An Insight into the Application of Gradations of Circularity in the Food Packaging Industry: A Systematic Literature Review and a Multiple Case Study

Abstract

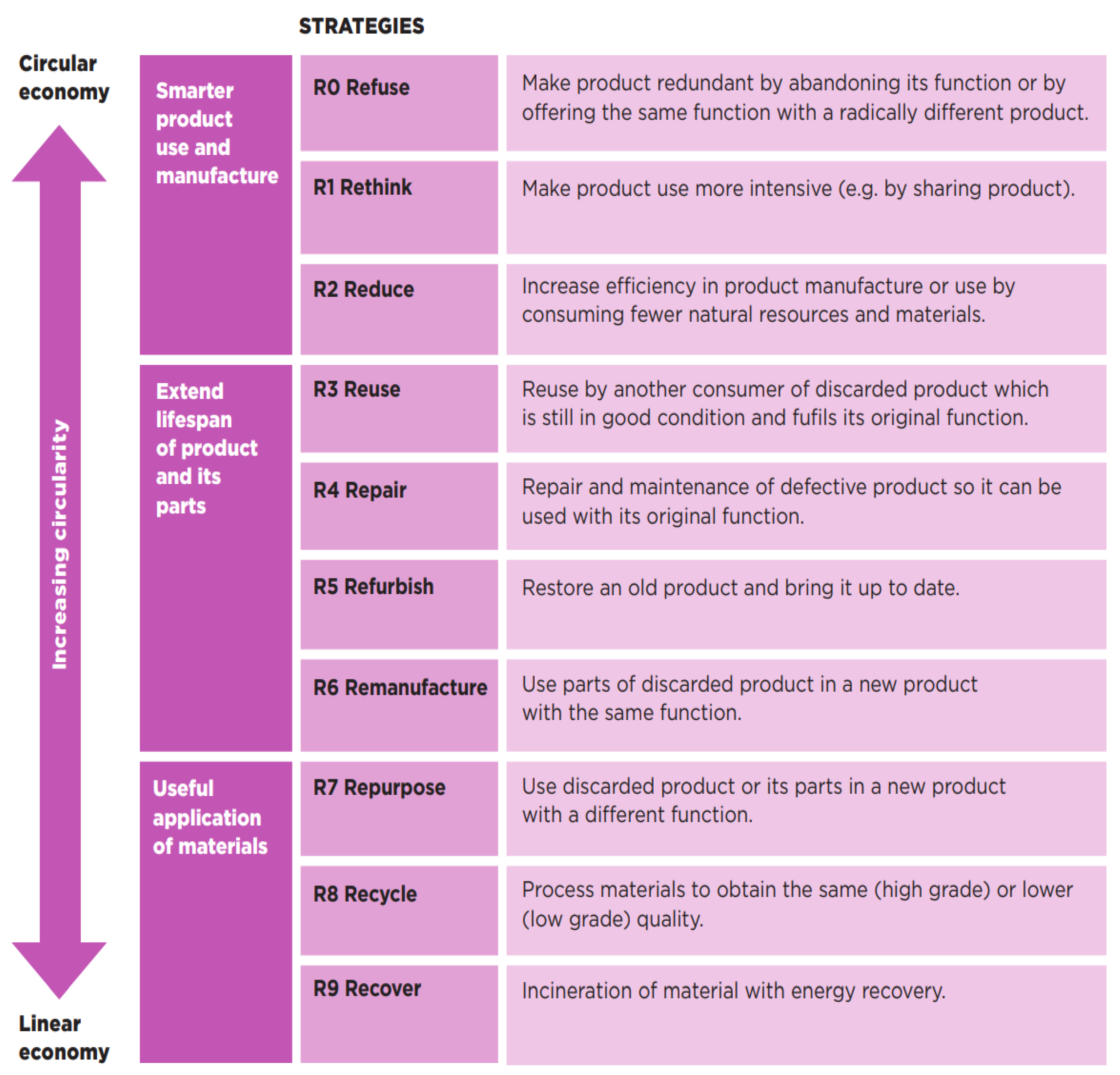

:1. Introduction

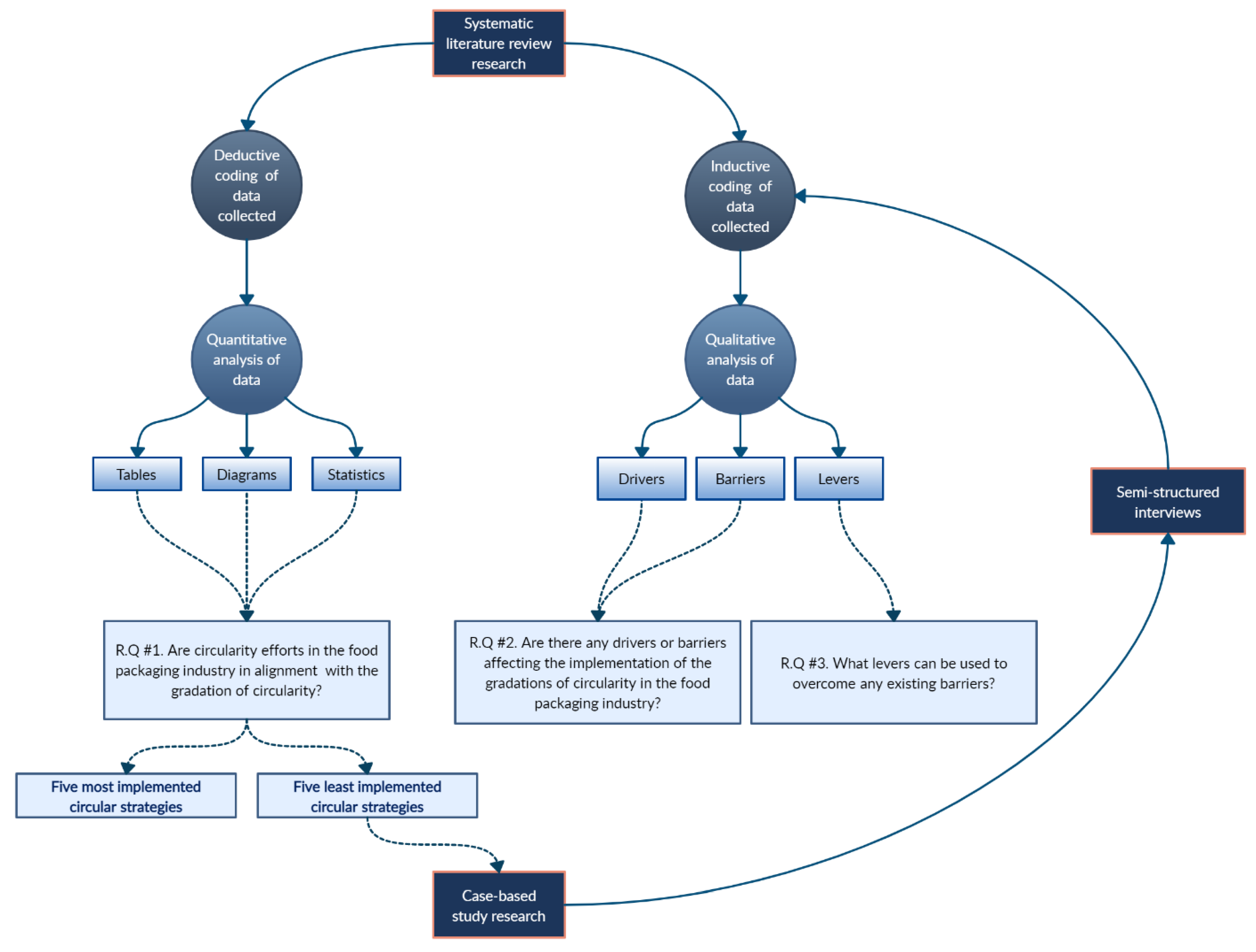

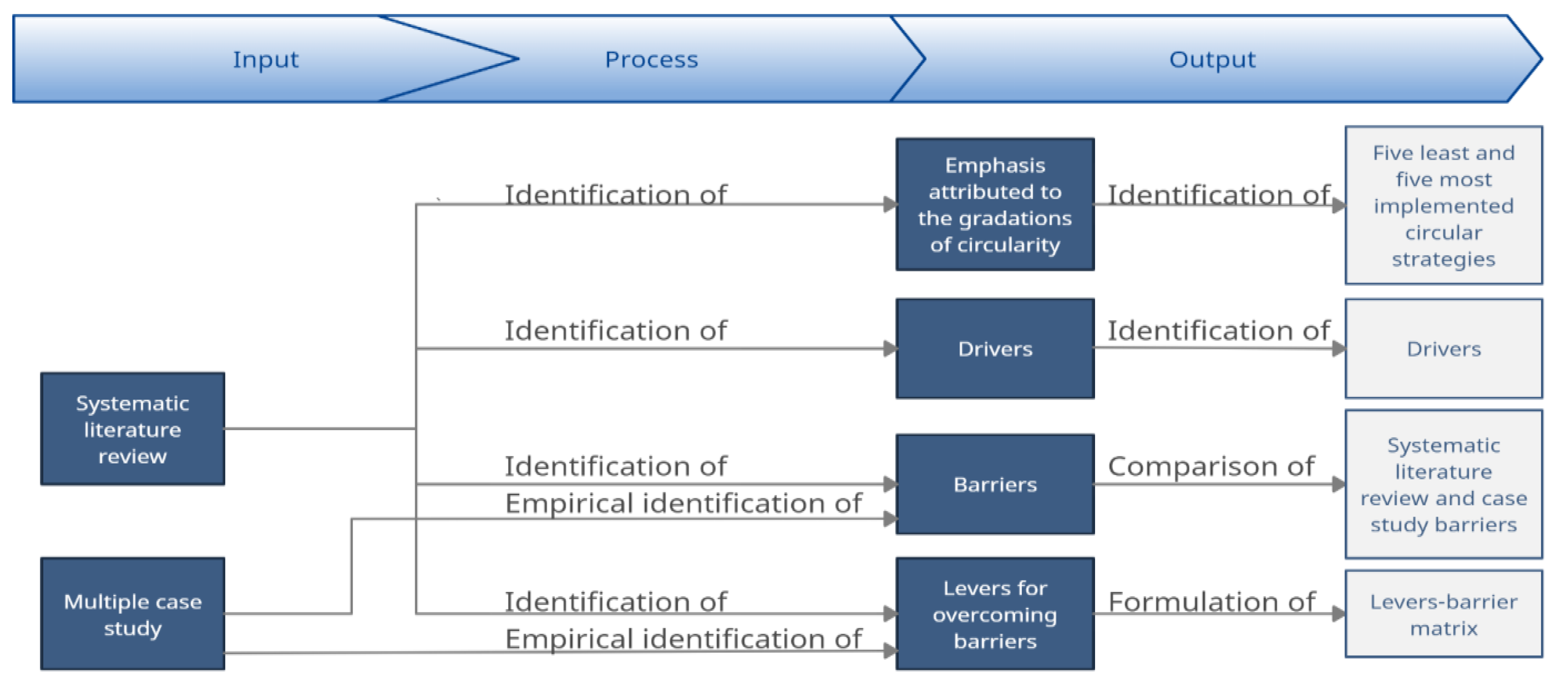

2. Materials and Methods

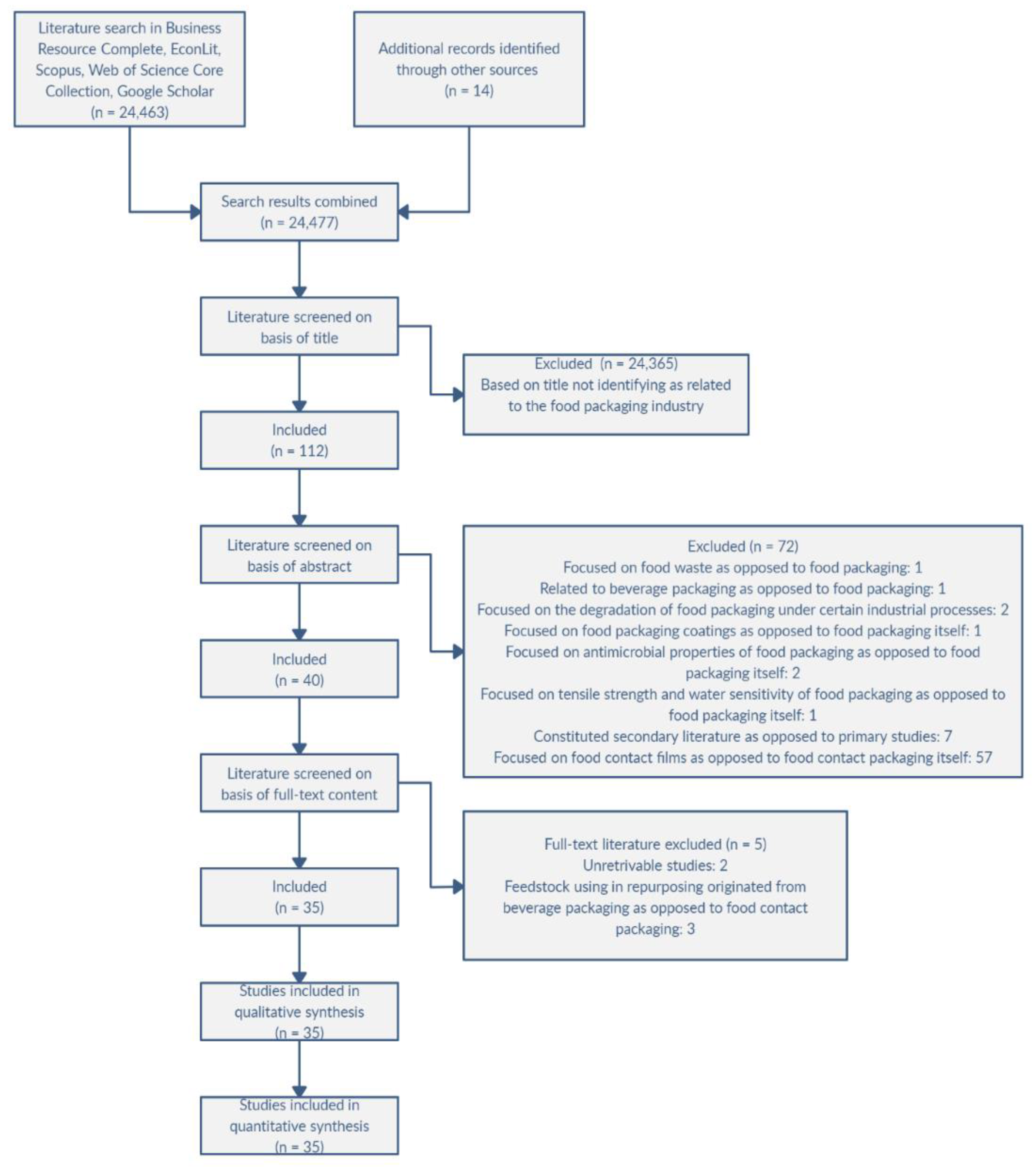

2.1. Literature Review

2.2. Methodology

2.3. Methodology Pursued for SLR

2.4. Methodology for Case Study Research

3. Results

3.1. Quantitative Findings through SLR

3.2. Qualitative Findings

3.2.1. Drivers

3.2.2. Barriers

3.2.3. Levers

4. Conclusions

- Are efforts towards the circularity of the food packaging industry in alignment with the gradations of circularity?;

- Are there any drivers or barriers affecting the implementation of the gradations of circularity in the food packaging industry?;

