1. Introduction

Industries and businesses experiment with various strategies, such as becoming digital, to address the high levels of environmental unpredictability and to stay competitive in today’s market. Uncertainty in the supply chain (SC) context regards the inability to predict the future confidently or make accurate decisions because of information asymmetry or a lack of relevant data [

1]. Notably, digitalization such as blockchain may be considered a solution for reducing SC risks [

2]. In the ever more volatile and uncertain corporate climate, with financial, economic, ecological, and social risks, SC digitalization is key to increasing SC resilience (SCR), adaptability, and long-term sustainability [

3]. Productivity improvements, decreased expenses, and creative innovations are some benefits of digitalization that impact digital transformation [

4]. Given dynamic environments, changes in customer demand, increased product diversity, and decreased product life cycles [

5], organizations are increasingly aware of possible fundamental changes regarding their SCs and acutely aware of the value digital SC solutions may provide for enterprises [

6]. The increasing development and deployment of Industry 4.0 (I4.0) and its accompanying technologies can profoundly impact production in every enterprise and organization aspect, yielding significant enhancements to SC and logistics management [

7]. However, effective I4.0 adoption and deployment require integration between employees, machines, and production processes within and across SCs to provide benefits for businesses and enhance competition with others via reduced manufacturing costs, shorter lead times, and high product quality [

8].

In the current paradigm of globalized markets, manufacturing sectors are increasingly aligning their operations to changing customer requirements and adapting to shifting market demands via reduced lead time, increased diversity of goods, and flexible production processes [

9]. Therefore, applying advanced digital technologies progressively empowers SCs to be more effective by increasing their sensitivity to market demands and reducing production costs and potential human errors [

5]. Global competition is increasing, making it progressively more challenging for businesses to build long-term competitive advantages [

10]. Supply networks have emerged as a major source of competition for businesses [

11,

12]. The integration of a company, suppliers, and consumers forms an SC network. Given the dynamic environment of the rapidly evolving world, inter-company competition hinges on SC effectiveness. Indeed, innovation and collecting more data can induce SC improvement, which is key to competitive advantage [

13,

14]. The absorptive capacity (ACAP) is an organization’s ability to absorb, integrate, convert, and apply external information for innovation, adaptability, and performance [

15,

16]. Much of the value created via information technology stems from its integration with other corporate sources and processes [

17]. Thus, information technology competence fosters organizational agility via ACAP [

15]. Firms can improve their performance by effectively implementing their ACAP to develop and improve new products, improve management practices, and enhance firm routines [

10].

Amid the COVID-19 pandemic, SCs were redesigned and redefined, emphasizing the importance of SCR [

18] for innovative solutions [

19] and competitive advantages [

20]. Firms that invest in I4.0 technologies exhibit greater adaptability and resilience than those that do not [

21]. With an ever-growing volume and variety of environmental disturbances and in a dynamic environment, supply networks must develop new ways to react better to crises quickly and efficiently [

22]. In other words, SCs must aim to respond quickly to unexpected events. Carvalho et al. [

23] posit that agile and resilient techniques influence SC performance and competitiveness. However, no study examines the effect of the innovative of digital technologies in improving SC agility (SCA) and resilience for improved firm performance.

Given SC disruptions, countries aim to strengthen their local SC and adapt to the need for agility. A strong SC network is built on a strong, well-integrated database that allows stakeholders to make important business decisions [

24]. Accordingly, it is important to lay the groundwork for digitalization to strengthen the local SC [

24]. The Saudi annual report of the National Industrial Development and Logistic Program (NIDLP) 2020 notes that maintaining smooth operations even amid emergencies is the foundation of a strong SC. The pandemic has exposed many SC infrastructure weaknesses worldwide, highlighting the need for anticipating and preparing for potential disruptions in supply deliveries. Such challenges underline the significance of SCs and logistics systems, per the NIDLP. The program ensures I4.0 technology implementation such that SC disturbances will not affect production, thus establishing a digital database for the crucial sectors (food, medical, and military) by considering any risks and recovery plans. Additionally, per a sustainability development program issued by the Saudi government, Saudi Arabia aims to create an exceptionally sustainable and responsible SC via sophisticated planning systems to optimize products flow. Thus, it intends to use technology to complete inventory visibility and advanced infrastructure to increase transportation efficiency, build employee skills by providing training programs, and promote logistics modeling that employs tools to boost warehouse and terminal location, size, and transportation [

