Construction and Cost Analysis of BladeBridges Made from Decommissioned FRP Wind Turbine Blades

Abstract

:1. Introduction

2. Cork, Ireland BladeBridge

2.1. Planning, Funding, and Blade Sourcing

2.2. Geometric Characterization of the Wind Blade

2.3. Material Testing

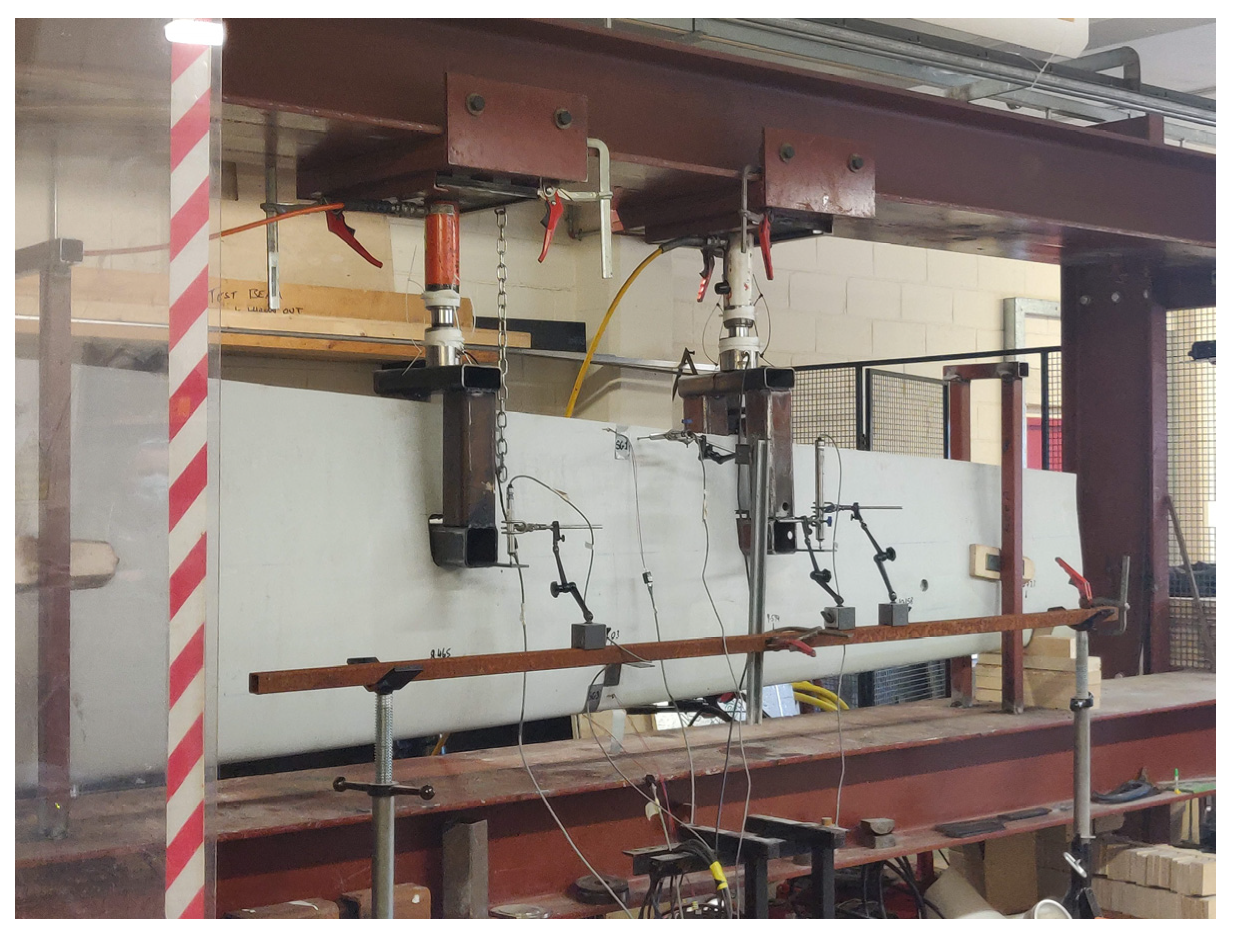

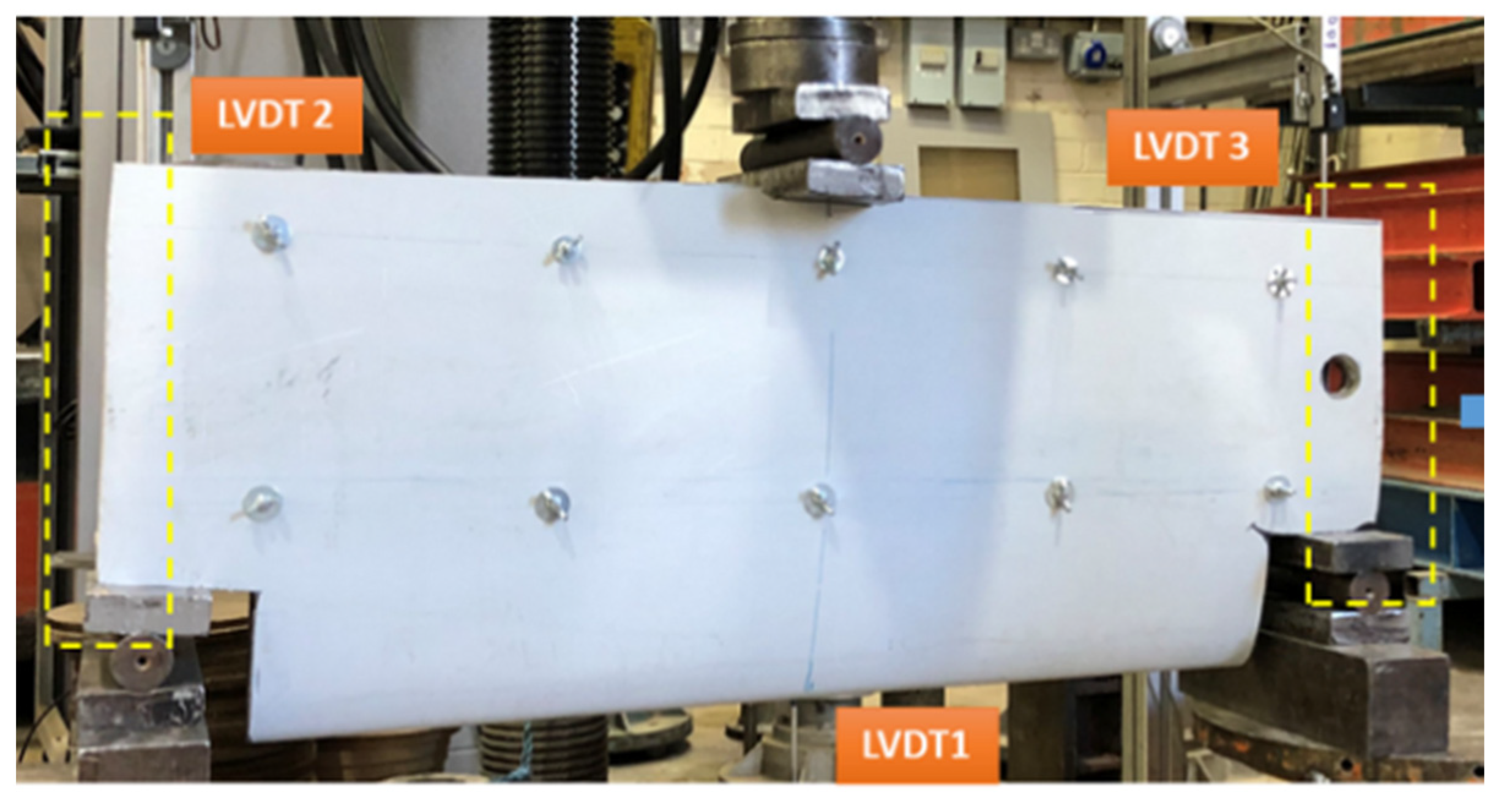

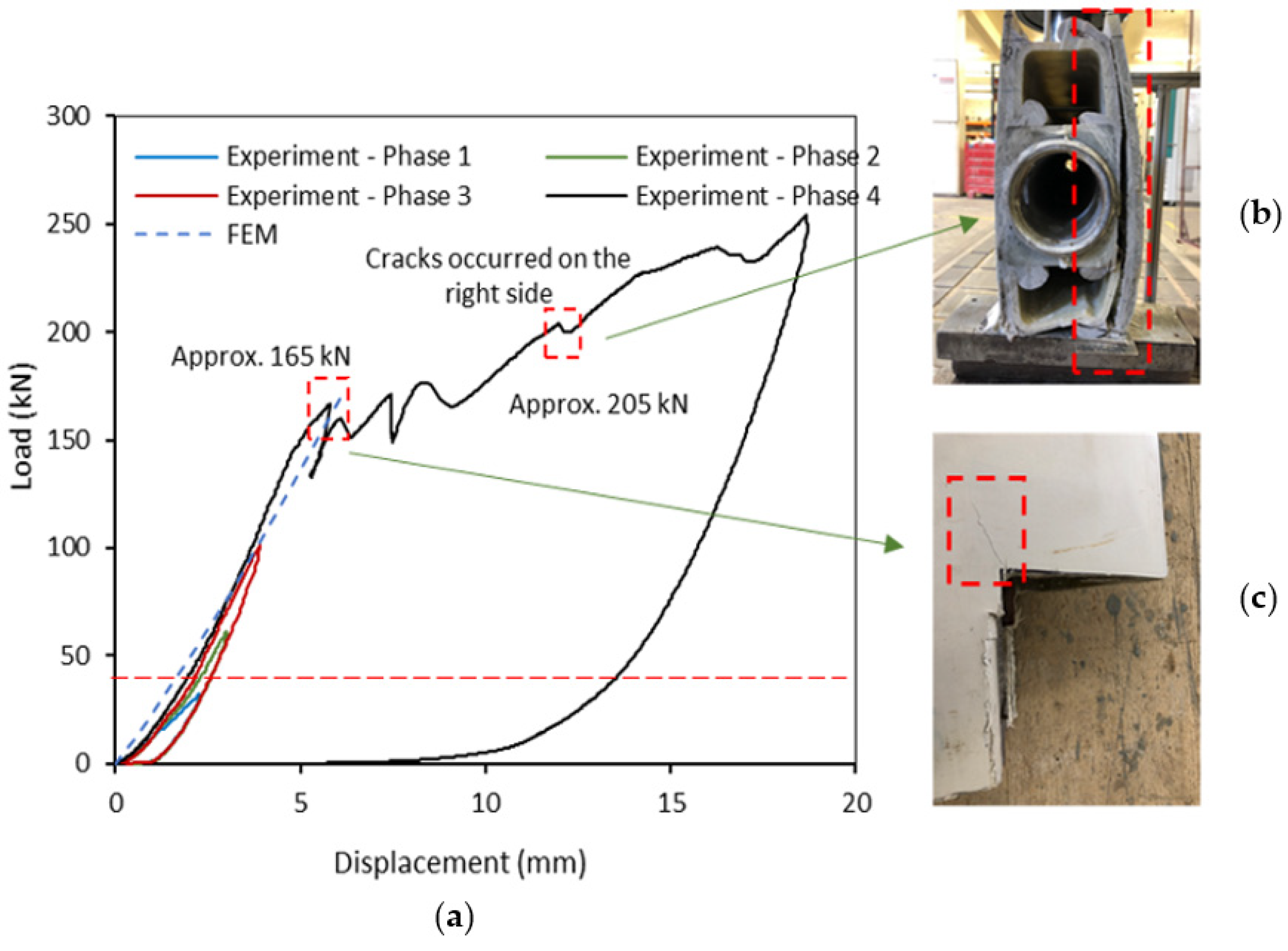

2.4. Structural Testing

