Using an Axiomatic Design Approach to Develop a Product Innovation Process with Circular and Smart Design Aspects

Abstract

1. Introduction

2. Literature Review

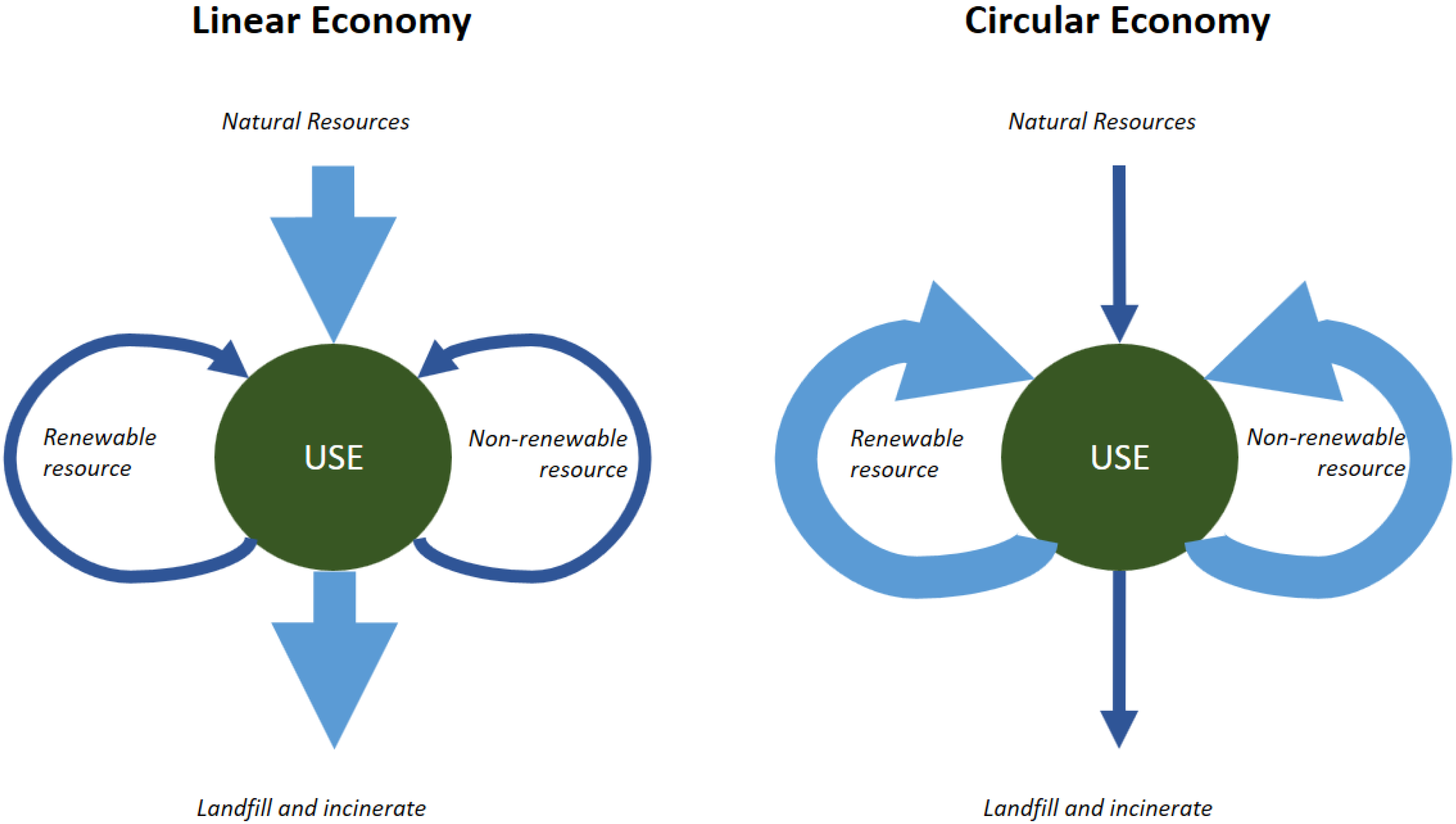

2.1. Circular Design

2.2. Smart Design

- Conform to the surrounding situation (R1);

- Adjust to the user or other products (R2);

- Conform to business constraints (R3).

- Situadtedness: analyzing the situation and community condition (R1);

- Personalization: identifying the product based on the customer preference (R2);

- Adaptiveness: adjusting product behavior based on the customer (R2);

- Pro-activity: anticipating the user’s plan and intention (R2);

- Business awareness: consideration of business and legal constraints (R3);

- Network capability: ability to interact and assort with other products (R3).

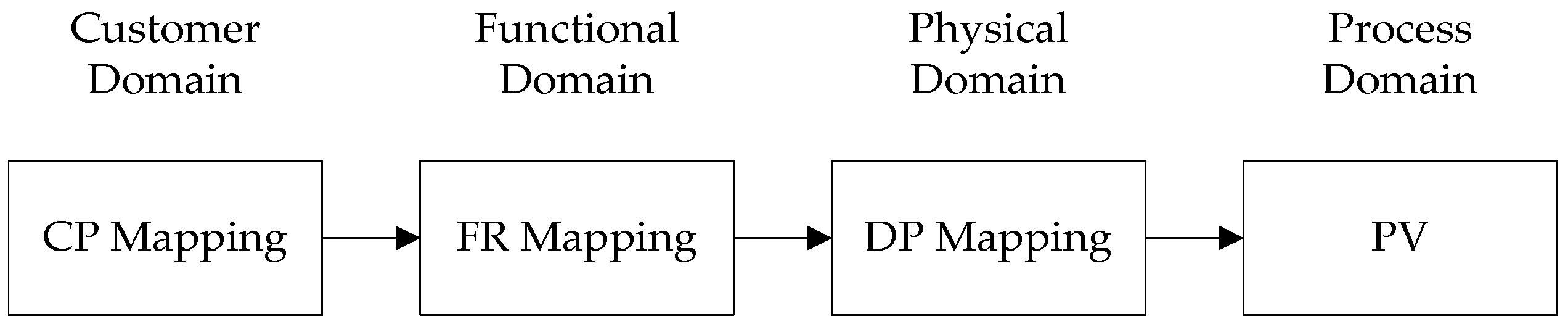

2.3. Axiomatic Design

- Customer domain: It focuses on what the customer needs and desires in the product. The customer domain describes the customer preference (CP) about the product and things that must be avoided in the product, system, and process.

- Functional domain: It identifies the functional requirements (FR), which describes what the design must have. FR is developed to satisfy the customer attributes and features.

- Physical domain: It is characterized by design parameters (DP). It describes the actual physical component to satisfy the functional requirement of the product to fulfill the design process. This domain focuses on applying the conceptualized product that was already developed in the functional requirement domain. DP describes what the design looks like, so the physical item of the product already fulfilled FR independently.

- Process domain: It figures out the required process of the physical domain. Process variables (PV) explain how the DP is produced. PV can be a manufacturing process, such as machining, injection molding, and assembly. PV must be developed one by one with the DP independently.

