A Blockchain-Driven Food Supply Chain Management Using QR Code and XAI-Faster RCNN Architecture

Abstract

1. Introduction

- A blockchain-based elliptic curve integrated encrypted scheme is presented to validate every communication token and prevent a fraudster from entering the network;

- An explainable artificial intelligence (XAI) technique is presented to make the user more competent in the field of artificial intelligence (AI) application and machine learning;

- An XAI-based Faster RCNN model is proposed to digitize the food product information, retrieve it, and identify the hidden details in the QR code that affects food safety;

- Artificial rabbit optimization (ARO) is implemented to register each user and provide him with the key including data storage.

2. Related Works

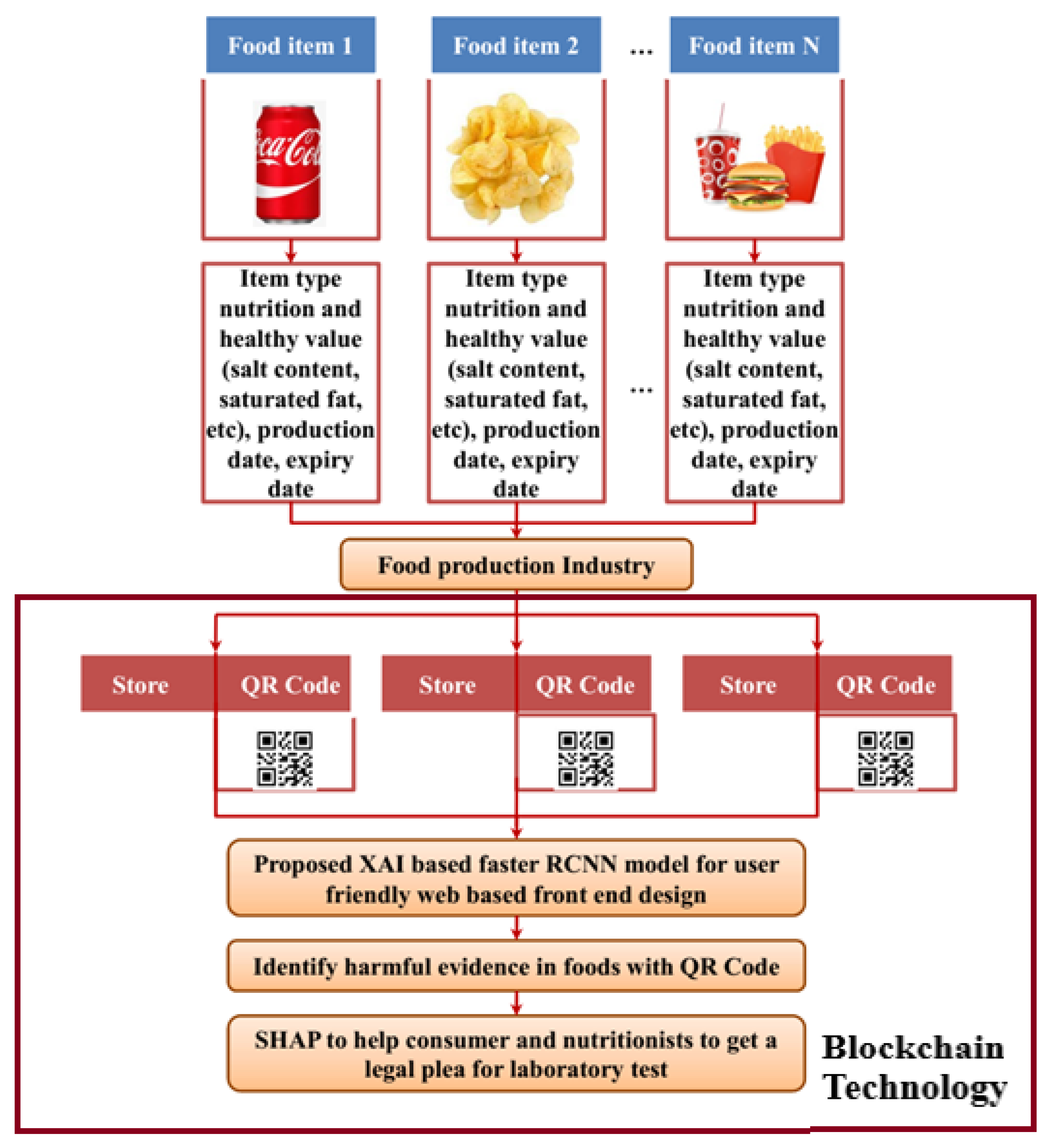

3. Proposed Blockchain-based Secure Food Recommendation Framework Using QR Mechanism

- Production: All FPI-related operations are represented by the first stage of production;

