Decentral Production of Green Hydrogen for Energy Systems: An Economically and Environmentally Viable Solution for Surplus Self-Generated Energy in Manufacturing Companies?

Abstract

:1. Introduction and Motivation

2. State of the Art

2.1. Designing Industrial Energy Supply Systems

2.2. Investigation of Hydrogen Applications

2.3. Need for Research

- A specific method has to be developed to model, simulate, and conduct economic and environmental evaluations of different energy supply system variants with hydrogen production and utilization at manufacturing companies.

- This method should be applied to relevant use cases based on representative company data in order to determine whether hydrogen production and utilization offers transferable economic and environmental potential for manufacturing companies.

3. Scientific Approach and Simulation-Based Method

- Collection of input data from the use case, e.g., energy and media consumption, on-site energy generation, general and economic boundary conditions

- Definition of relevant energy and media supply technologies

- Definition of target criteria for dimensioning the technology model

- Definition and selection of technology combinations

- Simulation and dimensioning of components

- Evaluation

4. Modeling and Simulation

4.1. Utilisation Paths

- Hydrogen as an energy storage medium for electricity

- Hydrogen production via electrolysis using electricity from photovoltaic (PV) systems

- Hydrogen storage in pressurized storage tanks

- Hydrogen utilization for power generation in fuel cells to cover phases of low PV power generation

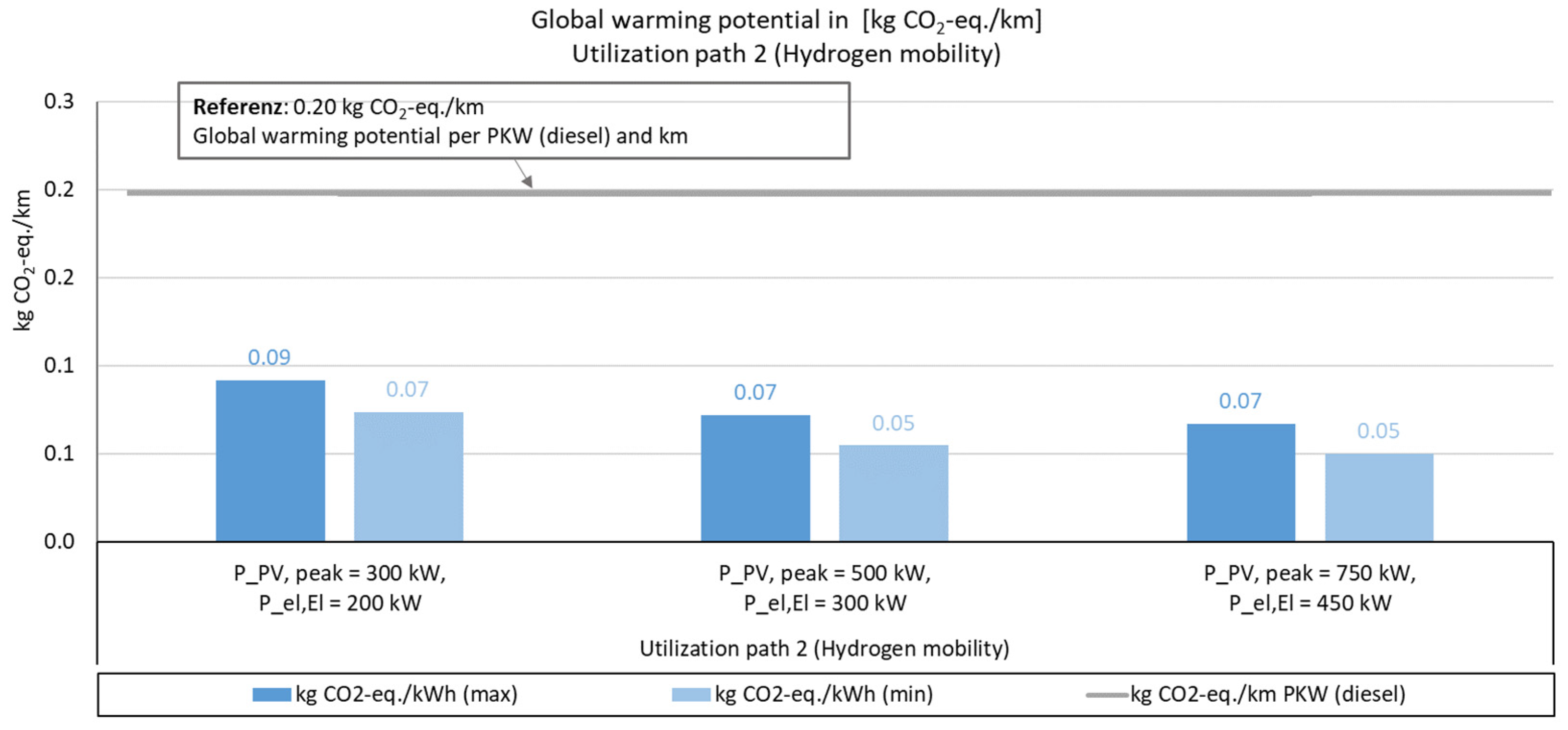

- 2.

- Hydrogen mobility

- Hydrogen production via electrolysis using electricity from photovoltaic (PV) systems

- Hydrogen compression to 400 bar

- Use of compressed hydrogen for mobility applications in passenger cars, trucks, and intralogistics vehicles (e.g., industrial trucks)

