Life Cycle Assessment of Mortars with Fine Recycled Aggregates from Industrial Waste: Evaluation of Transports Impact in the Italian Context

Abstract

:1. Introduction

2. Research Framework

2.1. Phase 1–LCA Analysis–Local Scenario

2.2. Phase 2–Sensitivity Analysis

2.3. Phase 3–Analysis of Alternative Scenarios of Transport

3. Materials and Methods

3.1. Materials

- -

- REF1 and DELTA mortar (compressive strength class 30 M [39]);

- -

- REF2 and HP mortar (compressive strength class 20 M),

3.2. Methods

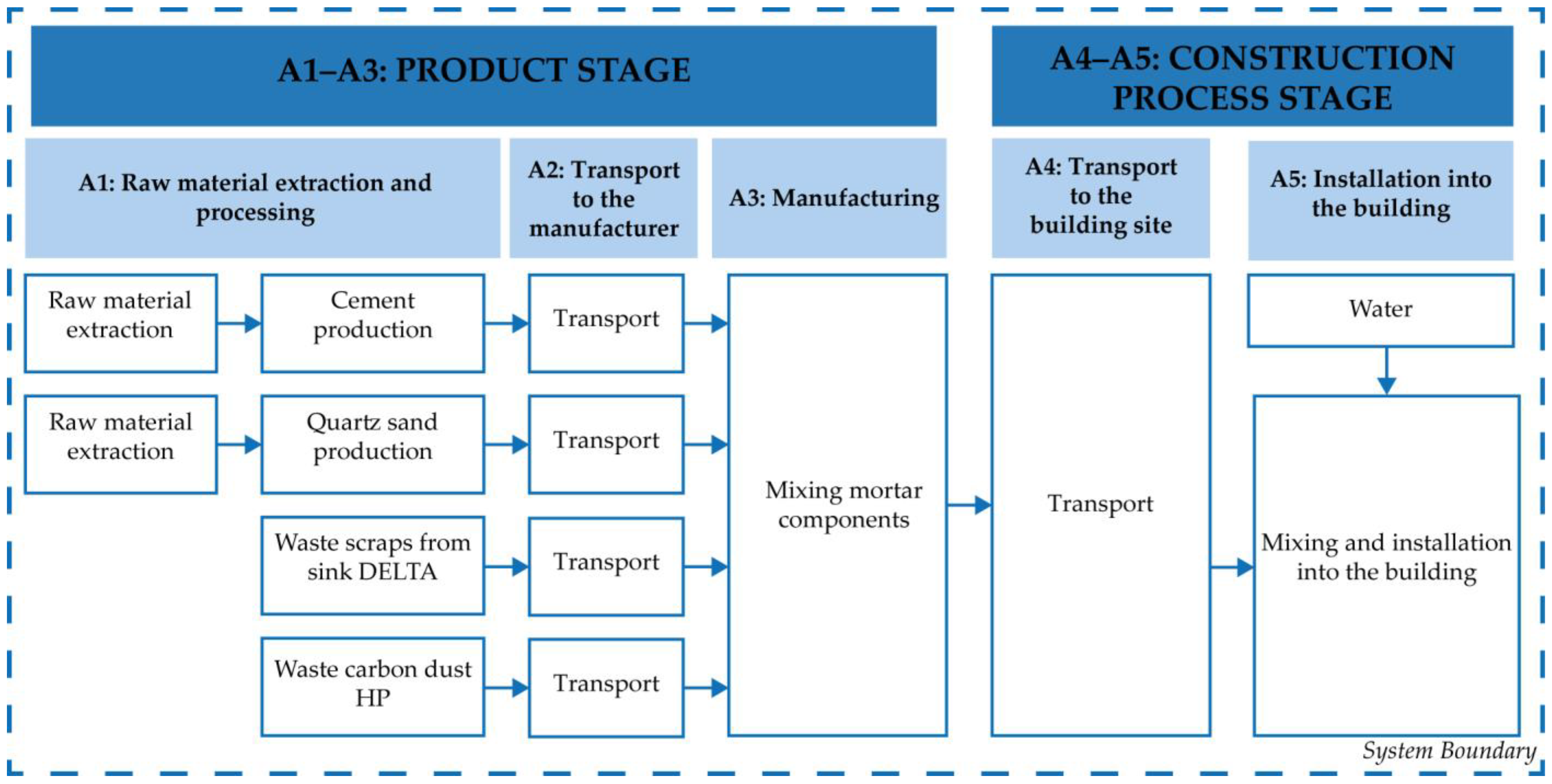

3.2.1. Goal and Scope Definition

3.2.2. Declared Unit

- -

- 1 L of mortar mixture of 32 MPa compressive strength (compressive strength class M30), for REF1 and DELTA mortars.

