Strength Performance and Stabilization Mechanism of Fine Sandy Soils Stabilized with Cement and Metakaolin

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Apparatus

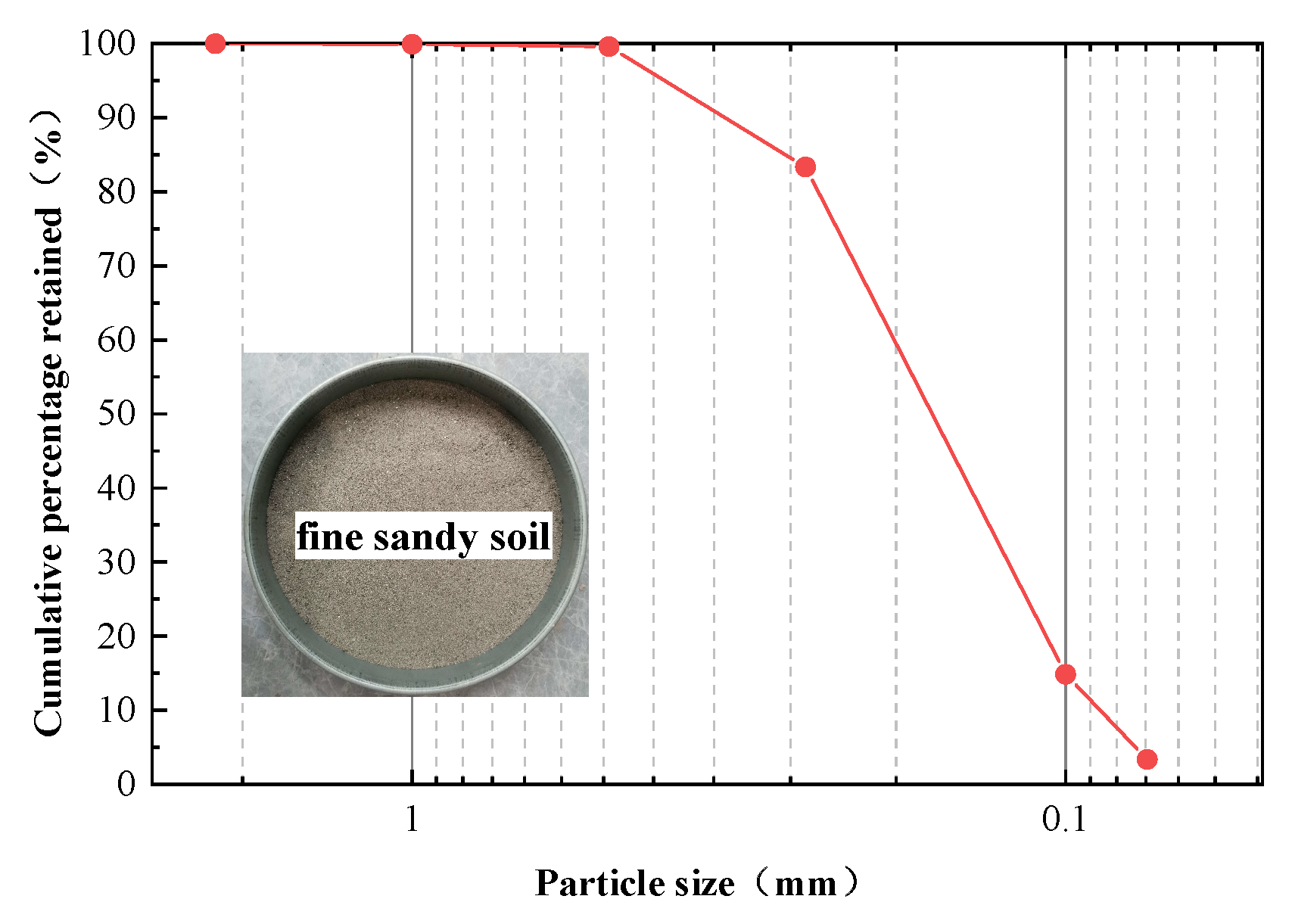

2.1.1. Materials

2.1.2. Apparatus

2.2. Experimental Scheme

- (1)

- Tests for the cement–metakaolin ratio

- (2)

- Tests for the water–binder ratio

- (3)

- Tests for the dosage of the binder

- (4)

- Tests for the curing age

- (5)

- Scanning Electronic Microscopy (SEM) tests

- (6)

