Techno-Economic Assessment of APS-Based Poultry Feed Production with a Circular Biorefinery Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Modelling Smart Feed: Techno-Economic Assessment Methodology and Procedure

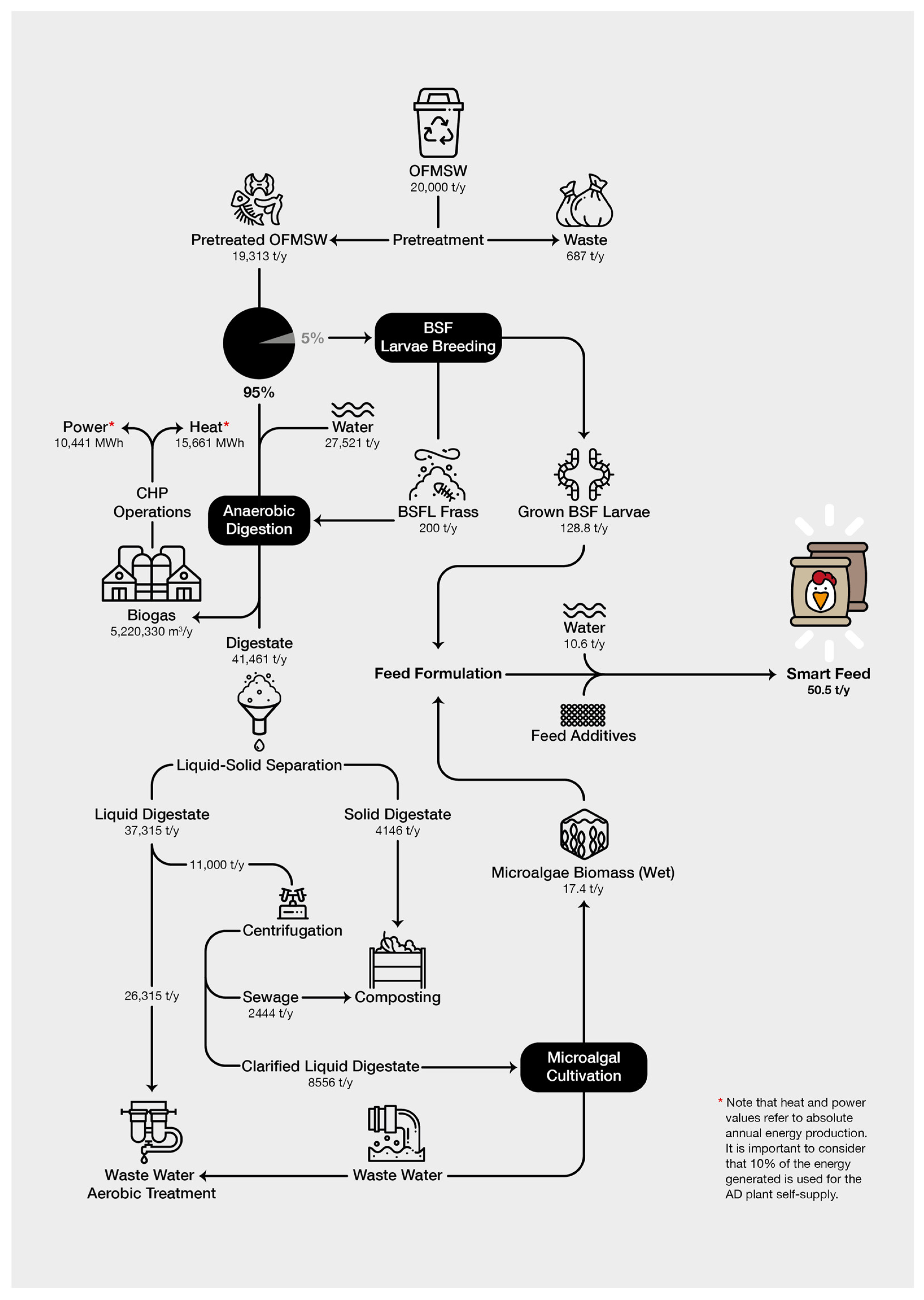

Process Flow and Mass and Energy Balance

2.2. Definition of Sustainability: Thematic Analysis Methodology

3. Results

3.1. The Outcomes from the Techno-Economic Assessment

3.1.1. Process Flow and Mass and Energy Balance

3.1.2. Economic Results

Initial Total Investment Cost (Fixed Cost)

