Economic Feasibility of a Hybrid Microgrid System for a Distributed Substation

Abstract

1. Introduction

2. HOMER Analysis

3. Microgrid Components

3.1. Location of Selected Village

3.2. Survey of Electrical Load

3.3. Energy Components

4. Microgrid Modelling

4.1. PV–Generator–Battery (Off-Grid)

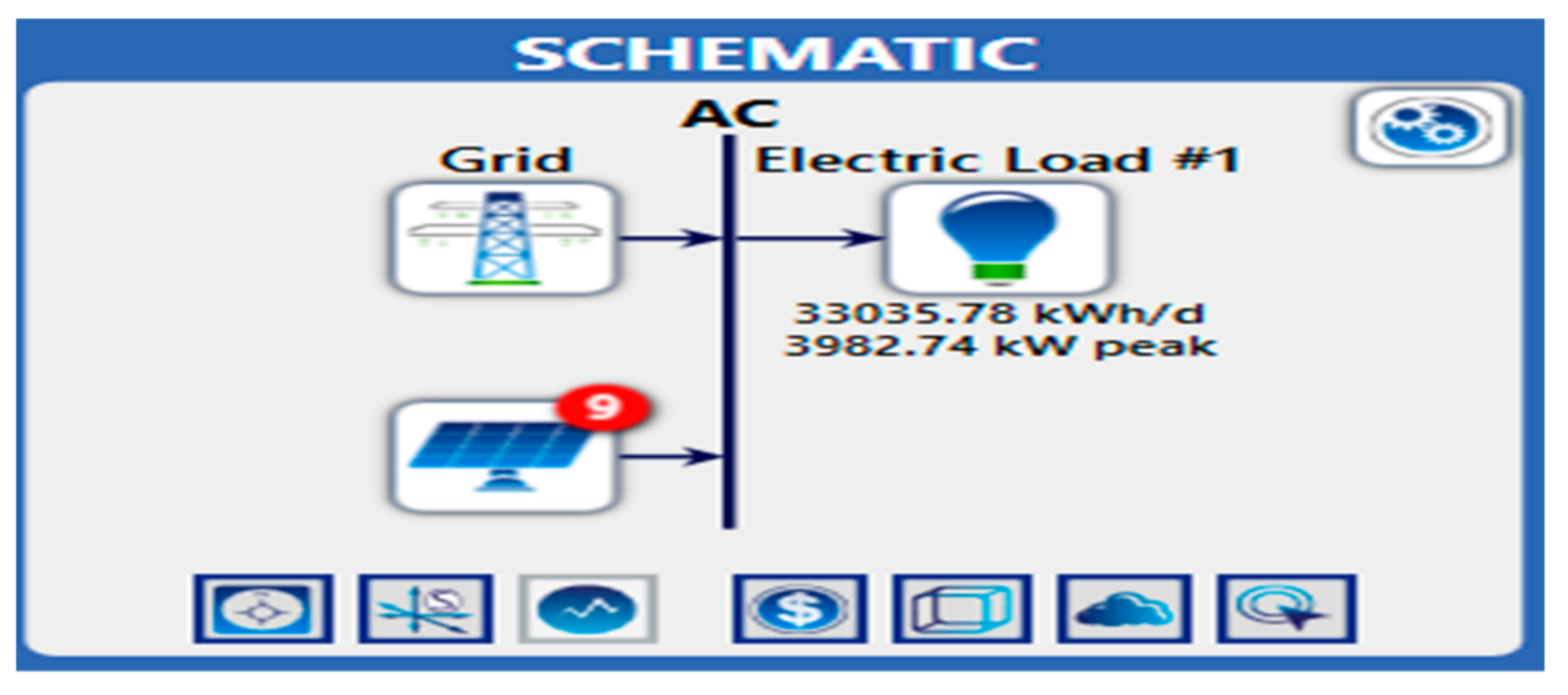

4.2. PV–Grid–Battery (Hybrid)

4.3. PV–Grid (On-Grid)

5. Results and Discussions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fayek, H.H.; Rusu, E. Novel Combined Load Frequency Control and Automatic Voltage Regulation of a 100% Sustainable Energy Interconnected Microgrids. Sustainability 2022, 14, 9428. [Google Scholar] [CrossRef]