2.5. Structural Design

2.6. Fabrication and Installation

2.7. Material and Labour Costs

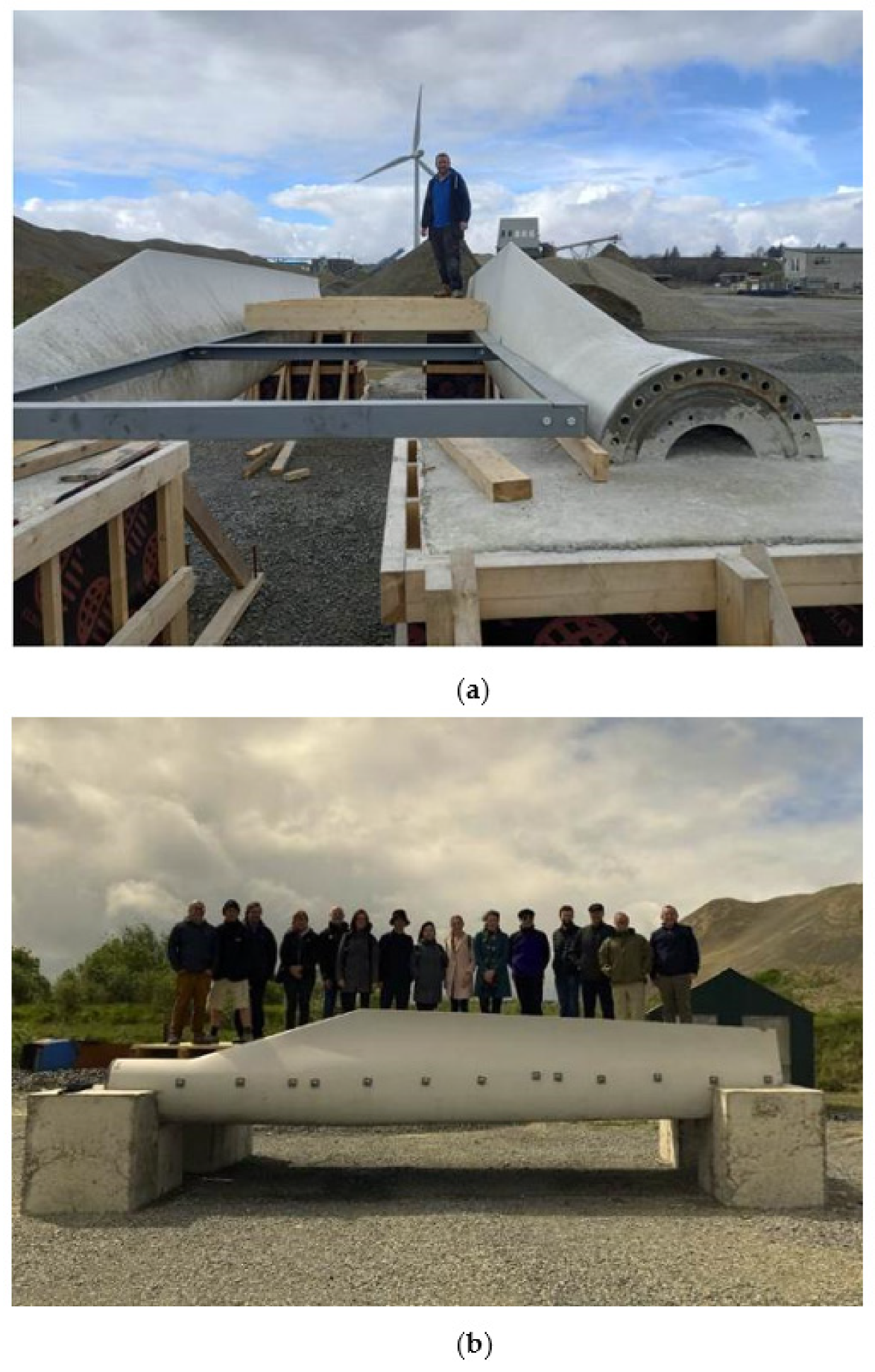

3. Draperstown, Northern Ireland BladeBridge

3.1. Planning, Funding, and Blade Sourcing

3.2. Structural Testing

3.3. BladeBridge Design

3.4. Fabrication and Installation

3.5. Material and Labour Costs

4. Atlanta, USA BladeBridges

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bank, L.C.; Delaney, E.; Mckinley, J.; Gentry, T.R.; Leahy, P. Defining the Landscape for Wind Blades at the End of Service Life. CompositesWorld. 2021. Available online: https://www.compositesworld.com/articles/defining-the-landscape-for-wind-blades-at-the-end-of-service-life (accessed on 28 December 2022).

- Gentry, T.R.; Al-Haddad, T.; Bank, L.C.; Arias, F.R.; Nagle, A.; Leahy, P. Structural Analysis of a Roof Extracted from a Wind Turbine Blade. J. Arch. Eng. 2020, 26, 04020040. [Google Scholar] [CrossRef]

- Deeney, P.; Nagle, A.J.; Gough, F.; Lemmertz, H.; Delaney, E.L.; McKinley, J.M.; Graham, C.; Leahy, P.G.; Dunphy, N.P.; Mullally, G. End-of-Life alternatives for wind turbine blades: Sustainability Indices based on the UN sustainable development goals. Resour. Conserv. Recycl. 2021, 171, 105642. [Google Scholar] [CrossRef]