Operating Costs

Revenues

Financial Assumptions and Profitability Metrics

3.2. How Poultry Supply Chain Operators Define Sustainability: The Outcomes from the Thematic Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AD | Anaerobic digestion |

| AI | Artificial intelligence |

| APS | Alternative protein sources |

| BSFL | Black soldier fly larvae |

| CHP | Combined heat and power |

| DM | Dry matter |

| DMP | Biochemical methane production |

| EBIT | Earnings before interest and taxes |

| EBITDA | Earnings before interests taxes depreciation and amortization |

| FW | Fresh weight |

| HRT | Retention time |

| IPIFF | International Platform of Insects for Food and Feed |

| O&M | Operation and maintenance |

| ODM | Organic dry matter |

| OFMSW | Organic fraction of municipal solid waste |

| PAPs | Processed animal proteins |

| TEA | Techno-economic assessment |

References

- World Population Prospects 2022: Summary of Results | Population Division. Available online: https://www.un.org/development/desa/pd/content/World-Population-Prospects-2022 (accessed on 5 December 2022).

- FAO High-Level Expert Forum on “How to Feed the World in 2050”. In Proceedings of the Panel 1: Global Agriculture towards 2050: The Outlook for Food and Agriculture in a Dynamically Changing Economic and Demographic Environment Session Held during the High-Level Expert Forum on “How to Feed the World in 2050”, FAO Headquarters (Red Room), Rome, Italy, 12 October 2009.

- Ritchie, H.; Rosado, P.; Roser, M. Meat and Dairy Production. Our World Data 2017, 12, 064016. [Google Scholar] [CrossRef]

- OECD/FAO. OECD-FAO Agricultural Outlook 2021–2030; OECD Publishing: Paris, France, 2021. [Google Scholar] [CrossRef]

- Makkar, H.P.S. Review: Feed Demand Landscape and Implications of Food-Not Feed Strategy for Food Security and Climate Change. Animal 2018, 12, 1744–1754. [Google Scholar] [CrossRef] [Green Version]

- Parisi, G.; Tulli, F.; Fortina, R.; Marino, R.; Bani, P.; Dalle Zotte, A.; De Angelis, A.; Piccolo, G.; Pinotti, L.; Schiavone, A.; et al. Protein Hunger of the Feed Sector: The Alternatives Offered by the Plant World. Ital. J. Anim. Sci. 2020, 19, 1204–1225. [Google Scholar] [CrossRef]

- El-Shemy, H. (Ed.) Soybean and Nutrition; InTech: Rijeka, Croatia, 2011; ISBN 978-953-307-536-5. [Google Scholar]

- Rockstrom, J.; Steffen, W.; Noone, K.; Persson, A.; Stuart, F.; Chapin, I.; Lambin, E.; Lenton, T.M.; Scheffr, M.; Folke, C.; et al. Planetary Boundaries: Exploring the Safe Operating Space for Humanity. Ecol. Soc. 2009, 14, 32. [Google Scholar] [CrossRef]

- Lefroy, T. Land Use Intensification: Effects on Agriculture, Biodiversity and Ecological Processes. Australas. J. Environ. Manag. 2013, 20, 260–262. [Google Scholar] [CrossRef]

- Van Gelder, J.W.; Kammeraat, K.; Kroes, H. Soy Consumption for Feed and Fuel in the European Union; Profundo Economic Research: Castricum, The Netherlands, 2008. [Google Scholar]

- Otero, D.M.; da Rocha Lemos Mendes, G.; da Silva Lucas, A.J.; Christ-Ribeiro, A.; Ribeiro, C.D.F. Exploring Alternative Protein Sources: Evidence from Patents and Articles Focusing on Food Markets. Food Chem. 2022, 394, 133486. [Google Scholar] [CrossRef]

- van Huis, A.; Oonincx, D.G.A.B. The Environmental Sustainability of Insects as Food and Feed. A Review. Agron. Sustain. Dev. 2017, 37, 43. [Google Scholar] [CrossRef] [Green Version]

