Statistical Approach Model to Evaluate Permanent Deformation of Steel Fiber Modified Asphalt Mixtures

Abstract

:1. Introduction

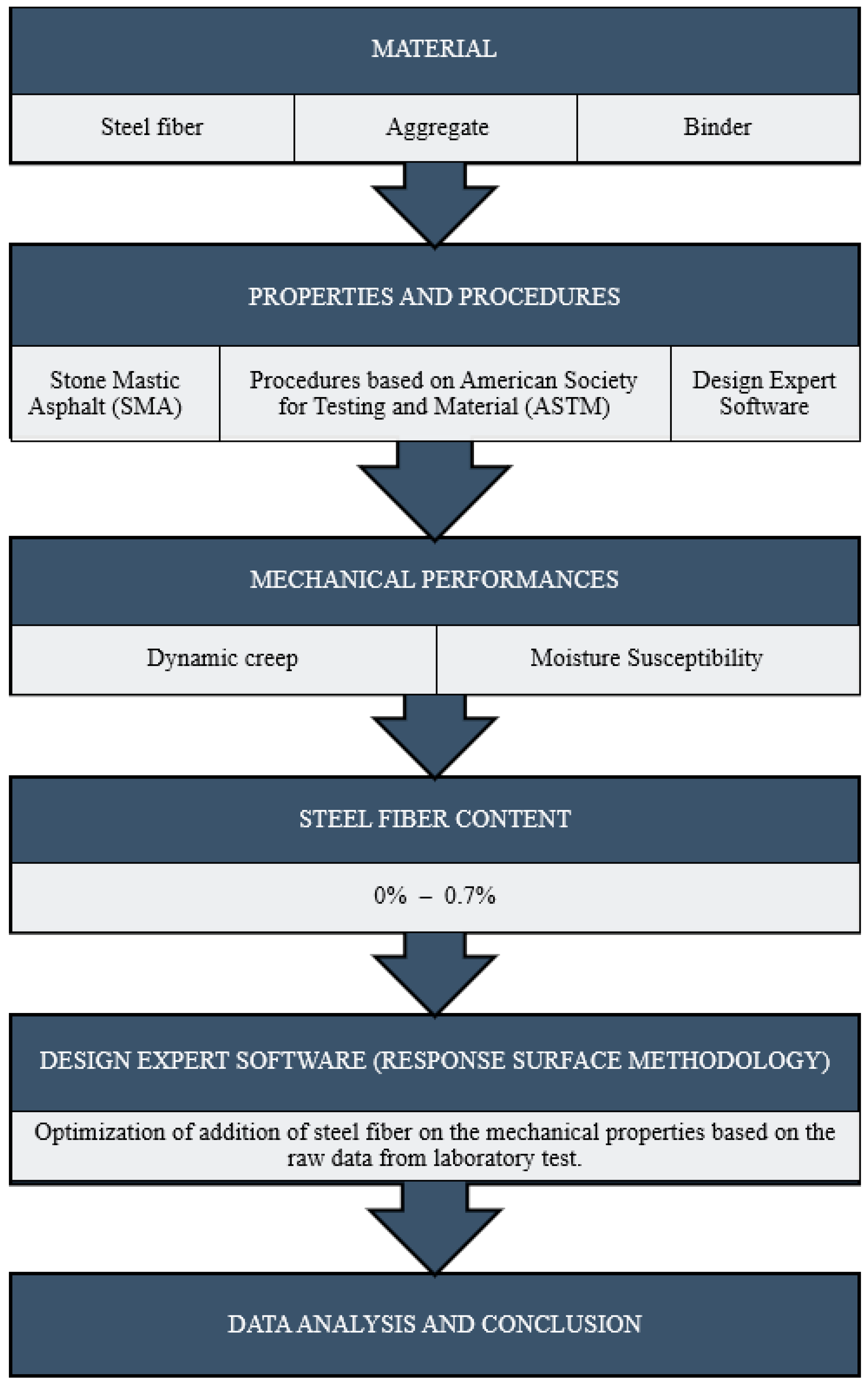

2. Materials and Methodology

2.1. Materials and Sample Preparation

2.2. Marshall Stability & Flow

2.3. Dynamic Creep Test

2.4. Moisture Susceptibility Test

2.5. Design of Experiment

3. Results and Discussion

3.1. Marshall Stability and Flow

3.2. Dynamic Creep

3.3. Moisture Susceptibility

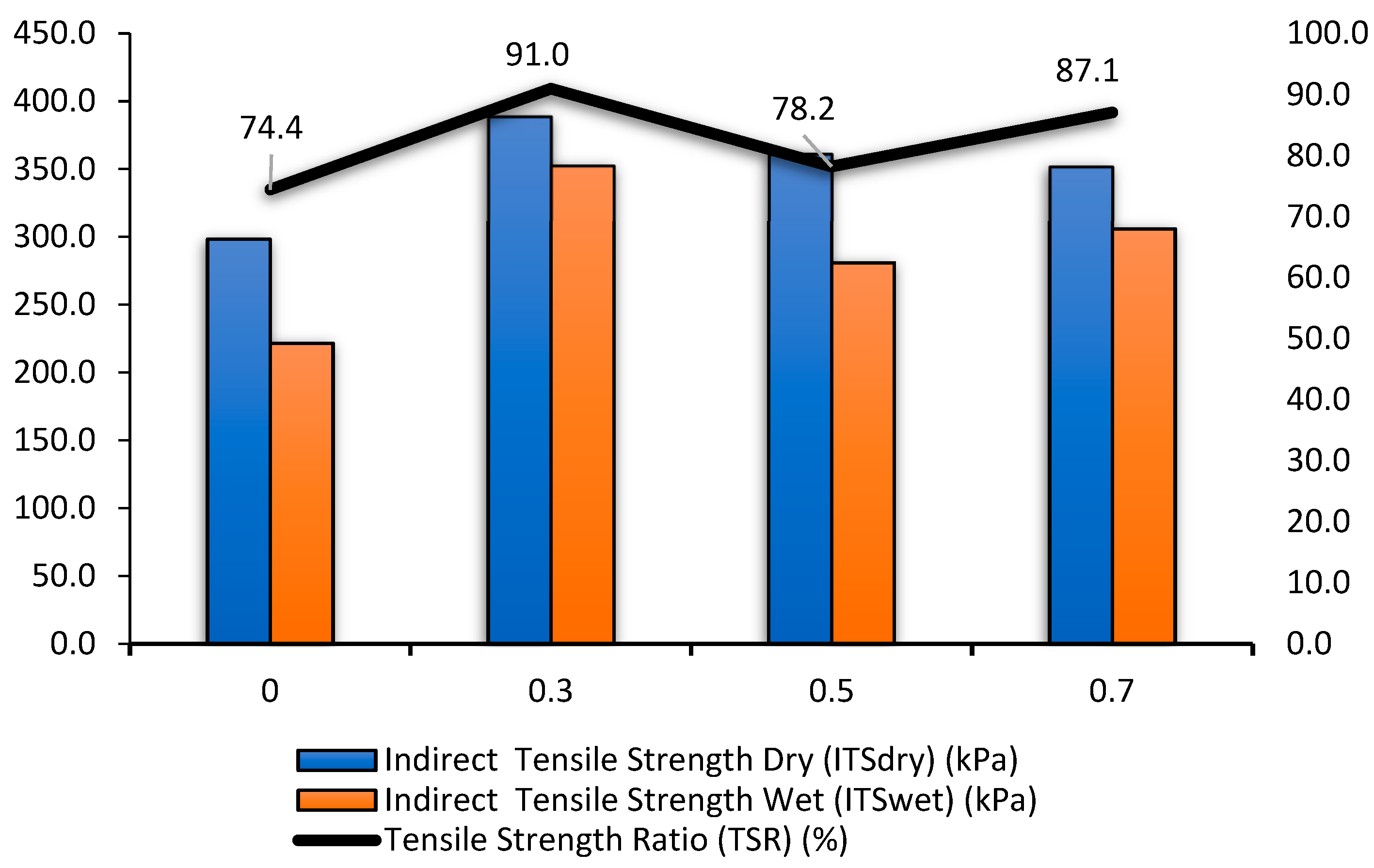

3.4. Experimental Design Layout

3.5. Effects of One Factor on the Responses

3.5.1. Dynamic Creep

3.5.2. Moisture Susceptibility

3.5.3. Targeted Percentage of Steel Fiber

3.6. Effects of Two Factors on the Responses

3.6.1. Dynamic Creep

3.6.2. Moisture Susceptibility

3.6.3. Targeted Percentage of Steel Fiber

3.7. Model Fitting

3.8. Comparison between Laboratory and Statistical Experiment

4. Conclusions

- It can be indicated that the incorporation of steel fiber in the asphalt mixture increases the stability compared to the conventional mixture. In the meantime, the flow values go through reduction. In relation to these indications, it can be said that the optimum percentage of steel fiber to be utilized in the SMA mixture in terms of stability is 0.3 percent.

