Innovative Hybrid Condensing Radiant System for Industrial Heating: An Energy and Economic Analysis

Abstract

1. Introduction

1.1. Review of the Literature on Energy Use and Savings in Industry

1.2. Review of the Literature on the Heating and Cooling of Industrial Buildings

1.3. Scope and Novelty of the Study

- minimise the annual amount of total non-renewable primary energy consumed by the hybrid plant (PEnren,tot). This is given by the sum of the non-renewable primary energy consumed with natural gas by the radiant tubes and the non-renewable quota of the electricity imported from the grid;

- minimise CO2 specific emissions of the plant (kgCO2 per square metre of available area);

- maximise the total annual non-renewable primary energy saving compared with traditional heating systems (PESnren,tot);

- maximise the primary energy ratio (PER), that is, the ratio between the total annual useful thermal energy produced by the plant and the PEnren,tot;

- satisfy the requirement of the minimum value of the renewable quota (QR), that is 60% according to Italian Legislative Decree 28/2011 [41], D.M. 26/06/2015 [42], UNI/TS 11300-5 [43] and, more recently, Legislative Decree 199/2021 [44] (implementation of the Renewable Energy Source II Directive). QR is the ratio between yearly amounts of primary energy:

- ○

- the denominator is the sum of the total primary energy used (renewable + non-renewable) (total primary energy delivered or produced on site, calculated using conversion factors fp,tot = fp,ren + fp,nren [42] for each energy carrier delivered or produced on site);

- ○

- the numerator is the sum of the renewable primary energy produced on site or delivered, calculated using the conversion factor fp,ren [42] for each energy carrier (electricity from the photovoltaic system, electricity from the grid, natural gas, ambient thermal energy as heat pump evaporator heat source).

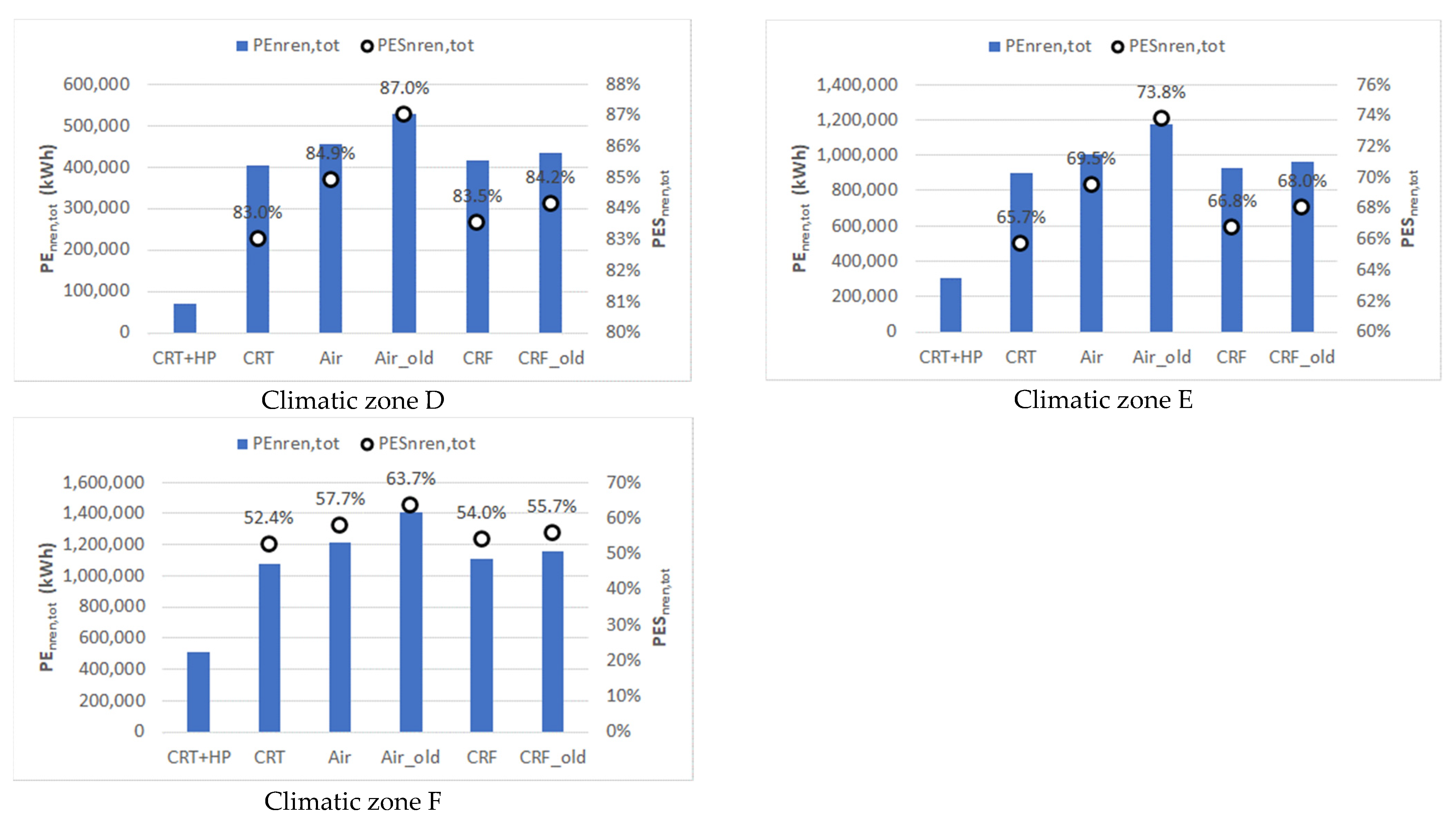

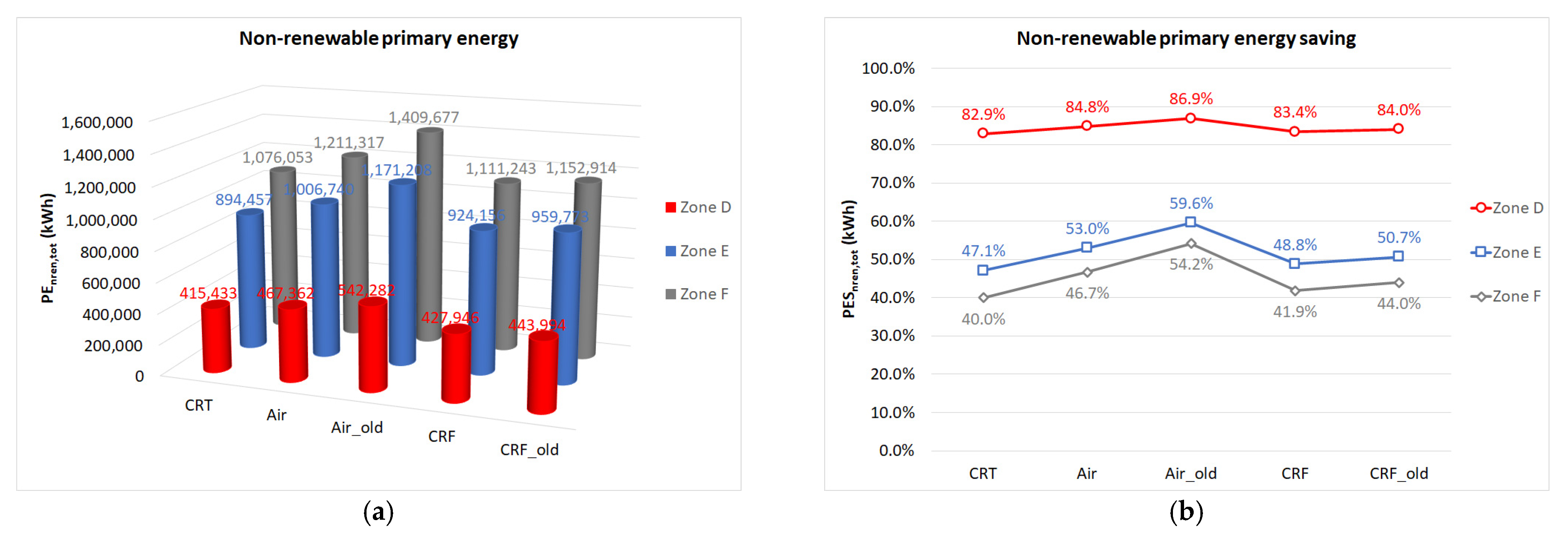

- condensing radiant tubes (CRT) (no hybrid system, i.e., without the heat pump);