- Mercury Intrusion Porosimetry (MIP) tests

2.3. Specimen Preparation

3. Results and Analysis

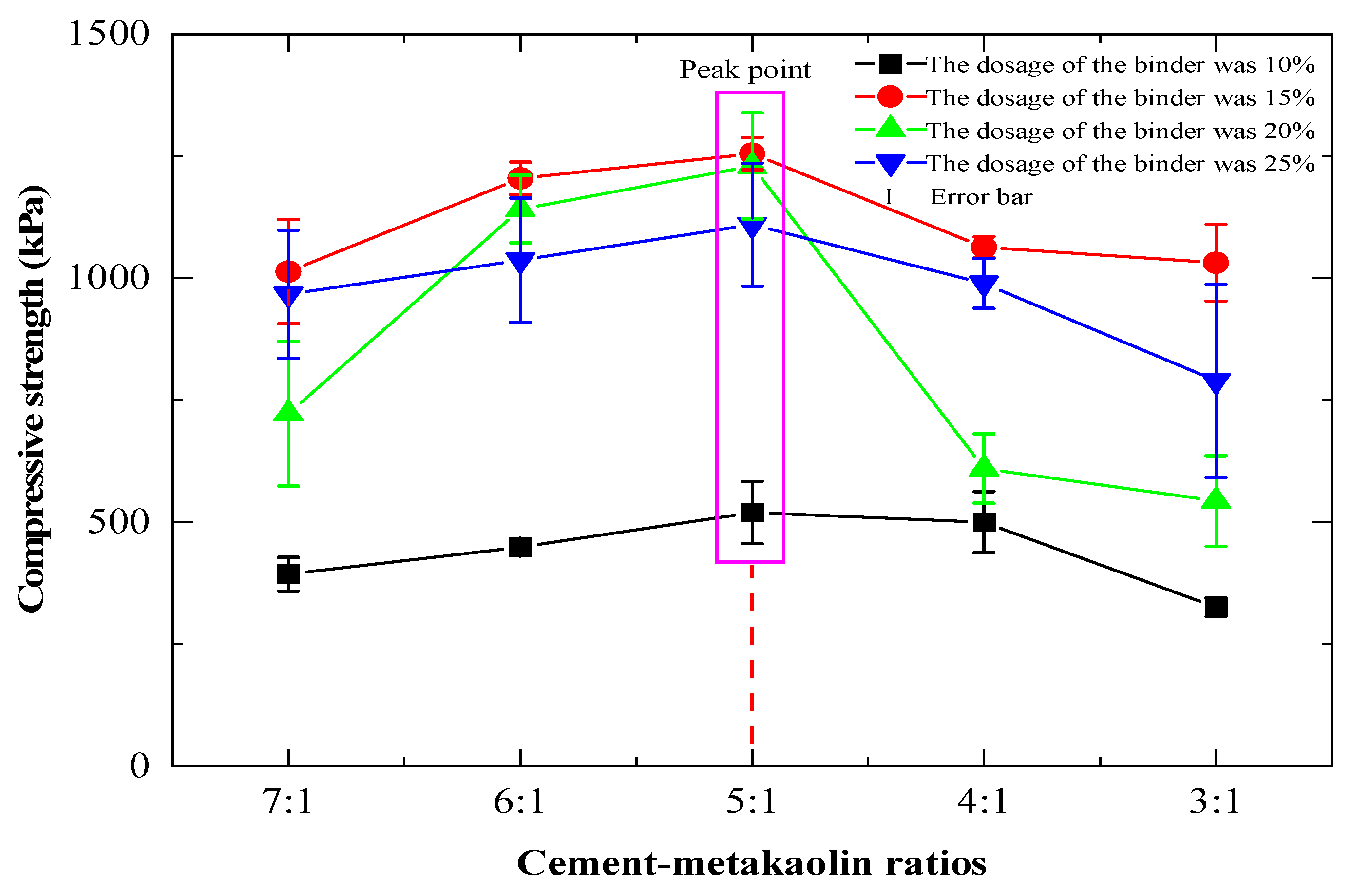

3.1. Cement–Metakaolin Ratio

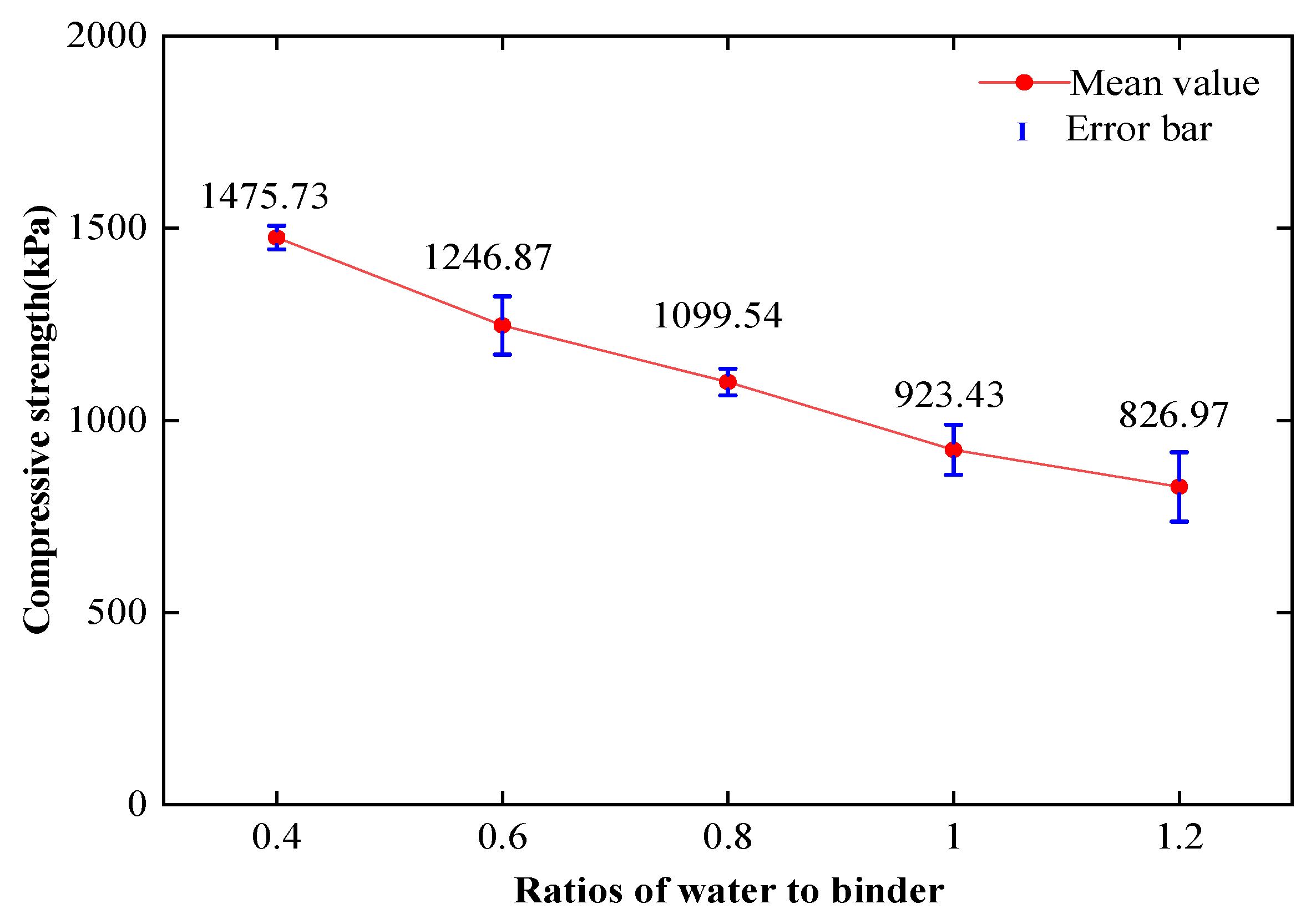

3.2. Water–Binder Ratio

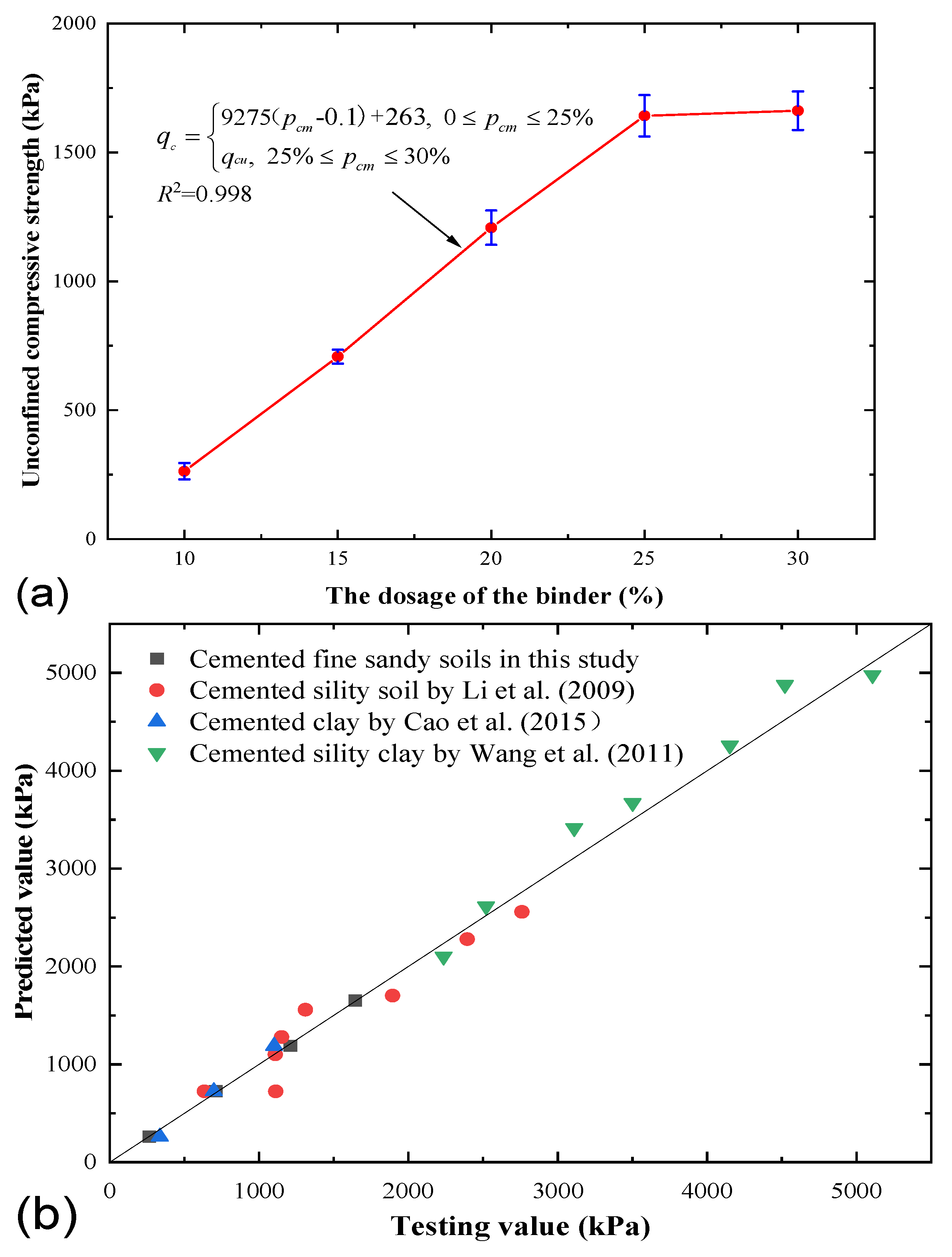

3.3. Dosage of Binder

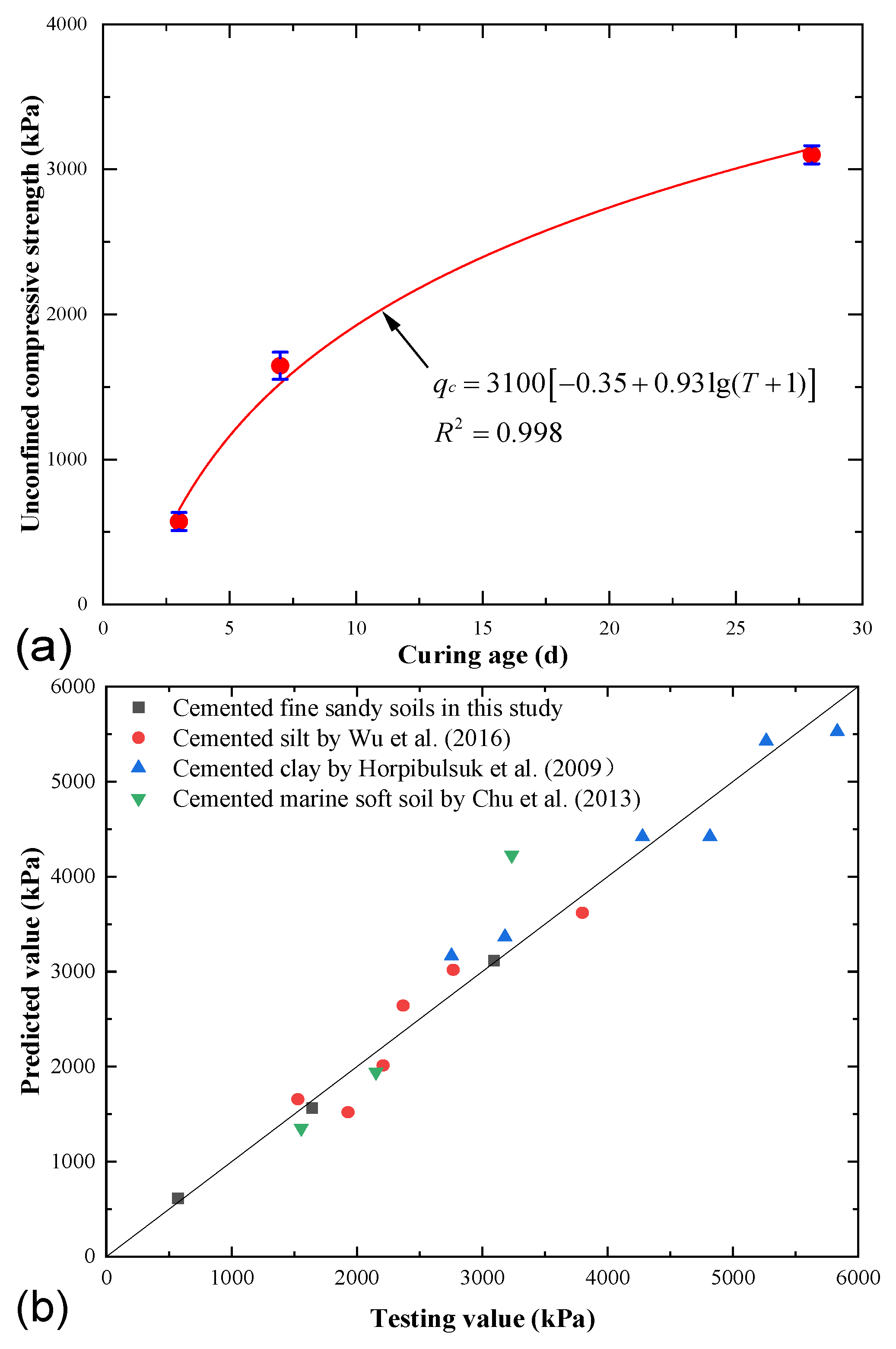

3.4. Curing Age

4. Discussion

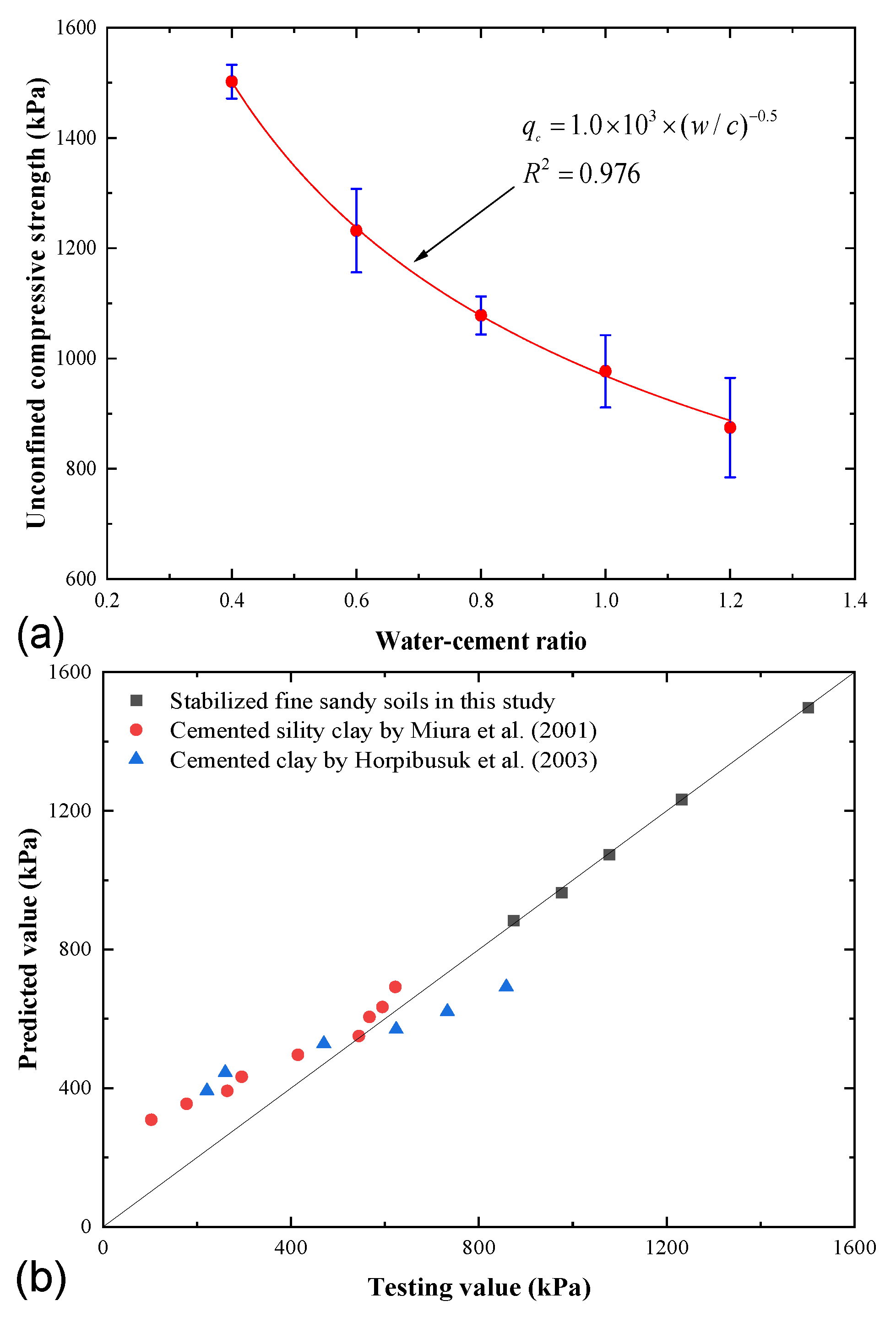

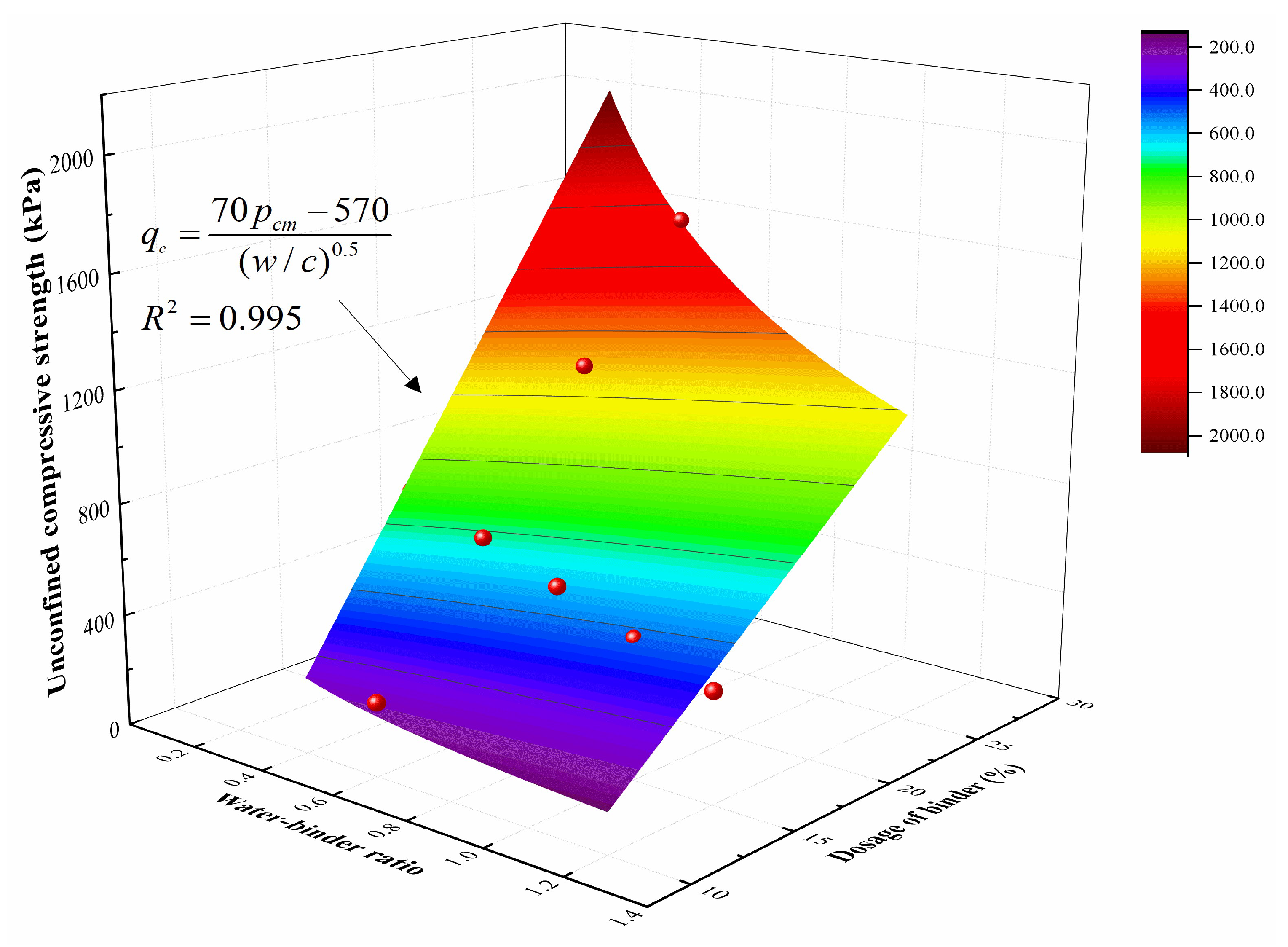

4.1. Relationship of Compressive Strength vs. Water–Binder Ratio

4.2. Relationship of Compressive Strength vs. Dosage of Binder

4.3. Relationship of Compressive Strength vs. Dosage of Binder and Water–Binder Ratio

