A Suggestion of the Alternatives Evaluation Method through IFC-Based Building Energy Performance Analysis

Abstract

1. Introduction

1.1. Research Background

1.2. Literature Review

1.2.1. Evaluation Method for Building Design Alternatives

1.2.2. Analysis of Building Energy Performance

1.2.3. Deriving Analysis Results and Implications

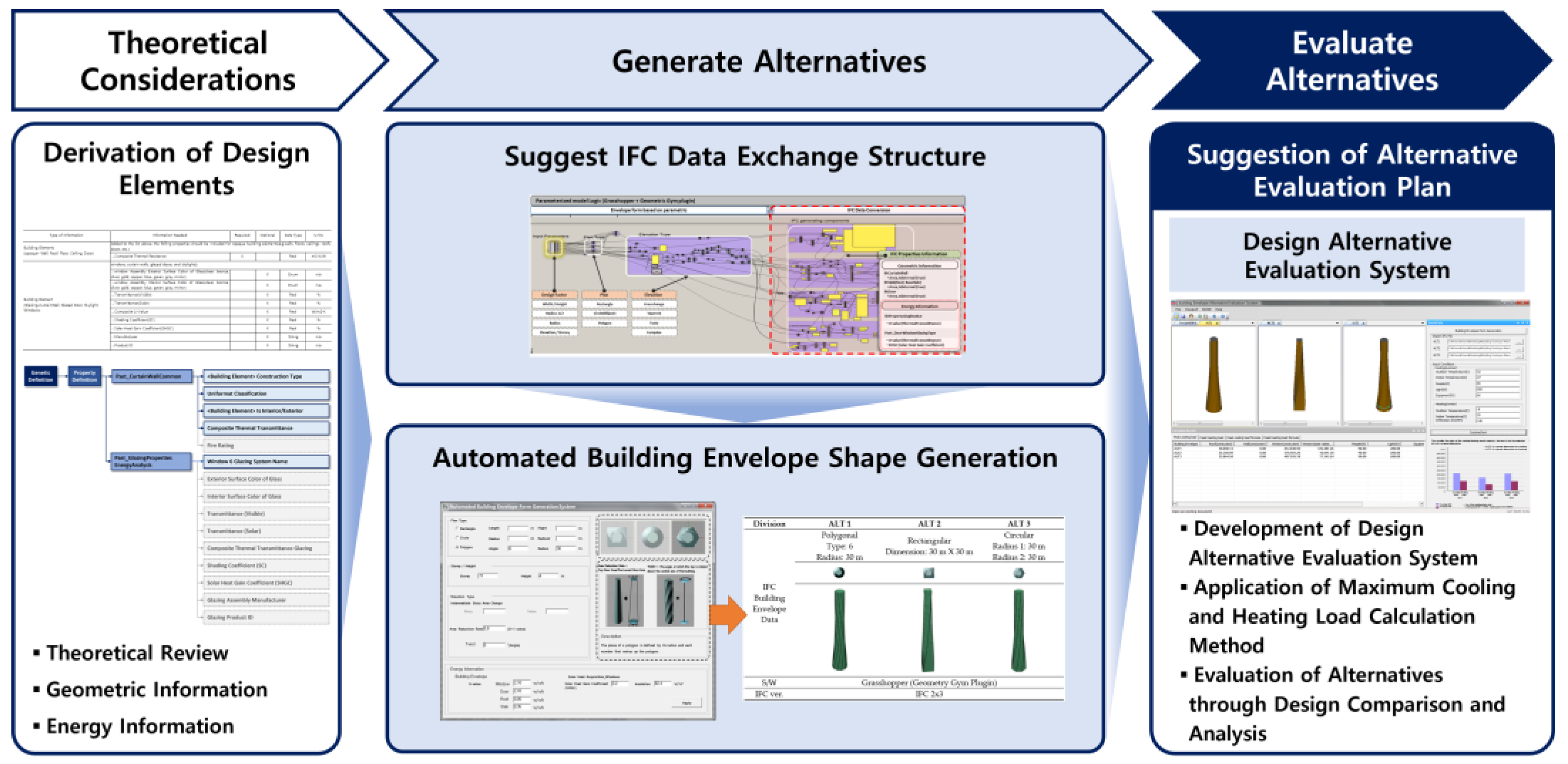

2. Methodology for Creating IFC-Based Building Envelope Automation Alternatives

2.1. Deriving Design Elements for Energy Performance Evaluation

2.2. Suggestion of IFC Data Exchange Structure

2.3. Development of Automated Building Envelope Form Generation System

3. Evaluation of Alternative Automation for Building Envelope Based on IFC

3.1. Development of Building Envelope Alternative Evaluation System

3.2. Analysis and Verification Results for Buildinig Envelope Alternative Evaluation System

- (1)

