Performance Assessment of Giant Reed-Based Building Components

Abstract

:1. Introduction

2. State of the Art and Relevance

3. Materials and Methods

- One is a mixture of lime and cement, with a predominance of cement, sand and reeds (cement–reed).

- Two of them are a mixture of different limes, sand and reeds (Lime–reed White Calix NHL and lime–reed Villaga NHL)

- One is a mixture of lime and cement, with a predominance of lime, sand and reeds (lime–reed Calce Fiore + Cement)

3.1. Raw Materials

3.1.1. Natural by-Products: Giant Reed (Arundo Donax)

3.1.2. Binders

3.1.3. Aggregates

3.1.4. Additives

3.2. Mix Design and Sample Manufacturing

3.2.1. Lime–Reed Mixtures

- A mix using hydraulic natural lime White Calix NHL 3.5 (from now on, “Lime–reed, White Calix NHL”);

- A mix using hydraulic natural lime Villaga NHL 3.5 (from now on, “Lime–reed, Villaga NHL”);

- A mix using powder hydrated lime made hydraulic by the addition of cement, in a percentage lower than 50% of lime (from now on, “Lime–reed, Calce Fiore + Cement”). This kind of lime is classified as EL by [28].

3.2.2. Cement–Reed Mixture

3.2.3. Samples Manufacturing

- Shredding. The residuals of the industrial treatment of the reeds were first cleaned by removing the leaves (with an industrial sugarcane leaf remover/stripper machine). Then, they were reduced to fragments of length smaller than 3 cm using bio-grinders.

- Treatments for reducing the lignin content (mercerization). The lignin contained in the reeds reduces adherence between the fibers and the binders. Therefore, before preparing the composite, the shredded reeds were pre-treated by immersion into a watery solution with additives. The treatment is called mercerization [35] and develops a rough texture on the surface of the reed that improves the adhesion fiber matrix. In addition, the treatment of the reed with alkali determines a variation in the degree of polymerization and enhances the percentage of crystal cellulose, causing an improvement in the fiber’s stiffness. Two different solutions for the treatment of the reeds were tested to carry out the mercerization:

- Solution of water and quicklime.

- Solution of water and caustic soda (NaOH).

- Preparation of the composite. The consistency of the mixtures was determined by means of a shaking table, according to the procedure indicated in [36].

- Filling of the formworks. Several formworks were filled by the lime–reed and the cement–reed mixtures by means of a trowel and a hand tamper.

- Curing. The samples were cured for 28 days. In the first seven days, they were placed in an environment with almost 100% relative humidity; after that, once hardened, they were removed from the formworks. In the case of the cement–reed composites, the samples were removed from the formwork after 14 days.