- Liu, P.; Barlow, C.Y. Wind turbine blade waste in 2050. Waste Manag. 2017, 62, 229–240. [Google Scholar] [CrossRef] [PubMed]

- Bank, L.C.; Arias, F.R.; Yazdanbakhsh, A.; Gentry, T.R.; Al-Haddad, T.; Chen, J.-F.; Morrow, R. Concepts for Reusing Composite Materials from Decommissioned Wind Turbine Blades in Affordable Housing. Recycling 2018, 3, 3. [Google Scholar] [CrossRef]

- Suhail, R.; Chen, J.-F.; Gentry, T.R.; Tasistro-Hart, B.; Xue, Y.; Bank, L.C. Analysis and Design of a Pedestrian Bridge with Decommissioned FRP Windblades and Concrete. In Proceedings of the 14th International Symposium on Fiber-Reinforced Polymer Reinforcement of Concrete Structures (FRPRCS), Belfast, UK, 4–7 June 2019; IIFC: Belfast, UK; pp. 1–5. Available online: https://www.re-wind.info/product/2019/6/10/analysis-and-design-of-a-pedestrian-bridge-with-decommissioned-frp-windblades-and-concrete (accessed on 28 December 2022).

- Nehls, G. Re-Wind Network Successfully Installs Repurposed Wind Blade Pedestrian Bridge. CompositesWorld. 2022. Available online: https://www.compositesworld.com/news/re-wind-network-successfully-installs-repurposed-wind-blade-pedestrian-bridge (accessed on 20 October 2022).

- Al-Haddad, T.; Alshannaq, A.; Bank, L.; Bermek, M.; Gentry, R.; Henao-Barragan, Y.; Li, S.; Poff, A.; Respert, J.; Woodham, C. Strategies for Redesigning High Performance FRP Wind Blades as Future Electrical Infrastructure. In Proceedings of the ARCC-EAAE 2022 International Conference-Resilient City: Physical, Social, and Economic Perspectives, Miami, FL, USA, 2–5 March 2022; pp. 282–288. Available online: http://www.arcc-arch.org/wp-content/uploads/2022/09/ARCC-EAAE-2022_Proceedings_Digital-Version.pdf (accessed on 28 December 2022).

- Alshannaq, A.A.; Bank, L.C.; Scott, D.W.; Gentry, T.R. Structural Analysis of a Wind Turbine Blade Repurposed as an Electrical Transmission Pole. J. Compos. Constr. 2021, 25, 04021023. [Google Scholar] [CrossRef]

- McDonald, A.; Kiernicki, C.; Bermek, M.; Zhang, Z.; Poff, A.; Kakkad, S.; Lau, E.; Arias, F.; Gentry, R.; Bank, L. Re-Wind Design Catalog Fall 2022. Available online: https://doi.org/10.13140/RG.2.2.24487.42401 (accessed on 28 December 2022).

- Cork County Council. Midleton Youghal Greenway. 2022. Available online: https://www.corkcoco.ie/en/community-safety-education-roads-motor-tax/midleton-youghal-greenway (accessed on 28 December 2022).

- Tasistro-Hart, B.; Al-Haddad, T.; Bank, L.C.; Gentry, R. Reconstruction of Wind Turbine Blade Geometry and Internal Structure from Point Cloud Data. In Proceedings of the 2019 ASCE International Conference on Computing in Civil Engineering (i3CE 2019), Atlanta, GA, USA, 17–19 June 2019; pp. 130–137. [Google Scholar]

- Kiernicki, C.; Kakkad, S.D.; Bermek, M.S.; Gentry, T.R. A Digital Process for Reconstructing Wind Turbine Blade Geometry from Point Cloud Data. In Proceedings of the 5th International Conference on Structures and Architecture, Aalborg, Denmark, 6–8 July 2022. [Google Scholar]

- ASTM D2584; Standard Test Method for Ignition Loss of Cured Reinforced Resins. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D3410; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials with Unsupported Gage Section by Shear Loading. ASTM International: West Conshohocken, PA, USA, 2016.