- Conducting load (IfcSlab (top), IfcSlab (base), IfcCurtainWall) = Area (IfcElementQuantity) × U-value (Pest_CurtainWallCommon-ThermalTransmittance) × design temperature.

- (2)

- Solar load (IfcCurtainWall) = Area (IfCElementQuantity) × SHGC (Pest_DoorWindowGlazingType-SolarHeatGainTransmittance) × SolarAbsorption.

- (3)

- Human body heat + Equipment heat + Light heat (see basic analysis conditions in Table 3).

- (1)

- Conducting load (IfcSlab (top), IfcSlab (base), IfcCurtainWall) = Area (IfcElementQuantity) × U-value (Pest_CurtainWallCommon-ThermalTransmittance) × design temperature.

- (4)

- Infiltration heat (see basic analysis conditions in Table 3).

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baln, D. Summary of findings from the tenth annual BIM survey. In 10th Annual BIM Report; Waterhouse, R., Ed.; NBS: Newcastle upon Tyne, UK, 2020; pp. 15–29. [Google Scholar]

- The Ministry of Land, Infrastructure and Transport. 2030 Building BIM Activation Roadmap; The Ministry of Land, Infrastructure and Transport: Sejong-si, Republic of Korea, 2020. [Google Scholar]

- Lee, S. The role of smart buildings in response to climate change. In Planning and Policy; Korea Research Institute for Human Settlements.; Korea Research Institute for Human Settlements: Sejong-si, Republic of Korea, 2020; Volume 462, pp. 29–35. [Google Scholar]

- Schodek, D.; Bechthold, M. Digital Design and Manufacturing; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Kang, H. A Study on Informal Architectural Form Creation based on the Digital Transformation Method. J. Archit. Inst. Korea Plan. Design 2006, 22, 149–158. [Google Scholar]

- Park, S.M. Tall Building form Generation by Parametric Design Process. Ph.D. Thesis, Illinois Institute of Technology, Ann Arbor, CA, USA, 2005. [Google Scholar]

- Kim, C.K.; Lee, S.; Choi, H. A study on parametric modeler to generate structural analysis model. In Proceedings of the Computational Structural Engineering Institute Conference, Jeju-si, Republic of Korea, 9 April 2010. [Google Scholar]

- Tabadkani, A.; Shoubi, M.V.; Soflaei, F.; Banihashemi, S. Integrated parametric design of adaptive facades for user’s visual comfort. Autom. Constr. 2019, 106, 102857. [Google Scholar] [CrossRef]

- Kyivska, K.I.; Tsiutsiura, S.V.; Tsiutsiura, M.I.; Kryvoruchko, O.V.; Yerukaiev, A.V.; Hots, V.V. A Study of the Concept of Parametric Modeling of Construction Objects. Int. J. Adv. Res. Eng. Technol. 2019, 10, 636–646. [Google Scholar] [CrossRef]

- Kim, H.; Clayton, M.J. A multi-objective optimization approach for climate-adaptive building envelope design using parametric behavior maps. Build. Environ. 2020, 185, 107292. [Google Scholar] [CrossRef]

- Kaliakatsos, D.; Nicolletti, F.; Paradisi, F.; Bevilacqua, P.; Arcuri, N. Evaluation of Building Energy Savings Achievable with an Attached Bioclimatic Greenhouse: Parametric Analysis and Solar Gain Control Techniques. Buildings 2022, 12, 2186. [Google Scholar] [CrossRef]

- Guan, Z.; Xu, X.; Xue, Y.; Wang, C. Multi-Objective Optimization Design of Geometric Parameters of Atrium in nZEB Based on Energy Consumption, Carbon Emission and Cost. Sustainability 2023, 15, 147. [Google Scholar] [CrossRef]