- Calculation of mileage range that can be covered by hydrogen fuel

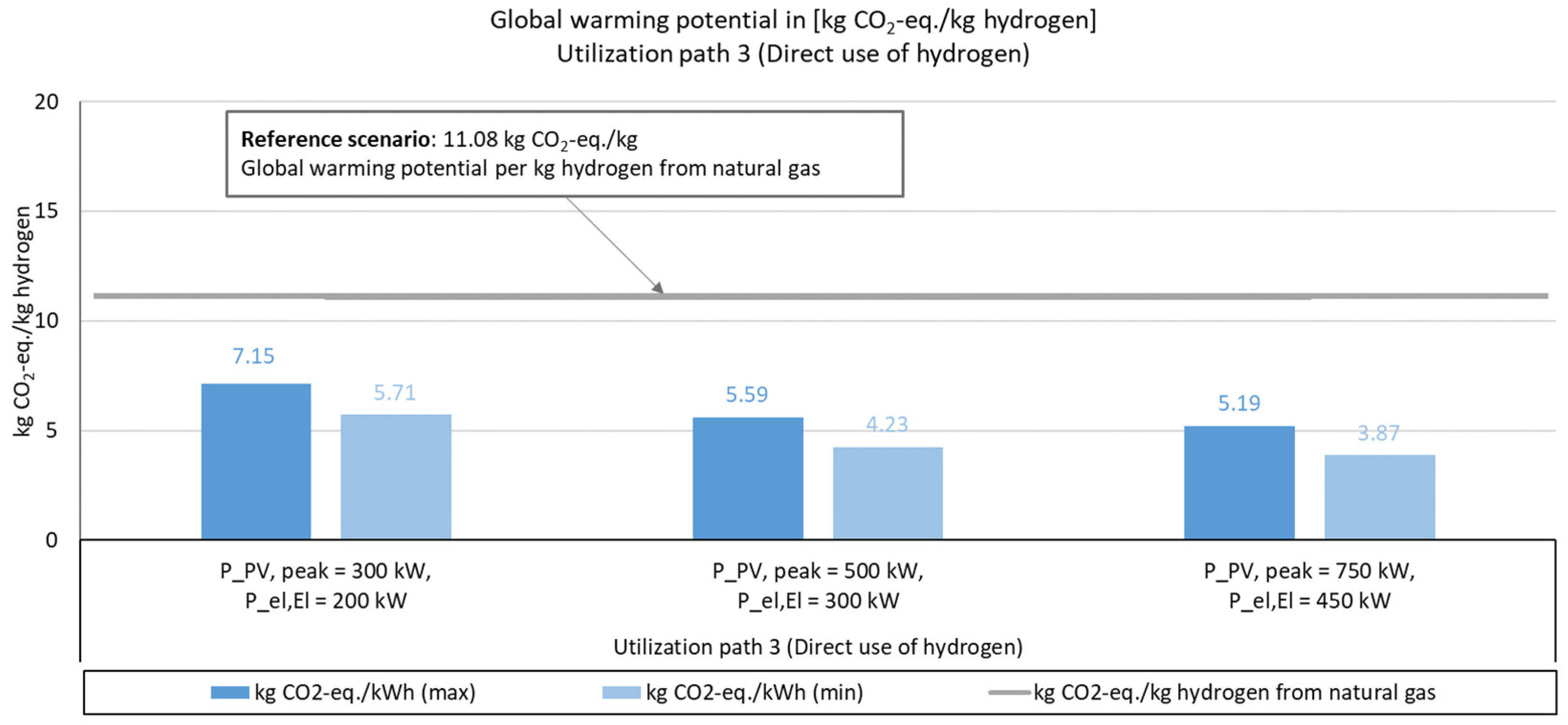

- 3.

- Direct use of hydrogen, e.g., as process gas or fuel substitute

- Hydrogen production via electrolysis using electricity from photovoltaic (PV) systems

- No compression or storage

- Direct use of hydrogen as a material in processes or for blending with natural gas in thermal energy production, e.g., for building heating or heat treatment processes