- air-heater-based system (Air). A 1600 kW ground air heater is installed with a supply air flow rate and a temperature variable as a function of, respectively, the indoor and outdoor air temperature;

- condensing boiler and radiant floor (condensing radiant floor, CRF). It is a radiant floor (distance between tubes 0.3 m, outer diameter and thickness of tubes 0.02 m and 0.002 m respectively, water flow rate 30 kg h−1 m−2) coupled to a condensing boiler plant (nominal thermal power 1600 kW, supply water temperature variable as function of outdoor air).

2. Materials and Methods

- modelling of a typical industrial building whose characteristics are based on a real case to calculate the annual heating load in three different climates;

- modelling of the hybrid CRT+HP system and analysis of the energy performance. The main scope of this step is to find, for each climate, the best set of:

- useful thermal power of the HP (Pth_HP);

- bivalent temperature in alternative bivalent operation (Tbiv). In this case, the heat pump has priority; when the external temperature is below the “bivalent” value, the radiant tubes are turned on and the heat pump is switched off;

- cut-off temperature in parallel bivalent operation (Tcut-off), that is, the heat pump remains in operation even with external air below the bivalent temperature and until a further threshold, the “cut-off” temperature, in parallel with the radiant tubes;

- peak power of the PV field (PPV).

- modelling of the three benchmark heating systems as described above to be compared with the CRT+HP hybrid system. The comparison is carried out from both an energy and economic point of view.

2.1. Industrial Building Modelling

2.2. Heating Systems Modelling

- alternative bivalent mode: HP shutdown is when Text < Tbiv (bivalent temperature Tbiv has to be optimised);

- parallel bivalent mode: HP shutdown occurs when Text < Tcut-off < Tbiv with parallel operation of HP and CRT when Tcut-off < Text < Tbiv (cut-off temperature Tcut-off has to be optimised).

