Development and Implementation of Photovoltaic Integrated Multi-Skin Façade (PV-MSF) Design Based on Geometrical Concepts to Improve Building Energy Efficiency Performance

Abstract

:1. Introduction

2. The Development of a Simulation Model

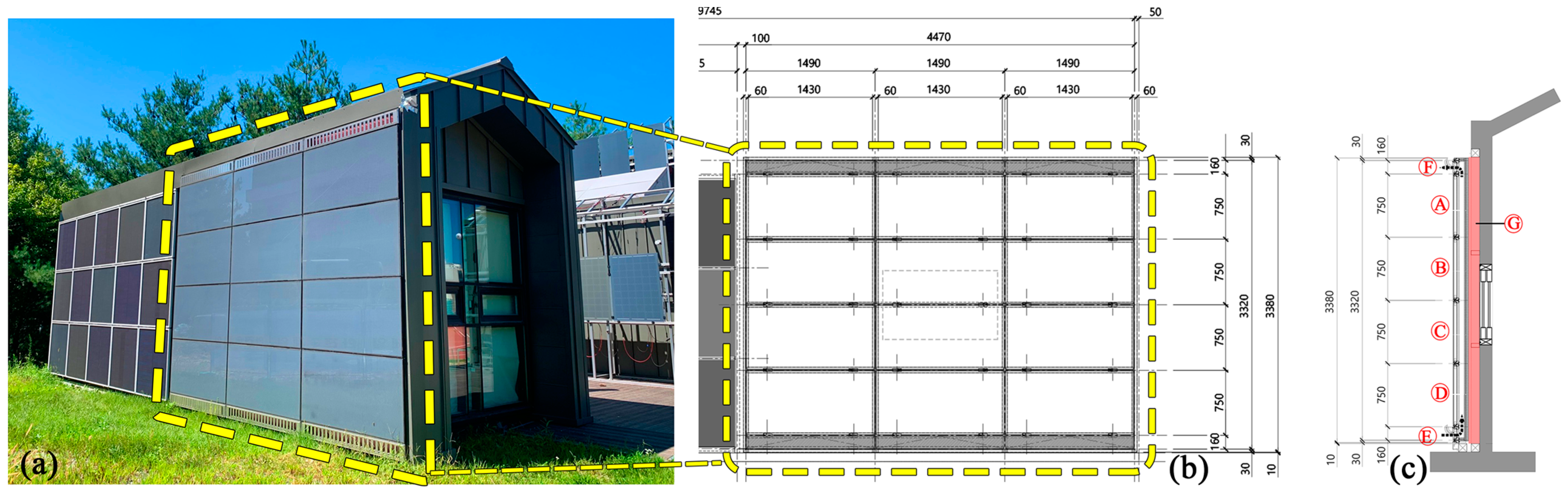

2.1. The Overview of the Full-Scale BIPV Mock-Up

2.2. Field Measurement for Model Validation

2.3. Description of the Simulation Model Development

2.3.1. Airflow Network Algorithm Model

2.3.2. Simulation Model Setups

2.3.3. Weather Data Modification

2.4. Validation Process of the PV-MSF Model

2.4.1. Validation Flowchart

2.4.2. Model Validation for Thermal Behaviors

2.5. Validated Results

2.5.1. Validated Results under Condition 1

2.5.2. Validated Results under Condition 2

3. The Proposal for Geometrical Designs

3.1. Design Concepts

3.2. The Selection of Base Case Building

3.3. Comparative Analysis of Proposed Design Conditions

4. Results and Discussion

4.1. Base Case Versus Triangular Pyramid Patterns

4.2. Base Case Versus Rectangular Pyramid Patterns

4.3. Detailed Comparison of Base Case Versus Triangular Pyramid and Rectangular Pyramid Patterns

4.3.1. Base Case Versus One-Unit Patterns and Four-Unit Patterns

4.3.2. Base Case Versus Nine-Unit Patterns and Sixteen-Unit Patterns

5. Conclusions

- The heating and cooling energy were significantly reduced in all TP and RP configurations compared to the base case. The heating and cooling demands difference between the TP and RP patterns was insignificant. The designs of the above two arrangements acted as window awnings, providing positive effects in the form of effective shading and reducing the building’s energy end uses.

