Environmental Sustainability of Industrial Waste-Based Cementitious Materials: A Review, Experimental Investigation and Life-Cycle Assessment

Abstract

:1. Introduction

2. Methods

3. Review of the Performance of Waste-Based Cementitious Materials

3.1. Fly Ash (FA)

3.2. Blast Furnace Slag (BFS)

3.3. Bottom Ash (BA)

3.4. Recycled Glass (RG)

3.5. Ferronickel Slag (FNS)

3.6. Expanded Polystyrene (EPS)

3.7. Wood Waste

4. Mix Design and Compressive Strength

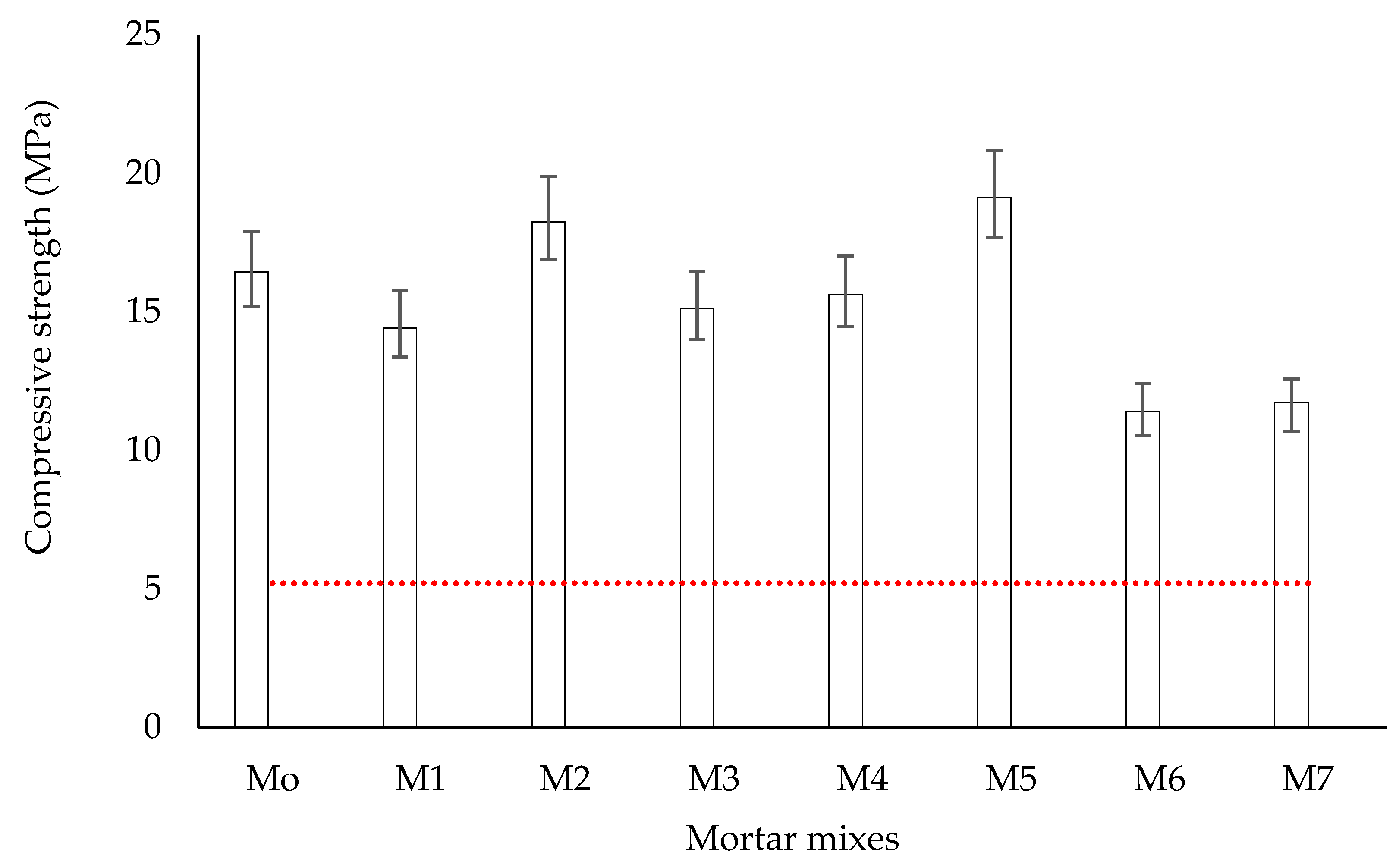

Compressive Strength Tests

5. Environmental Impact Analysis

- This LCA did not assign the impact allocation. This was due to the inadequate available data, as it was difficult to obtain all the waste-based materials. Furthermore, the waste materials are produced as a by-product and not produced for the cementitious materials. Thus, this creates small impacts in environmental impact analysis. Similar approaches have been used by many studies [38,98,99,102,103,104].

- The transport distance of fine aggregates and both cement and waste-based materials to mortar manufacture was assumed to be 50 km and 100 km, respectively.

- The transport travel distance of mortar to the building construction site was assumed to be 40 km.