4.4. Relationship of Compressive Strength vs. the Curing Age

5. Stabilization Mechanism Analysis

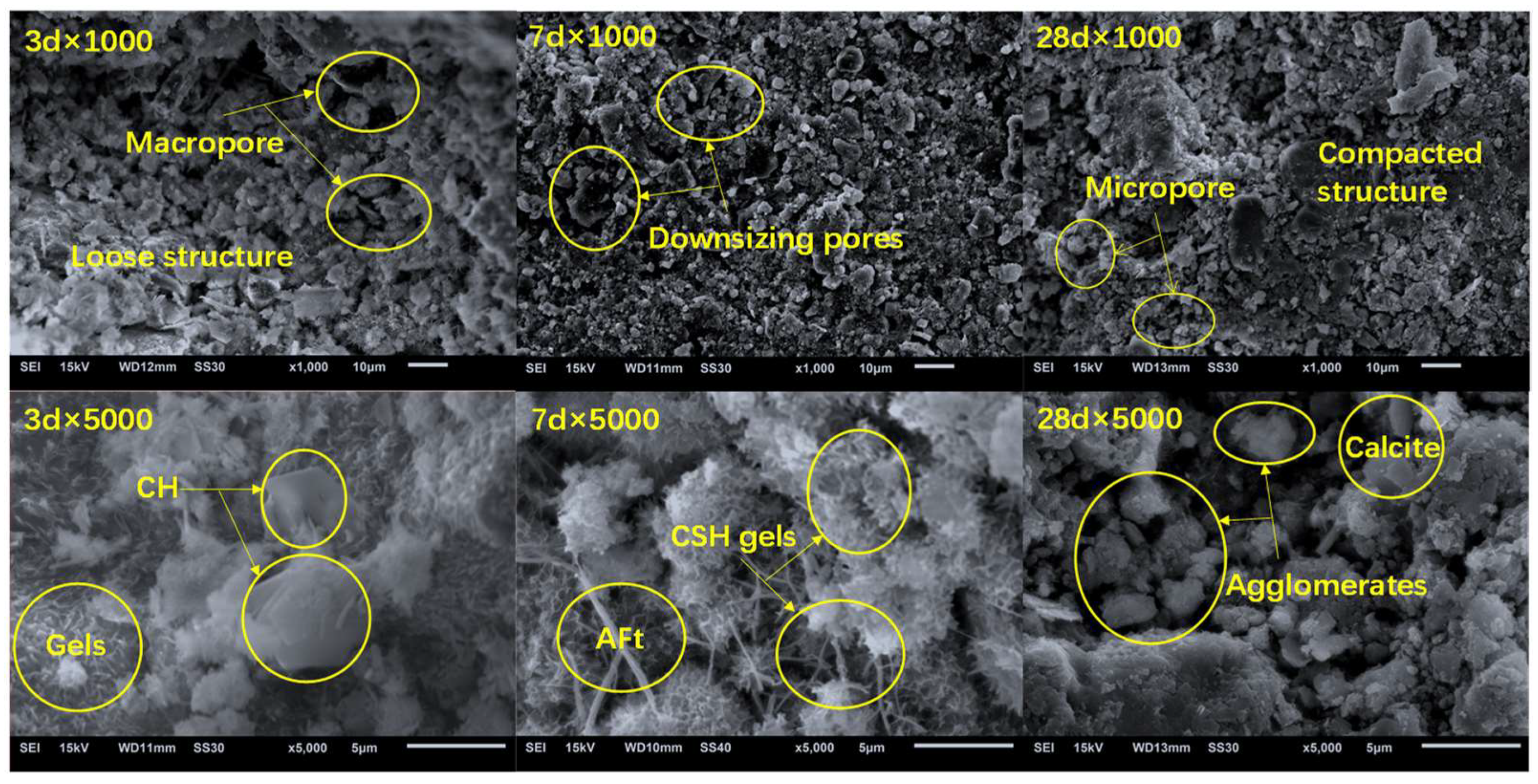

5.1. SEM

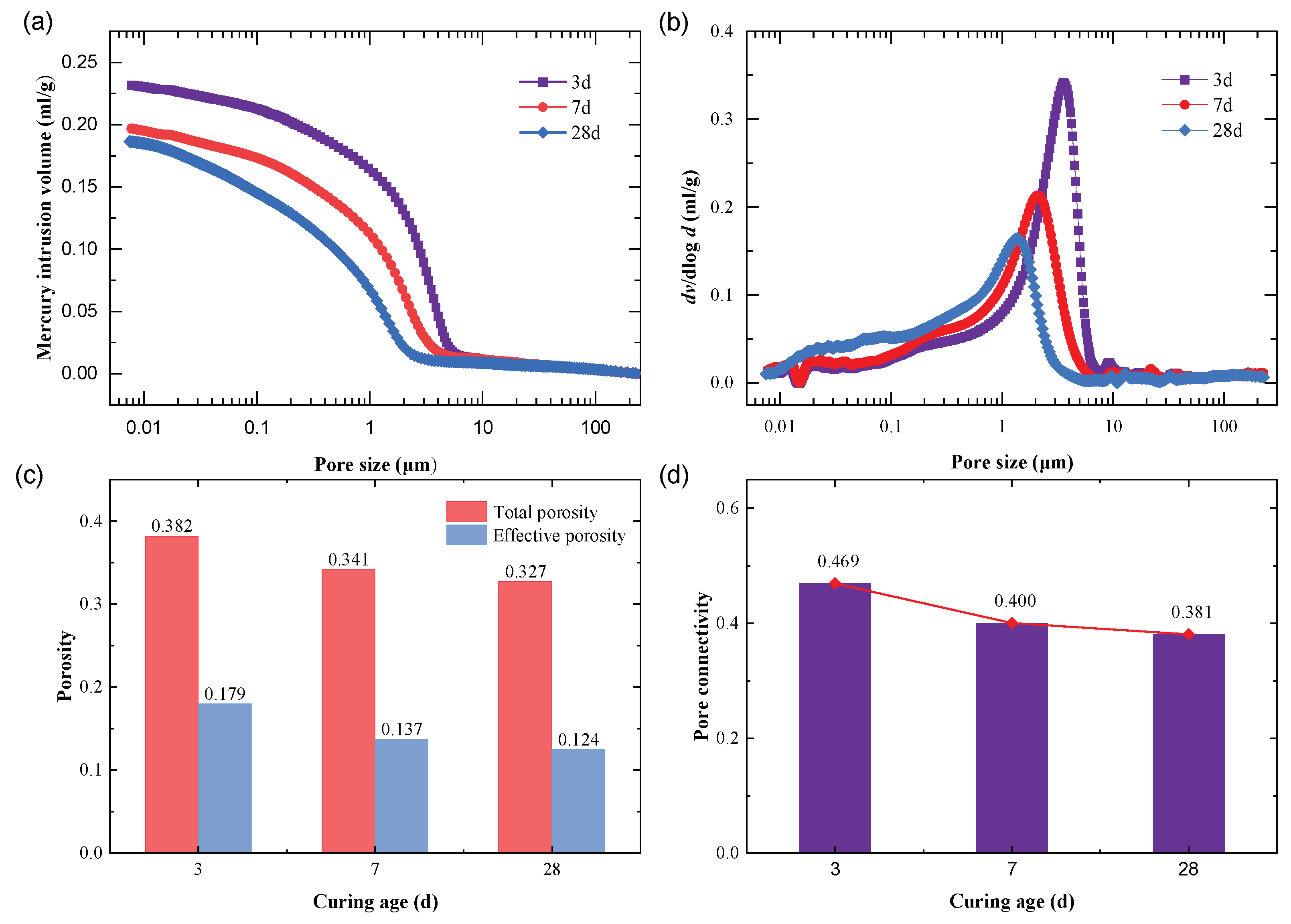

5.2. MIP

6. Conclusions

- (1)

- The compressive strength of CMSFSS initially increased and then decreased with the cement–metakaolin ratio. Their peak strength value was obtained when the cement–metakaolin ratio was 5:1, and this mixing ratio did not vary with changes in the dosage of cement and metakaolin.

- (2)

- The compressive strength of CMSFSS decreased with the water–binder ratio but increased linearly