- Fayek, H.H.; Abdalla, O.H. Operation of the Egyptian Power Grid with Maximum Penetration Level of Renewable Energies Using Corona Virus Optimization Algorithm. Smart Cities 2022, 5, 34–53. [Google Scholar] [CrossRef]

- Pakkan, S.; Sudhakar, C.; Tripathi, S.; Rao, M. A correlation study of sustainable development goal (SDG) interactions. In Quality & Quantity; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Pradhan, P.; Costa, L.; Rybski, D.; Lucht, W.; Kropp, J.P. A Systematic Study of Sustainable Development Goal (SDG) Interactions. Earth’s Futur. 2017, 5, 1169–1179. [Google Scholar] [CrossRef]

- Habib, H.U.R.; Wang, S.; Elkadeem, M.R.; Elmorshedy, M.F. Design optimization and model predictive control of a standalone hybrid renewable energy system: A case study on a small residential load in Pakistan. IEEE Access 2019, 7, 117369–117390. [Google Scholar] [CrossRef]

- Kamal, A.; Mohsine, B.; Abdelali, A.; Abdellatif, B.A. Sizing methods and optimization techniques for PV-wind based hybrid renewable energy system: A review. Renew. Sustain. Energy Rev. 2018, 93, 652–673. [Google Scholar] [CrossRef]

- Kaluthanthrige, R.; Rajapakse, A.D.; Lamothe, C.; Mosallat, F. Optimal Sizing and Performance Evaluation of a Hybrid Renewable Energy System for an Off-Grid Power System in Northern Canada. Technol. Econ. Smart Grids Sustain. Energy 2019, 4, 4. [Google Scholar] [CrossRef]

- Nandi, S.K.; Ghosh, H.R. Prospect of wind–PV-battery hybrid power system as an alternative to grid extension in Bangladesh. Energy 2010, 35, 3040–3047. [Google Scholar] [CrossRef]

- Bekele, G.; Tadesse, G. Feasibility study of small Hydro/PV/Wind hybrid system for off-grid rural electrification in Ethiopia. Appl. Energy 2012, 97, 5–15. [Google Scholar] [CrossRef]

- Sen, R.; Bhattacharyya, S.C. Off-grid electricity generation with renewable energy technologies in India: An application of HOMER. Renew. Energy 2014, 62, 388–398. [Google Scholar] [CrossRef]

- Rajbongshi, R.; Borgohain, D.; Mahapatra, S. Optimization of PV-biomass-diesel and grid base hybrid energy systems for rural electrification by using HOMER. Energy 2017, 126, 461–474. [Google Scholar] [CrossRef]

- Ahmad, J.; Imran, M.; Khalid, A.; Iqbal, W.; Rehan, S. Techno-economic analysis of a wind-photovoltaic-biomass hybrid renewable energy system for rural electrification: A case study of Kallar Kahar. Energy 2018, 148, 208–234. [Google Scholar] [CrossRef]

- Das, N.K.; Sarma, T.R. Social Cost–Benefit Analysis of Rajiv Gandhi Grameen Vidyutikaran Yojana: An Analysis. J. Infrastruct. Dev. 2016, 8, 137–152. [Google Scholar] [CrossRef]

- Kaabeche, A.; Belhamel, M.; Ibtiouen, R. Sizing optimization of grid-independent hybrid photovoltaic/wind power generation system. Energy 2011, 36, 1214–1222. [Google Scholar] [CrossRef]

- Li, Y.; Yue, D.; Liu, H.; Liu, Y. Wind-solar complementary power inverter based on intelligent control. In Proceedings of the 4th IEEE Conference on Industrial Electronics and Applications, Xi’an, China, 25–27 May 2009; pp. 3635–3638. [Google Scholar] [CrossRef]

- Takle, E.S.; Shaw, R.H. Complimentary nature of wind and solar energy at a continental mid-latitude station. Int. J. Energy Res. 1979, 3, 103–112. [Google Scholar] [CrossRef]

