Evaluation Model Research of Coal Mine Intelligent Construction Based on FDEMATEL-ANP

Abstract

:1. Introduction

2. Literature Review

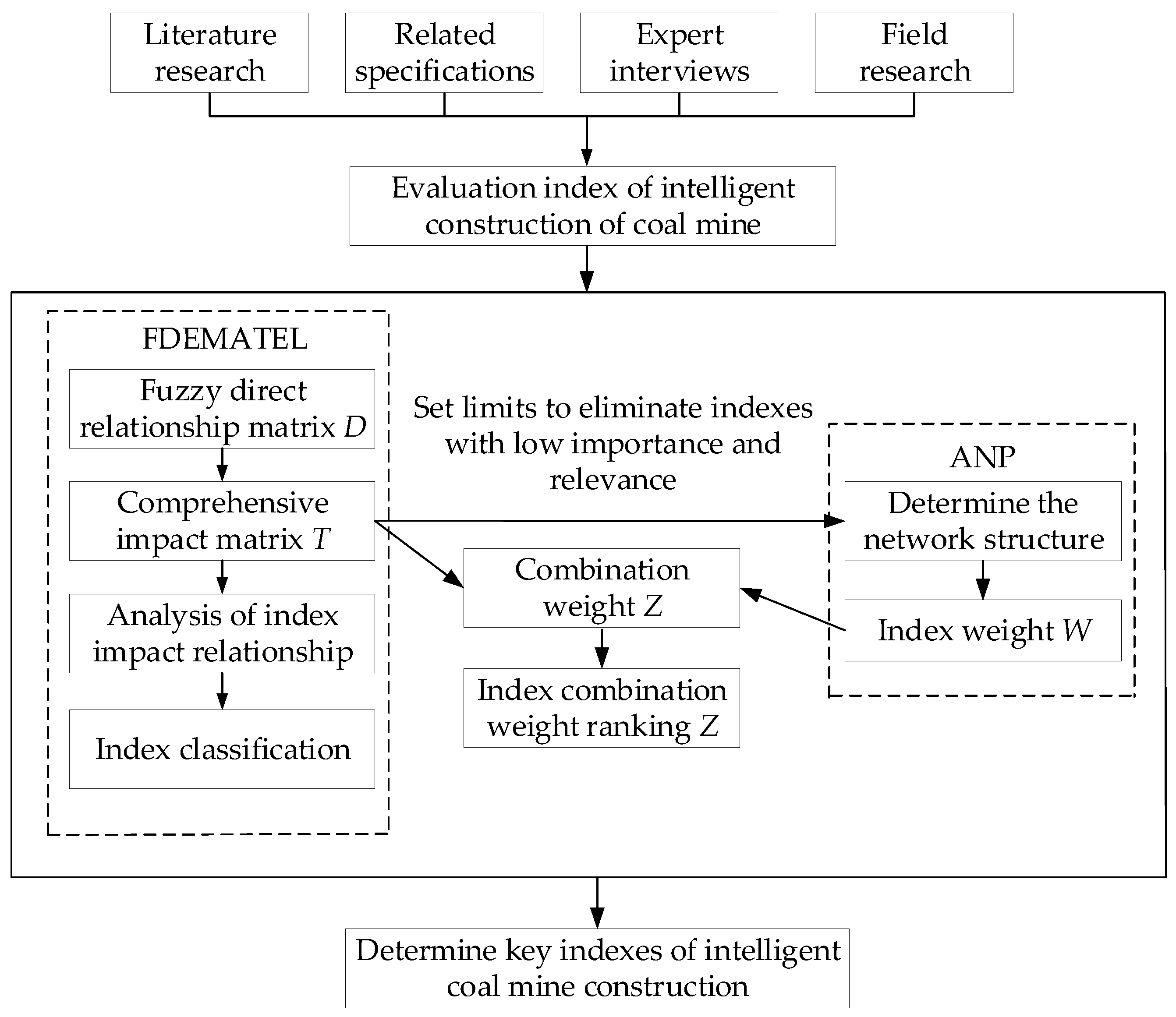

3. Materials and Methods

3.1. Intelligent Coal Mine Construction Connotations

3.2. Coal Mine Intelligent Construction Evaluation Index System

3.3. FDEMATEL Model

- (1)

- Standardized triangular fuzzy numbers.

- (2)

- Normalized left and right values.

- (3)

- Calculate the total standardized value

- (4)

- Calculate the exact value of expert k triangular fuzzy judgment value

- (5)

- Calculate the standard exact value of the evaluation by p experts

- (6)

- Determine the fuzzy direct relationship matrix D.