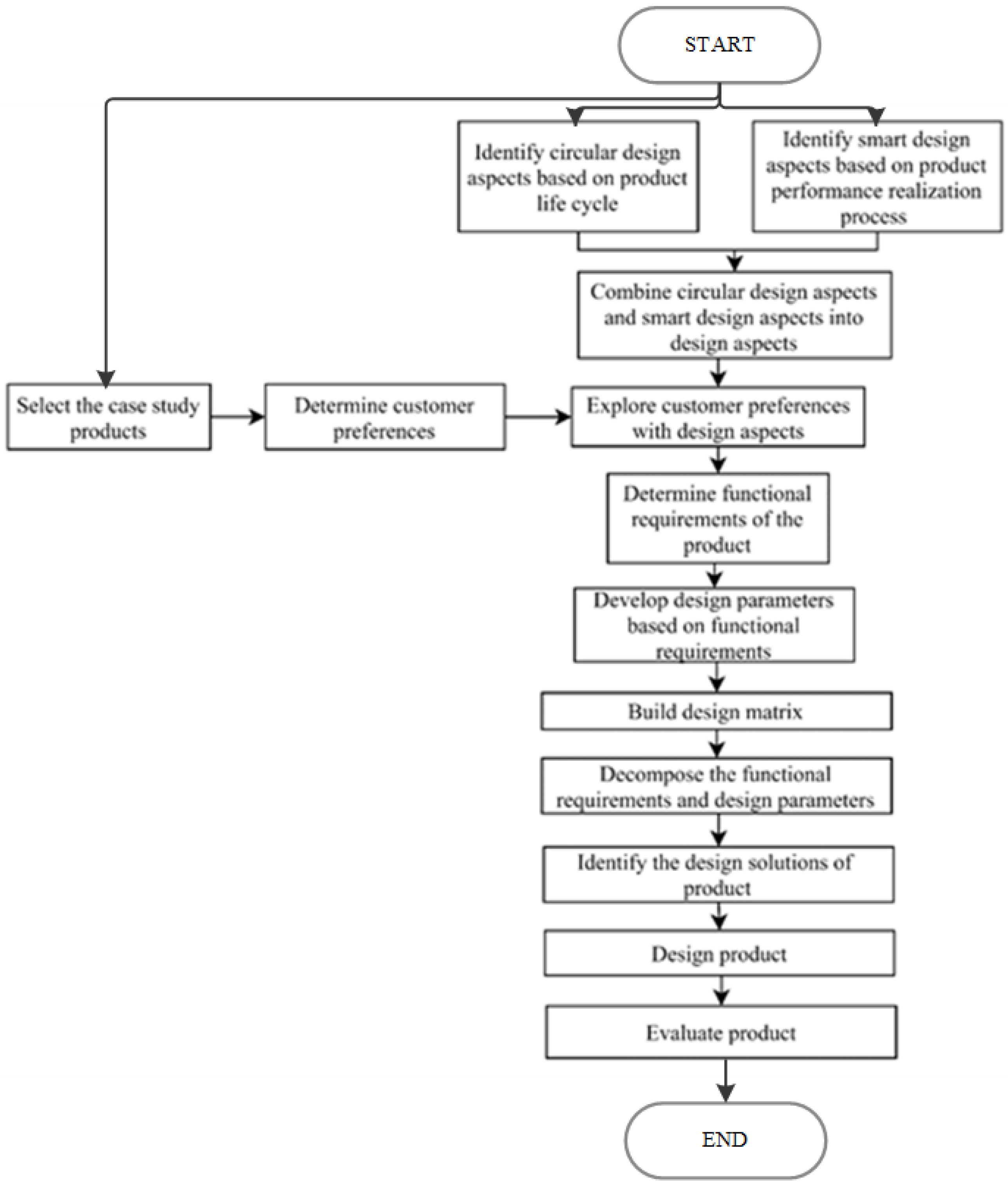

3. Methodology

3.1. Research Methodology

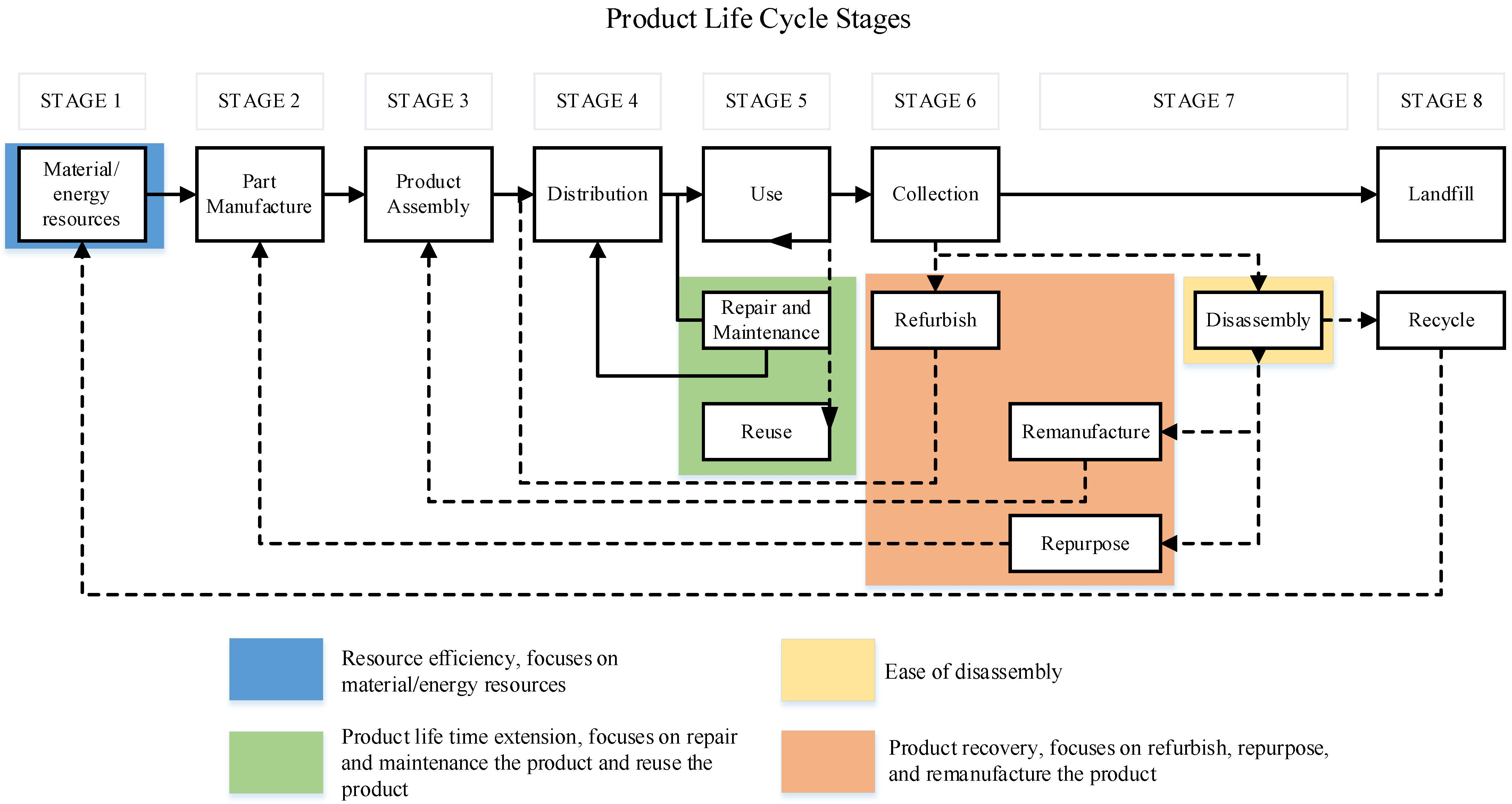

3.2. Identification of the Circular Design and Smart Design Aspects

3.2.1. Identify Circular Design Aspects through the Product Life Cycle

3.2.2. Identify Smart Design Aspects through the Product Performance Realization Process

3.3. Develop Design Aspects

3.4. Building of Design Matrix with Axiomatic Design Approach

4. Case Study of Water Dispenser

4.1. Identifying Customer Preferences

4.2. Defining the Customer Preference for Design Aspects

4.3. Determine the Functional Requirements of the Product

4.4. Develop Design Parameters Based on Functional Requirements

4.5. Build the Design Matrix

4.6. Create the Final Design Concept

4.7. Product Evaluation

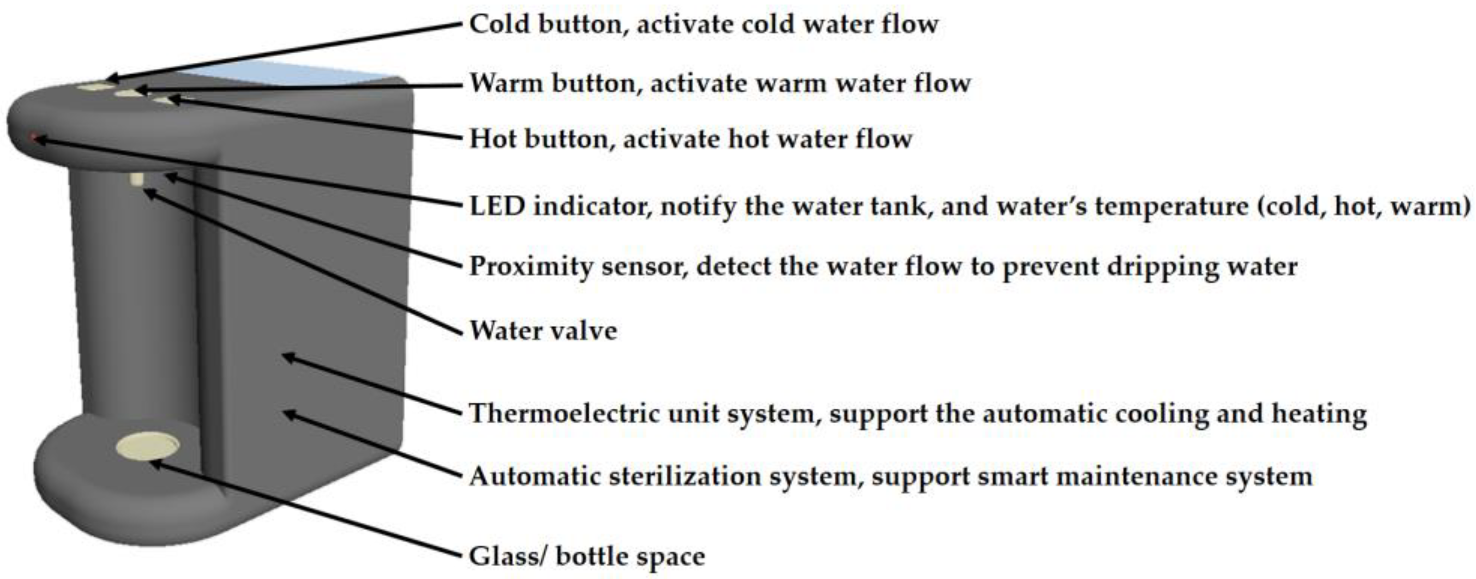

4.7.1. The Developed Water Dispenser

4.7.2. Counter Top Bottle Water Dispenser

4.7.3. Bottom Loading Water Dispenser

4.7.4. Evaluation Summary

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Avenyo, E.K.; Konte, M.; Mohnen, P. The Employment Impact of Product Innovations in Sub-Saharan Africa: Firm-Level Evidence. Res. Policy 2019, 48, 103806. [Google Scholar] [CrossRef]

- Ye, T.; Wang, N.; Wang, N. Analysis on Product Rollover Strategies: The Innovation Level Perspective. Ind. Mark. Manag. 2020, 88, 59–69. [Google Scholar] [CrossRef]

- Castellani, D.; Piva, M.; Schubert, T.; Vivarelli, M. R&D and Productivity in the US and the EU: Sectoral Specificities and Differences in the Crisis. Technol. Forecast. Soc. Chang. 2019, 138, 279–291. [Google Scholar] [CrossRef]

- Heldenreich, S.; Handrich, M. What About Passive Innovation Resistance? Investigating Adoption-Related Behavior from a Resistance Perspective. J. Prod. Innov. Manag. 2015, 32, 878–903. [Google Scholar] [CrossRef]