- Huis, A.; Van Itterbeeck, J.; Klunder, H.; Mertens, E.; Halloran, A.; Muir, G.; Vantomme, P. Edible Insects: Future Prospects for Food and Feed Security; FAO: Rome, Italy, 2013; Volume 171. [Google Scholar]

- Biasato, I.; Renna, M.; Gai, F.; Dabbou, S.; Meneguz, M.; Perona, G.; Martinez, S.; Lajusticia, A.C.B.; Bergagna, S.; Sardi, L.; et al. Partially Defatted Black Soldier Fly Larva Meal Inclusion in Piglet Diets: Effects on the Growth Performance, Nutrient Digestibility, Blood Profile, Gut Morphology and Histological Features. J. Anim. Sci. Biotechnol. 2019, 10, 12. [Google Scholar] [CrossRef]

- Onsongo, V.O.; Osuga, I.M.; Gachuiri, C.K.; Wachira, A.M.; Miano, D.M.; Tanga, C.M.; Ekesi, S.; Nakimbugwe, D.; Fiaboe, K.K.M. Insects for Income Generation Through Animal Feed: Effect of Dietary Replacement of Soybean and Fish Meal With Black Soldier Fly Meal on Broiler Growth and Economic Performance. J. Econ. Entomol. 2018, 111, 1966–1973. [Google Scholar] [CrossRef]

- Iaconisi, V.; Marono, S.; Parisi, G.; Gasco, L.; Genovese, L.; Maricchiolo, G.; Bovera, F.; Piccolo, G. Dietary Inclusion of Tenebrio Molitor Larvae Meal: Effects on Growth Performance and Final Quality Treats of Blackspot Sea Bream (Pagellus Bogaraveo). Aquaculture 2017, 476, 49–58. [Google Scholar] [CrossRef]

- van der Fels-Klerx, H.J.; Camenzuli, L.; Belluco, S.; Meijer, N.; Ricci, A. Food Safety Issues Related to Uses of Insects for Feeds and Foods. Compr. Rev. Food Sci. Food Saf. 2018, 17, 1172–1183. [Google Scholar] [CrossRef] [Green Version]

- Fowles, T.M.; Nansen, C. Insect-Based Bioconversion: Value from Food Waste BT. In Food Waste Management: Solving the Wicked Problem; Närvänen, E., Mesiranta, N., Mattila, M., Heikkinen, A., Eds.; Springer International Publishing: Cham, Germany, 2020; pp. 321–346. ISBN 978-3-030-20561-4. [Google Scholar]

- Gahukar, R.T. Edible Insects Farming: Efficiency and Impact on Family Livelihood, Food Security, and Environment Compared With Livestock and Crops. In Insects as Sustainable Food Ingredients; Elsevier: Amsterdam, The Netherlands, 2016; pp. 85–111. [Google Scholar]

- Madau, F.A.; Arru, B.; Furesi, R.; Pulina, P. Insect Farming for Feed and Food Production from a Circular Business Model Perspective. Sustainability 2020, 12, 5418. [Google Scholar] [CrossRef]

- Lähteenmäki-Uutela, A.; Grmelová, N. European Law on Insects in Food and Feed. Eur. Food Feed Law Rev. 2016, 11, 2–8. [Google Scholar]

- Nyakeri, E.M.; Ogola, H.J.O.; Ayieko, M.A.; Amimo, F.A. Valorisation of Organic Waste Material: Growth Performance of Wild Black Soldier Fly Larvae (Hermetia Illucens ) Reared on Different Organic Wastes. J. Insects Food Feed 2017, 3, 193–202. [Google Scholar] [CrossRef]

- Ashizawa, R.; Rubio, N.; Letcher, S.; Parkinson, A.; Dmitruczyk, V.; Kaplan, D.L. Entomoculture: A Preliminary Techno-Economic Assessment. Foods 2022, 11, 3037. [Google Scholar] [CrossRef]

- Toscano, A.; Balzarotti, M.; Re, I. Sustainability Practices and Greenwashing Risk in the Italian Poultry Sector: A Grounded Theory Study. Sustainability 2022, 14, 14088. [Google Scholar] [CrossRef]