- Ruane, K.; Zhang, Z.; Nagle, A.; Huynh, A.; Alshannaq, A.; McDonald, A.; Leahy, P.; Soutsos, M.; McKinley, J.; Gentry, R.; et al. Material and Structural Characterization of a Wind Turbine Blade for Use as a Bridge Girder. Transp. Res. Rec. J. Transp. Res. Board 2022, 2676, 354–362. [Google Scholar] [CrossRef]

- IS EN 1991-2:2003+NA:2009; Eurocode 1: Actions on Structures—Part 2: Traffic Loads on Bridges (Inc. National Annex to IS EN 1991-2:2003). National Standards Authority of Ireland: Dublin, Ireland, 2009.

- Zhang, Z.; Ruane, K.; Huynh, A.; McDonald, A.; Leahy, P.; Alshannaq, A.; Gentry, T.R.; Nagle, A.; Bank, L.C. BladeBridge-Design and Construction of a Pedestrian Bridge using Decommissioned Wind Turbine Blades. In Proceedings of the 5th International Conference on Structures and Architecture, Aalborg, Denmark, 6–8 July 2022. [Google Scholar]

- Nagle, A.J. Sustainability Assessment of the Repurposing of Wind Turbine Blades. Ph.D. Thesis, School of Engineering & Architecture, Environmental Research Institute University, College Cork, Cork, Ireland, 2022. [Google Scholar]

- Nagle, A.J.; Ruane, K.; Gentry, T.R.; Bank, L.C.; Dunphy, N.; Mullally, G.; Leahy, P.G. Life Cycle Sustainability Assessment of a Pedestrian Bridge Made from Repurposed Wind Turbine Blades. In Proceedings of the Civil Engineering Research in Ireland 2022, Dublin, Ireland, 25–26 August 2022; Available online: http://cerai.net/page/15/past-conferences/index.html (accessed on 28 December 2022).

| Item | Description | BladeBridge Cost (€) |

|---|---|---|

| Surveying | External Surveyor | 1800 |

| Fasteners | Blind bolts | 1250 |

| Steel | Bespoke welded cleats, steel beams, deck plates | 5775 |

| Steel | Galvanization | 1650 |

| Sealants | Bolt hole sealant | 70 |

| Labour | Fabricator Time | 7425 |

| FRP Layup | Root end cap FRP | 825 |

| FRP Layup | Trailing edge treatment | 413 |

| Reinforced Concrete | On-site reinforced concrete works | 2800 |

| Transportation and Crane | Truck and driver | 1200 |

| Total | Excluding design and testing costs | 23,208 |

| Item | Supplier | BladeBridge Cost (£) |

|---|---|---|

| Plywood | IJK timber | 456 |

| Steel | K&M | 593 |

| Wood formwork | IJK timber | 1227 |

| Screws | K&M | 150 |

| Bolts, washers, nuts | K&M | 432 |

| Steel tubing | K&M | 50 |

| Decking | Eglantine timber | 723 |

| Concrete | Quarry owner | 500 |

| Technician hours | 3 technicians, approx. 120 h total | 6675 |

| Total | Excluding design and testing costs | 10,808 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruane, K.; Soutsos, M.; Huynh, A.; Zhang, Z.; Nagle, A.; McDonald, K.; Gentry, T.R.; Leahy, P.; Bank, L.C. Construction and Cost Analysis of BladeBridges Made from Decommissioned FRP Wind Turbine Blades. Sustainability 2023, 15, 3366. https://doi.org/10.3390/su15043366

Ruane K, Soutsos M, Huynh A, Zhang Z, Nagle A, McDonald K, Gentry TR, Leahy P, Bank LC. Construction and Cost Analysis of BladeBridges Made from Decommissioned FRP Wind Turbine Blades. Sustainability. 2023; 15(4):3366. https://doi.org/10.3390/su15043366

Chicago/Turabian StyleRuane, Kieran, Marios Soutsos, An Huynh, Zoe Zhang, Angela Nagle, Kenny McDonald, T Russell Gentry, Paul Leahy, and Lawrence C. Bank. 2023. "Construction and Cost Analysis of BladeBridges Made from Decommissioned FRP Wind Turbine Blades" Sustainability 15, no. 4: 3366. https://doi.org/10.3390/su15043366

APA StyleRuane, K., Soutsos, M., Huynh, A., Zhang, Z., Nagle, A., McDonald, K., Gentry, T. R., Leahy, P., & Bank, L. C. (2023). Construction and Cost Analysis of BladeBridges Made from Decommissioned FRP Wind Turbine Blades. Sustainability, 15(4), 3366. https://doi.org/10.3390/su15043366