25]. Thus, Saudi Arabia is keen on the important role of I4.0 and technologies in improving SCs. This study considers the effect of digitalization and the benefits of collecting more SC data to enhance SCA, resilience, and capability, thus improving supply chain innovation performance (SCIP). Specifically, it addressed the following research questions. How can ACAP enhance SCIP through digital innovation (DI), SCA, and SCR? Does the DI, SCA, and SCR mediate the relationship between ACAP and SCIP?

Different studies show the importance of the innovative of digital technologies in improving an SC. Acquiring more data internally and externally (customers, suppliers, or even competitors) yields up-to-date awareness of the dynamic environment. This study assumes that the role of ACAP is important in an SC, enhancing agility, resilience, and hence, innovation performance. High performance stems from highly developed technological capabilities, as firms master process innovations when they acquire innovative technologies for competitive advantage [

26]. The value of technological skills increases with time as it is embedded in organizational routines, thereby comprising a major source of ACAP [

27]. Firms need dynamic capabilities to quantify an organization’s ACAP or its ability to receive and digest new information to generate new goods and services [

28]. Several factors to consider include an organization’s capacity to manage and use digital technology in the innovation process beyond the relevance of an organization’s attitude toward digital technology adoption [

29]. Digital capabilities (DCAPs) describe a mix of capabilities that boost an organization’s ability to improve, mobilize, and successfully utilize its resources and to develop its processes by leveraging digital technology [

30,

31].

