Investigation of the Physical Mechanical Properties and Durability of Sustainable Ultra-High Performance Concrete with Recycled Waste Glass

Abstract

:1. Introduction

Research Significance

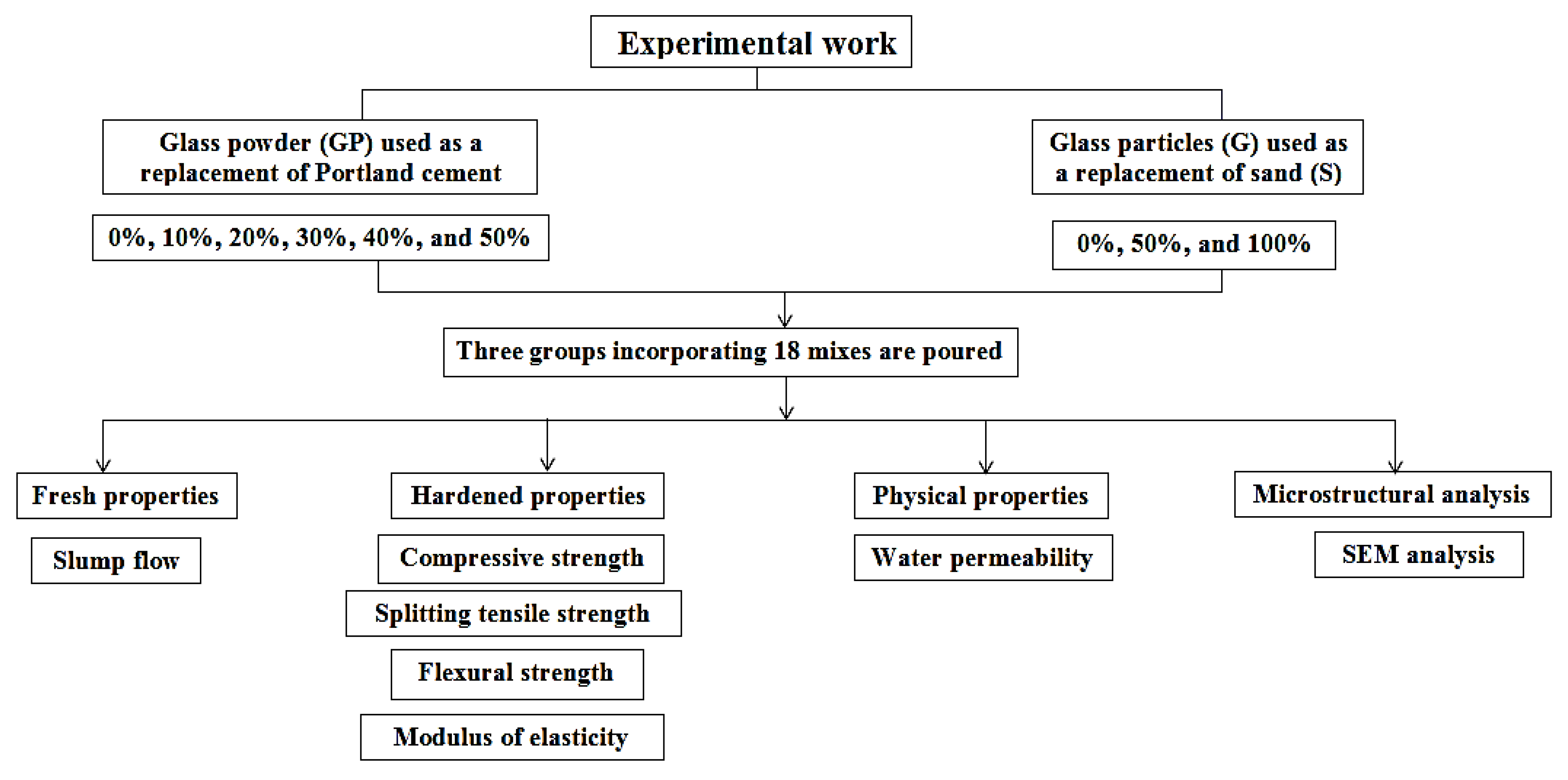

2. Experimental Work

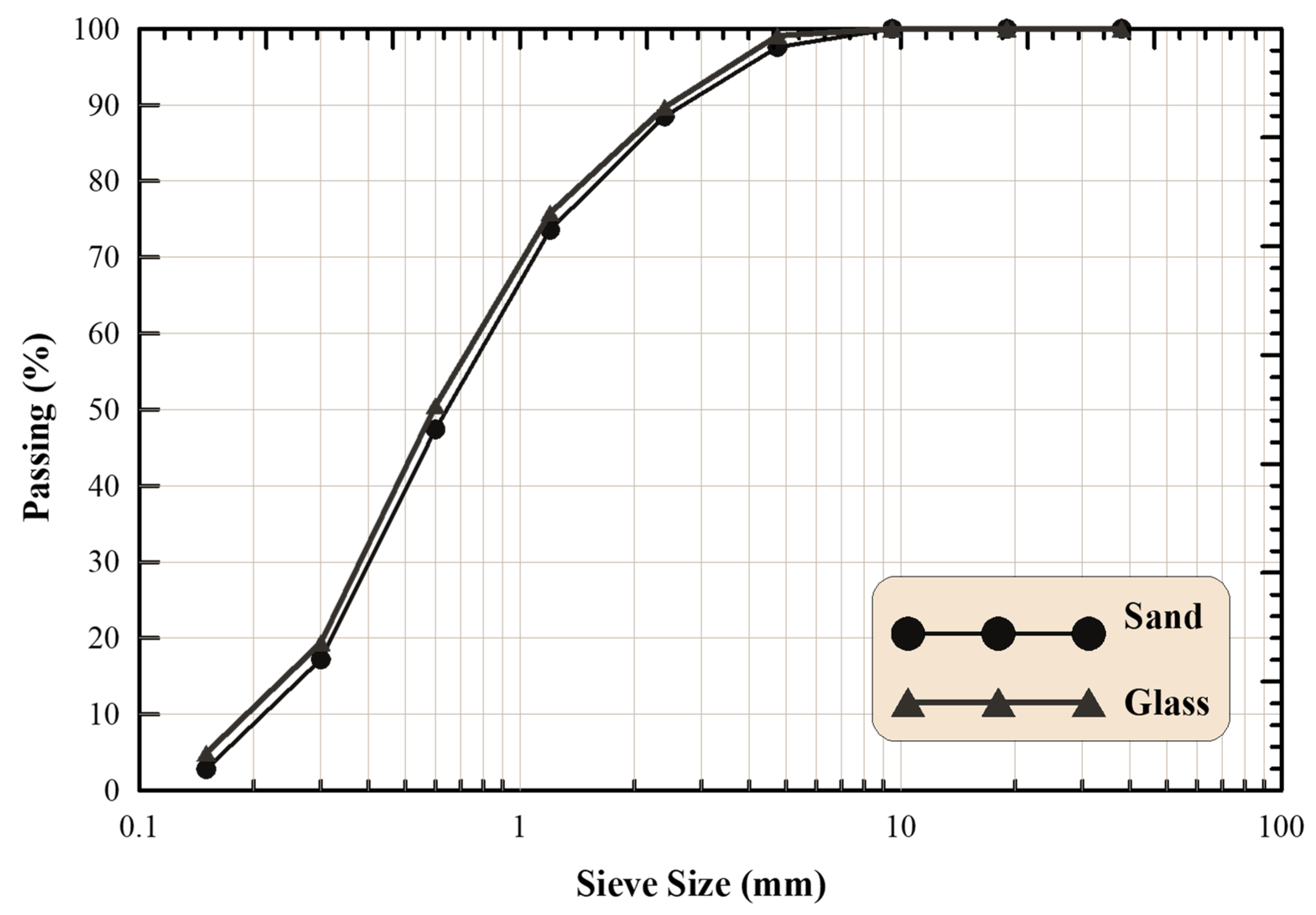

2.1. Materials Used

2.2. Research Methodology

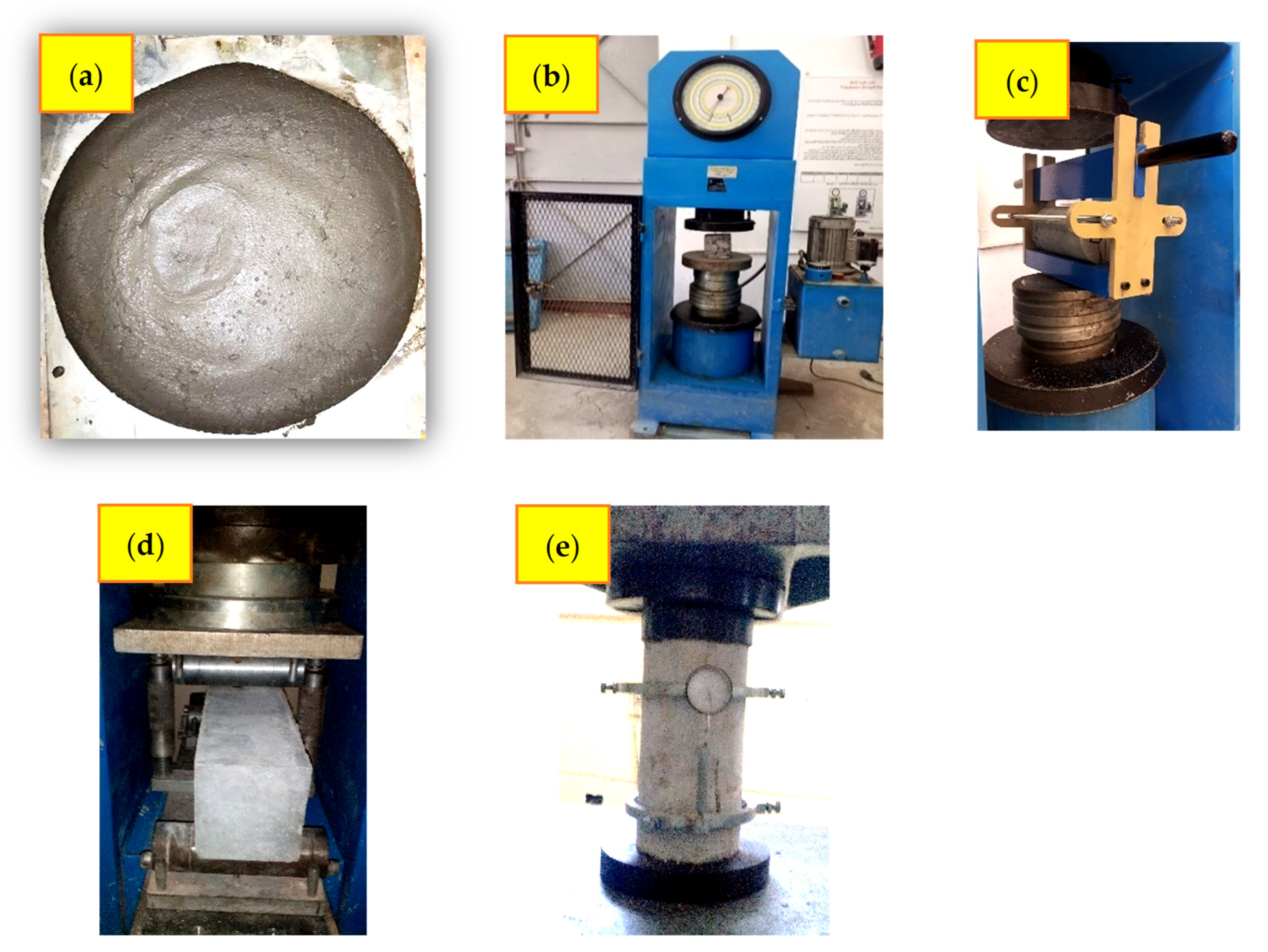

2.3. Test Procedure

3. Results and Discussion

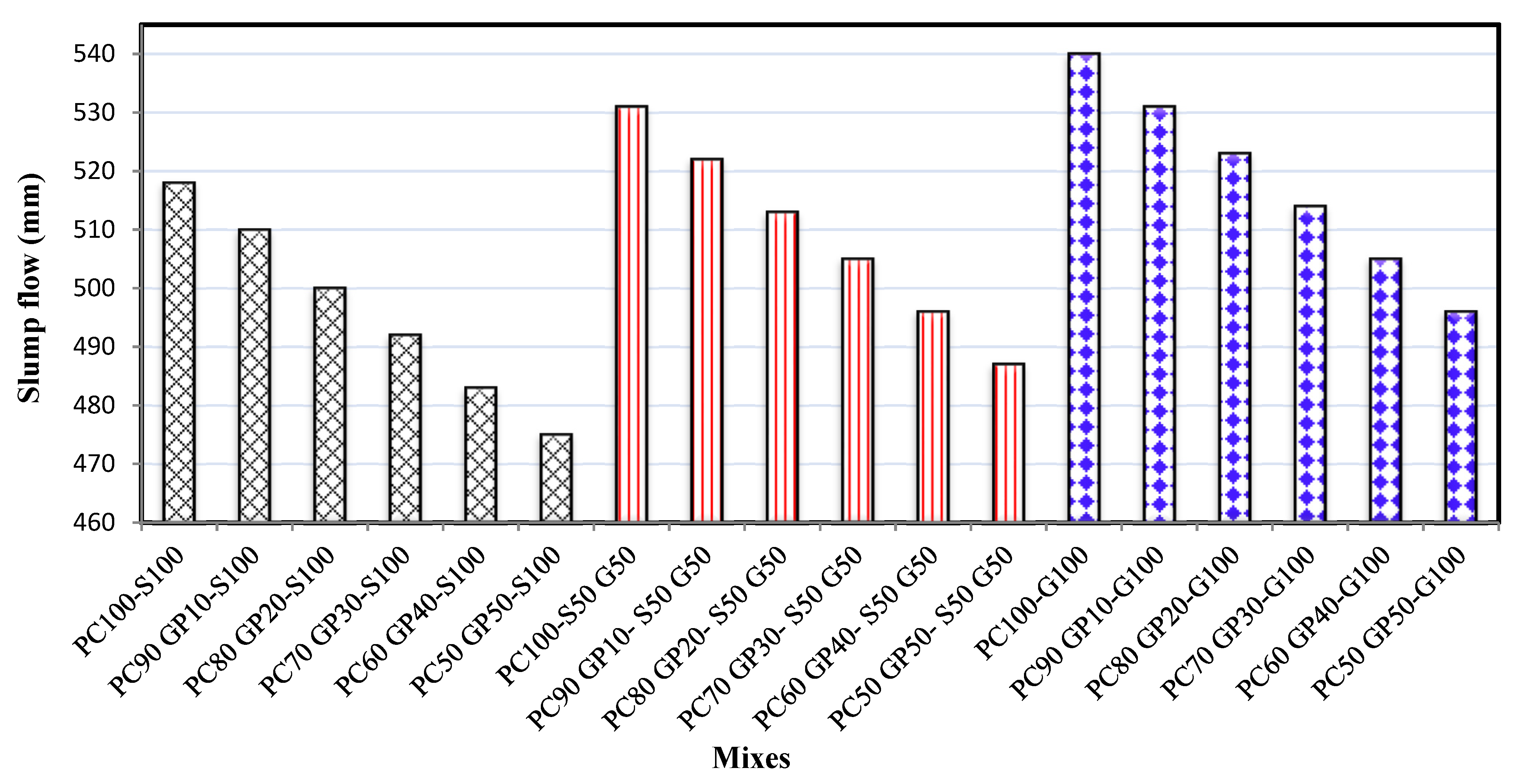

3.1. Slump Flow

3.2. Mechanical Characteristics

3.2.1. Compressive Strength

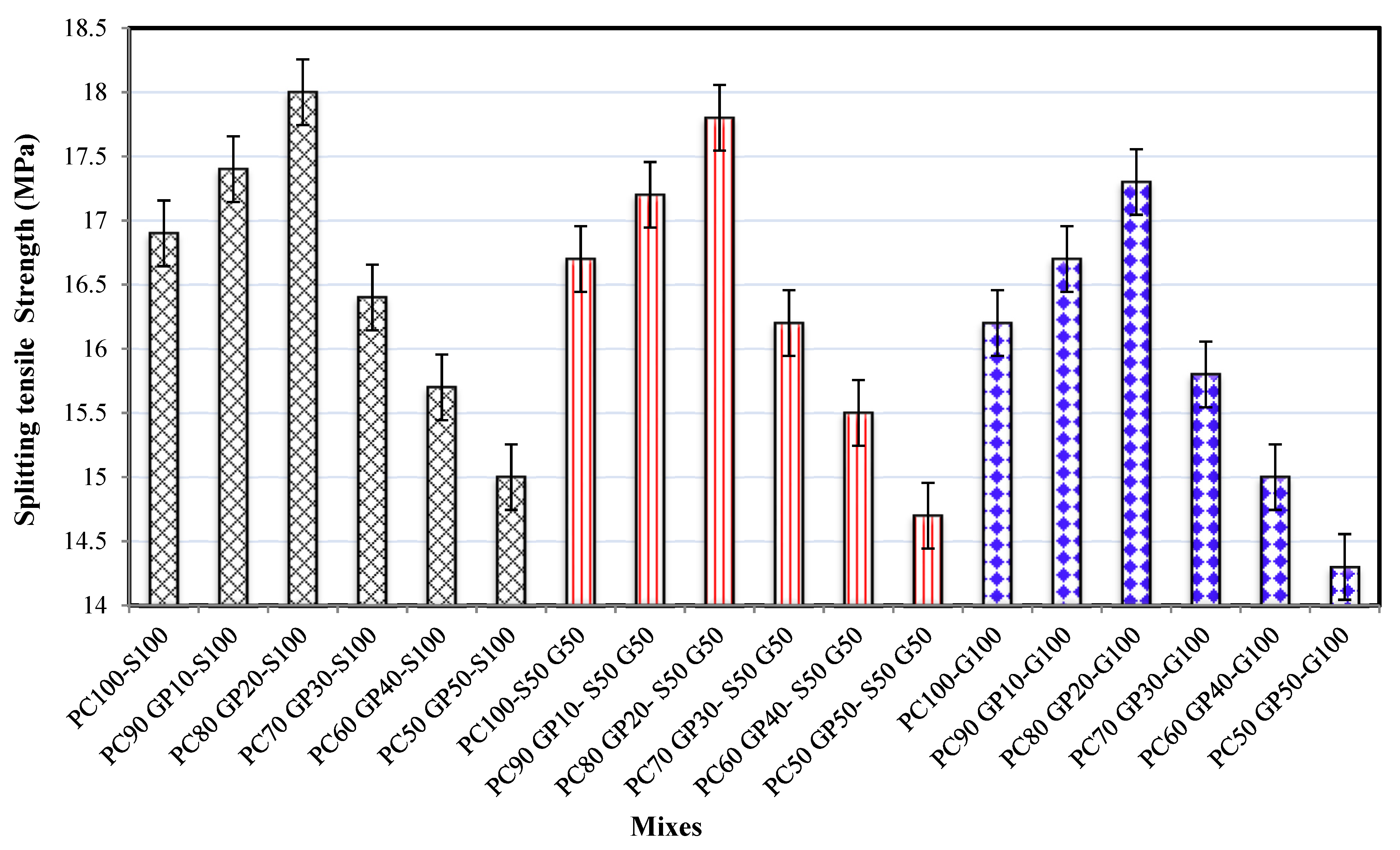

3.2.2. Splitting Tensile Strength

3.2.3. Flexural Strength

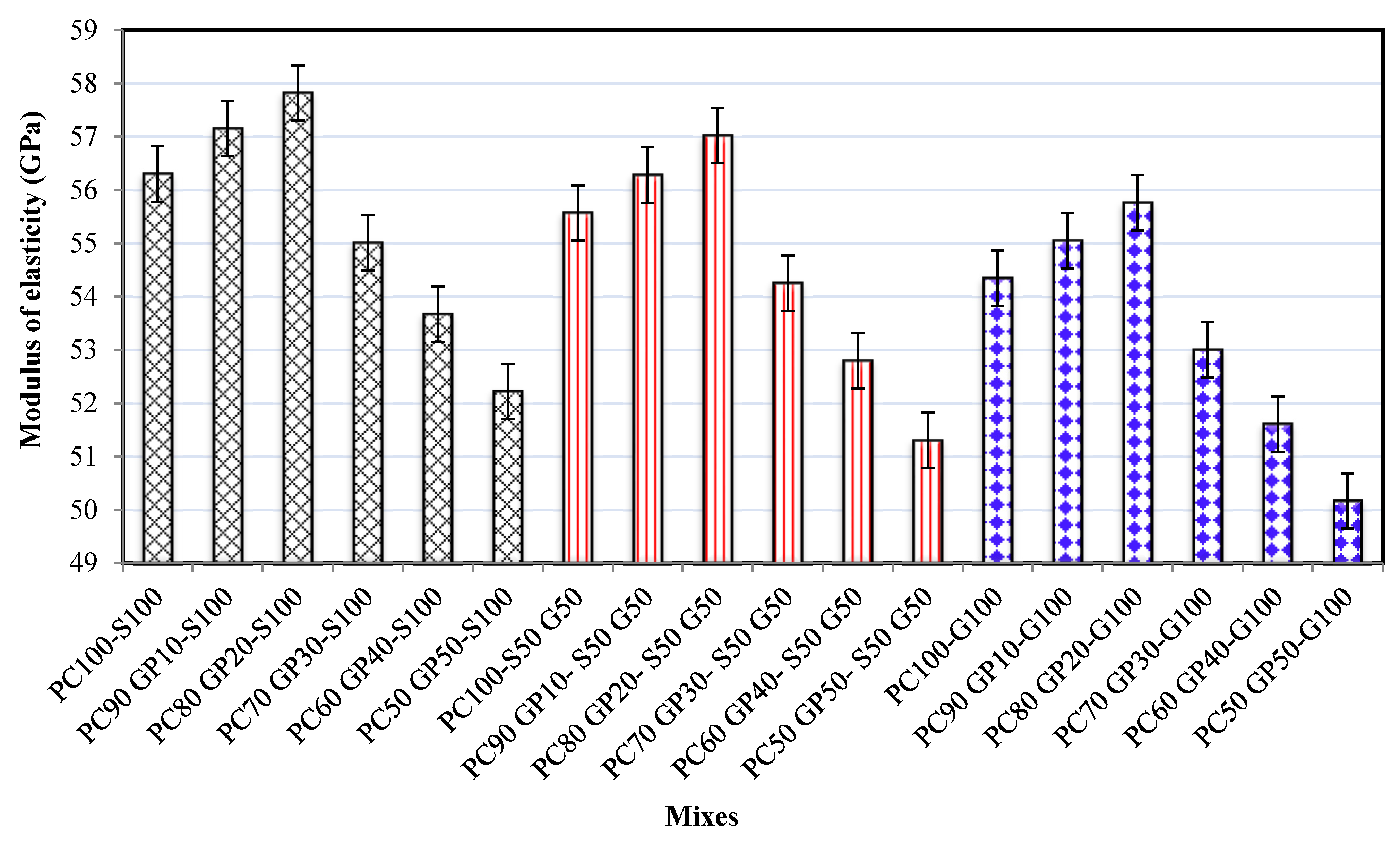

3.2.4. Modulus of Elasticity

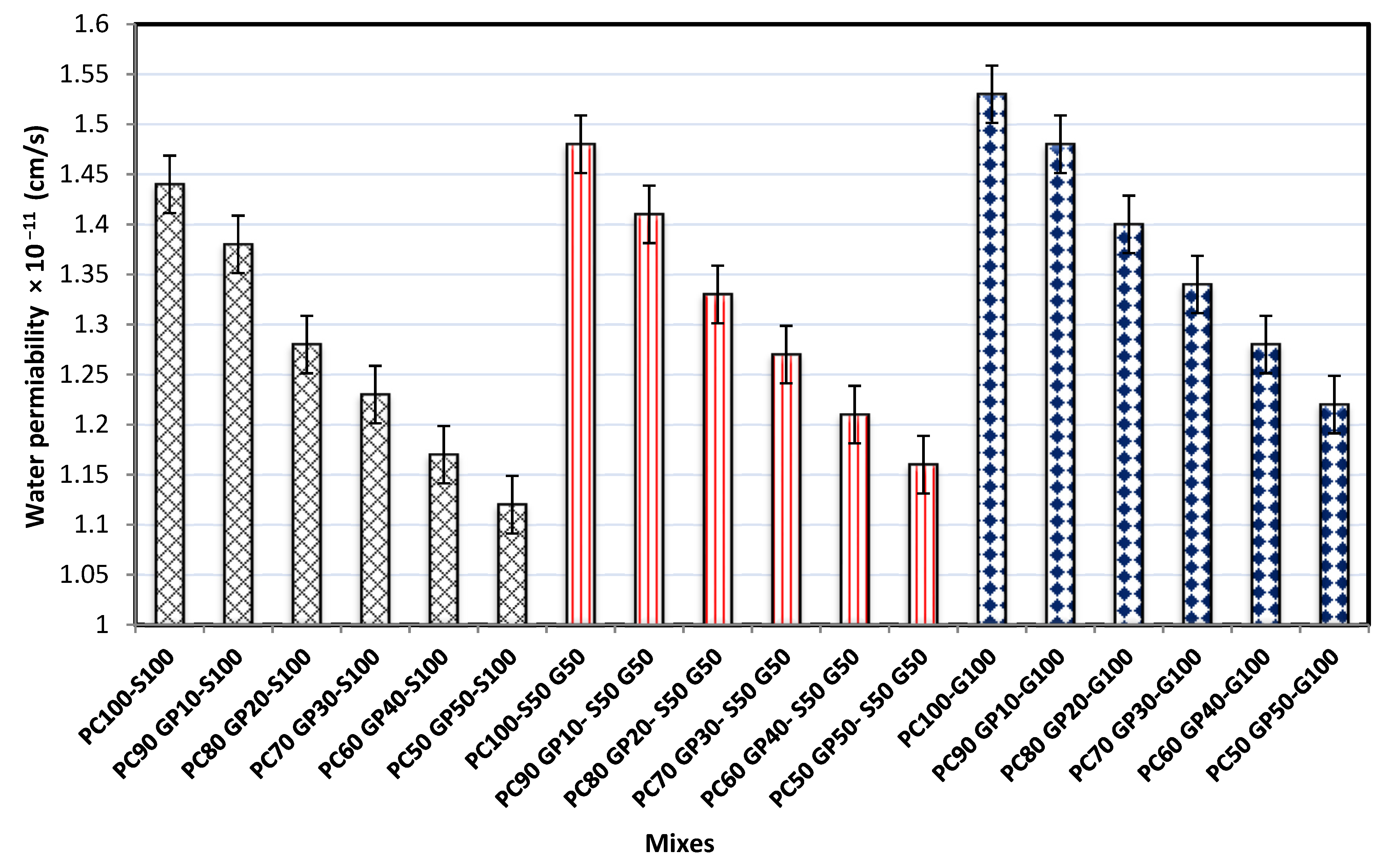

3.3. Water Permeability

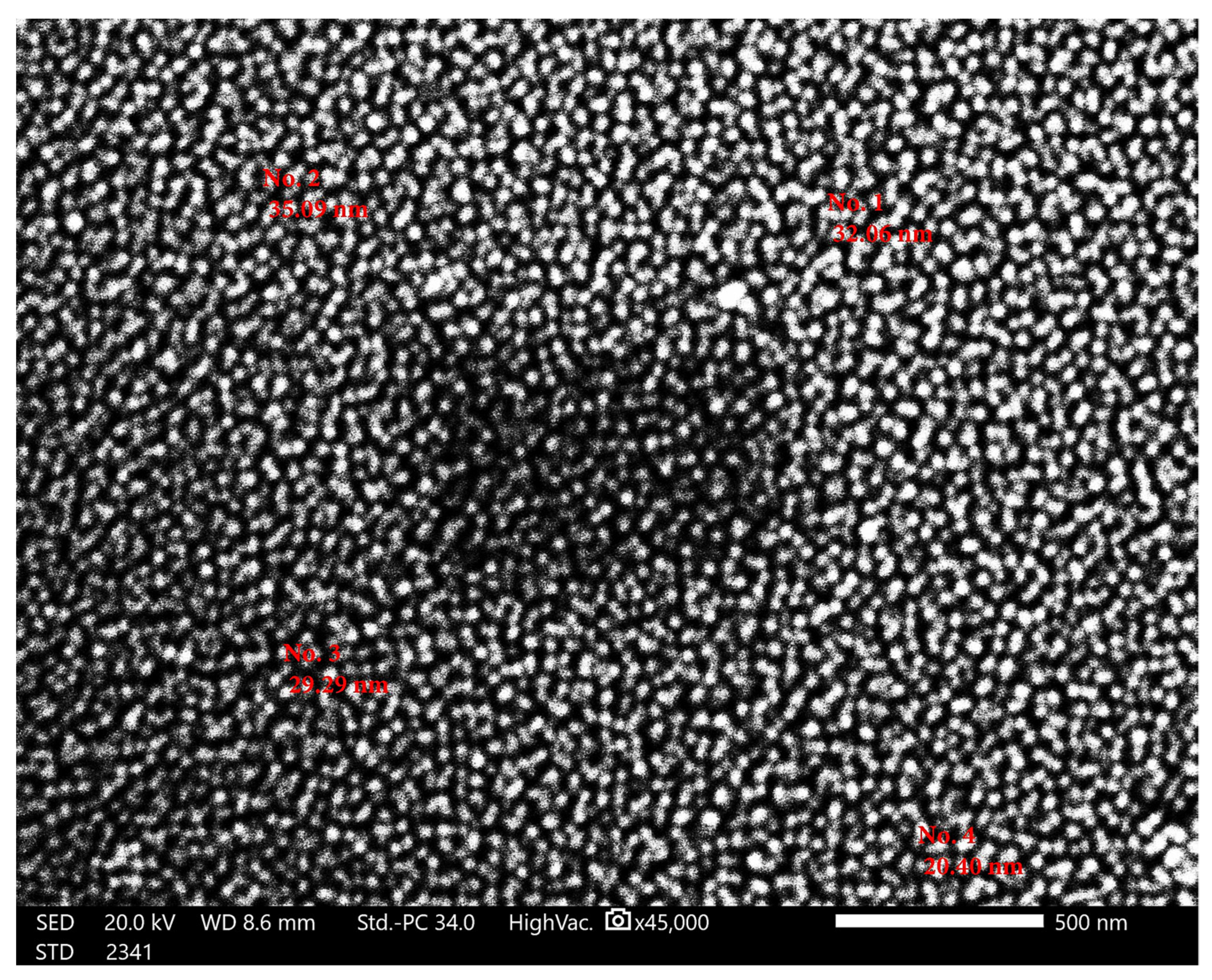

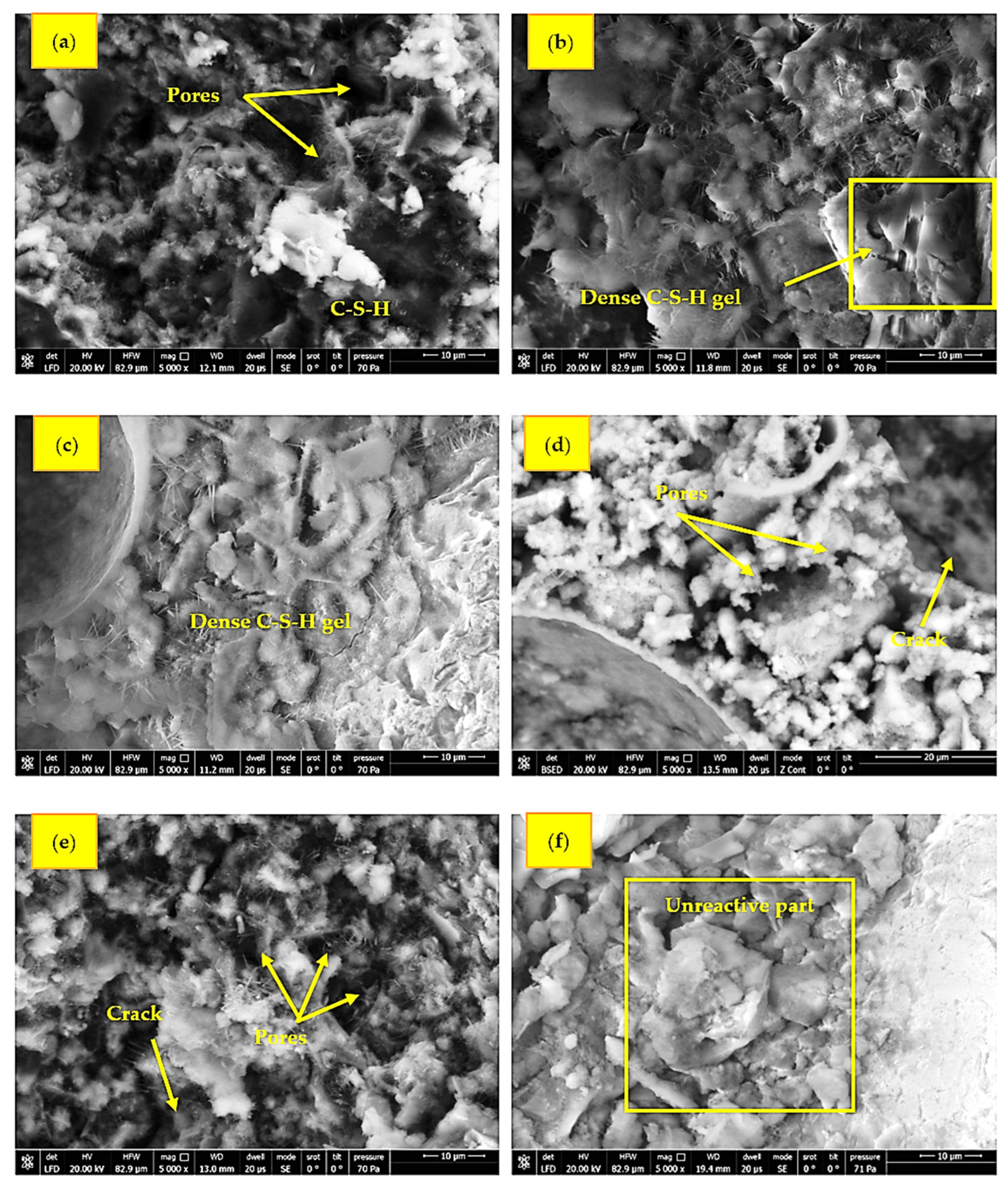

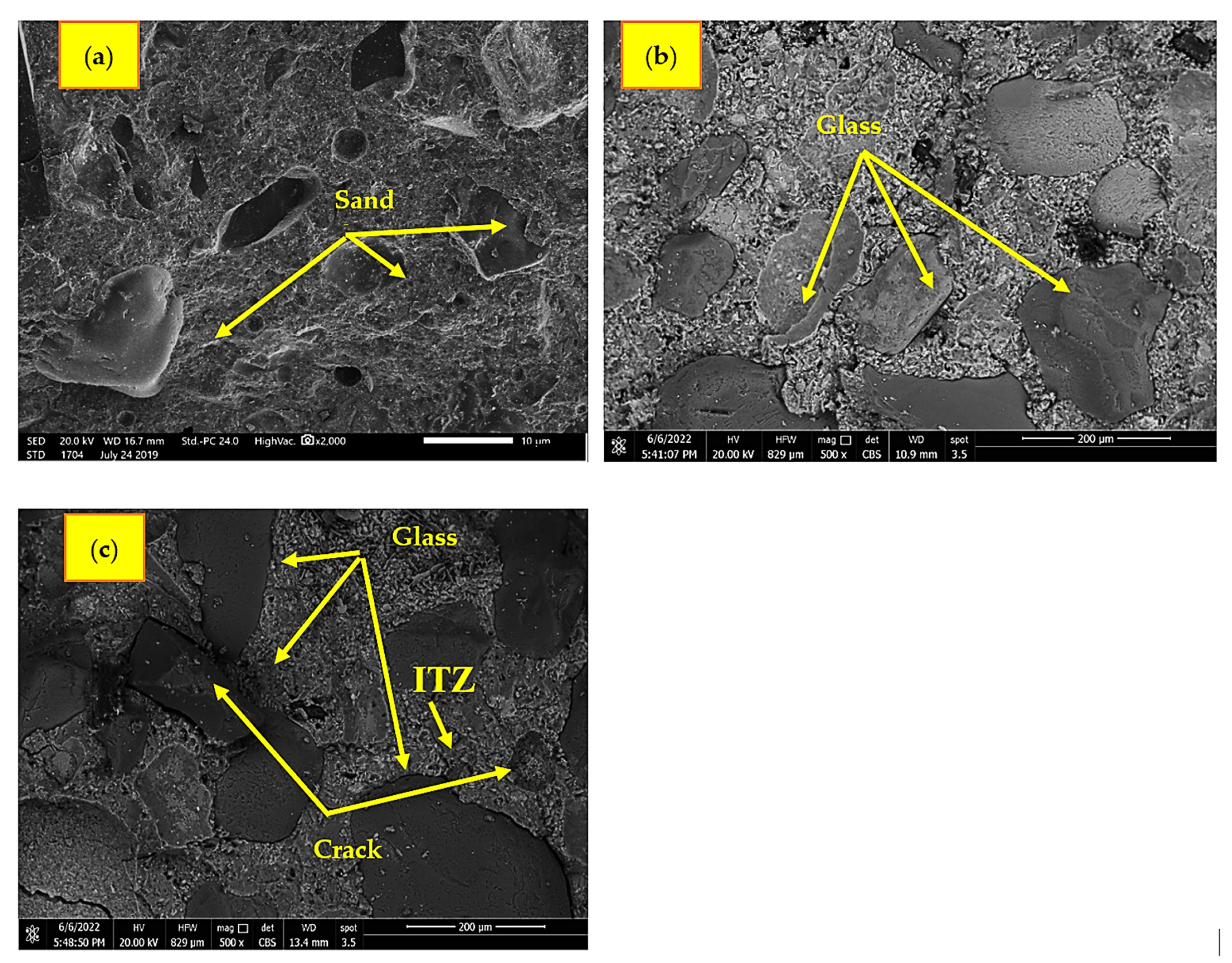

3.4. Microstructure

4. Conclusions

- Due to raising the substitution level of S with G, the workability of UHPC is enhanced. On the other hand, raising the replacement ratio of PC with GP reduces the workability of UHPC when the replacement ratio of S with G is constant;