- Tama, I.P.; Azlia, W.; Hardiningtyas, D. Development of Customer Oriented Product Design Using Kansei Engineering and Kano Model: Case Study of Ceramic Souvenir. Procedia Manuf. 2015, 4, 328–335. [Google Scholar] [CrossRef]

- Gheorghe, R.; Ishii, K. Eco-design value Alignment-Keys to Success. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, IMECE, Seattle, WA, USA, 11–15 November 2007; Volume 15, pp. 267–277. [Google Scholar]

- Bemporad, R.; Baranowski, M. Conscious Consumers Are Changing the Rules of Marketing. Are You Ready? The BBMG Conscious Consumer Reports Marketing. 2007. Available online: https://www.bbmg.com (accessed on 9 June 2021).

- Chang, C.-H. The Determinants of Green Product Innovation Performance. Corp. Soc. Responsib. Environ. Manag. 2016, 23, 65–76. [Google Scholar] [CrossRef]

- Winans, K.; Kendall, A.; Deng, H. The History and Current Applications of the Circular Economy Concept. Renew. Sustain. Energy Rev. 2017, 68, 825–833. [Google Scholar] [CrossRef]

- Pisitsankkhakarn, R.; Vassanadumrongdee, S. Enhancing Purchase Intention in Circular Economy: An Empirical Evidence of Remanufactured Automotive Product in Thailand. Resour. Conserv. Recycl. 2020, 156, 104702. [Google Scholar] [CrossRef]

- Rabta, B. An Economic Order Quantity Inventory Model for a Product with a Circular Economy Indicator. Comput. Ind. Eng. 2020, 140, 106215. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Alcayaga, A.; Wiener, M.; Hansen, E.G. Towards a Framework of Smart-Circular Systems: An Integrative Literature Review. J. Clean. Prod. 2019, 221, 622–634. [Google Scholar] [CrossRef]

- Marikyan, D.; Papagiannidis, S.; Alamanos, E. A Systematic Review of the Smart Home Literature: A User Perspective. Technol. Forecast. Soc. Chang. 2019, 138, 139–154. [Google Scholar] [CrossRef]

