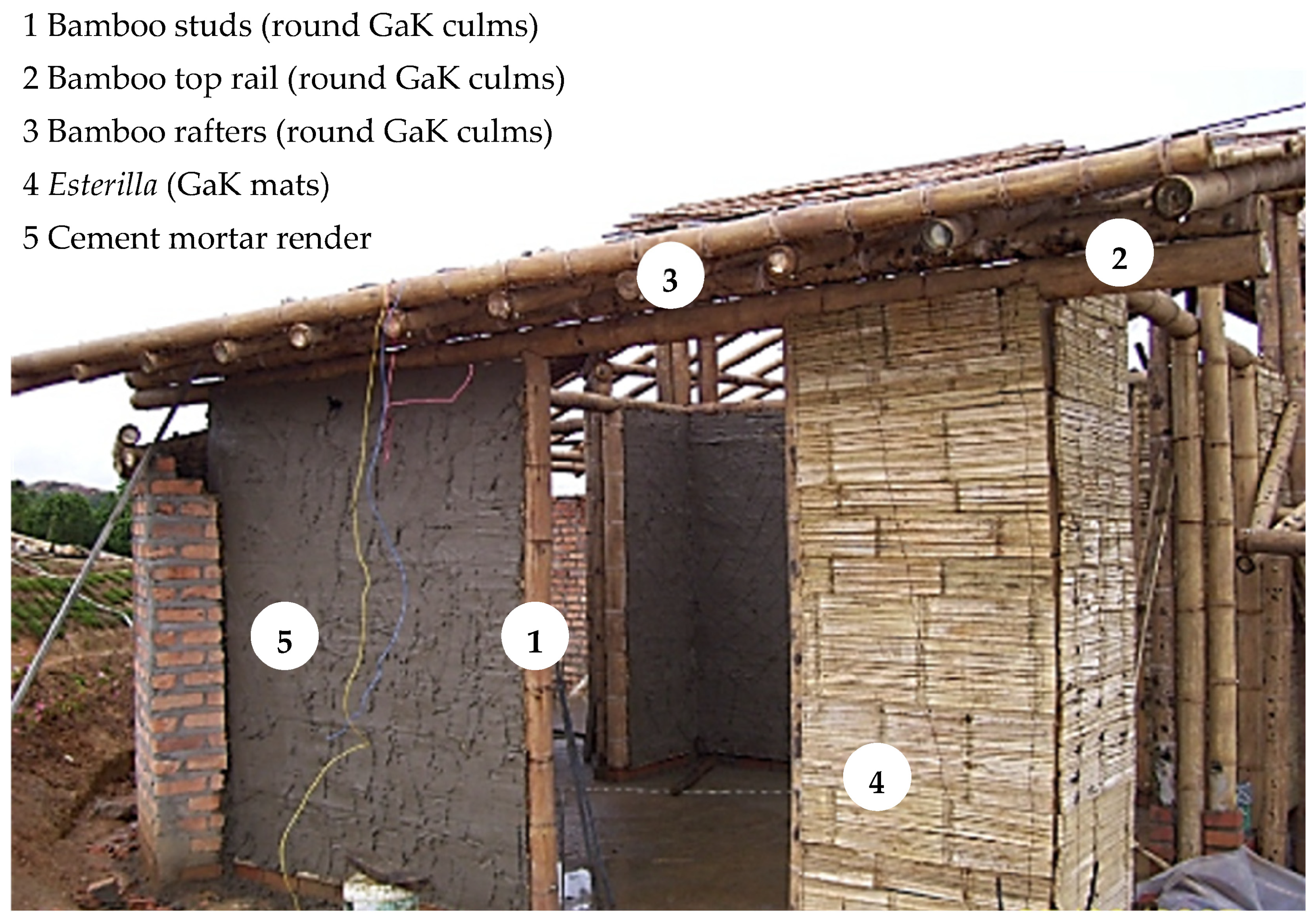

:1. Introduction

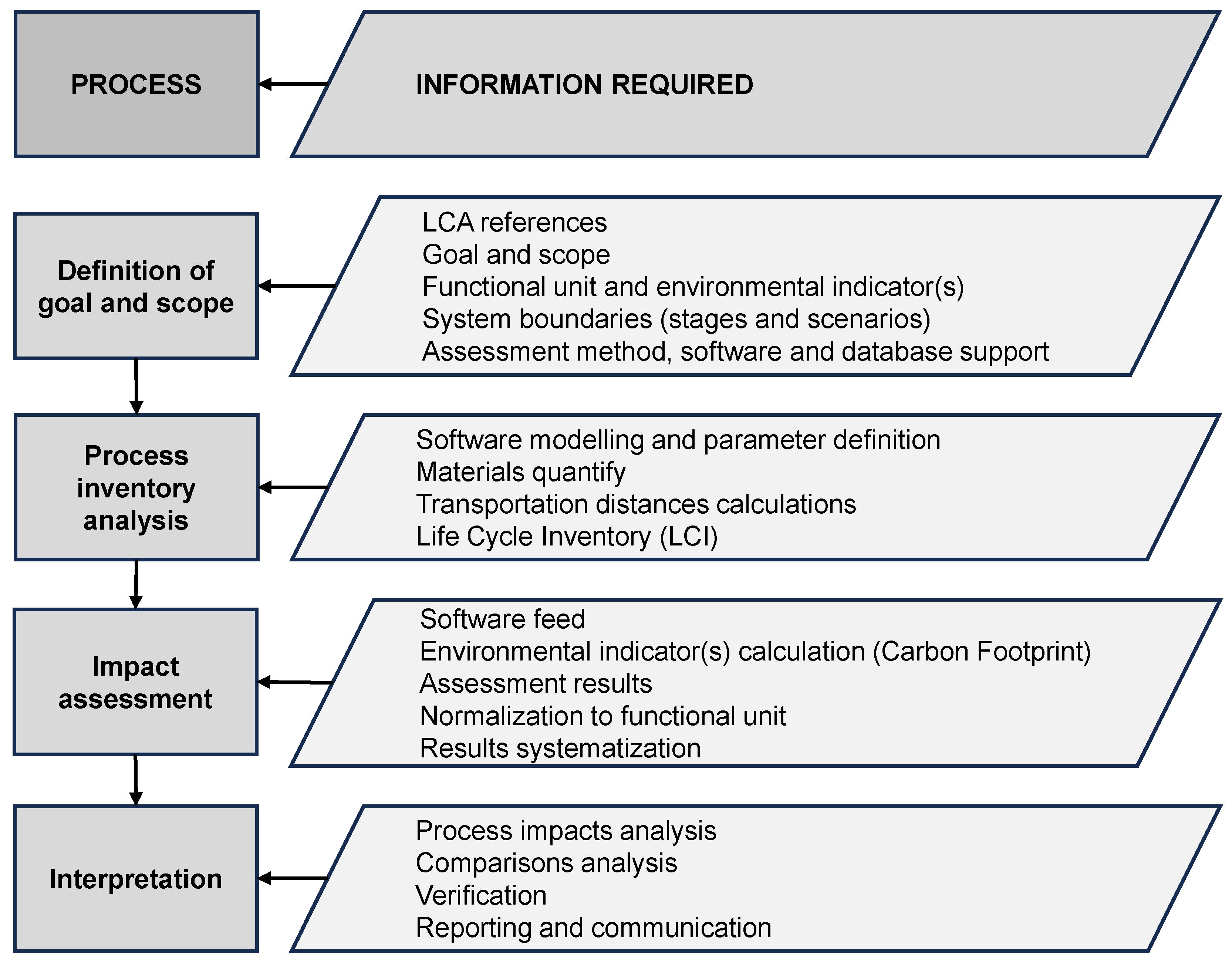

2. Materials and Methods

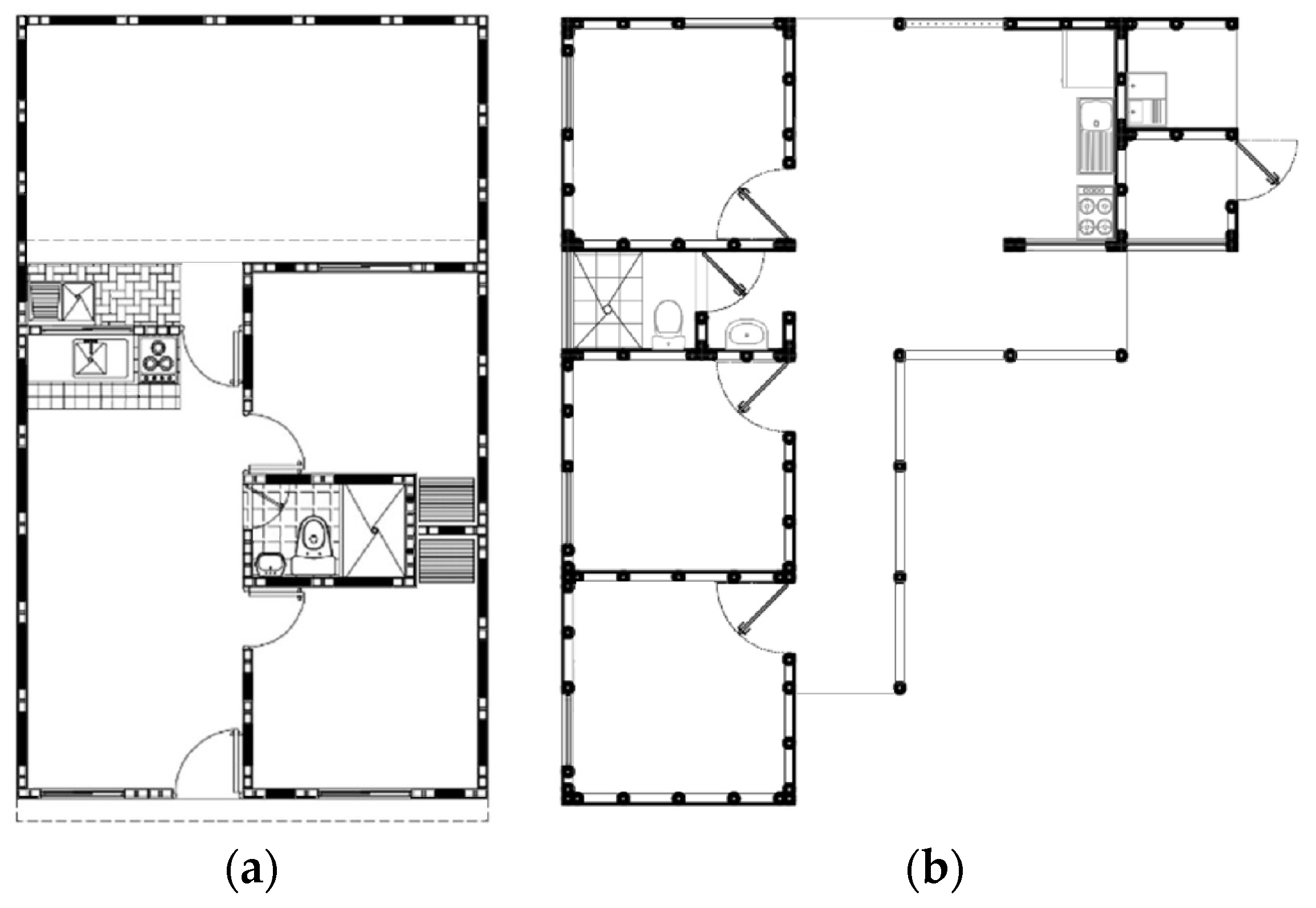

2.1. Definition of the Goal and Scope of the Life Cycle Assessment (LCA)

2.1.1. Goal and Scope

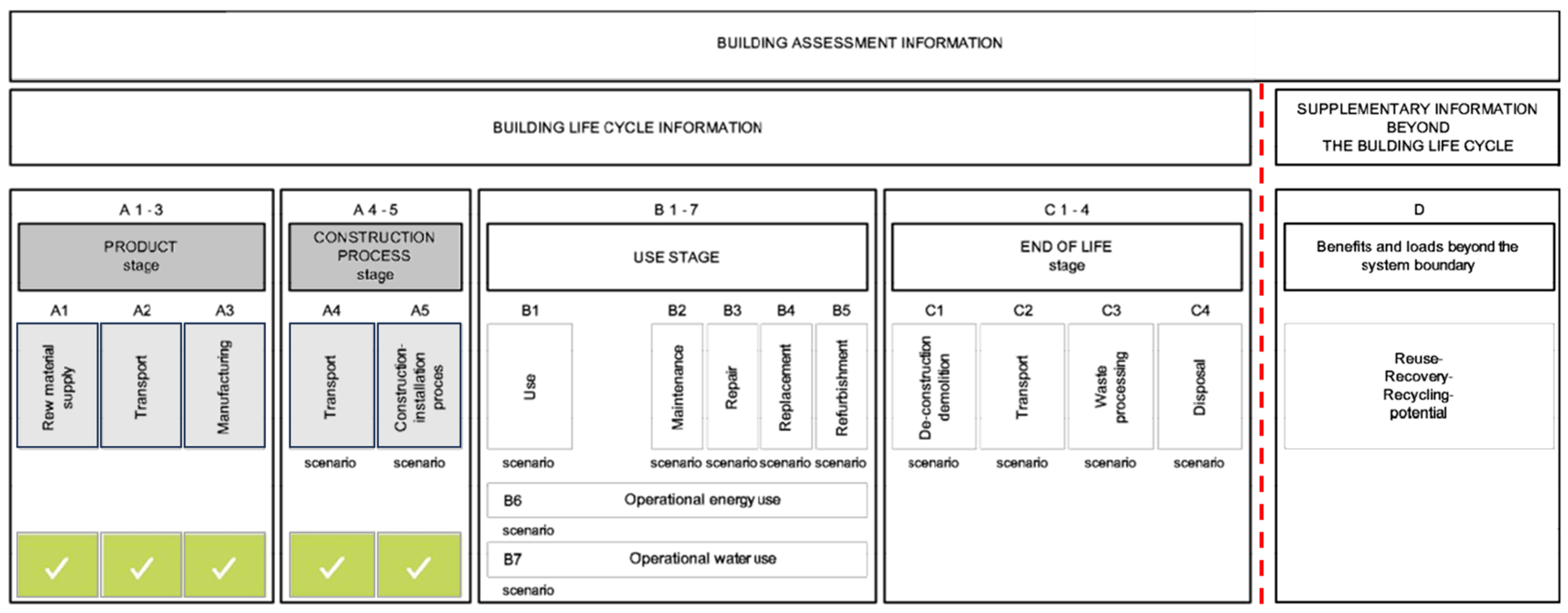

2.1.2. Functional Unit and System Boundaries

2.2. Process Inventory Analysis

2.2.1. Transportation Distance Calculations

2.2.2. Life Cycle Inventory (LCI)

2.3. Impact Assessment

2.4. Interpretation

3. Results and Discussion

3.1. Environmental Indicator Calculation: Carbon Footprint

3.2. Normalisation to Functional Unit

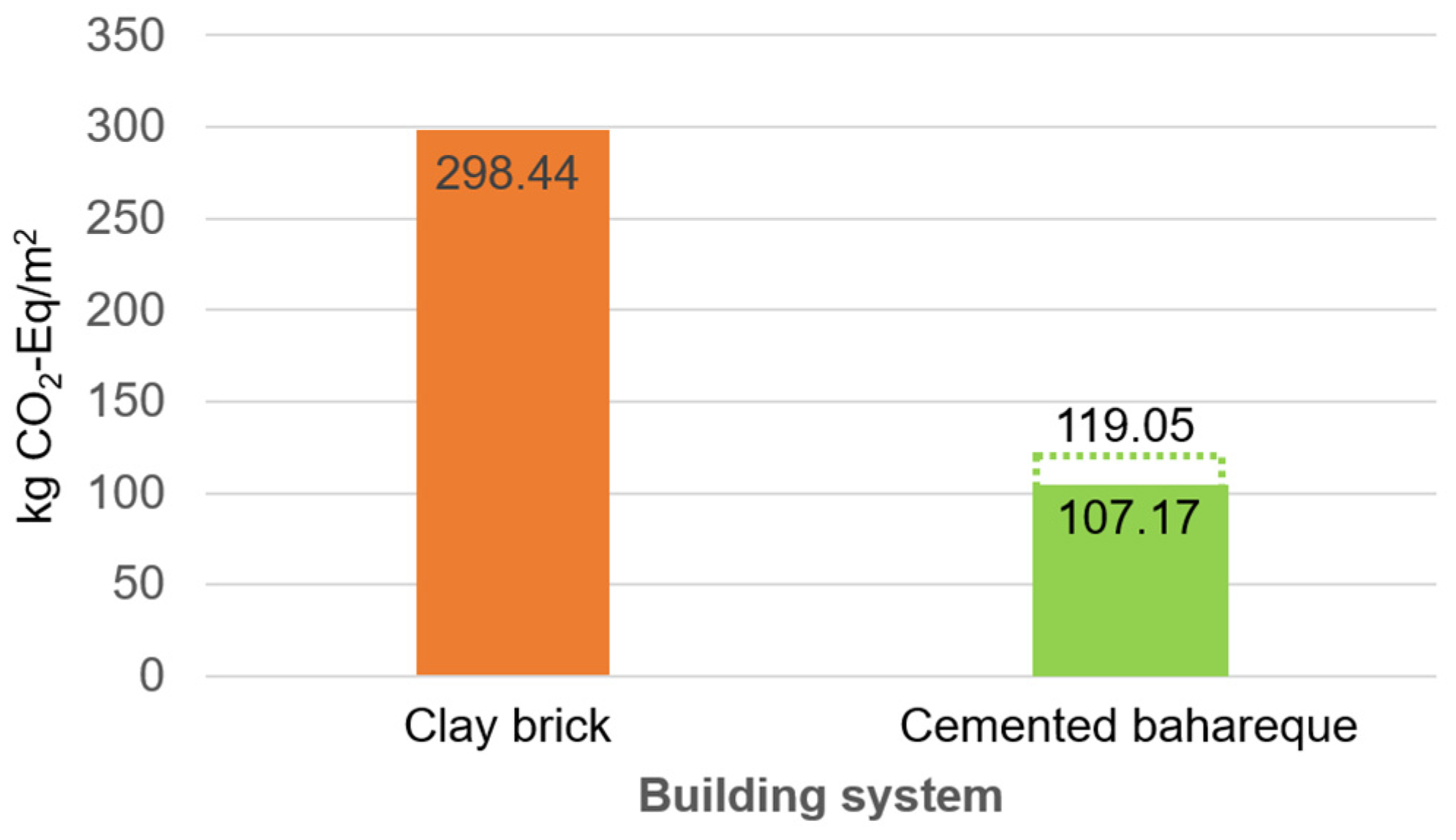

3.3. Comparative Carbon Footprint of CSB House vs. GaKB House

3.4. Process Impact Analysis

3.5. Carbon Footprint Balance

- A total of 126.41 t/ha of CO2 are stored per hectare;