- Which levers can be used to overcome any of the existing barriers associated with implementing the gradations of circularity in the FPI?

4.1. Theoretical Implications

4.2. Managerial Implications

4.3. Limitations and Future Research

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Naukowe, Z.; Nauk, P.A. Challenges for the packaging industry in the Circular Economy. Pol. Akad. Nauk. 2019, 5–16. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- United Nations. World Population Prospects: The 2015 Revision, Key Findings and Advance Tables. 2015. Available online: http://library1.nida.ac.th/termpaper6/sd/2554/19755.pdf (accessed on 12 October 2022).

- Govindan, K.; Hasanagic, M. A systematic review on drivers, barriers, and practices towards circular economy: A supply chain perspective. Int. J. Prod. Res. 2018, 56, 278–311. [Google Scholar] [CrossRef]

- Tanveer, U.; Ishaq, S.; Gough, A. Circular Economy in Agri-Food Sector: Food Waste Management Perspective. In Environmental Footprints and Eco-Design of Products and Processes; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- EMF. Towards a Circular Economy: Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation (EMF): Isle of Wight, UK, 2015; Volume 20. [Google Scholar]

- Clark, S.; Jung, S.; Lamsal, B. Food Processing: Principles and Applications, 2nd ed.; Wiley Blackwell: West Sussex, UK, 2014; 592p. [Google Scholar]

- Marsh, K.S.; Bugusu, B. Food packaging and its environmental impact. Food Technol. 2007, 61, 46–50. Available online: https://www.researchgate.net/publication/296867329_Food_packaging_and_its_environmental_impact (accessed on 4 July 2020).