4.2. Simulation Models

4.3. Simulation Scenarios

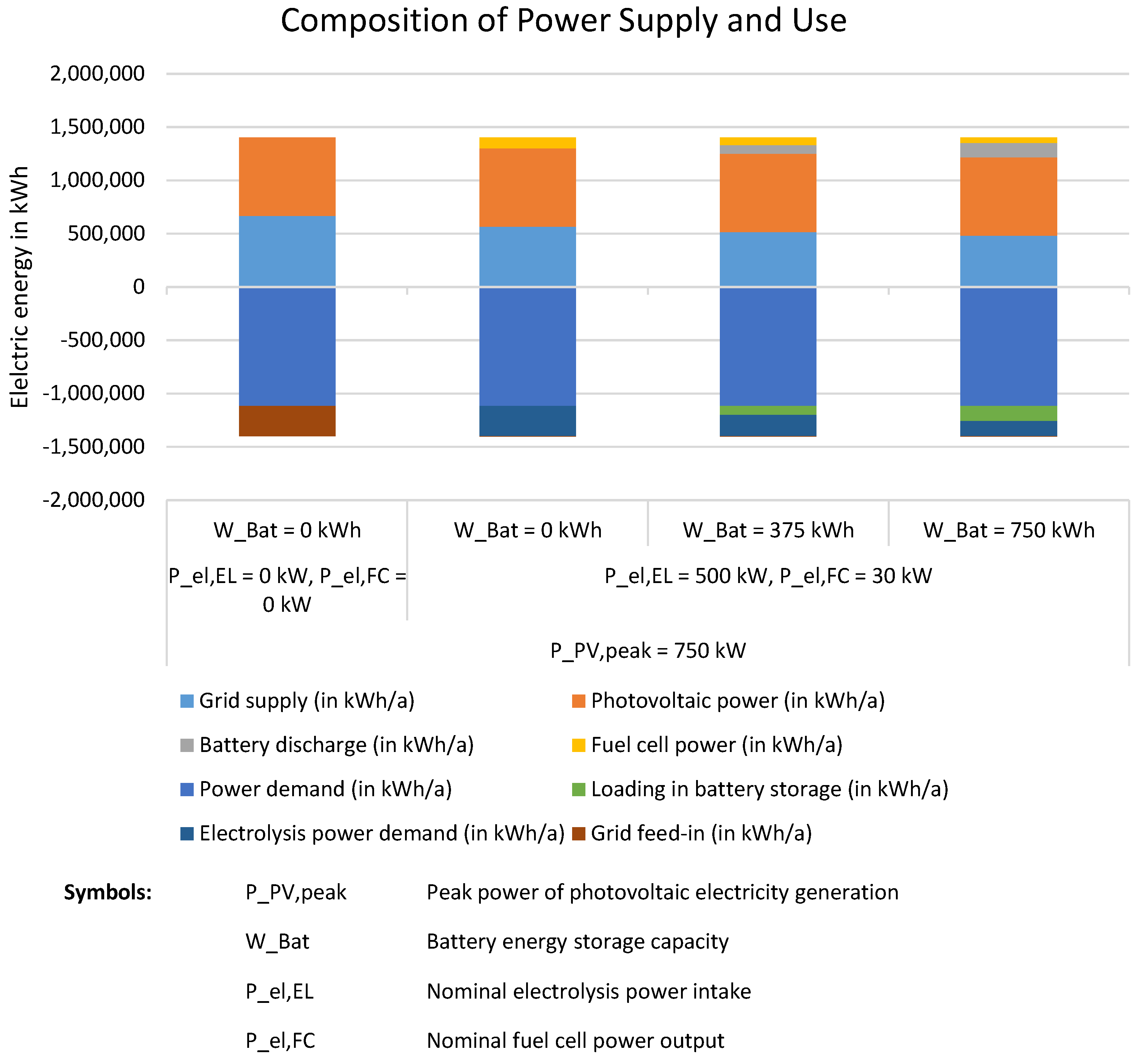

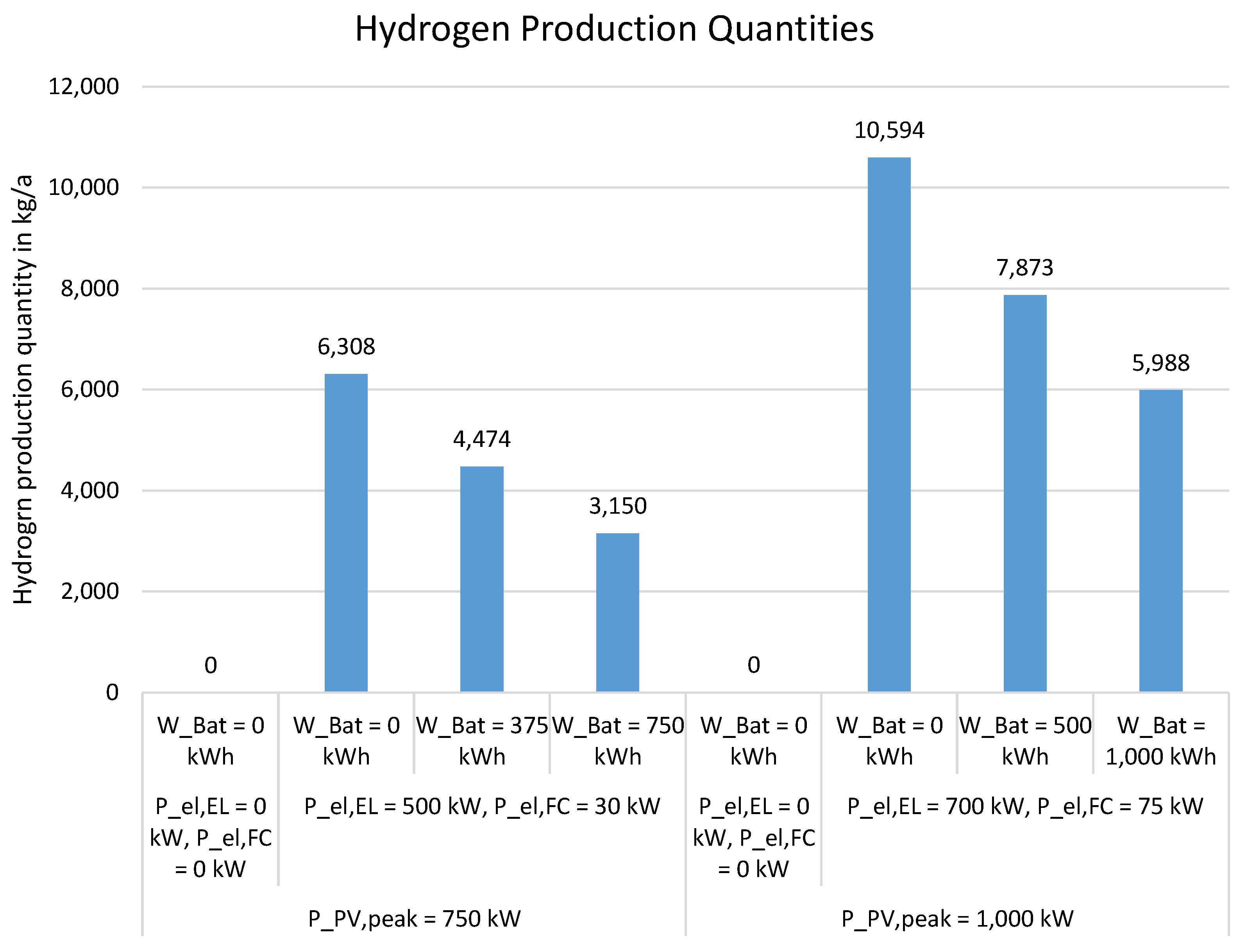

- Reference variant without battery storage or hydrogen technologies

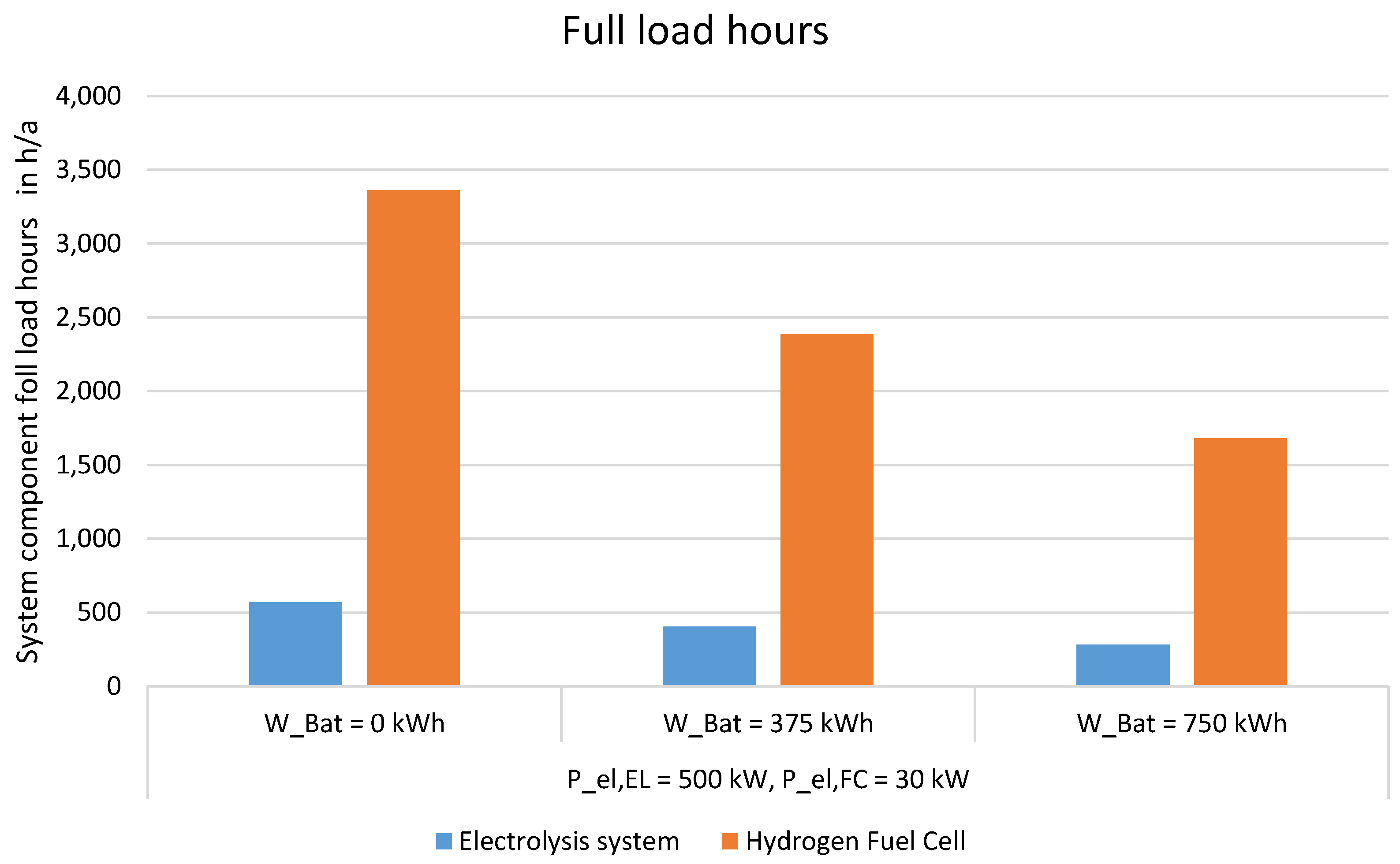

- Variant without battery storage but with electrolyzer (nominal electrical power consumption 500 kW) and fuel cell (nominal electrical power 30 kW)

- Variant with battery storage capacity of 375 kWh, electrolyzer (nominal electrical power consumption 500 kW), and fuel cell (nominal electrical power 30 kW)

- Variant with battery storage capacity of 750 kWh, electrolyzer (nominal electrical power consumption 500 kW), and fuel cell (nominal electrical power 30 kW)