- Himri, Y.; Stambouli, A.B.; Draoui, B.; Himri, S. Techno-economical study of hybrid power system for a remote village in Algeria. Energy 2008, 33, 1128–1136. [Google Scholar] [CrossRef]

- Bekele, G.; Palm, B. Feasibility study for a standalone solar-wind-based hybrid energy system for application in Ethiopia. Appl. Energy 2010, 87, 487–495. [Google Scholar] [CrossRef]

- Dali, M.; Belhadj, J.; Roboam, X. Hybrid solar-wind system with battery storage operating in grid-connected and standalone mode: Control and energy management-experimental investigation. Energy 2010, 35, 2587–2599. [Google Scholar] [CrossRef]

- Badawe, M.E.; Iqbal, T.; Mann, G.K.I. Optimization and modeling of a stand-alone wind/PV hybrid energy system. In Proceedings of the 25th IEEE Canadian Conference on Electrical and Computer Engineering (CCECE), Montreal, QC, Canada; 2012; pp. 1–6. [Google Scholar] [CrossRef]

- Mandal, S.; Das, B.K.; Hoque, N. Optimum sizing of a stand-alone hybrid energy system for rural electrification in Bangladesh. J. Clean. Prod. 2018, 200, 12–27. [Google Scholar] [CrossRef]

- Razak, J.A.; Sopian, K.; Nopiah, Z.M.; Zaharim, A.; Ali, Y. Optimal operational strategy for hybrid renewable energy system using genetic algorithms. ISESCO Since Technol. Vis. 2008, 4, 55–59. [Google Scholar] [CrossRef]

- Okedu, K.E.; Uhunmwangho, R. Optimization of Renewable Energy Efficiency using HOMER. Int. J. Renew. Energy Res. 2014, 4, 421–427. [Google Scholar] [CrossRef]

- Kumar, A.; Deng, Y.; Xiangning, H.; Kumar, P.; Bansal, R.C. Energy management system controller for a rural microgrid. J. Eng. 2017, 13, 834–839. [Google Scholar] [CrossRef]

- Kashif, S.M.; Adeem, Z.; Tanzeel, U.R.; Mirza, A.R.; Muzaffar, A.; Mueen, A. Techno-economic feasibility analysis of a solar-biomass off grid system for the electrification of remote rural areas in Pakistan using HOMER software. Renew. Energy 2017, 106, 264–273. [Google Scholar] [CrossRef]

- Margaret, A.W.; Rajini, V. Cost benefit and technical analysis of rural electrification alternatives in southern India using HOMER. Renew. Sustain. Energy Rev. 2016, 62, 236–246. [Google Scholar] [CrossRef]

- Muhammad, S.J.; Tao, M. Techno-economic assessment of a hybrid solar-wind-battery system with genetic algorithm. Energy Procedia 2019, 158, 6384–6392. [Google Scholar] [CrossRef]

- Tsai, C.T.; Beza, T.M.; Wu, W.B.; Kuo, C.C. Optimal Configuration with Capacity Analysis of a Hybrid Renewable Energy and Storage System for an Island Application. Energies 2020, 13, 8. [Google Scholar] [CrossRef]

- Chalishazar, V.H.; Poudel, S.; Hanif, S.; Thekkumparambath Mana, P. Power System Resilience Metrics Augmentation for Critical Load Prioritization; Pacific Northwest National Laboratory: Richland, DC, USA, 2021. [Google Scholar] [CrossRef]

- Balamurugan, P.; Ashok, S.; Jose, T.L. Optimal Operation of Biomass/Wind/PV Hybrid Energy System for Rural Areas. Int. J. Green Energy 2009, 6, 104–116. [Google Scholar] [CrossRef]

- Fasihi, M.; Breyer, C. Baseload electricity and hydrogen supply based on hybrid PV-wind power plants. J. Clean. Prod. 2020, 243, 118466. [Google Scholar] [CrossRef]