3. Results and Discussion

3.1. Energy Analysis with Photovoltaic Power

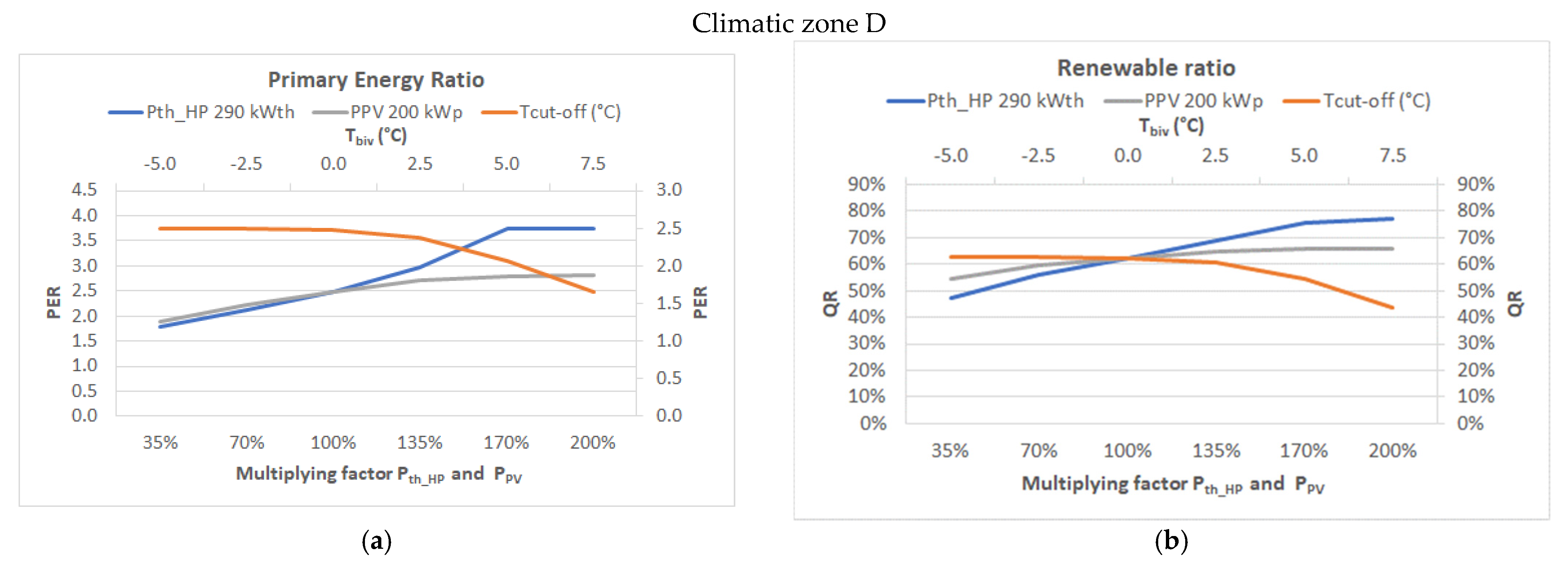

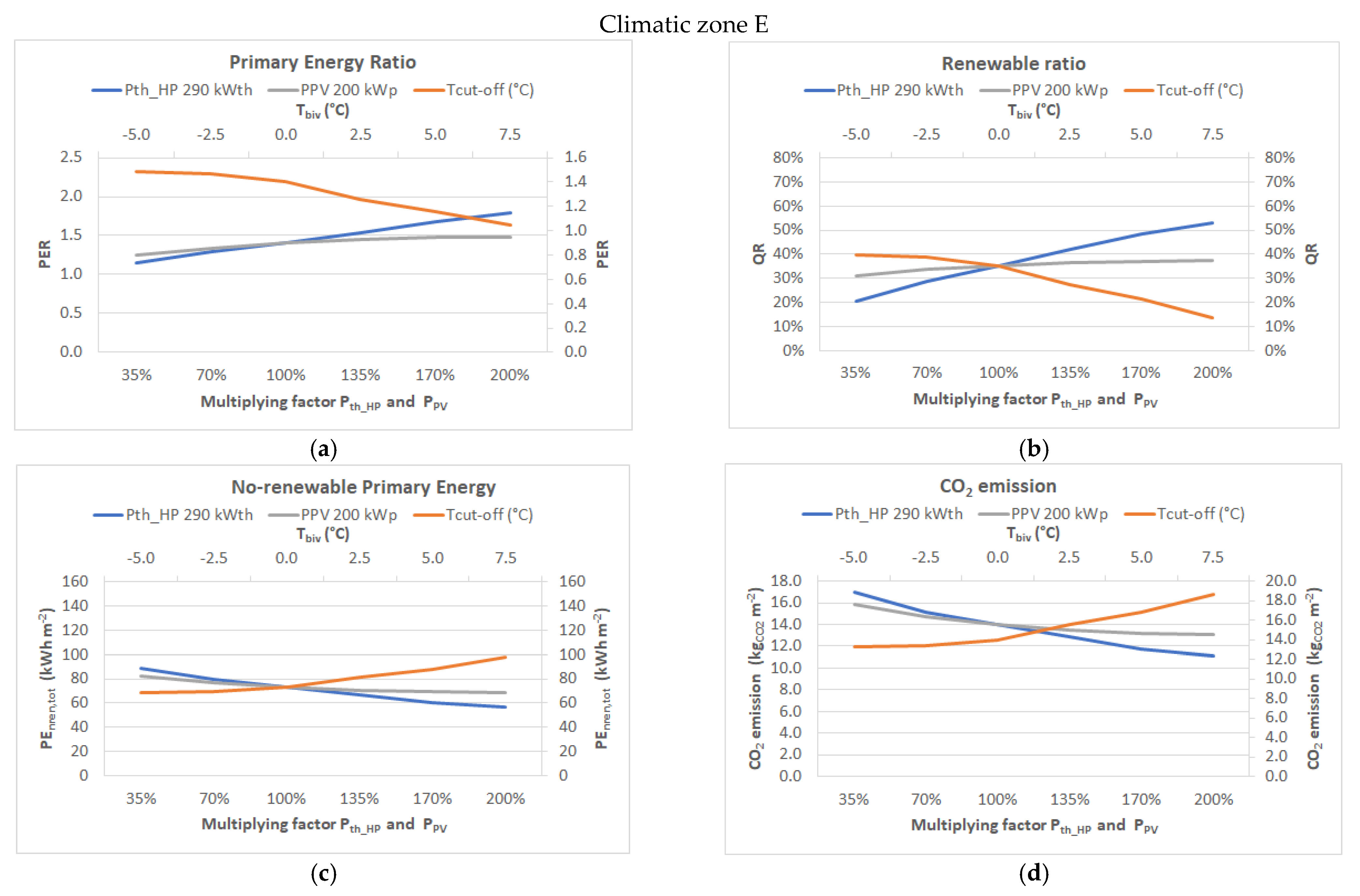

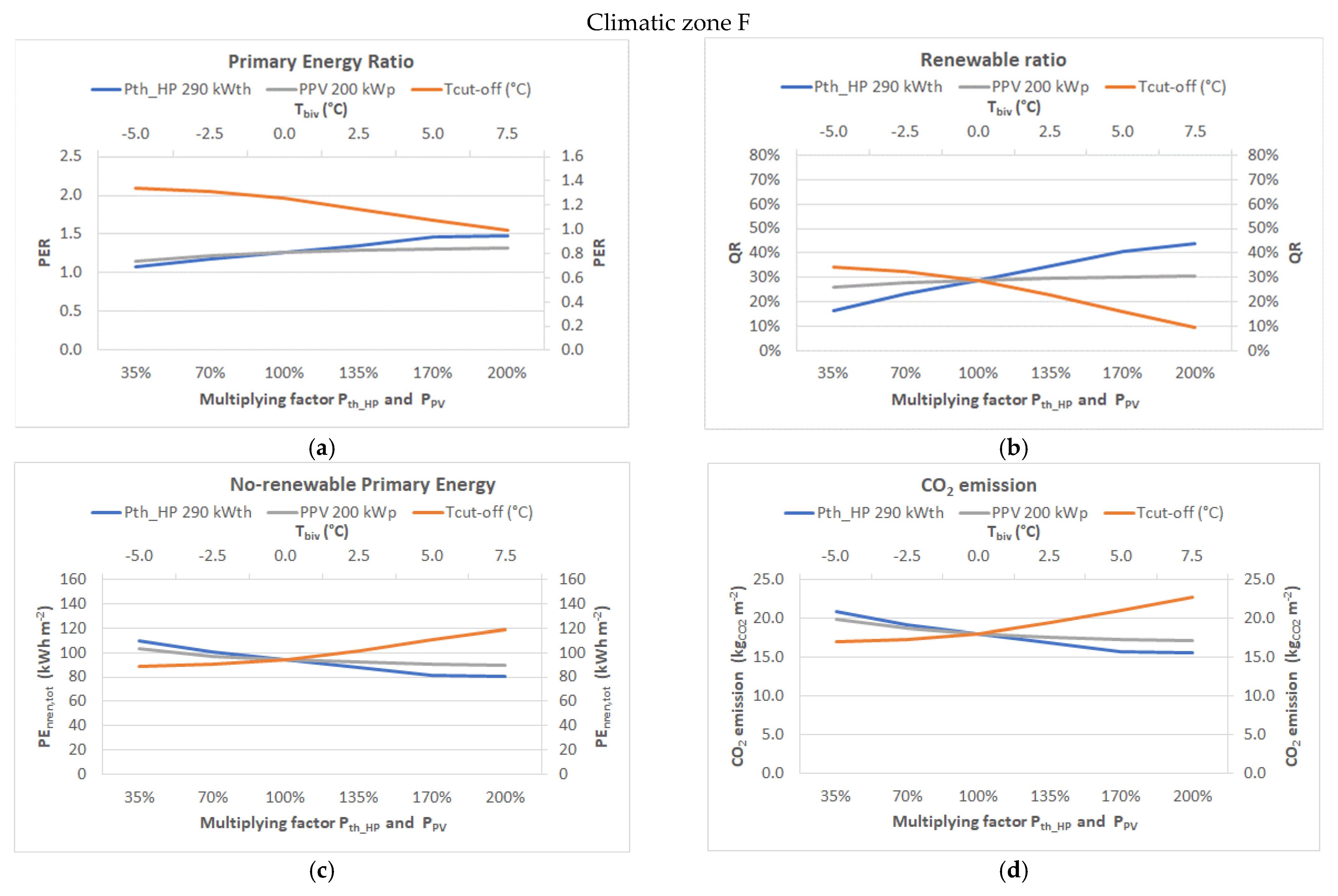

3.1.1. Bivalent Parallel Operation

3.1.2. Bivalent Alternative Operation

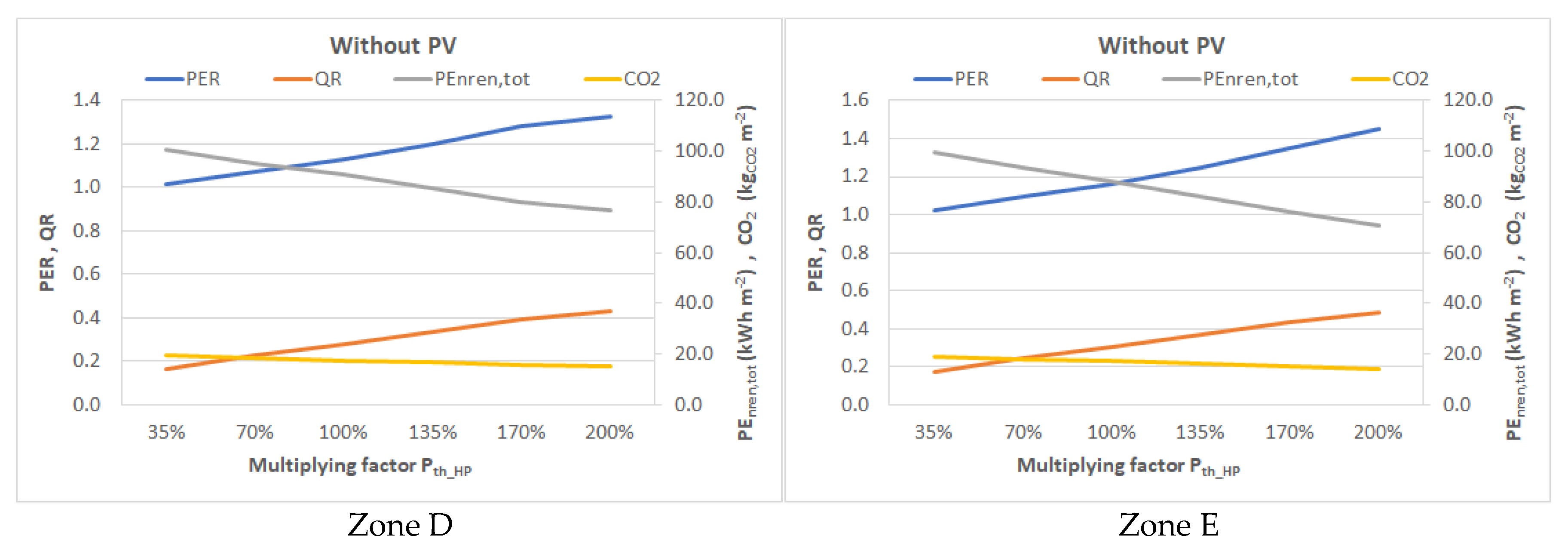

3.2. Energy Analysis without PV

3.2.1. Bivalent Parallel Operation

3.2.2. Bivalent Alternative Operation

3.3. Remarks on the Energy Performance of the Hybrid System

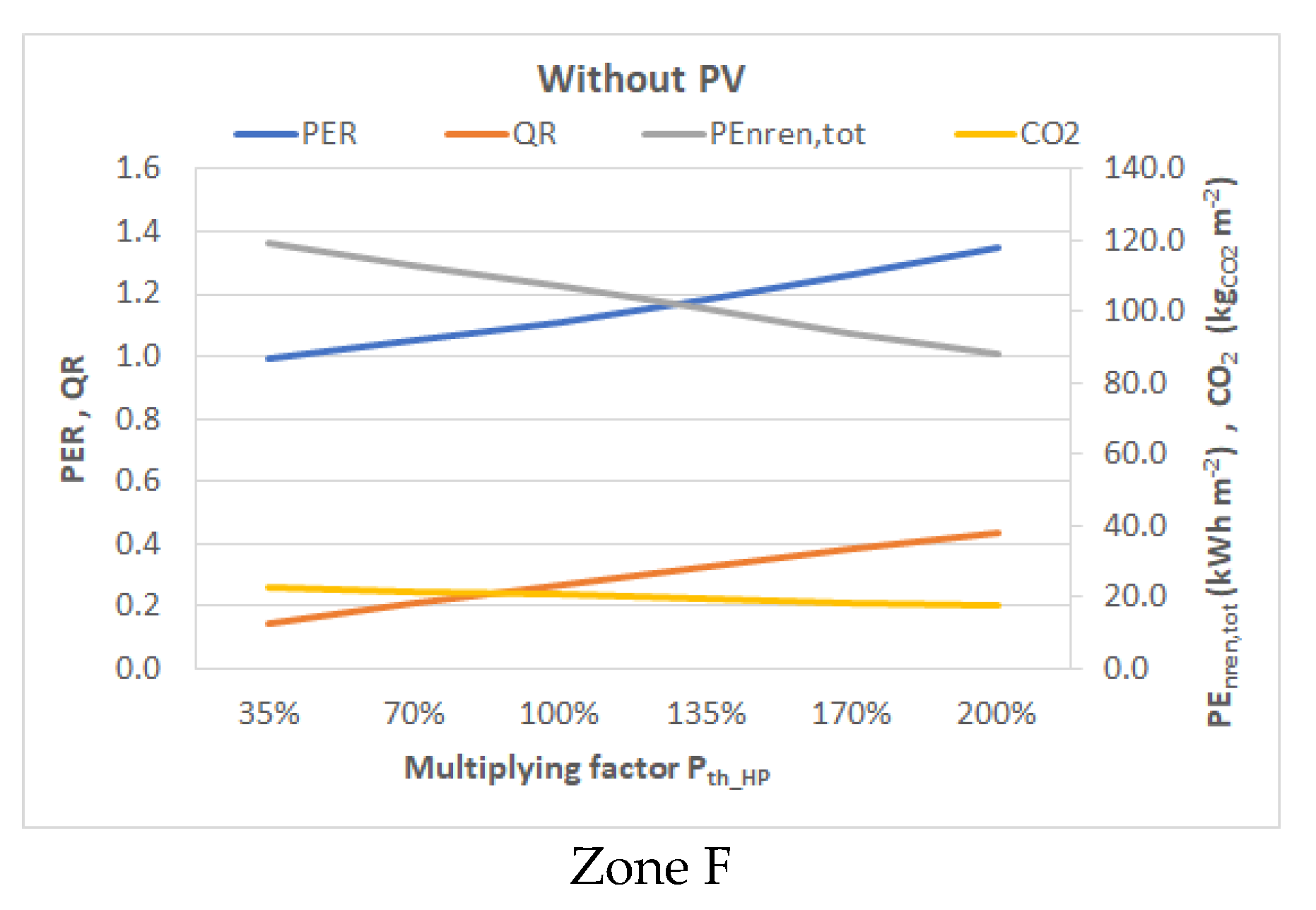

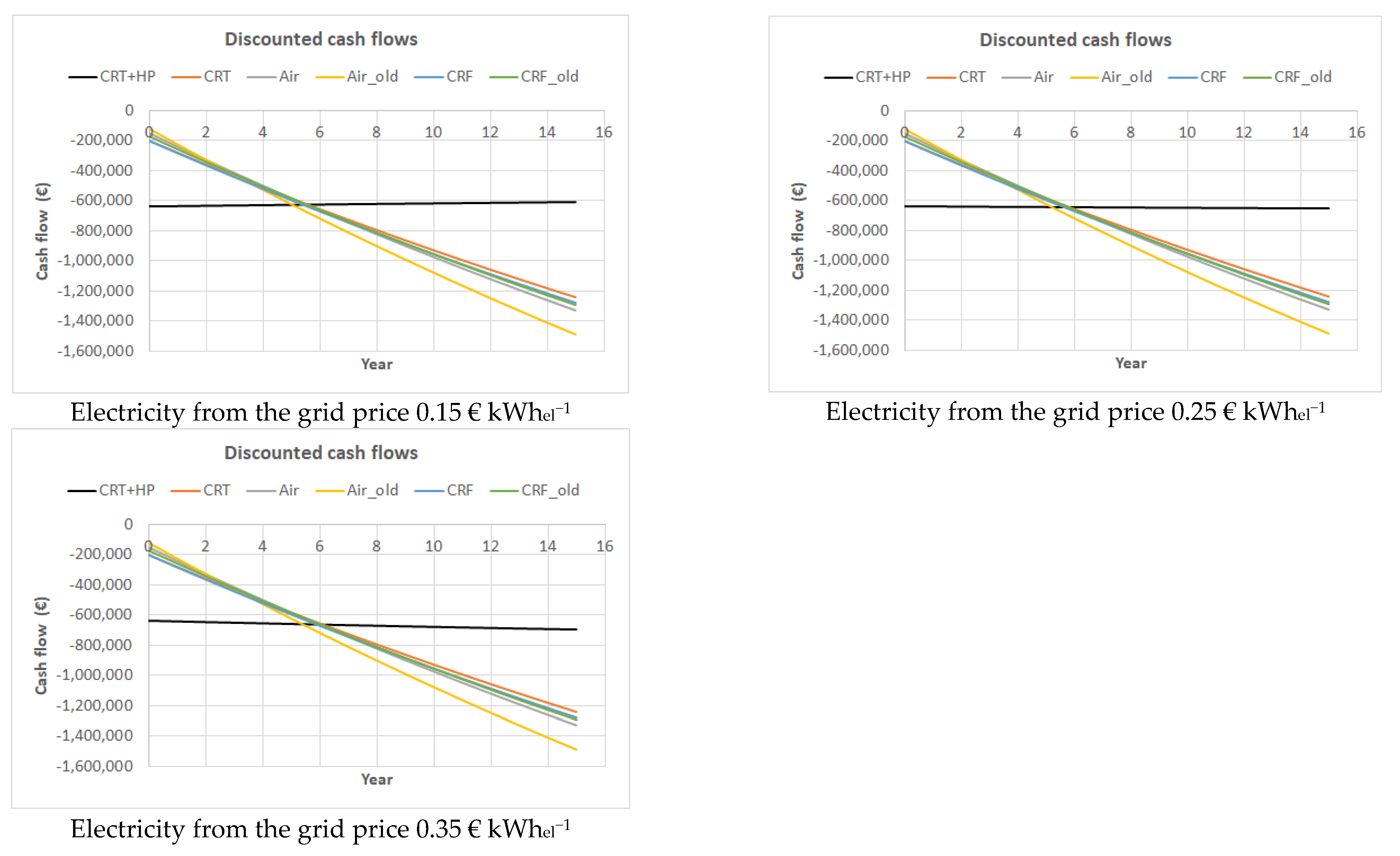

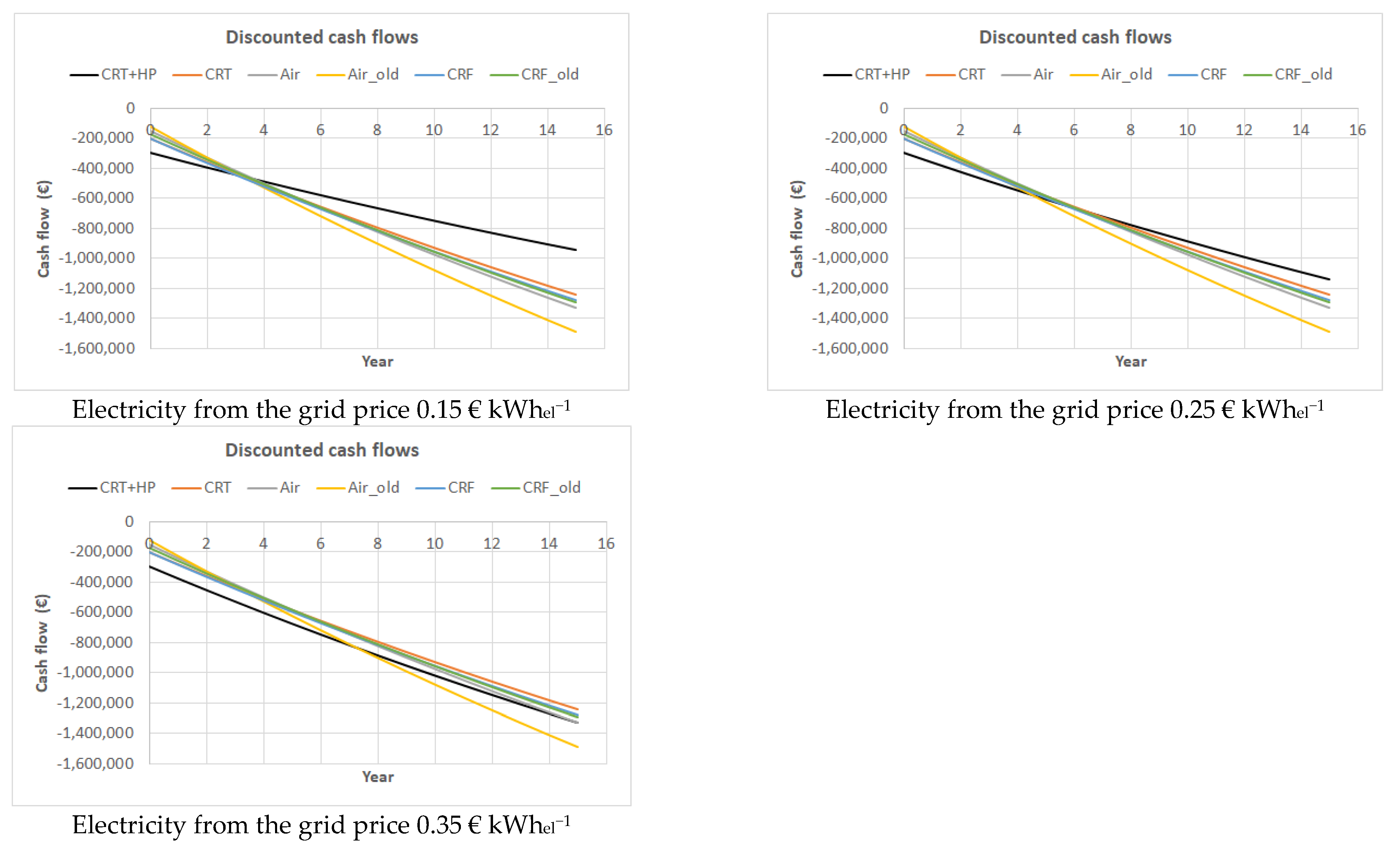

3.4. Economic Analysis

3.5. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Meaning | Unit |

| COP | Coefficient of performance | - |

| fp | Primary energy factor | - |

| G | Mass flow rate | [kg s−1] |

| P | Power | [kW] |