- -

- 1 L of mortar mixture of 25 MPa compressive strength (compressive strength class M20), for REF2 and HP mortars.

3.2.3. System Boundary

3.2.4. Environmental Impact Categories

3.2.5. LCA Assumptions and Limitations

- -

- According to the cut-off criteria of EN 15,804 + A2 [40], no additives are included in the LCA analyses because they never exceed 5% of total mass.

- -

- For processes modeling, secondary (generic) data are retrieved from the internationally recognized databases ecoinvent v.3 and ELCD (European Platform on LCA).

- -

- The factories producing waste used as aggregates are considered in their real locations.

- -

- No environmental impacts are associated with sieving processes.

- -

- The transports distance is always considered to be one-way delivering.

- -

- Concerning transport distances from the gate to the site (A4), two assessment scenarios are assumed: 50 km (scenario A) and 500 km (scenario B).

3.3. Life Cycle Inventory

3.3.1. Raw Material Extraction and Processing (A1)

3.3.2. Transport (A2)

3.3.3. Manufacturing (A3)

3.3.4. Transport from the Gate to the Site (A4)

3.3.5. Assembly (A5)

3.3.6. Benefits of Uncollected Wastes

4. Results: Life Cycle Impact Assessment

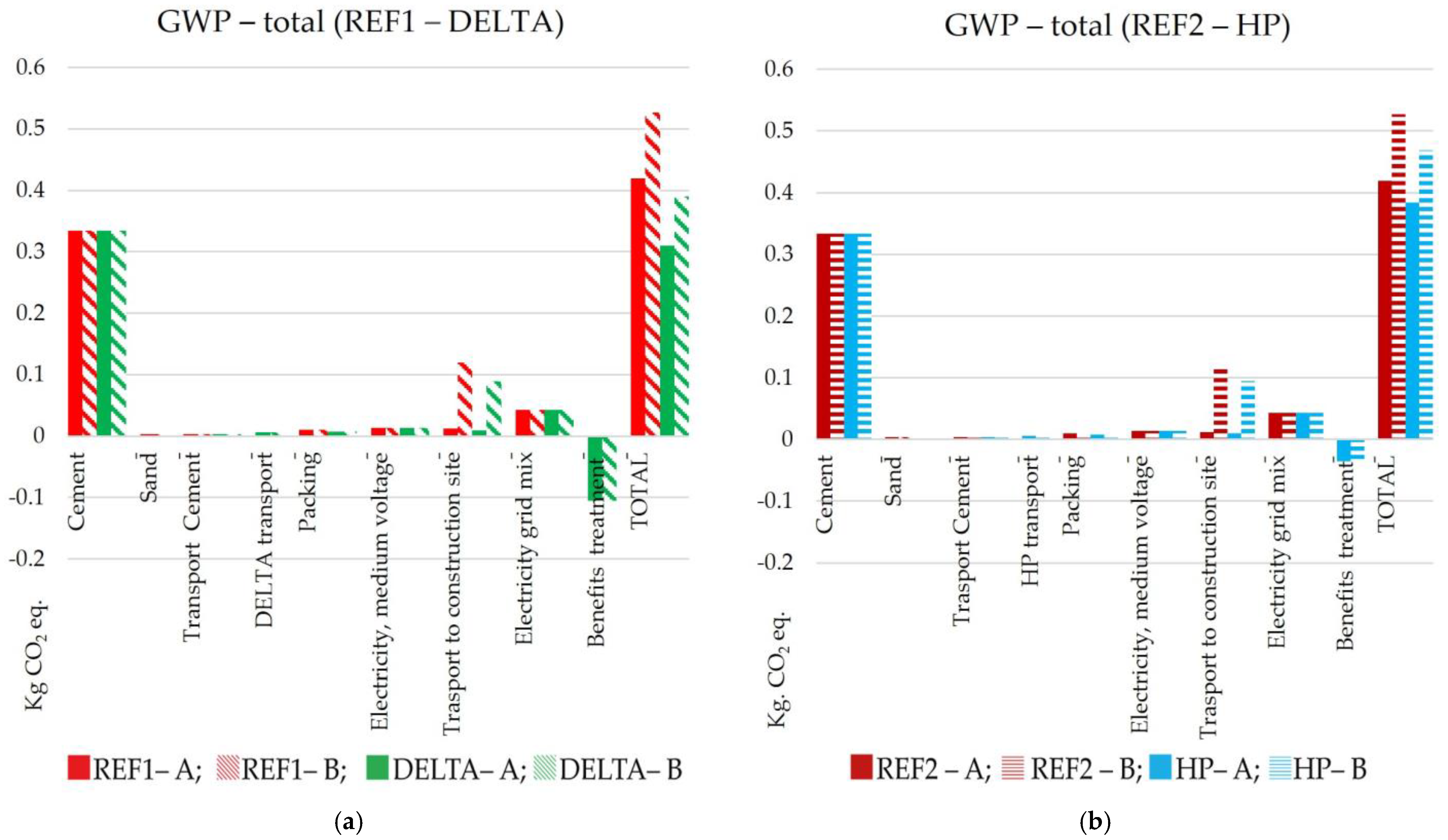

4.1. Local Scenario

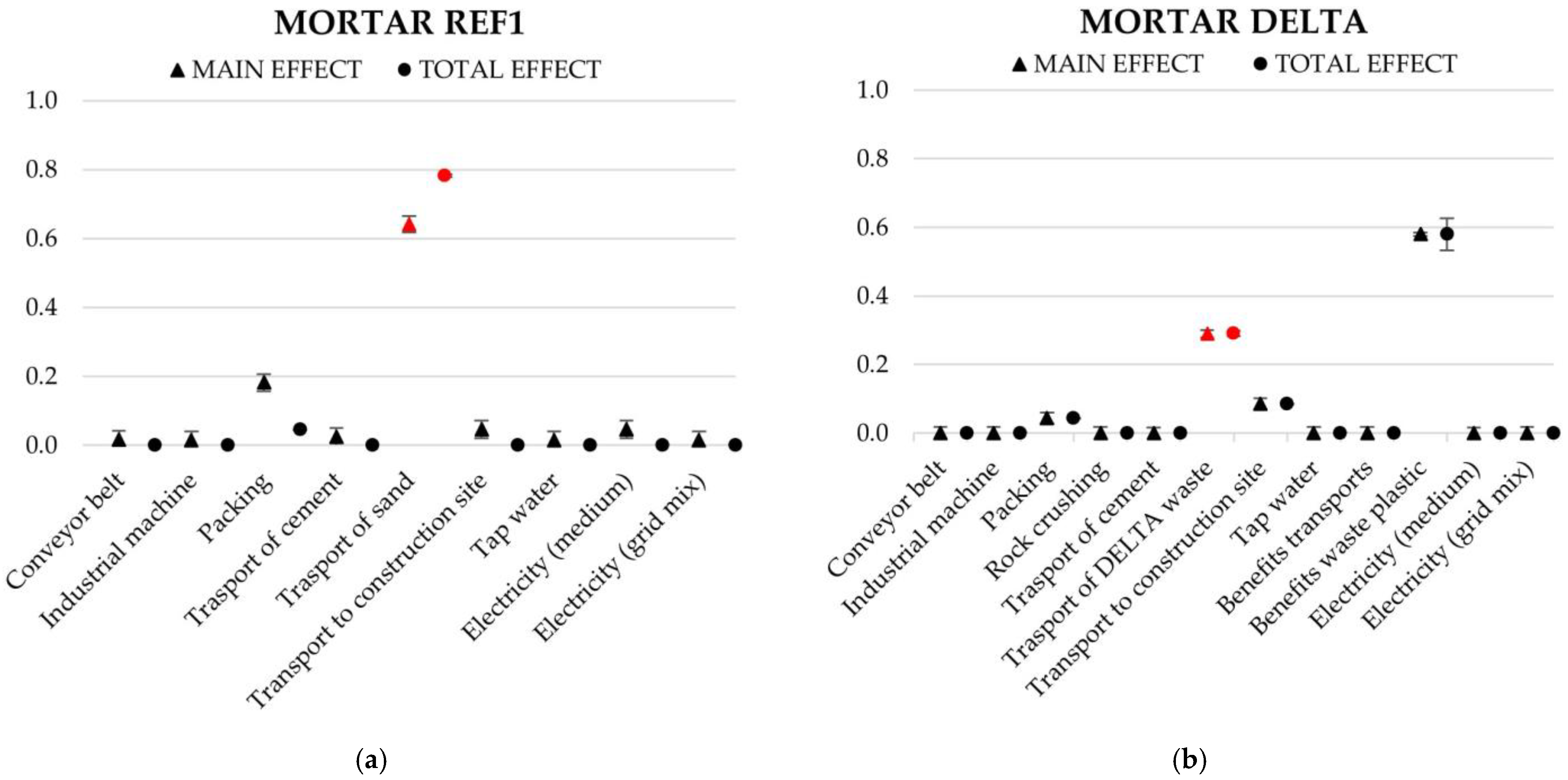

4.2. Sensitivity Analysis

4.3. Impact of Transport Scenarios on LCA Results

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Colangelo, F.; Petrillo, A.; Cioffi, R.; Borrelli, C.; Forcina, A. Life Cycle Assessment of Recycled Concretes: A Case Study in Southern Italy. Sci. Total Environ. 2018, 615, 1506–1517. [Google Scholar] [CrossRef]

- European Commission, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, “Circular Economy Action Plan–For a Cleaner and More Competitive Europe”; COM(2020) 98 Final, Brussels, Belgium, 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=COM:2020:98:FIN (accessed on 6 February 2023).