3.4. ANP Model

3.5. Mixed Weights

4. Results

4.1. Influence Relationship Determination Based on FDEMATEL

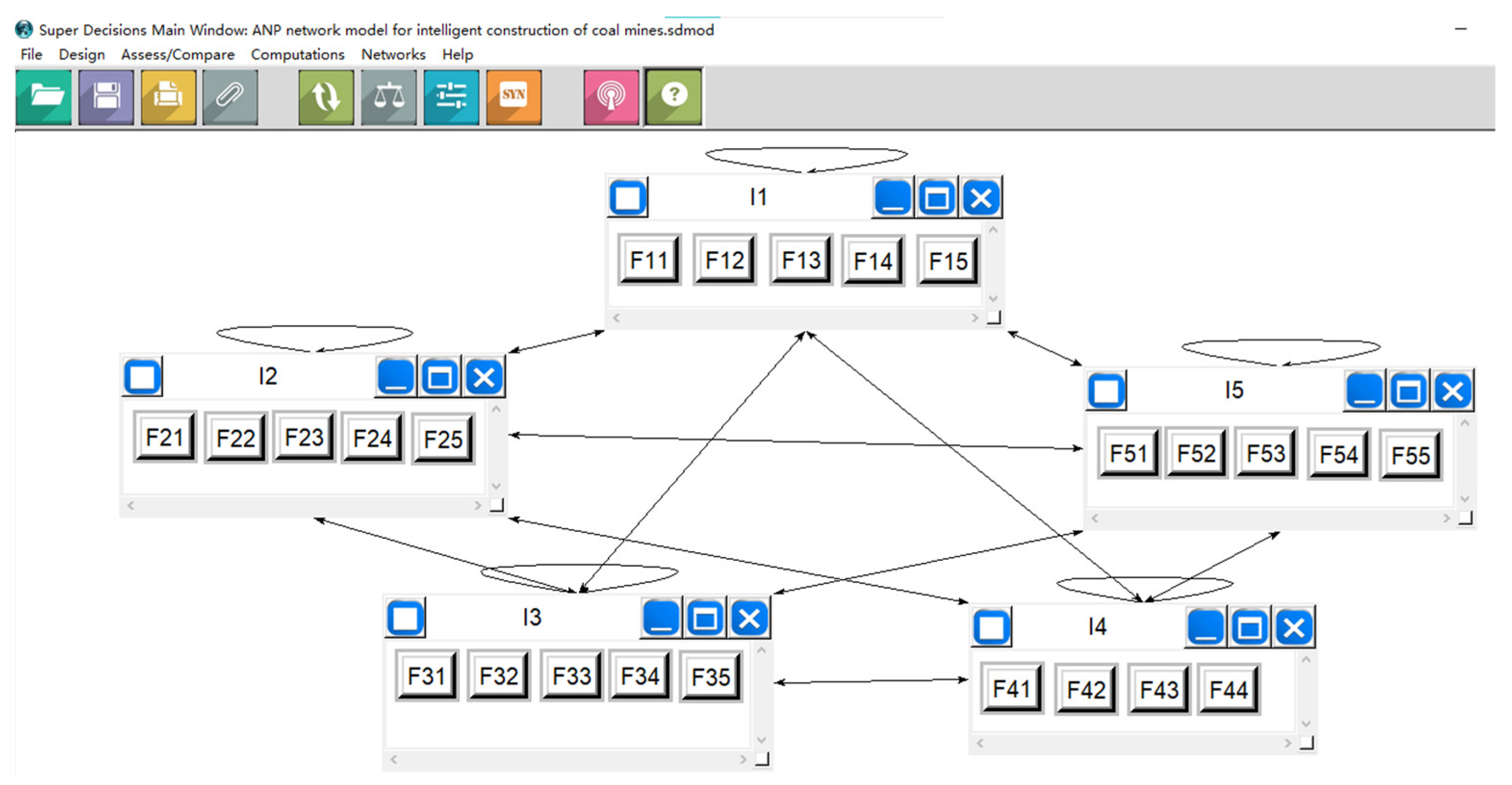

4.2. Index Weight Calculation Based on ANP

4.3. Mixed Weight Calculation

5. Discussion

5.1. Comparative Validation

5.2. Results Analysis

- (1)

- Analysis of index influence relationship. From the calculation results of the FDEMATEL method, it can be seen that the influence degree of the basic platform intelligence (I1) is 3.340, which is the highest in the ranking of the influence degrees in the first-grade index, and the influence degrees in the other first-grade indexes are less than three. This shows that the basic platform intelligence is an important cornerstone of the intelligent construction of coal mines, which can provide comprehensive services for the construction of various business systems at a later stage and ensure reliable data collection, transmission, storage, and application. The influence degrees of mobile internet construction (F14), database construction (F11), and big data support (F12) are ranked in the top three in all second-grade indexes, and these three indexes belong to the basic platform intelligence (I1) in the first-grade indexes. Once again, it confirms the key influence of the intelligent construction of the basic platform in promoting the process of intelligent coal mining. Green development intelligence (I5) is the most influenced index among the first-grade indexes, with an influence degree of 3.629, and the influence degrees of other first-grade indexes are less than three. It shows that coal mining should pay attention to the green service of the whole life cycle, to achieve the essential green of coal mining, in order to reach the green development goal of the intelligent construction of coal mines. The top three influenced second-grade indexes are electrical equipment safety monitoring (F33), emergency rescue control (F35), and geological monitoring (F31), and these three indexes belong to the first-grade indexes of safety monitoring intelligence (I3). It shows that the services and applications of safety monitoring are based on the collection of real-time and historical data related to coal mine production scenarios and industrial scenarios, which are realized by integrating and analyzing the collected data.