| PE | Primary energy | [kWh] |

| PER | Primary energy ratio | - |

| PES | Primary energy saving | - |

| QR | Renewable ratio | - |

| η | Efficiency | - |

| Subscript | Meaning | |

| biv | Bivalent | |

| cond | Condenser | |

| cut-off | Cut-off | |

| el | Electricity from the grid | |

| exp | Electricity exported to the grid | |

| ext | External | |

| fuel | Fuel | |

| heat_source | Heat source of the heat pump (at the evaporator) | |

| nren | Non-renewable | |

| out | Outlet | |

| ren | Renewable | |

| th | Thermal | |

| tot | Total | |

| Acronym | Meaning | Unit |

| Air | Air heating system | |

| CFD | Computational fluid dynamics | |

| CHP | Combined heat and power | |

| CRF | Condensing radiant floor | |

| CRT | Condensing radiant tube | |

| DPP | Discounted payback period | [y] |

| DSM | Demand side management | |

| EED | Energy Efficiency Directive | |

| EU | European Union | |

| HHV | High heating value | [MJ Sm−3] |

| HP | Heat pump | |

| HVAC | Heating, ventilation, air conditioning | |

| NG | Natural gas | |

| NPW | Net Present Worth | [€] |

| PCM | Phase change material | |

| PV | Photovoltaic | |

| TES | Thermal energy storage |

References

- European Commission. Communication from the Commission: A Clean Planet for All. EUR-Lex—52018DC0773—EN—EUR-Lex. 2018. Available online: https://eur-lex.europa.eu/legal-content/en/TXT/?uri=CELEX%3A52018DC0773 (accessed on 2 March 2022).

- European Union. Directive (EU) 2018/2002 of the European Parliament and of the Council—Of 11 December 2018—Amending Directive 2012/27/EU on Energy Efficiency. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv%3AOJ.L_.2018.328.01.0210.01.ENG (accessed on 2 March 2022).