- Kim, S.H.; Kim, S.H.; Na, J.S. New RTS load calculation method. Mag. SAREK 2006, 35, 46–58. [Google Scholar]

- Edition, S.; Erbe, D.; Lane, M.; Anderson, S.; Baselici, P.; Hanson, S.; Heinisch, R.; Humble, J.; Taylor, S.; Kurtz, R. Energy Standard for Buildings Except Low-Rise Residential Buildings; ASHRAE: Atlanta, GA, USA, 2010. [Google Scholar]

- Kim, K.S.; Kim, Y.; Oh, M.D. Introduction of RTS method and load calculation program. In Proceedings of the SAREK 2008 Summer Annual Conference, Gangwon-do, Republic of Korea, 21 June 2008. [Google Scholar]

- Moon, H.J.; Kim, S.K. Development of a BIM based energy performance evaluation method for buildings with a twisted shape in early design stage. J. Comput. Struct. Eng. Inst. Korea 2012, 28, 289–296. [Google Scholar]

- Jeung, W.S.; Kim, Y.D.; Kim, Y.Y.; Song, K.D. A study on extraction of data from gbXML format BIM for heating and cooling load calculation. In Proceedings of the SAREK 2010 Summer Annual, Gangwon-do, Republic of Korea, 24 June 2010. [Google Scholar]

- Moon, H.J.; Choi, M.S. gbXML based BIM model energy performance analysis process. In Proceedings of the SAREK 2010 Summer Annual, Gangwon-do, Republic of Korea, 24 June 2010. [Google Scholar]

- Chardon, S.; Brangeon, B.; Bozonnet, E.; Inard, C. Construction cost and energy performance of single family houses: From integrated design to automated optimization. Autom. Constr. 2016, 70, 1–13. [Google Scholar] [CrossRef]

- Wang, Z.; Srinivasan, R.S. A review of artificial intelligence based building energy use prediction: Contrasting the capabilities of single and ensemble prediction models. Renew. Sustain. Energy Rev. 2017, 75, 796–808. [Google Scholar] [CrossRef]

- Jun, J.H.; Park, H.J.; Lee, K.H.; Choo, S.Y. Multi-family housing block design strategy development by BIM-based energy performance analysis—focusing on the block types and the variation in stories. J. Archit. Inst. Korea Plan. Des. 2018, 34, 3–11. [Google Scholar]

- Alothman, A.; Ashour, S.; Krishnaraj, L. Energy performance analysis of building for sustainable design using BIM: A case study on institute building. Int. J. Renew. Energy Res. 2021, 11, 556–565. [Google Scholar]

- Yuan, Z.; Zhou, J.; Qiao, Y.; Zhang, Y.; Liu, D.; Zhu, H. BIM-VE-Based Optimization of Green Building Envelope from the Perspective of both Energy Saving and Life Cycle Cost. Sustainability 2020, 12, 7862. [Google Scholar] [CrossRef]

- Galiano-Garrigós, A.; Domenech-Mataix, M.; González-Avilés, Á.B.; Rizo-Maestre, C. Evaluation of Energy Performance and Comfort: Case-Study of University Buildings with Design Adapted to Local Climate. Sustainability 2021, 13, 7155. [Google Scholar] [CrossRef]

- Simhachalam, V.; Wang, T.; Liu, Y.; Wamelink, H.; Montenegro, L.; Gorp, G.V. Accelerating Building Energy Retrofitting with BIM-Enabled BREEAM-NL Assessment. Energies 2021, 14, 8225. [Google Scholar] [CrossRef]

- Filho, M.V.A.P.M.; Costa, B.B.F.D.; Najjar, M.; Figueiredo, K.V.; Mendonça, M.B.D.; Haddad, A.N. Sustainability Assessment of a Low-Income Building: A BIM-LCSA-FAHP-Based Analysis. Buildings 2022, 12, 181. [Google Scholar] [CrossRef]

- Zhan, Z.; Xu, W.; Lin Xu, L.; Qi, X.; Song, W.; Wang, C.; Huang, Z. BIM-Based Green Hospital Building Performance Pre-Evaluation: A Case Study. Sustainability 2022, 14, 2066. [Google Scholar] [CrossRef]

- Albdour, M.S.; Shalby, M.; Salah, A.A.; Alhomaidat, F. Evaluating and Enhancing the Energy Efficiency of Representative Residential Buildings by Applying National and International Standards Using BIM. Energies 2022, 15, 7763. [Google Scholar] [CrossRef]