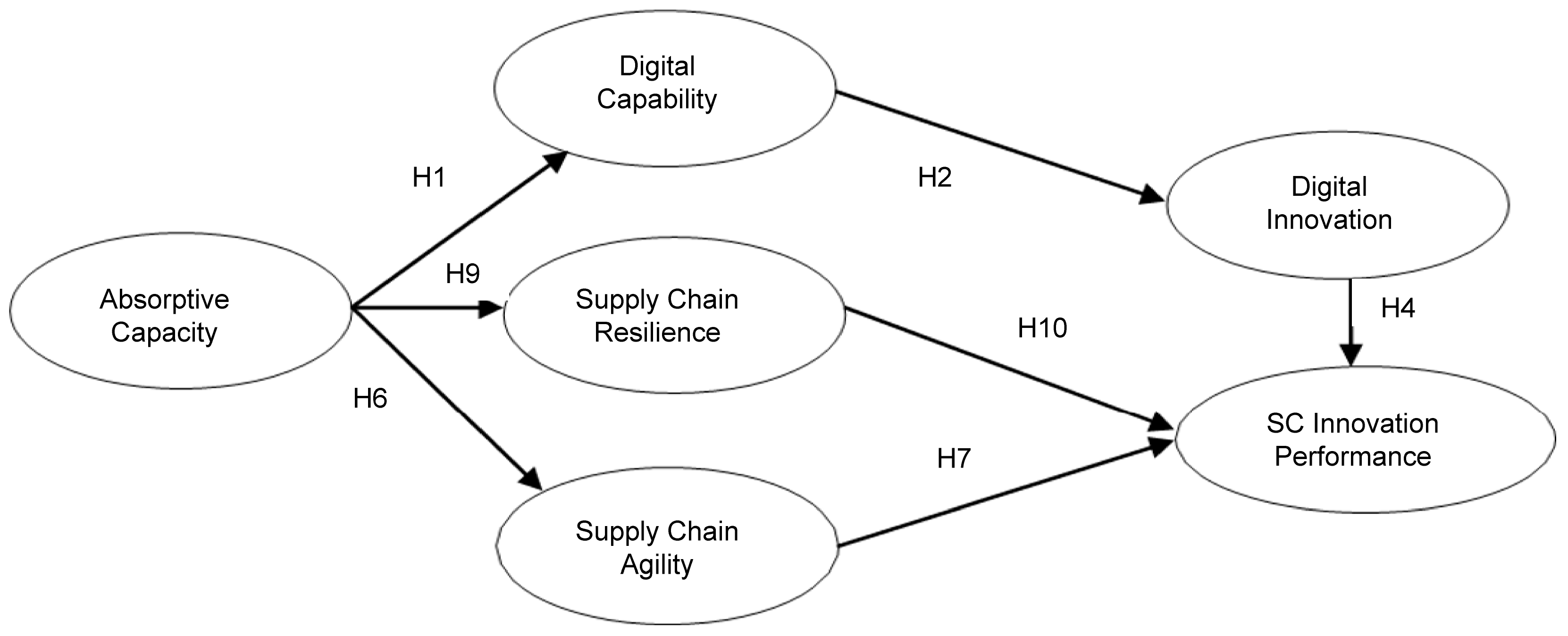

Given the lack of relevant studies on the mediation role of SCR, SCA, and DI, the current study examines the role of digital technologies and ACAP in enhancing SCIP via DI, SCR, and SCA in the context of Saudi Arabia during the COVID-19 pandemic. Moreover, given insufficient evidence, the authors highlight the role of DCAPs, DI, SCR, and SCA in contributing to SCIP improvement. This study contributes to the extant literature in several ways. First, it examines the role and effect of digital technologies of the innovation in enhancing SCR and SCA to improve SCIP. Second, it analyzes the importance of ACAP in enhancing SCA, SCR, and the DCAP through DI, which will finally improve the SCIP. Third, it adopts the RBV and DC as the research framework, and the role of digital capabilities as an antecedent of digital innovation is investigated, along with its capability to improve firms’ innovation performances. Fourth, it tests the effects of SCR, SCA, and DI as mediators between ACAP and SCIP. Finally, to the best of our knowledge, this study is the first in the context of Saudi Arabia to analyze the role of digital technologies in SC.

The remainder of the paper is organized as follows.

Section 2 reviews the theoretical background and develops hypotheses. Furthermore,

Section 2.4 presents the conceptual model, and

Section 3 describes the research methodology. Subsequently,

Section 4 presents the results, and

Section 5 discusses these results. Finally,

Section 6 concludes the study and highlights the implications and limitations of the study and future research directions.

4. Results

Out of 350 questionnaires, 116 were returned for analysis. The 33% were over the minimum required response rate for online surveys of 30%; thus, it was considered acceptable [

117], and the sample size was adequate to test the hypotheses. As per Hair et al. [

118], the sample size complies with the required ratio of 15 observations per variable and the chosen minimum sample size of 90 observations to perform the analysis successfully. Normality tests require that the data obtained be distributed proportionally [

119]. Given that no outliers were found, all complete responses were included in the study. To determine whether the data were normally distributed, a preliminary check was performed. The validity of results is provided by skewness, and the kurtosis values, which are ±1 [

120], met the cut-off. Univariate normality testing was undertaken using the “skewness–kurtosis technique,” with cut-off points of 3 and 8, respectively [

120]. Overall, the researcher utilized the skewness–kurtosis technique, signifying that the statistical outputs were within the expected range. This study meets the criterion of data violation of normality by using Smart-PLS [

121].

4.1. Descriptive Analysis

A total of 116 respondents participated in this study, and 58.93% work in a firm with 501 or more employees, followed by 25% in a firm with 51–500 employees and 16.07% in a firm with 50 or fewer employees. Half of the respondents were aged 49 years or more, followed by those aged 11–40 years (30.36%) and 10 years or less (9.64%). Half of the respondents had revenue of less than SAR 59 million, followed by those with 501 million or more (35.71%), 51–250 million (21.43%), and 251–500 million (17.86%). Furthermore, 41% were general managers, followed by 16.07% each for executive and senior managers and 10.71% for directors; the rest accounted for less than 10%. See

Table 1 for the results.

4.2. Common Method Bias and Variance

A variance inflation factor (VIF) larger than 3.3 is an indicator of pathological collinearity, and a model may be exposed by common method bias (CMB). Thus, the model may be declared free of CMB if all the inner model VIF values from a thorough collinearity test are greater than or equal to 3.3 [

122]. Moreover, to identify common method variance (CMV) problems in partial least-squares-based structural equation modeling (PLS-SEM) models, the measured latent marker variable method may be used [

123]. A random variable was initiated to test the CMB in the model. Accordingly, the outer (inner) VIF model is <5 (less than 3.3). Both tests indicate that there are no CMB and CMV.