6. Results and Discussion

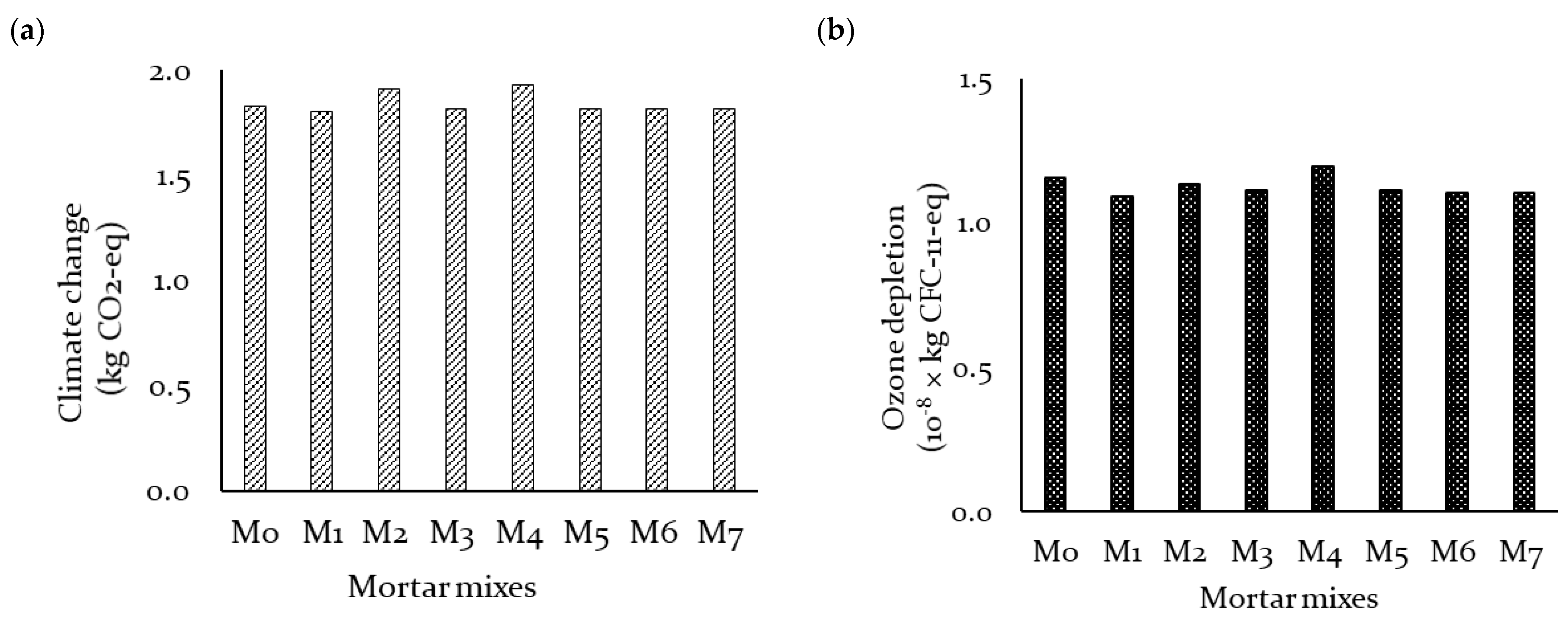

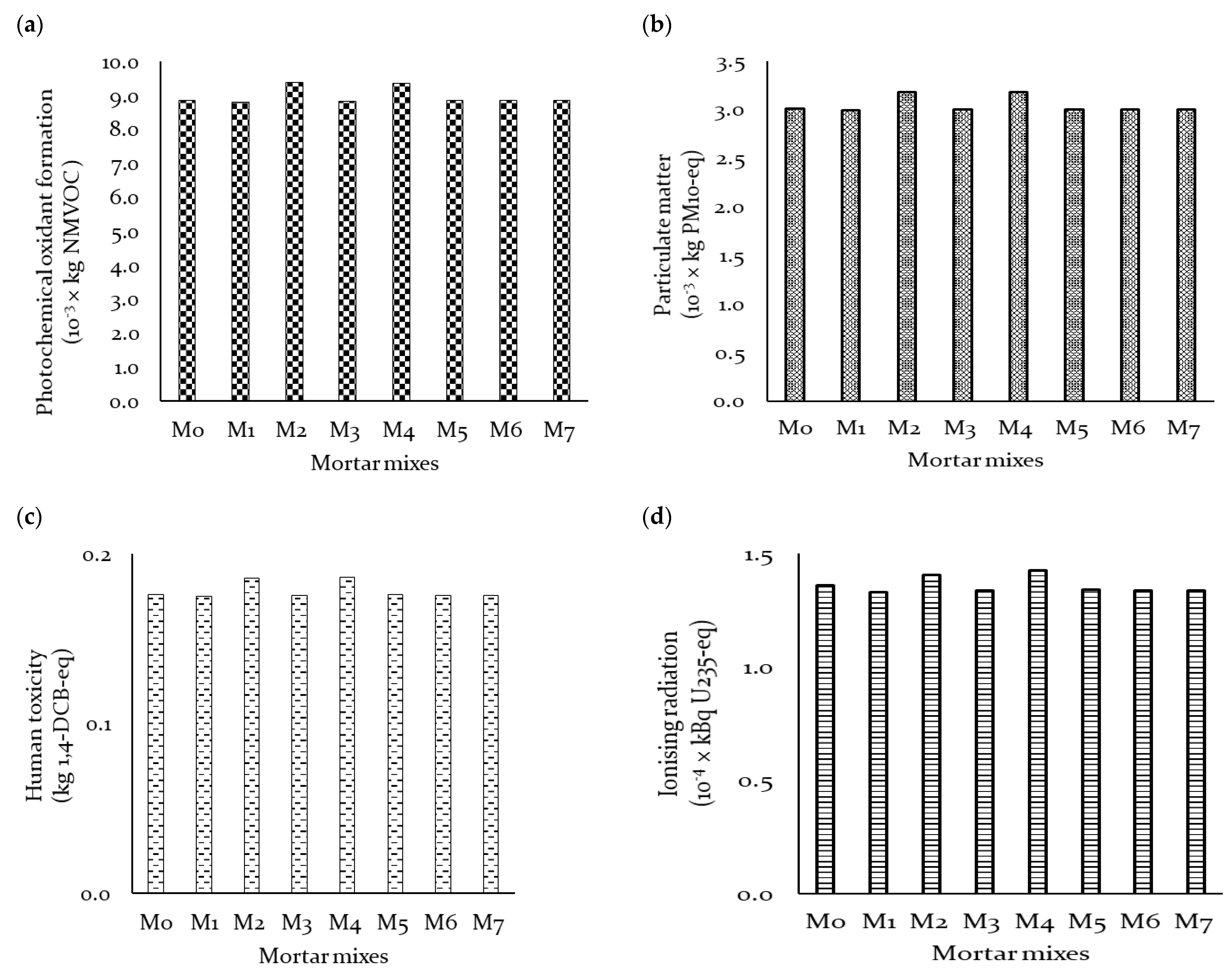

6.1. Impacts on Human Health

6.2. Impacts on the Ecosystem Quality

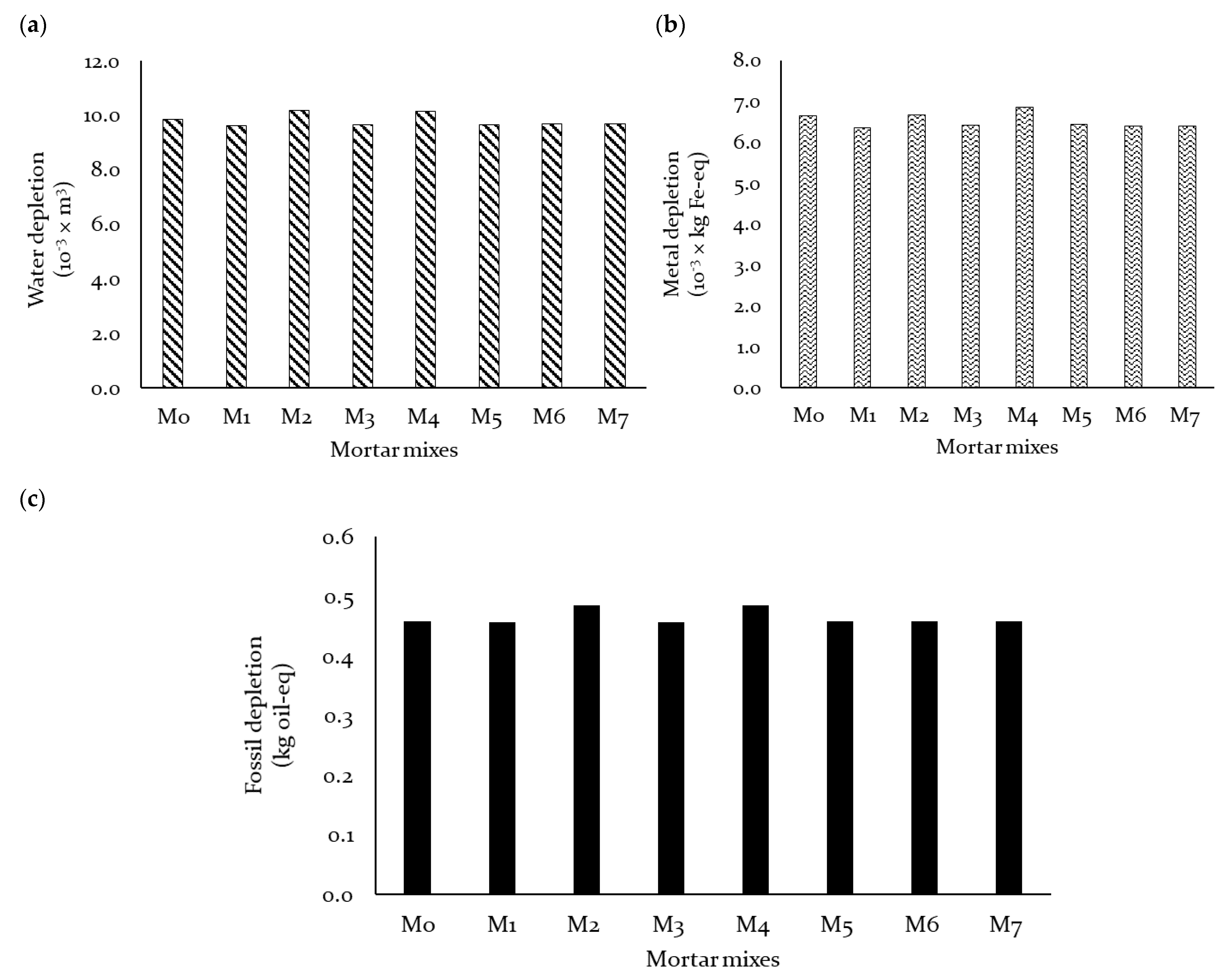

6.3. Impacts on Resources

6.4. Uncertainty Analysis on Design Mixture

6.5. Endpoint Impact Assessment of Design Mix

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nguyen, K.T.Q.; Navaratnam, S.; Mendis, P.; Zhang, K.; Barnett, J.; Wang, H. Fire safety of composites in prefabricated buildings: From fibre reinforced polymer to textile reinforced concrete. Compos. Part B Eng. 2020, 187, 107815. [Google Scholar] [CrossRef]

- Keerthan, P.; Mahendran, M. Improved shear design rules of cold-formed steel beams. Eng. Struct. 2015, 99, 603–615. [Google Scholar] [CrossRef] [Green Version]

- Satheeskumar, N. Wind Load Sharing and Vertical Load Transfer from Roof to Wall in a Timber-Framed House; James Cook University: Townsville, Australia, 2016. [Google Scholar]

- Acordi, J.; Luza, A.; Fabris, D.C.N.; Raupp-Pereira, F.; De Noni, A., Jr.; Montedo, O.R.K. New waste-based supplementary cementitious materials: Mortars and concrete formulations. Constr. Build. Mater. 2020, 240, 117877. [Google Scholar] [CrossRef]

- Gao, S.; Zhang, S.; Guo, L. Application of Coal Gangue as a Coarse Aggregate in Green Concrete Production: A Review. Materials 2021, 14, 6803. [Google Scholar] [CrossRef]

- Gao, S.; Cui, X.; Zhang, S. Utilization of Molybdenum Tailings in Concrete Manufacturing: A Review. Appl. Sci. 2020, 10, 138. [Google Scholar] [CrossRef] [Green Version]

- Dash, M.K.; Patro, S.K.; Rath, A.K. Sustainable use of industrial-waste as partial replacement of fine aggregate for preparation of concrete—A review. Int. J. Sustain. Built Environ. 2016, 5, 484–516. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Zhang, W.; Li, C.; Monteiro, P.J. Eco-friendly mortar with high-volume diatomite and fly ash: Performance and life-cycle assessment with regional variability. J. Clean. Prod. 2020, 261, 121224. [Google Scholar] [CrossRef]