with the dosage of cement and metakaolin. With the increase curing age, their strength performance improvement was initially fast and then slow. Namely, the contribution of the binder to the strength performance improvement would be very small when the dosage of the binder reached a certain level.

- (3)

- Four empirical formulas regarding the water–binder ratio, the dosage of binder, and the curing age were proposed. Their correctness and applicability were verified by comparing to previous similar studies on fine-grained soils.

- (4)

- The microstructural observations showed that the addition of metakaolin was conducive to producing more cementitious substances to fill the internal pores of the soil, promoting the continuous reduction of pore sizes and thereby improving the structural compactness and integrity of fine sandy soils. The results of this study could provide a reference for soil stabilization practices with cement and metakaolin.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Y.; He, Q.L.; Jiang, Y.; Sun, M.M.; Chen, E.J.; Lee, F.H. Effect of in Situ Water Content Variation on the Spatial Variation of Strength of Deep Cement-mixed Clay. Géotechnique 2018, 69, 391–405. [Google Scholar] [CrossRef]

- Emmanuel, M.; Hussein, M.; Laurent, L.; Robert, M.E. Physicochemical and Consolidation Properties of Compacted Lateritic Soil Treated with Cement. Soils Found 2017, 57, 60–79. [Google Scholar]

- Pu, S.Y.; Zhu, Z.D.; Zhao, L.M.; Song, W.L.; Wan, Y.; Huo, W.W.; Wang, H.R.; Yao, K.; Hu, L.L. Microstructural Properties and Compressive Strength of Lime or/and Cement Solidified Silt: A Multi-scale Study. Bull. Eng. Geol. Environ. 2020, 79, 5141–5159. [Google Scholar] [CrossRef]

- Zhang, R.; Santoso, A.M.; Tan, T.; Phoon, K.K. Strength of High Water-Content Marine Clay Stabilized by Low Amount of Cement. J. Geotech. Geoenvironmental Eng. 2013, 139, 2170–2181. [Google Scholar] [CrossRef]