- Whitmore, A.; Agarwal, A.; Xu, L.D. The Internet of Things—A Survey of Topics and Trends. Inf. Syst. Front. 2015, 17, 261–274. [Google Scholar] [CrossRef]

- Kahle, J.H.; Marcon, É.; Ghezzi, A.; Frank, A.G. Smart products value creation in SMEs innovation ecosystems. Technol. Forecast. Soc. Chang. 2020, 156, 120024. [Google Scholar] [CrossRef]

- Hultink, E.J.; Rijsdijk, S.A. How Today’s Consumers Perceive Tomorrow’s Smart Products. J. Prod. Innov. Manag. 2009, 26, 24–42. [Google Scholar]

- Tang, D.; Zhang, G.; Dai, S. Design as Integration of Axiomatic Design and Design Structure Matrix. Robot. Comput. -Integr. Manuf. 2009, 25, 610–619. [Google Scholar] [CrossRef]

- Botsaris, P.N.; Anagnostopoulos, K.P.; Demesouka, O. Using Axiomatic Design Principles for Designing a Simple and Innovative Product: A Case Study. Int. J. Des. Eng. 2008, 1, 300. [Google Scholar] [CrossRef]

- Linke, B.S.; Dornfeld, D.A. Application of Axiomatic Design Principles to Identify More Sustainable Strategies for Grinding. J. Manuf. Syst. 2012, 31, 412–419. [Google Scholar] [CrossRef]

- Li, X.; Qiu, S.; Ming, H.X.G. An Integrated Module-Based Reasoning and Axiomatic Design Approach for New Product Design under Incomplete Information Environment. Comput. Ind. Eng. 2019, 127, 63–73. [Google Scholar] [CrossRef]

- Circular Economy: Measuring Innovation in the Product Chain—Policy Report. Available online: https://www.pbl.nl/sites/default/files/downloads/pbl-2016-circular-economy-measuring-innovation-in-product-chains-2544.pdf (accessed on 9 June 2021).

- Medkova, K.; Fifield, B. Circular Design—Design for Circular Economy. Lahti Cleantech Annu. Rev. 2016, 24, 32–47. [Google Scholar]

- Foster, G. Circular Economy Strategies for Adaptive Reuse of Cultural Heritage Buildings to Reduce Environmental Impacts. Resour. Conserv. Recycl. 2020, 152, 104507. [Google Scholar] [CrossRef]

- Den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- European Environment Agency; Gillabel, J.; De Schoenmakere, M. Circular by design: Products in the circular economy, Publications Office. 2017. Available online: https://data.europa.eu/doi/10.2800/860754 (accessed on 9 June 2021).

- Kane, G.M.; Bakker, C.A.; Balkenende, A.R. Towards Design Strategies for Circular Medical Products. Resour. Conserv. Recycl. 2018, 135, 38–47. [Google Scholar] [CrossRef]

- Shahbazi, S.; Jönbrink, A.K. Design Guidelines to Develop Circular Products: Action Research on Nordic Industry. Sustainability 2020, 12, 3679. [Google Scholar] [CrossRef]

- Bovea, M.D.; Pérez-Belis, V. Identifying Design Guidelines to Meet The Circular Economy Principles: A Case Study on Electric and Electronic Equipment. J. Environ. Manag. 2018, 228, 483–494. [Google Scholar] [CrossRef]

- Mysen, A.G. Smart Products: An Introduction for Design Students. AmI 2007 Workshops. 2007, pp. 158–164. Available online: https://www.ntnu.no/documents/10401/1264433962/AndreasArtikkel.pdf/6f72baa3-1100-4c8c-9a4b-290a1b4809ec (accessed on 9 June 2021).

- Maass, W.; Varshney, U. Preface to the Focus Theme Section: “Smart Products”. Electron. Mark. 2008, 18, 211–215. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical Systems in Manufacturing. CIRP Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Cronin, M.J. Strategies for Embedded Control. In Smart Products, Smarter Services; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar] [CrossRef]

- Maass, W.; Janzen, S. Dynamic Product Interfaces: A Key Element for Ambient Shopping Environments. In Proceedings of the 20th Bled EConference—EMergence: Merging and Emerging Technologies, Processes, and Institutions—Conference Proceedings, Bled, Slovenia, 25 April–3 May 2007; pp. 457–470. [Google Scholar]

- Schultze, U.; Carte, T.A. Contextualizing Usage Research for Interactive Technology: The Case of Car E-Tailing. Data Base Adv. Inf. Syst. 2007, 38, 29–59. [Google Scholar] [CrossRef]

- Truffelli, M. Dynamic Pricing: New Game, New Rules, New Mindset. J. Revenue Pricing Manag. 2006, 5, 81–82. [Google Scholar] [CrossRef]

- Zawadzki, P.; Zywicki, K. Smart Product Design and Production Control for Effective Mass Customization in the Industry 4.0 Concept. Manag. Prod. Eng. Rev. 2016, 7, 105–112. [Google Scholar] [CrossRef]

- Suh, N.P. Ergonomics, Axiomatic Design and Complexity Theory. Theor. Issues Ergon. Sci. 2017, 8, 101–121. [Google Scholar] [CrossRef]

- Cavique, M.; Gonçalves-Coelho, A.M. Axiomatic Design and HVAC Systems: An Efficient Design Decision-Making Criterion. Energy Build. 2009, 41, 146–153. [Google Scholar] [CrossRef]

- Ferent, C.; Doboli, A.; Doboli, S. An Axiomatic Model for Concept Structure Description and Its Application to Circuit Design. Knowl. -Based Syst. 2013, 45, 114–133. [Google Scholar] [CrossRef]

- Alon, S.; Lehrer, E. Competitive Equilibrium as a Bargaining Solution: An Axiomatic Approach. Games Econ. Behav. 2019, 118, 60–71. [Google Scholar] [CrossRef]

- Karatas, M. Hydrogen Energy Storage Method Selection Using Fuzzy Axiomatic Design and Analytic Hierarchy Process. Int. J. Hydrog. Energy 2020, 45, 16227–16238. [Google Scholar] [CrossRef]

- Girgenti, A.; Giorgetti, A.; Anselmi, M.; Scatena, A. Improvement of the Test Equipment for a Stress Corrosion Lab through the Axiomatic Design. Procedia CIRP 2015, 34, 162–167. [Google Scholar] [CrossRef]

- Monti, C.; Giorgetti, A.; Girgenti, A. An Axiomatic Design Approach for a Motorcycle Steering Damper. Procedia CIRP 2015, 34, 150–155. [Google Scholar] [CrossRef]

- Shao, J.; Lu, F.; Zeng, C.; Xu, M. Research Progress Analysis of Reliability Design Method Based on Axiomatic Design Theory. Procedia CIRP 2016, 53, 107–112. [Google Scholar] [CrossRef]

- Donati, F.; Aguilar-Hernandez, G.A.; Sigüenza-Sánchez, C.P.; de Koning, A.; Rodrigues, J.F.D.; Tukker, A. Modeling the Circular Economy in Environmentally Extended Input-Output Tables: Methods, Software and Case Study. Resour. Conserv. Recycl. 2020, 152, 104508. [Google Scholar] [CrossRef]