- Creating only one unit in one pattern for the TP configuration was most efficient. The highest electricity generation potential pattern was the 1TP_36.35 pattern, with the inclination of the roof-integrated PV corresponding with the local latitude (the local degree 36.35°) since the reach of the peak point was wide enough with the cavity depth of 1.41 m.

- For the RP configuration, the roof PV-integrated surface angle according to the local latitude did not significantly impact the power generation potential. The power generation potential of RP patterns tended to increase with a roof slope of 21.35°, 36.35° and 51.35°. Generating nine units in one design was the most efficient power generation potential.

- The base case had a much smaller PV module area than the TP patterns, so the energy yield was also lower. However, in terms of energy yield rate per unit area, the base case was slightly more dominant, 17.5% higher than the 1TP_36.35 pattern—which was the highest performance pattern in the TP patterns. The base case had a PV module area close to that of the RP patterns, but the PV power generation potential and energy yield per unit area were the lowest. Specifically, the plan with the highest energy yield value of RP patterns was 9RP_51.35, which was 49.4% higher than the base case and 46.6% higher in comparison based on the energy yield rate per unit area.

- Considering the power generation potential and energy yield rate per unit area of the entire patterns of the two TP and RP configurations with the base case, the RP patterns accounted for the highest and most optimal proportion, with the conclusion that RP patterns had a great potential to achieve high efficiency in the design and installation of the MSF systems. RP patterns also improved practical efficiency for smaller PV installation areas, and maintainability was highly appreciated in the event of power generation problems.

- This result could help to find specific solutions to increase the number of units (up to nine units) on a surface of a pattern (RP configuration) to decrease the cavity depth and maintain the best-performing PV installation area while keeping the heating and cooling loads of the perimeter zone not significantly affected. As for the TP configuration, it was necessary to increase the cavity depth and install the PV with a roof slope according to the local latitude for power generation efficiency and overall energy efficiency.

Author Contributions

Funding

Conflicts of Interest

References

- Sartori, I.; Napolitano, A.; Voss, K. Net Zero Energy Buildings: A Consistent Definition Framework. Energy Build. 2012, 48, 220–232. [Google Scholar] [CrossRef]

- Khan, M.; Asif, M.; Stach, E. Rooftop PV Potential in the Residential Sector of the Kingdom of Saudi Arabia. Buildings 2017, 7, 46. [Google Scholar] [CrossRef]

- 11 Abu Dhabi Government Buildings Go Solar. Available online: https://scholar.google.com/scholar?q=11 Abu Dhabi Government Buildings Go Solar (accessed on 2 September 2022).

- Whole Building Design Guide 2011. Available online: https://scholar.google.com/scholar?q=Whole Building Design Guide 2011. (accessed on 2 September 2022).

- Yamina, S.; Sophie, S. From Nearly-Zero Energy Buildings to Net-Zero Energy Districts; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Gibson, R. Energy Behavior Change and Army Net Zero Energy; Gaps in the Army’s Approach to Changing Energy Behavior; Command and General Staff College: Leavenworth, Kansas, 2014. [Google Scholar]

- Pons-Valladares, O.; Nikolic, J. Sustainable Design, Construction, Refurbishment and Restoration of Architecture: A Review. Sustainability 2020, 12, 9741. [Google Scholar] [CrossRef]

- Lazar, N.; Chithra, K. A Comprehensive Literature Review on Development of Building Sustainability Assessment Systems. J. Build. Eng. 2020, 32, 101450. [Google Scholar] [CrossRef]

- Ghaleb, B.; Asif, M. Assessment of Solar PV Potential in Commercial Buildings. Renew. Energy 2022, 187, 618–630. [Google Scholar] [CrossRef]

- Babatunde, A.A.; Abbasoglu, S.; Senol, M. Analysis of the Impact of Dust, Tilt Angle and Orientation on Performance of PV Plants. Renew. Sustain. Energy Rev. 2018, 90, 1017–1026. [Google Scholar] [CrossRef]