- Mailar, G.; Sujay Raghavendra, N.; Hiremath, P.; Sreedhara, B.M.; Manu, D.S. Sustainable utilization of discarded foundry sand and crushed brick masonry aggregate in the production of lightweight concrete. Eng. Struct. Technol. 2017, 9, 52–61. [Google Scholar] [CrossRef]

- Javali, S.; Chandrashekar, A.R.; Naganna, S.R.; Manu, D.S.; Hiremath, P.; Preethi, H.G.; Kumar, N.V. Eco-concrete for sustainability: Utilizing aluminium dross and iron slag as partial replacement materials. Clean Technol. Environ. Policy 2017, 19, 2291–2304. [Google Scholar] [CrossRef]

- Naganna, S.R.; Jayakesh, K.; Anand, V.R. Nano-TiO2 particles: A photocatalytic admixture to amp up the performance efficiency of cementitious composites. Sādhanā 2020, 45, 280. [Google Scholar] [CrossRef]

- Sikora, P.; Horszczaruk, E.; Skoczylas, K.; Rucinska, T. Thermal Properties of Cement Mortars Containing Waste Glass Aggregate and Nanosilica. Procedia Eng. 2017, 196, 159–166. [Google Scholar] [CrossRef]

- Zhang, B.; He, P.; Poon, C.S. Improving the high temperature mechanical properties of alkali activated cement (AAC) mortars using recycled glass as aggregates. Cem. Concr. Compos. 2020, 112, 103654. [Google Scholar] [CrossRef]

- Guo, M.-Z.; Tu, Z.; Poon, C.S.; Shi, C. Improvement of properties of architectural mortars prepared with 100% recycled glass by CO2 curing. Constr. Build. Mater. 2018, 179, 138–150. [Google Scholar] [CrossRef]

- Sales, R.B.C.; Sales, F.A.; Figueiredo, E.P.; dos Santos, W.J.; Mohallem, N.D.S.; Aguilar, M.T.P. Durability of Mortar Made with Fine Glass Powdered Particles. Adv. Mater. Sci. Eng. 2017, 2017, 3143642. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Ling, T.-C.; Mo, K.H. Functions and impacts of plastic/rubber wastes as eco-friendly aggregate in concrete – A review. Constr. Build. Mater. 2020, 240, 117869. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Mazzoli, A.; Moriconi, G. Mechanical Behaviour and Thermal Conductivity of Mortars with Waste Plastic Particles. Key Eng. Mater. 2011, 466, 115–120. [Google Scholar] [CrossRef]

- Lanzón, M.; Cnudde, V.; De Kock, T.; Dewanckele, J. Microstructural examination and potential application of rendering mortars made of tire rubber and expanded polystyrene wastes. Constr. Build. Mater. 2015, 94, 817–825. [Google Scholar] [CrossRef]

- Ameri, F.; Shoaei, P.; Musaeei, H.R.; Zareei, S.A.; Cheah, C.B. Corrigendum to “Partial replacement of copper slag with treated crumb rubber aggregates in alkali-activated slag mortar”. Constr. Build. Mater. 2020, 256, 119468, Erratum in Constr. Build. Mater. 2021, 283, 123212. [Google Scholar] [CrossRef]

- Di Mundo, R.; Seara-Paz, S.; Gonzalez-Fonteboa, B.; Notarnicola, M. Masonry and render mortars with tyre rubber as aggregate: Fresh state rheology and hardened state performances. Constr. Build. Mater. 2020, 245, 118359. [Google Scholar] [CrossRef]

- Saha, A.K.; Sarker, P.K.; Golovanevskiy, V. Thermal properties and residual strength after high temperature exposure of cement mortar using ferronickel slag aggregate. Constr. Build. Mater. 2019, 199, 601–612. [Google Scholar] [CrossRef]

- Cheah, C.B.; Ramli, M. The implementation of wood waste ash as a partial cement replacement material in the production of structural grade concrete and mortar: An overview. Resour. Conserv. Recycl. 2011, 55, 669–685. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Mazzoli, A.; Siddique, R. Characterization of lightweight mortars containing wood processing by-products waste. Constr. Build. Mater. 2016, 123, 281–289. [Google Scholar] [CrossRef]

- Pavlíková, M.; Zemanová, L.; Pokorný, J.; Záleská, M.; Jankovský, O.; Lojka, M.; Sedmidubský, D.; Pavlík, Z. Valorization of wood chips ash as an eco-friendly mineral admixture in mortar mix design. Waste Manag. 2018, 80, 89–100. [Google Scholar] [CrossRef]

- Ottosen, L.M.; Hansen, E.Ø.; Jensen, P.E.; Kirkelund, G.M.; Golterman, P. Wood ash used as partly sand and/or cement replacement in mortar. Int. J. Sustain. Dev. Plan. 2016, 11, 781–791. [Google Scholar] [CrossRef] [Green Version]

- Tamanna, K.; Raman, S.N.; Jamil, M.; Hamid, R. Utilization of wood waste ash in construction technology: A review. Constr. Build. Mater. 2020, 237, 117654. [Google Scholar] [CrossRef]

- Milling, A.; Mwasha, A.; Martin, H. Exploring the full replacement of cement with expanded polystyrene (EPS) waste in mortars used for masonry construction. Constr. Build. Mater. 2020, 253, 119158. [Google Scholar] [CrossRef]

- Shi, J.; Liu, Y.; Liu, B.; Han, D. Temperature Effect on the Thermal Conductivity of Expanded Polystyrene Foamed Concrete: Experimental Investigation and Model Correction. Adv. Mater. Sci. Eng. 2019, 2019, 8292379. [Google Scholar] [CrossRef] [Green Version]

- Ferrándiz-Mas, V.; Bond, T.; García-Alcocel, E.; Cheeseman, C.R. Lightweight mortars containing expanded polystyrene and paper sludge ash. Constr. Build. Mater. 2014, 61, 285–292. [Google Scholar] [CrossRef] [Green Version]

- Singh, M.; Siddique, R. Effect of coal bottom ash as partial replacement of sand on properties of concrete. Resour. Conserv. Recycl. 2013, 72, 20–32. [Google Scholar] [CrossRef]