- (2)

- Analysis of index attributes. The FDEMATEL method analysis shows that the basic platform intelligence (I1), safety monitoring intelligence (I3), and information management intelligence (I4) are the cause factors, and the production process intelligence (I2) and green development intelligence (I5) are the result factors in the first-grade indexes. This indicates that the most important thing to consider in the intelligent construction of coal mines is the application of information technology and the development of safe production. In the whole intelligent coal mine construction evaluation index system, there are 13 second-grade indexes with positive cause degrees, which are cause factors and easily influence other factors in the system. Among them, safety prevention closed-loop decisions (F25), database construction (F11), and big data support (F12) are strong cause factors, and their cause degree is 2.846, 2.269, and 2.025, respectively, while the cause degree of other cause factors is less than two. It indicates that the strong cause factors have an important influence on promoting the intelligent construction of coal mines and should be focused on in the intelligent construction of coal mines. The cause degrees of the remaining 11 second-grade indexes are negative. These indexes are result factors, which are easily influenced by the above-mentioned cause factors in the system, and focusing on the changes in these factors can clarify the improvement path and development direction of coal mine intelligent construction. Among the result factors, electrical equipment safety monitoring (F33) and emergency rescue control (F35) are strong result factors with a cause degree of −3.193 and −2.115, respectively, while the cause degree of other result factors is greater than −2. It indicates that real-time online monitoring of coal mine hazards, determination of risk types, levels, and corresponding solutions through the application of information technology, such as big data, the internet of things, and artificial intelligence, are effective ways to achieve intelligent coal mine safety production and management.

- (3)

- Analysis of index importance. Mixed weights are the comprehensive influence weights obtained by considering the interaction between the evaluation indexes and combining the ANP method. It reflects the weight and correlation degree of each element, provides the priority order of each element, and its ranking result is the ranking of each evaluation index in the whole coal mine intelligent construction evaluation system. Therefore, the best way to promote the intelligent construction of coal mines is to improve the evaluation indexes that have greater weight and relevance in the whole evaluation system. Improving such indexes will increase the value of other evaluation indexes and can promote the high-quality development of the whole intelligent construction of coal mines. From the mixed weights in Table 10, it can be seen that the relative importance of the first-grade indexes is ranked as I1 > I3 > I5 > I4 > I2, the highest relative importance is the basic platform intelligence (I1), and the lowest is the production process intelligence (I2). This is because the information technology system provides technology and equipment support for the intelligent construction of coal mines, which is an important cornerstone of the intelligent construction of coal mines. Therefore, coal mine intelligent construction enterprise managers need to pay more attention to the intelligent construction of the basic platform. The lowest weight of production process intelligence (I2) does not mean that the construction of production process intelligence is insignificant, but it is the least important compared with other first-grade indexes, and it is still an important goal to promote coal mining enterprises to realize a reduction in field staff and efficient development of resources. In the mixed weight ranking of second-grade indexes, database construction (F11), mobile internet construction (F14), big data support (F12), and model algorithm support (F13) are the top four, and all of them belong to the first-grade index base platform intelligence (I1), so the base platform intelligence will provide the basic guarantee for the construction of various business systems in the coal mine.

5.3. Countermeasures and Suggestions to Promote the Intelligent Construction of Coal Mines

- (1)

- Refine the top-level design of the industry and form a unified construction standard. In promoting the construction of intelligent mines, we should further refine the construction standards and standardize the standards of various intelligent parameters, interfaces, and protocols to lay a good foundation for later unified management. At the same time, promote the technical support and security forces, promote teaching and research forces integration, and strengthen long-term stable cooperation with well-known universities, research institutes, and leading information technology enterprises at home and abroad in related fields, to make up for the lack of their own strength.

- (2)

- Strengthen the integration of advanced technologies and accelerate the process of mine intelligence. Promote the integration of cloud computing, big data, the internet of things, artificial intelligence, mobile internet, and other new generation information technology with intelligent mines in depth, and promote the integration of cross-disciplinary technologies.

- (3)

- Strengthen the cultivation of professional talents and build innovative technical teams. Strengthen academic exchanges within the industry, vigorously promote cooperation between mining enterprises and relevant research institutes, and support the application and transformation of scientific and technological achievements. Continuously improve the ability of mine managers and technicians to use data to analyze problems and solve them, strengthen training and education on the quality of information technology for all staff, and build a composite and innovative core talent team.

5.4. Limitations and Future Research

6. Conclusions

- (1)

- The factors influencing the intelligent construction of coal mines are summarized. Through literature research, expert consultation, and a questionnaire survey, the evaluation index system of coal mine intelligent construction was constructed. It includes 5 first-grade indexes and 24 second-grade indexes.

- (2)

- The FDEMATEL-ANP evaluation model was applied to analyze the comprehensive impact of various influencing factors on the intelligent construction of coal mines. The results show that safety prevention closed-loop decisions, database construction, and big data support have a significant impact on the intelligent construction of coal mines. Database construction, mobile internet construction, big data support, and model algorithm support are the key factors affecting the intelligent construction of coal mines.