- Processing: The produce is harvested and transformed into products during the processing stage. Through a production batch code, every packet is identified, and the phase includes the product’s packaging and preparation;

- Distribution: After the product has been labeled and packed, the product is distributed to various warehouses and product storage in other distribution centers which are conducted in the distribution phase;

- Retailing: products are supplied from the distribution centers to the retailers during retailing phase so they can sell them to the customers;

- Consumption: The food supply chain’s final user is the consumer who purchases the product, demands the traceability of quality standards, and accesses other pertinent information about the product like the expiration date.

3.1. Faster RCNN Model

- Faster RCNN:

- a.

- Region proposal Networks:

- b.

- Anchors:

- c.

- Translation-Invariant Anchors:

- d.

- Multi-scale Anchors as Regression references

- Loss function

- e.

- Training RPNs

3.2. Formation of Blockchain-Driven XAI-Based Faster RCNN Model

- System design: A layered system is developed for the creation of our BT framework. The 3 layers of our system are as follows:

- Physical layer: Various food items from various FPI and manufacturers along the supply chain frame the physical layer;

- Digital information layer: The physical layer’s production is associated with the digital information layer, which will be used for accessibility and traceability. The food item’s expiration date is an example of the data related to the product;

- Cloud layer: Through the usage of BT, which is employed for accessibility and traceability, digital information is processed in the cloud in the cloud layer.

3.2.1. Input Module

3.2.2. Output Module

3.2.3. SHAP Analysis

3.3. Artificial Rabbits Optimization (ARO) for Secure Cloud Storage

4. Results and Discussion

4.1. Experimental Evaluation

- Response time: It computes the time that the mobile client device takes to send the messages to the agent, and then it is transferred between the agent and the server. It includes the time it takes to save data in the database, which is measured in milliseconds (MS);

- Payload size: It defines the volume of data transferred together which is represented in bytes;

- User numbers: These refer to the users simultaneously using the system and requests for service along the network. It denotes the true scalability of the system.

4.2. Comparative Analysis

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Toledo, R.Y.; Alzahrani, A.A.; Martinez, L. A food recommender system considering nutritional information and user preferences. IEEE Access 2019, 7, 96695–96711. [Google Scholar] [CrossRef]

- Kakani, V.; Nguyen, V.H.; Kumar, B.P.; Kim, H.; Pasupuleti, V.R. A critical review on computer vision and artificial intelligence in food industry. J. Agric. Food Res. 2020, 2, 100033. [Google Scholar] [CrossRef]

- Vecchio, R.; Cavallo, C. Increasing healthy food choices through nudges: A systematic review. Food Qual. Prefer. 2019, 78, 103714. [Google Scholar] [CrossRef]

- Dey, S.; Saha, S.; Singh, A.K.; McDonald-Maier, K. FoodSQRBlock: Digitizing food production and the supply chain with blockchain and QR code in the cloud. Sustainability 2021, 13, 3486. [Google Scholar] [CrossRef]

- Al-Rakhami, M.S.; Al-Mashari, M. ProChain: Provenance-Aware Traceability Framework for IoT-Based Supply Chain Systems. IEEE Access 2021, 10, 3631–3642. [Google Scholar] [CrossRef]

- Chan, K.Y.; Abdullah, J.; Khan, A.S. A framework for traceable and transparent supply chain management for agri-food sector in malaysia using blockchain technology. Int. J. Adv. Comput. Sci. Appl. 2019, 10, 1–8. [Google Scholar] [CrossRef]

- Gadekallu, T.R.; Pham, Q.V.; Nguyen, D.C.; Maddikunta, P.K.R.; Deepa, N.; Prabadevi, B.; Pathirana, P.N.; Zhao, J.; Hwang, W.J. Blockchain for edge of things: Applications, opportunities, and challenges. IEEE Internet Things J. 2021, 9, 964–988. [Google Scholar] [CrossRef]