- Experimental results from the dynamic creep and moisture susceptibility have shown that the addition of steel fiber into the asphalt mixture improves the SMA mixture performance. Comparing the result with conventional and different proportions of steel fiber, 0.3 percent of steel fiber in SMA showed the greatest improvement in terms of permanent deformation. The addition of 0.3 percent of steel fiber to the mix decreases the strain value considerably as compared to the control mix. This means that the SMA mixture with 0.3 percent of steel fiber is resistant to permanent deformation. In addition, steel fiber in SMA strengthened the bonding between the aggregate and binder, resulting in increased stiffness. It was also revealed that the indirect tensile strength, and also TSR ratio, peaked at 0.3 percent of steel fiber content. It is proved that the presence of steel fiber reduces moisture-induced damage or stripping potential of SMA compared to the conventional mixture. This indicates that steel fiber strengthens the interconnecting bonds between the bitumen molecules, enhancing the cohesion and adhesion properties of SMA when being exposed to moisture.

- The research revealed that the Response Surface Methodology (RSM) is an effective statistical method for providing an appropriate empirical model for relating parameters and predicting the optimum performance of asphaltic mixture to reduce flexible pavement failure. RSM is proven to be one of the efficient ways of an experiment; not only does it save cost and time but it can also give similar results to the laboratory result. From one-factor and two-factor analysis, it was found in one and multiple interactions that the value of relative error is still small, and the percentage difference is less than 15 percent from laboratory results which indicates that the model is fitted with the experiment. An amount of 0.3 percent was found to be the most optimum steel fiber content from the optimization by using Response Surface Methodology, which thus proves that additional steel fiber in the SMA mixture enhanced the performance of the mixture.

- Future research on the dynamic creep performance with three different temperatures should be conducted to check the suitability of the steel fiber-modified SMA mixture due to the various weather conditions, and should conduct a laboratory experiment along with the statistical experiment in research based on the value from software.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Darma, Y.; Karim, M.R.; Abdullah, S. An analysis of Malaysia road traffic death distribution by road environment. Sadhana—Acad. Proc. Eng. Sci. 2017, 42, 1605–1615. [Google Scholar] [CrossRef]

- Sengul, C.E.; Oruc, S.; Iskender, E.; Aksoy, A. Evaluation of SBS modified stone mastic asphalt pavement performance. Constr. Build. Mater. 2013, 41, 777–783. [Google Scholar] [CrossRef]

- Bindu, C.S. Influence of Additives on the Characteristics of Stone Matrix Asphalt. Ph.D. Thesis, Cochin University of Science and Technology, Kochi, India, 2012. [Google Scholar]

- Mokhtari, A.; Nejad, F.M. Mechanistic approach for fiber and polymer modified SMA mixtures. Constr. Build. Mater. 2012, 36, 381–390. [Google Scholar] [CrossRef]

- Sarang, G.; Lekha, B.; Krishna, G.; Shankar, A.R. Comparison of Stone Matrix Asphalt mixtures with polymer-modified bitumen and shredded waste plastics. Road Mater. Pavement Des. 2015, 17, 933–945. [Google Scholar] [CrossRef]

- Ibrahim, A.N.H.; Ahmad, A.S.; Akhir, N.M.; Borhan, M.N. Performance evaluation of Stone Mastic Asphalt (SMA) using geopolymer as an asphalt modifier. Jordan J. Civ. Eng. 2016, 10, 442–450. [Google Scholar]

- Punith, V.S.; Veeraragavan, A. Behavior of Reclaimed Polyethylene Modified Asphalt Cement for Paving Purposes. J. Mater. Civ. Eng. 2010, 23, 833–845. [Google Scholar] [CrossRef]

- Maurer, D.A.; Malasheskie, G.J. Field performance of fabrics and fibers to retard reflective cracking. Geotext. Geomembr. 1989, 8, 239–267. [Google Scholar] [CrossRef]