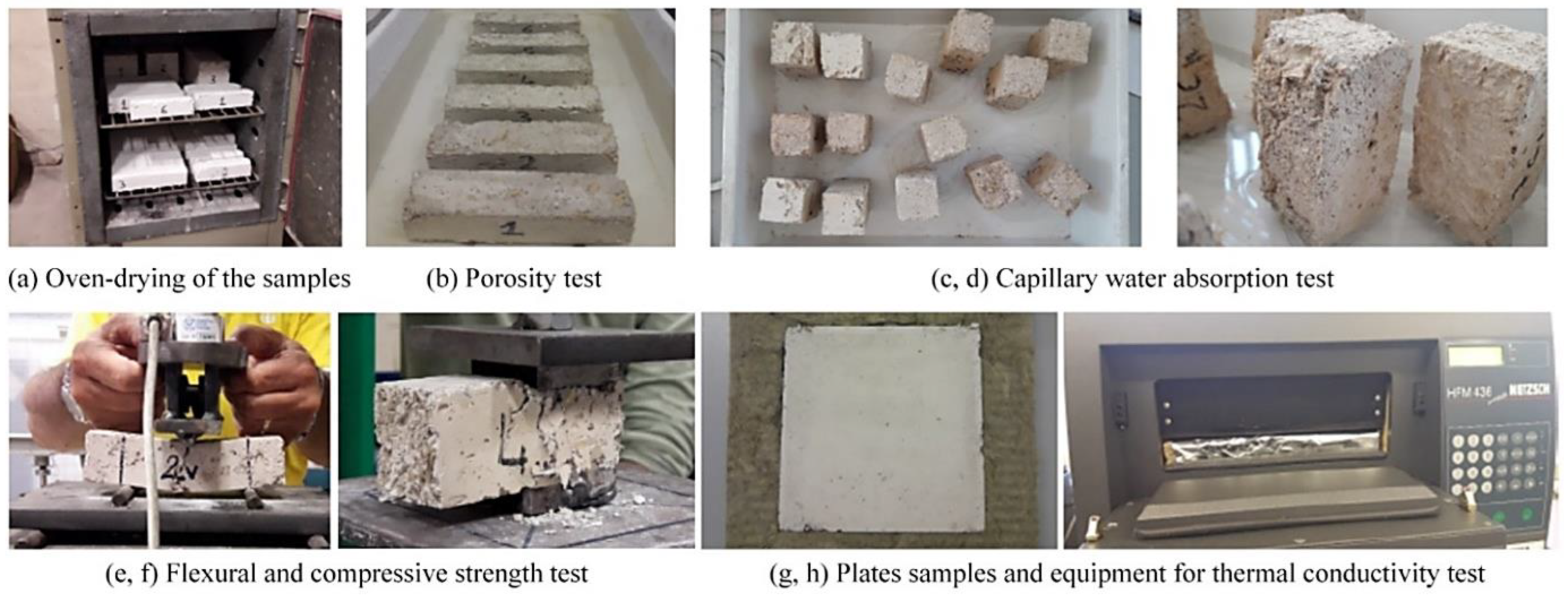

3.3. Experimental Procedure

3.4. Thermal Performance Assessment on a Wall Scale

4. Results and Discussion

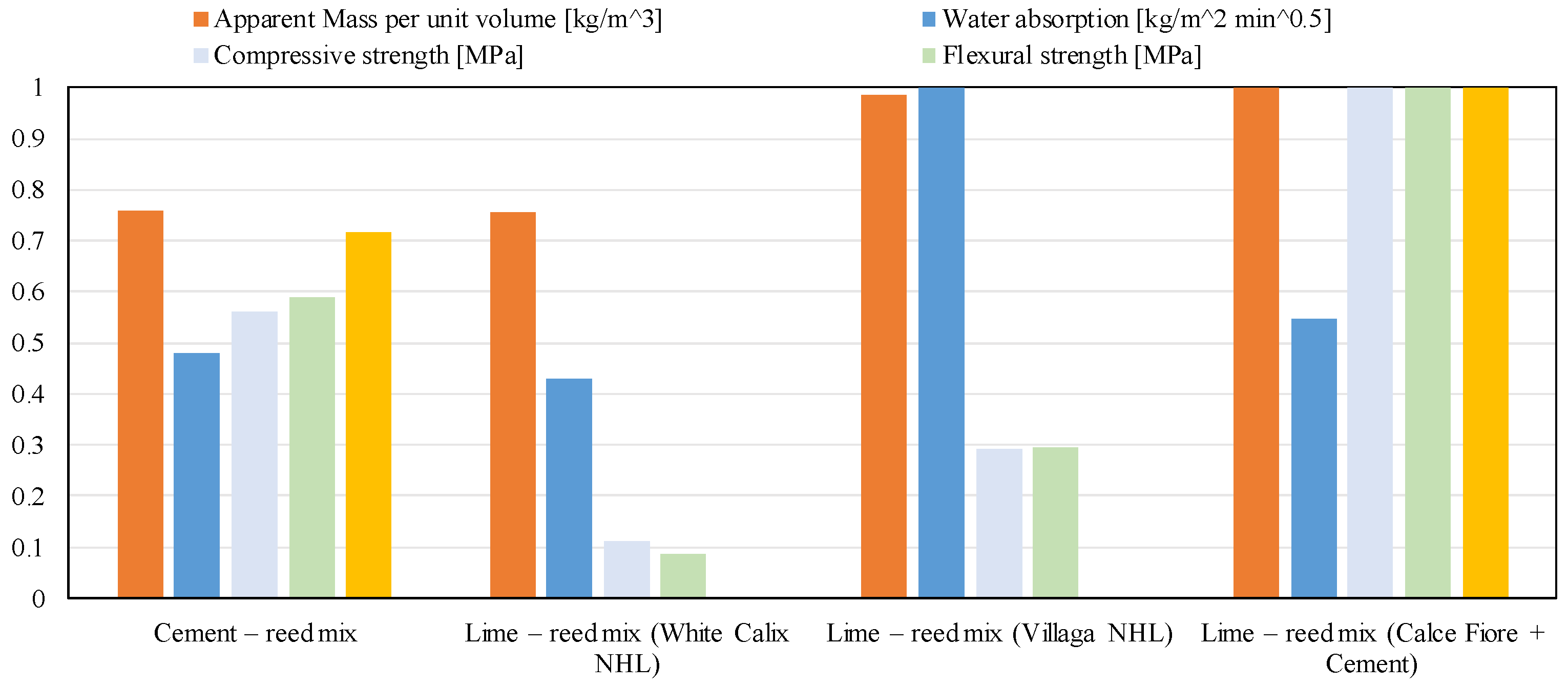

4.1. Physical, Mechanical and Thermal Characterization of the Composites

4.2. Discussion of the Results and Comparison with Previous Studies

4.3. Wall-Scale Behavior of Lime–Reed Blocks and Comparison with Competitors’ Products

5. Conclusions

- The lime–reed (Calce Fiore + cement) mixture presents the best results concerning mechanical (with a flexural strength of 0.826 MPa and a compressive strength of 1.510 MPa) and thermal properties (k = 0.191 W/mk), but it also has the highest density value (1152 kg/m3).

- The cement–reed mixture presents slightly lower mechanical (a compressive strength of 0.849 MPa and a flexural strength of 0.483 MPa) and thermal performances (thermal conductivity is equal to 0.245 W/mK) but also a lower density value (872.8 kg/m3).

- The lime–reed (White Calix NHL) and lime–reed (Villaga NHL) mixtures present low compressive and flexural strengths, which were deemed to be insufficient even for non-load-bearing applications.

- The Surface Mass of lime–reed blocks is 345 kg/m2, which is higher than that of hollow clay blocks (300 kg/m2) and of lime–hemp blocks (135 kg/m2), making it the best scenario among the analyzed ones in warmer climates for the direct effect of moderating the magnitude of the thermal excursion.

- The U-values of the 30 cm-thick lime–reed wall is 0.55 W/m2K, in an intermediate position between that of hollow clay block wall (0.65 W/m2K) and that of lime–hemp blocks (0.30 W/m2K).