- Thellesen, T.B.; Sustainability, M.G.; Affairs, E. Food Packaging for a Circular Economy. Available online: https://cirkulaerkemi.dk/media/209588/case-faerch.pdf (accessed on 4 July 2020).

- Sheriff, K.M.M.; Subramanian, N.; Rahman, S.; Jayaram, J. Integrated optimization model and methodology for plastics recycling: Indian empirical evidence. J. Clean. Prod. 2017, 153, 707–717. [Google Scholar] [CrossRef]

- EPA. Getting up to Speed: Ground Water Contamination. Environmental Protection Agency, 2015. Available online: https://www.epa.gov/sites/production/files/2015-08/documents/mgwc-gwc1.pdf (accessed on 3 July 2020).

- De Angelis, R.; Howard, M.; Miemczyk, J. Supply chain management and the circular economy: Towards the circular supply chain. Prod. Plan. Control 2018, 29, 425–437. [Google Scholar] [CrossRef]

- Van Buren, N.; Demmers, M.; van der Heijden, R.; Witlox, F. Towards a circular economy: The role of Dutch logistics industries and governments. Sustainability 2016, 8, 647. [Google Scholar] [CrossRef]

- Potting, J.; Hekkert, M.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain Policy Report; Planbureau voor de Leefomgeving: The Hague, The Netherlands, 2017. [Google Scholar]

- Nilsen, H.R. The hierarchy of resource use for a sustainable circular economy. Int. J. Soc. Econ. 2019, 47, 27–40. [Google Scholar] [CrossRef]

- De Koeijer, B.; de Lange, J.; Wever, R. Desired, perceived, and achieved sustainability: Trade-offs in strategic and operational packaging development. Sustainability 2017, 9, 1923. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ulgiati, S. Circular economy transition in Italy. Achievements, perspectives and constraints. J. Clean. Prod. 2020, 243, 118360. [Google Scholar] [CrossRef]

- Geueke, B.; Groh, K.; Muncke, J. Food packaging in the circular economy: Overview of chemical safety aspects for commonly used materials. J. Clean. Prod. 2018, 193, 491–505. [Google Scholar] [CrossRef]

- Batista, L.; Gong, Y.; Pereira, S.; Jia, F.; Bittar, A. Circular supply chains in emerging economies–a comparative study of packaging recovery ecosystems in China and Brazil. Int. J. Prod. Res. 2019, 57, 7248–7268. [Google Scholar] [CrossRef]

- Franklin-Johnson, E.; Figge, F.; Canning, L. Resource duration as a managerial indicator for Circular Economy performance. J. Clean. Prod. 2016, 133, 589–598. [Google Scholar] [CrossRef]

- Park, J.Y.; Chertow, M.R. Establishing and testing the “reuse potential” indicator for managing wastes as resources. J. Environ. Manag. 2014, 137, 45–53. [Google Scholar] [CrossRef]

- Su, B.; Heshmati, A.; Geng, Y.; Yu, X. A review of the circular economy in China: Moving from rhetoric to implementation. J. Clean. Prod. 2013, 42, 215–227. [Google Scholar] [CrossRef]

- Köksal, D.; Strähle, J.; Müller, M.; Freise, M. Social Sustainable Supply Chain Management in the Textile and Apparel Industry—A Literature Review. Sustainability 2017, 9, 100. [Google Scholar] [CrossRef]

- Pearce, D.W.; Turner, R.K. Economics of Natural Resources and the Environment; The Johns Hopkins University Press: Baltimore, MD, USA, 1989. [Google Scholar]

- Potočnik, J. Speaking Points by Environment Commissioner Janez Potocnik on Circular Economy. 2014. Available online: http://europa.eu/rapid/press-release_SPEECH-14-527_en.htm (accessed on 31 December 2022).

- Boulding, K.E. Environmental Quality in a Growing Economy; RFF Press: Washington, DC, USA, 1966; pp. 3–14. Available online: http://www.tandfebooks.com/isbn/9781315064147 (accessed on 31 December 2022).

- Ghisellini, P.; Cialani, C.; Ulgiati, S. A review on circular economy: The expected transition to a balanced interplay of environmental and economic systems. J. Clean. Prod. 2016, 114, 11–32. [Google Scholar] [CrossRef]

- Hawken, P.; Lovins, A.; Lovins, H. Natural Capitalism: Creating the Next Industrial Revolution, 3rd ed.; Little, Brown & Company: New York, NY, USA, 1999. [Google Scholar]

- Ghisellini, P.; Ulgiati, S. Managing the transition to the circular economy. In Handbook of the Circular Economy; Edward Elgar Publishing Ltd.: Cheltenham, UK, 2020; Available online: https://www.researchgate.net/publication/335475059 (accessed on 31 December 2022).

