Thermal, Acoustic, and Hygrothermal Properties of Recycled Bovine Leather Cutting Waste-Based Panels with Different Compositions

Abstract

1. Introduction

2. Materials and Methods

- ¯

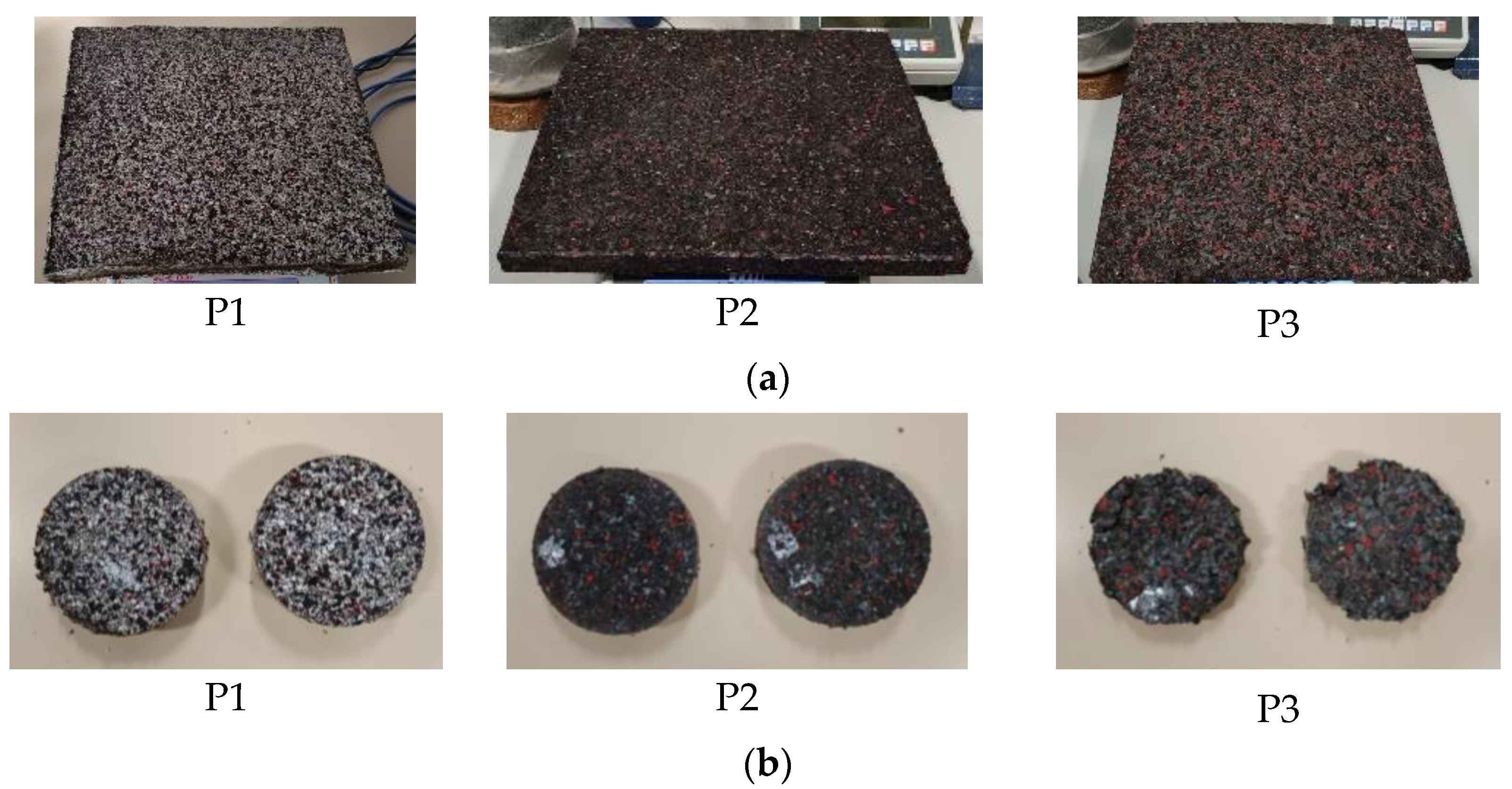

- P1, leather cutting waste panel with vinyl glue, composed of leather scraps (1.3 kg), vinyl glue (0.65 kg, 50% by weight of the leather), and distilled water (0.27 kg, 20% by weight of the leather). The glue consists of polyvinyl alcohol emulsifying agent in liquid form [25];