- Hassan, H.F.; Oraimi, S.A.; Taha, A. Evaluation of open-graded friction course mixtures containing cellulose fibers and styrene butadiene rubber polymer. J. Mater Civil. Eng. 2005, 17, 416–422. [Google Scholar] [CrossRef]

- Serfass, J.P.; Samanos, J. Fiber-modified asphalt concrete characteristics, applications and behavior. J. Assoc. Asphalt. Paving. Technol. 1996, 64, 193–230. [Google Scholar]

- Wu, S.; Ye, Q.; Li, N.; Yue, H. Effects of fibers on the dynamic properties of asphalt mixtures. J. Wuhan Univ. Technol. Sci. Ed. 2007, 22, 733–736. [Google Scholar] [CrossRef]

- Putman, B.J.; Amirkhanian, S.N. Utilization of waste fibers in stone matrix asphalt mixtures. Resour. Conserv. Recycl. 2004, 42, 265–274. [Google Scholar] [CrossRef]

- McDaniel, R.S. Asphalt Additives to Control Rutting and Cracking. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2001. [Google Scholar]

- Chen, H.; Li, N.; Hu, C.; Zhang, Z. Mechanical performance of fibers-reinforced asphalt mixture. J. Chang’an Univ. (Nat. Sci. Ed.) 2004, 24, 1–5. [Google Scholar]

- Tapkın, S. The effect of polypropylene fibers on asphalt performance. Build. Environ. 2008, 43, 1065–1071. [Google Scholar] [CrossRef]

- Chen, H.; Xu, Q.; Chen, S.; Zhang, Z. Evaluation and design of fiber-reinforced asphalt mixtures. Mater. Des. 2009, 30, 2595–2603. [Google Scholar] [CrossRef]

- Al-Bdairi, A.; Al-Taweel, H.M.; Noor, H.M. Improving the properties of asphalt mixture using fiber materials. IOP Conf. Series: Mater. Sci. Eng. 2020, 870, 012092. [Google Scholar] [CrossRef]

- Serin, S.; Morova, N.; Saltan, M.; Terzi, S. Investigation of usability of steel fibers in asphalt concrete mixtures. Constr. Build. Mater. 2012, 36, 238–244. [Google Scholar] [CrossRef]

- Putman, B.J. Effects of Fiber Finish on the Performance of Asphalt Binders and Mastics. Adv. Civ. Eng. 2011, 2011, 172634. [Google Scholar] [CrossRef]

- Shaffie, E.; Ahmad, J.; Arshad, A.K.; Kamarun, D. Evaluation Of Volumetric Properties And Resilient Modulus Performance Of Nanopolyacrylate Polymer Modified Binder (NPMB) Asphalt Mixes. J. Teknol. 2015, 73, 21–25. [Google Scholar] [CrossRef]

- Sarsam, S.I. Comparative evaluation of moisture susceptibility for Porous And Stone Matrix Asphalt concrete. Indian J. Eng. 2021, 18, 424–432. [Google Scholar]

- AL-Ridha, A.S.; Ibrahim, A.L.S.K.; Dheyab, E.L.S. Steel fiber effect on the behavior of hot mixture asphalt with variable asphalt content. Int. J. Adv. Technol. Eng. Sci. 2016, 4, 204–213. [Google Scholar]

- AL-Ridha, A.S.; Ali, K.I.; Hayder, M.A.T.; Layth, S.D. Effect of steel fiber on ultrasonic pulse velocity and mechanical properties of self-compact light weight concrete. IOP Conf. Ser. Mater. Sci. Eng. 2019, 518, 022017. [Google Scholar] [CrossRef]

- Al-Ridha, A.S.D.; Abbood, A.A.; Atshan, A.F. Assessment of the Effect of Replacing Normal Aggregate by Porcelinite on the Behaviour of Layered Steel Fibrous Self-Compacting Reinforced Concrete Slabs under Uniform Load. J. Eng. 2020, 2020, 3650363. [Google Scholar] [CrossRef]

- Al-Sarraf, D.S.; Al-Shaarbaf, D.I.; Diab, D.A. Effect of steel fiber on the behavior of deep beams with and without web Opening. Eng. Technol. 2011, 29, 1–19. [Google Scholar]