- Lewandowski, M. Designing the business models for circular economy-towards the conceptual framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef]

- Moreno, M.; de los Rios, C.; Rowe, Z.; Charnley, F. A conceptual framework for circular design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef]

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; de Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461. [Google Scholar] [CrossRef] [PubMed]

- Agyemang, M.; Kusi-Sarpong, S.; Khan, S.A.; Mani, V.; Rehman, S.T.; Kusi-Sarpong, H. Drivers and barriers to circular economy implementation: An explorative study in Pakistan’s automobile industry. Manag. Decis. 2019, 57, 971–994. [Google Scholar] [CrossRef]

- Hart, J.; Adams, K.; Giesekam, J.; Tingley, D.D.; Pomponi, F. Barriers and drivers in a circular economy: The case of the built environment. Procedia CIRP 2019, 80, 619–624. [Google Scholar] [CrossRef]

- De Jesus, A.; Mendonna, S. Lost in Transition? Drivers and Barriers in the Eco-Innovation Road to the Circular Economy. Ecol. Econ. 2018, 145, 75–89. [Google Scholar] [CrossRef]

- Ranta, V.; Aarikka-Stenroos, L.; Ritala, P.; Mäkinen, S.J. Exploring institutional drivers and barriers of the circular economy: A cross-regional comparison of China, the US, and Europe. Resour. Conserv. Recycl. 2018, 135, 70–82. [Google Scholar] [CrossRef]

- Geng, Y.; Fu, J.; Sarkis, J.; Xue, B. Towards a national circular economy indicator system in China: An evaluation and critical analysis. J. Clean. Prod. 2012, 23, 216–224. [Google Scholar] [CrossRef]

- Bals, L.; Tate, W.L. Sustainable Supply Chain Design in Social Businesses: Advancing the Theory of Supply Chain. J. Bus. Logist. 2018, 39, 57–79. [Google Scholar] [CrossRef]

- Genovese, A.; Acquaye, A.A.; Figueroa, A.; Koh, S.C.L. Sustainable supply chain management and the transition towards a circular economy: Evidence and some applications. Omega 2017, 66, 344–357. [Google Scholar] [CrossRef]

- Nasir, M.H.A.; Genovese, A.; Acquaye, A.A.; Koh, S.C.L.; Yamoah, F. Comparing linear and circular supply chains: A case study from the construction industry. Int. J. Prod. Econ. 2017, 183, 443–457. [Google Scholar] [CrossRef]

- Pan, S.-Y.; Du, M.A.; Huang, I.-T.; Liu, I.-H.; Chang, E.-E.; Chiang, P.-C. Strategies on implementation of waste-to-energy (WTE) supply chain for circular economy system: A review. J. Clean. Prod. 2015, 108, 409–421. [Google Scholar] [CrossRef]

- Zeng, H.; Chen, X.; Xiao, X.; Zhou, Z. Institutional pressures, sustainable supply chain management, and circular economy capability: Empirical evidence from Chinese eco-industrial park firms. J. Clean. Prod. 2017, 155, 54–65. [Google Scholar] [CrossRef]

- European Commission. Circular Economy Scoping Study; European Commission: Brussels, Brussels, 2014. [Google Scholar]

- Yuan, Z.; Bi, J.; Moriguichi, Y. The Circular Economy. Ind. Ecol. Asia 2016, 10, 1–7. [Google Scholar]

- Sakai, S.I.; Yoshida, H.; Hirai, Y.; Asari, M.; Takigami, H.; Takahashi, S.; Tomoda, K.; Peeler, M.V.; Wejchert, J.; Schmid-Unterseh, T.; et al. International comparative study of 3R and waste management policy developments. J. Mater. Cycles Waste Manag. 2011, 13, 86–102. [Google Scholar] [CrossRef]

- Ma, S.H.; Wen, Z.G.; Chen, J.N.; Wen, Z.C. Mode of circular economy in China’s iron and steel industry: A case study in Wu’an city. J. Clean. Prod. 2014, 64, 505–512. [Google Scholar] [CrossRef]

- Guillard, V.; Gaucel, S.; Fornaciari, C.; Angellier-Coussy, H.; Buche, P.; Gontard, N. The Next Generation of Sustainable Food Packaging to Preserve Our Environment in a Circular Economy Context. Front Nutr. 2018, 5, 121. [Google Scholar] [CrossRef]

- Molina-Besch, K.; Pålsson, H. A simplified environmental evaluation tool for food packaging to support decision-making in packaging development. Packag. Technol. Sci. 2020, 33, 141–157. [Google Scholar] [CrossRef]

- Svanes, E.; Vold, M.; Møller, H.; Pettersen, M.K.; Hanne, L.; Hanssen, O.J. Sustainable Packaging Design: A Holistic Methodology for Packaging Design. Packag. Technol. Sci. 2010, 23, 161–175. [Google Scholar] [CrossRef]

- Beitzen-Heineke, E.F.; Balta-Ozkan, N.; Reefke, H. The prospects of zero-packaging grocery stores to improve the social and environmental impacts of the food supply chain. J. Clean. Prod. 2017, 140, 1528–1541. [Google Scholar] [CrossRef]

- Gutierrez, M.M.; Meleddu, M.; Piga, A. Food losses, shelf life extension and environmental impact of a packaged cheesecake: A life cycle assessment. Food Res. Int. 2017, 91, 124–132. [Google Scholar] [CrossRef] [PubMed]

- Andersen, H.; Røvik, K.A. Lost in translation: A case-study of the travel of lean thinking in a hospital. BMC Health Serv. Res. 2015, 15, 401. [Google Scholar] [CrossRef]

- Gorissen, L.; Vrancken, K.; Manshoven, S. Transition thinking and business model innovation-towards a transformative business model and new role for the reuse centers of Limburg, Belgium. Sustainability 2016, 8, 112. [Google Scholar] [CrossRef]

- Nasr, N.; Thurston, M. Remanufacturing: A key enabler to sustainable product systems. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, LCE 2006, Leuven, Belguim, 31 May–2 June 2006; pp. 15–18. [Google Scholar]

- Price, J.L.; Joseph, J.B. Demand management—A basis for waste policy: A critical review of the applicability of the waste hierarchy in terms of achieving sustainable waste management. Sustain. Dev. 2000, 8, 96–105. [Google Scholar] [CrossRef]

- McDonough, W.; Braungart, M.; Anastas, P.T.; Zimmerman, J.B. Peer Reviewed: Applying the Principles of Green Engineering to Cradle-to-Cradle Design. Environ. Sci. Technol. 2003, 37, 434A–441A. [Google Scholar] [CrossRef]