- ¯

- P2, leather cutting waste + internal support leather materials (infustiture) panel with vinyl glue, composed of leather scraps (0.455 kg, 35% of the total waste), infustiture (0.845 kg, 65% of the total waste), vinyl glue (0.65 kg, 50% by weight of the leather + infustiture matrix), and distilled water (0.24 kg, 18% by weight of the leather + infustiture matrix). The infustiture was composed of 50% of polyurethane and 50% of polyamide, as declared by the company. The vinyl is the same type as in the panel P1;

- ¯

- P3, leather cutting waste panel with ECHO PU 249/F glue [26], composed of leather scraps (1.3 kg), ECHO PU 249/F glue (0.65 kg, 50% by weight of the leather), and distilled water (0.24 kg, 18% by weight of the leather). The glue used is a water-based polyurethane adhesive.

3. Results and Discussion

3.1. Thermal Properties

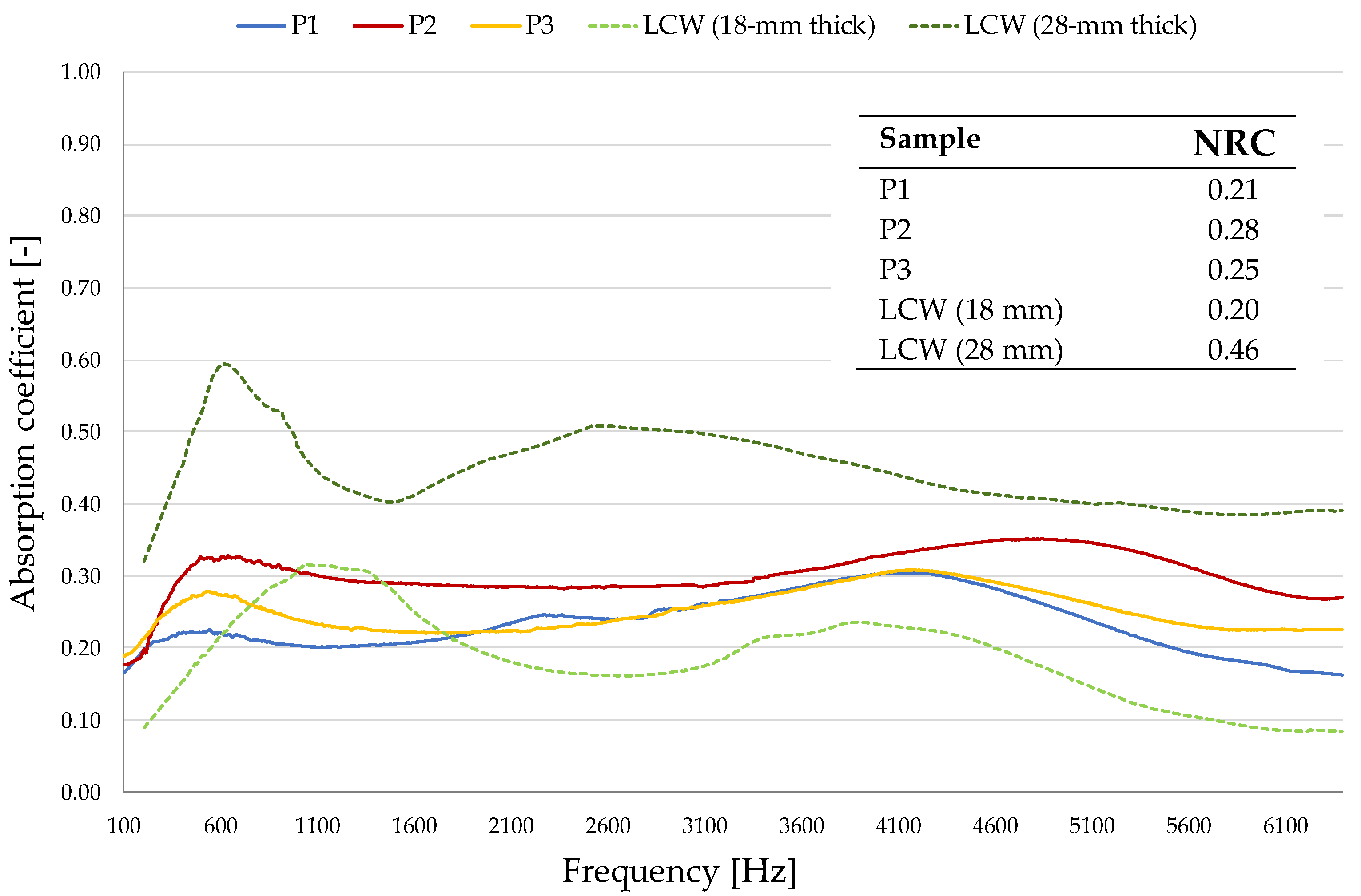

3.2. Acoustic Properties

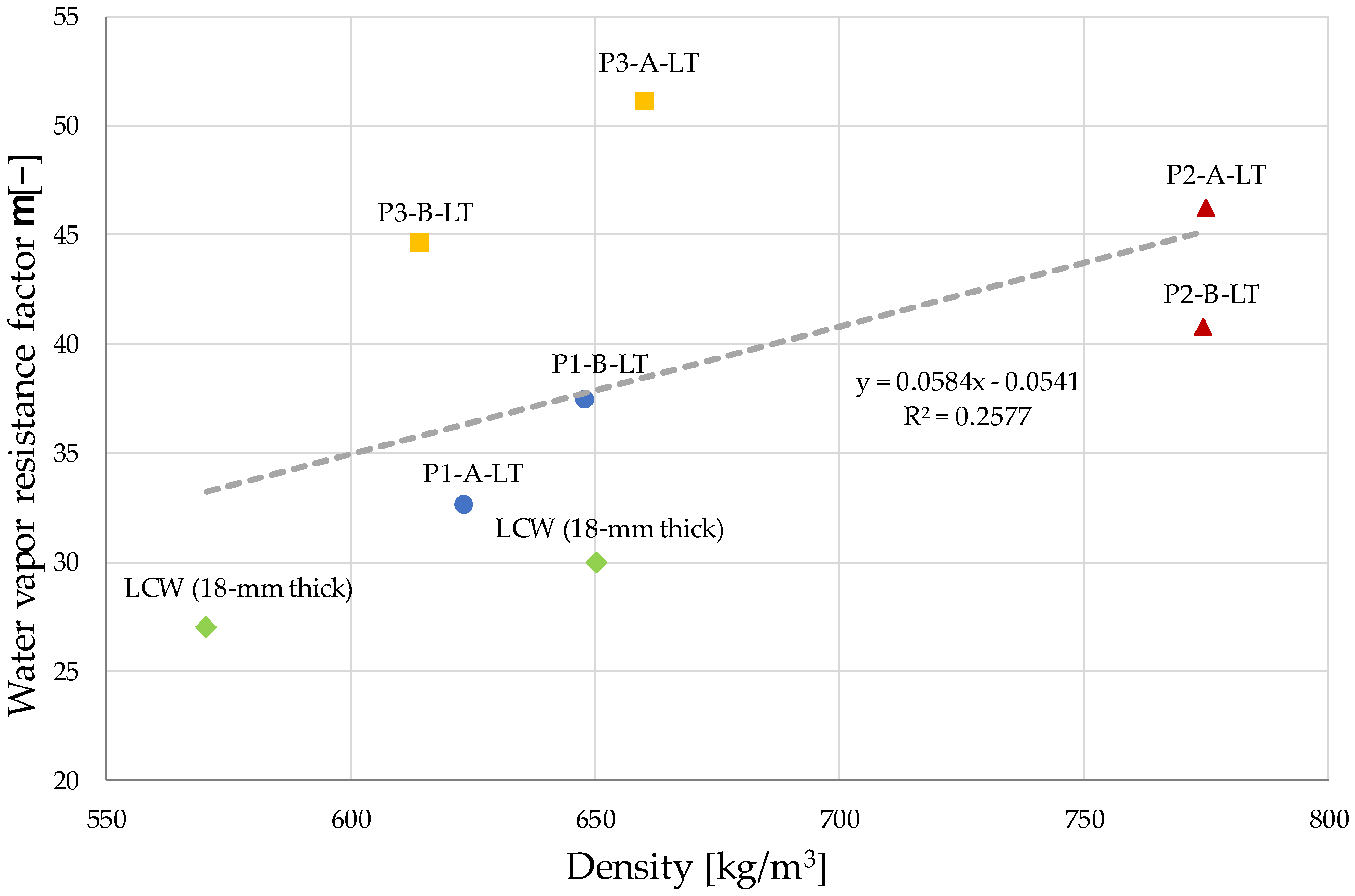

3.3. Permeability Properties

4. Conclusions

- ¯

- The leather cutting waste with internal support leather materials panel (P2) has a higher density and better thermo-acoustic performance; thermal conductivity is 0.064 W/mK at 10 °C, the noise reduction coefficient is 0.28, and the Transmission Loss is in the 38–59 dB range;

- ¯

- The use of natural glue leads to a slight deterioration in thermal performance (λ = 0.078 W/mK). However, sound insulation properties are comparable with those of the leather cutting waste panel with vinyl glue (P1), whereas the absorption coefficient values are higher (NRC equal to 0.25 and 0.21 for P3 and P1, respectively);