- Sassanelli, C.; Urbinati, A.; Rosa, P.; Chiaroni, D.; Terzi, S. Addressing Circular Economy through Design for X Approaches: A Systematic Literature Review. Comput. Ind. 2020, 120, 103245. [Google Scholar] [CrossRef]

- Mesa, J.; Esparragoza, I.; Maury, H. Developing a Set of Sustainability Indicators for Product Families Based on the Circular Economy Model. J. Clean. Prod. 2018, 196, 1429–1442. [Google Scholar] [CrossRef]

- Moreno, M.; De los Rios, C.; Rowe, Z.; Charnley, F. A Conceptual Framework for Circular Design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef]

- Goo, B.; Lee, J.; Seo, S.; Chang, D.; Chung, H. Design of reliability critical system using axiomatic design with FMECA. Int. J. Nav. Archit. Ocean Eng. 2019, 11, 11–21. [Google Scholar] [CrossRef]

- Güler, M.; Büyüközkan, G. Analysis of digital transformation strategies with an integrated fuzzy AHP-axiomatic design methodology. IFAC-Pap. 2019, 52, 1186–1191. [Google Scholar] [CrossRef]

- Rauch, E.; Morandell, F.; Matt, D.T. AD Design Guidelines for Implementing I4.0 Learning Factories. Procedia Manuf. 2019, 31, 239–244. [Google Scholar] [CrossRef]

- Aydoğan, S.; Günay, E.E.; Akay, D.; Okudan Kremer, G.E. Concept design evaluation by using Z-axiomatic design. Comput. Ind. 2020, 122, 103278. [Google Scholar] [CrossRef]

- Clauer, D.; Fottner, J.; Rauch, E.; Prüglmeier, M. Usage of Autonomous Mobile Robots Outdoors—An Axiomatic Design Approach. Procedia CIRP 2020, 96, 242–247. [Google Scholar] [CrossRef]

- Rauch, E.; Brown, C.A. Teaching Axiomatic Design for a Long-Term Sustainable Introduction of Industry 4.0 in SMEs. Procedia CIRP 2020, 96, 169–174. [Google Scholar] [CrossRef]

- Verma, A.; Maiti, J.; Boustras, G. Analysis of categorical incident data and design for safety interventions using axiomatic design framework. Saf. Sci. 2020, 123, 104557. [Google Scholar] [CrossRef]

- Liu, A.; Lu, S. Functional design framework for innovative design thinking in product development. CIRP J. Manuf. Sci. Technol. 2020, 30, 105–117. [Google Scholar] [CrossRef]

- Karampure, R.; Wang, C.Y.; Vashi, Y. UML sequence diagram to axiomatic design matrix conversion: A method for concept improvement for software in integrated systems. Procedia CIRP 2021, 100, 457–462. [Google Scholar] [CrossRef]

- Lapinskienė, V.; Motuzienė, V. Integrated building design technology based on quality function deployment and axiomatic design methods: A case study. Sustain. Cities Soc. 2021, 65, 102631. [Google Scholar] [CrossRef]

- Liu, A.H.; Wan, S.P.; Dong, J.Y. An axiomatic design-based mathematical programming method for heterogeneous multi-criteria group decision making with linguistic fuzzy truth degrees. Inf. Sci. 2021, 571, 649–675. [Google Scholar] [CrossRef]

- Li, J.; Wu, X.; Zhang, X.; Song, Z.; Li, W. Design of distributed hybrid electric tractor based on axiomatic design and Extenics. Adv. Eng. Inform. 2022, 54, 101765. [Google Scholar] [CrossRef]

- Fazeli, H.R.; Peng, Q. Generation and evaluation of product concepts by integrating extended axiomatic design, quality function deployment and design structure matrix. Adv. Eng. Inform. 2022, 54, 101716. [Google Scholar] [CrossRef]

- Sundin, E. Product and Process Design. In Manufacturing Process Design and Costing (Issue 906); Springer: London, UK, 2004. [Google Scholar] [CrossRef]

- ECMA. ECMA-341 Environmental Design Considerations for ICT & CE Products. December. 2010. Available online: https://www.ecma-international.org/wp-content/uploads/ECMA-341_4th_edition_december_2010.pdf (accessed on 9 June 2021).

- Ingemarsdotter, E.; Jamsin, E.; Kortuem, G.; Balkenende, R. Circular strategies enabled by the internet of things-a framework and analysis of current practice. Sustain. (Switz.) 2019, 11, 5689. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Primc, K.; Kalar, B.; Slabe-erker, R.; Dominko, M.; Ogorevc, M. Circular economy con fi guration indicators in organizational life cycle theory. Ecol. Indic. 2020, 116, 106532. [Google Scholar] [CrossRef]

- Dowie, T.; Simon, M. Guidelines for Designing for Disassembly and Recycling. 1994. Available online: https://docplayer.net/12541797-Guidelines-for-designing-for-disassembly-and-recycling.html (accessed on 9 June 2021).

- Ellen MacArthur Foundation. Circularity Indicators: An approach to measuring cicularity. In Granta Design. 2010. Available online: http://www.truevaluemetrics.org/DBpdfs/Circular-Economy/Ellen-MacArthur-Circularity-Indicators-Non-Technical-Case-Studies-May-2015.pdf (accessed on 9 June 2021).

- Boothroyd, G.; Girard, A. Design for disassembly. Appliance(USA) 2005, 53, 76–78. [Google Scholar]

- Allwood, J. The future in practice sustainable materials—With both eyes open. Future Pract. State Sustain. Leadersh. 2012, 3, 3–5. [Google Scholar]

- Suzanne, E.; Absi, N.; Borodin, V. Towards circular economy in production planning: Challenges and opportunities. Eur. J. Oper. Res. 2020, 287, 168–190. [Google Scholar] [CrossRef]

- Di Maio, F.; Rem, P.C. A robust indicator for promoting circular economy through recycling. J. Environ. Prot. 2015, 6, 1095–1104. [Google Scholar] [CrossRef]

- Bahn-Walkowiak, B.; Steger, S. Resource targets in Europe and worldwide: An overview. Resources 2015, 4, 597–620. [Google Scholar] [CrossRef]

- Pollard, J.; Osmani, M.; Cole, C.; Grubnic, S.; Colwill, J.; Díaz, A.I. Developing and Applying Circularity Indicators for the Electrical and Electronic Sector: A Product Lifecycle Approach. Sustainability 2022, 14, 1154. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product Design and Business Model Strategies for a Circular Economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Alamerew, Y.A.; Brissaud, D. Circular Economy Assessment Tool for End of Life Product Recovery Strategies. J. Remanufacturing 2019, 9, 169–185. [Google Scholar] [CrossRef]

- Mulvaney, D.; Richards, R.M.; Bazilian, M.D.; Hensley, E.; Clough, G.; Sridhar, S. Progress Towards a Circular Economy in Materials to Decarbonize Electricity and Mobility. Renew. Sustain. Energy Rev. 2021, 137, 110604. [Google Scholar] [CrossRef]

- Tomiyama, T.; Lutters, E.; Stark, R.; Abramovici, M. Development Capabilities for Smart Products. CIRP Ann. 2019, 68, 727–750. [Google Scholar] [CrossRef]