- The periodic thermal Transmittance (Yie) is lower than 0.10 W/m2K for all the examined scenarios.

- The Decrement Factor (DF) of the lime–reed wall is the lowest among all the wall configurations in all the examined scenarios.

- The Time lag of lime–reed blocks wall for Italian Climate zone B and D is, respectively, 10 h and 9 h, similar to that of Poroton blocks (respectively, 11 h and 10 h) and better than that of lime–hemp blocks (respectively, 9 h and 8 h), thanks to the higher density value of the lime–reed mixture.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A. Application of agro-waste for sustainable construction materials: A review. Constr. Build. Mater. 2013, 38, 872–878. [Google Scholar] [CrossRef]

- Giuffrida, G.; Caponetto, R.; Nocera, F. Hygrothermal Properties of Raw Earth Materials: A Literature Review. Sustainability 2019, 11, 5342. [Google Scholar]

- Claramunt, J.; Fernandez-Carrasco, L.J.; Ventura, H.; Ardanuy, M. Natural fiber nonwoven reinforced cement composites as sustainable materials for building envelopes. Constr. Build. Mater. 2016, 115, 230–239. [Google Scholar] [CrossRef] [Green Version]

- Jami, T.; Karade, S.R.; Singh, L.P. A review of the properties of hemp concrete for green building Applications. J. Clean. Prod. 2019, 239, 117852. [Google Scholar] [CrossRef]

- Rahima, M.; Douzanea, O.; Tran Lea, A.D.; Promisa, G.; Laidoudib, B.; Crigny, A.; Dupreb, B.; Langlet, T. Characterization of flax lime and hemp lime concretes: Hygric properties and moisture buffer capacity. Energy Build. 2015, 88, 91–99. [Google Scholar] [CrossRef]