- Ghosh, A. Potential of Building Integrated and Attached/Applied Photovoltaic (BIPV/BAPV) for Adaptive Less Energy-Hungry Building’s Skin: A Comprehensive Review. J. Clean. Prod. 2020, 276, 123343. [Google Scholar] [CrossRef]

- Kim, H.R.; Boafo, F.E.; Kim, J.H.; Kim, J.T. Investigating the Effect of Roof Configurations on the Performance of BIPV System. Energy Procedia 2015, 78, 1974–1979. [Google Scholar] [CrossRef]

- Toth, S.; Muller, M.; Miller, D.C.; Moutinho, H.; To, B.; Micheli, L.; Linger, J.; Engtrakul, C.; Einhorn, A.; Simpson, L. Soiling and Cleaning: Initial Observations from 5-Year Photovoltaic Glass Coating Durability Study. Sol. Energy Mater. Sol. Cells 2018, 185, 375–384. [Google Scholar] [CrossRef]

- Moschetti, R.; Brattebø, H.; Sparrevik, M. Exploring the Pathway from Zero-Energy to Zero-Emission Building Solutions: A Case Study of a Norwegian Office Building. Energy Build. 2019, 188–189, 84–97. [Google Scholar] [CrossRef]

- Izquierdo, S.; Rodrigues, M.; Fueyo, N. A Method for Estimating the Geographical Distribution of the Available Roof Surface Area for Large-Scale Photovoltaic Energy-Potential Evaluations. Sol. Energy 2008, 82, 929–939. [Google Scholar] [CrossRef]

- Ran, L.H. The Thermal Stress between the Interfaces of Different Materials of the Axis Symmetric Structural. Mater. Sci. Forum 2011, 694, 591–596. [Google Scholar] [CrossRef]

- Lukač, N.; Žlaus, D.; Seme, S.; Žalik, B.; Štumberger, G. Rating of Roofs’ Surfaces Regarding Their Solar Potential and Suitability for PV Systems, Based on LiDAR Data. Appl. Energy 2013, 102, 803–812. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Pearce, J.M. Incorporating Shading Losses in Solar Photovoltaic Potential Assessment at the Municipal Scale. Sol. Energy 2012, 86, 1245–1260. [Google Scholar] [CrossRef]

- Catita, C.; Redweik, P.; Pereira, J.; Brito, M.C. Extending Solar Potential Analysis in Buildings to Vertical Facades. Comput. Geosci. 2014, 66, 1–12. [Google Scholar] [CrossRef]

- Scopus-Document Details-Arsenic Concentrations in Water, Sediment, and Aquatic Animals from the Pearl River Estuaries and Its Distribution Characteristics and Ecological Risk Evaluation. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0- 84962121484&origin=inward&txGid=ef52672380590b961f9458f99e39f62f (accessed on 5 September 2022).

- Zhang: 3D Modeling of Urban Buildings and Trees and Its Application in Building Scale Solar Energy Potential Mapping. Available online: https://scholar.google.com/scholar_lookup?title=Trees and its application in building- scale solar energy potential mapping&publication_year=2014&author=Xianfeng Zhang&author=Lv Yang&author=Liu Yu (accessed on 5 September 2022).

- Scopus-Document Details-Designing and Implementing Assessment System of Solar Energy Potential for Urban Building. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-84997576833&origin=inward&txGid=3168066f973e0712fea8e92d4eeedfcc (accessed on 5 September 2022).

- Carneiro, C.; Morello, E.; Desthieux, G.; Golay, F. Urban Environment Quality Indicators: Application to Solar Radiation and Morphological Analysis on Built Area. In Proceedings of the 3rd WSEAS International Conference on Visualization, Imaging and Simulation, Faro, Portugal, 3–5 November 2010. [Google Scholar]

- Moghtadernejad, S.; Chouinard, L.E.; Mirza, M.S. Design Strategies Using Multi-Criteria Decision-Making Tools to Enhance the Performance of Building Façades. J. Build. Eng. 2020, 30, 101274. [Google Scholar] [CrossRef]