4.3. Measurement Model

4.3.1. Convergent Validity

This study employs SEM using Smart-PLS version 3.0 to verify the hypothesized connections between the variables presented in the study framework (

Figure 1). SEM is important because multiple indicators may be included in the hypothesized and final model, and the link between independent and dependent variables can be tested concurrently [

124].

After collecting the responses to the survey, we analyzed the data using SEM to clarify the significance of factor loading, weight, and path coefficients. First, to evaluate the validity, reliability, and fitness of the data, we used confirmatory factor analysis to achieve the best model fit. Subsequently, we employed bootstrapping (1000 resample) to determine the relationships between the variables. Per the theoretical background, paths, or hypotheses, they were presented using the value of

β = coefficient path,

T = T-statistic, and square = R2 [

125,

126].

Table 2 presents the hypothesized model. The factor loading (FL) values satisfy the recommended values (FL > 0.70) [

126]; all items and indicators were over 0.70. Moreover, the values of VIF were less than the cut-off value of 5 [

126]. Some items—ACAP6, DCAP1, DI2, and 5, SCA1, 4, 5, 7, 9, 10, 13, and 14, SCR2, SCIP1, 2, 3, and 4—were eliminated from the model because of high VIF values to reduce multicollinearity.

The standardized root mean squared residual (SRMR) value was below 1.00 (SRMR = 0.078), which is acceptable. Moreover, the average variance extracted (AVE) values met the recommended values of >0.50. Likewise, the composite reliability (CR) and Cronbach alpha (α) were significant (CR and α > 0.71). This study examined the significant value of path estimations (

β) based on the t value (

p < 0.05). R

2 is a function of the influence of the independent variable on the dependent variable. Thus, R

2 of the SCIP was predicted by 0.814—81% of the influence from independent variables affects the dependent variables. Moreover, the mean scores of the variables indicated a moderate level, ranging between (5.06 ± 1.640 moderate–high level) and (4.59 ± 1.558 moderate level). Furthermore, there are significant and positive correlations between the constructs, ranging between (r = 0.804,

p < 0.01) and (r = 0.569,

p < 0.01). The approach of predictive sample reuse (Q

2) may be used for predictive relevance [

127]. Q

2 demonstrates how well-collected data may be empirically rebuilt using the model and PLS parameters based on the blindfolding technique. Q

2 was determined utilizing cross-validated redundancy approaches, following Chin [

124]. If Q

2 > 0, then the model has a predictive relevance [

128]. Q

2 for SCIP is 0.569; for all other variables Q

2 > 0, indicating that all variables have acceptable predictive relevance. See

Table 3 for the results.

4.3.2. Discriminant Validity

After establishing the reliability and convergent validity of reflectively assessed constructs, the following stage determines their discriminant validity. This analysis illustrates the amount to which a construct is empirically different from other constructs regarding its correlation with other constructs and the degree to which indicators uniquely reflect this single concept. Accordingly, the lowest square root of AVE (0.829) was higher than the highest correlation (r = 0.804). Thus, we can accept the model for testing the hypotheses (see

Table 4). Moreover, discriminant validity is determined by examining the heterotrait–monotrait ratio (

Table 5). All values are less than 0.9 [

129].

4.4. Evaluating the Structural Model

This segment describes the influence of independent variables on the dependent variable (see

Table 6 and

Figure 2). Smart-PLS 4.0 was used to test the hypotheses and structural model, with a 5000-iteration bootstrapping approach to determine the statistical significance of the weights of sub-constructs and path coefficients [

127].