- Eurostat–Waste Database. Available online: https://ec.europa.eu/eurostat/waste (accessed on 31 January 2023).

- Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 laying down harmonised conditions for the marketing of construction products and repealing Council Directive 89/106/EEC. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:02011R0305-20140616 (accessed on 6 February 2023).

- European Green Public Procurement. Available online: https://ec.europa.eu/environment/gpp/index_en.htm (accessed on 6 February 2023).

- Farinha, C.B.; Silvestre, J.D.; de Brito, J.; Veiga, M.D.R. Life Cycle Assessment of Mortars with Incorporation of Industrial Wastes. Fibers 2019, 7, 59. [Google Scholar] [CrossRef]

- Santos, T.; Almeida, J.; Silvestre, J.D.; Faria, P. Life Cycle Assessment of Mortars: A Review on Technical Potential and Drawbacks. Constr. Build. Mater. 2021, 288, 123069. [Google Scholar] [CrossRef]

- Colangelo, F.; Forcina, A.; Farina, I.; Petrillo, A. Life Cycle Assessment (LCA) of Different Kinds of Concrete Containing Waste for Sustainable Construction. Buildings 2018, 8, 70. [Google Scholar] [CrossRef]

- Colangelo, F.; Farina, I.; Travaglioni, M.; Salzano, C.; Cioffi, R.; Petrillo, A. Eco-Efficient Industrial Waste Recycling for the Manufacturing of Fibre Reinforced Innovative Geopolymer Mortars: Integrated Waste Management and Green Product Development through LCA. J. Clean. Prod. 2021, 312, 127777. [Google Scholar] [CrossRef]

- Brás, A.; Gomes, V. LCA Implementation in the Selection of Thermal Enhanced Mortars for Energetic Rehabilitation of School Buildings. Energy Build. 2015, 92, 1–9. [Google Scholar] [CrossRef]

- Cuenca-Moyano, G.M.; Martín-Morales, M.; Bonoli, A.; Valverde-Palacios, I. Environmental Assessment of Masonry Mortars Made with Natural and Recycled Aggregates. Int. J. Life Cycle Assess. 2019, 24, 191–210. [Google Scholar] [CrossRef]

- Braga, A.M.; Silvestre, J.D.; de Brito, J. Compared Environmental and Economic Impact from Cradle to Gate of Concrete with Natural and Recycled Coarse Aggregates. J. Clean. Prod. 2017, 162, 529–543. [Google Scholar] [CrossRef]

- Jiménez, C.; Barra, M.; Josa, A.; Valls, S. LCA of Recycled and Conventional Concretes Designed Using the Equivalent Mortar Volume and Classic Methods. Constr. Build. Mater. 2015, 84, 245–252. [Google Scholar] [CrossRef]

- Blengini, G.A.; Garbarino, E. Resources and Waste Management in Turin (Italy): The Role of Recycled Aggregates in the Sustainable Supply Mix. J. Clean. Prod. 2010, 18, 1021–1030. [Google Scholar] [CrossRef]

- Diaz-Basteris, J.; Sacramento Rivero, J.C.; Menéndez, B. Life Cycle Assessment of Restoration Mortars and Binders. Constr. Build. Mater. 2022, 326, 126863. [Google Scholar] [CrossRef]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of Incorporation of High Volume of Recycled Concrete Aggregates and Fly Ash on the Strength and Global Warming Potential of Concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Göswein, V.; Gonçalves, A.B.; Silvestre, J.D.; Freire, F.; Habert, G.; Kurda, R. Transportation Matters–Does It? GIS-Based Comparative Environmental Assessment of Concrete Mixes with Cement, Fly Ash, Natural and Recycled Aggregates. Resour. Conserv. Recycl. 2018, 137, 1–10. [Google Scholar] [CrossRef]

- Moreira, A.; António, J.; Tadeu, A. Lightweight Screed Containing Cork Granules: Mechanical and Hygrothermal Characterization. Cem. Concr. Compos. 2014, 49, 1–8. [Google Scholar] [CrossRef]