- Bahramara, S.; Parsa, M.M.; Haghifam, M.R. Optimal planning of hybrid renewable energy systems using HOMER: A review. Renew. Sustain. Energy Rev. 2016, 62, 609–620. [Google Scholar] [CrossRef]

- Jamalaiah, A.; Raju, C.P.; Srinivasarao, R. Optimization and operation of a renewable energy based pv-fc-micro grid using HOMER. In Proceedings of the International Conference on Inventive Communication and Computational Technologies (ICICCT), Coimbatore, India, 10–11 March 2017; pp. 450–455. [Google Scholar] [CrossRef]

- Masud, A. The application of HOMER optimization software to investigate the prospects of hybrid renewable energy system in rural communities of Sokoto in Nigeria. Int. J. Electr. Comput. Eng. 2017, 7, 596–603. [Google Scholar] [CrossRef]

- Solar Resource Assessment and Mapping for India. Available online: https://www.nrel.gov/international/india (accessed on 25 January 2018).

- Solar Radiance Data Online. Available online: http://www.synergyenviron.com/tools/solar-irradiance/kancheepuram (accessed on 25 January 2018).

- Ashari, M.; Nayar, C.V. An optimum dispatch strategy using set points for a photovoltaic (PV)/diesel/battery hybrid power system. Sol. Energy 1999, 66, 1–9. [Google Scholar] [CrossRef]

- Azoumah, Y.; Yamegueu, D.; Ginies, P.; Coulibaly, Y.; Girard, P. Sustainable electricity generation for rural and peri-urban populations of sub-Saharan Africa: The flexy-energy concept. Energy Policy 2011, 39, 131–141. [Google Scholar] [CrossRef]

- Deshmukh, M.K.; Deshmukh, S.S. Modeling of hybrid renewable energy systems. Renew. Sustain. Energy Rev. 2008, 12, 235–249. [Google Scholar] [CrossRef]

| Village Name | Total Services | Name of the Feeder |

|---|---|---|

| Annaikundram | 510 | Elapakkam |

| Ammarur | 488 | Elapakkam |

| Kalliyakulam | 447 | Elapakkam |

| Mogalvadi | 439 | Elapakkam |

| Velamur | 431 | Ramapuram |

| Melnatham | 443 | Elapakkam |

| Ramapuram | 956 | Ramapuram |

| Elapakkam | 877 | Elapakkam |

| Rettipalayam | 311 | Ramapuram |

| Kattukarani | 614 | Mathur |

| Mathur | 431 | Mathur |

| Kottaikayapakkam | 253 | Elapakkam |

| Type of Load | Total Services |

|---|---|

| Domestic | 4040 |

| Light, schools, temples | 338 |

| Industrial | 86 |

| Agricultural | 1234 |

| Commercial | 476 |

| Temporary | 26 |

| Time in Hours | Ramapuram Feeder (MW) | Elapakkam Feeder (MW) | Mathur Feeder (MW) |

|---|---|---|---|

| 1 | 12 | 20 | 10 |

| 2 | 10 | 19 | 10 |

| 3 | 10 | 20 | 10 |

| 4 | 14 | 28 | 14 |

| 5 | 16 | 41 | 17 |

| 6 | 22 | 64 | 19 |

| 7 | 30 | 92 | 29 |

| 8 | 28 | 97 | 27 |

| 9 | 25 | 99 | 36 |

| 10 | 27 | 81 | 33 |

| 11 | 23 | 71 | 32 |

| 12 | 23 | 67 | 30 |

| 13 | 22 | 63 | 26 |

| 14 | 24 | 65 | 24 |

| 15 | 24 | 63 | 22 |

| 16 | 24 | 64 | 29 |

| 17 | 22 | 52 | 20 |

| 18 | 21 | 48 | 19 |

| 19 | 19 | 34 | 17 |

| 20 | 17 | 30 | 16 |

| 21 | 16 | 29 | 15 |

| 22 | 18 | 28 | 14 |

| 23 | 15 | 26 | 14 |

| 24 | 15 | 22 | 14 |

| Parameters | Characteristics | Value |

|---|---|---|

| PV panel | Schneider Conext Core XC generic PV | 680.08 kW |

| Diesel generator | Generic fixed capacity | 1000 kW |

| Battery | Generic Li-ion | 1000 kW |

| Converter | System converter | 5000 kW |

| Dispatch strategy | HOMER cycle charging |

| PV (kW) | Genset (kW) | Battery (kW) | Dispatch Strategy | COE (INR/kWh) | NPC (INR) | Renewable Penetration (%) | PV Generation (kWh/year) | Diesel Production (kWh) |