- ¯

- The thermo-acoustic behavior of the samples is close to that of other natural fiber-based panels with similar thickness, such as wood (λ = 0.065–0.084 W/mK), rice husk (λ = 0.066 W/mK), and coffee chaff (λ = 0.071 W/mK) boards;

- ¯

- The thermal properties of the leather panels are slightly worse than those of standard insulating materials. However, their benefit is the low environmental impact;

- ¯

- Excellent permeability properties were obtained for the studied samples, especially when natural glue was used; water vapor resistance factor values equal to 35, 44, and 48 were measured for P1, P2, and P3 panels, respectively;

- ¯

- he reduction in the leather pieces’ dimension resulted in an improvement in thermal (thermal conductivity reduction up to 36%), acoustic (NRC increase up to 30%, and TL outperforms the thickest panel with the largest pieces), and permeability properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| R [m2K/W] | thermal resistance |

| ΔTs [K] | mean surface temperatures |

| Φ [W/m2] | heat flux |

| λ [W/mK] | thermal conductivity |

| [%] | relative uncertainty type B |

| α [-] | absorption coefficient |

| TL [dB] | Transmission Loss |

| NRC [-] | Noise Reduction Coefficient |

| μ [-] | water vapor resistance factor |

References

- Vasilache, M.; Pruteanu, M.; Avram, C. Use of waste materials for thermal insulation in buildings. Environ. Eng. Manag. J. 2010, 9, 1275–1280. [Google Scholar] [CrossRef]