- Yin, D.; Ming, X.; Zhang, X. Sustainable and Smart Product Innovation Ecosystem: An Integrative Status Review and Future Perspectives. J. Clean. Prod. 2020, 274, 123005. [Google Scholar] [CrossRef]

- Yang, X.; Wang, R.; Tang, C.; Luo, L.; Mo, X. Emotional design for smart product-service system: A case study on smart beds. J. Clean. Prod. 2021, 298, 126823. [Google Scholar] [CrossRef]

- Gutierrez, C.; Garbajosa, J.; Diaz, J.; Yague, A. Providing a Consensus Definition for the Term “Smart Product”. In Proceedings of the International Symposium and Workshop on Engineering of Computer Based Systems, Scottsdale, AZ, USA, 22–24 April 2013; pp. 203–211. [Google Scholar] [CrossRef]

- Porter, M.E.; Heppelmann, J.E. How Smart, Connected Products Are Transforming Competition. Harv. Bus. Rev. 2014, 114, 96–112. [Google Scholar]

- Hui, T.K.L.; Sherratt, R.S.; Sánchez, D.D. Major Requirements for Building Smart Homes in Smart Cities Based on Internet of Things Technologies. Future Gener. Comput. Syst. 2017, 76, 358–369. [Google Scholar] [CrossRef]

- Rogers, E. Diffusion of Innovation, 5th ed.; Free Press United States: Washington, DC, USA, 2003. [Google Scholar]

- Borgia, E. The internet of things vision: Key features, applications and open issues. Comput. Commun. 2014, 54, 1–31. [Google Scholar] [CrossRef]

- Lee, I.; Lee, K. The Internet of Things (IoT): Applications, investments, and challenges for enterprises. Bus. Horiz. 2015, 58, 431–440. [Google Scholar] [CrossRef]

- Valencia, A.; Mugge, R.; Schoormans, J.P.L.; Schifferstein, H.N.J. The design of smart product-service systems (PSSs): An exploration of design characteristics. Int. J. Des. 2015, 9, 13–28. [Google Scholar]

- Miranda, J.; Rodriguez, R.P.; Borja, V.; Wright, P.K.; Molina, A. Sensing, smart and sustainable product development (S3 product) reference framework. Int. J. Prod. Res. 2017, 57, 4391–4412. [Google Scholar] [CrossRef]

- Roy, S.K.; Balaji, M.S.; Quazi, A.; Quaddus, M. Predictors of customer acceptance of and resistance to smart technologies in the retail sector. J. Retail. Consum. Serv. 2018, 42, 147–160. [Google Scholar] [CrossRef]

- Kropp, E.; Totzek, D. How institutional pressures and systems characteristics shape customer acceptance of smart product-service systems. Ind. Mark. Manag. 2020, 91, 468–482. [Google Scholar] [CrossRef]

- Idoje, G.; Dagiuklas, T.; Iqbal, M. Survey for smart farming technologies: Challenges and issues. Comput. Electr. Eng. 2021, 92, 107104. [Google Scholar] [CrossRef]

- Sabou, M.; Kantorovitch, J.; Nokolov, A.; Tokmakoff, A.; Zhou, X.; Motta, E. Position Paper on Real Smart Products: Challenges for Semantic Web Technologies. In Proceedings of the International Workshop on Semantic Sensor Networks, Washington, DC, USA, 25–29 October 2009; Volume 522, pp. 135–147. [Google Scholar]

- Chang, Y.W.; Chen, J. What Motivates Customers to Shop in Smart Shops? The Impacts of Smart Technology and Technology Readiness. J. Retail. Consum. Serv. 2021, 58, 102325. [Google Scholar] [CrossRef]

- White Water Cooler Stock Illustration 153299009. Shutterstock. (n.d.). Available online: https://www.shutterstock.com/image-illustration/white-water-cooler-153299009 (accessed on 18 January 2023).

- Cheng, W.Z.; Cheng, R.G.; Chou, S.Y. Power-saving for IoT-enabled Water Dispenser System. In Proceedings of the 2019 42nd International Conference on Telecommunications and Signal Processing, TSP, Budapest, Hungary, 1–3 July 2019; pp. 736–739. [Google Scholar] [CrossRef]

- Gunasinghe, A.; Tharmaseelan, J. Smart Water Dispenser. Int. J. Innov. Sci. Res. Technol. 2019, 4, 365–368. [Google Scholar]

- Kokane, S.; Joshi, D.; Patil, A. Root Cause Analysis of Water Wastage in Hot-Cold Water Dispenser. Int. J. Eng. Res. Appl. (IJERA) 2015, 5, 135–139. [Google Scholar]

- Franceschini, F.; Rupil, A. Rating scales and prioritization in QFD. Int. J. Qual. Reliab. Manag. 1999, 16, 85–97. [Google Scholar] [CrossRef]

- Water cooler refreshment bottle office plastic stock vector (royalty free) 274260623. Shutterstock. (n.d.). Available online: https://www.shutterstock.com/image-vector/water-cooler-refreshment-bottle-office-plastic-274260623 (accessed on 18 January 2023).

- Two models water dispensers vector stock vector (royalty free) 320429369. Shutterstock. (n.d.). Available online: https://www.shutterstock.com/image-vector/two-models-water-dispensers-vector-320429369 (accessed on 18 January 2023).

| Authors | Proposed Method | Aspects | Case Studies | ||

|---|---|---|---|---|---|

| Functional | Smart | Circular | |||

| Alcayaga et al. [13] | An integrative literature review | ✓ | ✓ | Service business models | |

| Li et al. [21] | Module-based reasoning and axiomatic design | ✓ | The blanking mold | ||

| Karatas [42] | Axiomatic design and AHP | ✓ | Hydrogen energy storage selection | ||

| Girgenti et al. [43] | Axiomatic design | ✓ | A stress corrosion lab | ||

| Monti et al. [44] | Axiomatic design | ✓ | Motorcycle steering damper | ||

| Shao et al. [45] | Solution variants method and axiomatic design | ✓ | 3D printing head | ||

| Oliveira and Álvares [46] | Axiomatic design | ✓ | CNC machine | ||

| Fan et al. [47] | Quality function deployment and axiomatic design | ✓ | Machine-made sand | ||

| Yang et al. [48] | Axiomatic design, bench-marking method | ✓ | ✓ | Hand rehabilitation device | |

| Chen et al. [49] | Fuzzy axiomatic design and extended regret theory | ✓ | Logistics provider selection | ||

| Goo et al. [50] | Axiomatic design and FMECA | ✓ | LNG fuel gas supply system | ||

| Güler and Büyüközkan [51] | Axiomatic design, fuzzy logic, and AHP | ✓ | The banking sector | ||

| Rauch et al. [52] | Axiomatic design | ✓ | Implementing industry 4.0 in factories | ||

| Aydoğan et al. [53] | Fuzzy, Axiomatic design | ✓ | Adhesive tape dispenser | ||

| Clauer et al. [54] | Axiomatic design | ✓ | ✓ | Autonomous Mobile Robots Outdoors | |

