Comprehensive Low Voltage Microgrid Planning Methodology for Rural Electrification

Abstract

1. Introduction

- An integration of LV distribution system design and operation optimization in the microgrid planning process;

- A novel algorithm for PVs and BES sizing and sitting as well as BES operation, especially in an AC/DC structure;

- A gradual electrification option to avoid initial prohibitive capital expenditures (CAPEX) that would limit the progress of electrification, especially in remote and rural areas;

- A comprehensive microgrid methodology that not only finds distributed energy resources as usual software do, but also adds the choice of distribution type (AC/DC) and topology.

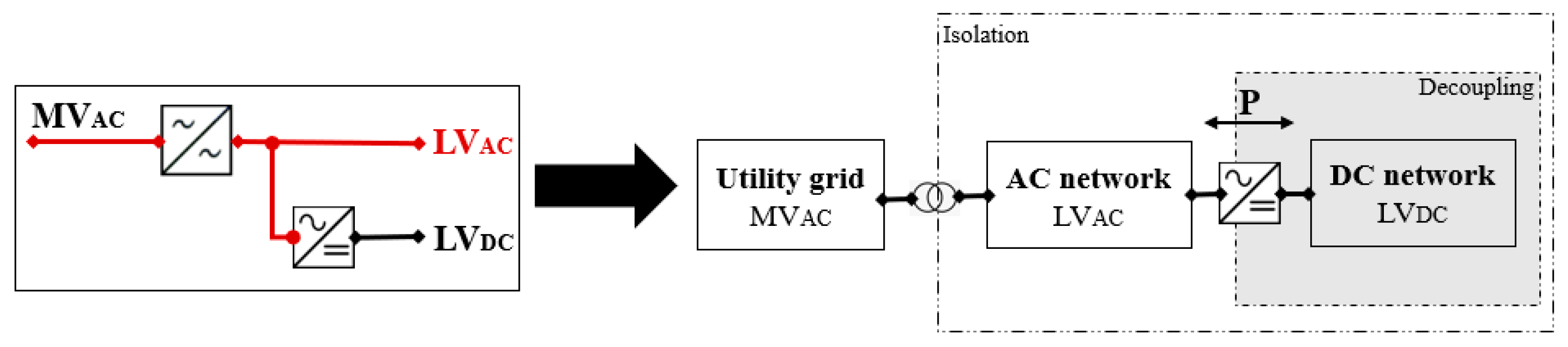

2. Traditional Microgrid Topologies

3. Problem Formulation

3.1. LV Microgrid Comprehensive Planning Tool

- to : weights allocated to objectives

- : total cost of the microgrid (defined in Section 4.4)

- : amount of CO2 emissions generated (defined in Section 4.4)

- : percentage of time the microgrid is autonomous from the MV grid (in case of grid-connected mode) or in operation (in case of off-grid mode) (defined in Section 4.4)

- : percentage of energy produced by the microgrid (in grid-connected mode) (defined in Section 4.4)

- : decision variables which consist of the electrical topology (location, type, and size of lines) and DERs (distributed energy resources) sitting and sizing (PV, storage, transformer, diesel generator)

- : voltage at node n of the microgrid composed of N nodes

- : current in line l of the microgrids consisted of M lines

- : maximal admissible current in line l

3.2. Four-Stage Proposed Algorithm Description

- Loads description: coordinates (latitude and longitude), estimation of one or several daily power profiles (either from real measurements or from data bases if available) and yearly peak power consumed.

- Grid elements description: coordinates and connection of poles, coordinates of the interconnection point, LV conductor data base (technology, section, resistance, reactance, maximal admissible current, cost), transformers database (installed power, cost).

- Grid architecture: choice of distribution (AC, DC, or AC/DC), type of topology (tree or cluster structure), management mode (grid-connected or off-grid).

- PV and BES technologies available in the market (installed powers, life durations, and capacities for BES).

- Economic data: lifetime of the project, discount ratio, cost of the electricity in the considered country.