- (3)

- By analyzing and constructing the index system of influencing factors on coal mine intelligent construction, this study can effectively guide the intelligent construction of coal mines. The case verification shows that the comprehensive weights of indexes calculated by the FDEMATEL-ANP model are basically consistent with the results calculated by the ANP model and consistent with the results calculated by the SWARA model. This calculation result matches with the actual situation and verifies the scientific nature and applicability of the evaluation model. Based on this, the coal mining industry and related enterprises can improve the corresponding standards and take corresponding measures to promote the high-quality development of intelligent coal mine construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| First-Grade Indexes | I1 | I2 | I3 | I4 | I5 |

|---|---|---|---|---|---|

| I1 | 0 | 4 | 4 | 1 | 3 |

| I2 | 5 | 0 | 4 | 3 | 5 |

| I3 | 2 | 3 | 0 | 2 | 2 |

| I4 | 4 | 2 | 1 | 0 | 1 |

| I5 | 5 | 3 | 3 | 2 | 0 |

| First-Grade Indexes | I1 | I2 | I3 | I4 | I5 |

|---|---|---|---|---|---|

| I1 | 0 | 1 | 3 | 1 | 1 |

| I2 | 1 | 0 | 2 | 1 | 3 |

| I3 | 2 | 2 | 0 | 2 | 2 |

| I4 | 3 | 2 | 1 | 0 | 1 |

| I5 | 2 | 4 | 2 | 4 | 0 |

| First-Grade Indexes | I1 | I2 | I3 | I4 | I5 |

|---|---|---|---|---|---|

| I1 | 0 | 1 | 3 | 4 | 5 |

| I2 | 1 | 0 | 3 | 1 | 4 |

| I3 | 3 | 3 | 0 | 2 | 4 |

| I4 | 1 | 3 | 4 | 0 | 5 |

| I5 | 1 | 4 | 4 | 5 | 0 |

| First-Grade Indexes | I1 | I2 | I3 | I4 | I5 |

|---|---|---|---|---|---|

| I1 | 0 | 1 | 1 | 1 | 4 |

| I2 | 1 | 0 | 1 | 2 | 3 |

| I3 | 2 | 2 | 0 | 2 | 2 |

| I4 | 1 | 1 | 1 | 0 | 1 |

| I5 | 1 | 3 | 1 | 4 | 0 |

| First-Grade Indexes | I1 | I2 | I3 | I4 | I5 |

|---|---|---|---|---|---|

| I1 | 0 | 5 | 1 | 5 | 1 |

| I2 | 1 | 0 | 1 | 2 | 1 |

| I3 | 2 | 2 | 0 | 3 | 2 |

| I4 | 1 | 1 | 1 | 0 | 3 |

| I5 | 1 | 3 | 1 | 1 | 0 |

References

- Shang, Y.Q.; Wang, X.Q. Visual Analysis of Intelligent Knowledge Atlas of Coal Mines in China. Min. Res. Dev. 2021, 41, 192–198. (In Chinese) [Google Scholar]

- Tian, Y.; Yang, X.; Yang, J.; Mao, K.K.; Yao, Y.J.; Liang, H.S. Evolution dynamic of intelligent construction strategy of coal mine enterprises in China. Heliyon 2022, 8, e10933. [Google Scholar] [CrossRef] [PubMed]

- Fu, E.S.; Liu, G.W.; Zhao, H.; Qu, Y.M.; Di, S.; Jiang, L. Research on the overall framework and key technologies of intelligent open-pit mines. Ind. Mine Autom. 2021, 47, 27–32. (In Chinese) [Google Scholar]

- Wei, D.; Wang, Z.B.; Si, L.; Tan, C.; Lu, X.L. Online shearer-onboard personnel detection method for the intelligent fully mechanized mining face. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 3058–3072. [Google Scholar] [CrossRef]

- Zhang, K.X.; Kang, L.; Chen, X.X.; He, M.C.; Zhu, C.; Li, D. A Review of Intelligent Unmanned Mining Current Situation and Development Trend. Energies 2022, 15, 513. [Google Scholar] [CrossRef]

- Luo, X.Y.; Li, J.A.; Lang, D. Basic connotation, core problems and key technologies of wisdom mine. Ind. Mine Autom. 2019, 45, 61–64. (In Chinese) [Google Scholar]

- He, S.; Wang, H.Y.; Zhao, L. Key technology and intelligent management and control concept of intelligent construction of open-pit coal mine. Saf. Coal Mines 2020, 51, 298–304. (In Chinese) [Google Scholar]

- Li, J.G.; Zhan, K. Intelligent mining technology for an underground metal mine based on unmanned equipment. Engineering 2018, 4, 381–391. [Google Scholar] [CrossRef]

- Wang, J.H.; Huang, Z.H. The recent technological development of intelligent mining in China. Engineering 2017, 3, 439–444. [Google Scholar] [CrossRef]

- Bing, Z.; Wang, X.; Dong, Z.L.; Dong, L.B.; He, T. A novel edge computing architecture for intelligent coal mining system. Wirel. Netw. 2022, 1–10. [Google Scholar] [CrossRef]

- Wang, G.F.; Ren, H.W.; Zhao, G.R.; Zhang, D.S.; Wen, Z.G.; Meng, L.Y.; Gong, S.X. Research and practice of intelligent coal mine technology systems in China. Int. J. Coal Sci. Technol. 2022, 9, 24. [Google Scholar] [CrossRef]