- Bressanelli, G.; Perona, M.; Saccani, N. Challenges in supply chain redesign for the Circular Economy: A literature review and a multiple case study. Int. J. Prod. Res. 2019, 57, 7395–7422. [Google Scholar] [CrossRef]

- Xiao, Y.; Watson, M. Guidance on Conducting a Systematic Literature Review. J. Plan. Educ. Res. 2019, 39, 93–112. [Google Scholar] [CrossRef]

- Istas, D. Expansion of the local, organic and zero-packaging food concept in three contexts: Zero-packaging grocery stores, conventional supermarkets, and ecostores. Maastricht Univ. Neth. 2019, 3021, 1–90. [Google Scholar]

- Aytac, Z.; Ipek, S.; Durgun, E.; Tekinay, T.; Uyar, T. Antibacterial electrospun zein nanofibrous web encapsulating thymol/cyclodextrin-inclusion complex for food packaging. Food Chem. 2017, 233, 117–124. [Google Scholar] [CrossRef] [PubMed]

- Saridewi, N.; Malik, M. Food packaging development of bioplastic from basic waste of cassava peel (manihot uttilisima) and shrimp shell. IOP Conf. Ser. Mater. Sci. Eng. 2019, 602, 012053. [Google Scholar]

- Molt, F.; Jacobsen, J.; Malskær, J.F. Packaging in a Circular Economy: Exploring the Ability to Implement Recyclable Design to Plastic Packaging in the Danish Food-Industry. Master’s Thesis, Aalborg University, Aalborg, Denmark, 2019. [Google Scholar]

- Clark, N.; Trimingham, R.; Storer, I. Understanding the views of the UK food packaging supply chain in order to support a move to circular economy systems. Packag. Technol. Sci. 2019, 32, 577–591. [Google Scholar] [CrossRef]

- Saraiva, A.B.; Pacheco, E.B.; Gomes, G.M.; Visconte, L.L.; Bernardo, C.A.; Simoes, C.L.; Soares, A.G. Comparative lifecycle assessment of mango packaging made from a polyethylene/natural fiber-composite and from cardboard material. J. Clean. Prod. 2016, 139, 1168–1180. [Google Scholar] [CrossRef]

- Syamsiro, M.; Mufrodi, Z.; Rafly, R.; Machmud, S. Energy Recovery from Food Packaging Plastics by Thermal and Catalytic Pyrolysis Processes. Univers. J. Mech. Eng. 2020, 8, 51–58. [Google Scholar] [CrossRef]

- Li, L.; Diederick, R.; Flora, J.R.V.; Berge, N.D. Hydrothermal carbonization of food waste and associated packaging materials for energy source generation. Waste Manag. 2013, 33, 2478–2492. [Google Scholar] [CrossRef]

- Agarwal, R.; Gera, Y.; Amar, A.; Thomas, M.R. Generation Z preference on reusable food container on subscription basis. Indian J. Commer. Manag. Stud. 2020, 11, 53–62. [Google Scholar] [CrossRef]

- Silano, V.; Barat Baviera, J.M.; Bolognesi, C.; Chesson, A.; Cocconcelli, P.S.; Crebelli, R.; Gott, D.M.; Grob, K.; Mortensen, A.; Riviere, G.; et al. Safety assessment of the process Quinn Packaging, based on Erema Basic technology, used to recycle post-consumer PET into food contact materials. EFSA J. 2019, 17, e05771. [Google Scholar] [PubMed] [Green Version]

- European Union. European Implementation Assessment Study Food Contact Materials Regulation (EC) 1935/2004. In Official Journal of the European Union; European Union: Brussels, Belgium, 2016; Volume PE 581.411, 4p, Available online: http://www.europarl.europa.eu/thinktank (accessed on 31 December 2022).

- Mohammadhosseini, H.; Alyousef, R.; Lim, N.H.A.S.; Tahir, M.; Alabduljabbar, H.; Mohamed, A.M.; Samadi, M. Waste metalized film food packaging as low cost and ecofriendly fibrous materials in the production of sustainable and green concrete composites. J. Clean. Prod. 2020, 258, 120726. [Google Scholar] [CrossRef]

- European Union. Directive 2008/122/EC of the European Parliament and of the Council. In Fundamental Texts on European Private Law; European Union: Brussels, Belgium, 2008. [Google Scholar]

- European Union. Strategy for Plastics in a Circular Economy; Seikei-Kakou; European Union: Brussels, Belgium, 2018; Volume 30. [Google Scholar]

- Maga, D.; Hiebel, M.; Aryan, V. A comparative life cycle assessment of meat trays made of various packaging materials. Sustainability 2019, 11, 5324. [Google Scholar] [CrossRef]

- Toniolo, S.; Mazzi, A.; Niero, M.; Zuliani, F.; Scipioni, A. Comparative LCA to evaluate how much recycling is environmentally favourable for food packaging. Resour. Conserv. Recycl. 2013, 77, 61–68. [Google Scholar] [CrossRef]

- Trott, P.; Simms, C. An examination of product innovation in low- and medium-technology industries: Cases from the UK packaged food sector. Res. Policy 2017, 46, 605–623. [Google Scholar] [CrossRef]

- Accorsi, R.; Cascini, A.; Cholette, S.; Manzini, R.; Mora, C. Economic and environmental assessment of reusable plastic containers: A food catering supply chain case study. Int. J. Prod. Econ. 2014, 152, 88–101. [Google Scholar] [CrossRef]

- Jäger, J.K. Joint Efforts for Circular Food Packaging How Focal Firms Find and Set-Up Collaborations for Reusable and Recyclable Food Packaging. Master’s Thesis, Utrecht University, Utrecht, The Netherlands, 2020. [Google Scholar]