The results confirm H1 (β = 0.749, t = 14.581, p > 0.000), demonstrating that ACAP significantly influences DCAP. Moreover, the results show a significant and positive structural path between DCAP and DI (β = 0.692, t = 13.821, p < 0.000), supporting H2. Furthermore, the results show that the structural path between DI and SCIP is significant (β = 0.309, t = 4.751, p < 0.000), supporting H4. The SEM results show a positive effect of ACAP on SCA (β = 0.698, t = 10.441, p < 0.000), supporting H6. H7 was ultimately supported (β = 0.336, t = 4.453, p < 0.000), demonstrating that SCA significantly influences SCIP. Regarding the effect of ACAP on SCR, the results (β = 0.649, t = 7.154, p < 0.000) support H9. Additionally, the results (β = 0.377, t = 5.151, p < 0.000) support H10.

4.5. Mediation Analysis

The study examined the mediating effect of the constructs through a bootstrapping procedure using 5000 resamples. It performed the mediation analysis to assess the mediating role of DCAP between ACAP and DI. The relationships between ACAP and DI (p < 0.000), ACAP and DCAP (p < 0.000), and DCAP and DI are significant. Thus, DCAP partially mediates the relationship between ACAP and DI (β = 0.519, t = 9.254, p < 0.000), supporting H3. Moreover, DI partially mediates the relation between DCAP and SCIP (β = 0.214, t = 4.268, p < 0.000), supporting H5. Moreover, for H8, the relationships between all paths are significant (β = 0.234, t = 3.348, p < 0.001), supporting the hypothesis. Additionally, for H11, the relationships between all paths were significant (β = 0.245, t = 4.123, p < 0.001), supporting the hypothesis.

5. Discussion

Prior studies indicate that digital technologies are crucial for supply chain efficiency. They demonstrated how implementing digital technology may improve an organization in general and SC in particular. This study examines how SC may improve their innovation performance based on their ACAP via DI, resilience, and agility. Organizational innovation is a critical dimension in enabling businesses to adapt to dynamic business environments, as it helps them produce new and distinctive services that serve as the foundation for an unmatched and long-term competitive edge [

19]. Almost 89% of the companies participating in this study were somehow impacted by the COVID-19 pandemic. The findings of this study also confirm that supply chains can benefit from implementing digital solutions and innovations [

130]. Thus, SCs that adapt technologies and are driven by data-based decisions via ACAP can survive and thrive. The model presented in this study shows that innovative SCs contribute to dynamic resilience, agility, and SCIP.

By testing the impact of ACAP on three variables—DCAP, SCIP, and SCA—via H1, H6, and H9, respectively, this study (as can be seen in

Figure 2) finds that ACAP positively impacts DCAP. The significance and improvement of ACAP and digitalized activities can develop DCAPs, according to Vigren et al. [

28]. Moreover, ACAP, as predicted, positively impacts SCR. Following prior research [

89,

131,

132], this study examined the relationship between ACAP and SCR. An SC can achieve SCR by having strong relationships with its key suppliers and customers, running a well-integrated business process and increasing employees’ skills and abilities for improved performance, with reduced costs and improved quality. Furthermore, there is a positive impact of ACAP on SCA [

10]. Better responsiveness and agility in the SC are achieved by constantly upgrading technology and integration with partners [

133] to provide quick and agile responses [

134]. Organizations rely on innovation to remain competitive in the market [

135]. Firms adapt by using technology to improve processes, create new products, and provide flexible shipping in response to market needs [

136]. Increased ACAP enables businesses to have up-to-date information and control over their SC [

66]. Organizations with a higher ACAP are better equipped to react to changing client requirements and recognize market developments faster [

10].

In the wake of the COVID-19 pandemic, digital technology has proven to be crucial in the SC. The capacity to manage digital technologies is critical to the success of digital product creation, which is heavily reliant on how successfully a company manages digital technology. DCAP is a positive predictor of DI [

29,

46,

47]. Innovation and data collection induce SC development for competitive advantage [

14]. Businesses require DCAPs to update, activate, and build processes using digital technologies [

31]. To swiftly create new processes and products in response to the ever-changing market orientation, organizations must adapt and align their rules and procedures and create innovation to tailor goods to market demand [

134].