- Casagrande, D.; Sinito, E.; Izzi, M.; Pasetto, G.; Polastri, A. Structural Performance of a Hybrid Timber Wall System for Emergency Housing Facilities. J. Build. Eng. 2021, 33, 101566. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Kaklauskas, A.; Turskis, Z.; Tamošaitiene, J.; Kazimieras Zavadskas, E.; Tamošaitien, J. Selection of the Effective Dwelling House Walls by Applying Attributes Values Determined at Intervals. J. Civ. Eng. Manag. 2010. [Google Scholar] [CrossRef]

- O’Brien, W.; Athienitis, A. Modeling, Design, and Optimization of Net-Zero Energy Buildings; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Xiang, C.; Matusiak, B.S. Façade Integrated Photovoltaics Design for High-Rise Buildings with Balconies, Balancing Daylight, Aesthetic and Energy Productivity Performance. J. Build. Eng. 2022, 57, 104950. [Google Scholar] [CrossRef]

- Vulkan, A.; Kloog, I.; Dorman, M.; Erell, E. Modeling the Potential for PV Installation in Residential Buildings in Dense Urban Areas. Energy Build. 2018, 169, 97–109. [Google Scholar] [CrossRef]

- IEA: Technology Roadmap: Solar Photovoltaic Energy. Available online: https://scholar.google.com/scholar_lookup?title=Technology roadmap solar photovoltaic energy&publication_year=2014&author=IEA (accessed on 5 September 2022).

- Stevanović, S. Optimization of Passive Solar Design Strategies: A Review. Renew. Sustain. Energy Rev. 2013, 25, 177–196. [Google Scholar] [CrossRef]

- Preet, S.; Mathur, J.; Mathur, S. Influence of Geometric Design Parameters of Double Skin Façade on Its Thermal and Fluid Dynamics Behavior: A Comprehensive Review. Sol. Energy 2022, 236, 249–279. [Google Scholar] [CrossRef]

- Scopus-Document Details-Null. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-85123794503&origin=inward&txGid=79d3cbe195e22f1d4e8dc5cf5c3a8dec (accessed on 5 September 2022).

- Tan, C.-B.; Medica, N.C.A.O.C.M.; Chang, C.-Q.; He, C.-L.; Zhang, L.-H.; Liu, X.-L. Separation and synthesis of the new DSFs. Rev. Roum. Chim. 2020, 65, 403–406. [Google Scholar] [CrossRef]

- GhaffarianHoseini, A.; GhaffarianHoseini, A.; Berardi, U.; Tookey, J.; Li, D.H.W.; Kariminia, S. Exploring the Advantages and Challenges of Double-Skin Façades (DSFs). Renew. Sustain. Energy Rev. 2016, 60, 1052–1065. [Google Scholar] [CrossRef]

- Sharma, M.K.; Preet, S.; Mathur, J.; Chowdhury, A.; Mathur, S. Exploring the Advantages of Photo-Voltaic Triple Skin Façade in Hot Summer Conditions. Sol. Energy 2021, 217, 317–327. [Google Scholar] [CrossRef]

- Preet, S.; Sharma, M.K.; Mathur, J.; Chowdhury, A.; Mathur, S. Analytical model of semi-transparent photovoltaic double-skin façade system (STPV-DSF) for natural and forced ventilation modes. Int. J. Vent. 2021, 1–30. [Google Scholar] [CrossRef]

- Ioannidis, Z.; Buonomano, A.; Athienitis, A.K.; Stathopoulos, T. Modeling of Double Skin Façades Integrating Photovoltaic Panels and Automated Roller Shades: Analysis of the Thermal and Electrical Performance. Energy Build. 2017, 154, 618–632. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Li, Z. A Novel Productive Double Skin Façades for Residential Buildings: Concept, Design and Daylighting Performance Investigation. Build. Environ. 2022, 212, 108817. [Google Scholar] [CrossRef]

- Oesterle, L.; Lutz, M.; Heusler, W. Double Skin Facades: Integrated Planning; Prestell: Munich, Germany, 1999; p. 208. [Google Scholar]