- Malinauskaite, J.; Jouhara, H.; Egilegor, B.; Al-Mansour, F.; Ahmad, L.; Pusnik, M. Energy efficiency in the industrial sector in the EU, Slovenia, and Spain. Energy 2020, 208, 118398. [Google Scholar] [CrossRef] [PubMed]

- Malinauskaite, J.; Jouhara, H.; Ahmad, L.; Milani, M.; Montorsi, L.; Venturelli, M. Energy efficiency in industry: EU and national policies in Italy and the UK. Energy 2019, 172, 255–269. [Google Scholar] [CrossRef]

- Muriel de Oliveira, G. Research and Development Financing in the Renewable Energy Industry in Brazil. J. Sustain. Dev. Energy Water Environ. Syst. 2014, 2, 208–218. [Google Scholar] [CrossRef]

- Leobner, I.; Smolek, P.; Heinzl, B.; Raich, P.; Schirrer, A.; Kozek, M.; Rössler, M.; Mörzinger, B. Simulation-based Strategies for Smart Demand Response. J. Sustain. Dev. Energy Water Environ. Syst. 2018, 6, 33–46. [Google Scholar] [CrossRef]

- Paulus, M.; Borggrefe, F. The potential of demand-side management in energy-intensive industries for electricity markets in Germany. Appl. Energy 2011, 88, 432–441. [Google Scholar] [CrossRef]

- Mikulčić, H.; Vujanović, M.; Duić, N. Reducing the CO2 emissions in Croatian cement industry. Appl. Energy 2013, 101, 41–48. [Google Scholar] [CrossRef]

- López Pérez, S.; Herrero López, S.; Ubieta Astigarraga, E.; del Hoyo Arce, I.; Gómez de Arteche Botas, M.; Iturralde Iñarga, J.; Fernández de Arroiabe Txapartegi, P.; Mounir Bou-Ali, M.; Unamuno Iriondo, I. Design of a Radiant Heat Capturing Device for Steel Mills. J. Sustain. Dev. Energy Water Environ. Syst. 2021, 9, 1080365. [Google Scholar] [CrossRef]

- Alshehhi, I.; Alnahdi, W.; Ali, M.; Bouabid, A.; Sleptchenko, A. Assessment of Waste Heat Recovery in the Steel Industry. J. Sustain. Dev. Energy Water Environ. Syst. 2023, 11, 1100440. [Google Scholar] [CrossRef]

- Lazzarin, R.; Noro, M. Energy efficiency opportunities in the service plants of cast iron foundries in Italy. Int. J. Low Carbon Technol. 2017, 12, 96–109. [Google Scholar] [CrossRef]

- Lazzarin, R.; Noro, M. Energy efficiency opportunities in the production process of cast iron foundries: An experience in Italy. Appl. Therm. Eng. 2015, 90, 509–520. [Google Scholar] [CrossRef]

- López-Sabirón, A.M.; Royo, P.; Ferreira, V.J.; Aranda-Usón, A.; Ferreira, G. Carbon footprint of a thermal energy storage system using phase change materials for industrial energy recovery to reduce the fossil fuel consumption. Appl. Energy 2014, 135, 616–624. [Google Scholar] [CrossRef]

- Righetti, G.; Lazzarin, R.; Noro, M.; Mancin, S. Phase Change Materials embedded in porous matrices for hybrid thermal energy storages: Experimental results and modelling. Int. J. Refrig. 2019, 106, 266–277. [Google Scholar] [CrossRef]

- Lazzarin, R.; Mancin, S.; Noro, M.; Righetti, G. Hybrid PCM—Aluminium foams’ thermal storages: An experimental study. Int. J. Low Carbon Technol. 2018, 13, 286–291. [Google Scholar] [CrossRef]

- Gambini, M.; Vellini, M.; Stilo, T.; Manno, M.; Bellocchi, S. High-Efficiency Cogeneration Systems: The Case of the Paper Industry in Italy. Energies 2019, 12, 335. [Google Scholar] [CrossRef]

- Vialetto, G.; Noro, M.; Colbertaldo, P.; Rokni, M. Enhancement of energy generation efficiency in industrial facilities by SOFC—SOEC systems with additional hydrogen production. Int. J. Hydrog. Energy 2019, 44, 9608–9620. [Google Scholar] [CrossRef]

- Vialetto, G.; Noro, M. An innovative approach to design cogeneration systems based on big data analysis and use of clustering methods. Energy Convers. Manag. 2020, 214, 112901. [Google Scholar] [CrossRef]

- Vialetto, G.; Noro, M. Enhancement of a Short-Term Forecasting Method Based on Clustering and kNN: Application to an Industrial Facility Powered by a Cogenerator. Energies 2019, 12, 4407. [Google Scholar] [CrossRef]

- Schützenhofer, S.; Kovacic, I.; Rechberger, H. Assessment of sustainable use of material resources in the Architecture, Engineering and Construction industry—A conceptual Framework proposal for Austria. J. Sustain. Dev. Energy Water Environ. Syst. 2022, 10, 1100417. [Google Scholar] [CrossRef]

- European Union. Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018L0844&from=IT (accessed on 2 March 2022).

- Trianni, A.; Cagno, E.; De Donatis, A. A framework to characterize energy efficiency measures. Appl. Energy 2014, 118, 207–220. [Google Scholar] [CrossRef]

- Katunska, J.; Oberleova, J.; Rusnak, A.; Toth, S. Diagnosis of elected industrial hall object and idea for its reconstruction. Adv. Mater. Res. 2014, 1057, 19–26. [Google Scholar] [CrossRef]

- Chinese, D.; Nardin, G.; Saro, O. Multi-criteria analysis for the selection of space heating systems in an industrial building. Energy 2011, 36, 556–565. [Google Scholar] [CrossRef]

- Caputo, A.C.; Pelagagge, P.M. Upgrading mixed ventilation systems in industrial conditioning. Appl. Therm. Eng. 2009, 29, 3204–3211. [Google Scholar] [CrossRef]

- Gourlis, G.; Kovacic, I. A study on building performance analysis for energy retrofit of existing industrial facilities. Appl. Energy 2016, 184, 1389–1399. [Google Scholar] [CrossRef]

- Gourlis, G.; Kovacic, I. Passive measures for preventing summer overheating in industrial buildings under consideration of varying manufacturing process loads. Energy 2017, 137, 1175–1185. [Google Scholar] [CrossRef]

- Kovacic, I.; Waltenbereger, L.; Gourlis, G. Tool for life cycle analysis of facade-systems for industrial buildings. J. Clean. Prod. 2016, 130, 260–272. [Google Scholar] [CrossRef]

- Smolek, P.; Leobner, I.; Gourlis, G.; Mörzinger, B.; Heinzl, B.; Ponweiser, K. Hybrid Building Performance Simulation Models for Industrial Energy Efficiency Applications. J. Sustain. Dev. Energy Water Environ. Syst. 2018, 6, 381–393. [Google Scholar] [CrossRef]

- Gourlis, G.; Kovacic, I. Building Information Modelling for analysis of energy efficient industrial buildings—A case study. Renew. Sustain. Energy Rev. 2017, 68, 953–963. [Google Scholar] [CrossRef]

- Stamponi, E.; Lattanzi, N.; Moretti, E. Experimental and numerical assessment for HVAC management in an industrial building: A preliminary optimization. J. Phys. Conf. Ser. 2021, 2069, 012111. [Google Scholar] [CrossRef]

- Selim, O.M.; Abousabae, M.; Hasan, A.; Amano, R.S. Analysis of energy savings and CO2 emission reduction contribution for industrial facilities in USA. J. Energy Resour. Technol. Trans. ASME 2021, 143, 082303. [Google Scholar] [CrossRef]

- Lazzarin, R. Interview on Space Heating in Industry; SGE: Padova, Italy, 2002. (In Italian) [Google Scholar]

- Brunello, P.; De Carli, M.; Magagnin, P.; Polito, A.; Zecchin, R. Gas radiant heating in industrial environments: Phenomenology, design, verification. In Proceedings of the AiCARR Congress “Progettare L’involucro Edilizio: Correlazioni Tra il Sistema Edificio e i Sistemi Impiantistici”, Bologna, Italy, 18 October 2001; pp. 183–204. (In Italian). [Google Scholar]

- De Carli, M.; Polito, A. Radiant air conditioning systems. In Proceedings of the AiCARR Congress “Riduzione dei Fabbisogni, Recupero di Efficienza e Fonti Rinnovabili per il Risparmio Energetico Nel Settore Industriale”, Padova, Italy, 17 June 2010; pp. 43–80. (In Italian). [Google Scholar]