- Koh, H.W.; Le, D.K.; Ng, G.N.; Zhang, X.W.; Phan-Thien, N.; Kureemun, U.; Duong, H.M. Advanced recycled polyethylene terephthalate aerogels from plastic waste for acoustic and thermal insulation applications. Gels 2018, 4, 43. [Google Scholar] [CrossRef] [PubMed]

- Massoudinejad, M.; Amanidaz, N.; Santos, R.M.; Bakhshoodeh, R. Use of municipal, agricultural, industrial, construction and demolition waste in thermal and sound building insulation materials: A review article. J. Environ. Health Sci. Eng. 2019, 17, 1227–1242. [Google Scholar] [CrossRef] [PubMed]

- Reixach, R.; Del Rey, R.; Alba, J.; Arbat, G.; Espinach, F.X.; Mutjé, P. Acoustic properties of agroforestry waste orange pruning fibers reinforced polypropylene composites as an alternative to laminated gypsum boards. Constr. Build. Mater. 2015, 77, 124–129. [Google Scholar] [CrossRef]

- Seidman, M.D.; Standring, R.T. Noise and quality of life. Int. J. Environ. Res. Public Health 2010, 7, 3730–3738. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Le, D.; Nguyen, S.T.; Nien, V.T.C.; Jewell, D.; Duong, H.M. Silica cellulose hybrid aerogels for thermal and acoustic insulation applications. Colloids Surf. A 2016, 506, 298–305. [Google Scholar] [CrossRef]

- Del Rey, R.; Alba, J.; Arenas, J.P.; Sanchis, V.J. An empirical modelling of porous sound absorbing materials made of recycled foam. Appl. Acoust. 2012, 73, 604–609. [Google Scholar]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel insulation for building applications: A state-of-the-art review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef]