4. Algorithms Description

4.1. A01: Topology Optimization

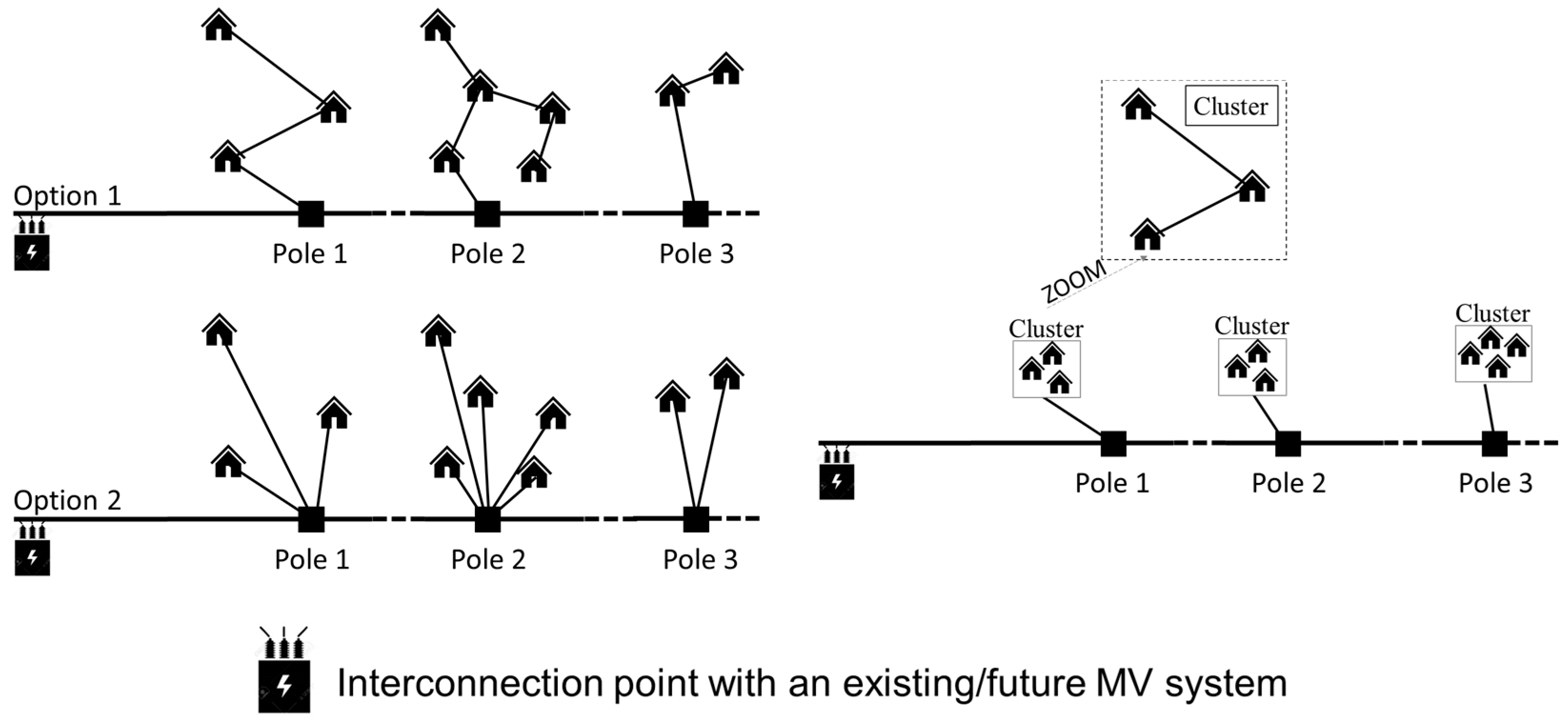

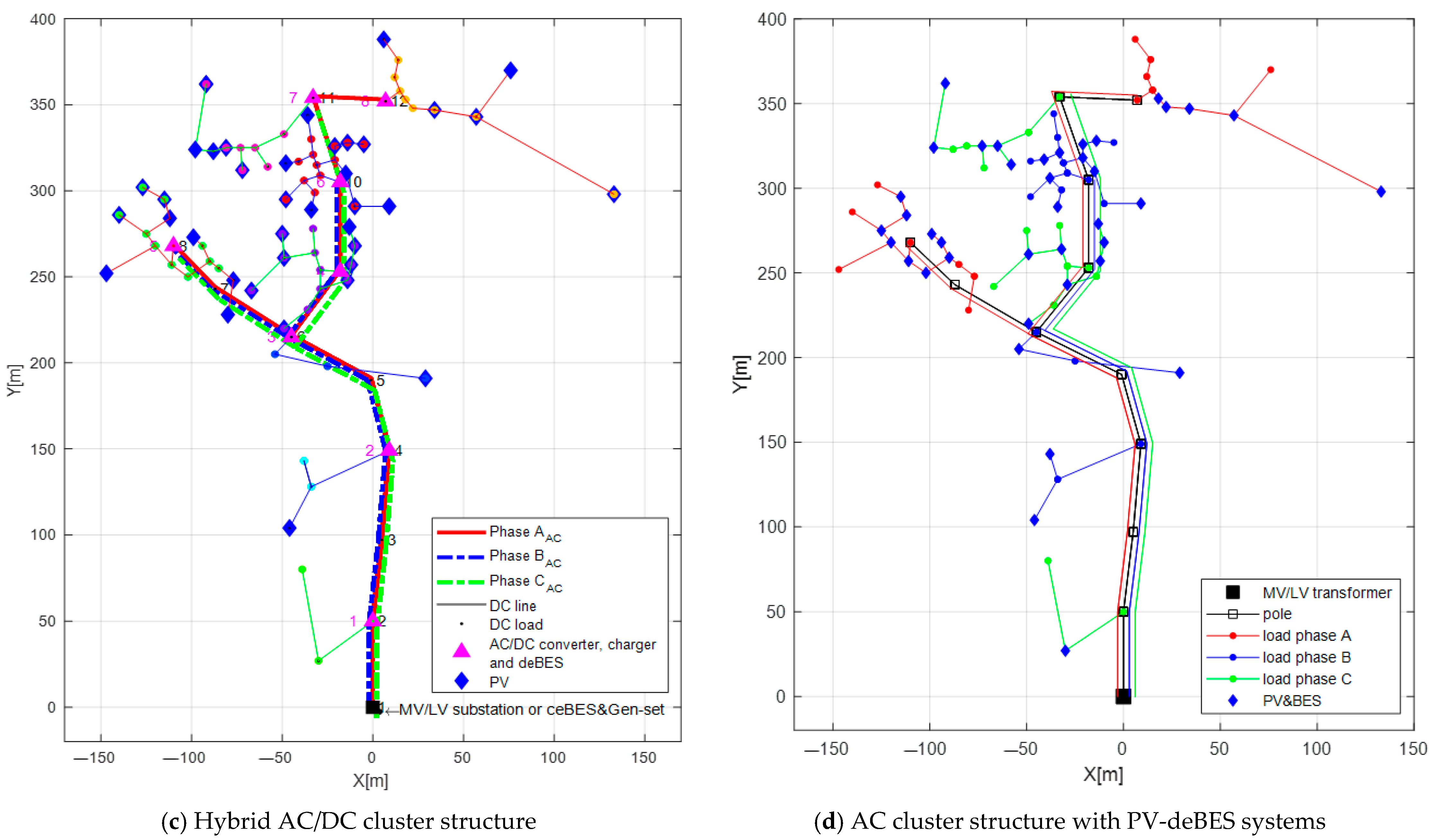

4.1.1. Proposed Topologies

4.1.2. Algorithms Developed

- each load is first allocated to a phase using a mixed integer linear programming (MILP [43]) formulation in order to balance power consumption between phases (see Equations (4)–(9)) and then three trees are built (one per phase) using the minimum spanning tree algorithm.

- first all loads and poles are connected together with MST, then the poles (with the loads connected to them) are allocated to phases.