- Matias, G.; Faria, P.; Torres, I. Lime Mortars with Ceramic Wastes: Characterization of Components and Their Influence on the Mechanical Behaviour. Constr. Build. Mater. 2014, 73, 523–534. [Google Scholar] [CrossRef]

- Farinha, C.; de Brito, J.; Veiga, R. Incorporation of Fine Sanitary Ware Aggregates in Coating Mortars. Constr. Build. Mater. 2015, 83, 194–206. [Google Scholar] [CrossRef]

- Farinha, C.B.; de Brito, J.; Veiga, R. Assessment of Glass Fibre Reinforced Polymer Waste Reuse as Filler in Mortars. J. Clean. Prod. 2019, 210, 1579–1594. [Google Scholar] [CrossRef]

- Rezende Leite, F.; Lúcia Pereira Antunes, M.; Aparecido Lopes Silva, D.; Cipriano Rangel, E.; Cristino da Cruz, N. An Ecodesign Method Application at the Experimental Stage of Construction Materials Development: A Case Study in the Production of Mortar Made with Ornamental Rock Wastes. Constr. Build. Mater. 2021, 293, 123505. [Google Scholar] [CrossRef]

- Tadeu, A.; Moreira, A.; António, J.; Simões, N.; Simões, I. Thermal Delay Provided by Floors Containing Layers That Incorporate Expanded Cork Granule Waste. Energy Build. 2014, 68, 611–619. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Termkhajornkit, P.; Kim, Y.H. Review of Concrete with Expanded Polystyrene (EPS): Performance and Environmental Aspects. J. Clean. Prod. 2022, 366, 132919. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Atanes-Sánchez, E.; Saíz, P. Dissolved Recycled Expanded Polystyrene as Partial Replacement in Plaster Composites. J. Build. Eng. 2023, 65, 105697. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management–Life Cycle Assessment–Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- ISO 14040:2006; Environmental Management–Life Cycle Assessment–Principles and Framework. ISO: Geneva, Switzerland, 2006.

- EN 1504-3:2005; Products and Systems for the Protection and Repair of Concrete Structures—Definitions, Requirements, Quality Control and Evaluation of Conformity—Part 3: Structural and Non-Structural Repair. European Committee for Standardization (CEN): Brussels, Belgium, 2005.

- Guinée, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life Cycle Assessment: Past, Present, and Future. Environ. Sci. Technol. 2011, 45, 90–96. [Google Scholar] [CrossRef]

- Turk, J.; Cotič, Z.; Mladenovič, A.; Šajna, A. Environmental Evaluation of Green Concretes versus Conventional Concrete by Means of LCA. Waste Manag. 2015, 45, 194–205. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative Environmental Assessment of Natural and Recycled Aggregate Concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- Baldoni, E.; Coderoni, S.; di Giuseppe, E.; D’Orazio, M.; Esposti, R.; Maracchini, G. A Software Tool for a Stochastic Life Cycle Assessment and Costing of Buildings’ Energy Efficiency Measures. Sustainability 2021, 13, 7975. [Google Scholar] [CrossRef]

- Di Giuseppe, E.; D’Orazio, M.; Du, G.; Favi, C.; Lasvaux, S.; Maracchini, G.; Padey, P. A Stochastic Approach to LCA of Internal Insulation Solutions for Historic Buildings. Sustainability 2020, 12, 1535. [Google Scholar] [CrossRef]

- Favi, C.; Di Giuseppe, E.; D’Orazio, M.; Rossi, M.; Germani, M. Building Retrofit Measures and Design: A Probabilistic Approach for LCA. Sustainability 2018, 10, 3655. [Google Scholar] [CrossRef]

- Favi, C.; Meo, I.; Di Giuseppe, E.; Iannaccone, M.; D’Orazio, M.; Germani, M. Towards a Probabilistic Approach in LCA of Building Retrofit Measures. Energy Procedia 2017, 134, 394–403. [Google Scholar] [CrossRef]

- The R Project for Statistical Computing. Available online: http://www.r-project.org/ (accessed on 6 February 2023).

- Why Does the Ecoinvent Database Love the Lognormal Distribution? Available online: https://chris.mutel.org/ecoinvent-lognormal.html#:~:text=First%2C%20because%20the%20lognormal%20distribution,and%20crosses%20the%20zero%20line (accessed on 6 February 2023).

- Saltelli, A.; Ratto, M.; Andres, T.; Campolongo, F.; Jessica, G.; Gatelli, D.; Saisana, M.; Tarantola, S. Global Sensitivity Analysis: The Primer; Wiley: Chichester, UK, 2008; ISBN 978-0-470-05997-5. [Google Scholar]

- EN 998-2:2016; Specification for Mortar for Masonry—Part 2: Masonry Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 2016.