- Ahmed, S.D.; Ridha, A.L. The influence of size of lightweight aggregate on the mechanical properties of self-compacting concrete with and without steel fiber. Int. J. Struct. Civ. Eng. Res. 2014, 3, 54–68. [Google Scholar]

- Ahmed, L.S.A.; Mahmood, L.O.T. Influence of Mineral Fibers Properties on the Performance of Hot Mix Asphalt for the Surface Layer of Pavement. Int. J. Eng. Trends Technol. 2015, 26, 145–151. [Google Scholar] [CrossRef]

- Kikuchi, S.; Kronprasert, N.; Easa, S.M. Aggregate blending using fuzzy optimization. J. Constr. Eng. Manag. 2012, 138, 1411–1420. [Google Scholar] [CrossRef]

- Tharazi, I.; Sulong, A.B.; Salleh, F.M.; Abdullah, A.H.; Ismail, N.F. Application of response surface methodology for parameters optimization in hot pressing kenaf reinforced biocomposites. J. Mech. Eng. 2020, 17, 131–144. [Google Scholar] [CrossRef]

- Nassar, A.I.; Thom, N.; Parry, T. Optimizing the mix design of cold asphalt binder emulsion mixtures using response surface methodology. Constr. Build. Mater. 2016, 104, 216–229. [Google Scholar] [CrossRef]

- Soltani, M.; Moghaddam, T.B.; Karim, M.R.; Baaj, H. Analysis of fatigue properties of unmodified and polyethylene terephthalate modified asphalt mixtures using response surface methodology. Eng. Fail. Anal. 2015, 58, 238–248. [Google Scholar] [CrossRef]

- JKR/SPJ/S4; Standard Specification for Road Works. Public Works Department: Kuala Lumpur, Malaysia, 2008.

- EN 12697-25; Bituminous Mixtures Test Methods: Cyclic Compression Test. European Committee for Standardization: Brussels, Belgium, 2016.

- AASHTO T283-07; Resistance of compacted Hot Mix Asphalt (HMA) to Mixture-Induced Damage. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2008.

- Jasni, N.E.; A Masri, K.; Ramadhansyah, P.J.; Arshad, A.K.; Shaffie, E.; Ahmad, J.; Norhidayah, A.H. Mechanical Performance of Stone Mastic Asphalt Incorporating Steel Fiber. IOP Conf. Series: Mater. Sci. Eng. 2020, 712, 012026. [Google Scholar] [CrossRef]

- Moghaddam, T.B.; Soltani, M.; Karim, M.R. Evaluation of permanent deformation characteristics of unmodified and polyethylene terephthalate modified asphalt mixtures using dynamic creep test. Mater. Des. 2014, 53, 317–324. [Google Scholar] [CrossRef]

- Katman, H.Y.; Ibrahim, M.R.; Karim, M.R.; Mashaan, N.S.; Koting, S. Evaluation of Permanent Deformation of Unmodified and Rubber-Reinforced SMA Asphalt Mixtures Using Dynamic Creep Test. Adv. Mater. Sci. Eng. 2015, 2015, 247149. [Google Scholar] [CrossRef]

- Gilani, V.N.M.; Hamedi, G.H.; Esmaeeli, M.R.; Habibzadeh, M.; Eshkiknezhad, M.H. Presentation of thermodynamic and dynamic modules methods to investigate the effect of nano hydrated lime on moisture damage of stone matrix asphalt. Aust. J. Civ. Eng. 2022. [Google Scholar] [CrossRef]

- Raza, A.; Khan, I.; Tufail, R.F.; Frankovska, J.; Mushtaq, M.U.; Salmi, A.; Awad, Y.A.; Javed, M.F. Evaluation of moisture damage potential in hot mix asphalt using polymeric aggregate treatment. Materials 2022, 15, 5437. [Google Scholar] [CrossRef] [PubMed]

- Shaffie, E.; Rashid, H.A.; Shiong, F.; Arshad, A.K.; Ahmad, J.; Hashim, W.; Putra Jaya, R.; Masri, K.A. Performance characterization of Stone Mastic Asphalt using steel fiber. J. Adv. Ind. Technol. Appl. 2021, 2, 22–33. [Google Scholar] [CrossRef]

- Khodaii, A.; Haghshenas, H.F.; Tehrani, H.K.; Khedmati, M. Application of response surface methodology to evaluate stone matrix asphalt stripping potential. KSCE J. Civ. Eng. 2013, 17, 117–121. [Google Scholar] [CrossRef]