5. Results and Discussion

5.1. Energy-Related and Operational Evaluation

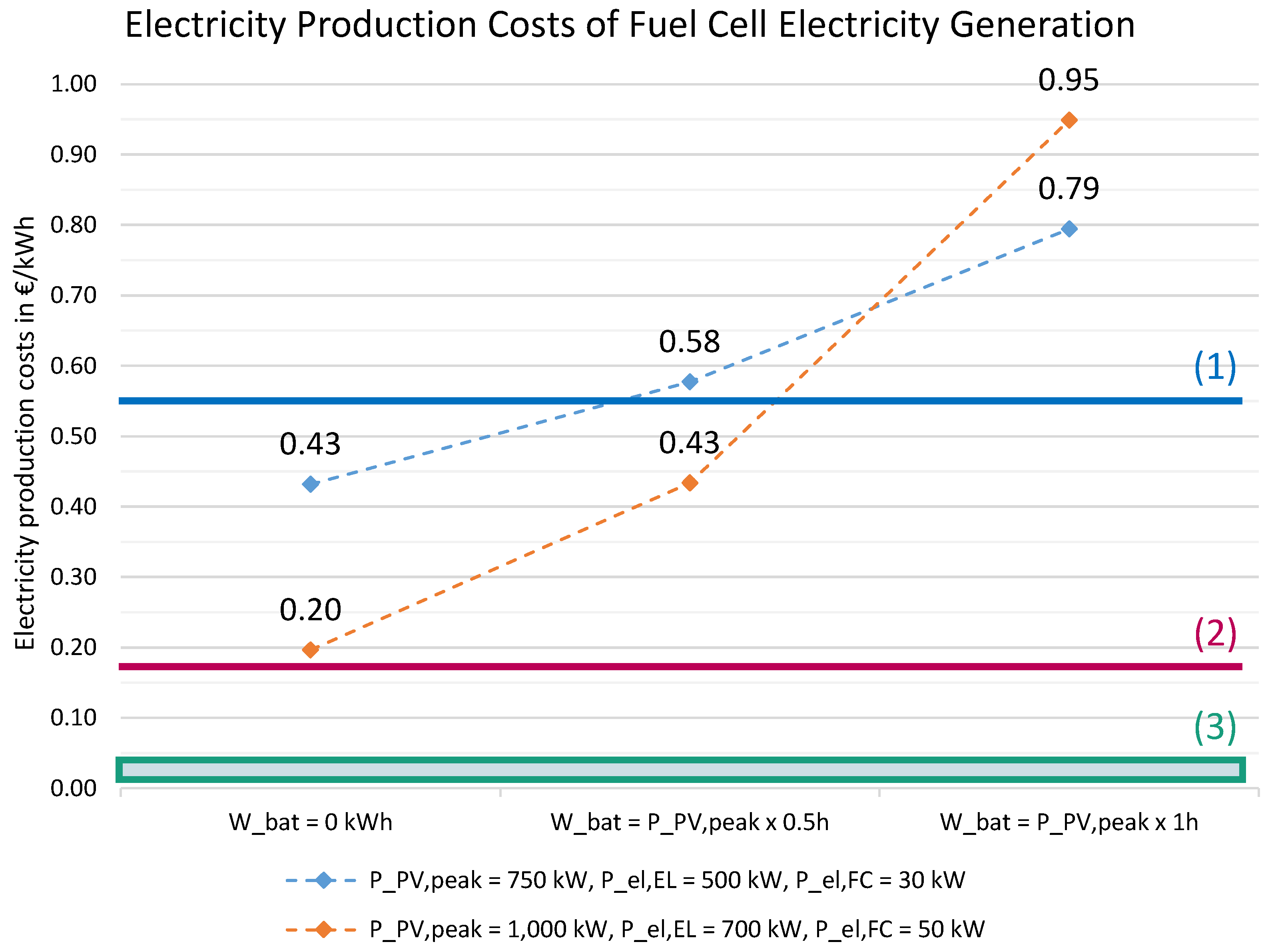

5.2. Economic Evaluation

- Change in the annuity of the investment cost:

- Change in annual operating cost:

- Change in annual energy purchasing cost:

- Change in annual revenue from feed-in of surplus electricity:

- Annual water cost for electrolysis operation:

- Annual revenue from sales of generated oxygen:

- Annual utilization-path-specific cost changes; for example, the change in fuel costs in the hydrogen mobility utilization path:

- Generally, the output of the photovoltaic systems under consideration is too low to generate significant electricity surplus for use in electrolysis.