- EN 15804:2012+A2:2019; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- EPD International AB, PCR 2019:14 Construction Products, Version 1.11. 2021. Available online: https://portal.environdec.com/ (accessed on 6 February 2023).

- SimaPro Tutorial. Available online: https://pre-sustainability.com/legacy/download/SimaPro8Tutorial.pdf (accessed on 6 February 2023).

| REF1/REF2 | DELTA | HP | ||||

|---|---|---|---|---|---|---|

| Scenario A | Scenario B | Scenario A | Scenario B | Scenario A | Scenario B | |

| (km) | (km) | (km) | (km) | (km) | (km) | |

| Transport of cement | 60 | 60 | 60 | 60 | 60 | 60 |

| Transport of sand | 0 | 0 | - | - | 0 | 0 |

| Transport of DELTA waste | - | - | 53 | 53 | - | - |

| Transport of HP waste | - | - | - | - | 150 | 150 |

| Transport of mortar to building site | 50 | 500 | 50 | 500 | 50 | 500 |

| Missed waste transport to landfill | - | - | 20 | 20 | 7 | 7 |

| REF1/REF2 | DELTA | HP | ||||

|---|---|---|---|---|---|---|

| Scenario A | Scenario B | Scenario A | Scenario B | Scenario A | Scenario B | |

| (km) | (km) | (km) | (km) | (km) | (km) | |

| Scenario 0 | REF–A0 | REF–B0 | DELTA–A0 | DELTA–B0 | HP–A0 | HP–B0 |

| Transport of sand | 0 | 0 | - | - | 0 | 0 |

| Transport of DELTA wastes | - | - | 0 | 0 | - | - |

| Transport of HP wastes | - | - | - | - | 0 | 0 |

| Transport of mortar to building site | 50 | 500 | 50 | 500 | 50 | 500 |

| Scenario 1 | REF–A1 | REF–B1 | DELTA–A1 | DELTA–B1 | HP–A1 | HP–B1 |

| Transport of sand | 100 | 100 | - | - | 50 | 50 |

| Transport of DELTA wastes | - | - | 100 | 100 | - | - |

| Transport of HP wastes | - | - | - | - | 50 | 50 |

| Transport of mortar to building site | 50 | 500 | 50 | 500 | 50 | 500 |

| Scenario 2 | REF–A2 | REF–B2 | DELTA–A2 | DELTA–B2 | HP–A2 | HP–B2 |

| Transport of sand | 200 | 200 | - | - | 100 | 100 |

| Transport of DELTA wastes | - | - | 200 | 200 | - | - |

| Transport of HP wastes | - | - | - | - | 100 | 100 |

| Transport of mortar to building site | 50 | 500 | 50 | 500 | 50 | 500 |

| Scenario 3 | REF–A3 | REF–B3 | DELTA–A3 | DELTA–B3 | HP–A3 | HP–B3 |

| Transport of sand | 300 | 300 | - | - | 150 | 150 |

| Transport of DELTA wastes | - | - | 300 | 300 | - | - |

| Transport of HP wastes | - | - | - | - | 150 | 150 |

| Transport of mortar to building site | 50 | 500 | 50 | 500 | 50 | 500 |

| Scenario 4 | REF–A4 | REF–B4 | DELTA–A4 | DELTA–B4 | HP–A4 | HP–B4 |

| Transport of sand | 400 | 400 | - | - | 200 | 200 |

| Transport of DELTA wastes | - | - | 400 | 400 | - | - |

| Transport of HP wastes | - | - | - | - | 200 | 200 |

| Transport of mortar to building site | 50 | 500 | 50 | 500 | 50 | 500 |

| Scenario 5 | REF–A5 | REF–B5 | DELTA–A5 | DELTA–B5 | HP–A5 | HP–B5 |

| Transport of sand | 500 | 500 | - | - | 250 | 250 |

| Transport of DELTA wastes | - | - | 500 | 500 | - | - |

| Transport of HP wastes | - | - | - | - | 250 | 250 |

| Transport of mortar to building site | 50 | 500 | 50 | 500 | 50 | 500 |

| REF1 | DELTA | REF2 | HP | |

|---|---|---|---|---|

| Compressive strength | 32 MPa | 32 MPa | 25 MPa | 25 MPa |

| Compressive strength class | M30 | M30 | M20 | M20 |

| Volumetric mass | 2100 kg/m3 | 1700 kg/m3 | 2100 kg/m3 | 1600 kg/m3 |

| Components | (Kg) | (Kg) | (Kg) | (Kg) |

| Water | 0.280 | 0.290 | 0.300 | 0.290 |

| Cement CEM II/A-LL 42,5 R | 0.450 | 0.450 | 0.450 | 0.450 |

| Sand 0/2 | 1.350 | - | 1.350 | 0.675 |

| Composite dust DELTA | - | 0.900 | - | - |

| Carbon dust HP | - | - | - | 0.300 |

| Superplasticising admixture | - | 0.010 | - | - |

| Description | Process | Database |

|---|---|---|

| Known inputs from Technosphere (materials/fuels) | ||

| Cement CEM II/A-LL 42,5 R | Cement, limestone 6–20% [RoW], cement production, limestone 6–20%|APOS, U | Ecoinvent 3 |