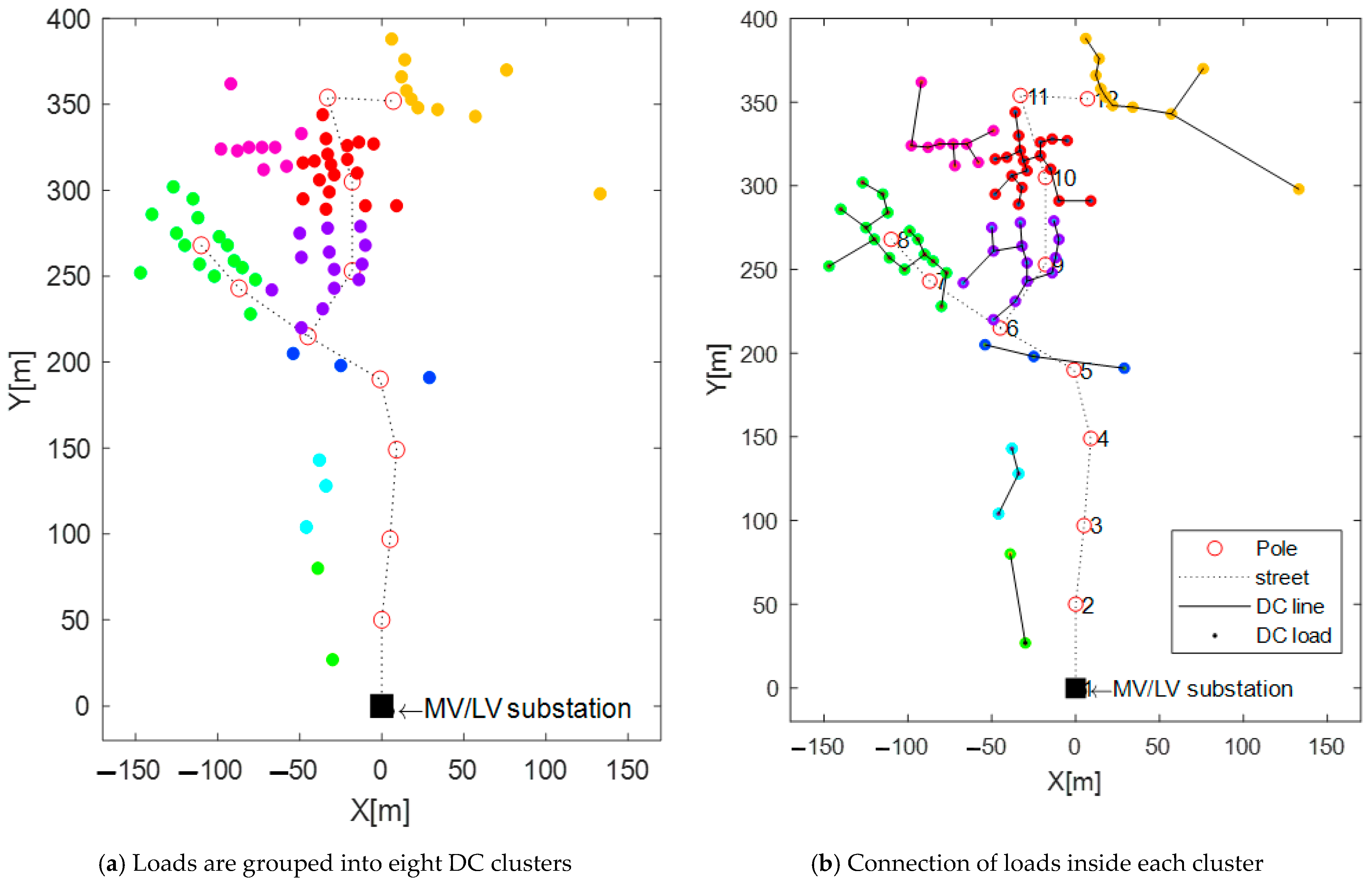

- Clustering: loads are packed into a given number of clusters using the K-means method [46] to minimize the total length of conductors inside each cluster. The optimal number of clusters is selected using the elbow method [47]. Loads inside each cluster are connected together with a minimum spanning tree (Kruskal’s algorithm).

- Connection of clusters to poles: for each cluster, the shortest path algorithm finds the shortest length from each load to poles. Then, we select among the poles the one with the shortest distance to the considered cluster. Loadflows (AC unbalanced or DC) enable sizing the cross-sections of lines to respect the voltage and current constraints. Finally, the chosen connection is the one which minimizes power losses.

- Power balancing: clusters are allocated to a phase (same MILP formulation as for the tree structure).

- Sizing of the main feeder: Loadflows (AC unbalanced or DC) make it possible to select the optimal cross-section of the main lines in order to respect voltage and current constraints.

4.1.3. Phase Power Balancing

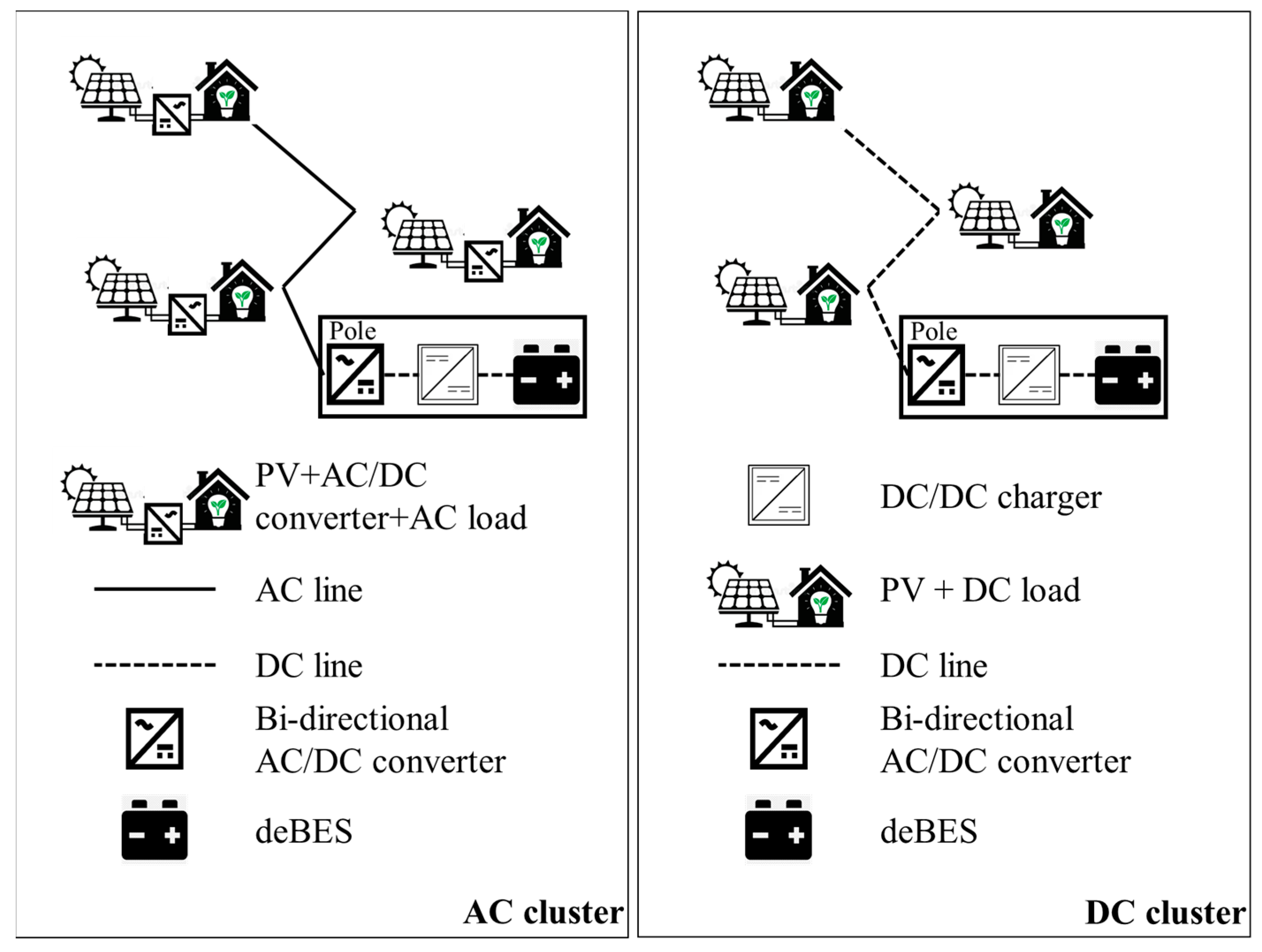

4.2. A02: Distribution Energy Resources Allocation

4.2.1. Tree-Structure

4.2.2. Cluster Structure

PV Allocation

- With:

- k: index of clusters,

- j: index of loads in clusters,

- h: index of hours

- d: index of day

- is the difference of the instantaneous power of loads () and PVs ()

- : total power of cluster k (kW)

- : normalized installed power of one PV unit (kW)

- : number of loads in cluster k

- : number of clusters

- : energy of the cluster k over the year

- : power of cluster k with PV (including DC losses) at time h (kW)