| Rauch and Brown [55] | Axiomatic design | ✓ | Small and medium enterprise | ||

| Verma et al. [56] | Descriptive analytics and axiomatic design | ✓ | Safety interventions | ||

| Liu and Lu [57] | Axiomatic design | ✓ | Framework for innovative design | ||

| Karampure et al. [58] | Axiomatic design, Conceptual design | ✓ | The Software system architecture of FDM 3D printer | ||

| Lapinskienė and Motuzienė [59] | Quality function deployment and axiomatic design | ✓ | ✓ | Building design | |

| Liu et al. [60] | Axiomatic design, fuzzy truth degrees | ✓ | Block-chain service provider selection | ||

| Li et al. [61] | Axiomatic design, Extenics | ✓ | Tractor powertrain | ||

| Fazeli and Peng [62] | Fuzzy axiomatic design, quality function deployment | ✓ | Hand rehabilitation device | ||

| This Research | Axiomatic design and scoring approach | ✓ | ✓ | ✓ | Water Dispenser |

| No | Circular Design Characteristics | Reference |

|---|---|---|

| 1 | Minimize the weight of material | [29,48,63,64,65,66,67,68] |

| 2 | Increase the durability and reliability | [23,25,29,30,47,48,63,68] |

| 3 | Use non Hazardous and toxic material usage | [29,63,64,69,70] |

| 4 | Use pure material | [70] |

| 5 | Use high quality components | [29,30] |

| 6 | Minimize the number of joint | [30,63,64,66,69,71] |

| 7 | Use Recyclable material | [22,28,29,63,64,66,68,69,70,71,72,73] |

| 8 | Reuse the product | [22,24,46,51,68,73,74] |

| 9 | Use separable connector type | [30,63,69,71] |

| 10 | Apply easy to repair product | [25,29,49,65,67] |

| 11 | Use standardized joints or connectors | [51,65,71] |

| 12 | Reduce the type of material | [51,64,69,71,75] |

| 13 | Reduce the type of connector or joint | [48,51] |

| 14 | Minimize energy use | [29,47,51,63,64,67,68,75] |

| 15 | Implement easy to maintain product | [25,67] |

| 16 | Develop upgraded product | [25,30,51,70] |

| 17 | Remanufacture product | [25,28,30,46,49,70,73] |

| 18 | Repurpose product | [24,25,29,30,68] |

| 19 | Refurbish the product | [25,70] |

| Circular Design Aspect | Description | |

|---|---|---|

| 1 | Resource efficiency | It aims at minimizing the use of resources by improving and developing the product of the same and better quality [46,76]. |

| 2 | Safe material for the environment | Pure and non-toxic material can help in minimizing the cost of recycling and protect the environment [49]. |

| 3 | Product lifetime extension | Product lifetime extension is the condition of the product which is still functional for a longer use period [49,77]. |

| 4 | Ease of disassembly | It focuses on products and components that can be separated and reassembled easily [78]. |

| 5 | Recyclability of disassembled materials | This refers to reprocessing of disassembled materials into a product with an equivalent or a different use [78]. |

| 6 | Product recovery | Recovery refers to the product and components that are not recycled yet. It is related to how the product and material are collected and recovered, either from manufacturing scrap or post-consumer [79,80]. |

| Characteristics | Human Like Interaction of the Product | Multi-Functionality | Situatedness | Intelligent | Product Integration | Service Integration | Sensing Ability | smart Human Interaction | Autonomy Capability | Customization | Resilience to the External Impact | Reconfiguration | Personalize | Adaptability into the User | Pro-Active | Business-Aware | Network Capability | Easier User Interaction | Product Dependency |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mysen [30] | ✓ | ✓ | |||||||||||||||||

| Cronin [33] | ✓ | ✓ | |||||||||||||||||

| Maass and Janzen [34] | ✓ | ✓ | ✓ | ✓ | ✓ | ||||||||||||||

| Porter and Heppelmann [59] | ✓ | ✓ | ✓ | ✓ | |||||||||||||||

| Tomiyama et al. [81] | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |||||||||

| Yin et al. [82] | ✓ | ✓ | ✓ | ||||||||||||||||

| Yang et al. [83] | ✓ | ||||||||||||||||||

| Gutierrez et al. [84] | ✓ | ✓ | ✓ | ||||||||||||||||

| Porter and Heppelmann [85] | ✓ | ||||||||||||||||||

| Hui et al. [86] | ✓ | ||||||||||||||||||

| Rogers [87] | ✓ | ||||||||||||||||||

| Borgia [88] | ✓ | ✓ | |||||||||||||||||

| Lee and Lee [89] | ✓ | ||||||||||||||||||

| Valencia et al. [90] | ✓ | ✓ | ✓ | ||||||||||||||||

| Miranda et al. [91] | ✓ | ||||||||||||||||||

| Roy et al. [92] | ✓ | ||||||||||||||||||

| Kropp and Totzek [93] | ✓ | ✓ | |||||||||||||||||

| Idoje et al. [94] | ✓ | ✓ |

| Smart Design Aspect | Description | |

|---|---|---|

| 1 | Action like human | The product can imitate human actions which interact naturally and does not give any big gap between user and product [30,81,82,83]. |

| 2 | Actuation | This characteristic focuses on the product’s capability in doing user orders, controlling, and making decision based on the collected information. Alcayaga et al. [13] identified that actuating is controlling and personalizing experience remotely. |

| 3 | Dynamism | The ability to learn and adapt to the user and environment situations by collecting the required data [34,84]. |

| 4 | Connectivity | The product can be connected through the network with other devices due to the sensing capability and functionality of the product [35,59,60]. |

| 5 | Market fulfillment | The customization of the product to fulfill the market target for increasing the high purchase intention of the customer [35,54,95]. |

| 6 | Product usefulness | The capability of the product to obtain some purposes or function advantages, and ease of use. Chang and Chen [96] identified that ease of use and multi-functionality are categorized as usability. |

| 7 | Awareness | The capability of the product in responding to the external impacts and user’s intention without changing its structure [34,81]. |

| No | Code | Design Aspects |

|---|---|---|

| 1 | CA1 | Resource efficiency |

| 2 | CA2 | Safe material for the environment |

| 3 | CA3 | Product lifetime extension |

| 4 | CA4 | Ease of disassembly |

| 5 | CA5 | Recyclability of disassembled materials |

| 6 | CA6 | Product recovery |

| 7 | SA1 | Action like human |

| 8 | SA2 | Actuation |

| 9 | SA3 | Dynamism |

| 10 | SA4 | Connectivity |

| 11 | SA5 | Market fulfillment |

| 12 | SA6 | Product usefulness |

| 13 | SA7 | Awareness |

| Customer Preferences | Reference | |

|---|---|---|

| CP1 | The water dispenser should not consume a lot of electricity. | [97,98] |

| CP2 | The water dispenser can retain its clean, fresh, and taste condition. | [100] |

| CP3 | The size should be small. | [98] |

| CP4 | The water should be not dripping easily. | [100] |

| Customer Preferences | Design Aspects | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CA1 | CA2 | CA3 | CA4 | CA5 | CA6 | SA1 | SA2 | SA3 | SA4 | SA5 | SA6 | SA7 | |