- Kinnane, O.; Reilly, A.; Grimes, J.; Pavia, S.; Walker, R. Acoustic absorption of hemp-lime construction. Constr. Build. Mater. 2016, 122, 674–682. [Google Scholar] [CrossRef] [Green Version]

- Seng, B.; Magniont, C.; Lorente, S. Characterization of a precast hemp concrete. Part I: Physical and thermal properties. J. Build. Eng. 2019, 24, 100540. [Google Scholar] [CrossRef]

- Hussain, A.; Calabria-Holley, J.; Lawrence, M.; Jiang, Y. Hygrothermal and mechanical characterisation of novel hemp shiv based thermal insulation composites. Constr. Build. Mater. 2019, 212, 561–568. [Google Scholar] [CrossRef]

- Haba, B.; Agoudjil, B.; Boudenne, A.; Benzarti, K. Hygric properties and thermal conductivity of a new insulation material for building based on date palm concrete. Constr. Build. Mater. 2017, 154, 963–971. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Lanos, C. Chemical and multi-physical characterization of agro-resources’ by-product as a possible raw building material. Ind. Crops Prod. 2018, 120, 214–237. [Google Scholar] [CrossRef]

- Viel, M.; Collet, F.; Lanos, C. Development and characterization of thermal insulation materials from renewable resources. Constr. Build. Mater. 2019, 214, 685–697. [Google Scholar] [CrossRef]

- Helepciuc-Gradinaru, C.M.; Barbuta, M.; Serbanoiu, A.A. Characterization of a lightweight concrete with sunflower ag-gregates. Procedia Manuf. 2018, 22, 154–159. [Google Scholar] [CrossRef]

- Kidalova, L.; Stevulova, N.; Terpakova, E.; Sicakova, A. Utilization of alternative materials in lightweight composites. J. Clean. Prod. 2012, 34, 116–119. [Google Scholar] [CrossRef]

- Echeverría-Maggi, E.; Flores-Alés, V.; Martín-Del-Río, J.J. Reuse of banana fiber and peanut shells for the design of new prefabricated products for buildings. Rev. De La Construcción 2022, 21, 461–472. [Google Scholar] [CrossRef]

- Charai, M.; Mezrhab, A.; Moga, L.; Karkri, M. Hygrothermal, mechanical and durability assessment of vegetable concrete mixes made with Alfa fibers for structural and thermal insulating applications. Constr. Build. Mater. 2022, 335, 127518. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Akinrinade, A.D.; De Sousa Galdino, A.G.; Althoey, F.; Serkan Kirgiz, M.; Tayeh, B.A. Thermal insulation and me-chanical characteristics of cement mortar reinforced with mineral wool and rice straw fibers. J. Build. Eng. 2022, 53, 104568. [Google Scholar] [CrossRef]

- Prusty, J.K.; Patro, S.K.; Basarkar, S.S. Concrete using agro-waste as fine aggregate for sustainable built environment: A review. Int. J. Sustain. Built Environ. 2016, 5, 312–333. [Google Scholar] [CrossRef] [Green Version]

- Ismail, Z.Z.; Jaeel, A.J. Environmental-friendly concrete using giant reed as undesirable wild species. In Proceedings of the SCMT3: Third International Conference on Sustainable Construction Materials and Technologies, Kyoto, Japan, 18–22 August 2013; Available online: http://www.claisse.info/2013%20papers/data/e186.pdf (accessed on 13 January 2023).

- Botryk, M.; Pawluczuk, E. Properties of a lightweight cement composite with an ecological organic filler. Constr. Build. Mater. 2014, 51, 97–105. [Google Scholar] [CrossRef]

- Badagliacco, D.; Megna, B.; Valenza, A. Induced Modification of Flexural Toughness of Natural Hydraulic Lime Based Mor-tars by Addition of Giant Reed Fibers. Case Stud. Constr. Mater. 2020, 13, 00425. [Google Scholar]

- Shon, C.-S.; Mukashev, T.; Lee, D.; Zhang, D.; Kim, J.R. Can Common Reed Fiber Become an Effective Construction Material? Physical, Mechanical, and Thermal Properties of Mortar Mixture Containing Common Reed Fiber. Sustainability 2019, 11, 903. [Google Scholar] [CrossRef] [Green Version]