- Ghafoori, N.; Bucholc, J. Properties of high-calcium dry bottom ash concrete. ACI Mater. J. 1997, 94, 90–101. [Google Scholar]

- Erdoğdu, K.; Türker, P. Effects of fly ash particle size on strength of portland cement fly ash mortars. Cem. Concr. Res. 1998, 28, 1217–1222. [Google Scholar] [CrossRef]

- Bentz, D.P.; Peltz, M.A.; Duran-Herrera, A.; Valdez, P.; Juarez, C.A. Thermal properties of high-volume fly ash mortars and concretes. J. Build. Phys. 2010, 34, 263–275. [Google Scholar] [CrossRef]

- Adesanya, E.; Aladejare, A.; Adediran, A.; Lawal, A.; Illikainen, M. Predicting shrinkage of alkali-activated blast furnace-fly ash mortars using artificial neural network (ANN). Cem. Concr. Compos. 2021, 124, 104265. [Google Scholar] [CrossRef]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Antiohos, S.; Papadakis, V.; Tsimas, S. Rice husk ash (RHA) effectiveness in cement and concrete as a function of reactive silica and fineness. Cem. Concr. Res. 2014, 61–62, 20–27. [Google Scholar] [CrossRef]

- Zain, M.; Islam, M.; Mahmud, F.; Jamil, M. Production of rice husk ash for use in concrete as a supplementary cementitious material. Constr. Build. Mater. 2011, 25, 798–805. [Google Scholar] [CrossRef]

- Selvaranjan, K.; Navaratnam, S.; Gamage, J.; Thamboo, J.; Siddique, R.; Zhang, J.; Zhang, G. Thermal and environmental impact analysis of rice husk ash-based mortar as insulating wall plaster. Constr. Build. Mater. 2021, 283. [Google Scholar] [CrossRef]

- Selvaranjan, K.; Gamage, J.; De Silva, G.; Navaratnam, S. Development of sustainable mortar using waste rice husk ash from rice mill plant: Physical and thermal properties. J. Build. Eng. 2021, 43, 102614. [Google Scholar] [CrossRef]

- ASTM C 270-07; Standard Specification for Mortar for Unit Masonry. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM C 1437-07; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2009.

- Singh, N.; Shehnazdeep; Bhardwaj, A. Reviewing the role of coal bottom ash as an alternative of cement. Constr. Build. Mater. 2020, 233, 117276. [Google Scholar] [CrossRef]

- Bhatt, A.; Priyadarshini, S.; Mohanakrishnan, A.A.; Abri, A.; Sattler, M.; Techapaphawit, S. Physical, chemical, and geotechnical properties of coal fly ash: A global review. Case Stud. Constr. Mater. 2019, 11, e00263. [Google Scholar] [CrossRef]

- Petersen; Pandian, N.; Rajasekhar, C.; Sridharan, A. Studies of the Specific Gravity of Some Indian Coal Ashes. J. Test. Evaluation 1998, 26, 177. [Google Scholar] [CrossRef]

- Shaikh, F.U.; Supit, S.W. Mechanical and durability properties of high volume fly ash (HVFA) concrete containing calcium carbonate (CaCO3) nanoparticles. Constr. Build. Mater. 2014, 70, 309–321. [Google Scholar] [CrossRef]

- Ma, J.; Wang, D.; Zhao, S.; Duan, P.; Yang, S. Influence of Particle Morphology of Ground Fly Ash on the Fluidity and Strength of Cement Paste. Materials 2021, 14, 283. [Google Scholar] [CrossRef]

- Mirza, J.; Mirza, M.; Roy, V.; Saleh, K. Basic rheological and mechanical properties of high-volume fly ash grouts. Constr. Build. Mater. 2002, 16, 353–363. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Supit, S.W.M.; Sarker, P.K. A study on the effect of nano silica on compressive strength of high volume fly ash mortars and concretes. Mater. Des. 2014, 60, 433–442. [Google Scholar] [CrossRef]

- Supit, S.W.; Shaikh, F.U.; Sarker, P.K. Effect of Nano Silica and Ultrafine Fly Ash on Compressive Strength of High Volume Fly Ash Mortar. Appl. Mech. Mater. 2013, 368-370, 1061–1065. [Google Scholar] [CrossRef]

- Li, L.; Zhou, W.; Dao, V.; Ozgakkaloglu, T.; Liu, X. Properties of cement-based materials containing fly ash. In Proceedings of the International Conference on Performance-Based and Life-Cycle Structural Engineering, Brisbane, Australia, 9–11 December 2015; pp. 1543–1554. [Google Scholar] [CrossRef] [Green Version]

- Jiang, L.; Guan, Y. Pore structure and its effect on strength of high-volume fly ash paste. Cem. Concr. Res. 1999, 29, 631–633. [Google Scholar] [CrossRef]

- Shi, C.; Qian, J. Activated blended cement containing high volume coal fly ash. Adv. Cem. Res. 2001, 13, 157–163. [Google Scholar] [CrossRef]

- Ghosh, A.; Ghosh, A.; Neogi, S. Reuse of fly ash and bottom ash in mortars with improved thermal conductivity performance for buildings. Heliyon 2018, 4, e00934. [Google Scholar] [CrossRef] [Green Version]

- Bicer, A. Effect of fly ash particle size on thermal and mechanical properties of fly ash-cement composites. Therm. Sci. Eng. Prog. 2018, 8, 78–82. [Google Scholar] [CrossRef]

- Sakir, S.; Raman, S.N.; Safiuddin; Kaish, A.B.M.A.; Mutalib, A.A. Utilization of By-Products and Wastes as Supplementary Cementitious Materials in Structural Mortar for Sustainable Construction. Sustainability 2020, 12, 3888. [Google Scholar] [CrossRef]

- Colangelo, F.; Forcina, A.; Farina, I.; Petrillo, A. Life Cycle Assessment (LCA) of Different Kinds of Concrete Containing Waste for Sustainable Construction. Buildings 2018, 8, 70. [Google Scholar] [CrossRef] [Green Version]