|---|---|---|---|---|---|---|---|---|

| 680 (10) | 1000 | 1000 | CC | 3.65 | 569 M | 94.9 | 13,402,550 | 508,353 |

| 680 (9) | 1000 | 1000 | CC | 4.43 | 690 M | 86.8 | 12,062,295 | 1,101,118 |

| 680 (8) | 1000 | 1000 | CC | 5.68 | 886 M | 78.7 | 10,722,040 | 1,820,930 |

| 680 (7) | 1000 | 1000 | CC | 7.94 | 1.24 B | 62.4 | 9,381,785 | 3,290,868 |

| 680 (6) | 1000 | 1000 | CC | 8.82 | 1.38 B | 56 | 8,041,530 | 3,832,204 |

| Sensitivity Variables with HOMER Cycle Charging | Generator Fuel Cost = INR 65 per Liter | PV Capital Multiplier = 1 | Solar Resource Scaled Annual Average = 5.14 kWh/m2 per Day | ||

|---|---|---|---|---|---|

| Cost Summary (NPC) | System (INR) | Schneider Conext CoreXC 680 kW with Generic PV (INR) | Generic 1 MW Fixed Capacity Genset (INR) | Generic 1 MWh Li-ion (INR) | System Converter (INR) |

| Capital | 236,864,291 | 15,001,764 | 300,000 | 84,700,000 | 1,546,644 |

| Replacement | 36,592,194 | 0.00 | 0.00 | 35,935,993 | 656,200 |

| O&M | 145,030,530 | 12,929,037 | 69,679 | 15,642,295 | 0.00 |

| Fuel | 156,973,173 | 0.00 | 110,568,616 | 0.00 | 0.00 |

| Salvage | 6,940,082 | 0.00 | 7306 | 6,763,516 | 123,503 |

| Total | 568,520,107 | 27,930,802 | 110,930,989 | 46,686,983 | 2,079,341 |

| Components | Generation (kWh/year) | Fraction (%) |

|---|---|---|

| PV (10) | 1,340,255x10 | 94.9 |

| Diesel generator | 508,353 | 3.6 |

| Diesel generator (1) | 213,822 | 1.5 |

| Total | 14,124,728 | 100 |

| Emission | Quantity (kg/year) |

|---|---|

| Carbon dioxide | 31,758 |

| Carbon monoxide | 39.8 |

| Unburned hydrocarbons | 0.554 |

| Particulate matter | 2.7 |

| Sulphur dioxide | 0.465 |

| Nitrogen oxide | 486 |

| Parameters | Characteristics | Value |

|---|---|---|

| PV panel rated capacity | Schneider Conext CoreXC Generic PV | 680.08 kW |

| Grid power | Grid | 999,999 kW |

| Battery power | Generic Li-ion | 1000 kW |

| Converter power | System converter | 5000 kW |

| Dispatch strategy | HOMER cycle charging |

| PV (kW) | Grid (kW) | Converter (kW) | Dispatch Strategy | COE (INR per kWh) | NPC (INR) | Renewable Penetration (%) | PV Generation (kWh/year) | Grid Energy Purchased (kWh) |

|---|---|---|---|---|---|---|---|---|

| 680 (9) | 999,999 | 9162 | CC | 2.92 | 476 M | 83.6 | 11,961,954 | 2,065,681 |

| 680 (8) | 999,999 | 8819 | CC | 3.41 | 539 M | 75.5 | 10,632,848 | 2,998,322 |

| 680 (7) | 999,999 | 2894 | CC | 3.77 | 594 M | 66.5 | 9,303,742 | 4,087,118 |

| 680 (9) | 999,999 | - | CC | 3.01 | 722 M | 64.5 | 11,961,954 | 6,591,030 |

| 680 (8) | 999,999 | - | CC | 3.25 | 731 M | 61.2 | 10,632,848 | 6,744,267 |

| Cost Summary (NPC) | System (INR) | Schneider Conext CoreXC 680 kW with Generic PV (INR) | Grid Power (INR) | Generic 1 MWh Li-ion (INR) | System Converter (INR) |