deBESs Sizing

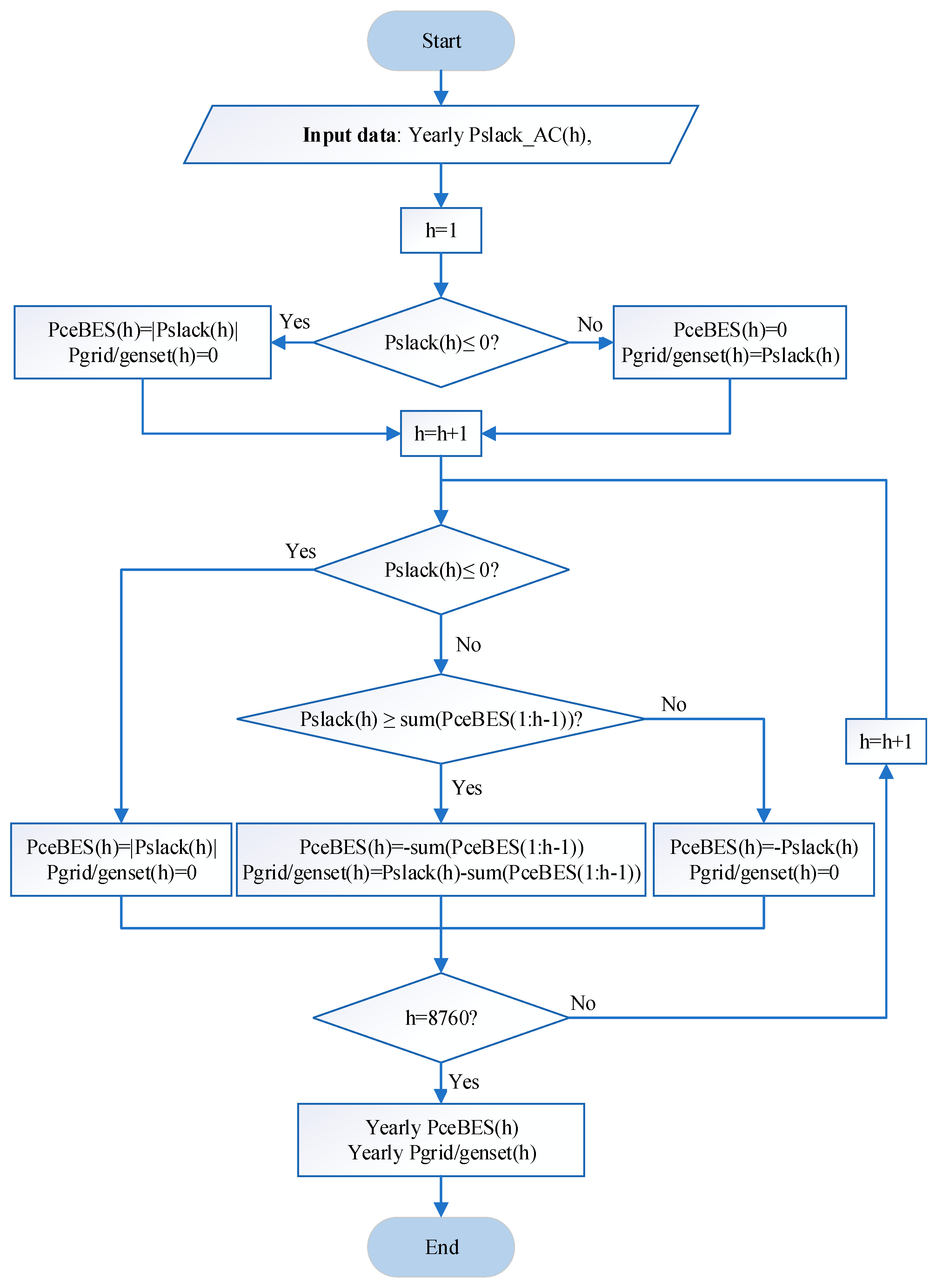

4.3. A03: Microgrid Balancing

- : required power at the interconnection node et time h,

- : ceBES power at time h,

- : power provided by the grid or the diesel generator at time h,

- N.B. it is also possible to consider PV-deBES system and to apply the allocation method of the tree-structure.