- Each hectare has 4050 Guadua culms;

4. Conclusions and Future Research

Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bataille, C. Low and Zero Emissions in the Steel and Cement Industries: Barriers, Technologies and Policies—Issue Paper 2019. pp. 1–42. Available online: https://www.oecd.org/greengrowth/GGSD2019_Steel%20and%20Cemement_Final.pdf (accessed on 20 October 2023).

- Correia, M. Versus: Lessons from Vernacular Heritage to Sustainable Architecture; Éditions CRAterre: Grenoble, France, 2008; Volume 71, ISBN 9782906901780. [Google Scholar]

- Correia, M.; Dipasquale, L.; Mecca, S. Versus Heritage for Tomorrow. Vernacular Knowledge for Sustainable Architecture, 2014th ed.; Firenze University Press: Firenze, Italy, 2014; ISBN 978-88-6655-742-5. [Google Scholar]

- Ben-Alon, L.; Loftness, V.; Harries, K.A.; Cochran Hameen, E. Life Cycle Assessment (LCA) of Natural vs Conventional Building Assemblies. Renew. Sustain. Energy Rev. 2021, 144, 110951. [Google Scholar] [CrossRef]

- Osorio Velásquez, J.E. El Patio y El Corredor de Las Casas de Bahareque: Espacios de La Experiencia Humana En El Paisaje Cultural Cafetero de Colombia. Ph.D. Thesis, Universidad Pablo de Olavide, Sevilla, España, 2016. [Google Scholar]

- Kaminski, S.; Lawrence, A.; Trujillo, D. Design Guide for Engineered Bahareque Housing; Beijing, China, 2016; ISBN 978-92-990082-3-2. [Google Scholar]

- Van Der Lugt, P.; Vogtländer, J.; Brezet, H. Bamboo, a Sustainable Solution for Western Europe Design Cases, LCAs and Land-Use; Delft, The Netherlands, 2009. [Google Scholar]

- Zea Escamilla, E.; Habert, G.; Daza, J.F.C.; Archila, H.F.; Fernández, J.S.E.; Trujillo, D. Industrial or Traditional Bamboo Construction? Comparative Life Cycle Assessment (LCA) of Bamboo-Based Buildings. Sustainability 2018, 10, 3096. [Google Scholar] [CrossRef]