- Sankh, A.C.; Biradar, P.M.; Naghathan, S.J.; Ishwargol, M.B. Recent Trends in Replacement of Natural Sand with Different Alternatives. In Proceedings of the International Conference on Advances in Engineering and Technology, Unnao, Kanpur, India, 1–2 August 2014. [Google Scholar]

- Yuksel, I.; Genç, A. Properties of concrete containing non-ground ash and slag as fine aggregate. Aci Mater. J. 2007, 104, 397–403. [Google Scholar]

- Yüksel, İ.; Bilir, T.; Özkan, Ö. Durability of concrete incorporating non-ground blast furnace slag and bottom ash as fine aggregate. Build. Environ. 2007, 42, 2651–2659. [Google Scholar] [CrossRef]

- Yüksel, I.; Özkan, Ö.; Bilir, T. Use of Granulated Blast-Furnace Slag in Concrete as Fine Aggregate. Aci Mater. J. 2006, 103, 203–208. [Google Scholar]

- Mohamed, O.A. A Review of Durability and Strength Characteristics of Alkali-Activated Slag Concrete. Materials 2019, 12, 1198. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- López, M.M.; Pineda, Y.; Gutiérrez, O. Evaluation of Durability and Mechanical Properties of the Cement Mortar Added with Slag Blast Furnace. Procedia Mater. Sci. 2015, 9, 367–376. [Google Scholar] [CrossRef] [Green Version]

- Khatib, J.; Hibbert, J. Selected engineering properties of concrete incorporating slag and metakaolin. Constr. Build. Mater. 2005, 19, 460–472. [Google Scholar] [CrossRef]

- Rashad, A.M.; Sadek, D.M.; Hassan, H.A. An investigation on blast-furnace stag as fine aggregate in alkali-activated slag mortars subjected to elevated temperatures. J. Clean. Prod. 2016, 112, 1086–1096. [Google Scholar] [CrossRef]

- Singh, M. 1-Coal bottom ash. In Waste and Supplementary Cementitious Materials in Concrete; Siddique, R., Cachim, P., Eds.; Woodhead Publishing: Sawston, UK, 2018; pp. 3–50. [Google Scholar]

- Hashemi, S.S.G.; Bin Mahmud, H.; Djobo, J.N.Y.; Tan, C.G.; Ang, B.C.; Ranjbar, N. Microstructural characterization and mechanical properties of bottom ash mortar. J. Clean. Prod. 2018, 170, 797–804. [Google Scholar] [CrossRef]

- Hannan, N.I.R.R.; Shahidan, S.; Ali, N.; Maarof, M.Z. A Comprehensive Review on the Properties of Coal Bottom Ash in Concrete as Sound Absorption Material. MATEC Web Conf. 2017, 103, 1005. [Google Scholar] [CrossRef] [Green Version]

- Jaturapitakkul, C.; Cheerarot, R. Development of Bottom Ash as Pozzolanic Material. J. Mater. Civ. Eng. 2003, 15, 48–53. [Google Scholar] [CrossRef]

- Abdulmatin, A.; Tangchirapat, W.; Jaturapitakkul, C. An investigation of bottom ash as a pozzolanic material. Constr. Build. Mater. 2018, 186, 155–162. [Google Scholar] [CrossRef]

- Oruji, S.; Brake, N.A.; Nalluri, L.; Guduru, R.K. Strength activity and microstructure of blended ultra-fine coal bottom ash-cement mortar. Constr. Build. Mater. 2017, 153, 317–326. [Google Scholar] [CrossRef]

- Torkittikul, P.; Nochaiya, T.; Wongkeo, W.; Chaipanich, A. Utilization of coal bottom ash to improve thermal insulation of construction material. J. Mater. Cycles Waste Manag. 2015, 19, 305–317. [Google Scholar] [CrossRef]

- Lu, J.-X.; Duan, Z.-H.; Poon, C.S. Combined use of waste glass powder and cullet in architectural mortar. Cem. Concr. Compos. 2017, 82, 34–44. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete–A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Borhan, T. Properties of glass concrete reinforced with short basalt fibre. Mater. Des. 2012, 42, 265–271. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Effect of particle size on alkali–silica reaction in recycled glass mortars. Constr. Build. Mater. 2014, 66, 275–285. [Google Scholar] [CrossRef]

- Rashad, A.M. Recycled waste glass as fine aggregate replacement in cementitious materials based on Portland cement. Constr. Build. Mater. 2014, 72, 340–357. [Google Scholar] [CrossRef]

- Islam, G.S.; Rahman, M.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Nassar, R.-U.; Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar] [CrossRef]

- Aly, M.; Hashmi, M.; Olabi, A.; Messeiry, M.; Hussain, A. Effect of nano clay particles on mechanical, thermal and physical behaviours of waste-glass cement mortars. Mater. Sci. Eng. A 2011, 528, 7991–7998. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Properties of high volume glass powder concrete. Cem. Concr. Compos. 2017, 75, 22–29. [Google Scholar] [CrossRef]

- Liu, S.; Xie, G.; Wang, S. Effect of curing temperature on hydration properties of waste glass powder in cement-based materials. J. Therm. Anal. Calorim. 2015, 119, 47–55. [Google Scholar] [CrossRef]

- Saha, A.K.; Sarker, P.K. Sustainable use of ferronickel slag fine aggregate and fly ash in structural concrete: Mechanical properties and leaching study. J. Clean. Prod. 2017, 162, 438–448. [Google Scholar] [CrossRef]

- Bouasria, M.; Babouri, L.; Khadraoui, F.; Chateigner, D.; Gascoin, S.; Pralong, V.; Benzaama, M.-H.; Orberger, B.; El Mendili, Y. Insight into the partial replacement of cement by ferronickel slags from New Caledonia. Eur. J. Environ. Civ. Eng. 2020, 26, 3662–3680. [Google Scholar] [CrossRef]

- Saha, A.K.; Khan, M.; Sarker, P.K. Value added utilization of by-product electric furnace ferronickel slag as construction materials: A review. Resour. Conserv. Recycl. 2018, 134, 10–24. [Google Scholar] [CrossRef] [Green Version]