- Reeves, T. Design-based research from a technology perspective. In Educational Design-based Research (52–66); Akker, J.V.D., Gravemeijer, K., McKenney, S., Eds.; Routledge: New York, NY, USA, 2006. [Google Scholar]

- Cosentino, S.L.; Scordia, D.; Sanzone, E.; Copani, V. Response of giant reed (Arundo donax L.) to nitrogen fertilization and soil water availability in semi-arid Mediterranean environment. Eur. J. Agron. 2014, 60, 22–32. [Google Scholar] [CrossRef]

- Pascoal Neto, C.; Seca, A.; Nunes, A.M.; Coimbra, M.A.; Domingues, F.; Evtuguin, D.; Silvestre, A.; Cavaleiro, J.A.S. Var-iations in chemical composition and structure of macromolecular components in different morphological regions and maturity stages of Arundo donax. Ind. Crops Prod. 1997, 6, 51–58. [Google Scholar] [CrossRef]

- Abdullatif, A.; Al-Attar, T. Structural behaviour of reed: Evaluation of tensile strength, elasticity and stress-strain relation-ships. Int. J. Adv. Res. Eng. Technol. 2013, 4, 105–113. [Google Scholar]

- Scordia, D.; Testa, G.; Cosentino, S.L. Perennial grasses as lignocellulosic feedstock for second-generation bioethanol production in Mediterranean environment. Ital. J. Agron. 2014, 9, 84–92. [Google Scholar] [CrossRef]

- Monti, A.; Zanetti, F.; Scordia, D.; Testa, G.; Cosentino, S.L. What to harvest when? Autumn, winter, annual and biennial harvesting of giant reed, miscanthus and switchgrass in northern and southern Mediterranean area. Ind. Crops Prod. 2015, 75, 129–134. [Google Scholar] [CrossRef]

- Standard UNI EN 459-1:2015; Calci da Costruzione—Parte 1: Definizioni, Specifiche e Criteri di Conformità. UNI Italian Standards Body: Italy, 2015.

- Standard UNI EN 197-1:2011; Cemento—Parte 1: Composizione, Specificazioni e Criteri di Conformità per Cementi Comuni. UNI Italian Standards Body: Italy, 2011.

- Giuffrida, G.; Costanzo, V.; Nocera, F.; Cuomo, M.; Caponetto, R. Natural and Recycled Stabilizers for Rammed Earth Material Optimization. In Sustainability in Energy and Buildings 2022. SEB 2022. Smart Innovation, Systems and Technologies; Littlewood, J., Howlett, R.J., Jain, L.C., Eds.; Springer: Singapore, 2023; Volume 336, pp. 164–174. [Google Scholar]

- Standard UNI EN 933-1:2012; Prove per Determinare le Caratteristiche Geometriche degli aggregati—Parte 1: Determinazione Della Distribuzione Granulometrica—Analisi Granulometrica per Setacciatura. UNI Italian Standards Body: Italy, 2012.

- Belfiore, C.M.; Visalli, R.; Ortolano, G.; Barone, G.; Mazzoleni, P. A GIS-based image processing approach to investigate the hydraulic behavior of mortars induced by volcanic aggregates. Constr. Build. Mater. 2022, 342, 128063. [Google Scholar] [CrossRef]

- Battiato, G.; Le malte del centro storico di Catania. Materiali e Tecniche Costruttive Della tradizione Siciliana; Margani, L., Salemi, A., Eds.; Doc. 16 Istituto Dipartimentale di Architettura e Urbanistica (IDAU) dell’Universita di Catania: Catania, Italy, 1988; pp. 85–107. [Google Scholar]

- Columbu, S.; Lisci, C.; Sitzia, F.; Lorenzetti, G.; Lezzerini, M.; Pagnotta, S.; Raneri, S.; Legnaioli, S.; Palleschi, V.; Gallello, G.; et al. Mineralogical, petrographic and physical-mechanical study of Roman construction materials from the Mari-time Theatre of Hadrian’s Villa (Rome, Italy). Measurement 2018, 127, 264–276. [Google Scholar] [CrossRef]

- Noori, A.; Lu, Y.; Saffari, P.; Liu, J.; Ke, J. The effect of mercerization on thermal and mechanical properties of bamboo fibers as a biocomposite material: A review. Constr. Build. Mater. 2021, 279, 122519. [Google Scholar] [CrossRef]

- Standard UNI EN 1015-3:2007; Metodi di Prova per Malte per Opere Murarie—Parte 3: Determinazione Della Consistenza Della Malta Fresca (Mediante Tavola a Scosse). UNI Italian Standards Body: Italy, 2007.