- Bai, J.Y.; Zheng, D.Z.; Jia, C. Safety Technology Risks and Countermeasures in the Intelligent Construction of Coal Mines. Geofluids 2022, 2022, 4491044. [Google Scholar] [CrossRef]

- Chen, W.; Wang, X.Z. Coal mine safety intelligent monitoring based on wireless sensor network. IEEE Sens. J. 2020, 21, 25465–25471. [Google Scholar] [CrossRef]

- Wo, X.F.; Li, G.C.; Sun, Y.T.; Li, J.H.; Yang, S.; Hao, H.R. The Changing Tendency and Association Analysis of Intelligent Coal Mines in China: A Policy Text Mining Study. Sustainability 2022, 14, 11650. [Google Scholar] [CrossRef]

- Lu, Z.L.; Zhu, X.D.; Wang, H.L.; Li, Q. Mathematical modeling for intelligent prediction of gas accident number in Chinese coal mines in recent years. J. Intell. Fuzzy Syst. 2018, 35, 2649–2655. [Google Scholar] [CrossRef]

- Lu, J.; Li, P.; Xu, Q.Y.; Ning, Z.X.; Zhang, W.J.; Zheng, J.L. Path research of smart mines in Shanxi Province under the background of carbon peak and carbon neutrality. Coal Eng. 2022, 54, 186–192. (In Chinese) [Google Scholar]

- Qiu, S.H.; Tan, Z.L. Study on index system of intelligent mine construction degree in coal enterprises. Coal Sci. Technol. 2019, 47, 259–266. (In Chinese) [Google Scholar]

- Li, A.L.; Zhang, J.X.; Zhou, N.; Li, M.; Zhang, W.Q. A model for evaluating the production system of an intelligent mine based on unascertained measurement theory. J. Intell. Fuzzy Syst. 2020, 38, 1865–1875. [Google Scholar] [CrossRef]

- Guo, Y.J. Research on intelligent evaluation system of open-pit mine. Saf. Coal Mines 2022, 53, 247–251+256. (In Chinese) [Google Scholar]

- He, Y.Y. Discussion on evaluation index system and architecture of smart mine. Ind. Mine Autom. 2017, 43, 16–20. (In Chinese) [Google Scholar]

- Wang, L.F. The Theory and Algorithm of Analytic Network Process. Syst. Eng. Theory Pract. 2001, 3, 44–50. [Google Scholar]

- Cheng, L.H.; Guo, H.M. Study on factors influencing coal mine work safety based on SEM. China Saf. Sci. J. 2018, 28, 137–142. [Google Scholar]

- Cheng, L.H.; Guo, H.M.; Lin, H.F. Evolutionary model of coal mine safety system based on multi-agent modeling. Process Saf. Environ. Prot. 2021, 147, 1193–1200. [Google Scholar] [CrossRef]

- Qiu, Z.X.; Liu, Q.L.; Li, X.C.; Zhang, J.J.; Zhang, Y.Q. Construction and analysis of a coal mine accident causation network based on text mining. Process Saf. Environ. Prot. 2021, 153, 320–328. [Google Scholar] [CrossRef]

- Jiang, X.Y.; Lu, K.; Xia, B.; Liu, Y.; Cui, C.Y. Identifying significant risks and analyzing risk relationship for construction PPP projects in China using integrated FISM-MICMAC approach. Sustainability 2019, 11, 5206. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.L.; Cao, Q.G.; Zhou, L.J. Research on the influencing factors in coal mine production safety based on the combination of DEMATEL and ISM. Saf. Sci. 2018, 103, 51–61. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, G.; Wu, P.; Qiu, J. An Integrated Gray DEMATEL and ANP Method for Evaluating the Green Mining Performance of Underground Gold Mines. Sustainability 2022, 14, 6812. [Google Scholar] [CrossRef]

- Mardani, A.; Jusoh, A.; Zavadskas, E.K.; Cavallaro, F.; Khalifah, Z. Sustainable and Renewable Energy: An Overview of the Application of Multiple Criteria Decision Making Techniques and Approaches. Sustainability 2015, 7, 13947–13984. [Google Scholar] [CrossRef] [Green Version]

- Rakhmangulov, A.; Burmistrov, K.; Osintsev, N. Selection of Open-Pit Mining and Technical System’s Sustainable Development Strategies Based on MCDM. Sustainability 2022, 14, 8003. [Google Scholar] [CrossRef]

- Lenarczyk, A.; Jaskólski, M.; Bućko, P. The Application of a Multi-Criteria Decision-Making for Indication of Directions of the Development of Renewable Energy Sources in the Context of Energy Policy. Energies 2022, 15, 9629. [Google Scholar] [CrossRef]

- Wang, X.P.; Zhang, C.; Deng, J.; Su, C.; Gao, Z.Z. Analysis of factors influencing miners’ unsafe behaviors in intelligent mines using a novel hybrid MCDM model. Int. J. Environ. Res. Public Health 2022, 19, 7368. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Li, H.X.; Tian, S.C. Application of AHP and DEMATEL for Identifying Factors Influencing Coal Mine Practitioners’ Unsafe State. Sustainability 2022, 14, 14511. [Google Scholar] [CrossRef]