4.4. A04: KPIs Computaions

4.4.1. TOTEX

4.4.2. LCOE, Autonomous Time and Energy, and CO2 Emissions

5. Case study

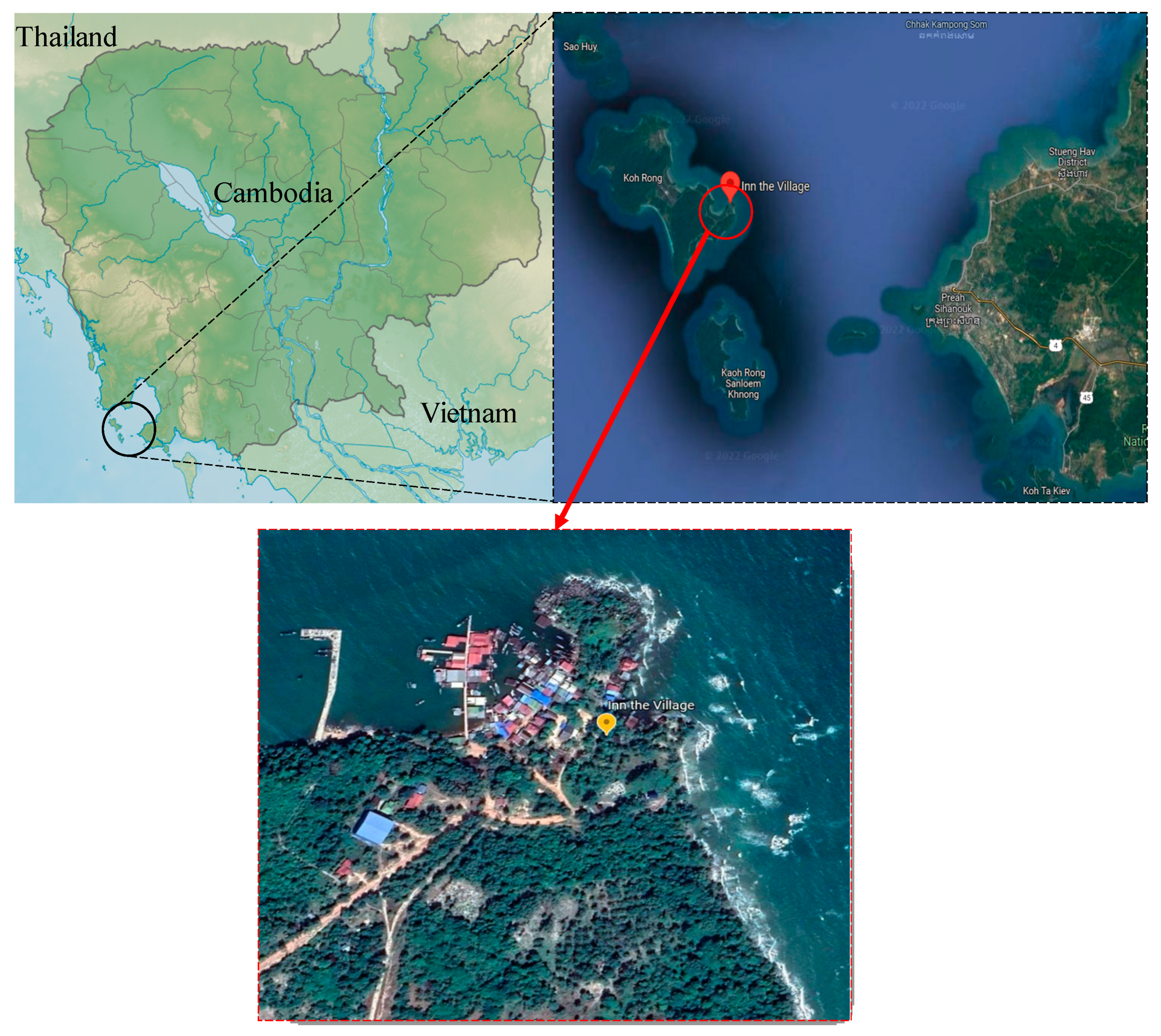

5.1. Description

5.2. AC versus AC/DC Microgrids

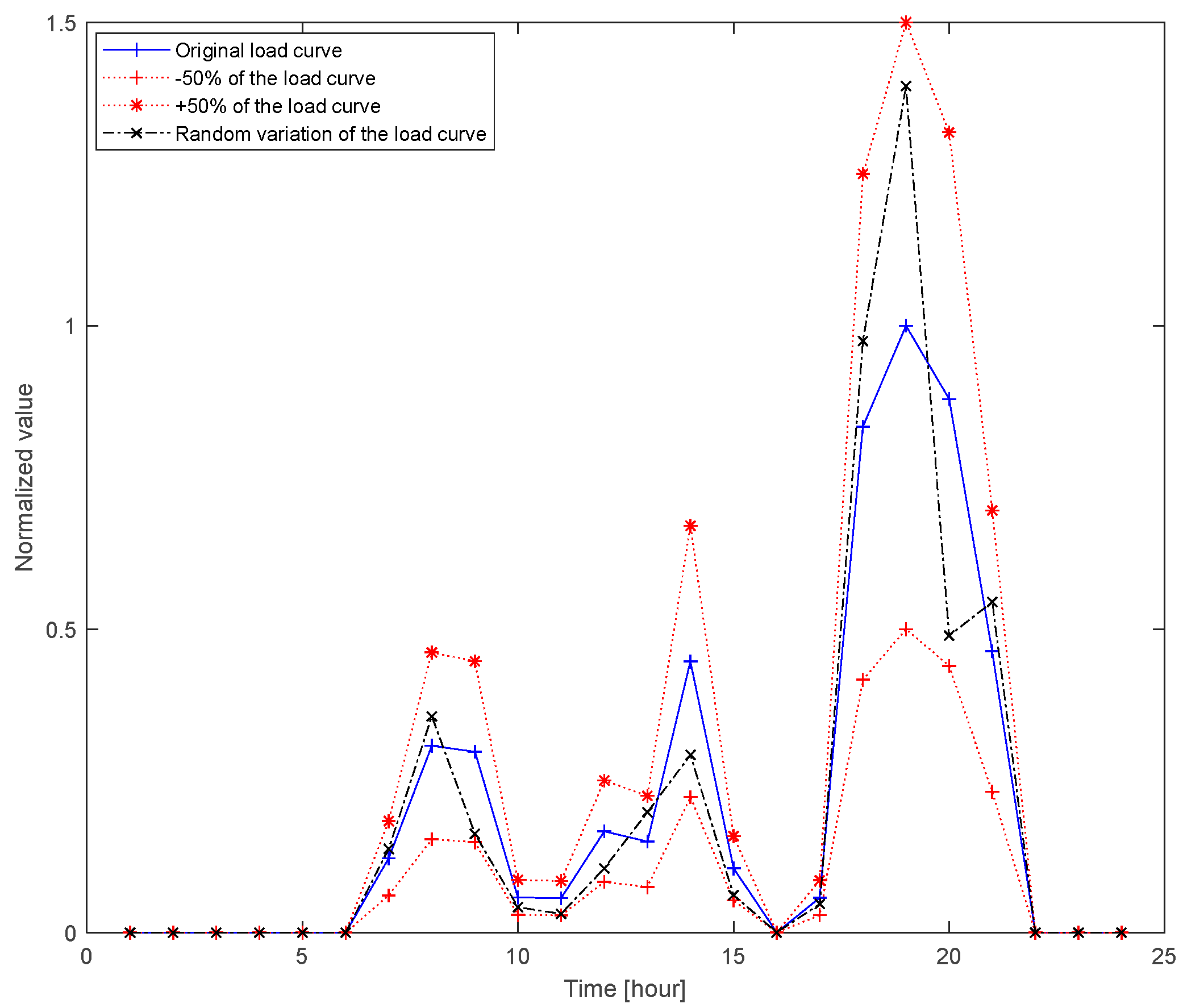

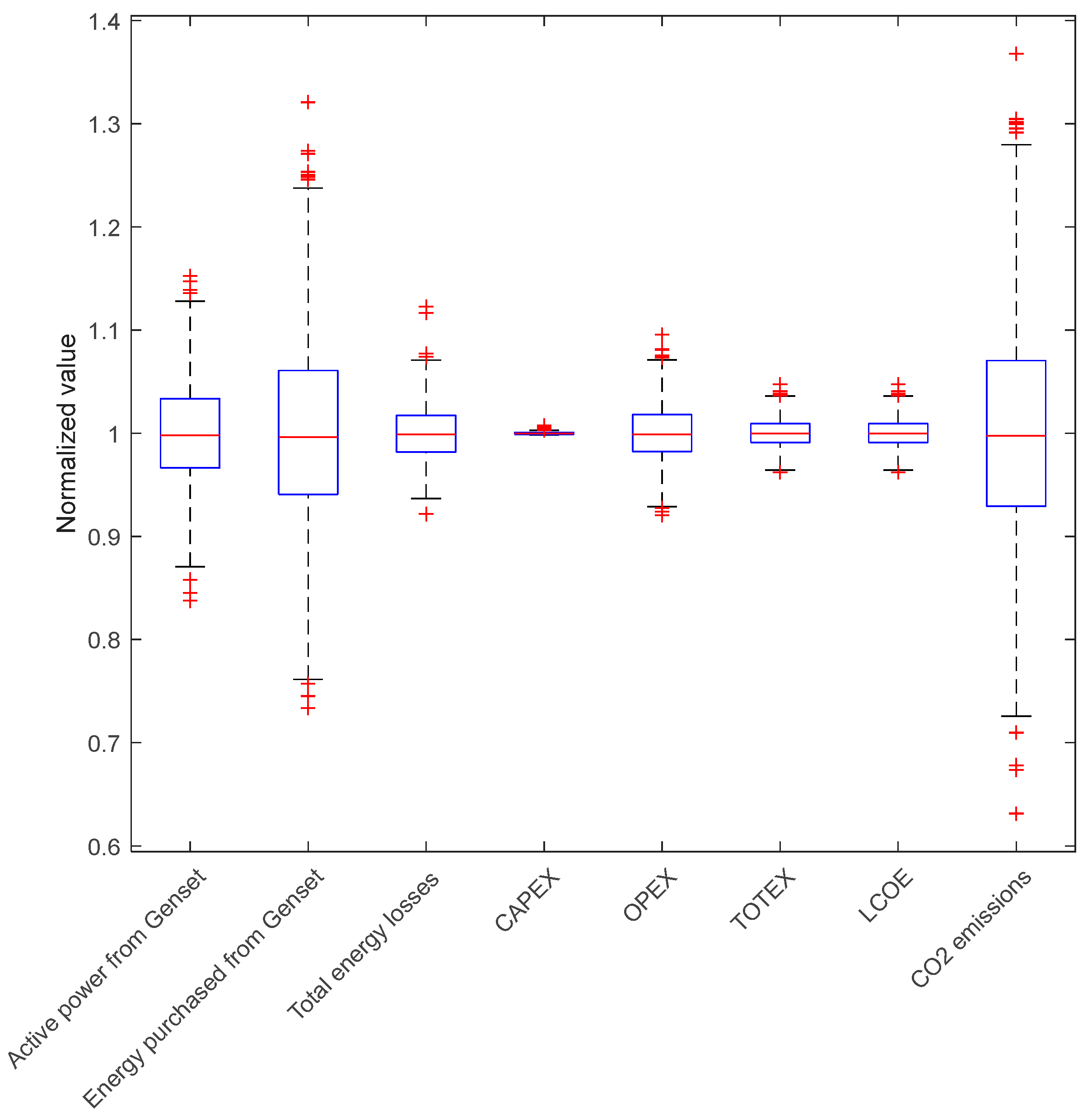

5.3. Sensitivity Analysis of the Load Curve

5.4. Discussion

6. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| No. | Coordinate | P (kW) | No. | Coordinate | P (kW) | No. | Coordinate | P (kW) | No. | Coordinate | P (kW) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Xn (m) | Yn (m) | Xn (m) | Yn (m) | Xn (m) | Yn (m) | Xn (m) | Yn (m) | ||||||||