| Sand 0/2 | Sand 0/2, wet and dry quarry, production mix, at plant, undried RER S | ELCD 3.0 |

| Industrial machine | Industrial machine, heavy, unspecified [RoW]|Market for industrial machine, heavy, unspecified|APOS, U | Ecoinvent 3 |

| Conveyor belt | Conveyor belt [GLO]|market for|APOS, U | Ecoinvent 3 |

| Rock Crushing of wastes | Rock Crushing (RER)|processing|APOS, U | Ecoinvent 3 |

| Packing | Packing, cement [GLO]|market for|APOS, U | Ecoinvent 3 |

| Transport | Transport, freight, lorry, unspecified [RER]|market for transport, freight, lorry, unspecified|APOS, U | Ecoinvent 3 |

| Treatment of waste plastic in sanitary landfill | Waste plastic, mixture {RoW}|treatment of waste plastic, mixture, sanitary landfill|APOS, U | Ecoinvent 3 |

| Tap water | Tap water (Eurpe without Switzerland)|market for|APOS, U | Ecoinvent 3 |

| Known inputs from Technosphere (electricity/heat) | ||

| Electricity, medium voltage | Electricity, medium voltage (IT)|market for|APOS, U | Ecoinvent 3 |

| Electricity grid mix | Electricity grid mix, AC, consumption mix, at consumer, 230 V IT S | Ecoinvent 3 |

| REF1–DELTA Comparison | Scenario A–B Comparison | ||||

|---|---|---|---|---|---|

| A | B | REF1 | DELTA | ||

| GWP | kg CO2 eq. | −26% | −26% | 26% | 26% |

| ODP | kg CFC11 eq. | −18% | −22% | 136% | 124% |

| POCP | kg NMVOC eq. | −13% | −18% | 65% | 56% |

| AP | mol H + eq. | −9% | −14% | 46% | 38% |

| EP—freshwater | kg P eq. | −9% | −14% | 46% | 38% |

| EP—marine | kg N eq. | −523% | −338% | 59% | 11% |

| EP—terrestrial | mol N eq. | −10% | −16% | 59% | 49% |

| ADP—minerals & metals | kg Sb eq. | −0,50% | −3% | 11% | 8% |

| ADP– fossil | MJ | −11% | −16% | 60% | 51% |

| PE-Nre | MJ | −11% | −16% | 60% | 50% |

| PE-Re | MJ | −14% | −14% | 6% | 5% |

| REF2–HP Comparison | Scenario A–B Comparison | ||||

|---|---|---|---|---|---|

| A | B | REF2 | HP | ||

| GWP | kg CO2 eq. | −8% | −11% | 26% | 22% |

| ODP | kg CFC11 eq. | −3% | −13% | 136% | 111% |

| POCP | kg NMVOC eq. | −3% | −10% | 65% | 54% |

| AP | mol H + eq. | −3% | −8% | 46% | 37% |

| EP—freshwater | kg P eq. | −3% | −8% | 46% | 37% |

| EP—marine | kg N eq. | −174% | −117% | 59% | 64% |

| EP—terrestrial | mol N eq. | −2% | −9% | 59% | 48% |

| ADP—minerals & metals | kg Sb eq. | +0,07% | −2% | 11% | 8% |

| ADP—fossil | MJ | −3% | −9% | 60% | 49% |

| PE-Nre | MJ | −3% | −9% | 60% | 49% |

| PE-Re | MJ | −11% | −11% | 6% | 5% |

| REF1 | DELTA | |||||||

|---|---|---|---|---|---|---|---|---|

| Distribution | Mean | Median | SD | Distribution | Mean | Median | SD | |

| Cement, limestone 6–20% | Lognormal | 0.33213 | 0.31031 | - | Lognormal | 0.33213 | 0.31031 | - |

| Conveyor belt | Lognormal | 0.00004 | 0.00003 | - | Lognormal | 0.00004 | 0.00003 | - |

| Industrial machine | Lognormal | 0.00001 | 0.00001 | - | Lognormal | 0.00001 | 0.00001 | - |