- Wang, X.; Cui, J.; Shen, J.H.; Wang, X.Z.; Zhu, C.Q. Particle breakage behavior of a foundation filling material on island-reefs in the South China Sea under impact loading. Bull. Eng. Geol. Environ. 2022, 81, 1–24. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Liao, C.; Cui, J.; Shen, J.H.; Wang, X.Z.; Zhu, C.Q. Particle breakage mechanism and particle shape evolution of calcareous sand under impact loading. B Eng. Geol. Environ. 2022, 81, 372. [Google Scholar] [CrossRef]

- Dermatas, D.; Dutko, P.; Balorda-Barone, J.; Deok-hyun, M. Evaluation of Engineering Properties of Cement Treated Hudson River Dredged Sediments for Reuse as Fill Material. J. Mar. Environ. Eng. 2003, 7, 101–124. [Google Scholar]

- Liu, Y.; Lee, F.H.; Quek, S.T.; Chen, E.J.; Yi, J.T. Effect of Spatial Variation of Strength and Modulus on the Lateral Compression Response of Cement-admixed Clay Slab. Géotechnique 2015, 65, 851–865. [Google Scholar] [CrossRef]

- Chen, M.; Shen, S.L.; Arulrajah, A.; Wu, H.N.; Hou, D.W.; Xu, Y.S. Laboratory Evaluation on the Effectiveness of Polypropylene Fibers on the Strength of Fiber-reinforced and Cement-stabilized Shanghai Soft Clay. Geotext. Geomembr. 2015, 43, 515–523. [Google Scholar] [CrossRef]

- Li, N.; Zhu, Y.L.; Zhang, F.; Lim, S.M.; Wu, W.Y.; Wang, W. Unconfined Compressive Properties of Fiber-stabilized Coastal Cement Clay Subjected to Freeze—Thaw Cycles. J. Mar. Sci. Eng. 2021, 9, 143. [Google Scholar] [CrossRef]

- Zhang, D.W.; Chen, L.; Liu, S.Y. Key Parameters Controlling Electrical Resistivity and Strength of Cement Treated Soils. J. Central South Univ. 2012, 19, 2991–2998. [Google Scholar] [CrossRef]

- Chen, S.L.; Hou, R.; Ni, C.L.; Wang, J.X. Research on the Mechanical Properties of Cemented Soil Based on Triaxial Compression Tests. Bull. Chin. Ceram. Soc. 2018, 37, 4012–4017. [Google Scholar]

- Thanakorn, C.; Krisdha, T.; Suched, L. Swell-shrink Behaviour of Cement with Fly Ash-stabilised Lakebed Sediment. Bull. Eng. Geol. Environ. 2021, 80, 2617–2628. [Google Scholar]

- Ma, Z.C.; Wang, L. Technical Progess of Emssion-reduction and Utilization of Corbon Dioxide in Cement Industey. Mater. Rev. 2011, 25, 150–154. [Google Scholar]

- Edil, T.B.; Acosta, H.A.; Benson, C.H. Stabilizing soft fine-grained soils with fly ash. J. Mater. Civ. Eng. 2006, 18, 283–294. [Google Scholar] [CrossRef]

- Kolias, S.; Kasselouri-Rigopoulou, V.; Karahalios, A. Stabilisation of cCayey soils with High Calcium Fly Ash and Cement. Cem. Concr. Compos. 2004, 27, 301–313. [Google Scholar] [CrossRef]

- Soumendra, K.M.; Pradip, K.P.; Chitta, R.M. Stabilization of Expansive Soil Using Industrial Wastes. Geomech. Eng. 2017, 12, 012238. [Google Scholar]

- Takeshi, K.; Aly, A.; Toshihide, S. The Use of Recycled Bassanite and Coal Ash to Enhance the Strength of Very Soft Clay in Dry and Wet Environmental Conditions. Constr. Build. Mater. 2013, 38, 224–235. [Google Scholar]

- Wu, Y.K.; Shi, K.J.; Yu, J.L.; Han, T.; Li, D.D. Research on Strength Degradation of Soil Solidified by Steel Slag Powder and Cement in Seawater Erosion. J. Mater. Civil. Eng. 2020, 32, 04020181. [Google Scholar] [CrossRef]

- Asskar, J.C.; Saman, S.K. Microstructure Characteristics of Cement-stabilized Sandy Soil Using Nanosilica. J. Rock Mech. Geotech. 2017, 9, 981–988. [Google Scholar]

- Tongwei, Z.; Xibing, Y.; Yongfeng, D.; Dingwen, Z.; Songyu, L. Mechanical Behaviour and Micro-structure of Cement-stabilised Marine Clay with a Metakaolin Agent. Constr. Build. Mater. 2014, 73, 51–57. [Google Scholar]

- Wang, S.N.; Xue, Q.P.; Zhu, Y.; Li, G.Y.; Wu, Z.J.; Zhao, K. Experimental study on material ratio and strength performance of geopolymer-improved soil. Constr. Build. Mater. 2021, 267, 120469. [Google Scholar] [CrossRef]

- Kai, F.; Jun, Z.Y.; Yang, H.P.; Chao, H.Z. Preparation and Catalytic Performance of Acid-Activated Zinc Slag-Metakaolin Geopolymer. Bull. Chin. Ceram. Soc. 2021, 49, 2061–2069. [Google Scholar]

- Kolovos, K.G.; Asteris, P.G.; Cotsovos, D.M.; Badogiannis, E.; Tsivilis, S. Mechanical Properties of Soilcrete Mixtures Modified with Metakaolin. Constr. Build. Mater. 2013, 47, 1026–1036. [Google Scholar] [CrossRef]

- Wu, Z.L.; Deng, Y.F.; Liu, S.Y.; Liu, Q.W.; Chen, Y.G.; Zha, F.S. Strength and Micro-structure Evolution of Compacted Soils Modified by Admixtures of Cement and Metakaolin. Appl. Clay Sci. 2016, 127–128, 44–51. [Google Scholar] [CrossRef]

- Wang, L.H.; Li, X.Y.; Cheng, Y.; Bai, X.H. Effects of Coal-metakaolin on the Properties of Cemented Sandy Soil and its Mechanisms. Constr. Build. Mater. 2018, 166, 592–600. [Google Scholar] [CrossRef]

- Deng, Y.F.; Wu, Z.L.; Liu, S.Y.; Yue, X.B.; Zhu, L.L. Influence of Geopolymer on Strength of Cement-stabilized Soils and its Mechanism. Chin. J. Geotech. Eng. 2016, 38, 446–453. [Google Scholar]