- Ma, G.; Liu, Y.; Shang, S. A Building Information Model (BIM) and Artificial Neural Network (ANN) Based System for Personal Thermal Comfort Evaluation and Energy Efficient Design of Interior Space. Sustainability 2019, 11, 4972. [Google Scholar] [CrossRef]

- Pučko, Z.; Maučec, D.; Šuman, N. Energy and Cost Analysis of Building Envelope Components Using BIM: A Systematic Approach. Energies 2020, 13, 2643. [Google Scholar] [CrossRef]

- Otero, R.; Frías, E.; Lagüela, S.; Arias, P. Automatic gbXML Modeling from LiDAR Data for Energy Studies. Remote Sens. 2020, 12, 2679. [Google Scholar] [CrossRef]

- Jeon, M.Y.; Yu, J.H. Comparison DOE-2 based Input Data of Building Energy simulation using IFC File Format. In Proceedings of the KICEM Annual Conference, Incheon-si, Republic of Korea, 5 November 2010. [Google Scholar]

- Abdalla, J.A.; Law, K.H. A Framework for a Building Energy Model to Support Energy Performance Rating and Simulation. In Proceedings of the 2014 International Conference on Computing in Civil and Building Engineering, Orlando, FL, USA, 24 June 2014. [Google Scholar]

- Chalal, M.L.; Benachir, M.; White, M.; Shrahily, R. Energy planning and forecasting approaches for supporting physical improvement strategies in the building sector: A review. Renew. Sustain. Energy Rev. 2016, 64, 761–776. [Google Scholar] [CrossRef]

- Eleftheriadis, S.; Mumovic, D.; Greening, P. Life cycle energy efficiency in building structures: A review of current devel-opments and future outlooks based on BIM capabilities. Renew. Sustain. Energy Rev. 2017, 67, 811–825. [Google Scholar] [CrossRef]

- Jeon, S.; Choi, G.S. A study on energy performance index scoring items by level of detail and level of development for BIM. Korean J. Air Cond. Refrig. Eng. 2021, 33, 579–588. [Google Scholar] [CrossRef]

- Abouhamad, M.; Abu-Hamd, M. Life Cycle Assessment Framework for Embodied Environmental Impacts of Building Construction Systems. Sustainability 2021, 13, 461. [Google Scholar] [CrossRef]

- Abanda, F.; Byers, L. An investigation of the impact of building orientation on energy consumption in a domestic building using emerging BIM (Building Information Modelling). Energy 2016, 97, 517–527. [Google Scholar] [CrossRef]

- Cao, X.; Dai, X.; Liu, J. Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Industry Foundation Classes (IFC). Available online: https://www.buildingsmart.org/standards/bsi-standards/industry-foundation-classes/ (accessed on 26 December 2022).

- Information Delivery Manual (IDM). Available online: https://technical.buildingsmart.org/standards/information-delivery-manual/ (accessed on 26 December 2022).

- Model View Definitions (MVD). Available online: https://technical.buildingsmart.org/standards/ifc/mvd/ (accessed on 26 December 2022).

- Korea Law Information Center. Available online: https://www.law.go.kr/ (accessed on 26 December 2022).

| Type of Information | Information Needed | Required | Optional | Data Type | Units |

|---|---|---|---|---|---|

| Building Elements (Opaque-Wall, Roof, Floor, Ceiling, Door) | Added to the list above, the following properties should be included for opaque building elements (e.g., walls, floors, ceilings, roofs, doors, etc.) | ||||

| Composite Thermal Resistance | X | Real | m2-K/W | ||

| Building Elements (Glazing-Curtain Wall, Glazed Door, Skylight, Window) | Windows, curtain walls, glazed doors, and skylights | ||||

| Window Assembly Exterior Surface Color of Glass (clear, bronze, silver, gold, copper, blue, green, gray, mirror) | X | Enum | n/a | ||

| Window Assembly Interior Surface Color of Glass (clear, bronze, silver, gold, copper, blue, green, gray, mirror) | X | Enum | n/a | ||