- The optimum replacement ratios for PC with GP and S with G to manufacture an environmentally friendly and economical UHPC with high mechanical characteristics are 20% and 0%, respectively;

- Increasing the GP content in UHPC as a partial replacement for PC from 0% up to 50%, with a constant replacement ratio of S with G, has a negative impact on the compressive strength of UHPC after 1 day. On the contrary, after 7, 28, and 91 days it is noted that the compressive strength increases up to 20% replacement ratio while after that, it decreases;

- For all investigated mixtures of UHPC, the maximum obtained values for compressive strength, splitting tensile strength, flexural strength, and modulus of elasticity at 28 days were 176.3 MPa, 18 MPa, 25.7 MPa, and 57.82 GPa, respectively, when 20% replacement of PC with GP in addition to 0% replacement of S with G is implemented;

- Raising the replacement ratio of GP with PC, while keeping the substitution level of G with S constant, results in a remarkable reduction in water permeability. However, boosting the substitution level of S with G, with a constant GP to PC ratio, increases the water permeability values and leads to a notable reduction in drying shrinkage values.

5. Recommendations for Future Studies

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bilodeau, A.; Malhotra, V.M. High-volume fly ash system: Concrete solution for sustainable development. Mater. J. 2000, 97, 41–48. [Google Scholar]

- Ma, Z.; Shen, J.; Wang, C.; Wu, H. Characterization of sustainable mortar containing high-quality recycled manufactured sand crushed from recycled coarse aggregate. Cem. Concr. Compos. 2022, 132, 104629. [Google Scholar] [CrossRef]

- Darwin, D.; Dolan, C.W.; Nilson, A.H. Design of Concrete Structures; McGraw-Hill Education: New York, NY, USA, 2016; Volume 2. [Google Scholar]

- Naik, T.R.; Moriconi, G. Environmental-friendly durable concrete made with recycled materials for sustainable concrete construction. In Proceedings of the International Symposium on Sustainable Development of Cement, Concrete and Concrete Structures, Toronto, ON, Canada, 5–7 October 2005. [Google Scholar]

- Zai, A.A.R.; Salhotra, S. Effect of waste foundry sand and glass fiber on mechanical properties and fire resistance of high-strength concrete. Mater. Today Proc. 2020, 33, 1733–1740. [Google Scholar]