|---|---|---|---|---|---|

| Capital | 167,164,382 | 15,001,764 | 0.00 | 29,400,000 | 2,748,500 |

| Replacement | 13,639,767 | 0.00 | 0.00 | 12,473,650 | 1,166,116 |

| O&M | 297,882,090 | 12,929,037 | 176,091,196 | 5,429,556 | 0.00 |

| Fuel | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Salvage | 2,567,141 | 0.00 | 0.00 | 2,347,666 | 19,474 |

| Total | 476,119,098 | 27,930,802 | 176,091,196 | 44,955,540 | 3,695,141 |

| System Configuration | Cost Component | Value |

|---|---|---|

| PV(9)–grid–battery | Total NPC LCOE | 476,119,098.54 INR/kWh 2.92 |

| PV(9)–grid | Total NPC LCOE | 721,871,900.00 INR/kWh 3.01 |

| Components | Generation (kWh/year) | Fraction (%) |

|---|---|---|

| PV (9) | 1,329,106 × 9 | 85.3 |

| Grid purchases | 2,065,681 | 14.7 |

| Total | 14,027,634 | 100 |

| Emission | Quantity (kg/year) |

|---|---|

| Carbon dioxide | 30,551 |

| Carbon monoxide | 37.6 |

| Unburned hydrocarbons | 0.542 |

| Particulate matter | 2.6 |

| Sulphur dioxide | 0.460 |

| Nitrogen oxide | 768 |

| Parameters | Characteristics | Value |

|---|---|---|

| PV panel rated capacity | Schneider Conext Core XC generic PV | 680.08 kW |

| Grid power | Grid | 999,999 kW |

| Dispatch strategy | HOMER cycle charging |

| PV (kW) | Grid (kW) | Dispatch Strategy | COE (INR/kWh) | NPC (INR) | Renewable Penetration (%) | PV Generation (kWh/year) | Grid Energy Purchased (kWh) |

|---|---|---|---|---|---|---|---|

| 680 (9) | 999,999 | CC | 2.20 | 522 M | 64.0 | 11,757,564 | 6,319,829 |

| 680 (8) | 999,999 | CC | 2.46 | 548 M | 60.7 | 10,451,168 | 6,770,910 |

| 680 (7) | 999,999 | CC | 2.82 | 586 M | 56.8 | 9,144,772 | 6,953,344 |

| 680 (6) | 999,999 | CC | 3.22 | 626 M | 52.2 | 7,838,376 | 7,179,154 |

| 680 (5) | 999,999 | CC | 3.69 | 668 M | 46.6 | 6,531,980 | 7,472,905 |

| Cost Summary (NPC) | System (INR) | Schneider Conext CoreXC 680 kW with Generic PV (INR) | Grid Power (INR) |

|---|---|---|---|

| Capital | 135,015,882 | 15,001,764 | 0.00 |

| Replacement | 0.00 | 0.00 | 0.00 |

| O&M | 386,711,040 | 12,929,037 | 270,349,703 |

| Fuel | 0.00 | 0.00 | 0.00 |

| Salvage | 0.00 | 0.00 | 0.00 |

| Total | 521,726,922 | 27,930,802 | 270,349,703 |

| System Configuration | Cost Component | Value |

|---|---|---|

| PV(9)–grid Multiplier = 0.6 | Total NPC LCOE | INR 510,554,600.00/kWh INR 2.15 |

| PV(9)–grid Multiplier = 1.0 | Total NPC LCOE | INR 521,726,900.00/kWh INR 2.20 |