- The use of power purchase agreements (PPAs) to supply more green energy from external PV or wind power capacity was not taken into account.

- The stated goal of maximizing self-consumption rates (target: 100%) tends to lead to over-sized plants and correspondingly high investment costs. Designing the plants for maximum utilization instead of maximum self-consumption could avoid this effect.

- The rigid switch-on sequences and priority rules specified in the simulation do not allow for optimization in terms of energy-related or technical elements when controlling the technologies.

- As this last point implies, the development of strategies for optimized operation of hydrogen technologies in combination with battery storage should be addressed in future research.

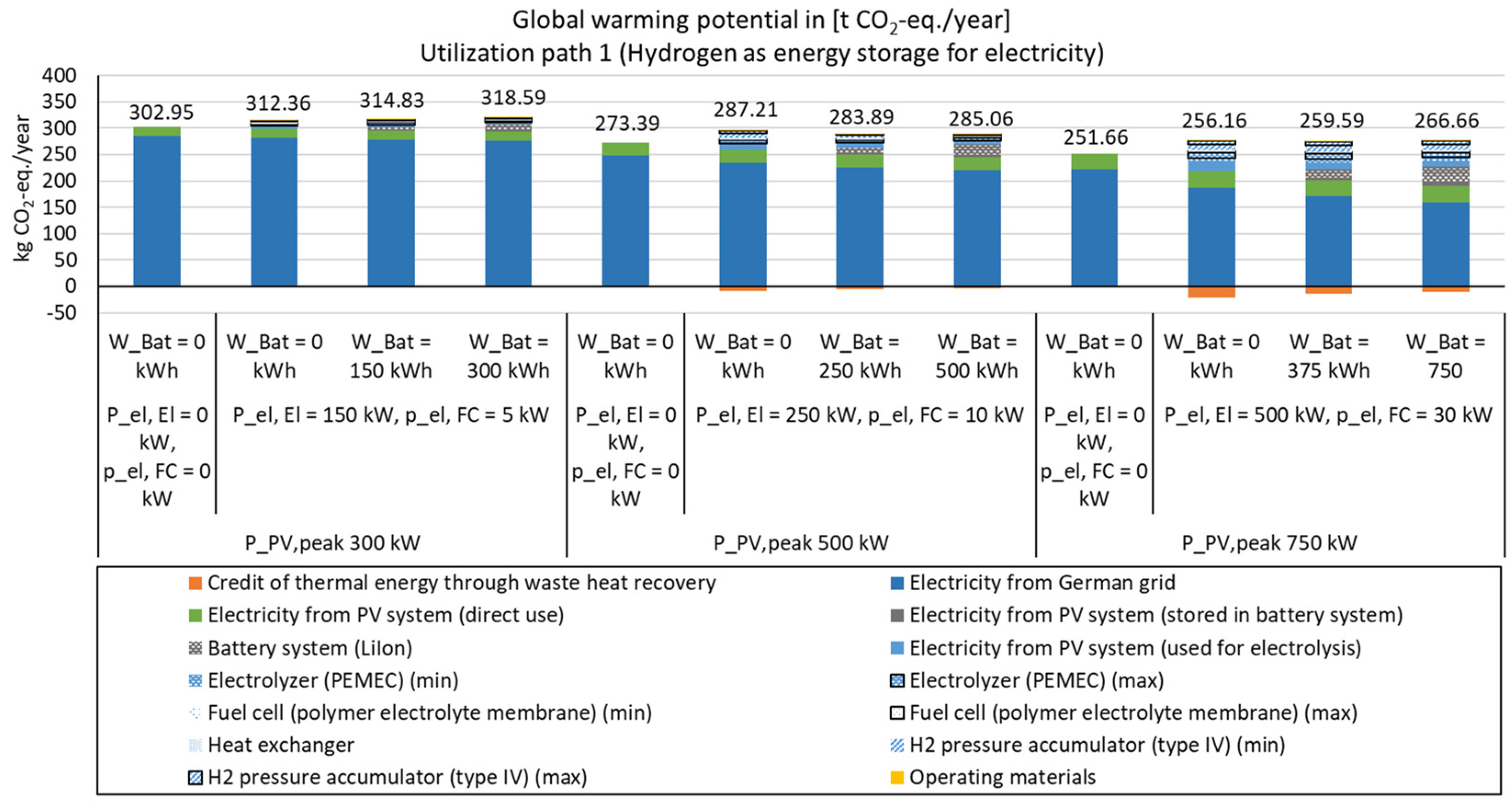

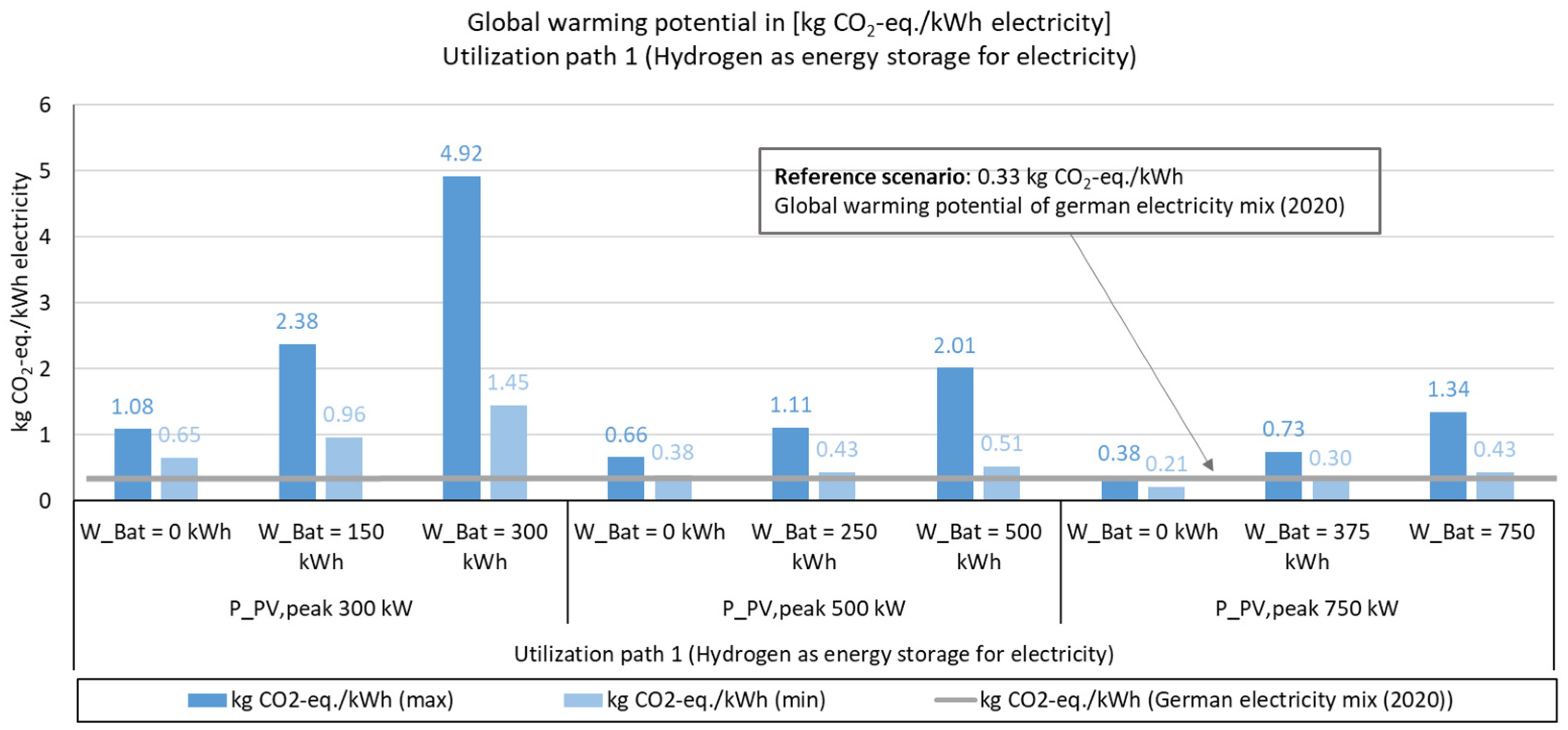

5.3. Environmental Assessment of Impact on Gobal Warming Potential

- Total global warming potential of the energy supply model in kg CO2-eq./year: GWPtotal

- Global warming potential of energy source i in kg CO2-eq./kWh: GWP factori

- Global warming potential of operation material j in kg CO2-eq./kg: GWP factorj

- Global warming potential of equipment component (production phase) k in CO2-eq./plant: GWP factork

- Amount of energy supplied by energy source i in kWh/year: ai

- Amount of operation material j in kg/year: bj

- Expected durability of equipment component k in years: uk

- Number of energy sources (e.g., electricity supplied by PV system): n

- Number of operation materials (e.g., cooling water): m

- Number of equipment components (e.g., li-ion battery): o

6. Conclusions and Prospects for Further Research

6.1. Conclusions

6.2. Prospects for Further Research

- The operating strategies of the individual plants need to be developed further, taking into account complex control options, interactions, and constraints. In this work, these strategies have only been mapped out in a rough sense in the simulation software and used for long-term periods of consideration.

- The frequent adjustments of the components and their parameterizations in the models need to be simplified by means of interfaces between the energy management systems and other company software. On the output side, for example, interfaces between simulation data and life cycle assessment software require improvement. This would make it possible to carry out a large number of simulation studies and compare the results more efficiently.