| 1 | −30 | 27 | 0.296 | 20 | −112 | 284 | 0.374 | 39 | −48 | 316 | 0.422 | 58 | −15 | 310 | 0.361 |

| 2 | −39 | 80 | 0.360 | 21 | −99 | 273 | 0.397 | 40 | −41 | 317 | 0.464 | 59 | −21 | 318 | 0.382 |

| 3 | −46 | 104 | 0.420 | 22 | −94 | 268 | 0.317 | 41 | −31 | 315 | 0.411 | 60 | −21 | 326 | 0.332 |

| 4 | −34 | 128 | 0.365 | 23 | −90 | 259 | 0.433 | 42 | −33 | 321 | 0.434 | 61 | −5 | 327 | 0.347 |

| 5 | −38 | 143 | 0.376 | 24 | −85 | 255 | 0.431 | 43 | −72 | 312 | 0.437 | 62 | −14 | 328 | 0.454 |

| 6 | 29 | 191 | 0.372 | 25 | −77 | 248 | 0.389 | 44 | −98 | 324 | 0.292 | 63 | 9 | 291 | 0.451 |

| 7 | −25 | 198 | 0.399 | 26 | −67 | 242 | 0.499 | 45 | −88 | 323 | 0.369 | 64 | 6 | 388 | 0.469 |

| 8 | −54 | 205 | 0.398 | 27 | −29 | 243 | 0.453 | 46 | −81 | 325 | 0.445 | 65 | 14 | 376 | 0.372 |

| 9 | −49 | 220 | 0.443 | 28 | −29 | 254 | 0.420 | 47 | −73 | 325 | 0.446 | 66 | 12 | 366 | 0.389 |

| 10 | −36 | 231 | 0.489 | 29 | −49 | 261 | 0.405 | 48 | −65 | 325 | 0.381 | 67 | 15 | 358 | 0.494 |

| 11 | −80 | 228 | 0.421 | 30 | −32 | 264 | 0.459 | 49 | −49 | 333 | 0.333 | 68 | 18 | 353 | 0.357 |

| 12 | −102 | 250 | 0.390 | 31 | −50 | 275 | 0.389 | 50 | −34 | 330 | 0.371 | 69 | 22 | 348 | 0.426 |

| 13 | −111 | 257 | 0.455 | 32 | −33 | 278 | 0.434 | 51 | −36 | 344 | 0.435 | 70 | 34 | 347 | 0.359 |

| 14 | −120 | 268 | 0.434 | 33 | −34 | 289 | 0.428 | 52 | −92 | 362 | 0.414 | 71 | 57 | 343 | 0.439 |

| 15 | −147 | 252 | 0.385 | 34 | −48 | 295 | 0.444 | 53 | −14 | 248 | 0.423 | 72 | 76 | 370 | 0.358 |

| 16 | −125 | 275 | 0.415 | 35 | −32 | 299 | 0.408 | 54 | −12 | 257 | 0.332 | 73 | 133 | 298 | 0.410 |

| 17 | −140 | 286 | 0.417 | 36 | −38 | 306 | 0.444 | 55 | −10 | 268 | 0.477 | ||||

| 18 | −127 | 302 | 0.361 | 37 | −29 | 309 | 0.423 | 56 | −13 | 279 | 0.412 | ||||

| 19 | −115 | 295 | 0.355 | 38 | −58 | 314 | 0.393 | 57 | −10 | 291 | 0.336 | ||||

Appendix B

| No. | Coordinate | No. | Coordinate | ||

|---|---|---|---|---|---|

| Xn (m) | Yn (m) | Xn (m) | Yn (m) | ||

| 1 | 0 | 0 | 7 | −87 | 243 |

| 2 | 0 | 50 | 8 | −110 | 268 |

| 3 | 5 | 97 | 9 | −18 | 253 |

| 4 | 9 | 149 | 10 | −18 | 305 |

| 5 | −1 | 190 | 11 | −33 | 354 |

| 6 | −45 | 215 | 12 | 7 | 352 |

References

- Ourworldindata. Access to Energy. 2022. Available online: https://ourworldindata.org/energy-access#access-to-electricity (accessed on 22 August 2022).

- WorldBank. Access to Electricity for Rural Areas. 2022. Available online: https://data.worldbank.org/indicator/eg.elc.accs.ru.zs (accessed on 22 August 2022).

- Electricity Authority of Cambodia. Salient Features of Power Development in the Kingdom of Cambodia. 2022. Available online: https://www.eac.gov.kh/site/index?lang=en (accessed on 31 December 2022).

- Mackay, L. Steps Towards the Universal Direct Current Distribution System. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2018. [Google Scholar]

- Vai, V.; Alvarez-Herault, M.-C.; Raison, B.; Bun, L. Optimal low-voltage distribution topology with integration of PV and storage for rural electrification in developing countries: A case study of Cambodia. J. Mod. Power Syst. Clean Energy 2020, 8, 531–539. [Google Scholar] [CrossRef]

- Vai, V.; Bun, L.; Khon, K.; Alvarez-Herault, M.C.; Raison, B. Integrated PV and Battery Energy Storage in LVAC for a Rural Village: A Case Study of Cambodia. In Proceedings of the IECON 2020 The 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020; pp. 1602–1607. [Google Scholar] [CrossRef]

- Vai, V.; Eng, S. Study of Grid-Connected PV System for a Low Voltage Distribution System: A Case Study of Cambodia. Energies 2022, 15, 5003. [Google Scholar] [CrossRef]

- Chhlonh, C.; Alvarez-Herault, M.C.; Vai, V.; Raison, B. Comparative Planning of LVAC for Microgrid Topologies With PV-Storage in Rural Areas—Cases Study in Cambodia. In Proceedings of the 2022 IEEE PES Innovative Smart Grid Technologies Conference Europe, Novi Sad, Serbia, 10–12 October 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Nandini, K.K.; Jayalakshmi, N.S.; Jadoun, V.K. An overview of DC Microgrid with DC distribution system for DC loads. Mater. Today Proc. 2021, 51, 635–639. [Google Scholar] [CrossRef]

- Montoya, O.D.; Gil-González, W.; Grisales-Noreña, L.F. Solar Photovoltaic Integration in Monopolar DC Networks via the GNDO Algorithm. Algorithms 2022, 15, 277. [Google Scholar] [CrossRef]

- Basto-Gil, J.D.; Maldonado-Cardenas, A.D.; Montoya, O.D. Optimal Selection and Integration of Batteries and Renewable Generators in DC Distribution Systems through a Mixed-Integer Convex Formulation. Electronics 2022, 11, 3139. [Google Scholar] [CrossRef]

- Grisales-Noreña, L.F.; Ocampo-Toro, J.A.; Rosales-Muñoz, A.A.; Cortes-Caicedo, B.; Montoya, O.D. An Energy Management System for PV Sources in Standalone and Connected DC Networks Considering Economic, Technical, and Environmental Indices. Sustainability 2022, 14, 16429. [Google Scholar] [CrossRef]