- Baum, T.; Cheung, C.; Kong, H.; Kralj, A.; Mooney, S.; Nguyễn Thị Thanh, H.; Ramachandran, S.; Dropulić Ružić, M.; Siow, M. Sustainability and the Tourism and Hospitality Workforce: A Thematic Analysis. Sustainability 2016, 8, 809. [Google Scholar] [CrossRef] [Green Version]

- Lakshmi, V.; Corbett, J. How Artificial Intelligence Improves Agricultural Productivity and Sustainability: A Global Thematic Analysis. In Proceedings of the 53rd Hawaii International Conference on System Sciences, Maui, HI, USA, 7–10 January 2020. [Google Scholar] [CrossRef] [Green Version]

- Opoku, D.-G.J.; Ayarkwa, J.; Agyekum, K. Barriers to Environmental Sustainability of Construction Projects. Smart Sustain. Built Environ. 2019, 8, 292–306. [Google Scholar] [CrossRef]

- Aldulaimi, S.H.; Abdeldayem, M.M. A Thematic Analysis of Leadership Behaviours and Change Management in Higher Education to Boost Sustainability. Int. J. High. Educ. Sustain. 2020, 3, 34. [Google Scholar] [CrossRef]

- The European Parliament and The Council of the European Union. Regulation (EC) No 1069/2009 of the European Parliament and of the Council of 21 October 2009 Laying down Health Rules as Regards Animal by-Products and Derived Products Not Intended for Human Consumption and Repealing Regulation (EC) No 1774/2002 (Animal by-Products Regulation). Off. J. Eur. Union 2009, L-300, 1–33. [Google Scholar]

- Sailer, G.; Hülsemann, B.; Eichermüller, J.; Empl, F.; Poetsch, J.; Pelz, S.; Kuptz, D.; Oechsner, H.; Müller, J. Datasets on Material Properties and Energy Yields of Lab-Designed Organic Fraction of Municipal Solid Waste (OFMSW) Components. Data Br. 2022, 44, 108519. [Google Scholar] [CrossRef]

- Gligorescu, A.; Fischer, C.H.; Larsen, P.F.; Nørgaard, J.V.; Heckman, L.-H.L. Production and Optimization of Hermetia illucens (L.) Larvae Reared on Food Waste and Utilized as Feed Ingredient. Sustainability 2020, 12, 9864. [Google Scholar] [CrossRef]

- Gärttling, D.; Schulz, H. Compilation of Black Soldier Fly Frass Analyses. J. Soil Sci. Plant Nutr. 2022, 22, 937–943. [Google Scholar] [CrossRef]

- APAT Agenzia per La Protezione Dell’ambiente e per i Servizi Tecnici—Digestione Anaerobica Della Frazione Organica Dei Rifiuti Solidi. Available online: https://www.isprambiente.gov.it/contentfiles/00003400/3482-manuali-linee-guida-2005.pdf (accessed on 6 December 2022).

- Centro Ricerche Produzioni Animali C.R.P.A., S.p.A. Recupero e Valorizzazione Energetica (Biogas) e Di Materia (Fertilizzanti e Mangimi) Degli Scarti Organici Dell’industria Di Trasformazione Delle Produzioni Vegetali Ed Animali. Available online: https://www.ilbiogas.it/biogas-ricerche-e-studi/impianti-crpa-modelli.pdf (accessed on 6 December 2022).

- CRPA Soc. Cons. p. A. Prodotti e Servizi-Progetti-Progetti Life-Seq-Cure-Sportelli Di Filiera-FAQ Sportelli-FAQ Sportello BIOGAS-Versione Stampabile. Available online: http://www.crpa.it/nqcontent.cfm?a_id=7234&tt=crpa_www&sp=seq-cure&print_in=1 (accessed on 5 December 2022).

- Drosg, B.; Fuchs, W.; Al, T.; Madsen, S.M.; Linke, B. Nutrient Recovery by Biogas Digestate Processing. 2015. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC97163 (accessed on 5 December 2022).