- Two other general areas requiring further development have been identified in the context of simulation-based evaluations of use cases:

- The use cases are not exhaustive and could be expanded. For example, there are opportunities to use or sell the oxygen produced from electrolysis. The use of the waste heat from the electrolyzer and fuel cell should also be analyzed in more detail. Furthermore, combinations of different use cases should be analyzed for individual energy systems, such as the simultaneous use of fuel cells and mobility applications, for example. The fuel cell may also be used for emergency power supply.

- The use cases need to be subjected to a comprehensive economic analysis. This evaluation should cover funding opportunities and price developments in relation to the technologies and regional, national, and international hydrogen markets. The results of the analysis will serve as the basis for make-or-buy decisions, as well as the self-consumption vs. the sale of energy. The electrolyzer and fuel cell can also offer flexibility for power grids, thus possibly increasing economic efficiency through additional revenues.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- BDEW Bundesverband der Energie- und Wasserwirtschaft e.V. BDEW-Strompreisanalyse Dezember 2022: Haushalte und Industrie. 2022. Available online: https://www.bdew.de/service/daten-und-grafiken/bdew-strompreisanalyse/ (accessed on 2 February 2023).

- Deutscher Industrie- und Handelskammertag. Hohe Strom- und Gaspreise Belasten Wirtschaft Massiv: DIHK-Unternehmensumfrage. 2021. Available online: https://www.dihk.de/resource/blob/61666/38665d703678c137fa95c8b28d8c8d3f/strom-gaspreis-umfrage-data.pdf (accessed on 21 March 2022).

- BDEW—Bundesverband der Energie- und Wasserwirtschaft e.V. Erdgas: Zahlen, Daten, Fakten; BDEW: Berlin, Germany, 2019. [Google Scholar]

- Deutscher Bundestag. Bundes-Klimaschutzgesetz: KSG; Deutscher Bundestag: Berlin, Germany, 2021. [Google Scholar]

- Neugebauer, R. (Ed.) Wasserstofftechnologien, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2022; ISBN 978-3-662-64834-6. [Google Scholar]

- Deutscher Industrie- und Handelskammertag. Wasserstoff-DIHK-Faktenpapier. 2020. Available online: https://www.ihk.de/blueprint/servlet/resource/blob/4827334/91b01c35285997020b1cf61497909ce5/faktenpapier-wasserstoff-1--data.pdf (accessed on 11 November 2022).