- Rahman, M.A.; Sarker, P.K.; Shaikh, F.U.A.; Saha, A.K. Soundness and compressive strength of Portland cement blended with ground granulated ferronickel slag. Constr. Build. Mater. 2017, 140, 194–202. [Google Scholar] [CrossRef] [Green Version]

- Kan, A.; Demirboğa, R. A new technique of processing for waste-expanded polystyrene foams as aggregates. J. Mater. Process. Technol. 2009, 209, 2994–3000. [Google Scholar] [CrossRef]

- Babavalian, A.; Ranjbaran, A.H.; Shahbeyk, S. Uniaxial and triaxial failure strength of fiber reinforced EPS concrete. Constr. Build. Mater. 2020, 247, 118617. [Google Scholar] [CrossRef]

- Koksal, F.; Mutluay, E.; Gencel, O. Characteristics of isolation mortars produced with expanded vermiculite and waste expanded polystyrene. Constr. Build. Mater. 2020, 236, 117789. [Google Scholar] [CrossRef]

- Tittarelli, F.; Giosuè, C.; Mobili, A.; di Perna, C.; Monosi, S. Effect of Using Recycled Instead of Virgin EPS in Lightweight Mortars. Procedia Eng. 2016, 161, 660–665. [Google Scholar] [CrossRef] [Green Version]

- Moriconi, G.; Tittarelli, F.; Corinaldesi, V. Review of silicone-based hydrophobic treatment and admixtures for concrete. Indian Concr. J. 2002, 76, 637–642. [Google Scholar]

- Brás, A.; Leal, M.; Faria, P. Cement-cork mortars for thermal bridges correction. Comparison with cement-EPS mortars performance. Constr. Build. Mater. 2013, 49, 315–327. [Google Scholar] [CrossRef]

- Navaratnam, S.; Wijaya, H.; Rajeev, P.; Mendis, P.; Nguyen, K. Residual stress-strain relationship for the biochar-based mortar after exposure to elevated temperature. Case Stud. Constr. Mater. 2021, 14, e00540. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Koh, H.J. Application of biochar from food and wood waste as green admixture for cement mortar. Sci. Total. Environ. 2018, 619–620, 419–435. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Low, C.Y. Use of biochar as carbon sequestering additive in cement mortar. Cem. Concr. Compos. 2018, 87, 110–129. [Google Scholar] [CrossRef]

- Goedkoop, M.; Oele, M.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction to LCA with SimaPro Colophon. 2016. Available online: www.pre-sustainability.com (accessed on 18 June 2022).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- AS ISO 14040; Environmental Management-Life Cycle Assessment-Principles and Framework. Standards Australia: Sydney, Australia, 2019.

- DS/EN 15978; Sustainability of construction works–Assessment of environmental performance of buildings–Calculation method. NSAI: Dublin, Ireland, 2012.

- Sathurshan, M.; Yapa, I.; Thamboo, J.; Jeyakaran, T.; Navaratnam, S.; Siddique, R.; Zhang, J. Untreated rice husk ash incorporated high strength self-compacting concrete: Properties and environmental impact assessments. Environ. Challenges 2020, 2, 100015. [Google Scholar] [CrossRef]

- Pushkar, S. The Effect of Different Concrete Designs on the Life-Cycle Assessment of the Environmental Impacts of Concretes Containing Furnace Bottom-Ash Instead of Sand. Sustainability 2019, 11, 4083. [Google Scholar] [CrossRef] [Green Version]

- ELCD, European reference Life Cycle Database (ECLD), EU SCIENCE HUB. 2016. Available online: www.ec.europa.eu (accessed on 15 May 2021).

- AusLCI, Australian National Life Cycle Inventory Database (AusLCI), alcas.asn.au, Auustralia. 2016. Available online: https://www.auslci.com.au/ (accessed on 15 May 2021).

- Seto, K.E.; Churchill, C.J.; Panesar, D.K. Influence of fly ash allocation approaches on the life cycle assessment of cement-based materials. J. Clean. Prod. 2017, 157, 65–75. [Google Scholar] [CrossRef]

- Dissanayake, D.; Jayasinghe, C.; Jayasinghe, M. A comparative embodied energy analysis of a house with recycled expanded polystyrene (EPS) based foam concrete wall panels. Energy Build. 2017, 135, 85–94. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Tucker, E.L.; Ferraro, C.C.; Laux, S.J.; Townsend, T.G. Economic and life cycle assessment of recycling municipal glass as a pozzolan in portland cement concrete production. Resour. Conserv. Recycl. 2018, 129, 240–247. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A.; Ventura, A. LCA allocation procedure used as an incitative method for waste recycling: An application to mineral additions in concrete. Resour. Conserv. Recycl. 2010, 54, 1231–1240. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Zhu, Y.; Yang, T.; Li, L.; Zhu, H.; Wang, H. Conversion of local industrial wastes into greener cement through geopolymer technology: A case study of high-magnesium nickel slag. J. Clean. Prod. 2017, 141, 463–471. [Google Scholar] [CrossRef]

- Gomes, R.; Silvestre, J.D.; de Brito, J. Environmental life cycle assessment of the manufacture of EPS granulates, lightweight concrete with EPS and high-density EPS boards. J. Build. Eng. 2020, 28, 101031. [Google Scholar] [CrossRef]

- Tushar, Q.; Santos, J.; Zhang, G.; Bhuiyan, M.A.; Giustozzi, F. Recycling waste vehicle tyres into crumb rubber and the transition to renewable energy sources: A comprehensive life cycle assessment. J. Environ. Manag. 2022, 323, 116289. [Google Scholar] [CrossRef]

- Korol, J.; Burchart-Korol, D.; Pichlak, M. Expansion of environmental impact assessment for eco-efficiency evaluation of biocomposites for industrial application. J. Clean. Prod. 2016, 113, 144–152. [Google Scholar] [CrossRef]