- Standard UNI EN 1015-10:2007; Metodi di Prova per Malte per Opere Murarie—Parte 10: Determinazione Della Massa Volumica Apparente Della Malta Indurita Essiccata. UNI Italian Standards Body: Italy, 2007.

- Standard UNI EN 1015-18:2004; Metodi di Prova per Malte per Opere Murarie—Determinazione del Coefficiente di Assorbimento D’acqua per Capillarità Della Malta Indurita. UNI Italian Standards Body: Italy, 2004.

- Standard UNI EN 1015-11:2019; Metodi di Prova per Malte per Opere Murarie—Parte 11: Determinazione Della Resistenza a Flessione e a Compressione Della Malta Indurita. UNI Italian Standards Body: Italy, 2019.

- Standard ISO 8301:1991; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. International Organization for Standardization: London, UK, 1991.

- Asan, H.; Sancaktar, Y.S. Effects of Wall’s Thermophysical Properties on Time Lag and Decrement Factor. Energy Build. 1998, 28, 159–166. [Google Scholar] [CrossRef]

- Decreto del Presidente della Repubblica 26 agosto 1993, n. 412. Regolamento recante norme per la progettazione, l’installazione, l’esercizio e la manutenzione degli impianti termici degli edifici ai fini del contenimento dei consumi di energia. Available online: https://www.gazzettaufficiale.it/eli/id/1993/10/14/093G0451/sg (accessed on 18 January 2023).

- Standard UNI EN ISO 6946:2018; Componenti ed Elementi per Edilizia—Resistenza Termica e Trasmittanza Termica—Metodo di Calcolo. UNI Italian Standards Body: Italy, 2018.

- Standard UNI EN ISO 13786:2008; Prestazione Termica dei Componenti per Edilizia—Caratteristiche Termiche Dinamiche—Metodo di Calcolo. UNI Italian Standards Body: Italy, 2008.

- Decreto del Ministero dello Sviluppo Economico 26/06/2015. Applicazione delle Metodologie di Calcolo delle Prestazioni Energetiche e Definizione delle Prescrizioni e dei Requisiti Minimi Degli Edifici. Available online: https://www.gazzettaufficiale.it/eli/id/2015/07/15/15A05198/sg (accessed on 18 January 2023).

| Lime–Reed (White Calix NHL) | Lime–Reed (Villaga NHL) | Lime–Reed (Calce Fiore + Cement) | |||||

|---|---|---|---|---|---|---|---|

| Materials | Density (kg/m3) | Volume ratio (%) | Dose per 30 lt (g) | Volume ratio (%) | Dose per 30 lt (g) | Volume ratio (%) | Dose per 30 lt (g) |

| Saturated reeds | 357.00 | 50 | 5355 | 50 | 5355 | 54.55 | 5840 |

| NHL Villaga Lime | 809.00 | - | - | 25 | 6070 | - | - |

| NHL Calix Lime | 643.53 | 25 | 4830 | - | - | - | - |

| Calce Fiore | 520.00 | 4.17 | 650 | 4.17 | 650 | 16.36 | 2550 |

| Cement | 1193.39 | - | - | - | - | 8.18 | 2930 |

| Azolo (0.5–3 mm) | 1494.14 | 16.67 | 7470 | 16.67 | 7470 | 16.36 | 7335 |

| Recycled clay aggregate (1–4 mm) | 1338.04 | 4.17 | 16.70 | 4.17 | 16.70 | 4.55 | 1825 |