- Shaffie, E.; Ahmad, H.E.; Arshad, A.K.; Hashim, W.; Yaacob, H.; Shiong, F. Performance evaluation of stone mastic asphalt containing steel fiber as additive. In Green Infrastructure; Springer: Singapore, 2022. [Google Scholar] [CrossRef]

| Sieve | Gradation | Percentage Passing | Percentage Retained | Mass Passing | Mass Retained | |

|---|---|---|---|---|---|---|

| Size | Lower | Upper | ||||

| 19.0 | 100 | 100 | 100 | 0.0 | 1200.0 | 0 |

| 12.5 | 85 | 95 | 90 | 10.0 | 1080.0 | 120 |

| 9.5 | 65 | 75 | 70 | 20.0 | 840.0 | 360 |

| 4.75 | 20 | 28 | 24 | 46.0 | 288.0 | 912 |

| 2.36 | 16 | 24 | 20 | 4.0 | 240.0 | 960 |

| 0.60 | 12 | 16 | 14 | 6.0 | 168.0 | 1032 |

| 0.30 | 12 | 15 | 13.5 | 0.5 | 162.0 | 1038 |

| 0.075 | 8 | 10 | 9 | 4.5 | 108.0 | 1092 |

| Pan | 9.0 | 108 | ||||

| Parameters | Values | |

|---|---|---|

| Pre-conditioning | Test temperature | 40 °C |

| Applies axial stress | 150 kPa | |

| Loading frequency | 0.5 Hz | |

| Loading time | 0.2 s | |

| Rest period | 1.8 s | |

| No. of cycles | 30 | |

| Testing | Test temperature | 40 °C |

| Applies axial stress | 300 kPa | |

| Loading frequency | 0.5 Hz | |

| Loading time | 0.2 s | |

| Rest period | 1.8 s | |

| No. of cycles | 3600 | |

| Steel Fiber (Percent) | Stability (kN) | Flow (mm) |

|---|---|---|

| 0 | 8.7 | 6.25 |

| 0.3 | 10.7 | 4.87 |

| 0.5 | 10.6 | 4.70 |

| 0.7 | 9.8 | 4.42 |

| Steel Fiber Content (Percent) | Creep Strain Slope (CSS) (Percent) | Average Creep Strain Slope (CSS) (Percent) |

|---|---|---|

| 0 | 0.092 | 0.09 |

| 0.082 | ||

| 0.3 | 0.048 | 0.07 |

| 0.096 | ||

| 0.5 | 0.068 | 0.12 |

| 0.163 | ||

| 0.7 | 0.161 | 0.15 |

| 0.142 |

| Steel Fiber Content (Percent) | Sample No. | Indirect Tensile Strength Dry (ITSdry) (kPa) | Indirect Tensile Strength Wet (ITSwet) (kPa) |

|---|---|---|---|

| 0 | 1 | 308 | 214 |

| 2 | 289 | 236 | |

| 3 | 298 | 215 | |

| 0.3 | 1 | 358 | 303 |

| 2 | 377 | 399 | |

| 3 | 432 | 356 | |

| 0.5 | 1 | 335 | 272 |

| 2 | 429 | 315 | |

| 3 | 320 | 256 | |

| 0.7 | 1 | 369 | 306 |

| 2 | 347 | 296 | |

| 3 | 340 | 316 |

| Factor 1 | Factor 2 | Response 1 | ||

|---|---|---|---|---|

| Std | Run | A: Binder Content | B: Steel Fiber | R1: Creep Strain Slope (CSS) |