- Zeybek, Ö.; Özkılıç, Y.O.; Karalar, M.; Çelik, A.İ.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of Replacing Cement with Waste Glass on Mechanical Properties of Concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef] [PubMed]

- Saeed, A.; Najm, H.M.; Hassan, A.; Sabri, M.M.S.; Qaidi, S.; Mashaan, N.S.; Ansari, K. Properties and Applications of Geopolymer Composites: A Review Study of Mechanical and Microstructural Properties. Materials 2022, 15, 8250. [Google Scholar] [CrossRef]

- Dili, A.; Santhanam, M. Investigations on reactive powder concrete: A developing ultra high-strength technology. Indian Concr. J. 2004, 78, 33–38. [Google Scholar]

- Chan, Y.-W.; Chu, S.-H. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Morin, V.; Cohen-Tenoudji, F.; Feylessoufi, A.; Richard, P. Evolution of the capillary network in a reactive powder concrete during hydration process. Cem. Concr. Res. 2002, 32, 1907–1914. [Google Scholar] [CrossRef]

- Chen, B.; Ji, T.; Huang, Q.; Wu, H.; Ding, Q.; Zhan, Y. Review of research on ultra-high performance concrete. J. Archit. Civ. Eng. 2014, 31, 1–24. [Google Scholar]