| Air-entraining agent | - | - | 22.5 | - | 22.5 | - | 22.5 |

| Water | - | - | 5000 | - | 5000 | - | 3100 |

| Water/binder ratio | - | 0.57 | - | 0.57 | - | 0.41 | - |

| Air-entraining/binder ratio | - | 0.004 | - | 0.004 | - | 0.004 | - |

| Materials | Density (kg/m3) | Volume Ratio (%) | Dose Per 30 lt (g) |

|---|---|---|---|

| Saturated reeds | 357.00 | 52.17 | 5590 |

| Calce Fiore | 520.88 | 4.35 | 680 |

| White Cement | 1125.23 | 21.74 | 7340 |

| Azolo (0.5–3 mm) | 1494.14 | 17.40 | 7800 |

| Recycled clay aggregate (1–4 mm) | 1338.04 | 4.35 | 1745 |

| Air-entraining agent | - | - | 22 |

| Water | - | - | 4600 |

| Water/binder ratio | - | 0.51 | - |

| Air-entraining/binder ratio | - | 0.003 | - |

| Type of Solution | Reed (kg) | Active Component (kg) | Water (l) | Duration of Immersion |

|---|---|---|---|---|

| Caustic soda | 1 | 0.23 | 25 | 8 days |

| Quicklime | 1 | 2.0 | 25 | 13 days |

| Mix | Apparent Mass and Porosity | Capillary Water Absorption | Compressive Strength | Flexural Strength | Thermal Conductivity |

|---|---|---|---|---|---|

| Cement–reed | X | X | X | X | X |

| Lime–reed (White Calix NHL) | X | X | X | X | - |

| Lime–reed (Villaga NHL) | X | X | X | X | - |

| Lime–reed (Calce Fiore + Cement) | X | X | X | X | X |

| Properties | Unit | Cement–Reed | Lime–Reed (White Calix NHL) | Lime–Reed (Villaga NHL) | Lime–Reed (Calce Fiore + Cement) |

|---|---|---|---|---|---|

| Apparent mass per unit volume | kg/m3 | 872.81 | 870.85 | 1134.34 | 1152.31 |

| Apparent porosity | % | 31.02 | 44.40 | 47.21 | 44.74 |

| Thermal conductivity | W/m K | 0.245 | - | - | 0.191 |

| Compressive strength | MPa | 28 days 0.849 | 28 days 0.073 90 days 0.168 | 28 days 0.256 90 days 0.440 | 28 days 1.029 90 days 1.510 |

| Flexural strength | MPa | 28 days 0.483 | 28 days 0.075 | 28 days 0.256 | 28 days 0.829 |

| Water absorption | kg/m2 min 0.5 | 0.0013 | 0.0014 | 0.0006 | 0.0011 |

| Composite | Apparent Mass Per Unit Volume (kg/m3) | Compressive Strength (MPa) | Flexural Strength (MPa) | Thermal Conductivity (W/m K) |

|---|---|---|---|---|

| Lime–hemp [6,7,13] | 510 | 1.040 | 0.230 | 0.06–0.18 |

| Date Palm–cement [9] | 954 | - | - | 0.185 |

| Corn cob-binder [11] | 488 | 0.3625 | - | 0.126 |

| Lime–reed mortar [20] | 1802 | 6.069 | 1.954 | - |

| Hemp and MgO–cement [13] | 1100 | 2.230 | - | - |

| Wood cellulose–cement [13] | 1100 | 3.430 | - | 0.18 |

| Alfa fiber concrete [15] | 1463 | 6.335 | 1.185 | 0.392 |

| Rock wool and rice straw mortar [16] | 1974 | 7.700 | 1.200 | 0.298 |

| Cement–reed (present study) | 872.8 | 0.849 | 0.483 | 0.245 |

| Lime–reed (present study) | 1152.3 | 28 days 1.029 90 days 1.510 | 0.826 | 0.191 |

| Type | Density (kg/m3) | Thermal Conductivity (W/mK) | Compressive Strength (MPa) |

|---|---|---|---|

| Hollow clay aerated block (Poroton 700) | 700 | 0.23 | > 3.5 |

| Lime–hemp | 450 | 0.10 | 1.040 |

| Lime–reed (Calce Fiore + Cement) composite | 1152 | 0.19 | 1.510 |

| Parameters | Catania | Rome | Milan | ||

|---|---|---|---|---|---|

| Climate zone | - | - | B | D | E |

| Winter degree—days | GG | - | 833 | 1415 | 2404 |

| Latitude | - | - | 37,47 | 41,54 | 45,27 |

| Longitude | - | - | 15,05 | 12,29 | 9,11 |

| Height above sea level | H | m | 7 | 20 | 122 |

| Average irradiance in the month of maximum insolation | I | W/m2 | 298.1 | 321 | 269.6 |