- Simms, C.; Trott, P.; van den Hende, E.; Hultink, E.J. Barriers to the adoption of waste-reducing eco-innovations in the packaged food sector: A study in the UK and the Netherlands. J. Clean. Prod. 2020, 244, 118792. [Google Scholar] [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The Circular Economy: An Interdisciplinary Exploration of the Concept and Application in a Global Context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef] [Green Version]

| Main Search Keywords and Strategies | ||

|---|---|---|

| refus* OR redesign OR re-design OR eco-design OR ecodesign | AND | food packaging industry OR food package* |

| rethink* OR shar* OR sharing product OR sharing platform OR service | AND | food packaging industry OR food package* |

| reduce OR reduc* | AND | food packaging industry OR food package* |

| reus* O R re-use OR re-us* | AND | food packaging industry OR food package* |

| repair* OR maintenance | AND | food packaging industry OR food package* |

| refurbish* OR re-furbish* OR revamp* | AND | food packaging industry OR food package* |

| remanufacture* OR re-manufactur* OR rediscover* OR re-discover* | AND | food packaging industry OR food package* |

| repurpose* OR re-purpos* OR repurpose | AND | food packaging industry OR food package* |

| recyc* OR re-cyc* | AND | food packaging industry OR food package* |

| recover* OR energy recovery | AND | food packaging industry OR food package* |

| Inductive Coding Classification | Sources |

|---|---|

| Refuse | 10 |

| Rethink | 1 |

| Reduce | 3 |

| Reuse | 6 |

| Repair | 0 |

| Refurbish | 1 |

| Remanufacture | 0 |

| Repurpose | 2 |

| Recycle | 6 |

| Recover | 4 |

| Food packaging and CE | 2 |

| Total | 35 |

| Company Name | Legal Nature | Year Established | Geographical Location | Circular Strategy | Tranformation Undertaken | Transformational Means | Transformational Methods |

|---|---|---|---|---|---|---|---|

| Company 1 | Private Company Limited by Guarantee | 2017 | Durham, North Carolina, United States | Rethink | Transforming single-use food takeout packaging approach. | Intensive use of takeout packaging through reusable food takeout packaging service | Digital technology (digital application) for locating participating restaurants and return stations and QR codes for renting and dropping-off reusable assets. |

| Company 2 | Public Limited Company (PLC) | 1946 | New South Wales, Australia | Repair | Transforming unsustainable pallet utilisation for goods’ transportation and handling | Providing pooling services based on a circular business model (leasing and repairing of sharable and reusable pallets) | Advanced reverse logistics, high- capacity infeed lines, digital inspection technology (high definition cameras and laser sensors) and robotic repair. |

| Company 3 | Private Company Limited by Shares (Ltd) | 1951 | Lund, Sweden and Lausanne, Switzerland | Refurbish/Revamp | Providing a wide range of highly innovative and sustainable packaging solutions for various food packaging needs. | Increase primary packaging’s renewable material content and recyclability within existing waste streams as well as introducing cutting edge retort able cartoon packaging as alternative to steel cans and glass jars. | In-house team of engineers, technology teams as well as customers and consumers engagement. |

| Company 4 | Public Limited Company (PLC) | 1932 | Luxembourg, Luxembourg | Remanufacture | Transforming glass manufacturing processes’ resource consumption, waste production and carbon footprint. | Utilising discarded glass cullet as feedstock for remanufacturing glass bottles. | Closed-loop manufacturing process and glass cullet colour sorting lines. |

| Company 5 | Private Company Limited by Guarantee | 1996 | Madrid, Spain | Repurpose | Providing a sustainable solution for managing a difficult waste flow (EPS fish boxes) and reducing PS resource consumption for food-contact packaging | Utilising discarded EPS fish boxes to convert them into PS sheets combined with virgin material to produce food -contact packaging with different functionality. | Collecting, sorting and pre-treating (briquetting, hot caustic washing, rinsing, drying), decontamination (volatilization with vacuum and temperature) and extrusion processes. |

| S.No | Circular Strategy | No of Studies | Product Characteristics | Environmental | Health and Saftey | User’s Behaviour | Scale | Stakeholders’ Behaviour | Technological | Opeational | Economic-Financial | Political | Product Availablility | Market Uncertainty | Feedstockilability | Circularbound | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Refuse | 10 | L | L | L | L | L | L | L | L | L | 9 | |||||

| 2 | Rethink | 1 | C | C | L + C | C | 4 | ||||||||||

| 3 | Reduce | 3 | L | L | L | L | 4 | ||||||||||

| 4 | Reuse | 6 | L | L | L | L | L | L | L | 7 | |||||||

| 5 | Repair | 0 | L | C | L | L | C | L | 6 | ||||||||

| 6 | Refurbish/Revamp | 1 | C | L | L | C | L | L | L | L + C | C | 9 | |||||

| 7 | Remanufacture | 0 | L | L + C | L + C | L | L | C | 6 | ||||||||

| 8 | Repurpose | 2 | L | L + C | L | L | L + C | C | L + C | L + C | 8 | ||||||

| 9 | Recycle | 6 | L | L | L | L | L | L | L | L | L | L | 10 | ||||

| 10 | Recover | 4 | L | L | L | L | L | L | 6 | ||||||||

| Total | 7 | 3 | 6 | 6 | 3 | 9 | 5 | 8 | 8 | 6 | 2 | 4 | 1 | 1 | |||

| L = From SLR, C = From Case Study, L + C = From both SLR and Case Study | |||||||||||||||||

| S.No | Circular Strategy | No of Studies | Product Characteristics | Environmental | Health and Saftey | User’s Behaviour | Scale | Stakeholders’ Behaviour | Technological | Opeational | Economic-Financial | Political | Product Availablility | Market Uncertainty | Feedstock Availability | Circular Rebound | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Refuse | 10 | L | L | L | L | L | L | L | L | L | 9 | |||||