- Sterner, M.; Specht, M. Power-to-Gas and Power-to-X—The History and Results of Developing a New Storage Concept. Energies 2021, 14, 6594. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Technology Roadmap: Hydrogen and Fuel Cells. 2015. Available online: https://iea.blob.core.windows.net/assets/e669e0b6-148c-4d5c-816b-a7661301fa96/TechnologyRoadmapHydrogenandFuelCells.pdf (accessed on 16 November 2022).

- Hebling, C.; Ragwitz, M.; Fleiter, T.; Groos, U.; Härle, D.; Held, A.; Jahn, M.; Müller, N.; Pfeifer, T.; Plötz, P.; et al. Eine Wasserstoff-Roadmap für Deutschland. 2019. Available online: https://www.ieg.fraunhofer.de/content/dam/ieg/documents/pressemitteilungen/2019-10_Fraunhofer_Wasserstoff-Roadmap_fuer_Deutschland.pdf (accessed on 16 November 2022).

- Breyer, C.; Khalili, S.; Bogdanov, D.; Ram, M.; Oyewo, A.S.; Aghahosseini, A.; Gulagi, A.; Solomon, A.A.; Keiner, D.; Lopez, G.; et al. On the History and Future of 100% Renewable Energy Systems Research. IEEE Access 2022, 10, 78176–78218. [Google Scholar] [CrossRef]

- Bundesministerium für Wirtschaft und Klimaschutz. Die Nationale Wasserstoffstrategie. Available online: https://www.bmwi.de/Redaktion/DE/Publikationen/Energie/die-nationale-wasserstoffstrategie.html (accessed on 13 March 2022).

- DIHK. Energiewende-Barometer 2021 der IHK-Organisation: Unternehmensumfrage zur Umsetzung der Energiewende, Berlin. 2021. Available online: https://www.dihk.de/resource/blob/58460/aca53bacc14cea080320089a6c57214b/energiewende-barometer-2021-data.pdf (accessed on 22 November 2022).

- Project H2StorFa. Available online: https://www.igcv.fraunhofer.de/de/forschung/referenzprojekte/wasserstoff_gruen_energie_industrie_h2storfa.html (accessed on 18 November 2022).

- Ringkjøb, H.-K.; Haugan, P.M.; Solbrekke, I.M. A review of modelling tools for energy and electricity systems with large shares of variable renewables. Renew. Sustain. Energy Rev. 2018, 96, 440–459. [Google Scholar] [CrossRef]

- DeCarolis, J.; Daly, H.; Dodds, P.; Keppo, I.; Li, F.; McDowall, W.; Pye, S.; Strachan, N.; Trutnevyte, E.; Usher, W.; et al. Formalizing best practice for energy system optimization modelling. Appl. Energy 2017, 194, 184–198. [Google Scholar] [CrossRef]

- Guo, X.; Sepanta, M. Evaluation of a new combined energy system performance to produce electricity and hydrogen with energy storage option. Energy Rep. 2021, 7, 1697–1711. [Google Scholar] [CrossRef]

- Fu, P.; Pudjianto, D.; Zhang, X.; Strbac, G. Integration of Hydrogen into Multi-Energy Systems Optimisation. Energies 2020, 13, 1606. [Google Scholar] [CrossRef]

- Ince, A.C.; Colpan, C.O.; Hagen, A.; Serincan, M.F. Modeling and simulation of Power-to-X systems: A review. Fuel 2021, 304, 121354. [Google Scholar] [CrossRef]

- Imdahl, C.; Blume, C.; Blume, S.; Zellmer, S.; Gensicke, M.; Herrmann, C. Potentials of Hydrogen Technologies for Sustainable Factory Systems. Procedia CIRP 2021, 98, 583–588. [Google Scholar] [CrossRef]

- Schulz, J.; Leinmüller, D.; Misik, A.; Zaeh, M.F. Renewable On-Site Power Generation for Manufacturing Companies—Technologies, Modeling, and Dimensioning. Sustainability 2021, 13, 3898. [Google Scholar] [CrossRef]

- Kuhlmann, T.; Bauernhansl, T. Method for Designing an Energy-agile Energy System for Industrial Manufacturing. Procedia CIRP 2015, 29, 179–184. [Google Scholar] [CrossRef]

- Kuhlmann, T. Methode zur Gestaltung der energetischen Wandlungsfähigkeit in Fabriken; Fraunhofer Verlag: Stuttgart, Germany, 2020; ISBN 978-3-8396-1596-6. [Google Scholar]

- Thiede, S.; Herrmann, C.; Kara, S. State of Research and an innovative Approach for simulating Energy Flows of Manufacturing Systems. In Glocalized Solutions for Sustainability in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 335–340. [Google Scholar] [CrossRef]

- Schmeling, L.; Buchholz, A.A.I.; Heineke, H.; Klement, P.; Hanke, B.; von Maydell, K. Planning, Optimisation and Evaluation of Small Power-to-Gas-to-Power Systems: Case Study of a German Dairy. Sustainability 2022, 14, 6050. [Google Scholar] [CrossRef]

- NOW GmbH. HyLand—Wasserstoffregionen in Deutschland. Available online: https://www.hy.land/ (accessed on 18 November 2022).

- Stadt Straßburg. Energieregion Staßfurt: Grüne Energie aus der Region für die Region. Available online: https://www.stassfurt.de/de/wirtschaftsstandort/energieregion-stassfurt.html (accessed on 23 June 2022).

- Birth, T.; Scheffler, M.; Eggers, N. HyPerFerment—Ein Neues Verfahren zur mikrobiologischen Wasserstofferzeugung. In Proceedings of the 6. Info-Veranstaltung zum Klimaschutz—Schwerpunkt Landwirtschaft und Bioenergie—Zukunft der Biogasanlagen, Online, 12 March 2021. [Google Scholar] [CrossRef]

- Bundesministerium für Bildung und Forschung. Living Laboratory—Demonstration eines kopmlett reinen Wasserstoff-Brennstoffzellen-Systems. Available online: https://www.fenes.net/forschung/energiespeicher/laufende-projekte/livingh2 (accessed on 18 November 2022).

- Khalid, F.; Dincer, I.; Rosen, M.A. Analysis and assessment of an integrated hydrogen energy system. Int. J. Hydrog. Energy 2016, 41, 7960–7967. [Google Scholar] [CrossRef]

- HYPOS East Germany. LocalHy. Available online: https://www.hypos-eastgermany.de/wasserstoffprojekte/zwanzig20/chemische-umwandlung/localhy/ (accessed on 23 June 2022).