| 1 | 1 | 5 | 0 | 0.082 |

| 8 | 2 | 6 | 0.7 | 0.161 |

| 5 | 3 | 5 | 0.5 | 0.068 |

| 2 | 4 | 7 | 0.3 | 0.06 |

| 7 | 5 | 6 | 0 | 0.092 |

| 3 | 6 | 5 | 0.7 | 0.142 |

| 4 | 7 | 7 | 0.5 | 0.163 |

| 6 | 8 | 7 | 0.3 | 0.096 |

| Std | Factor 1 | Factor 2 | Response 1 | Response 2 | |

|---|---|---|---|---|---|

| Run | A: ITSdry | B: ITSwet | R1: Steel | A: ITSdry | |

| kPa | kPa | Percent | Percent | ||

| 6 | 1 | 308 | 214 | 0 | 69.481 |

| 10 | 2 | 289 | 236 | 0 | 81.661 |

| 12 | 3 | 298 | 215 | 0 | 72.148 |

| 4 | 4 | 358 | 303 | 0.3 | 84.637 |

| 8 | 5 | 377 | 399 | 0.3 | 105.836 |

| 7 | 6 | 432 | 356 | 0.3 | 82.407 |

| 2 | 7 | 335 | 272 | 0.5 | 81.194 |

| 9 | 8 | 429 | 315 | 0.5 | 73.427 |

| 11 | 9 | 320 | 256 | 0.5 | 80 |

| 3 | 10 | 369 | 306 | 0.7 | 82.927 |

| 1 | 11 | 347 | 296 | 0.7 | 85.303 |

| 5 | 12 | 340 | 316 | 0.7 | 92.941 |

| Parameter | Steel Fiber (Percent) | Creep Strain Slope (CSS) (Percent) | Tensile Strength Ratio (TSR) (Percent) |

|---|---|---|---|

| Experiment | 0.3 | 0.070 | 90.58 |

| One Factor | 0.3 | 0.077 | 89.93 |

| Targeted One Factor | 0.3 | 0.080 | 90.96 |

| Parameter | Binder Content (Percent) | Steel Fiber (Percent) | Creep Strain Slope (CSS) (Percent) | Tensile Strength Ratio (TSR) (Percent) |

|---|---|---|---|---|

| Experiment | 6 | 0.3 | 0.070 | 90.58 |

| Two Factor | 6 | 0.3 | 0.075 | 91.51 |

| Targeted Two- Factor | 6 | 0.3 | 0.075 | 91.32 |

| Description | Equation |

|---|---|

| Dynamic Creep | 0.0789 − 0.0403A + 0.0339B − 0.0059AB − 0.0172A2 − 0.0515B2 |

| Moisture Susceptibility (Steel Fiber) | 0.6145 − 0.0036A + 0.0263B − 0.4050AB − 0.0710A2 − 0.2323B2 |

| Moisture Susceptibility (TSR) | 85.02 − 16.87A + 25.66B − 5.20AB + 3.39A2 + 0.0932B2 + 0.5379A2B + 0.6946AB2 − 0.5691A3 − 0.2076B3 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Dynamic Creep | ||||||