| CP1 | ✔ | ||||||||||||

| CP2 | ✔ | ||||||||||||

| CP3 | ✔ | ||||||||||||

| CP4 | ✔ | ||||||||||||

| Initial CP | Design Aspects | CP for Design Aspects | |

|---|---|---|---|

| The water dispenser should not consume a lot of electricity. | CA1 | Resource efficiency | Develop the product to be more efficient when using the energy. |

| The water dispenser can retain its clean, fresh, and taste. | CA3 | Product lifetime | The water dispenser should be easy to maintain. |

| The size should be small. | SA5 | Market fulfillment | Customize the product to be smaller. |

| The water should be not dripping easily. | SA3 | Dynamism | The water dispenser adapts to the user’s situation and behavior. |

| CP for Design Aspects | Functional Requirements | |

|---|---|---|

| Develop the product to be more efficient when using the energy. | FR1 | Use less power energy. |

| The water dispenser should be easy to maintain. | FR2 | Simplify product care. |

| Customize the product to be smaller. | FR3 | Minimize the size of the water dispenser. |

| The water dispenser adapts to the user’s situation and behavior. | FR4 | Implement an automatic water dispenser. |

| FRs | DPs | ||

|---|---|---|---|

| FR1 | Use less power energy. | DP1 | Thermoelectric unit system |

| FR2 | Simplify product care. | DP2 | Maintainable product |

| FR3 | Minimize the size of the water dispenser. | DP3 | Compact size |

| FR4 | Implement an automatic water dispenser. | DP4 | Water monitoring system |

| FRs | DPs | ||

|---|---|---|---|

| FR21 | Install a high water filtration. | DP21 | Carbon fiber filter |

| FR22 | Set up water quality detector. | DP22 | Automatic sterilization system |

| FR31 | Use high-quality material. | DP31 | Polymer material |

| FR32 | Reduce the size of the product. | DP32 | Mini size product |

| FR41 | Pair up the water flow sensor. | DP41 | Proximity sensor |

| FR42 | Sense the water level. | DP42 | Ultrasonic sensor |

| DP1 | DP21 | DP22 | DP31 | DP32 | DP41 | DP42 | |

|---|---|---|---|---|---|---|---|

| FR1 | X | 0 | 0 | 0 | 0 | 0 | 0 |

| FR21 | 0 | X | 0 | 0 | 0 | 0 | 0 |

| FR22 | 0 | 0 | X | 0 | 0 | 0 | 0 |

| FR31 | 0 | 0 | 0 | X | 0 | 0 | 0 |

| FR32 | 0 | 0 | 0 | 0 | X | 0 | 0 |

| FR41 | 0 | 0 | 0 | 0 | 0 | X | 0 |

| FR42 | 0 | 0 | 0 | 0 | 0 | 0 | X |

| Product Name: Water Dispenser | ||

|---|---|---|

| Design Parameter | Design Concept | |

| Thermoelectric unit system | DC1 | Have an automatic cooling and heating system to prevent high energy consumption. |

| Carbon fiber filter | DC2 | Install a high-performance filter to guarantee precise and good taste water. |

| Automatic sterilization system | DC3 | Have a smart maintenance system that reminds the user of service times and the water quality. |

| Polymer material | DC4 | Use safe materials for food. |

| Mini-size water dispenser | DC5 | Save installing space for water dispenser with 25 cm length, 25 cm width, and 35 cm height. |

| Proximity sensor | DC6 | Automatic water flow system to prevent dripping water. |

| Ultrasonic sensor | DC7 | Obtain a notification about the left water inside the tank. |

| Product: Developed Water Dispenser | |||||||

|---|---|---|---|---|---|---|---|

| Dimension | Detail | Circular Aspect | Smart Aspect | Product Functionality | Operation Convenience | Ease of Manufacture | Cost |

| Material | DC4 | 9 | 3 | 3 | 9 | 9 | 9 |

| Appearance | DC5 | 9 | 9 | 9 | 9 | 9 | 9 |

| Feature | DC2 | 9 | 9 | 9 | 9 | 9 | 3 |

| DC3 | |||||||

| DC1 | |||||||

| DC6 | |||||||

| Total score | 27 | 21 | 21 | 27 | 27 | 21 | |

| Product: Counter-Top Water Dispenser | |||||||

|---|---|---|---|---|---|---|---|

| Dimension | Detail | Circular Aspect | Smart Aspect | Product Functionality | Operation Convenience | Ease of Manufacture | Cost |

| Material | Polymer material, which is a safe material for food. | 9 | 3 | 3 | 9 | 9 | 9 |

| Appearance | 31cm length, 31 cm width, and 59 cm height. | 1 | 1 | 9 | 1 | 9 | 9 |

| Feature | No filtration system. | 1 | 1 | 9 | 9 | 9 | 9 |

| User guideline book for maintenance. | |||||||

| Manual cool and heating system. | |||||||

| Manual valve system. | |||||||

| Total score | 11 | 5 | 21 | 19 | 27 | 27 | |

| Product: Bottom Loading Water Dispenser | |||||||

|---|---|---|---|---|---|---|---|

| Dimension | Detail | Circular Aspect | Smart Aspect | Product Functionality | Operation Convenience | Ease of Manufacture | Cost |

| Material | High-grade stainless steel material. | 9 | 9 | 3 | 9 | 9 | 9 |

| Appearance | 30 cm in length, 33 cm in width, and 104 cm in height. | 1 | 1 | 9 | 9 | 9 | 9 |

| Feature | No filtration system. | 3 | 3 | 9 | 9 | 9 | 9 |

| User guideline book for maintenance. | |||||||

| Manual cooling and heating system. | |||||||

| Manual valve system. | |||||||

| Total score | 13 | 13 | 21 | 27 | 27 | 27 | |

| Product | Circular Aspect | Smart Aspect | Product Functionality | Operation Convenience | Ease of Manufacture | Cost | Total Score |

|---|---|---|---|---|---|---|---|

| The developed product | 27 | 21 | 21 | 27 | 27 | 21 | 144 |

| Counter-top water dispenser | 11 | 5 | 21 | 19 | 27 | 27 | 110 |

| Bottom loading water dispenser | 13 | 13 | 21 | 27 | 27 | 27 | 128 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adilah, M.; Rau, H.; Procopio, K.M. Using an Axiomatic Design Approach to Develop a Product Innovation Process with Circular and Smart Design Aspects. Sustainability 2023, 15, 1933. https://doi.org/10.3390/su15031933

Adilah M, Rau H, Procopio KM. Using an Axiomatic Design Approach to Develop a Product Innovation Process with Circular and Smart Design Aspects. Sustainability. 2023; 15(3):1933. https://doi.org/10.3390/su15031933

Chicago/Turabian StyleAdilah, Muna, Hsin Rau, and Katrina Mae Procopio. 2023. "Using an Axiomatic Design Approach to Develop a Product Innovation Process with Circular and Smart Design Aspects" Sustainability 15, no. 3: 1933. https://doi.org/10.3390/su15031933

APA StyleAdilah, M., Rau, H., & Procopio, K. M. (2023). Using an Axiomatic Design Approach to Develop a Product Innovation Process with Circular and Smart Design Aspects. Sustainability, 15(3), 1933. https://doi.org/10.3390/su15031933