- Shafieifar, M.; Farzad, M.; Azizinamini, A. Experimental and numerical study on mechanical properties of Ultra High Performance Concrete (UHPC). Constr. Build. Mater. 2017, 156, 402–411. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Van Tuan, N.; Ye, G.; Van Breugel, K.; Fraaij, A.L.; Dai Bui, D. The study of using rice husk ash to produce ultra high performance concrete. Constr. Build. Mater. 2011, 25, 2030–2035. [Google Scholar] [CrossRef]

- Klemens, T. Flexible concrete offers new solutions. Concr. Constr. 2004, 49, 72. [Google Scholar]

- Schmidt, M.; Fehling, E. Ultra-high-performance concrete: Research, development and application in Europe. ACI Spec. Publ 2005, 228, 51–78. [Google Scholar]

- Steinberg, E. Structural reliability of prestressed UHPC flexure models for bridge girders. J. Bridge Eng. 2010, 15, 65–72. [Google Scholar] [CrossRef]

- Yang, R.; Yu, R.; Shui, Z.; Gao, X.; Xiao, X.; Fan, D.; Chen, Z.; Cai, J.; Li, X.; He, Y. Feasibility analysis of treating recycled rock dust as an environmentally friendly alternative material in Ultra-High Performance Concrete (UHPC). J. Clean. Prod. 2020, 258, 120673. [Google Scholar] [CrossRef]