- Zhang, R.R.; Ma, D.D. Effects of Curing Time on the Mechanical Property and Microstructure Characteristics of Metakaolin-based Geopolymer Cement-stabilized Silty Clay. Adv. Mater. Sci. Eng. 2020, 2020, 9605941. [Google Scholar]

- Ma, D.D.; Ma, Y.Q.; Kun, H.; Zhang, R.R. Pore Structure and Dynamic Mechanical Properties of Geopolymer Cement Soil Based on Nuclear Magnetic Resonance Technique. Chin. J. Geotech. Eng. 2021, 43, 572–578. [Google Scholar]

- Xing, H.F.; Xiong, F.; Zhou, F. Improvement for the Strength of Salt-rich Soft soil Reinforced by Cement. Mar. Georesour. Geotec. 2018, 36, 38–42. [Google Scholar]

- Wu, Z.L.; Zhu, X.Y.; Feng, D.Y.; Liu, H.S. Behavior and Micro-mechanism of Cement-based Modified Compaction Soils Compsed of Steel Slag and Metakaolin. China J. Highw. Transp. 2017, 30, 18–26. [Google Scholar]

- Zhi, T.Y.; Rui, K.; Lian, C.J.; Jun, W. Enhancing Durability of Lime-cement Solidified Sludge with Metakaolin. Rock Soil Mech. 2020, 41, 1146–1152. [Google Scholar]

- Wang, S.N.; Guo, S.F.; Gao, X.Q.; Zhang, P.; Li, G.Y. Effects of Cement Content and Soil Texture on Strength Hydraulic and Microstructural Characteristics of Cement-stabilized Composite Soils. Bull. Eng. Geol. Environ. 2022, 81, 264. [Google Scholar] [CrossRef]

- Anhad, S.G.; Rafat, S. Durability Properties of Self-compacting Concrete Incorporating Metakaolin and Rice Husk Ash. Constr. Build. Mater. 2018, 176, 323–332. [Google Scholar]

- Suksun, H.; Runglawan, R.; Apichat, S.; Avirut, C. Strength Development in Cement Admixed Bangkok Clay: Laboratory and Field Investigations. Soils Found. 2011, 51, 239–251. [Google Scholar]

- Horpibulsuk, S.; Miura, N.; Nagaraj, T. Assessment of Strength Development in Cement-admixed High Water Content Clays with Abrams’ law as a basis. Géotechnique 2003, 53, 439–444. [Google Scholar] [CrossRef]

- Miura, N.; Horpibulsuk, S.; Nagaraj, T.S. Engineering Behavior of Cement Stabilized Clay at High Water Content. Soils Found. 2001, 41, 33–45. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.L.; Shen, X.D. Effect of Cement Content on the Early Structual Formation of Stabilized Soil. Bull. Chin. Ceram. Soc. 2011, 30, 469–473. [Google Scholar]

- Cao, Z.G.; Zhang, D.W. Key Parameters Controlling Unconfined Compressive Strength of Soil-cement Mixtures. Chin. J. Rock Mech. Eng. 2015, 34, 3446–3454. [Google Scholar]

- Li, J.J.; Liang, R.W. Research on Compression Strength and Modulus of Deformation of Cemented Soil. Rock Soil Mech. 2009, 30, 473–477. [Google Scholar]

- Suksun, H.; Runglawan, R.; Yuttana, R. Role of fly Ash on Strength and Microstructure Development in Blended Cement Stabilized Silty Clay. Soils Found. 2009, 49, 85–98. [Google Scholar]

- Chu, C.F.; Li, X.C.; Deng, Y.F.; Tang, J.W. Influence of Metakaolin on Mechanical Properties of Cement-modified Marine Soft Soil. Chin. J. Geotech. Eng. 2013, 35, 170–174. [Google Scholar]

- Suksun, H.; Runglawan, R.; Avirut, C.; Yuttana, R.; Apichat, S. Analysis of Strength Development in Cement-stabilized Silty Clay from Microstructural Considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar]

- Azime, S.; Mehmet, E. Effect of Metakaolin Substitution on Physical Mechanical and Hydration Process of White Portland cement. Constr. Build. Mater. 2015, 95, 257–268. [Google Scholar]

| Chemical Component | Al2O3 | SiO2 | Fe2O3 | TiO2 |

|---|---|---|---|---|

| Proportion (%) | 41.30 | 53.03 | 0.81 | 1.00 |

| Testing Schemes | Designed Parameters | |||

|---|---|---|---|---|

| Cement–Metakaolin Ratio | Water–Binder Ratio | Dosage of the Binder (%) | Curing Age (d) | |

| Tests for the cement–metakaolin ratio | 3:1, 4:1, 5:1, 6:1, 7:1 | 0.6 | 10%, 15%, 20%, 25%, 30% | 7 |

| Tests for the water–binder ratio | 5:1 | 0.4, 0.6, 0.8, 1.0, 1.2 | 15 | 7 |

| Tests for the dosage of the binder | 5:1 | 0.6 | 10%, 15%, 20%, 25%, 30% | 7 |

| Tests for the curing age | 5:1 | 0.6 | 15 | 3, 7, 28 |

| SEM tests | 5:1 | 0.6 | 15 | 3, 7, 28 |

| MIP tests | 5:1 | 0.6 | 15 | 3, 7, 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Zhang, X.; Zhang, P.; Chen, Z. Strength Performance and Stabilization Mechanism of Fine Sandy Soils Stabilized with Cement and Metakaolin. Sustainability 2023, 15, 3431. https://doi.org/10.3390/su15043431

Wang S, Zhang X, Zhang P, Chen Z. Strength Performance and Stabilization Mechanism of Fine Sandy Soils Stabilized with Cement and Metakaolin. Sustainability. 2023; 15(4):3431. https://doi.org/10.3390/su15043431

Chicago/Turabian StyleWang, Shengnian, Xingjin Zhang, Peng Zhang, and Zewei Chen. 2023. "Strength Performance and Stabilization Mechanism of Fine Sandy Soils Stabilized with Cement and Metakaolin" Sustainability 15, no. 4: 3431. https://doi.org/10.3390/su15043431

APA StyleWang, S., Zhang, X., Zhang, P., & Chen, Z. (2023). Strength Performance and Stabilization Mechanism of Fine Sandy Soils Stabilized with Cement and Metakaolin. Sustainability, 15(4), 3431. https://doi.org/10.3390/su15043431