| Components | Generation (kWh/year) | Fraction (%) |

|---|---|---|

| PV (9) | 1,306,396 × 9 | 64.0 |

| Grid purchases | 6,620,328 | 36.0 |

| Total | 18,377,890 | 100 |

| Emission | Quantity (kg/year) |

|---|---|

| Carbon dioxide | 31,840 |

| Carbon monoxide | 40.1 |

| Unburned hydrocarbons | 0.551 |

| Particulate matter | 2.5 |

| Sulphur dioxide | 0.457 |

| Nitrogen oxide | 871 |

| Ref. | Country | Source 1 (kW) | Source 2 (kW) | Source 3 (kW) | Source 4 (kW) | COE (INR/kWh) | Lifespan (Years) | Dispatch Method | Renewable Fraction (%) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Existing methods | Nandi et al. 2010 | Bangladesh | Wind 14 | Battery 285 | PV 25 | - | 32.9 | 20 | CC | 92 |

| Bekele et al. 2012 | Ethiopia | Wind 0 | Hydro 34.2 | PV 0 | - | 7.07 | 25 | LF | 90 | |

| Sen et al. 2014 | India | Diesel 0 | Biomass 15 | PV 0 | Grid 100 | 4.48 | 25 | CC | 91 | |

| Rajbongshi et al. 2017 | India | Wind 0 | Hydro 29.98 | PV 20 | Biodiesel 10 | 29.4 | 20 | CC | 90 | |

| Ahmad et al. 2018 | Pakistan | Wind 15,000 | Biomass 20,000 | PV 15,000 | Grid 99,999 | 3.68 | 25 | CC | 88 | |

| Juhari Ab. Razak et al. 2007 | Malaysia | Wind | Hydro | PV | Battery | 14.18 | 20 | LF | 90 | |

| Proposed method | Case 1 | India | PV (10) 680 | Diesel (2) 1000 | Battery 1000 | - | 3.65 | 25 | CC | 94.9 |

| Case 2 | India | PV (9) 680 | Grid 99,999 | Battery 1000 | - | 2.92 | 25 | CC | 83.6 | |

| Case 3 | India | PV (9) 680 | Grid 99,999 | - | - | 2.20 | 25 | CC | 64 |

| S.No | Emission | Existing Method Sen et al. 2014 | Proposed Method | ||

|---|---|---|---|---|---|

| Case 1 | Case 2 | Case 3 | |||

| 1 | Carbon dioxide | 33,832 | 31,758 | 30,551 | 31,840 |

| 2 | Carbon monoxide | 44.3 | 39.8 | 37.6 | 40.1 |

| 3 | Unburned hydrocarbons | 0.688 | 0.554 | 0.542 | 0.551 |

| 4 | Particulate matter | 4.68 | 2.7 | 2.6 | 2.5 |

| 5 | Sulphur dioxide | 0.576 | 0.465 | 0.460 | 0.457 |

| 6 | Nitrogen oxide | 894 | 486 | 768 | 871 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arunachalam, R.K.; Chandrasekaran, K.; Rusu, E.; Ravichandran, N.; Fayek, H.H. Economic Feasibility of a Hybrid Microgrid System for a Distributed Substation. Sustainability 2023, 15, 3133. https://doi.org/10.3390/su15043133

Arunachalam RK, Chandrasekaran K, Rusu E, Ravichandran N, Fayek HH. Economic Feasibility of a Hybrid Microgrid System for a Distributed Substation. Sustainability. 2023; 15(4):3133. https://doi.org/10.3390/su15043133

Chicago/Turabian StyleArunachalam, Ramesh Kumar, Kumar Chandrasekaran, Eugen Rusu, Nagananthini Ravichandran, and Hady H. Fayek. 2023. "Economic Feasibility of a Hybrid Microgrid System for a Distributed Substation" Sustainability 15, no. 4: 3133. https://doi.org/10.3390/su15043133

APA StyleArunachalam, R. K., Chandrasekaran, K., Rusu, E., Ravichandran, N., & Fayek, H. H. (2023). Economic Feasibility of a Hybrid Microgrid System for a Distributed Substation. Sustainability, 15(4), 3133. https://doi.org/10.3390/su15043133