- Spruijt, J.; Schipperus, R.; Kootstra, M.; de Visser, C.L.M.; Parker, B. AlgaEconomics: Bioeconomic Production Models of Micro-Algae and Downstream Processing to Produce Bio Energy Carriers. 2015. Available online: https://www.enalgae.eu/pdf/Public%20Reports/WP2A7.10%20report%20Business%20economics%20microalgae%20and%20DSP.pdf (accessed on 5 December 2022).

- Chu, H.-Q.; Tan, X.-B.; Zhang, Y.-L.; Yang, L.-B.; Zhao, F.-C.; Guo, J. Continuous Cultivation of Chlorella Pyrenoidosa Using Anaerobic Digested Starch Processing Wastewater in the Outdoors. Bioresour. Technol. 2015, 185, 40–48. [Google Scholar] [CrossRef]

- Hosseinizand, H.; Sokhansanj, S.; Lim, C.J. Studying the Drying Mechanism of Microalgae Chlorella Vulgaris and the Optimum Drying Temperature to Preserve Quality Characteristics. Dry. Technol. 2018, 36, 1049–1060. [Google Scholar] [CrossRef]

- Small-Scale Drying Methods for Black Soldier Fly Larvae. Available online: https://www.eawag.ch/fileadmin/Domain1/Abteilungen/sandec/schwerpunkte/swm/Practical_knowhow_on_BSF/bsf_factsheet_drying.pdf (accessed on 5 December 2022).

- Ozuem, W.; Willis, M.; Howell, K. Thematic Analysis without Paradox: Sensemaking and Context. Qual. Mark. Res. An Int. J. 2022, 25, 143–157. [Google Scholar] [CrossRef]

- Vaismoradi, M.; Turunen, H.; Bondas, T. Content Analysis and Thematic Analysis: Implications for Conducting a Qualitative Descriptive Study. Nurs. Health Sci. 2013, 15, 398–405. [Google Scholar] [CrossRef]

- Castleberry, A.; Nolen, A. Thematic Analysis of Qualitative Research Data: Is It as Easy as It Sounds? Curr. Pharm. Teach. Learn. 2018, 10, 807–815. [Google Scholar] [CrossRef] [PubMed]

- Belotto, M. Data Analysis Methods for Qualitative Research: Managing the Challenges of Coding, Interrater Reliability, and Thematic Analysis. Qual. Rep. 2018, 23, 2622–2633. [Google Scholar] [CrossRef]

- Wresta, A.; Andriani, D.; Saepudin, A.; Sudibyo, H. Economic Analysis of Cow Manure Biogas as Energy Source for Electricity Power Generation in Small Scale Ranch. Energy Procedia 2015, 68, 122–131. [Google Scholar] [CrossRef] [Green Version]

- Live Black Soldier Fly Larvae for Sale—The Critter Depot. Available online: https://www.thecritterdepot.com/products/black-soldier-fly-larvae-for-sale-free-shipping?variant=40963376480394 (accessed on 5 December 2022).

- GME—Statistiche—Dati Di Sintesi MPE-MGP. Available online: https://www.mercatoelettrico.org/It/Statistiche/ME/DatiSintesi.aspx (accessed on 5 December 2022).

- Feed Pricing—Sunrise Farms. Available online: https://sunrisefarm.net/feed-pricing/ (accessed on 5 December 2022).

- Ramat, P. Form and Function in Language Research. In Papers in Honour of Christian Lehmann; Helmbrecht, J., Nishina, Y., Shin, Y.-M., Skopeteas, S., Verhoeven, E., Eds.; De Gruyter Mouton: Berlin, NY, USA, 2009; pp. 151–156. ISBN 9783110216134. [Google Scholar] [CrossRef]

- Rosch, E.; Mervis, C.B. Family Resemblances: Studies in the Internal Structure of Categories. Cogn. Psychol. 1975, 7, 573–605. [Google Scholar] [CrossRef]

- Commission Regulation (EU) 2021/1372 of 17 August 2021 Amending Annex IV to Regulation (EC) No 999/2001 of—Strada Lex Europe. Available online: https://www.stradalex.eu/en/se_src_publ_leg_eur_jo/toc/leg_eur_jo_3_20210818_295/doc/ojeu_2021.295.01.0001.01 (accessed on 5 December 2022).