- ISO 22156; Bamboo Structures–Bamboo Culms–Structural Design. International Organization for Standardization (ISO): Geneva, Switzerland, 2021; pp. 1–9.

- González, G.; Gutierrez, J. Structural Performance of Bamboo ‘Bahareque’ Walls under Cyclic Load. Bamboo Ratt. 2005, 4, 353–368. [Google Scholar] [CrossRef]

- Muñoz Robledo, J.F. Tecnoculturas de Las Arquitecturas de Baja Altura En El Municipio de Manizales—Colombia; Universidad Nacional de Colombia: Manizales, Colombia, 2015. [Google Scholar]

- Rincón González, C.E.; Montoya Arango, J.A. Estado Del Arte de La Sustentabilidad de La Arquitectura Regional de Bahareque de Guadua En El Eje Cafetero de Colombia. In Sustainable Materials for a Living World: Proceedings of the 6th Amazon & Pacific Green Materials Congress and Sustainable Construction Materials LAT-RILEM Conference, Cali, Colombia, 27–29 April 2016; Delvasto, S., Ed.; Track Comunicación: Cali, Colombia, 2016; pp. 88–105. ISBN 9789585954403. [Google Scholar]

- Muñoz Robledo, J.F. Tipificación de Los Sistemas Constructivos de “Bahareque” En El Paisaje Cultural Cafetero de Colombia; Universidad Nacional de Colombia sede Manizales: Manizales, Colombia, 2010; ISBN 978-958-8280-40-0. [Google Scholar]

- Ministerio de Ambiente, Vivienda y Desarrollo Territorial. Reglamento Colombiano de Construcción Sismo Resistente, NSR-10; Asociación Colombiana de Ingeniería Sísmica (AIS): Bogotá, Colombia, 2010; Volume 2. Available online: https://www.andi.com.co/Uploads/Reglamento_colombiano_construccion_sismo_resistente_636536179523160220.pdf (accessed on 4 July 2023).