- Zhang, K.X.; Yan, X.C.; He, M.C.; Chen, X.X.; Sun, J.D.; Li, D.; Wang, X.L.; Kang, L.; Yang, H.J.; Zhu, J.A.; et al. Study on intelligent adaptability evaluation of intelligent coal mining working face based on ANP and matter-element extension model. J. Min. Strat. Control Eng. 2022, 5, 016539. (In Chinese) [Google Scholar]

- Li, D.Y.; Sun, K.X.; Wang, S.; Wang, Z.G.; Zhang, X.H. Study on safety evaluation of intelligent working face based on extension theory with entropy weight approach. J. Henan Polytech. Univ. 2022, 41, 1–9. (In Chinese) [Google Scholar]

- Wang, G.F.; Peng, Y.H.; Ren, H.W. Research and development path of smart mine technology system. Metal Mine 2022, 51, 1–9. (In Chinese) [Google Scholar]

- Lu, P.F.; He, M.; Chen, X.J.; Bao, Y.T. Development and prospect of wisdom mine. Ind. Mine Autom. 2018, 44, 84–88. (In Chinese) [Google Scholar]

- Huo, Z.G.; Wu, X.L. Development tendency of internet plus intelligent mine. Coal Sci. Technol. 2016, 44, 28–33+63. (In Chinese) [Google Scholar]

- Sun, C.S.; Song, X.B.; Gong, H.J. Construction strategy of intelligent coal mine. Coal Eng. 2021, 53, 191–196. (In Chinese) [Google Scholar]

- Li, M.; Yang, S.W.; Sun, Z.M.; Wu, H. Study on framework and development prospects of intelligent mine. Coal Sci. Technol. 2017, 45, 121–128+134. (In Chinese) [Google Scholar]

- Hatefi, S.M.; Tamošaitienė, J. An integrated fuzzy DEMATEL-fuzzy ANP model for evaluating construction projects by considering interrelationships among risk factors. J. Civ. Eng. Manag. 2019, 25, 114–131. [Google Scholar] [CrossRef] [Green Version]

- Büyüközkan, G.; Güleryüz, S. An integrated DEMATEL-ANP approach for renewable energy resources selection in Turkey. Int. J. Prod. Econ. 2016, 182, 435–448. [Google Scholar] [CrossRef]

- Li, R.J. Fuzzy method in group decision making. Comput. Math. Appl. 1999, 38, 91–101. [Google Scholar] [CrossRef] [Green Version]

- OPRICOVIC, S.; TZENG, G.H. Defuzzification within a multicriteria decision model. Int. J. Uncertain. Fuzziness Knowl. Based Syst. 2003, 11, 635–652. [Google Scholar] [CrossRef]

- Zhao, X.N.; Xiao, T. Research on Factors Influencing Employee’s Green Behavior Based on Fuzzy-DEMATEL-ISM Method. Sci. Technol. Manag. Res. 2021, 41, 195–204. (In Chinese) [Google Scholar]

- Liu, J.; Hou, J.J.; Qi, Y. Research on evaluation of tourism industry structure optimization in China based on DEMATEI-ANP model. Geogr. Geo-Inf. Sci. 2021, 37, 102–112. (In Chinese) [Google Scholar]

- Karuppiah, K.; Sankaranarayanan, B.; Ali, S.M. A fuzzy ANP–DEMATEL model on faulty behavior risks: Implications for improving safety in the workplace. Int. J. Occup. Saf. Ergon. 2022, 28, 923–940. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.Q.; Wang, H.; Yan, C.G. Analysis on Human Factors in Aviation Maintenance Based on DEMATEL and ANP. Saf. Environ. Eng. 2014, 21, 128–133. (In Chinese) [Google Scholar]

- Şimşek, K.; Alp, S. Evaluation of Landfill Site Selection by Combining Fuzzy Tools in GIS-Based Multi-Criteria Decision Analysis: A Case Study in Diyarbakır, Turkey. Sustainability 2022, 14, 9810. [Google Scholar] [CrossRef]

- Dinçer, H.; Yüksel, S.; Aksoy, T.; Hacıoğlu, Ü. Application of M-SWARA and TOPSIS Methods in the Evaluation of Investment Alternatives of Microgeneration Energy Technologies. Sustainability 2022, 14, 6271. [Google Scholar] [CrossRef]

- Ighravwe, D.E. Assessment of Sustainable Maintenance Strategy for Manufacturing Industry. Sustainability 2022, 14, 13850. [Google Scholar] [CrossRef]

| Goal Layer | First-Grade Indexes | Second-Grade Indexes |

|---|---|---|

| Coal mine intelligent construction evaluation A | Basic platform intelligence I1 | Database construction F11 |

| Big data support F12 | ||

| Model algorithm support F13 | ||

| Mobile internet construction F14 | ||

| Information safety system construction F15 | ||

| Production process intelligence I2 | Reliability of working surface equipment F21 | |