- Brunello, P.; De Carli, M.; Polito, A.; Zecchin, R. Comfort criteria and design aspects in high temperature radiant heating. In Proceedings of the Indoor Air 2002, Monterey, CA, USA, 30 June–5 July 2002. [Google Scholar]

- D’Ambrosio Alfano, F.R. The thermal environment in industry. In Proceedings of the AiCARR Congress “Riduzione dei Fabbisogni, Recupero di Efficienza e Fonti Rinnovabili per il Risparmio Energetico Nel Settore Industriale”, Padova, Italy, 17 June 2010; pp. 11–30. (In Italian). [Google Scholar]

- Lazzarin, R. Condensing Boilers; PEG: Milano, Italy, 1986. (In Italian) [Google Scholar]

- Noro, M.; Lazzarin, R. Energy analysis of industrial climatization by an innovative radiant condensing system. AIP Conf. Proc. 2019, 2191, 020121. [Google Scholar] [CrossRef]

- Noro, M.; Mancin, S.; Cerboni, F. High efficiency hybrid radiant and heat pump heating plants for industrial buildings: An energy analysis. Int. J. Heat Technol. 2022, 40, 863–870. [Google Scholar] [CrossRef]

- Italian Government. DECRETO LEGISLATIVO 3 Marzo 2011, n. 28 Attuazione Della Direttiva 2009/28/CE Sulla Promozione Dell’uso Dell’energia da Fonti Rinnovabili, Recante Modifica e Successiva Abrogazione Delle Direttive 2001/77/CE e 2003/30/CE. (In Italian). Available online: https://www.gazzettaufficiale.it/eli/gu/2011/03/28/71/so/81/sg/pdf (accessed on 2 March 2022).

- Italian Economic Development Ministry. Decreto Interministeriale 26 Giugno 2015—Adeguamento Linee Guida Nazionali per la Certificazione Energetica Degli Edifici. (In Italian). Available online: https://www.mise.gov.it/index.php/it/normativa/decreti-interministeriali/decreto-interministeriale-26-giugno-2015-adeguamento-linee-guida-nazionali-per-la-certificazione-energetica-degli-edifici?fbclid=IwAR0b1hSl5RfM4gkwQl14MuTMPZTjoaQcbJc5TDupjldOBSihzHZsfJiILyM?hitcount=0?hitcount=0?hitcount=0?hitcount=0?hitcount=0?hitcount=0?hitcount=0?hitcount=0?hitcount=0?hitcount=0?hitcount=0 (accessed on 2 March 2022).

- UNI/TS 11300-5:2016; Prestazioni Energetiche Degli Edifici—Parte 5: Calcolo Dell’energia Primaria e Della Quota di Energia da Fonti Rinnovabili. Italian Standard Organization: Milano, Italy, 2016. (In Italian)

- Italian Government. DECRETO LEGISLATIVO 8 Novembre 2021, n. 199 Attuazione della Direttiva (UE) 2018/2001 del Parlamento Europeo e del Consiglio, dell’11 dicembre 2018, Sulla Promozione Dell’uso Dell’energia da Fonti Rinnovabili. (In Italian). Available online: https://www.gazzettaufficiale.it/eli/id/2021/11/30/21G00214/sg (accessed on 2 March 2022).

- Italian Government. Decreto del Presidente Della Repubblica 26 Agosto 1993, n. 412 Regolamento Recante Norme per la Progettazione, L’installazione, L’esercizio e la Manutenzione Degli Impianti Termici Degli Edifici ai Fini del Contenimento dei Consumi di Energia, in Attuazione Dell’art. 4, Comma 4, Della Legge 9 Gennaio 1991, n. 10. (In Italian). Available online: https://www.gazzettaufficiale.it/eli/id/1993/10/14/093G0451/sg (accessed on 2 March 2022).

- CTI—Comitato Termotecnico Italiano. Weather Reference Year. (In Italian). Available online: https://www.cti2000.it/index.php?controller=news&action=show&newsid=34985 (accessed on 15 July 2021).

- ENE. Azioni Amministrative e Comportamentali per la Riduzione del Fabbisogno Nazionale di Gas Metano. Settore Residenziale. 2022. Available online: https://www.enea.it/it/seguici/events/conferenza-stampa/RapportotecnicoAzioniperlariduzionedelFabbisognoNazionalediGas.pdf (accessed on 30 January 2023).

- Fraunhofer Institute for Solar Energy Systems. Photovoltaics Report. 2021. Available online: https://www.ise.fraunhofer.de/content/dam/ise/de/documents/publications/studies/Photovoltaics-Report.pdf (accessed on 1 September 2022).

| Parameter (Unit) | Value |

|---|---|

| Thermal transmittance (W m−2 K−1) | |

| External wall | 0.389 |

| Door | 3.50 |

| Main door | 3.50 |

| Wall-facing offices | 2.954 |

| Base-facing wall | 3.220 |

| Floor-facing ground | 0.128 |

| Ceiling | 4.086 |

| Ceiling shed | 0.208 |

| Window | 5.0 |

| Thermal bridge wall–floor facing ground (W m−2 K−1) | 0.353 |

| Thermal bridge wall–ceiling (W m−2 K−1) | 0.262 |

| Thermal Zone 1 | Thermal Zone 2 | |

|---|---|---|

| Floor area (m2) | 7119 | 716.5 |

| Net height (m) | 8.24 | 8.22 |

| Indoor air temp. (°C) | 18 | 18 |

| Net volume (m3) | 58,669 | 5886.2 |

| Heating scheduling | 6.00 am to 6.00 pm | 6.00 am to 6.00 pm |

| Heat gain for people and lighting (W m−2) | 5 | 5 |

| People and lighting scheduling | 8.00 am to 6.00 pm | 8.00 am to 6.00 pm |

| Presence of people | 40 | 8 |

| Degree of activity (met) | 2 met | 2 met |

| Clothing (clo) | 1 clo | 1 clo |

| Air infiltration (vol h−1) | 0.5 | 0.5 |

| Text (°C) | Tout,cond (°C) | ||||||

|---|---|---|---|---|---|---|---|

| D.B. | W.B. | 35 | 40 | ||||

| kWth | kWel | COP | kWth | kWel | COP | ||

| −7 | −8 | 205.0 | 60.8 | 3.37 | 203.0 | 67.8 | 2.99 |

| −5 | −6 | 216.0 | 61.2 | 3.53 | 214.0 | 68.0 | 3.15 |

| 0 | −1 | 245.0 | 62.4 | 3.93 | 243.0 | 68.9 | 3.53 |

| 2 | 1 | 260.0 | 62.8 | 4.14 | 256.0 | 69.4 | 3.69 |

| 7 | 6 | 297.0 | 64.1 | 4.63 | 290.0 | 70.7 | 4.10 |

| 12 | 11 | 344.0 | 65.7 | 5.24 | 336.0 | 72.1 | 4.66 |

| Symbol | Meaning | Value |

|---|---|---|

| fp,nren,NG | Non-renewable primary energy conversion factor for natural gas [42] | 1.05 |

| fp,nren,el | As above for electricity from the grid [42] | 1.95 |

| fp,ren,el | Renewable primary energy conversion factor for electricity from the grid [42] | 0.47 |