| Packing | Normal | 0.01045 | - | 0.005386 | Normal | 0.00736 | - | 0.00428 |

| Rock crushing | - | - | - | Lognormal | 0.00029 | 0.00029 | - | |

| Transport of cement | Lognormal | 0.00357 | 0.00356 | - | Lognormal | 0.00357 | 0.00356 | - |

| Transport of DELTA waste | - | - | - | - | Normal | 0.05035 | - | 0.02458 |

| Transport to construction site | Lognormal | 0.01192 | 0.01188 | - | Lognormal | 0.00893 | 0.00890 | - |

| Tap Water | Lognormal | 0.00010 | 0.00010 | - | Normal | 0.00010 | - | 0.000004 |

| Benefits transports | - | Normal | −0.00238 | - | 0.00008 | |||

| Benefits waste plastic | - | Normal | −0.10558 | - | 0.05798 | |||

| Electricity (medium) | Lognormal | 0.01374 | 0.01374 | - | Lognormal | 0.01374 | 0.01374 | - |

| Electricity (grid mix) | Normal | 0.04277 | - | 0.00000 | Normal | 0.04277 | - | 0.00000 |

| Sand | - | 0.00333 | 0.00333 | - | - | - | - | - |

| Min | Max | |||||||

| Transport of sand | Uniform | 0.01140 | 0.08841 | - | - | - | - | - |

| REF2 | HP | |||||||

|---|---|---|---|---|---|---|---|---|

| Distribution | Mean | Median | SD | Distribution | Mean | Median | SD | |

| Cement, limestone 6–20% | Lognormal | 0.332134 | 0.310317 | - | Lognormal | 0.332138 | 0.310317 | - |

| Conveyor belt | Lognormal | 0.000043 | 0.000034 | - | Lognormal | 0.000043 | 0.000034 | - |

| Industrial machine | Lognormal | 0.000016 | 0.000013 | - | Lognormal | 0.000016 | 0.000013 | - |

| Packing | Normal | 0.010452 | - | 0.005386 | Normal | 0.007905 | - | 0.004381 |

| Rock crushing | - | - | - | - | Lognormal | 0.000098 | 0.000098 | - |

| Transport of cement | Lognormal | 0.003571 | 0.003560 | - | Lognormal | 0.003571 | 0.003560 | - |

| Transport to construction site | Lognormal | 0.011923 | 0.011884 | - | Lognormal | 0.009440 | 0.009430 | - |

| Tap Water | Lognormal | 0.000108 | 0.000108 | - | Lognormal | 0.000144 | 0.000144 | - |

| Benefits transports | - | - | - | - | Normal | −0.000278 | - | 0.000009 |

| Benefits waste plastic | - | - | - | - | Normal | −0.034873 | - | 0.019016 |

| Electricity (medium) | Lognormal | 0.013741 | 0.013741 | 0.001437 | Lognormal | 0.013741 | 0.013741 | - |

| Electricity (grid mix) | Normal | 0.042770 | - | 0.000000 | Normal | 0.042770 | - | 0.000000 |

| Sand | - | 0.003334 | 0.003334 | - | - | 0.001669 | 0.001669 | - |

| Transport of HP waste | - | - | - | - | Normal | 0.018666 | - | 0.007674 |

| Min | Max | Min | Max | |||||

| Transport of sand | Uniform | 0.011409 | 0.088415 | Uniform | 0.005233 | 0.044020 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Orazio, M.; Di Giuseppe, E.; Carosi, M. Life Cycle Assessment of Mortars with Fine Recycled Aggregates from Industrial Waste: Evaluation of Transports Impact in the Italian Context. Sustainability 2023, 15, 3221. https://doi.org/10.3390/su15043221

D’Orazio M, Di Giuseppe E, Carosi M. Life Cycle Assessment of Mortars with Fine Recycled Aggregates from Industrial Waste: Evaluation of Transports Impact in the Italian Context. Sustainability. 2023; 15(4):3221. https://doi.org/10.3390/su15043221

Chicago/Turabian StyleD’Orazio, Marco, Elisa Di Giuseppe, and Marta Carosi. 2023. "Life Cycle Assessment of Mortars with Fine Recycled Aggregates from Industrial Waste: Evaluation of Transports Impact in the Italian Context" Sustainability 15, no. 4: 3221. https://doi.org/10.3390/su15043221

APA StyleD’Orazio, M., Di Giuseppe, E., & Carosi, M. (2023). Life Cycle Assessment of Mortars with Fine Recycled Aggregates from Industrial Waste: Evaluation of Transports Impact in the Italian Context. Sustainability, 15(4), 3221. https://doi.org/10.3390/su15043221