- Tushar, Q.; A Bhuiyan, M.; Zhang, G.; Maqsood, T.; Tasmin, T. Application of a harmonized life cycle assessment method for supplementary cementitious materials in structural concrete. Constr. Build. Mater. 2021, 316, 125850. [Google Scholar] [CrossRef]

- Tushar, Q.; Zhang, G.; Bhuiyan, M.A.; Giustozzi, F.; Navaratnam, S.; Hou, L. An optimized solution for retrofitting building façades: Energy efficiency and cost-benefit analysis from a life cycle perspective. J. Clean. Prod. 2022, 376, 134257. [Google Scholar] [CrossRef]

| Search String | Sources | |

|---|---|---|

| WoS | Scopus | |

| “Mortar” AND “Recycled glass” | 147 | 106 |

| “Mortar” AND “Bottom ash” | 261 | 251 |

| “Mortar” AND “Rubber waste” | 16 | 21 |

| “Mortar” AND “Ferronickel slag” | 46 | 32 |

| “Mortar” AND “Wood waste” | 37 | 28 |

| “Mortar” AND “Fly ash” | 3315 | 2934 |

| “Mortar” AND “Blast furnace slag” | 928 | 1098 |

| “Mortar” AND “EPS” AND “Expanded polystyrene” | 44 | 54 |

| “Mortar” AND “Date palm” | 45 | 35 |

| “Mortar” AND “Rice Husk Ash” AND “RHA” | 123 | 169 |

| Mixes (g) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Materials | Mo | M1 | M2 | M3 | M4 | M5 | M6 | M7 |

| Cement | 222 | 189 | 189 | 200 | 222 | 200 | 195 | 202 |

| Sand | 666 | 526 | 526 | 510 | 516 | 535 | 495 | 528 |

| Water | 112 | 135 | 135 | 140 | 112 | 115 | 160 | 120 |

| FA | 150 | |||||||

| BFS | 150 | |||||||

| BA | 150 | |||||||

| RG | 150 | |||||||

| FNS | 150 | |||||||

| EPS | 150 | |||||||

| WA | 150 | |||||||

| Impact Category | Unit | Mortar Mixes | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mo | M1 | M2 | M3 | M4 | M5 | M6 | M7 | ||

| Terrestrial acidification | 10−3 × kg SO2-eq | 9.49 | 9.45 | 10.05 | 9.47 | 10.04 | 9.49 | 9.48 | 9.48 |

| Freshwater eutrophication | 10−6 × kg P-eq | 6.26 | 6.00 | 6.30 | 6.07 | 6.50 | 6.09 | 6.05 | 6.05 |

| Marine eutrophication | 10−4 × kg N-eq | 2.92 | 2.90 | 3.09 | 2.91 | 3.09 | 2.92 | 2.91 | 2.91 |

| Terrestrial ecotoxicity | 10−5 × kg 1,4-DB-eq | 5.99 | 5.97 | 6.35 | 5.98 | 6.34 | 5.99 | 5.99 | 5.99 |

| Freshwater ecotoxicity | 10−3 × kg 1,4-DB-eq | 3.30 | 3.28 | 3.48 | 3.29 | 3.49 | 3.29 | 3.29 | 3.29 |

| Marine ecotoxicity | 10−3 × kg 1,4-DB-eq | 3.19 | 3.17 | 3.36 | 3.18 | 3.37 | 3.18 | 3.18 | 3.18 |

| Agricultural land occupation | 10−3 × m2a | 3.63 | 3.32 | 3.42 | 3.41 | 3.70 | 3.42 | 3.37 | 3.37 |

| Urban land occupation | 10−3 × m2a | 2.74 | 2.49 | 2.57 | 2.54 | 2.73 | 2.55 | 2.50 | 2.50 |

| Natural land transformation | 10−5 × m2 | 4.09 | 3.90 | 4.10 | 3.92 | 4.16 | 3.94 | 3.90 | 3.90 |

| Design Mixture | Mean | Median | Standard Deviation | Coefficient of Variation (CV) | Confidence Interval (CI) | |

|---|---|---|---|---|---|---|

| 2.5% | 97.5% | |||||

| Mo | 1.83 | 1.79 | 0.25 | 13.66 | 1.55 | 2.21 |

| M1 | 1.80 | 1.75 | 0.18 | 10.01 | 1.41 | 2.02 |

| M2 | 1.91 | 1.89 | 0.21 | 10.99 | 1.56 | 2.39 |

| M3 | 1.81 | 1.77 | 0.23 | 12.71 | 1.52 | 2.08 |

| M4 | 1.93 | 1.91 | 0.27 | 13.98 | 1.58 | 2.45 |

| M5 | 1.82 | 1.77 | 0.22 | 12.08 | 1.54 | 2.12 |

| M6 | 1.81 | 1.78 | 0.19 | 10.49 | 1.44 | 2.07 |

| M7 | 1.81 | 1.76 | 0.21 | 11.61 | 1.43 | 2.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navaratnam, S.; Tushar, Q.; Jahan, I.; Zhang, G. Environmental Sustainability of Industrial Waste-Based Cementitious Materials: A Review, Experimental Investigation and Life-Cycle Assessment. Sustainability 2023, 15, 1873. https://doi.org/10.3390/su15031873

Navaratnam S, Tushar Q, Jahan I, Zhang G. Environmental Sustainability of Industrial Waste-Based Cementitious Materials: A Review, Experimental Investigation and Life-Cycle Assessment. Sustainability. 2023; 15(3):1873. https://doi.org/10.3390/su15031873

Chicago/Turabian StyleNavaratnam, Satheeskumar, Quddus Tushar, Israt Jahan, and Guomin Zhang. 2023. "Environmental Sustainability of Industrial Waste-Based Cementitious Materials: A Review, Experimental Investigation and Life-Cycle Assessment" Sustainability 15, no. 3: 1873. https://doi.org/10.3390/su15031873

APA StyleNavaratnam, S., Tushar, Q., Jahan, I., & Zhang, G. (2023). Environmental Sustainability of Industrial Waste-Based Cementitious Materials: A Review, Experimental Investigation and Life-Cycle Assessment. Sustainability, 15(3), 1873. https://doi.org/10.3390/su15031873

_Zhang.png)