- Presidencia de la República de Colombia. Decreto 052, Por Medio Del Cual Se Modifica y Adiciona El Capítulo E Del Decreto 33 de 1998; Año CXXXVII No. 44686; Diario Oficial: Bogotá, Colombia, 2002. Available online: https://www.suin-juriscol.gov.co/viewDocument.asp?id=1011727 (accessed on 25 September 2023).

- López, L.F. Norma Andina para Diseño y Construcción de Casas de Uno y Dos Pisos en Bahareque Encementado; INBAR: Quito, Ecuador, 2015; ISBN 978-92-95098-73-2. Available online: https://sheltercluster.s3.eu-central-1.amazonaws.com/public/docs/norma_andina_sin_portada.pdf (accessed on 12 May 2023).

- Congreso de la República de Colombia. Ley 2079 de 2021; Ley de Vivienda y Hábitat: Bogota, Colombia, 2021. Available online: https://www.funcionpublica.gov.co/eva/gestornormativo/norma.php?i=160946#:~:text=Establecer%20mecanismos%20que%20permitan%20reducir,suelo%20urbanizable%20en%20el%20pa%C3%ADs (accessed on 25 September 2023).

- Consejo Nacional de Política Económica y Social. CONPES 3919; Política Nacional de Edificaciones Sostenibles: Bogotá, Colombia, 2018. Available online: https://www.minambiente.gov.co/wp-content/uploads/2021/08/conpes-3919-de-2018.pdf (accessed on 25 September 2023).

- Maury-Ramírez, A.; Illera-Perozo, D.; Mesa, J.A. Circular Economy in the Construction Sector: A Case Study of Santiago de Cali (Colombia). Sustainability 2022, 14, 1923. [Google Scholar] [CrossRef]

- Castiblanco, F.M.; Castiblanco, I.A.; Cruz, J.P. Qualitative Analysis of Lean Tools in the Construction Sector in Colombia. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, IGLC, Dublin, Ireland, 1–7 July 2019; pp. 1023–1036. [Google Scholar]

- Zea Escamilla, E.; Habert, G. Environmental Impacts of Bamboo-Based Construction Materials Representing Global Production Diversity. J. Clean. Prod. 2014, 69, 117–127. [Google Scholar] [CrossRef]

- Zea Escamilla, E.; Habert, G.; Wohlmuth, E. When CO2 Counts: Sustainability Assessment of Industrialized Bamboo as an Alternative for Social Housing Programs in the Philippines. Build. Environ. 2016, 103, 44–53. [Google Scholar] [CrossRef]

- Fedeguadua. Fortalecimiento de La Cadena de Valor de La Construcción Sostenible Con Guadua En El Área Del Paisaje Cultural Cafetero Colombiano (PCCC); Final Technical Report; Fedeguadua: Pereira, Colombia, 2021; pp. 1–46. [Google Scholar]

- ISO 14040; Environmental Management—Life Cycle Assessment–Principles and Framework, 2nd Edition. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment–Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Stocker, T.F.; Qin, D.; Plattner, G.K.; Tignor, M.M.B.; Allen, S.K.; Boschung, J.; Nauels, A.; Xia, Y.; Bex, V.; Midgley, P.M. Climate Change 2013 the Physical Science Basis: Working Group I Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2013; ISBN 9781107057999/9781107415324. [Google Scholar]

- Flórez Calderón, M.T. Análisis Ambiental de Una Vivienda Con Énfasis En Aprovechamiento de Recursos Locales (Guadua) y Gestión de Recursos Hídricos No Convencionales. Master’s Thesis, Universidad Tecnológica de Pereira, Pereira, Colombia, 2016. [Google Scholar]

- EN 15978; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. CEN: Brussels, Belgium, 2012.

- Hernández Londoño, A.; Montoya Arango, J.A.; Camargo García, J.C. Análisis Del Ciclo de Vida Aplicado a La Fase de Extracción de Guadua, En El Eje Cafetero Colombiano. Recur. Nat. Ambiente 2015, 1, 68–76. [Google Scholar]

- Arango Arango, Á.M. Posibilidades de La Guadua Para La Mitigación Del Cambio Climático. Caso: Eje Cafetero Colombiano 2011. pp. 1–114. Available online: https://repositorio.utp.edu.co/server/api/core/bitstreams/97f46a92-7e33-43a8-b820-4a1c98dda4b7/content (accessed on 9 December 2022).