- Bechtsis, D.; Tsolakis, N.; Bizakis, A.; Vlachos, D. A blockchain framework for containerized food supply chains. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; Volume 46, pp. 1369–1374. [Google Scholar]

- Tsang, Y.P.; Choy, K.L.; Wu, C.H.; Ho, G.T.S.; Lam, H.Y. Blockchain-driven IoT for food traceability with an integrated consensus mechanism. IEEE Access 2019, 7, 29000–129017. [Google Scholar] [CrossRef]

- Chen, H.; Chen, Z.; Lin, F.; Zhuang, P. Effective management for blockchain-based agri-food supply chains using deep reinforcement learning. IEEE Access 2021, 9, 36008–36018. [Google Scholar] [CrossRef]

- Hu, S.; Huang, S.; Huang, J.; Su, J. Blockchain and edge computing technology enabling organic agricultural supply chain: A framework solution to trust crisis. Comput. Ind. Eng. 2021, 153, 107079. [Google Scholar] [CrossRef]

- Casino, F.; Kanakaris, V.; Dasaklis, T.K.; Moschuris, S.; Rachaniotis, N.P. Modeling food supply chain traceability based on blockchain technology. Ifac-Pap. 2019, 52, 2728–2733. [Google Scholar] [CrossRef]

- Huang, H.; Zhou, X.; Liu, J. Food supply chain traceability scheme based on blockchain and EPC technology. In Proceedings of the International Conference on Smart Blockchain, Birmingham, UK, 11–13 October 2019; Springer: Cham, Switzeland; pp. 32–42. [Google Scholar]

- Li, Z.; Liu, G.; Liu, L.; Lai, X.; Xu, G. IoT-based tracking and tracing platform for prepackaged food supply chain. Ind. Manag. Data Syst. 2017, 117, 1906–1916. [Google Scholar] [CrossRef]

- Ahamed, N.N.; Karthikeyan, P.; Anandaraj, S.P.; Vignesh, R. Sea food supply chain management using blockchain. In Proceedings of the 2020 6th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India, 6–7 March 2020; pp. 473–476. [Google Scholar]

- Karumanchi, M.D.; Sheeba, J.I.; Devaneyan, S.P. Blockchain Enabled Supply Chain using Machine Learning for Secure Cargo Tracking. Int. J. Intell. Syst. Appl. Eng. 2022, 10, 434–442. [Google Scholar]

- Hu, H.; Xu, J.; Liu, M.; Lim, M.K. Vaccine supply chain management: An intelligent system utilizing blockchain, IoT and machine learning. J. Bus. Res. 2023, 156, 113480. [Google Scholar] [CrossRef] [PubMed]

- Dey, S.; Saha, S.; Singh, A.K.; McDonald-Maier, K. SmartNoshWaste: Using Blockchain, Machine Learning, Cloud Computing and QR Code to Reduce Food Waste in Decentralized Web 3.0 Enabled Smart Cities. Smart Cities 2022, 5, 11. [Google Scholar] [CrossRef]

- Mishra, N.; Mistry, S.; Choudhary, S.; Kudu, S.; Mishra, R. Food Traceability System Using Blockchain and QR Code. In IC-BCT 2019; Springer: Singapore, 2020; pp. 33–43. [Google Scholar]

- Tian, F. An agri-food supply chain traceability system for China based on RFID & blockchain technology. In Proceedings of the 2016 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016; pp. 1–6. [Google Scholar]

- Köhler, S.; Pizzol, M. Technology assessment of blockchain-based technologies in the food supply chain. J. Clean. Prod. 2020, 269, 122193. [Google Scholar] [CrossRef]

- Basnayake, B.M.A.L.; Rajapakse, C. A Blockchain-based decentralized system to ensure the transparency of organic food supply chain. In Proceedings of the 2019 International Research Conference on Smart Computing and Systems Engineering (SCSE), Colombo, Sri Lanka, 28 March 2019; pp. 103–107. [Google Scholar]

- Dong, Y.; Fu, Z.; Stankovski, S.; Wang, S.; Li, X. Nutritional quality and safety traceability system for China’s leafy vegetable supply chain based on fault tree analysis and QR code. IEEE Access 2020, 8, 161261–161275. [Google Scholar] [CrossRef]