- Shameri, M.A.; Alghoul, M.A.; Sopian, K.; Zain, M.F.M.; Elayeb, O. Perspectives of Double Skin Façade Systems in Buildings and Energy Saving. Renew. Sustain. Energy Rev. 2011, 15, 1468–1475. [Google Scholar] [CrossRef]

- Claessens, J.; DeHerte, A. Active Solar Heating and Photovoltaics. Solar Energy in European Office Buildings; Energy Research Group, School of Architecture, University College of Dublin: Dublin, Ireland, 2006. [Google Scholar]

- Pomponi, F.; Piroozfar, P.A.E.; Southall, R.; Ashton, P.; Farr, E.R.P. Energy Performance of Double-Skin Façades in Temperate Climates: A Systematic Review and Meta-Analysis. Renew. Sustain. Energy Rev. 2016, 54, 1525–1536. [Google Scholar] [CrossRef]

- Gratia, E.; De Herde, A. Natural Ventilation in a Double-Skin Facade. Energy Build. 2004, 36, 137–146. [Google Scholar] [CrossRef]

- Gratia, E.; De Herde, A. Optimal Operation of a South Double-Skin Facade. Energy Build. 2004, 36, 41–60. [Google Scholar] [CrossRef]

- Baldinelli, G. Double Skin Façades for Warm Climate Regions: Analysis of a Solution with an Integrated Movable Shading System. Build. Environ. 2009, 44, 1107–1118. [Google Scholar] [CrossRef]

- Ascione, F.; Bianco, N.; Iovane, T.; Mastellone, M.; Mauro, G.M. The Evolution of Building Energy Retrofit via Double-Skin and Responsive Façades: A Review. Sol. Energy 2021, 224, 703–717. [Google Scholar] [CrossRef]

- Peng, J.; Lu, L.; Yang, H. An Experimental Study of the Thermal Performance of a Novel Photovoltaic Double-Skin Facade in Hong Kong. Sol. Energy 2013, 97, 293–304. [Google Scholar] [CrossRef]

- Kim, D.; Cox, S.J.; Cho, H.; Yoon, J. Comparative Investigation on Building Energy Performance of Double Skin Façade (DSF) with Interior or Exterior Slat Blinds. J. Build. Eng. 2018, 20, 411–423. [Google Scholar] [CrossRef]

- Zomorodian, Z.S.; Tahsildoost, M. Energy and Carbon Analysis of Double Skin Façades in the Hot and Dry Climate. J. Clean. Prod. 2018, 197, 85–96. [Google Scholar] [CrossRef]

- Yang, S.; Cannavale, A.; Di Carlo, A.; Prasad, D.; Sproul, A.; Fiorito, F. Performance Assessment of BIPV/T Double-Skin Façade for Various Climate Zones in Australia: Effects on Energy Consumption. Sol. Energy 2020, 199, 377–399. [Google Scholar] [CrossRef]

- Burton, S. Energy-Efficient Office Refurbishment: Designing for Comfort; Routledge: London, UK, 2013; pp. 1–185. [Google Scholar] [CrossRef]

- Sun, K.; Luo, N.; Luo, X.; Hong, T. Prototype Energy Models for Data Centers. Energy Build. 2021, 231, 110603. [Google Scholar] [CrossRef]

- Wada, H.; Yamamoto, F.; Ueta, K. Generation Characteristics of 100 KW PV System with Various Tilt Angle and Direction Arrays; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Saber, E.M.; Lee, S.E.; Manthapuri, S.; Yi, W.; Deb, C. PV (Photovoltaics) Performance Evaluation and Simulation-Based Energy Yield Prediction for Tropical Buildings. Energy 2014, 71, 588–595. [Google Scholar] [CrossRef]

- Ng, K.M.; Adam, N.M.; Inayatullah, O.; Kadir, M.Z.A.A. Assessment of Solar Radiation on Diversely Oriented Surfaces and Optimum Tilts for Solar Absorbers in Malaysian Tropical Latitude. Int. J. Energy Environ. Eng. 2014, 5, 1–13. [Google Scholar] [CrossRef]