- Pamu, Y.; Kumar, V.S.S.; Shakir, M.A.; Ubbana, H. Life Cycle Assessment of a Building Using Open-LCA Software. Proc. Mater. Today 2022, 52, 1968–1978. [Google Scholar] [CrossRef]

- Kumbhar, S.; Kulkarni, N.; Rao, A.B.; Rao, B. Environmental Life Cycle Assessment of Traditional Bricks in Western Maharashtra, India. Proc. Energy Procedia 2014, 54, 260–269. [Google Scholar] [CrossRef]

- Zea Escamilla, E.; Habert, G. Method and Application of Characterisation of Life Cycle Impact Data of Construction Materials Using Geographic Information Systems. Int. J. Life Cycle Assess. 2017, 22, 1210–1219. [Google Scholar] [CrossRef]

- Camargo García, J.C.; Arango Arango, A.M.; Trinh, L. The Potential of Bamboo Forests as a Carbon Sink and Allometric Equations for Estimating Their Aboveground Biomass. Environ. Dev. Sustain. 2023. [Google Scholar] [CrossRef]

- Murphy, R.J.; Trujillo, D.; Londono, X. Life Cycle Assessment (LCA) of a Guadua House. In Proceedings of the Simposio Internacional Guadua, Pereira, Colombia, 27 September 2004; pp. 235–244, ISBN 958-8065-81-X. [Google Scholar]

- Archila, H.F.; Pesce, G.L.; Ansell, M.P.; Ball, R.J.; Heard, P.J. Limeboo: Lime as a Replacement for Cement in Wall-Framing Systems with Bamboo-Guadua (Bahareque Encementado). In Proceedings of the 16th International Conference on Non-conventional Materials and Technologies (NOCMAT 2015), Winnipeg, MB, Canada, 10 August 2015; p. 11. Available online: http://opus.bath.ac.uk/47630/ (accessed on 20 October 2023).

- Dipasquale, L.; Mecca, S.; Özel, B. Resilience of Vernacular Architecture. In Versus Heritage for Tomorrow: Vernacular Knowledge for Sustainable Architecture; Correia, M., Dipasquale, L., Mecca, S., Eds.; Firenze University Press: Firenze, Italy, 2014; pp. 65–73. [Google Scholar]

- Ministerio de Vivienda, Ciudad y Territorio de Colombia. Ley 2206, Por Medio de La Cual Se Incentiva El Uso de La Guadua y El Bambú y Su Sostenibilidad Ambiental En El Territorio Nacional. 2022. Available online: https://minvivienda.gov.co/normativa/ley-2206-2022 (accessed on 25 September 2023).

- Sharma, B.; Gatoo, A.; Bock, M.; Mulligan, H.; Ramage, M. Engineered Bamboo: State of the Art. Proc. Inst. Civ. Eng. Constr. Mater. 2015, 168, 57–67. [Google Scholar] [CrossRef]

- Harries, K.A.; Sharma, B. Nonconventional and Vernacular Construction Materials. Characterisation, Properties and Applications; Woodhead Publishing: Oxford, UK, 2016; ISBN 978-0-08-100871-3. [Google Scholar]

| Inputs—Materials | Place of Origin or Production | Distance to UTP Campus (km) |

|---|---|---|

| Reinforcing steel | Acerías Paz del Rio, Duitama, Boyacá | 530 |

| Cement | Yumbo, Valle del Cauca | 203 |

| Washed sand | Corregimiento Caimalito, Pereira, Risaralda | 58.2 |

| Gravel | Corregimiento Caimalito, Pereira, Risaralda | 58.2 |

| Preserved Guadua | Vereda El Laurel, Quimbaya, Quindío—Dosquebradas, Risaralda | 54.5 |

| Clay Brick | Corregimiento Cerritos, Pereira | 23.1 |

| Materials | CSB House (41.04 m2) kg/house | GaKB House (60.65 m2) kg/house |

|---|---|---|

| Round GaK culms | - | 1772.64 |

| GaK mats | - | 2048.48 |

| Concrete | 28,057.89 | 17,651.4 |

| Clay brick | 12,174.1 | 564.48 |

| Cement mortar | 1944.19 | 5189.6 |

| Steel * | 1047.15 | 515.51 |

| Materials | CSB House (41.04 m2) | GaKB House (60.65 m2) | GaKB/CSB Percentage Comparison (%) | ||||