- Gupta, A.; Siddiqui, S.T.; Alam, S.; Shuaib, M. Cloud computing security using blockchain. J. Emerg. Technol. Innov. Res. 2019, 6, 791–794. [Google Scholar]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster r-cnn: Towards real-time object detection with region proposal networks. In Proceedings of the Advances in Neural Information Processing Systems, Montreal, QC, Canada, 7–12 December 2015. [Google Scholar]

| Author | Technique | Aim | Advantage | Limitations |

|---|---|---|---|---|

| Bechtsis et al. [8] | TSFSC | Deploying a demonstration application using blockchain and verifying its traceability via critical parameters | Secure information sharing and improves process control | The properties of the products are not analyzed |

| Tsang et al. [9] | BIFTS | Integrate usage of blockchain, IoT, and fuzzy logic into a system that maintains the full traceability and shelf life of perishable goods. | Offers reliable decision support | The user is not able to verify the food source |

| Chen et al. [10] | DR-SCM | Making a decision that is efficient for food production and secure for the agri-food tracking data. | Consistent product tracing and food safety | Item level tracking is not conducted |

| Hu et al. [11] | OASC | To address the shortcomings of blockchain’s price and efficiency | Offers inexpensive traceability options for individuals | Prone to Byzantine faults |

| Casino et al. [12] | FSC | Create a distributed functional model based on smart contracts and blockchain technology to allow automatic, decentralized FSC traceability. | Prevents health risks and minimizes monetary loss | Still needs improvement in the decision-making process |

| Huang et al. [13] | Electronic Product Code and blockchain | Food tracking and tracing throughout the agricultural supply chain | Reduce the data explosion in the Internet of Things blockchain | Increase in capital construction cost |

| Dey et al. [4] | Food SQRBlock | Information retrieval using a BT and QR code-based framework for food production | Improved traceability | Arises storage issues |

| Li et al. [14] | XML, QR, and RF | To cut implementation costs while achieving fine-grained monitoring and tracing | All parties involved may stand to gain from the effective implementation of prepackaged food monitoring and tracking across its supply chain. | Failed to provide timely decision-making and improve consumer health |

| Ahamed et al. [15] | Blockchain and QR code | Using blockchain and specific product identifiers to enhance supply chain management | The benefits of a customized tag allow everyone from the manufacturer to the consumer to learn more about a product’s reliable production process. | Absence of smart sensors and AI technologies |

| Karumanchi et al. [16] | MRCNN-MT | Monitor the conditions of commercial products in the cargo industry | Secure communication and storage improvements | This study does not focus on minimizing the impact of product wastage |

| Hu et al. [17] | GRU and BILSTM | Vaccine supply chain management during COVID-19 | Accuracy nearly equal to 80% | Results in massive QR code generation |

| Dey et al. [18] | Reinforcement learning | Minimize food wastage | Reduces food wastage by up to 9.46% | The food surplus data is not easily available |

| Methods | Accuracy (%) | Precision (%) | Recall (%) | F1-Score |

|---|---|---|---|---|

| Proposed | 99.53 | 98.56 | 98.65 | 98.54 |

| DR-SCM | 95.24 | 94.56 | 95.69 | 94.89 |

| Fuzzy based BIFTS | 94.32 | 94.35 | 94.56 | 94.34 |

| FTS-BAEPC | 92.10 | 91.56 | 92.15 | 91.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bhatia, S.; Albarrak, A.S. A Blockchain-Driven Food Supply Chain Management Using QR Code and XAI-Faster RCNN Architecture. Sustainability 2023, 15, 2579. https://doi.org/10.3390/su15032579

Bhatia S, Albarrak AS. A Blockchain-Driven Food Supply Chain Management Using QR Code and XAI-Faster RCNN Architecture. Sustainability. 2023; 15(3):2579. https://doi.org/10.3390/su15032579

Chicago/Turabian StyleBhatia, Surbhi, and Abdulaziz Saad Albarrak. 2023. "A Blockchain-Driven Food Supply Chain Management Using QR Code and XAI-Faster RCNN Architecture" Sustainability 15, no. 3: 2579. https://doi.org/10.3390/su15032579

APA StyleBhatia, S., & Albarrak, A. S. (2023). A Blockchain-Driven Food Supply Chain Management Using QR Code and XAI-Faster RCNN Architecture. Sustainability, 15(3), 2579. https://doi.org/10.3390/su15032579