- Jafarkazemi, F.; Saadabadi, S.A. Optimum Tilt Angle and Orientation of Solar Surfaces in Abu Dhabi, UAE. Renew. Energy 2013, 56, 44–49. [Google Scholar] [CrossRef]

- Hachem, C.; Elsayed, M. Patterns of Façade System Design for Enhanced Energy Performance of Multistory Buildings. Energy Build. 2016, 130, 366–377. [Google Scholar] [CrossRef]

- Hachem, C.; Athienitis, A.; Fazio, P. Design of Curtain Wall Facades for Improved Solar Potential and Daylight Distribution. Energy Procedia 2014, 57, 1815–1824. [Google Scholar] [CrossRef]

- DOE. EnergyPlus Engineering Reference: The reference to EnergyPlus Calculations; Version 8.4; DOE: Washington, DC, USA, 2015.

- DOE. EnergyPlus Input Output Reference: The Encyclopedic Reference to EnergyPlus Input and Output; Version 8.4; DOE: Washington, DC, USA, 2015.

- Simulation, L.G.-B. Airflow Network Modeling in EnergyPlus. In Building Simulation; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Walton, G. AIRNET—A Computer Program for Building Airflow Network Modelling; US Department of Commerce, National Institute of Standards and Technology: Washington, DC, USA, 1989. [Google Scholar]

- ASHRAE Handbook of Fundamentals, American Society of Heating, Refrigerating and Air-Conditioning Engineering; ASHRAE: New York, NY, USA, 2001.

- Dutton, S.; Shao, L.; Riffat, S. Validation and Parametric Analysis of EnergyPlus: Air Flow Network Model Using Contam. 2008. Available online: https://www.researchgate.net/publication/230606208_VALIDATION_AND_PARAMETRIC_ANALYSIS_OF_ENERGYPLUS_AIR_FLOW_NETWORK_MODEL_USING_CONTAM (accessed on 7 September 2022).

- Elements Software. Available online: https://bigladdersoftware.com/projects/elements/ (accessed on 28 September 2022).

- The South Korea Meteorological Administration. The National Weather Station in South Korea, The National Weather Service Center. Available online: https://data.kma.go.kr/cmmn/main.do. (accessed on 28 September 2022).

- DesignBuilder Software Ltd. DesignBuilder 2021. Available online: http://designbuilder.co.uk (accessed on 30 September 2022).

- ANSIASHRAE. ASHRAE Guideline 14-2002 Measurement of Energy and Demand Savings. Available online: http://www.eeperformance.org/uploads/8/6/5/0/8650231/ashrae_guideline_14-2002_measurement_of_energy_and_demand_saving.pdf (accessed on 7 September 2022).

- MV Guidelines: Measurement and Verification for Performance-Based Contracts. Available online: https://scholar.google.com/scholar?q=MV%20Guidelines:%20Measurement%20and%20verification%20for%20performance-based%20contracts. (accessed on 7 September 2022).

- Adedeji, M.; Abbasoglu, S.; Senol, M. Determination of optimum tilt angle for photovoltaic systems in North Cyprus. In Proceedings of the SolarTR Conference, Izmir, Turkey, 19–21 November 2014. [Google Scholar]

- Ye, Y.; Hinkelman, K.; Zhang, J.; Zuo, W.; Wang, G. A Methodology to Create Prototypical Building Energy Models for Existing Buildings: A Case Study on U.S. Religious Worship Buildings. Energy Build. 2019, 194, 351–365. [Google Scholar] [CrossRef]

- Gui, C.; Yan, D.; Guo, S.; Heating, J.A.-S. Development of Prototype Building Model in Beijing Based on Actual Energy Consumption. Springer 2020, 66, 1187–1196. [Google Scholar] [CrossRef]

- US DOE. Commercial Prototype Building Models|Building Energy Codes Program; U.S. Department of Energy: Washington, DC, USA, 2013. Available online: https://www.energycodes.gov/development/commercial/prototype_models (accessed on 28 September 2022).