- Tu’ma, N.H.; Aziz, M.R. Flexural performance of composite ultra-high-performance concrete-encased steel hollow beams. Civ. Eng. J. 2019, 5, 1289–1304. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete containing waste glass as an environmentally friendly aggregate: A review on fresh and mechanical characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Heniegal, A.M.; Amin, M.; Nagib, S.; Youssef, H.; Agwa, I.S. Effect of nano ferrosilicon and heavyweight fine aggregates on the properties and radiation shielding of ultra-high performance heavyweight concrete. Case Stud. Constr. Mater. 2022, 17, e01543. [Google Scholar] [CrossRef]

- Salahaddin, S.D.; Haido, J.H.; Wardeh, G. The behavior of UHPC containing recycled glass waste in place of cementitious materials: A comprehensive review. Case Stud. Constr. Mater. 2022, 17, e01494. [Google Scholar] [CrossRef]

- Abdal, S.; Mansour, W.; Agwa, I.; Nasr, M.; Abadel, A.; Özkılıç, Y.; Akeed, M.H. Application of Ultra-High-Performance Concrete in Bridge Engineering: Current Status, Limitations, Challenges, and Future Prospects. Buildings 2023, 13, 185. [Google Scholar] [CrossRef]

- Amin, M.; Attia, M.M.; Agwa, I.S.; Elsakhawy, Y.; Abu El-hassan, K.; Abdelsalam, B.A. Effects of sugarcane bagasse ash and nano eggshell powder on high-strength concrete properties. Case Stud. Constr. Mater. 2022, 17, e01528. [Google Scholar] [CrossRef]

- Bawab, J.; Khatib, J.; El-Hassan, H.; Assi, L.; Kırgız, M.S. Properties of cement-based Materials Containing Cathode-Ray Tube (CRT) glass waste as fine aggregates—A Review. Sustainability 2021, 13, 11529. [Google Scholar] [CrossRef]

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Engineering properties of self-cured normal and high strength concrete produced using polyethylene glycol and porous ceramic waste as coarse aggregate. Constr. Build. Mater. 2021, 299, 124243. [Google Scholar] [CrossRef]

- Attia, M.M.; Abdelsalam, B.A.; Amin, M.; Agwa, I.S.; Abdelmagied, M.F. Metal-nails waste and steel slag aggregate as alternative and eco-friendly radiation shielding composites. Buildings 2022, 12, 1120. [Google Scholar] [CrossRef]

- Park, S.-B.; Lee, B.-C. Studies on expansion properties in mortar containing waste glass and fibers. Cem. Concr. Res. 2004, 34, 1145–1152. [Google Scholar] [CrossRef]

- Topcu, I.B.; Canbaz, M. Properties of concrete containing waste glass. Cem. Concr. Res. 2004, 34, 267–274. [Google Scholar] [CrossRef]

- Srikanth, K.S.; Lalitha, G. Durability properties of self compacting concrete partial replacement of fine aggregate with waste crushed glass. Mater. Today Proc. 2022, 51, 2411–2416. [Google Scholar] [CrossRef]

- Sharifi, Y.; Afshoon, I.; Firoozjaei, Z.; Momeni, A. Utilization of waste glass micro-particles in producing self-consolidating concrete mixtures. Int. J. Concr. Struct. Mater. 2016, 10, 337–353. [Google Scholar] [CrossRef]

- Adesina, A.; de Azevedo, A.R.; Amin, M.; Hadzima-Nyarko, M.; Agwa, I.S.; Zeyad, A.M.; Tayeh, B.A. Fresh and mechanical properties overview of alkali-activated materials made with glass powder as precursor. Clean. Mater. 2022, 3, 100036. [Google Scholar] [CrossRef]

- Khmiri, A.; Chaabouni, M.; Samet, B. Chemical behaviour of ground waste glass when used as partial cement replacement in mortars. Constr. Build. Mater. 2013, 44, 74–80. [Google Scholar] [CrossRef]

- Al-Saadi, T.H.A.; Daway, E.G.; Mohammad, S.H.; Mejbel, M.K. Effect of graphite additions on the intumescent behaviour of alkali-activated materials based on glass waste. J. Mater. Res. Technol. 2020, 9, 14338–14349. [Google Scholar] [CrossRef]

- Rakshvir, M.; Barai, S.V. Studies on recycled aggregates-based concrete. Waste Manag. Res. 2006, 24, 225–233. [Google Scholar] [CrossRef]

- Saeed, A.; Najm, H.M.; Hassan, A.; Qaidi, S.; Sabri, M.M.S.; Mashaan, N.S. A Comprehensive Study on the Effect of Regular and Staggered Openings on the Seismic Performance of Shear Walls. Buildings 2022, 12, 1293. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Hosseini, S.M.; Nosouhian, F.; Ozbakkaloglu, T.; Tehrani, B.N. Durability of concrete containing recycled concrete coarse and fine aggregates and milled waste glass in magnesium sulfate environment. J. Build. Eng. 2020, 29, 101182. [Google Scholar] [CrossRef]

- Sharifi, Y.; Houshiar, M.; Aghebati, B. Recycled glass replacement as fine aggregate in self-compacting concrete. Front. Struct. Civ. Eng. 2013, 7, 419–428. [Google Scholar] [CrossRef]

- Subramani, T.; Ram, S.S. Experimental study on concrete using cement with glass powder. Dep. Civ. Eng. VMKV Engg. Coll. Vinayaka Mission. Univ. Salem India 2015, 5, 43–53. [Google Scholar]

- Cadore, B.C.; Ribeiro, F.R.C.; Modolo, R.C.E.; Pacheco, F. Performance analysis of concrete with repurposed industrial glass waste. J. Build. Pathol. Rehabil. 2023, 8, 1–13. [Google Scholar] [CrossRef]

- Tamanna, N.; Sutan, N.M.; Tuladhar, R.; Lee, D.T.C.; Yakub, I. Pozzolanic properties of glass powder in cement paste. J. Civ. Eng. Sci. Technol. 2016, 7, 75–81. [Google Scholar] [CrossRef]

- Mahmoud, A.S.; Yassen, M.M.; Hama, S.M. Effect of glass powder as partial replacement of cement on concrete strength and stress-strain relationship. In Proceedings of the 2019 12th International Conference on Developments in eSystems Engineering (DeSE), Kazan, Russia, 7–10 October 2019; pp. 109–114. [Google Scholar]

- Srivastava, V.; Gautam, S.; Agarwal, V.; Mehta, P. Glass wastes as coarse aggregate in concrete. J. Environ. Nanotechnol. 2014, 3, 67–71. [Google Scholar]

- Harrison, E.; Berenjian, A.; Seifan, M. Recycling of waste glass as aggregate in cement-based materials. Environ. Sci. Ecotechnology 2020, 4, 100064. [Google Scholar] [CrossRef] [PubMed]

- Okeke, K.; Adedeji, A. A Review on the Properties of Concrete incorporated with Waste Glass as a Substitute for Cement. Epistem. Sci. Eng. Technol 2016, 5, 396–407. [Google Scholar]

- Oliveira, L.A.P.d.; Gomes, J.C.; Santos, P. Mechanical and durability properties of concrete with ground waste glass sand. In Proceedings of the 11DBMC International Conference on Durability of Building Materials and Components, Istanbul, Turkey, 11–14 May 2008. [Google Scholar]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Ahmed, H.U.; Al Dughaishi, H.; Al Lawati, J.; Sabri, M.M.; Alkhatib, F.; Milad, A. Fly Ash-Based Geopolymer Composites: A Review of the Compressive Strength and Microstructure Analysis. Materials 2022, 15, 7098. [Google Scholar] [CrossRef] [PubMed]

- Althoey, F.; Hakeem, I.Y.; Hosen, M.A.; Qaidi, S.; Isleem, H.F.; Hadidi, H.; Shahapurkar, K.; Ahmad, J.; Ali, E. Behavior of Concrete Reinforced with Date Palm Fibers. Materials 2022, 15, 7923. [Google Scholar] [CrossRef] [PubMed]

- Letelier, V.; Henríquez-Jara, B.I.; Manosalva, M.; Parodi, C.; Ortega, J.M. Use of waste glass as a replacement for raw materials in mortars with a lower environmental impact. Energies 2019, 12, 1974. [Google Scholar] [CrossRef]

- Shao, Y.; Lefort, T.; Moras, S.; Rodriguez, D. Studies on concrete containing ground waste glass. Cem. Concr. Res. 2000, 30, 91–100. [Google Scholar] [CrossRef]

- Khmiri, A.; Samet, B.; Chaabouni, M. A cross mixture design to optimise the formulation of a ground waste glass blended cement. Constr. Build. Mater. 2012, 28, 680–686. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Al-Hashmi, E.A. Recycling of waste glass as a partial replacement for fine aggregate in concrete. Waste Manag. 2009, 29, 655–659. [Google Scholar] [CrossRef]