- Orlik-Kozdon, B. Assessment of the application efficiency of recycling materials in thermal insulations. Constr. Build. Mater. 2017, 156, 476–485. [Google Scholar] [CrossRef]

- Corscadden, K.W.; Biggs, J.N.; Stiles, D.K. Sheep’s wool insulation: A sustainable alternative use for a renewable resource. Resour. Conserv. Recycl. 2014, 86, 9–15. [Google Scholar] [CrossRef]

- Cetiner, I.; Shea, A.D. Wood waste as an alternative thermal insulation for buildings. Energy Build. 2018, 168, 374–384. [Google Scholar] [CrossRef]

- Hurtado, P.L.; Rouilly, A.; Vandenbossche, V.; Raynaud, C. A review on the properties of cellulose fibre insulation. Build. Environ. 2016, 96, 170–177. [Google Scholar] [CrossRef]

- Briga-Sá, A.; Nascimento, D.; Texeira, N.; Pinto, J.; Caldeira, F.; Varum, H.; Paiva, A. Textile waste as an alternative thermal insulation building material solution. Constr. Build. Mater. 2013, 38, 155–160. [Google Scholar] [CrossRef]

- Tilioua, A.; Libessart, L.; Lassue, S. Characterization of the thermal properties of fibrous insulating materials made from recycled textile fibers for building applications: Theoretical and experimental analysis. Appl. Therm. Eng. 2018, 142, 56–67. [Google Scholar] [CrossRef]

- Trajković, D.; Jordeva, S.; Tomovska, E.; Zafirova, K. Polyester apparel cutting waste as insulation material. J. Textile Inst. 2017, 108, 1238–1245. [Google Scholar] [CrossRef]

- Zach, J.; Korjenic, A.; Petránek, V.; Hroudová, J.; Bednar, T. Performance evaluation and research of alternative thermal insulations based on sheep wool. Energy Build. 2012, 49, 246–253. [Google Scholar] [CrossRef]

- Bhat, G. Structure and Properties of High-Performance Fibers; Woodhead Publishing Series in Textiles: Amsterdam, The Netherlands, 2017; pp. 367–400. [Google Scholar]

- Islam, S.; Bhat, G. Environmentally-friendly thermal and acoustic insulation materials from recycled textiles. J. Environ. Manag. 2019, 251, 109536. [Google Scholar] [CrossRef]

- Zach, J.; Hroudová, J.; Korjenic, A. Environmentally efficient thermal and acoustic insulation based on natural and waste fibers. J. Chem. Technol. Biotechnol. 2016, 91, 2156–2161. [Google Scholar] [CrossRef]

- Sivaprakash, K.; Maharaja, P.; Pavithra, S.; Boopathy, R.; Sekaran, G. Preparation of light weight constructional materials from chrome containing buffing dust solid waste generated in leather industry. J. Mater. Cycles Waste Manag. 2017, 19, 928–938. [Google Scholar] [CrossRef]

- Rethinam, S.; Sundaramurthy, I.; Nallathambi, G.; Das, B.N.; Sastry, T.P. Utilisation of finished leather wastes for the production of blended fabrics. Clean Technol. Environ. Policy 2015, 17, 1535–1546. [Google Scholar]

- Dweck, J.; Buchler, P.M.; Coelho, A.C.V.; Cartledge, F.K. Solidifification/stabilisation of a tannery waste with blended cement and Wyoming bentonite. J. Environ. Sci. Health Part A 2000, 35, 715–740. [Google Scholar] [CrossRef]

- Webler, A.D.; Moreira, F.C.; Dezotti, M.W.C.; Mahler, C.F.; Segundo, I.D.B.; Boaventura, R.A.R.; Vilar, V.J.P. Development of an integrated treatment strategy for a leather tannery landfill leachate. Waste Manag. 2019, 89, 114–128. [Google Scholar] [CrossRef] [PubMed]

- Notarnicola, B.; Puig, R.; Raggi, A.; Fullana, P.; Tassielli, G.; Camillis, C.D.; Rius, A. Life cycle assessment of Italian and Spanish bovine leather production systems. Afinidad 2011, 68, 167–180. [Google Scholar]

- Barbanera, M.; Belloni, E.; Buratti, C.; Calabrò, G.; Marconi, M.; Merli, F.; Armentano, I. Recycled leather cutting waste-based boards: Thermal, acoustic, hygrothermal and ignitability properties. J. Mater. Cycles Waste Manag. 2020, 22, 1339–1351. [Google Scholar] [CrossRef]

- Technical Sheet. Available online: https://www.keck-chimie.fr/wp-content/uploads/2019/09/ECHO_PU_249_-249_F_249_R_decembre_2012-1.pdf (accessed on 15 March 2022).