- Thornton, B.; Rosenberg, M.; Richman, E.; Wang, W. Achieving the 30% Goal: Energy and Cost Savings Analysis of ASHRAE Standard 90.1-2010; Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2011. [Google Scholar]

| U-Value (W/m²K) | Visible Transmittance | Solar Heat Gain Coefficient (SHGC) | |

|---|---|---|---|

| External wall | 0.219 | N/A | N/A |

| Floor | 0.227 | N/A | N/A |

| Roof | 0.334 | N/A | N/A |

| Double clear window | 2.665 | 0.781 | 0.703 |

| Insulation (G, Figure 1c) | 0.217 | N/A | N/A |

| Aluminum frame | 5.881 | N/A | N/A |

| PV module (A, B, C, D, Figure 1c) | 2.690 | 0.260 | 0.590 |

| Dimensions [mm] | 1.07 m² (730 × 470 × 11) |

| Cells on module | 32 (4 × 8) |

| Maximum Power (Pmax) | 177.9 W |

| Surface | Glass |

| Module efficiency | 16.60% |

| Module voltage at max power (Vmp) | 19.8 V |

| Open circuit voltage (Voc) | 23.2 V |

| Module current at max power (Imp) | 9 A |

| Short circuit current (Isc) | 9.4 A |

| Parameter | Value | |

|---|---|---|

| Building Type | Low-Rise Building | |

| Vertical Opening | Air Mass Flow Coefficient When Opening is Closed | 0.00006 (kg/s-m) |

| Air Mass Flow Exponent When Opening is Closed | 0.7 (Dimensionless) | |

| Discharge Coefficient | 0.65 (Dimensionless) | |

| Horizontal Opening | Air Mass Flow Coefficient When Opening is Closed | 0.001 (kg/s-m) |

| Air Mass Flow Exponent When Opening is Closed | 0.5 (Dimensionless) | |

| Discharge Coefficient | 0.65 (Dimensionless) | |

| Effective Leakage Area (ELA) | Air Mass Flow Exponent | 0.667 (Dimensionless) |