- Bhandari, R.; Shah, R.R. Hydrogen as energy carrier: Techno-economic assessment of decentralized hydrogen production in Germany. Renew. Energy 2021, 177, 915–931. [Google Scholar] [CrossRef]

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen production for energy: An overview. Int. J. Hydrog. Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- Griffiths, S.; Sovacool, B.K.; Kim, J.; Bazilian, M.; Uratani, J.M. Industrial decarbonization via hydrogen: A critical and systematic review of developments, socio-technical systems and policy options. Energy Res. Soc. Sci. 2021, 80, 102208. [Google Scholar] [CrossRef]

- Qazi, U.Y. Future of Hydrogen as an Alternative Fuel for Next-Generation Industrial Applications; Challenges and Expected Opportunities. Energies 2022, 15, 4741. [Google Scholar] [CrossRef]

- Roth, S.; Sultani, D.; Artmann, I.; Klement, T.; Angerer, K.; Bank, L. Dekarbonisierung der Produktion: Ansätze und Anwendungsfälle für die nachhaltige Produktionsplanung und Brennstoffversorgung. ZWF Z. Wirtsch. Fabr. 2022, 117, 109–116. [Google Scholar] [CrossRef]

- Ulrich, P.; Hill, W. Wissenschaftstheoretische Grundlagen der Betriebswirtschaftslehre (Teil I). WiST Z. Ausbild. Hochschulkontakt 1976, 304–309. [Google Scholar]

- GFaI Gesellschaft zur Förderung angewandter Informatik e.V. TOP-Energy. Available online: https://www.top-energy.de/ (accessed on 18 November 2022).

- Bundesministerium der Justiz. Gesetz für den Ausbau Erneuerbarer Energien—Erneuerbare-Energien-Gesetz: EEG 2021; Bundesministerium der Justiz: Berlin, Germany, 2021.

- Kost, C.; Shammugam, S.; Fluri, V.; Peper, D.; Memar, A.D.; Schlegl, T. Stromgestehungskosten erneuerbare Energien: Juni 2021, Freiburg. 2021. Available online: https://www.ise.fraunhofer.de/content/dam/ise/de/documents/publications/studies/DE2021_ISE_Studie_Stromgestehungskosten_Erneuerbare_Energien.pdf (accessed on 1 June 2022).

- Statista. Durchschnittlicher Dieselpreis bis 2022. Available online: https://de.statista.com/statistik/daten/studie/779/umfrage/durchschnittspreis-fuer-dieselkraftstoff-seit-dem-jahr-1950/ (accessed on 20 March 2022).

- Hydrogen: A Renewable Energy Perspective: Report Prepared for the 2nd Hydrogen Energy Ministerial Meeting in Tokyo, Japan. 2019. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Sep/IRENA_Hydrogen_2019.pdf (accessed on 2 June 2022).

- Philipp, M.; Collath, N.; Roth, S.; Theumer, P.; Will-Ehlers, G.; Kellermann, M.; Hesse, H. Batteriespeicherlösungen zur energiewirtschaftlichen Optimierung von Industriebetrieben. ZWF Z. Wirtsch. Fabr. 2022, 117, 305–311. [Google Scholar] [CrossRef]

- Karlsruher Institut für Technologie KIT. Energy Lab 2.0 Produces System Knowledge for the Energy Transition. In lookKIT—The Magazine for Research, Teaching, Innovation; Karlsruher Institut für Technologie KIT: Karlsruhe, Germany, 2020. [Google Scholar]

- Wiendahl, H.-P.; El Maraghy, H.A.; Nyhuis, P.; Zäh, M.F.; Wiendahl, H.-H.; Duffie, N.; Brieke, M. Changeable Manufacturing—Classification, Design and Operation. CIRP Ann. Manuf. Technol. 2007, 56, 783–809. [Google Scholar] [CrossRef]

- Nyhuis, P.; Reinhart, G.; Abele, E. Wandlungsfähige Produktionssysteme: Heute die Industrie von morgen gestalten; PZH Produktionstechnisches Zentrum: Garbsen, Germany, 2008; ISBN 978-3-939026-96-9. [Google Scholar]

| Peak PV Power | Nominal Electrolyzer Power | Nominal Fuell Cell Power | Self-Consumption Rate |

|---|---|---|---|

| 300 kWp | 200 kW | 5 kW | 99.77% |

| 500 kWp | 300 kW | 10 kW | 99.87% |

| 750 kWp | 500 kW | 30 kW | 99.97% |

| 1000 kWp | 700 kW | 75 kW | 99.01% |

| P_Pv,Peak = 750 kW | ||||

|---|---|---|---|---|

| P_el,El = 0 kW P_el,FC = 0 kW W_Bat = 0 kWh | P_el,EL = 500 kW, P_el,FC = 30 kW | |||

| W_Bat = 0 kWh | W_Bat = 375 kWh | W_Bat = 750 kWh | ||

| Electricity self-sufficiency | 40.4% | 59.7% | 60.9% | 61.9% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalchschmid, V.; Erhart, V.; Angerer, K.; Roth, S.; Hohmann, A. Decentral Production of Green Hydrogen for Energy Systems: An Economically and Environmentally Viable Solution for Surplus Self-Generated Energy in Manufacturing Companies? Sustainability 2023, 15, 2994. https://doi.org/10.3390/su15042994

Kalchschmid V, Erhart V, Angerer K, Roth S, Hohmann A. Decentral Production of Green Hydrogen for Energy Systems: An Economically and Environmentally Viable Solution for Surplus Self-Generated Energy in Manufacturing Companies? Sustainability. 2023; 15(4):2994. https://doi.org/10.3390/su15042994

Chicago/Turabian StyleKalchschmid, Vincent, Veronika Erhart, Kerstin Angerer, Stefan Roth, and Andrea Hohmann. 2023. "Decentral Production of Green Hydrogen for Energy Systems: An Economically and Environmentally Viable Solution for Surplus Self-Generated Energy in Manufacturing Companies?" Sustainability 15, no. 4: 2994. https://doi.org/10.3390/su15042994

APA StyleKalchschmid, V., Erhart, V., Angerer, K., Roth, S., & Hohmann, A. (2023). Decentral Production of Green Hydrogen for Energy Systems: An Economically and Environmentally Viable Solution for Surplus Self-Generated Energy in Manufacturing Companies? Sustainability, 15(4), 2994. https://doi.org/10.3390/su15042994