- Buratti, C.; Belloni, E.; Lunghi, L.; Barbanera, M. Thermal Conductivity Measurements By Means of a new ‘Small Hot-Box’ Apparatus: Manufacturing, Calibration and Preliminary Experimental Tests on Different Materials. Int. J. Thermophys. 2016, 37, 47. [Google Scholar] [CrossRef]

- JCGM 100: 2008 GUM 1995 with Minor Corrections; Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement; CGM (Joint Committee for Guides in Metrology): Sèvres, France, 2008.

- ISO 10456; Building Materials and Products—Hygrothermal Properties—Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values. ISO: Geneva, Switzerland, 2007.

- ISO 10534-2; Acoustics—Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-function Method. ISO: Geneva, Switzerland, 1998.

- Jung, S.S.; Kim, Y.T.; Lee, Y.B.; Cho, S.; Lee, J.K. Measurement of sound transmission loss by using impedance tubes. J. Korean Phys. Soc. 2008, 53, 596–600. [Google Scholar] [CrossRef]

- Barnard, A.R.; Rao, D.M. Measurement of Sound Transmission Loss Using a Modified Four-Microphone Impedance Tube; NOISE-CON: Baltimore, MD, USA, 2004. [Google Scholar]

- UNI EN ISO 12572; Hygrothermal Performance of Building Materials and Products—Determination of Water Vapour Transmission Properties: Cup Method. ISO: Geneva, Switzerland, 2016.

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Available online: https://www.anit.it/wp-content/uploads/2015/02/Parte-7_v3.pdf (accessed on 9 June 2022).

- Merli, F.; Belloni, E.; Buratti, C. Eco-Sustainable Wood Waste Panels for Building Applications: Influence of Different Species and Assembling Techniques on Thermal, Acoustic, and Environmental Performance. Buildings 2021, 11, 361. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Lascaro, E.; Merli, F.; Ricciardi, P. Rice husk panels for building applications: Thermal, acoustic and environmental characterization and comparison with other innovative recycled waste materials. Constr. Build. Mater. 2018, 171, 338–349. [Google Scholar] [CrossRef]

- Available online: https://www.masacoustics.it/wp-content/uploads/2013/11/datasheet-kenaf-60-kg-30mm.pdf (accessed on 9 June 2022).

- Available online: https://www.iuav.it/SISTEMA-DE/Archivio-d/approfondi/materiali-/Materiali_Isolanti.pdf (accessed on 9 June 2022).

| Sample | Composition | ||

|---|---|---|---|

| P1 | 1.3 kg leather scraps, 0.65 kg vinyl glue, 0.27 kg distilled water | ||

| P2 | 0.455 kg leather scraps, 0.845 kg infustiture, 0.65 kg vinyl glue, 0.24 kg distilled water | ||

| P3 | 1.3 kg leather scraps, 0.65 kg water-based glue, 0.24 kg distilled water | ||

| Thermal characterization | |||

| Sample | Average thickness [m] | ||

| P1 | 0.018 | ||

| P2 | 0.019 | ||

| P3 | 0.017 | ||

| Acoustic and Hygrothermal characterizations | |||

| Sample | Diameter [m] | Average thickness [m] | Density [kg/m3] |

| P1-A-LT * | 0.100 | 0.021 | 623 |

| P1-A-ST * | 0.029 | 0.021 | 641 |

| P1-B-LT * | 0.100 | 0.020 | 648 |

| P1-B_ST * | 0.029 | 0.021 | 592 |

| P2-A-LT * | 0.100 | 0.017 | 775 |

| P2-A-ST * | 0.029 | 0.016 | 693 |

| P2-B-LT * | 0.100 | 0.018 | 775 |

| P2-B_ST * | 0.029 | 0.017 | 700 |

| P3-A-LT * | 0.100 | 0.014 | 660 |

| P3-A-ST * | 0.029 | 0.019 | 671 |

| P3-B-LT * | 0.100 | 0.016 | 614 |

| P3-B_ST * | 0.029 | 0.020 | 680 |

| Sample | Hot Side Test Condition [°C] | Φ [W/m2] | ΔTs [°C] | λ @31–35 °C [W/mK] | R@10 °C [W/mK] | [%] | λmean @10 °C [W/mK] |