| Discharge Coefficient | 1 (Dimensionless) | |

| Reference Pressure Difference | 4 (Pa) | |

| Opening/Crack Factor | 0.5 (Dimensionless) | |

| Minimum Venting Open Factor | 0.3 (Dimensionless) | |

| Inside Air Cavity Temperature | Z1 | Z2 | Z3 | Z4 | Z5 | Z6 | Z7 | Z8 | Z9 |

|---|---|---|---|---|---|---|---|---|---|

| CV-RMSE (%) | 24 | 14.2 | 15.1 | 20.5 | 14.4 | 13.2 | 16.8 | 13.6 | 15 |

| NMBE (%) | −1.4 | −4.2 | −0.5 | 7.5 | −9.6 | 1.8 | −6.58 | 2.5 | 1.6 |

| PV surface temperature | Z1 | Z2 | Z3 | Z4 | Z5 | Z6 | Z7 | Z8 | Z9 |

| CV-RMSE (%) | 16.4 | 15.1 | 16 | 15.2 | 16.2 | 17.1 | 14.8 | 16.7 | 16.6 |

| NMBE (%) | −3.5 | 4.7 | 5.2 | −0.8 | 9 | 7.9 | 9.1 | 9.9 | 6.7 |

| PV power generation | Z1 | Z2 | Z3 | Z4 | Z5 | Z6 | Z7 | Z8 | Z9 |

| CV-RMSE (%) | 27.7 | 26.9 | 28.2 | 21.8 | 26.8 | 29.3 | 29.5 | 27.1 | 29.3 |

| NMBE (%) | −3.3 | −7.8 | −7.6 | −5.1 | −7.6 | −7.6 | −6.8 | −8.9 | −8.7 |

| Inside Air Cavity Temperature | Z1 | Z2 | Z3 | Z4 | Z5 | Z6 | Z7 | Z8 | Z9 |

|---|---|---|---|---|---|---|---|---|---|

| CV-RMSE (%) | 10.1 | 10.1 | 8.2 | 9.9 | 9.9 | 8.6 | 11.4 | 9.7 | 8.2 |

| NMBE (%) | 2 | 1.6 | 1.6 | 2.4 | 1.7 | 2.4 | 4.5 | 2.8 | 2.2 |

| PV surface temperature | Z1 | Z2 | Z3 | Z4 | Z5 | Z6 | Z7 | Z8 | Z9 |

| CV-RMSE (%) | 15.5 | 14.3 | 11.2 | 16.4 | 14.5 | 12.6 | 15.9 | 14.3 | 12.3 |

| NMBE (%) | −2.1 | −2 | 1.4 | −2.5 | −1.3 | 0.3 | −0.5 | −0.5 | 1.6 |

| PV power generation | Z1 | Z2 | Z3 | Z4 | Z5 | Z6 | Z7 | Z8 | Z9 |

| CV-RMSE (%) | 19.2 | 12.4 | 19.4 | 19 | 17.7 | 20.7 | 19 | 12.9 | 19.9 |

| NMBE (%) | 4.2 | 6.3 | 6.1 | 4.4 | 6.9 | 8.3 | 3.4 | 5.4 | 7.1 |

| Parameter | Characteristic | |

|---|---|---|

| Weather/Location | Daejeon, South Korea | |

| Total conditioned floor area | 4982 m² | |

| Floor-to-ceiling height | 2.74 m (1.22 m above-ceiling plenum) | |

| Window-to-wall ratio (South façade) | 27% (1st floor), 32% (2nd and 3rd floor) | |

| Window-to-wall ratio (North, East, and West façade) | 33% | |

| PV area (MSF) | 67.5 m² (1st floor), 82.5 m² (2nd floor), 82.5 m² (3rd floor) | |

| Glazing area (MSF) | 52.3 m² (1st floor), 64 m² (2nd floor), 64 m² (3rd floor) | |

| Glazing (MSF) | U-factor | 5.89 W/m²-K |

| SHGC | 0.86 | |

| Window | U-factor | 0.36 W/m²-K |

| SHGC | 0.36 | |

| Exterior wall construction | Type | Steel-frame walls |

| U-factor | 0.36 W/m²-K | |

| Roof construction | Type | Built-up roof: roof membrane, insulation, and metal decking |

| U-factor | 0.18 W/m²-K | |

| Floor construction | Type | Slab-on-grade floors |

| U-factor | 0.23 W/m²-K | |

| Occupancy density | 18.57 m²/person | |

| HVAC type | Rooftop unit (RTU) with variable air volume (VAV) fan and reheat box | |

| Lighting power density (LPD) | 6.89 W/m² | |

| Equipment power density (EPD) | 8.1 W/m² | |

| Zone thermostat set-point | Cooling: 24 °C/Heating: 21 °C | |

| Zone thermostat set-back | Cooling: 26.7 °C/Heating:15.6 °C | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tran, T.N.; Seomun, G.; Lee, R.; Lee, H.; Yoon, J.; Kim, D. Development and Implementation of Photovoltaic Integrated Multi-Skin Façade (PV-MSF) Design Based on Geometrical Concepts to Improve Building Energy Efficiency Performance. Sustainability 2023, 15, 2788. https://doi.org/10.3390/su15032788

Tran TN, Seomun G, Lee R, Lee H, Yoon J, Kim D. Development and Implementation of Photovoltaic Integrated Multi-Skin Façade (PV-MSF) Design Based on Geometrical Concepts to Improve Building Energy Efficiency Performance. Sustainability. 2023; 15(3):2788. https://doi.org/10.3390/su15032788

Chicago/Turabian StyleTran, Tien Nhat, Gu Seomun, Ruda Lee, Hyomun Lee, Jongho Yoon, and Dongsu Kim. 2023. "Development and Implementation of Photovoltaic Integrated Multi-Skin Façade (PV-MSF) Design Based on Geometrical Concepts to Improve Building Energy Efficiency Performance" Sustainability 15, no. 3: 2788. https://doi.org/10.3390/su15032788

APA StyleTran, T. N., Seomun, G., Lee, R., Lee, H., Yoon, J., & Kim, D. (2023). Development and Implementation of Photovoltaic Integrated Multi-Skin Façade (PV-MSF) Design Based on Geometrical Concepts to Improve Building Energy Efficiency Performance. Sustainability, 15(3), 2788. https://doi.org/10.3390/su15032788