| Model | 0.0110 | 5 | 0.0022 | 3.34 | 0.048 | significant |

| A-Binder Content | 0.0030 | 1 | 0.0030 | 7.68 | 0.1093 | |

| B-Steel Fiber | 0.0023 | 1 | 0.0023 | 5.95 | 0.1349 | |

| AB | 0.0000 | 1 | 0.0000 | 0.0918 | 0.7905 | |

| A² | 0.0004 | 1 | 0.0004 | 1.06 | 0.4122 | |

| B² | 0.0036 | 1 | 0.0036 | 9.33 | 0.0926 | |

| Residual | 0.0008 | 2 | 0.0004 | |||

| Cor Total | 0.0118 | 7 | ||||

| Moisture Susceptibility (Steel Fiber) | ||||||

| Model | 0.6572 | 5 | 0.1314 | 5.43 | 0.0313 | significant |

| A-ITSdry | 9.487 × 10−6 | 1 | 9.487 × 10−6 | 0.0004 | 0.9849 | |

| B-ITSwet | 0.0005 | 1 | 0.0005 | 0.0223 | 0.8861 | |

| AB | 0.0109 | 1 | 0.0109 | 0.4510 | 0.5268 | |

| A² | 0.0013 | 1 | 0.0013 | 0.0520 | 0.8272 | |

| B² | 0.0162 | 1 | 0.0162 | 0.6693 | 0.4446 | |

| Residual | 0.1453 | 6 | 0.0242 | |||

| Cor Total | 0.8025 | 11 | ||||

| Moisture Susceptibility (TSR) | ||||||

| Model | 1033.51 | 9 | 114.83 | 1.480 × 108 | <0.0001 | significant |

| A-ITSdry | 4.31 | 1 | 4.31 | 5.549 × 106 | <0.0001 | |

| B-ITSwet | 3.50 | 1 | 3.50 | 4.514 × 106 | <0.0001 | |

| AB | 0.0286 | 1 | 0.0286 | 36,841.10 | <0.0001 | |

| A² | 0.0336 | 1 | 0.0336 | 43,312.45 | <0.0001 | |

| B² | 0.0002 | 1 | 0.0002 | 217.96 | 0.0046 | |

| A²B | 0.0000 | 1 | 0.0000 | 29.35 | 0.0324 | |

| AB² | 0.0000 | 1 | 0.0000 | 36.00 | 0.0267 | |

| A³ | 0.0003 | 1 | 0.0003 | 408.39 | 0.0024 | |

| B³ | 0.0000 | 1 | 0.0000 | 29.32 | 0.0325 | |

| Residual | 1.552 × 10−6 | 2 | 7.759 × 10−7 | |||

| Cor Total | 1033.51 | 11 | ||||

| Parameter | Dynamic Creep | Moisture Susceptibility (Steel Fiber) | Moisture Susceptibility (TSR) |

|---|---|---|---|

| Std. Dev. | 0.0197 | 0.1556 | 0.0009 |

| Mean | 0.1083 | 0.3750 | 82.66 |

| C.V. percent | 18.21 | 41.50 | 0.0011 |

| R2 | 0.9340 | 0.8189 | 1.0000 |

| Adjusted R2 | 0.7691 | 0.6679 | 1.0000 |

| Predicted R2 | −0.3247 | −1.1317 | 0.9999 |

| Adeq Precision | 5.2253 | 6.0149 | 45,212.9481 |

| Description | Steel Fiber % | Creep Strain Slope (CSS)% | Tensile Strength Ratio (TSR)% |

|---|---|---|---|

| Laboratory Experiment | 0.3 | 0.07 | 90.58 |

| Statistical (One factor) | 0.25 ≈ 0.3 | 0.077 | - |

| 0.32 ≈ 0.3 | - | 89.93 | |

| Difference | 0 | 0.007 | 0.65 |

| Percentage Difference (percent) | 0 | 9 | 0.07 |

| Statistical (Targeted one factor) | 0.3 | 0.08 | - |

| 0.3 | - | 90.96 | |

| Difference | N/A | 0.01 | 0.38 |

| Percentage Difference (percent) | N/A | 12.5 | 0.42 |

| Statistical (Two factor) | 0.3 | 0.075 | - |

| Residual | 0.31 ≈ 0.3 | - | 91.505 |

| Difference | 0 | 0.005 | 0.925 |

| Percentage Difference (percent) | 0 | 7.14 | 1.01 |

| Statistical (Targeted Two factor) | 0.3 | 0.075 | - |

| 0.3 | - | 91.32 | |

| Difference | N/A | 0.005 | 0.74 |

| Percentage Difference (percent) | N/A | 7.14 | 0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shaffie, E.; Mohd Nasir, A.A.; Putra Jaya, R.; Arshad, A.K.; Mohamad Rais, N.; Al-Saffar, Z.H. Statistical Approach Model to Evaluate Permanent Deformation of Steel Fiber Modified Asphalt Mixtures. Sustainability 2023, 15, 3476. https://doi.org/10.3390/su15043476

Shaffie E, Mohd Nasir AA, Putra Jaya R, Arshad AK, Mohamad Rais N, Al-Saffar ZH. Statistical Approach Model to Evaluate Permanent Deformation of Steel Fiber Modified Asphalt Mixtures. Sustainability. 2023; 15(4):3476. https://doi.org/10.3390/su15043476

Chicago/Turabian StyleShaffie, Ekarizan, Alma Aina Mohd Nasir, Ramadhansyah Putra Jaya, Ahmad Kamil Arshad, Nuryantizpura Mohamad Rais, and Zaid Hazim Al-Saffar. 2023. "Statistical Approach Model to Evaluate Permanent Deformation of Steel Fiber Modified Asphalt Mixtures" Sustainability 15, no. 4: 3476. https://doi.org/10.3390/su15043476

APA StyleShaffie, E., Mohd Nasir, A. A., Putra Jaya, R., Arshad, A. K., Mohamad Rais, N., & Al-Saffar, Z. H. (2023). Statistical Approach Model to Evaluate Permanent Deformation of Steel Fiber Modified Asphalt Mixtures. Sustainability, 15(4), 3476. https://doi.org/10.3390/su15043476