|---|---|---|---|---|---|---|---|

| kg/house | kg CO2-eq | kg CO2-eq/m2 | kg/house | kg CO2-eq | kg CO2-eq/m2 | ||

| Round GaK culms | 0.0 | 0.0 | 0.0 | 1772.6 | 365.0 | 6.0 | - |

| GaK mats | 0.0 | 0.0 | 0.0 | 2048.5 | 443.0 | 7.3 | - |

| Concrete | 28,057.9 | 2473.0 | 60.3 | 17,651.4 | 2126.0 | 35.1 | 58.2 |

| Clay brick | 12,174.1 | 4873.0 | 118.7 | 564.5 | 782.0 | 12.9 | 10.9 |

| Cement mortar | 1944.2 | 454.0 | 11.1 | 5189.6 | 1101.0 | 18.2 | 164.1 |

| Steel * | 1047.2 | 3588.0 | 87.4 | 515.5 | 1786.0 | 29.4 | 33.7 |

| Transportation | 860.0 | 21.0 | 617.3 | 10.2 | 48.6 | ||

| Total | 43,223.3 | 12,248.0 | 298.4 | 27,742.1 | 7220.3 | 119.0 | 39.9 |

| Materials | CSB House (41.04 m2) | GaKB House (60.65 m2) | ||

|---|---|---|---|---|

| kg CO2-eq/m2 | Percentage (%) | kg CO2-eq/m2 | Percentage (%) | |

| Concrete | 60.3 | 20.2 | 35.1 | 29.5 |

| Cement mortar | 11.1 | 3.7 | 18.2 | 15.3 |

| Steel * | 87.4 | 29.3 | 29.4 | 24.7 |

| Sub-total | 158.8 | 53.2 | 82.7 | 69.5 |

| Total | 298.4 | 100 | 82.8 | 100 |

| Materials | CSB House (41.04 m2) | GaKB House (60.65 m2) | Percentage (%) | ||

|---|---|---|---|---|---|

| kg/house | kg/m2 house | kg/house | kg/m2 house | ||

| Round GaK culm | - | - | 1772.6 | 29.23 | - |

| GaK mats | - | - | 2048.5 | 33.77 | - |

| Clay brick | 12,174.1 | 296.64 | - | - | - |

| Total | 12,174.1 | 296.64 | 3821.1 | 63.00 | 21.2 |

| Materials | Bamboo Demand | kg CO2 Captured | ||||||

|---|---|---|---|---|---|---|---|---|

| Guadua Poles (m) * | Guadua Lengths (m) | Guadua Poles (No.) | Guadua Poles/ m2 | kg CO2/Guadua | % Culm | kg CO2/house | kg CO2/m2 house | |

| Round GaK | 295.44 | 12.00 | 24.62 | 0.41 | −31.21 | 67 | −514.82 | −8.49 |

| GaK mat | 118.00 | 12.00 | 9.83 | 0.16 | −31.21 | 67 | −306.90 | −3.39 |

| Total bamboo | 413.44 | 12.00 | 34.45 | 0.57 | −31.21 | 67 | −1075.29 | −11.88 |

| Housing Typology | kg CO2-eq/m2 | GaKB/CSB Comparison (%) | kg CO2/m2 Captured | Balance kg CO2-eq/m2 | GaKB/CSB Comparison (%) |

|---|---|---|---|---|---|

| CSB | 298.44 | 100 | 0 | 298.44 | 100 |

| GaKB | 119.05 | 39.9 | −11.88 | 107.17 | 35.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rincón, C.E.; Montoya, J.A.; Archila, H.F. Bamboo Construction Inspired by Vernacular Techniques for Reducing Carbon Footprint: A Life Cycle Assessment (LCA). Sustainability 2023, 15, 16893. https://doi.org/10.3390/su152416893

Rincón CE, Montoya JA, Archila HF. Bamboo Construction Inspired by Vernacular Techniques for Reducing Carbon Footprint: A Life Cycle Assessment (LCA). Sustainability. 2023; 15(24):16893. https://doi.org/10.3390/su152416893

Chicago/Turabian StyleRincón, Carlos Eduardo, Jorge Augusto Montoya, and Hector F. Archila. 2023. "Bamboo Construction Inspired by Vernacular Techniques for Reducing Carbon Footprint: A Life Cycle Assessment (LCA)" Sustainability 15, no. 24: 16893. https://doi.org/10.3390/su152416893

APA StyleRincón, C. E., Montoya, J. A., & Archila, H. F. (2023). Bamboo Construction Inspired by Vernacular Techniques for Reducing Carbon Footprint: A Life Cycle Assessment (LCA). Sustainability, 15(24), 16893. https://doi.org/10.3390/su152416893