- Grisales-noreña, L.F.; Cortés-caicedo, B.; Alcalá, G.; Montoya, O.D. Applying the Crow Search Algorithm for the Optimal Integration of PV Generation Units in DC Networks. Mathematics 2023, 11, 387. [Google Scholar] [CrossRef]

- Samende, C.; Bhagavathy, S.M.; McCulloch, M. Power Loss Minimization of Off-Grid Solar DC Nano-Grids—Part I: Centralized Control Algorithm. IEEE Trans. Smart Grid 2021, 12, 4715–4725. [Google Scholar] [CrossRef]

- Samende, C.; Bhagavathy, S.M.; McCulloch, M. Power Loss Minimisation of Off-Grid Solar DC Nano-Grids—Part II: A Quasi-Consensus-Based Distributed Control Algorithm. IEEE Trans. Smart Grid 2022, 13, 38–46. [Google Scholar] [CrossRef]

- Kumar, P.; Pal, N.; Sharma, H. Optimization and techno-economic analysis of a solar photo-voltaic/biomass/diesel/battery hybrid off-grid power generation system for rural remote electrification in eastern India. Energy 2022, 247, 123560. [Google Scholar] [CrossRef]

- Krishan, O.; Suhag, S. Techno-economic analysis of a hybrid renewable energy system for an energy poor rural community. J. Energy Storage 2019, 23, 305–319. [Google Scholar] [CrossRef]

- Sari, A.; Majdi, A.; Opulencia, M.J.C.; Timoshin, A.; Huy, D.T.N.; Trung, N.D.; Alsaikhan, F.; Hammid, A.T.; Akhmedov, A. New optimized configuration for a hybrid PV/diesel/battery system based on coyote optimization algorithm: A case study for Hotan county. Energy Rep. 2022, 8, 15480–15492. [Google Scholar] [CrossRef]

- Khanahmadi, A.; Ghaffarpour, R. A cost-effective and emission-Aware hybrid system considering uncertainty: A case study in a remote area. Renew. Energy 2022, 201, 977–992. [Google Scholar] [CrossRef]

- Rehman, S.; Natrajan, N.; Mohandes, M.; Alhems, L.M.; Himri, Y.; Allouhi, A. Feasibility Study of Hybrid Power Systems for Remote Dwellings in Tamil Nadu, India. IEEE Access 2020, 8, 143881–143890. [Google Scholar] [CrossRef]

- Oladigbolu, J.O.; Ramli, M.A.M.; Al-Turki, Y.A. Feasibility study and comparative analysis of hybrid renewable power system for off-grid rural electrification in a typical remote village located in Nigeria. IEEE Access 2020, 8, 171643–171663. [Google Scholar] [CrossRef]

- Tsai, C.T.; Ocampo, E.M.; Beza, T.M.; Kuo, C.C. Techno-economic and sizing analysis of battery energy storage system for behind-the-meter application. IEEE Access 2020, 8, 203734–203746. [Google Scholar] [CrossRef]

- Iqbal, S.; Jan, M.U.; Rehman, A.U.; Rehman, A.U.; Shafique, A.; Rehman, H.U.; Aurangzeb, M. Feasibility Study and Deployment of Solar Photovoltaic System to Enhance Energy Economics of King Abdullah Campus, University of Azad Jammu and Kashmir Muzaffarabad, AJK Pakistan. IEEE Access 2022, 10, 5440–5455. [Google Scholar] [CrossRef]

- Das, B.K.; Alotaibi, M.A.; Das, P.; Islam, M.S.; Das, S.K.; Hossain, M.A. Feasibility and techno-economic analysis of stand-alone and grid-connected PV/Wind/Diesel/Batt hybrid energy system: A case study. Energy Strateg. Rev. 2021, 37, 100673. [Google Scholar] [CrossRef]

- Amupolo, A.; Nambundunga, S.; Chowdhury, D.S.P.; Grün, G. Techno-Economic Feasibility of Off-Grid Renewable Energy Electrification Schemes: A Case Study of an Informal Settlement in Namibia. Energies 2022, 15, 4235. [Google Scholar] [CrossRef]

- Odou, O.D.T.; Bhandari, R.; Adamou, R. Hybrid off-grid renewable power system for sustainable rural electrification in Benin. Renew. Energy 2020, 145, 1266–1279. [Google Scholar] [CrossRef]

- Shrivastwa, R.R.; Hably, A.; Melizi, K.; Bacha, S. Understanding microgrids and their future trends. In Proceedings of the 2019 IEEE International Conference on Industrial Technology (ICIT), Melbourne, Australia, 13–15 February 2019; pp. 1723–1728. [Google Scholar] [CrossRef]

- Justo, J.J.; Mwasilu, F.; Lee, J.; Jung, J.W. AC-microgrids versus DC-microgrids with distributed energy resources: A review. Renew. Sustain. Energy Rev. 2013, 24, 387–405. [Google Scholar] [CrossRef]

- Garces, A. Uniqueness of the power flow solutions in low voltage direct current grids. Electr. Power Syst. Res. 2017, 151, 149–153. [Google Scholar] [CrossRef]

- Montoya, O.D.; Grisales-Noreña, L.F.; González-Montoya, D.; Ramos-Paja, C.A.; Garces, A. Linear power flow formulation for low-voltage DC power grids. Electr. Power Syst. Res. 2018, 163, 375–381. [Google Scholar] [CrossRef]

- Rodriguez-Diaz, E.; Savaghebi, M.; Vasquez, J.C.; Guerrero, J.M. An overview of low voltage DC distribution systems for residential applications. In Proceedings of the 2015 IEEE International Conference on Consumer Electronics—Berlin, Berlin, Germany, 6–9 September 2015; pp. 318–322. [Google Scholar] [CrossRef]

- Okra. Okra Mini-Grid. Available online: https://okrasolar.com/project/steung-chrov/ (accessed on 31 August 2022).

- Richard, L.; Boudinet, C.; Ranaivoson, S.A.; Rabarivao, J.O.; Befeno, A.E.; Frey, D.; Alvarez-Hérault, M.-C.; Raison, B.; Saincy, N. Development of a DC Microgrid with Decentralized Production and Storage: From the Lab to Field Deployment in Rural Africa. Energies 2022, 15, 6727. [Google Scholar] [CrossRef]

- Unamuno, E.; Barrena, J.A. Hybrid ac/dc microgrids—Part I: Review and classification of topologies. Renew. Sustain. Energy Rev. 2015, 52, 1251–1259. [Google Scholar] [CrossRef]

- Radwan, A.A.A.; Mohamed, Y.A.R.I. Networked control and power management of AC/DC hybrid microgrids. IEEE Syst. J. 2017, 11, 1662–1673. [Google Scholar] [CrossRef]

- Rajkumar, A. A Novel Solar PV Equipped Flexible AC/DC Microgrid Based Energy Management for Effective Residential Power Distribution Une nouvelle gestion del’énergie basée sur un micro-réseau flexible CA/CC équipé de panneaux solaires photovoltaïques pour une d. IEEE Can. J. Electr. Comput. Eng. 2022, 45, 328–338. [Google Scholar] [CrossRef]

- Xu, Q.; Zhao, T.; Xu, Y.; Xu, Z.; Wang, P.; Blaabjerg, F. A Distributed and Robust Energy Management System for Networked Hybrid AC/DC Microgrids. IEEE Trans. Smart Grid 2020, 11, 3496–3508. [Google Scholar] [CrossRef]