- Stahel, W.R. The Circular Economy. Nature 2016, 531, 435–438. [Google Scholar] [CrossRef] [Green Version]

- Stubbs, W.; Cocklin, C. Conceptualizing a “Sustainability Business Model”. Organ. Environ. 2008, 21, 103–127. [Google Scholar] [CrossRef]

- Yuan, Z.; Bi, J.; Moriguichi, Y. The Circular Economy: A New Development Strategy in China. J. Ind. Ecol. 2008, 10, 4–8. [Google Scholar] [CrossRef] [Green Version]

- Rumpold, B.A.; Schlüter, O.K. Nutritional Composition and Safety Aspects of Edible Insects. Mol. Nutr. Food Res. 2013, 57, 802–823. [Google Scholar] [CrossRef]

- Hahn, T.; Figge, F.; Pinkse, J.; Preuss, L. A Paradox Perspective on Corporate Sustainability: Descriptive, Instrumental, and Normative Aspects. J. Bus. Ethics 2018, 148, 235–248. [Google Scholar] [CrossRef]

- Carmine, S.; De Marchi, V. Tensions and Outcomes in Corporate Sustainbility: The Moderating Role of Paradoxical Frame. J. Clean. Prod. 2022, 380, 134952. [Google Scholar] [CrossRef]

- Castro, P. Social Representations of Sustainability: Researching Time, Institution, Conflict and Communication. In The Cambridge Handbook of Social Representations; Cambridge University Press: Cambridge, UK, 2015; pp. 295–308. [Google Scholar]

- Raut, R.D.; Mangla, S.K.; Narwane, V.S.; Gardas, B.B.; Priyadarshinee, P.; Narkhede, B.E. Linking Big Data Analytics and Operational Sustainability Practices for Sustainable Business Management. J. Clean. Prod. 2019, 224, 10–24. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F. Towards a Conceptual Framework of ‘Business Models for Sustainability’. In Proceedings of the Knowledge Collaboration & Learning for Sustainable Innovation, ERSCP-EMSU Conference, Delft, The Netherlands, 25–29 October 2010; Wever, R., Quist, J., Tukker, A., Woudstra, J., Boons, F., Beute, N., Eds.; Available online: https://ssrn.com/abstract=2189922 (accessed on 5 December 2022).

- Bateh, J.; Heaton, C.; Arbogast, G.W.; Broadbent, A. Defining Sustainability In The Business Setting. J. Sustain. Manag. 2014, 1, 1–4. [Google Scholar] [CrossRef]

| Equipment/Activity | Power Consumption (MWh/Year) | Heat Consumption (MWh/Year) |

|---|---|---|

| Waste bag opener | 69.26 | - |

| Discs sieve | 9.99 | - |

| Iron separator | 9.99 | - |

| Screw press | 10.66 | - |

| Sludge trap | 10.66 | - |

| BSFL rearing plant | 103.32 | 120 |

| Solid–liquid digestate separation | 63.94 | - |

| Centrifuge (liq. digestate clarification) | 111.95 | - |

| Chlorella spp. oven-drying | - | 8.45 |

| BSFL oven-drying | - | 56.33 |

| Chlorella spp. cultivation (raceway ponds system) | 28.65 | 120 |

| Wastewater aerobic treatment | 32.08 | - |

| Grinding machine (BSFL) | 0.71 | - |

| Grinding machine (Chlorella spp.) | 0.07 | - |

| V-type mixer | 0.33 | - |

| Pellet extruder | 7.97 | - |

| Pellet oven-drying | - | 1.66 |

| Total | 459.56 | 306.44 |

| Equipment/Infrastructure | Cost (EUR ) |

|---|---|

| AD facility (pretreatment, digester, CHP section) | 10,000,000 |

| Composting system | 50,000 |

| Air purification system | 2175 |

| Collection tanks | 100,000 |

| Centrifuges | 249,606 |

| Screw presses | 51,662 |

| Microalgae cultivation facility (raceway pond infrastructure, mixing equipment, sparging equipment, process control, and biomass harvest infrastructure) | 143,000 |