| Layers | s (m) | k (W/m K) | ρ (kg/m3) | Cp (J/kg K) |

|---|---|---|---|---|

| Lime and cement mortar (Outer plaster) | 0.03 | 0.900 | 1800 | 1000 |

| Hollow clay aerated block–POROTON 700 | 0.30 | 0.212 | 700 | 1000 |

| Lime and cement mortar (Inner plaster) | 0.03 | 0.900 | 1800 | 1000 |

| Layers | s (m) | k (W/m K) | ρ (kg/m3) | Cp (J/kg K) |

|---|---|---|---|---|

| Lime and sand plaster (Outer plaster) | 0.03 | 0.800 | 1600 | 1000 |

| Lime–hemp block | 0.30 | 0.100 | 450 | 850 |

| Lime and sand plaster (Inner plaster) | 0.03 | 0.800 | 1600 | 1000 |

| Layers | s (m) | k (W/m K) | ρ (kg/m3) | Cp (J/kg K) |

|---|---|---|---|---|

| Lime and sand plaster (Outer plaster) | 0.03 | 0.800 | 1600 | 1000 |

| Lime–reed block | 0.30 | 0.191 | 1152 | 850 |

| Lime and sand plaster (Inner plaster) | 0.03 | 0.800 | 1600 | 1000 |

| Wall Configuration | U (W/m2K) | Ulim-CT (W/m2K) | Ulim-RO (W/m2K) | Ulim-MI (W/m2K) |

|---|---|---|---|---|

| Hollow clay aerated block (Bs) | 0.65 | ≤0.43 | ≤0.29 | ≤0.26 |

| Lime–hemp block (LHs) | 0.30 | ≤0.43 | ≤0.29 | ≤0.26 |

| Lime–reed block (LRs) | 0.55 | ≤0.43 | ≤0.29 | ≤0.26 |

| Wall configuration | SM (kg/m2) | SMlim (kg/m2) |

|---|---|---|

| Hollow clay aerated block (Bs) | 300 | ≥ 230 |

| Lime–hemp block (LHs) | 135 | ≥230 |

| Lime–reed block (LRs) | 345 | ≥ 230 |

| Scenario | Thermal Dynamic Features | Localities | ||

|---|---|---|---|---|

| Catania | Rome | Milan | ||

BS | s (m) | 0.36 | 0.36 | 0.36 |

| C (J/kgK) | 57.95 | 57.95 | 57.95 | |

| Yie (W/m2K) | 0.024 | 0.026 | 0.028 | |

| DF (-) | 0.037 | 0.040 | 0.043 | |

| TL (h) | 11 h | 10 h | 10 h | |

LHs | s (m) | 0.36 | 0.36 | 0.36 |

| C (J/kgK) | 49.04 | 49.04 | 49.04 | |

| Yie (W/m2K) | 0.0132 | 0.0135 | 0.141 | |

| DF (-) | 0.044 | 0.045 | 0.047 | |

| TL (h) | 9 h | 8 h | 8 h | |

LRs | s (m) | 0.36 | 0.36 | 0.36 |

| C (J/kgK) | 54.53 | 54.53 | 54.53 | |

| Yie (W/m2K) | 0.0165 | 0.0220 | 0.0231 | |

| DF (-) | 0.030 | 0.040 | 0.042 | |

| TL (h) | 10 h | 9 h | 8 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caponetto, R.; Cuomo, M.; Detommaso, M.; Giuffrida, G.; Presti, A.L.; Nocera, F. Performance Assessment of Giant Reed-Based Building Components. Sustainability 2023, 15, 2114. https://doi.org/10.3390/su15032114

Caponetto R, Cuomo M, Detommaso M, Giuffrida G, Presti AL, Nocera F. Performance Assessment of Giant Reed-Based Building Components. Sustainability. 2023; 15(3):2114. https://doi.org/10.3390/su15032114

Chicago/Turabian StyleCaponetto, Rosa, Massimo Cuomo, Maurizio Detommaso, Giada Giuffrida, Antonio Lo Presti, and Francesco Nocera. 2023. "Performance Assessment of Giant Reed-Based Building Components" Sustainability 15, no. 3: 2114. https://doi.org/10.3390/su15032114