- Yang, P.; Yu, M.; Wu, Q.; Wang, P.; Xia, Y.; Wei, W. Decentralized Economic Operation Control for Hybrid AC/DC Microgrid. IEEE Trans. Sustain. Energy 2020, 11, 1898–1910. [Google Scholar] [CrossRef]

- Lin, P.; Jin, C.; Xiao, J.; Li, X.; Shi, D.; Tang, Y.; Wang, P. A distributed control architecture for global system economic operation in autonomous hybrid AC/DC microgrids. IEEE Trans. Smart Grid 2019, 10, 2603–2617. [Google Scholar] [CrossRef]

- Xia, Y.; Wei, W.; Yu, M.; Wang, X.; Peng, Y. Power Management for a Hybrid AC/DC Microgrid with Multiple Subgrids. IEEE Trans. Power Electron. 2018, 33, 3520–3533. [Google Scholar] [CrossRef]

- Vai, V. Planning of Low Voltage Distribution System with Integration of PV Sources and Storage Means—Case of Power System of Cambodia. Ph.D. Thesis, University Grenoble Alpes, Grenoble, France, 2017. [Google Scholar]

- Ross, D.T.; Schoman, K.E. Structured Analysis for Requirements Definition. IEEE Trans. Softw. Eng. 1977, 3, 6–15. [Google Scholar] [CrossRef]

- Khon, K.; Vai, V.; Alvarez-Herault, M.-C.; Bun, L.; Bertrand, R. Planning of low voltage AC/DC microgrid for un-electrified areas. In Proceedings of the CIRED 2021, the 26th International Conference and Exhibition on Electricity Distribution, Geneva, Switzerland, 20–23 September 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Kruskal, J.B. On the Shortest Spanning Subtree of a Graph and the Traveling Salesman Problem. Source Proc. Am. Math. Soc. 1956, 7, 48–50. [Google Scholar] [CrossRef]

- Vai, V.; Alvarez-Hérault, M.C.; Bun, L.; Raison, B. Design of LVAC distribution system with PV and centralized battery energy storage integration-a case study of Cambodia. ASEAN Eng. J. 2019, 9, 1–16. [Google Scholar] [CrossRef]

- Rajabi, A.; Eskandari, M.; Ghadi, M.J.; Li, L.; Zhang, J.; Siano, P. A comparative study of clustering techniques for electrical load pattern segmentation. Renew. Sustain. Energy Rev. 2019, 120, 109628. [Google Scholar] [CrossRef]

- Delgado, H.; Anguera, X.; Fredouille, C.; Serrano, J. Novel Clustering Selection Criterion for Fast Binary Key Speaker Diarization. In Proceedings of the Interspeech 2015, the 16th Annual Conference of the International Speech Communication Association, Dresden, Germany, 6–10 September 2015; pp. 3091–3095. [Google Scholar] [CrossRef]

- Dijkstra, E.-W. A note on two problems in connexion with graphs. Numer. Math. 1959, 1, 269–271. [Google Scholar] [CrossRef]

- Ciric, R.M.; Feltrin, A.P.; Ochoa, L.F. Power Flow in Four-Wire Distribution Networks—General Approach. IEEE Trans. Power Syst. 2003, 18, 1283–1290. [Google Scholar] [CrossRef]

- Habib, H.U.R.; Waqar, A.; Junejo, A.K.; Elmorshedy, M.F.; Wang, S.; Buker, M.S.; Akindeji, K.T.; Kang, J.; Kim, Y.-S. Optimal planning and EMS design of PV based standalone rural microgrids. IEEE Access 2021, 9, 32908–32930. [Google Scholar] [CrossRef]

- Our World in Data. CO2 Intensity of Electricity 2021. 2022. Available online: https://ourworldindata.org/grapher/carbon-intensity-electricity (accessed on 8 June 2022).

- Jufri, F.H.; Aryani, D.R.; Garniwa, I.; Sudiarto, B. Optimal battery energy storage dispatch strategy for small-scale isolated hybrid renewable energy system with different load profile patterns. Energies 2021, 14, 3139. [Google Scholar] [CrossRef]

- Harrison, R.L. Introduction to Monte Carlo simulation. In Proceedings of the 2008 Winter Simulation Conference, Miami, FL, USA, 7–10 December 2008; pp. 91–100. [Google Scholar] [CrossRef]

| AC | Hybrid AC/DC | |||

|---|---|---|---|---|

| Parameters | “Grid-Connected” | “Off-Grid” | “Grid-Connected” | “Off-Grid” |

| Total load peak power (kW) | 29.52 | 29.52 | ||

| Number of PVs | 40 | 38 | ||

| Number of deBESs | 40 | 7 | ||

| Number of DC/DC chargers | 41 | 7 | ||

| Number of bi-directional AC/DC converters | 1 | 8 | ||

| (kW)/unit | 0.57 | 0.43 | ||

| Total of the system (kW) | 40.2 | 30.09 | ||

| Total of the system (kWh) | 126.48 | 91.84 | ||

| Total charger of the system (kW) | 40.2 | 30.09 | ||

| Total of the system (kW) | 40.2 | 15.52 | ||

| (kWh) | 0.075 | 0 | ||

| (kW) | 1.35 | 0 | ||

| Active peak power from the grid/genset (kW) | 0.77 | 14.80 | ||

| Energy purchased from the grid/genset (MWh/year) | 1.05 | 10.25 | ||

| Total energy losses (MWh/year) | 9.63 | 4.15 | ||

| CAPEX (k$) | 179.03 | 181.53 | 152.64 | 161.14 |

| OPEX (k$) | 20.68 | 23.8 | 68.45 | 191.08 |

| TOTEX (k$) | 199.71 | 205.34 | 221.09 | 352.22 |

| LCOE ($/kWh) | 0.2551 | 0.2608 | 0.2809 | 0.4475 |

| Autonomous time (%/year) | 54.16 | 100 | 37.50 | 100 |

| Autonomous energy (%/year) | 98.21 | 100 | 80.90 | 100 |

| CO2 emissions (kg/year) | 445 | 976 | 4344 | 9529 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khon, K.; Chhlonh, C.; Vai, V.; Alvarez-Herault, M.-C.; Raison, B.; Bun, L. Comprehensive Low Voltage Microgrid Planning Methodology for Rural Electrification. Sustainability 2023, 15, 2841. https://doi.org/10.3390/su15032841

Khon K, Chhlonh C, Vai V, Alvarez-Herault M-C, Raison B, Bun L. Comprehensive Low Voltage Microgrid Planning Methodology for Rural Electrification. Sustainability. 2023; 15(3):2841. https://doi.org/10.3390/su15032841

Chicago/Turabian StyleKhon, Kimsrornn, Chhith Chhlonh, Vannak Vai, Marie-Cecile Alvarez-Herault, Bertrand Raison, and Long Bun. 2023. "Comprehensive Low Voltage Microgrid Planning Methodology for Rural Electrification" Sustainability 15, no. 3: 2841. https://doi.org/10.3390/su15032841

APA StyleKhon, K., Chhlonh, C., Vai, V., Alvarez-Herault, M.-C., Raison, B., & Bun, L. (2023). Comprehensive Low Voltage Microgrid Planning Methodology for Rural Electrification. Sustainability, 15(3), 2841. https://doi.org/10.3390/su15032841