| Industrial mixer V-type | 2420 |

| Ovens | 9880 |

| Grinding machines | 8065 |

| Pellet extruder | 3865 |

| Total equipment | 10,677,275 |

| BSFL rearing warehouse | 500,000 |

| OFMSW pretreatment warehouse | 250,000 |

| Wastewater treatment facility | 300,000 |

| Building land | 6,000,000 |

| Microalgae cultivation warehouse | 500,000 |

| Total infrastructure | 7,550,000 |

| Total investment (equipment and infrastructure) | 18,227,275 |

| Cost Item | Unit | Annual Cost |

|---|---|---|

| Water | EUR /m3 | 38,544 |

| 6-day-old BSFL | EUR /kg | 78,795 |

| Wastewater aerobic treatment | EUR /m3 | 32,079 |

| Feed additives | EUR | 5298 |

| Total Consumables | EUR | 154,716 |

| Personnel | EUR | 234,000 |

| Maintenance | EUR | 24,000 |

| Contingencies | EUR | 20,000 |

| Total direct costs | EUR | 432,716 |

| General administration | EUR | 10,000 |

| Insurance | EUR | 20,000 |

| Staff training | EUR | 4500 |

| Plant security contributions | EUR | 3000 |

| Total indirect costs | EUR | 37,500 |

| Total costs | EUR | 470,216 |

| Revenue Item | Unit | Annual Revenue |

|---|---|---|

| Electric energy | EUR /MWh | 938,388 |

| OFMSW treatment | EUR | 1,000,000 |

| Smart Feed | EUR | 50,455 |

| Total revenues | EUR | 1,988,843 |

| Code | Theme | |

|---|---|---|

| Model Institutional framework Organizational view | General reduction of impact We do not deal with it | |

| General model | ||

| Animal welfare Health Cleanliness and hygiene No human exploitation | Environment Nature/ecology Overview | Environment, health, and welfare |

| Resource consumption No exploitation of land | Reduction of waste | Resource consumption/exploitation |

| Reduction of pollution | Pollution avoidance | Pollution |

| Reduction of energy consumption Renewable energy sources Saving/avoiding waste | Switch off machinery Automation | Energy consumption |

| Traceability of ingredients Ingredient selection Selection of raw materials | Supplier selection Customer selection | Supply |

| Logistics Transport optimization | Reduction of transportation costs Reduction of costs | Storage and transportation |

| Waste management Waste reduction | Reduction of disposal costs | Waste/scraps |

| Economic sustainability Marginality Costs of sustainability | Market dependence Economies of scale Foster the market | Company cost/benefit |

| Attention | Established practice | Effort/habit |

| What we do As we understand it | Brand | Identity |

| Officinal plants Antibiotics with essential oils Reduction of antibiotics | Replacement of chemical components Natural products Reduction of additives | Natural products |

| Single packages Packaging reduction Eco-friendly packaging | Avoiding plastic Recycled packaging | Packaging |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buccaro, M.; Toscano, A.; Balzarotti, M.; Re, I.; Bosco, D.; Bettiga, M. Techno-Economic Assessment of APS-Based Poultry Feed Production with a Circular Biorefinery Process. Sustainability 2023, 15, 2195. https://doi.org/10.3390/su15032195

Buccaro M, Toscano A, Balzarotti M, Re I, Bosco D, Bettiga M. Techno-Economic Assessment of APS-Based Poultry Feed Production with a Circular Biorefinery Process. Sustainability. 2023; 15(3):2195. https://doi.org/10.3390/su15032195

Chicago/Turabian StyleBuccaro, Marta, Armando Toscano, Melissa Balzarotti, Ilaria Re, Diego Bosco, and Maurizio Bettiga. 2023. "Techno-Economic Assessment of APS-Based Poultry Feed Production with a Circular Biorefinery Process" Sustainability 15, no. 3: 2195. https://doi.org/10.3390/su15032195

APA StyleBuccaro, M., Toscano, A., Balzarotti, M., Re, I., Bosco, D., & Bettiga, M. (2023). Techno-Economic Assessment of APS-Based Poultry Feed Production with a Circular Biorefinery Process. Sustainability, 15(3), 2195. https://doi.org/10.3390/su15032195