| Intelligent diagnosis technology of equipment fault F22 | ||

| Mining collaborative design F23 | ||

| Production closed-loop control F24 | ||

| Safety prevention closed-loop decision F25 | ||

| Safety monitoring intelligence I3 | Geological monitoring F31 | |

| Ventilation and fire safety monitoring F32 | ||

| Electrical equipment safety monitoring F33 | ||

| Personnel safety monitoring F34 | ||

| Emergency rescue control F35 | ||

| Information management intelligence I4 | Information collection coverage capability F41 | |

| Data resource mining capability F42 | ||

| Data statistical analysis ability F43 | ||

| Information management system integration capability F44 | ||

| Green development intelligence I5 | Intelligent dust control F51 | |

| Intelligent control of toxic and hazardous substances F52 | ||

| Drained water reuse F53 | ||

| Clean energy utilization F54 | ||

| Ecological restoration management F55 |

| Linguistic Variable | Expert Ratings | Triangular Fuzzy Number |

|---|---|---|

| Very low influence (VL) | 1 | (0, 0, 0.25) |

| Low influence (L) | 2 | (0, 0.25, 0.5) |

| Medium influence (M) | 3 | (0.25, 0.5, 0.75) |

| High influence (H) | 4 | (0.5, 0.75, 1) |

| Very high influence (VH) | 5 | (0.75, 1, 1) |

| Scale | Meaning Description |

|---|---|

| 1 | Index i and index j have the same importance |

| 3 | Index i is slightly more important than index j |

| 5 | Index i is significantly more important than index j |

| 7 | Index i is extremely more important than index j |

| 9 | Index i is strongly more important than index j |

| 2, 4, 6, 8 | Intermediate value of the above adjacent judgment |

| Reciprocal | The importance ratio of index i to index j is one of the values above, then the importance ratio of index j to index i is its reciprocal |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| RI | 0.00 | 0.00 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 |