| 2 | Rethink | 1 | C | C | L + C | C | 4 | ||||||||||

| 3 | Reduce | 3 | L | L | L | L | 4 | ||||||||||

| 4 | Reuse | 6 | L | L | L | L | L | L | L | 7 | |||||||

| 5 | Repair | 0 | L | C | L | L | C | L | 6 | ||||||||

| 6 | Refurbish/Revamp | 1 | C | L | L | C | L | L | L | L + C | C | 9 | |||||

| 7 | Remanufacture | 0 | L | L + C | L + C | L | L | C | 6 | ||||||||

| 8 | Repurpose | 2 | L | L + C | L | L | L + C | C | L + C | L + C | 8 | ||||||

| 9 | Recycle | 6 | L | L | L | L | L | L | L | L | L | L | 10 | ||||

| 10 | Recover | 4 | L | L | L | L | L | L | 6 | ||||||||

| Total | 7 | 3 | 6 | 6 | 3 | 9 | 5 | 8 | 8 | 6 | 2 | 4 | 1 | 1 | |||

| L = From SLR, C = From Case Study, L + C = From both SLR and Case Study | |||||||||||||||||

| S.No | Circular Strategy | Value added Proposition | Partnership/Collaboration | Improved Design | Alternative Financing | Communication and Awareness Generation | Changing Business Practices | Supply Chain Integration | Technology Employment | Skills and Competence | Legislation, Regulation and Guidelines | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Refuse | L | L | L | L | L | L | L | L | L | 10 | |

| 2 | Rethink | L + C | C | C | L + C | C | C | - | L + C | C | C | 9 |

| 3 | Reduce | L | - | L | - | L | L | - | L | L | L | 7 |

| 4 | Reuse | L | L | L | - | L | L | - | L | L | L | 8 |

| 5 | Repair | L | C | C | - | - | C | - | C | C | L | 7 |

| 6 | Refurbish/Revamp | C | C | - | - | - | - | C | L + C | L + C | C | 6 |

| 7 | Remanufacture | L + C | L + C | C | - | C | L + C | - | - | L + C | L | 7 |

| 8 | Repurpose | C | L + C | - | C | C | L + C | - | L + C | L + C | L + C | 8 |

| 9 | Recycle | - | L | L | L | L | L | - | L | L | L | 8 |

| 10 | Recover | L | - | - | - | - | L | - | L | L | - | 6 |

| Total | 9 | 8 | 7 | 4 | 7 | 9 | 1 | 9 | 10 | 9 | ||

| L = From SLR, C = From Case Study, L + C = From both SLR and Case Study | ||||||||||||

| Levers | Changing Business Practices | Legislatin, Regulation and Guidelines | Technology Employment | Iparthershipl/Collaboration | Improved Design | Communication and Awareness Generation | Value added Proposition | Skills and Competence | Supply Chain Intergration | Alternative Financing | Total | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Barrlers | ||||||||||||

| Opeational | L + C | L + C | L + C | L + C | L + C | L + C | L + C | L + C | C | L | 10 | |

| Economic-financial | L | L | L + C | L + C | L + C | L | L + C | L + C | - | L + C | 9 | |

| Stakeholders’ behaviour | L | L | - | L | L + C | L | L + C | - | L | - | 7 | |

| Product characteristics | L | L + C | L + C | C | L + C | - | L + C | - | - | - | 6 | |

| Health and Saftey | L | L + C | L + C | C | L | L | - | - | - | - | 6 | |

| User’s behaviour | L + C | L | - | - | L | L + C | L + C | - | - | C | 6 | |

| Technological | L | L + C | L + C | L | - | L + C | - | L + C | - | - | 6 | |

| Market uncertainty | L | L | - | - | - | L | L + C | - | L | - | 5 | |

| Political | L + C | L + C | L + C | L + C | - | - | - | - | - | - | 4 | |

| Environmental | C | L + C | C | - | L + C | - | - | - | - | - | 4 | |

| Scale | L | - | - | L + C | - | - | - | - | L | - | 3 | |

| Product availablility | - | - | L + C | - | C | - | - | C | - | - | 3 | |

| Circular Rebound | - | - | C | - | C | - | - | C | - | - | 3 | |

| Feedstock availability | - | - | C | - | - | - | - | - | - | 1 | ||

| Total | 11 | 10 | 9 | 9 | 9 | 7 | 6 | 5 | 4 | 3 | ||

| L = FromSLR, C = From Case study, L + C = From both SLR and Case Study | ||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tanveer, U.; Ishaq, S.; Oqueli, T. An Insight into the Application of Gradations of Circularity in the Food Packaging Industry: A Systematic Literature Review and a Multiple Case Study. Sustainability 2023, 15, 3007. https://doi.org/10.3390/su15043007

Tanveer U, Ishaq S, Oqueli T. An Insight into the Application of Gradations of Circularity in the Food Packaging Industry: A Systematic Literature Review and a Multiple Case Study. Sustainability. 2023; 15(4):3007. https://doi.org/10.3390/su15043007

Chicago/Turabian StyleTanveer, Umair, Shamaila Ishaq, and Tifany Oqueli. 2023. "An Insight into the Application of Gradations of Circularity in the Food Packaging Industry: A Systematic Literature Review and a Multiple Case Study" Sustainability 15, no. 4: 3007. https://doi.org/10.3390/su15043007

APA StyleTanveer, U., Ishaq, S., & Oqueli, T. (2023). An Insight into the Application of Gradations of Circularity in the Food Packaging Industry: A Systematic Literature Review and a Multiple Case Study. Sustainability, 15(4), 3007. https://doi.org/10.3390/su15043007