- Tejaswi, S.S.; Rao, R.C.; Vidya, B.; Renuka, J. Experimental investigation of waste glass powder as partial replacement of cement and sand in concrete. IUP J. Struct. Eng. 2015, 8, 14. [Google Scholar]

- Shayan, A. Value-added utilisation of waste glass in concrete, iabse symposium melbourne. Cem. Concr. Res. 2002, 23, 58–66. [Google Scholar]

- Ali, S.; Scott, A.; Mackechine, J. Effects of waste glass on strength and durability characteristics of self-compacting concrete. In Proceedings of the NZ Concrete Industry Conference 2015, Rotorua, New Zealand, 8–10 October 2015. [Google Scholar]

- Shi, C.; Wu, Y.; Riefler, C.; Wang, H. Characteristics and pozzolanic reactivity of glass powders. Cem. Concr. Res. 2005, 35, 987–993. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, Y.; Liao, S.; Huang, Y. Grinding kinetics of waste glass powder and its composite effect as pozzolanic admixture in cement concrete. Constr. Build. Mater. 2020, 239, 117876. [Google Scholar] [CrossRef]

- Onaizi, A.M.; Huseien, G.F.; Shukor Lim, N.H.A.; Tang, W.C.; Alhassan, M.; Samadi, M. Effective Microorganisms and Glass Nanopowders from Waste Bottle Inclusion on Early Strength and Microstructure Properties of High-Volume Fly-Ash-Based Concrete. Biomimetics 2022, 7, 190. [Google Scholar] [CrossRef]

- Rasid, N.N.A.; Khalid, N.H.A.; Mohamed, A.; Mohd.Sam, A.R.; Majid, Z.A.; Huseien, G.F. Ground palm oil fuel ash and calcined eggshell powder as SiO2–CaO based accelerator in green concrete. J. Build. Eng. 2023, 65, 105617. [Google Scholar] [CrossRef]

- Noor Abbas, A.-G.; Nora Aznieta Abdul Aziz, F.; Abdan, K.; Azline Mohd Nasir, N.; Fahim Huseien, G. Experimental evaluation and statistical modeling of kenaf fiber-reinforced geopolymer concrete. Constr. Build. Mater. 2023, 367, 130228. [Google Scholar] [CrossRef]

- Dong, Z.; Dai, J.; Deng, M.; Wu, Z. Experimental study on the mechanical properties of textile reinforced mortar (TRM) composites with different yarn shapes subjected to uniaxial tension. Arch. Civ. Mech. Eng. 2022, 22, 185. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.A.; Rafiq, S.; Mohammed, A.S.; Mosavi, A.; Sor, N.H.; Qaidi, S.M.A. Compressive Strength of Sustainable Geopolymer Concrete Composites: A State-of-the-Art Review. Sustainability 2021, 13, 13502. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Akeed, M.H.; Qaidi, S.; Bakar, B.H.A. Influence of the proportion of materials on the rheology and mechanical strength of ultrahigh-performance concrete. Case Stud. Constr. Mater. 2022, 17, e01433. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Tuyan, M.; Ramyar, K. Mechanical and durability performance of concrete incorporating fine recycled concrete and glass aggregates. Mater. Struct. 2015, 48, 2629–2640. [Google Scholar] [CrossRef]

- Gerges, N.N.; Issa, C.A.; Fawaz, S.A.; Jabbour, J.; Jreige, J.; Yacoub, A. Recycled glass concrete: Coarse and fine aggregates. Eur. J. Eng. Technol. Res. 2018, 3, 1–9. [Google Scholar]

- Park, S.B.; Lee, B.C.; Kim, J.H. Studies on mechanical properties of concrete containing waste glass aggregate. Cem. Concr. Res. 2004, 34, 2181–2189. [Google Scholar] [CrossRef]

- Ling, T.-C.; Poon, C.-S. A comparative study on the feasible use of recycled beverage and CRT funnel glass as fine aggregate in cement mortar. J. Clean. Prod. 2012, 29, 46–52. [Google Scholar] [CrossRef]

- Ali, E.E.; Al-Tersawy, S.H. Recycled glass as a partial replacement for fine aggregate in self compacting concrete. Constr. Build. Mater. 2012, 35, 785–791. [Google Scholar] [CrossRef]

- Sikora, P.; Augustyniak, A.; Cendrowski, K.; Horszczaruk, E.; Rucinska, T.; Nawrotek, P.; Mijowska, E. Characterization of mechanical and bactericidal properties of cement mortars containing waste glass aggregate and nanomaterials. Materials 2016, 9, 701. [Google Scholar] [CrossRef] [PubMed]

- Tan, K.H.; Du, H. Use of waste glass as sand in mortar: Part I–Fresh, mechanical and durability properties. Cem. Concr. Compos. 2013, 35, 109–117. [Google Scholar] [CrossRef]

- Tuaum, A.; Shitote, S.; Oyawa, W. Experimental study of self-compacting mortar incorporating recycled glass aggregate. Buildings 2018, 8, 15. [Google Scholar] [CrossRef]

- Turgut, P.; Yahlizade, E. Research into concrete blocks with waste glass. Int. J. Civ. Environ. Eng. 2009, 3, 186–192. [Google Scholar]

- Unis Ahmed, H.; Mahmood, L.J.; Muhammad, M.A.; Faraj, R.H.; Qaidi, S.M.A.; Hamah Sor, N.; Mohammed, A.S.; Mohammed, A.A. Geopolymer concrete as a cleaner construction material: An overview on materials and structural performances. Clean. Mater. 2022, 5, 100111. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Akeed, M.H.; Qaidi, S.; Bakar, B.H.A. Influence of microsilica and polypropylene fibers on the fresh and mechanical properties of ultra-high performance geopolymer concrete (UHP-GPC). Case Stud. Constr. Mater. 2022, 17, e01367. [Google Scholar] [CrossRef]

- Amin, M.; Tayeh, B.A.; Kandil, M.A.; Agwa, I.S.; Abdelmagied, M.F. Effect of rice straw ash and palm leaf ash on the properties of ultrahigh-performance concrete. Case Stud. Constr. Mater. 2022, 17, e01266. [Google Scholar] [CrossRef]

- Agwa, I.S.; Zeyad, A.M.; Tayeh, B.A.; Amin, M. Effect of different burning degrees of sugarcane leaf ash on the properties of ultrahigh-strength concrete. J. Build. Eng. 2022, 56, 104773. [Google Scholar] [CrossRef]

- EN 197-1:2011; Cement-Part 1: Composition, specifications and conformity criteria for common Cements. British Standards Institution: London, UK, 2011.

- ASTM C1240-20; Standard Specification for Silica Fume Used in Cementitious Mixtures. ASTM International: West Conshohocken, PA, USA, 2005.

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Effect of ferrosilicon and silica fume on mechanical, durability, and microstructure characteristics of ultra high-performance concrete. Constr. Build. Mater. 2022, 320, 126233. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Elgendy, G.M.; Amin, M. Mechanical properties of affordable and sustainable ultra-high-performance concrete. Case Stud. Constr. Mater. 2022, 16, e01069. [Google Scholar] [CrossRef]

- ASTM C33; Standard Specification for Concrete Aggregates. American Society for Testing and Materials: Philadelphia, PA, USA, 2003.

- Hakeem, I.Y.; Amin, M.; Abdelsalam, B.A.; Tayeh, B.A.; Althoey, F.; Agwa, I.S. Effects of nano-silica and micro-steel fiber on the engineering properties of ultra-high performance concrete. Struct. Eng. Mech. 2022, 82, 295–312. [Google Scholar]

- Soliman, N.; Tagnit-Hamou, A. Partial substitution of silica fume with fine glass powder in UHPC: Filling the micro gap. Constr. Build. Mater. 2017, 139, 374–383. [Google Scholar] [CrossRef]

- Esmaeili, J.; AL-Mwanes, A.O. Performance Evaluation of Eco-Friendly Ultra-High-Performance Concrete Incorporated with Waste Glass-A Review. In Proceedings of the 1st International Conference on Sustainable Engineering and Technology (INTCSET 2020), Baghdad, Iraq, 15–16 December 2020; p. 012030. [Google Scholar]

- Shayan, A.; Xu, A. Performance of glass powder as a pozzolanic material in concrete: A field trial on concrete slabs. Cem. Concr. Res. 2006, 36, 457–468. [Google Scholar] [CrossRef]

- Taha, B.; Nounu, G. Utilizing waste recycled glass as sand/cement replacement in concrete. J. Mater. Civ. Eng. 2009, 21, 709–721. [Google Scholar] [CrossRef]

- Soliman, N.; Tagnit-Hamou, A. Development of ultra-high-performance concrete using glass powder–Towards ecofriendly concrete. Constr. Build. Mater. 2016, 125, 600–612. [Google Scholar] [CrossRef]

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2018.