| fp,ren,PV | As above for electricity from the PV field [42] | 1 |

| fp,ren,heat_source_HP | As above for external air thermal energy [42] | 1 |

| QR | Minimum renewable ratio for new buildings [42] | 60% |

| PV [kWp] | (Reference) peak power | 200 |

| PV [ηnom] | (Reference) peak efficiency | 16.0% |

| PV [m2 kWp−1] | (Reference) specific area | 6.3 |

| Emiss. CO2 [kgCO2 kWh−1] | Specific CO2 emission factor | |

| Electricity from the grid | 0.4 | |

| Natural gas (NG) | 0.2 | |

| NG cost [€ Sm−3] | - | 1.00 |

| Electricity from the grid cost [€ kWh−1] | - | 0.20 |

| Electricity exported value [€ kWh−1] | - | 0.10 |

| CRT+HP investment cost [€] ** | - | 300,000 |

| PV investment cost [€ Wp−1] [48] | - | 1.0 |

| Interest rate/Period of the analysis [y] | - | 2.0%/15 |

| Symbol | Description | Unit | Zone D | Zone E | Zone F |

|---|---|---|---|---|---|

| PEren,el | Renewable quota of electricity from the grid | [kWh] | 3272 | 28,764 | 29,170 |

| PEnren,el | Non-renewable quota of electricity from the grid | [kWh] | 13,575 | 119,339 | 121,026 |

| PEren,PV | Renewable quota of electricity from the PV self-consumed | [kWh] | 77,500 | 120,191 | 107,408 |

| PEren,PV,exp | Renewable quota of electricity from the PV exp. to grid | [kWh] | 431,186 | 346,681 | 266,584 |

| PEren,heat_source_HP | Thermal energy as heat source of the HP | [kWh] | 246,431 | 452,206 | 415,447 |

| PEren,tot | Total renewable | [kWh] | 327,203 | 601,160 | 552,026 |

| PEnren,NG | Non-renewable as natural gas | [kWh] | 55,464 | 195,911 | 390,089 |

| PEnren,tot | Total non-renewable | [kWh] | 69,040 | 315,250 | 511,115 |

| PER | Primary energy ratio | 5.51 | 2.54 | 1.82 | |

| QR | Renewable ratio | 82.6% | 65.6% | 51.9% | |

| PEnren,tot | Specific total non-renewable | [kWh m−2] | 8.8 | 40.2 | 65.2 |

| CO2 | [kgCO2 m−2] | 1.7 | 7.9 | 12.7 |

| Zone D | Zone E | Zone F | |||

|---|---|---|---|---|---|

| PV– ALTERNATIVE | PER | 5.35 | 1.69 | 1.44 | |

| QR | 82.2% | 45.3% | 37.0% | ||

| PEnren,tot | [kWh m−2] | 9.1 | 60.4 | 82.4 | |

| CO2 | [kgCO2 m−2] | 1.8 | 11.5 | 15.8 | |

| PV– PARALLEL | PER | 5.51 | 2.54 | 1.82 | |

| QR | 82.6% | 65.6% | 51.9% | ||

| PEnren,tot | [kWh m−2] | 8.8 | 40.2 | 65.2 | |

| CO2 | [kgCO2 m−2] | 1.7 | 7.9 | 12.7 | |

| NO PV– ALTERNATIVE | PER | 1.73 | 1.33 | 1.21 | |

| QR | 56.5% | 43.2% | 37.1% | ||

| PEnren,tot | [kWh m−2] | 28.1 | 76.9 | 98.5 | |

| CO2 | [kgCO2 m−2] | 5.7 | 15.2 | 19.3 | |

| NO PV– PARALLEL | PER | 1.73 | 1.45 | 1.35 | |

| QR | 56.6% | 48.5% | 43.5% | ||

| PEnren,tot | [kWh m−2] | 28.0 | 70.5 | 88.3 | |

| CO2 | [kgCO2 m−2] | 5.6 | 14.1 | 17.5 |

| Zone D | Zone E | Zone F | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CAPEX [€] | OPEX [€] | NPW [€] | DPP [y] | CAPEX [€] | OPEX [€] | NPW [€] | DPP [y] | CAPEX [€] | OPEX [€] | NPW [€] | DPP [y] | ||

| PV–BIV. ALT. | CRT+HP | −640,000 | 36,521 | −170,736 | - | −640,000 | −6,439 | −722,732 | - | −640,000 | −30,548 | −1,032,515 | - |

| CRT | −200,000 | −36,557 | −669,732 | 6.5 | −200,000 | −81,238 | −1,243,850 | 6.3 | −200,000 | −97,486 | −1,452,620 | 7.1 | |

| Air | −150,000 | −41,143 | −678,655 | 6.8 | −150,000 | −91,429 | −1,324,790 | 6.2 | −150,000 | −109,714 | −1,559,748 | 6.7 | |

| Air_old | −120,000 | −47,871 | −735,113 | 6.6 | −120,000 | −106,381 | −1,486,917 | 5.5 | −120,000 | −127,657 | −1,760,300 | 5.7 | |

| CRF | −200,000 | −37,757 | −685,151 | 6.4 | −200,000 | −83,905 | −1,278,114 | 6.1 | −200,000 | −100,686 | −1,493,737 | 6.8 | |

| CRF_old | −170,000 | −39,214 | −673,875 | 6.7 | −170,000 | −87,143 | −1,289,722 | 6.3 | −170,000 | −104,571 | −1,513,666 | 6.9 | |

| PV–BIV. PAR. | CRT+HP | −640,000 | 36,696 | −168,490 | - | −640,000 | 4659 | −580,141 | - | −640,000 | −21,137 | −911,592 | - |

| CRT | 6.5 | 5.5 | 6.2 | ||||||||||

| Air | 6.8 | 5.4 | 5.9 | ||||||||||

| Air_old | 6.6 | 5 | 5.2 | ||||||||||

| CRF | 6.4 | 5.3 | 5.9 | ||||||||||

| CRF_old | 6.7 | 5.5 | 6 | ||||||||||

| NO PV–BIV. ALT. | CRT+HP | −300,000 | −27,109 | −648,331 | - | −300,000 | −71,771 | −1,222,198 | - | −300,000 | −86,201 | −1,407,615 | - |

| CRT | 12 | 12 | 9.9 | ||||||||||

| Air | 12.1 | 8.4 | 6.9 | ||||||||||

| Air_old | 9.6 | 5.5 | 4.6 | ||||||||||

| CRF | 10.5 | 9.1 | 7.5 | ||||||||||

| CRF_old | 12.2 | 9.4 | 7.7 | ||||||||||

| NO PV–BIV. PAR. | CRT+HP | −300,000 | −22,442 | −588,360 | - | −300,000 | −53,959 | −993,338 | - | −300,000 | −66,956 | −1,160,341 | - |

| CRT | 7.7 | 3.8 | 3.4 | ||||||||||

| Air | 8.8 | 4.2 | 3.7 | ||||||||||

| Air_old | 7.7 | 3.6 | 3.1 | ||||||||||

| CRF | 7.1 | 3.5 | 3.1 | ||||||||||

| CRF_old | 8.5 | 4.1 | 3.6 | ||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noro, M.; Mancin, S.; Busato, F.; Cerboni, F. Innovative Hybrid Condensing Radiant System for Industrial Heating: An Energy and Economic Analysis. Sustainability 2023, 15, 3037. https://doi.org/10.3390/su15043037

Noro M, Mancin S, Busato F, Cerboni F. Innovative Hybrid Condensing Radiant System for Industrial Heating: An Energy and Economic Analysis. Sustainability. 2023; 15(4):3037. https://doi.org/10.3390/su15043037

Chicago/Turabian StyleNoro, Marco, Simone Mancin, Filippo Busato, and Francesco Cerboni. 2023. "Innovative Hybrid Condensing Radiant System for Industrial Heating: An Energy and Economic Analysis" Sustainability 15, no. 4: 3037. https://doi.org/10.3390/su15043037

APA StyleNoro, M., Mancin, S., Busato, F., & Cerboni, F. (2023). Innovative Hybrid Condensing Radiant System for Industrial Heating: An Energy and Economic Analysis. Sustainability, 15(4), 3037. https://doi.org/10.3390/su15043037