| Transmittance (Visible) | X | Real | % | ||

| Transmittance (Solar) | X | Real | % | ||

| Composite U-Value | X | Real | W/m2-K | ||

| Shading Coefficient (SC) | X | Real | % | ||

| Solar Heat Gain Coefficient (SHGC) | X | Real | % | ||

| Manufacturer | X | String | n/a | ||

| Product ID | X | String | n/a | ||

| Division | ALT 1 | ALT 2 | ALT 3 |

|---|---|---|---|

| IFC Building Envelope Data | Polygonal Type: 6 Radius: 30 m | Rectangular Dimension: 30 m × 30 m | Circular Radius 1: 30 m Radius 2: 30 m |

|  |  | |

|  |  | |

| S/W | Grasshopper (Geometry Gym Plugin) | ||

| IFC ver. | IFC2 × 3 | ||

| Division | Contents | |

|---|---|---|

| Location | Seoul | |

| Latitude | 37.313394 | |

| Longitude | 126.554151 | |

| Scale | Height | 318 m |

| Storey | 69 | |

| Sky height | 4.6 | |

| Design Temperature | Cooling(°C) | Outside: 32 °C Inside: 27 °C |

| Heating (°C) | Outside: −8 °C Inside: 20 °C | |

| Indoor Heat | Occupant (W/m2) | Sensible heat: 20 Latent heat: 35 Residence density: 31 |

| Light (W/m2) | 20 | |

| Equipment (W/m2) | 20 | |

| Infiltration | Air change | 0.5 ac/h |

| U-value | External wall | 0.47 |

| Roof | 0.29 | |

| Slab | 0.58 | |

| Window/Door | 3.40 | |

| SHGC | Window/Door | 0.53 |

| Solar Absorption | Window/Door | 0.50 |

| ALT 1 | ALT 2 | ALT 3 | ||||

|---|---|---|---|---|---|---|

| Cooling (kW) | Heating (kW) | Cooling (kW) | Heating (kW) | Cooling (kW) | Heating (kW) | |

| External wall conduction | 80.9 | 96 | 67.9 | 96 | 93.9 | 96 |

| Roof conduction | 62.9 | 95.2 | 58.5 | 88.5 | 69 | 98.5 |

| Window conduction | 187.1 | 351.6 | 160.8 | 250.9 | 460.8 | 390.9 |

| Window sunrise | 590.8 | - | 331.6 | - | 691.6 | - |

| Occupational heat | 185 | - | 185 | - | 185 | - |

| Light heat | 298 | - | 298 | - | 298 | - |

| Equipment heat | 385.1 | - | 385.1 | - | 385.1 | - |

| Intrusion outside | 190.2 | 194.9 | 190.2 | 194.9 | 190.2 | 194.9 |

| Total | 1980.0 | 737.7 | 1677.1 | 630.3 | 2373.6 | 780.3 |

| ALT 1 | ALT 2 | ALT 3 | ||||

|---|---|---|---|---|---|---|

| Cooling (kW) | Heating (kW) | Cooling (kW) | Heating (kW) | Cooling (kW) | Heating (kW) | |

| Evaluation program developed in this study | 1980.0 | 737.7 | 1677.1 | 630.3 | 2373.6 | 780.3 |

| EnergyPlus | 2017.9 | 749.5 | 1720.9 | 640.8 | 2429.6 | 791.2 |

| Difference | −37.9 (1.97%) | −11.8 (1.65%) | −43.8 (2.70%) | −10.5 (1.73%) | −56 (2.42%) | −10.9 (1.44%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, J.; Lee, S. A Suggestion of the Alternatives Evaluation Method through IFC-Based Building Energy Performance Analysis. Sustainability 2023, 15, 1797. https://doi.org/10.3390/su15031797

Choi J, Lee S. A Suggestion of the Alternatives Evaluation Method through IFC-Based Building Energy Performance Analysis. Sustainability. 2023; 15(3):1797. https://doi.org/10.3390/su15031797

Chicago/Turabian StyleChoi, Jungsik, and Sejin Lee. 2023. "A Suggestion of the Alternatives Evaluation Method through IFC-Based Building Energy Performance Analysis" Sustainability 15, no. 3: 1797. https://doi.org/10.3390/su15031797

APA StyleChoi, J., & Lee, S. (2023). A Suggestion of the Alternatives Evaluation Method through IFC-Based Building Energy Performance Analysis. Sustainability, 15(3), 1797. https://doi.org/10.3390/su15031797