- Yu, R.; Spiesz, P.; Brouwers, H. Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- ASTM C 494; Standard Specification for Chemical Admixtures for Concrete. Annual Book of ASTM Standards. ASTM Standards: West Conshohocken, PA, USA, 2013.

- EN 934-2:2001; Admixtures for Concrete, Mortar and Grout—Part 2: Concrete Admixtures - Definitions, Requirements, Conformity, Marking and Labelling. British Standards Institution: London, UK, 2001.

- Aliabdo, A.A.; Abd Elmoaty, M.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- ASTM C192/C192M-14; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C1437; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2002.

- EN 12390-3:2019; Testing Hardened Concrete—Compressive Strength of Test Specimens. British Standards Institution: London, UK, 2002.

- ASTM C496-96; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2004.

- ASTM C78/C78M-22; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2010; pp. 12959–19428.

- ASTM C469–02; Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression. ASTM International: West Conshohocken, PA, USA, 2002.

- EN 12390-8:2019; Testing Hardened Concrete–Part 8: Depth of Penetration of Water under Pressure. British Standards Institution: London, UK, 2009.

- Mohammed, A.N.; Johari, M.A.M.; Zeyad, A.M.; Tayeh, B.A.; Yusuf, M.O. Improving the engineering and fluid transport properties of ultra-high strength concrete utilizing ultrafine palm oil fuel ash. J. Adv. Concr. Technol. 2014, 12, 127–137. [Google Scholar] [CrossRef]

- Johari, M.M.; Brooks, J.; Kabir, S.; Rivard, P. Influence of supplementary cementitious materials on engineering properties of high strength concrete. Constr. Build. Mater. 2011, 25, 2639–2648. [Google Scholar] [CrossRef]

- Tamanna, N.; Tuladhar, R.; Sivakugan, N. Performance of recycled waste glass sand as partial replacement of sand in concrete. Constr. Build. Mater. 2020, 239, 117804. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Tao, Z. A comprehensive review on performance of cementitious and geopolymeric concretes with recycled waste glass as powder, sand or cullet. Resour. Conserv. Recycl. 2021, 172, 105664. [Google Scholar] [CrossRef]

- Alani, A.H.; Bunnori, N.M.; Noaman, A.T.; Majid, T. Mechanical characteristics of PET fibre-reinforced green ultra-high performance composite concrete. Eur. J. Environ. Civ. Eng. 2022, 26, 2797–2818. [Google Scholar] [CrossRef]

- Faried, A.S.; Mostafa, S.A.; Tayeh, B.A.; Tawfik, T.A. Mechanical and durability properties of ultra-high performance concrete incorporated with various nano waste materials under different curing conditions. J. Build. Eng. 2021, 43, 102569. [Google Scholar] [CrossRef]

| Properties | Portland Cement | Silica Fume | Glass Powder |

|---|---|---|---|

| Physical | |||

| Specific gravity | 3.15 | 2.15 | 2.60 |

| Initial setting time (min) | 71 | - | - |

| Final setting time (min) | 309 | - | - |

| Specific area (cm2/gm) | 3495 | 21,160 | 5630 |

| Color | Gray | Light Gray | White |

| Chemical compositions (%) | |||

| SiO2 | 21.95 | 98.76 | 75.10 |

| Al2O3 | 3.97 | 0.27 | 1.69 |

| Fe2O3 | 4.28 | 0.28 | 0.36 |

| CaO | 60.86 | 0.15 | 10.97 |

| MgO | 4.55 | 0.14 | 0.90 |

| SO3 | 2.18 | 0.13 | 0.13 |

| K2O | 0.75 | 0.14 | 0.20 |

| Na2O | 0.83 | 0.13 | 10.65 |

| LOI | 0.63 | - | - |

| Properties | Quartz Powder |

|---|---|

| Physical | |

| Specific gravity | 2.57 |

| Specific area (cm2/gm) | 5520 |

| Color | White |

| Chemical compositions (%) | |

| SiO2 | 97.18 |

| Al2O3 | 0.38 |

| Fe2O3 | 0.49 |

| CaO | 0.86 |

| SO3 | 1.09 |

| Properties | Sand | Glass Particles |

|---|---|---|

| Specific gravity | 2.67 | 2.63 |

| Unit weight (kg/m3) | 1695 | 1865 |

| Water absorption (%) | 0.85 | 0.65 |

| Clay and fine materials (%) | 0.47 | 0.30 |

| Length (mm) | Diameter (µm) | Aspect Ratio | Modulus of Elasticity (GPa) | Density (g/cm3) |

|---|---|---|---|---|

| 12 | 150 | 80.3 | 190 | 7.85 |

| Mixture ID | Portland Cement | Silica Fume | Quartz Powder | Glass Powder | Sand | Glass Particles | Steel Fiber | Superplasticizer | Water |

|---|---|---|---|---|---|---|---|---|---|

| PC100-S100 | 1000 | 200 | 150 | 0 | 701.5 | 0 | 117 | 26.4 | 228 |

| PC90 GP10-S100 | 900 | 200 | 150 | 100 | 683.6 | 0 | 117 | 26.4 | 228 |

| PC80 GP20-S100 | 800 | 200 | 150 | 200 | 665.8 | 0 | 117 | 26.4 | 228 |

| PC70 GP30-S100 | 700 | 200 | 150 | 300 | 647.9 | 0 | 117 | 26.4 | 228 |

| PC60 GP40-S100 | 600 | 200 | 150 | 400 | 630.0 | 0 | 117 | 26.4 | 228 |

| PC50 GP50-S100 | 500 | 200 | 150 | 500 | 612.2 | 0 | 117 | 26.4 | 228 |

| PC100-S50 G50 | 1000 | 200 | 150 | 0 | 347.9 | 347.9 | 117 | 26.4 | 228 |

| PC90 GP10-S50 G50 | 900 | 200 | 150 | 100 | 339.1 | 339.1 | 117 | 26.4 | 228 |

| PC80 GP20-S50 G50 | 800 | 200 | 150 | 200 | 330.2 | 330.2 | 117 | 26.4 | 228 |

| PC70 GP30-S50 G50 | 700 | 200 | 150 | 300 | 321.3 | 321.3 | 117 | 26.4 | 228 |

| PC60 GP40-S50 G50 | 600 | 200 | 150 | 400 | 312.5 | 312.5 | 117 | 26.4 | 228 |

| PC50 GP50-S50 G50 | 500 | 200 | 150 | 500 | 303.6 | 303.6 | 117 | 26.4 | 228 |

| PC100-G100 | 1000 | 200 | 150 | 0 | 0 | 690.9 | 117 | 26.4 | 228 |

| PC90 GP10-G100 | 900 | 200 | 150 | 100 | 0 | 673.3 | 117 | 26.4 | 228 |

| PC80 GP20-G100 | 800 | 200 | 150 | 200 | 0 | 655.7 | 117 | 26.4 | 228 |

| PC70 GP30-G100 | 700 | 200 | 150 | 300 | 0 | 638.2 | 117 | 26.4 | 228 |

| PC60 GP40-G100 | 600 | 200 | 150 | 400 | 0 | 620.6 | 117 | 26.4 | 228 |

| PC50 GP50-G100 | 500 | 200 | 150 | 500 | 0 | 602.9 | 117 | 26.4 | 228 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amin, M.; Agwa, I.S.; Mashaan, N.; Mahmood, S.; Abd-Elrahman, M.H. Investigation of the Physical Mechanical Properties and Durability of Sustainable Ultra-High Performance Concrete with Recycled Waste Glass. Sustainability 2023, 15, 3085. https://doi.org/10.3390/su15043085

Amin M, Agwa IS, Mashaan N, Mahmood S, Abd-Elrahman MH. Investigation of the Physical Mechanical Properties and Durability of Sustainable Ultra-High Performance Concrete with Recycled Waste Glass. Sustainability. 2023; 15(4):3085. https://doi.org/10.3390/su15043085

Chicago/Turabian StyleAmin, Mohamed, Ibrahim Saad Agwa, Nuha Mashaan, Shaker Mahmood, and Mahmoud H. Abd-Elrahman. 2023. "Investigation of the Physical Mechanical Properties and Durability of Sustainable Ultra-High Performance Concrete with Recycled Waste Glass" Sustainability 15, no. 4: 3085. https://doi.org/10.3390/su15043085

APA StyleAmin, M., Agwa, I. S., Mashaan, N., Mahmood, S., & Abd-Elrahman, M. H. (2023). Investigation of the Physical Mechanical Properties and Durability of Sustainable Ultra-High Performance Concrete with Recycled Waste Glass. Sustainability, 15(4), 3085. https://doi.org/10.3390/su15043085