|---|---|---|---|---|---|---|---|

| P1 (s = 0.018 m) | 45 | 57.41 | 13.55 | 0.076 | 0.254 | 3.6 | 0.072 |

| 45 | 56.41 | 13.13 | 0.077 | 0.250 | 4.5 | ||

| 50 | 69.88 | 16.01 | 0.079 | 0.249 | 3.7 | ||

| 50 | 70.70 | 16.29 | 0.078 | 0.230 | 4.2 | ||

| P2 (s = 0.019 m) | 45 | 53.90 | 15.00 | 0.068 | 0.298 | 2.0 | 0.064 |

| 45 | 55.08 | 15.36 | 0.068 | 0.299 | 2.8 | ||

| 50 | 70.01 | 19.05 | 0.070 | 0.294 | 4.0 | ||

| 50 | 67.93 | 18.42 | 0.070 | 0.293 | 3.9 | ||

| P3 (s = 0.017 m) | 45 | 55.87 | 11.40 | 0.083 | 0.220 | 3.5 | 0.078 |

| 45 | 55.89 | 11.30 | 0.084 | 0.218 | 4.0 | ||

| 50 | 66.86 | 13.28 | 0.086 | 0.216 | 2.9 | ||

| 50 | 65.94 | 13.02 | 0.086 | 0.215 | 2.7 |

| Panel | λ @10 °C [W/mK] | |

|---|---|---|

| P1 | 0.072 |  |

| P2 | 0.064 | |

| P3 | 0.078 | |

| LCW [25] | 0.100 | |

| expanded and extruded polystyrene [25] | 0.035 | |

| kenaf [34,38] | 0.038 | |

| wood fiber [27,34,35] | 0.065 | |

| chipped wood [36] | 0.071–0.084 | |

| cork scraps * [37] | 0.052 | |

| rice husk * [37] | 0.066 | |

| coffee chaff * [37] | 0.071 | |

| wastepaper * [37] | 0.034–0.047 | |

| sheep wool * [16,35] | 0.036–0.038 | |

| granulated rubber * [37] | 0.127 |

| Sample | G [kg/s] | μ | μaverage |

|---|---|---|---|

| P1-A-LT | 3.30 × 10−9 | 33 | 35 (P1) |

| P1-B-LT | 3.02 × 10−9 | 37 | |

| P2-A-LT | 2.88 × 10−9 | 46 | 44 (P2) |

| P2-B-LT | 3.08 × 10−9 | 41 | |

| P3-A-LT | 3.16 × 10−9 | 51 | 48 (P3) |

| P3-B-LT | 3.16 × 10−9 | 45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Merli, F.; Fiorini, C.V.; Barbanera, M.; Pietroni, G.; Spaccini, F.; Buratti, C. Thermal, Acoustic, and Hygrothermal Properties of Recycled Bovine Leather Cutting Waste-Based Panels with Different Compositions. Sustainability 2023, 15, 1779. https://doi.org/10.3390/su15031779

Merli F, Fiorini CV, Barbanera M, Pietroni G, Spaccini F, Buratti C. Thermal, Acoustic, and Hygrothermal Properties of Recycled Bovine Leather Cutting Waste-Based Panels with Different Compositions. Sustainability. 2023; 15(3):1779. https://doi.org/10.3390/su15031779

Chicago/Turabian StyleMerli, Francesca, Costanza Vittoria Fiorini, Marco Barbanera, Giorgia Pietroni, Francesco Spaccini, and Cinzia Buratti. 2023. "Thermal, Acoustic, and Hygrothermal Properties of Recycled Bovine Leather Cutting Waste-Based Panels with Different Compositions" Sustainability 15, no. 3: 1779. https://doi.org/10.3390/su15031779

APA StyleMerli, F., Fiorini, C. V., Barbanera, M., Pietroni, G., Spaccini, F., & Buratti, C. (2023). Thermal, Acoustic, and Hygrothermal Properties of Recycled Bovine Leather Cutting Waste-Based Panels with Different Compositions. Sustainability, 15(3), 1779. https://doi.org/10.3390/su15031779