| First-Grade Indexes | I1 | I2 | I3 | I4 | I5 | fi | Mi | Ni |

|---|---|---|---|---|---|---|---|---|

| I1 | 0.350 | 0.771 | 0.739 | 0.549 | 0.931 | 3.340 | 5.075 | 1.605 |

| I2 | 0.338 | 0.326 | 0.520 | 0.355 | 0.634 | 2.172 | 4.692 | −0.347 |

| I3 | 0.362 | 0.583 | 0.469 | 0.538 | 0.862 | 2.814 | 5.608 | 0.021 |

| I4 | 0.301 | 0.401 | 0.493 | 0.000 | 0.707 | 1.901 | 3.722 | 0.081 |

| I5 | 0.384 | 0.438 | 0.573 | 0.379 | 0.495 | 2.270 | 5.899 | −1.359 |

| ei | 1.735 | 2.520 | 2.794 | 1.821 | 3.629 | - | - | - |

| Indexes | fi | ei | Mi | Ni |

|---|---|---|---|---|

| F11 | 5.812 | 3.534 | 9.355 | 2.269 |

| F12 | 5.694 | 3.669 | 9.364 | 2.025 |

| F13 | 5.574 | 5.274 | 10.848 | 0.300 |

| F14 | 5.964 | 4.471 | 10.435 | 1.494 |

| F15 | 5.024 | 3.739 | 8.762 | 1.285 |

| F21 | 4.662 | 4.260 | 8.921 | 0.402 |

| F22 | 4.392 | 6.013 | 10.405 | −1.622 |

| F23 | 4.028 | 4.754 | 8.781 | −0.726 |

| F24 | 3.994 | 5.734 | 9.728 | −1.741 |

| F25 | 5.512 | 2.666 | 8.179 | 2.846 |

| F31 | 4.815 | 6.648 | 11.463 | −1.834 |

| F32 | 4.635 | 6.247 | 10.882 | −1.613 |

| F33 | 4.478 | 7.672 | 12.150 | −3.193 |

| F34 | 5.610 | 3.766 | 9.376 | 1.845 |

| F35 | 4.850 | 6.965 | 11.815 | −2.115 |

| F41 | 5.219 | 4.481 | 9.699 | 0.738 |

| F42 | 5.562 | 5.050 | 10.612 | 0.512 |

| F43 | 5.283 | 5.061 | 10.344 | 0.222 |

| F44 | 5.277 | 4.772 | 10.048 | 0.505 |

| F51 | 5.330 | 5.975 | 11.305 | −0.644 |

| F52 | 4.750 | 4.557 | 9.307 | 0.194 |

| F53 | 4.929 | 5.302 | 10.230 | −0.373 |

| F54 | 4.579 | 5.105 | 9.684 | −0.525 |

| F55 | 4.694 | 4.947 | 9.641 | −0.253 |

| I2 | I1 | I2 | I3 | I4 | I5 | Weight |

|---|---|---|---|---|---|---|

| I1 | 1 | 1/2 | 1/3 | 1/2 | 3 | 0.134 |

| I2 | 2 | 1 | 1/2 | 3 | 2 | 0.244 |

| I3 | 3 | 2 | 1 | 4 | 3 | 0.395 |

| I4 | 2 | 1/3 | 1/4 | 1 | 2 | 0.142 |

| I5 | 1/3 | 1/2 | 1/3 | 1/2 | 1 | 0.085 |

| Consistency judgment | CR = 0.076 < 0.1 | |||||

| F14 | F41 | F42 | F43 | F44 | Weight |

|---|---|---|---|---|---|

| F41 | 1 | 3 | 2 | 1/2 | 0.285 |

| F42 | 1/3 | 1 | 3 | 1/3 | 0.166 |

| F43 | 1/2 | 1/3 | 1 | 1/4 | 0.097 |

| F44 | 2 | 3 | 4 | 1 | 0.452 |

| Consistency judgment | CR = 0.082 < 0.1 | ||||

| F23 | F51 | F52 | F53 | F54 | F55 | |

| F51 | 1 | 3 | 1/2 | 4 | 3 | 0.282 |

| F52 | 1/3 | 1 | 1/3 | 3 | 1/3 | 0.106 |

| F23 | F51 | F52 | F53 | F54 | F55 | |

| F53 | 2 | 3 | 1 | 3 | 4 | 0.387 |

| F54 | 1/4 | 1/3 | 1/3 | 1 | 1/3 | 0.065 |

| F55 | 1/3 | 3 | 1/4 | 3 | 1 | 0.159 |

| Consistency judgment | CR = 0.096 < 0.1 | |||||

| First-Grade Indexes | Weight Z | Second-Grade Indexes | Mixed Weight Z | Sort |

|---|---|---|---|---|

| Basic platform intelligence I1 | 0.247 | Database construction F11 | 0.054 | 1 |

| Big data support F12 | 0.049 | 3 | ||

| Model algorithm support F13 | 0.048 | 4 | ||

| Mobile internet construction F14 | 0.050 | 2 | ||

| Information safety system construction F15 | 0.045 | 8 | ||

| Production process intelligence I2 | 0.177 | Reliability of working surface equipment F21 | 0.037 | 17 |

| Intelligent diagnosis technology of equipment fault F22 | 0.034 | 21 | ||

| Mining collaborative design F23 | 0.032 | 23 | ||

| Production closed-loop control F24 | 0.031 | 24 | ||

| Safety prevention closed-loop decision F25 | 0.043 | 12 | ||

| Safety monitoring intelligence I3 | 0.207 | Geological monitoring F31 | 0.044 | 11 |

| Ventilation and fire safety monitoring F32 | 0.037 | 16 | ||

| Electrical equipment safety monitoring F33 | 0.041 | 15 | ||

| Personnel safety monitoring F34 | 0.044 | 10 | ||

| Emergency rescue control F35 | 0.041 | 14 | ||

| Information management intelligence I4 | 0.184 | Information collection coverage capability F41 | 0.046 | 6 |

| Data resource mining capability F42 | 0.048 | 5 | ||

| Data statistical analysis ability F43 | 0.044 | 9 | ||

| Information management system integration capability F44 | 0.046 | 7 | ||

| Green development intelligence I5 | 0.185 | Intelligent dust control F51 | 0.042 | 13 |

| Intelligent control of toxic and hazardous substances F52 | 0.036 | 20 | ||

| Drained water reuse F53 | 0.037 | 18 | ||

| Clean energy utilization F54 | 0.034 | 22 | ||

| Ecological restoration management F55 | 0.036 | 19 |

| Index Code | Expert 1 | Expert 2 | Expert 3 | Expert 4 | Expert 5 | Average Value |

|---|---|---|---|---|---|---|

| F11 | 0.235 | 0.174 | 0.111 | 0.059 | 0.302 | 0.176 |

| F12 | 0.059 | 0.140 | 0.093 | 0.135 | 0.038 | 0.093 |

| F13 | 0.035 | 0.060 | 0.074 | 0.209 | 0.077 | 0.091 |

| F14 | 0.139 | 0.038 | 0.139 | 0.345 | 0.195 | 0.171 |

| F15 | 0.116 | 0.236 | 0.031 | 0.029 | 0.028 | 0.088 |

| Applied Methods | F11 | F12 | F13 | F14 | F15 |

|---|---|---|---|---|---|

| ANP | 0.084 | 0.058 | 0.058 | 0.055 | 0.061 |

| Ranking | (1) | (3) | (4) | (5) | (2) |

| FDEMATEL-ANP | 0.054 | 0.049 | 0.048 | 0.050 | 0.045 |

| Ranking | (1) | (3) | (4) | (2) | (5) |

| SWARA | 0.176 | 0.093 | 0.091 | 0.171 | 0.088 |

| Ranking | (1) | (3) | (4) | (2) | (5) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, L.; Yuan, D.; Ren, L.; Huang, M.; Zhang, W.; Tan, J. Evaluation Model Research of Coal Mine Intelligent Construction Based on FDEMATEL-ANP. Sustainability 2023, 15, 2238. https://doi.org/10.3390/su15032238

He L, Yuan D, Ren L, Huang M, Zhang W, Tan J. Evaluation Model Research of Coal Mine Intelligent Construction Based on FDEMATEL-ANP. Sustainability. 2023; 15(3):2238. https://doi.org/10.3390/su15032238

Chicago/Turabian StyleHe, Lin, Dongliang Yuan, Lianwei Ren, Ming Huang, Wenyu Zhang, and Jie Tan. 2023. "Evaluation Model Research of Coal Mine Intelligent Construction Based on FDEMATEL-ANP" Sustainability 15, no. 3: 2238. https://doi.org/10.3390/su15032238