Various studies examine SC performance from different aspects [

68,

94,

137,

138,

139,

140]. This paper examined the direct effect of DI, SCR, and SCA on the SCIP. It demonstrates that DI significantly impacts the SCIP, as per Khin and Ho [

29]. The fast growth of digital technology has improved the speed of information storage, helping organizations learn and develop new products. It is necessary to acknowledge the role of DI in creating new products, manufacturing process improvement, organizational structure reformation, and business model development and modification. Improvements in SC performance may be achieved via process innovation, which is a subset of systems innovation that increases SC efficacy and efficiency [

140]. Moreover, product innovation may increase SC efficiency, given that they manufacture new items continuously [

141]. Reducing product delivery delays and customer attrition are two of the main goals of an innovation system, implemented by streamlining operations, establishing operational standards, and using technology [

134]. Furthermore, this study examined the relationship between SCR on SCIP. It confirmed that SCR determines innovation performance. As per Chowdhury et al. [

73] and Bahrami et al. [

94], there is a positive relationship between SCR and innovation performance. Similarly, SCA positively affects performance, as per the finding that IT integration and trust enhance SCA and innovation, improving the competitive advantage [

68,

138,

142]. Some studies relate agility to firm performance and show a positive relationship between SCA and organization performance [

10,

16,

70,

142,

143].

Furthermore, the study investigated the mediating role of DI between DCAPs and SCIP, finding that DI partially mediates the relationships. Given the discovery that DI mediates the influence of SCIP, companies devoted to adopting digital technologies and improving their abilities to better manage digital technology are more likely to generate new digital solutions. Therefore, if a firm improves its DCAPs to acquire more data and implements contemporary digital technology to address business challenges via process optimization, customer experience enhancement, and the introduction of novel business models, SCIP can improve. Indeed, prior studies confirm that SCA partially mediates the relation between ACAP and SCIP [

10,

16,

62,

67]. Adapting agility can help organizations adapt to changes based on customer needs and respond to dynamic demand using several innovative features [

71]. Furthermore, SCR mediates the relationship between ACAP and SCIP, as per Bahrami et al. [

94], where the impact of the innovative of digital technologies significantly improves SC performance through SCR.

6. Conclusions

In the wake of the COVID-19 pandemic, technology has proven to be critical to SC success. Studies show the importance of SC innovation and its gradually increased recognition of the difference between day-to-day interruptions and catastrophic occurrences. This study primarily addresses the factors that induce SCIP. It shows the importance of ACAP in enhancing SCIP with more data for resilience and agility. Dynamic SC resilience describes a company’s ability to use its innovation potential to start the dynamic recovery process and stay strong amid disturbances. Similarly, SCA shows the ability of companies to respond swiftly and effectively using their capabilities and innovation to recover quickly. Accordingly, a questionnaire was distributed and collected from companies operating in Saudi Arabia. Smart-PLS was used to analyze the data and demonstrate the findings. ACAP demonstrated its importance and impact on DCAP, agility, and resilience. Therefore, ACAP enhances the SCIP when this relationship is mediated by DCAP and DI. Moreover, ACAP improves SCR and SCA, improving SCIP. Notably, there is no systematic theory-driven empirical examination of the unique performance implications of SCA and SCR in the context of SC innovation. SC theory on the implications of agility and resilience in the SC context remains fragmented and without a foundation in established theoretical frameworks. As long as organizations improve the innovation of digital SC technologies, SCIP will improve. Finally, few studies examine the impact of ACAP and companies’ capabilities to enhance DI, agility, and resilience, thereby improving the SCIP.

6.1. Theoretical Implications

Given the moderate to severe impacts of the COVID-19 pandemic on companies, ACAP can improve SCIP. The greater the level of ACAP, the greater the SCIP. ACAP may be a crucial factor that favorably impacts SC connections. By assimilating, transforming, and exploiting the latest and most relevant externally acquired knowledge, businesses can better understand their customers’ needs or suppliers’ capabilities, allowing them to synchronize with suppliers, align and coordinate resources along the SC, and improve the overall SC’s responsiveness and efficiency more precisely.

Organizations may leverage existing information and communication technology to communicate data with customers, suppliers, and other businesses in the SC; therefore, ACAP may also help with data integration. For instance, organizations can integrate more knowledge and information, enhance their ability to spot market shifts quickly, respond to capture the need of new customers, and predict competitors’ movements. Thus, DCAPs, SCR, and SCA allow ACAP to increase firm performance.

Although the management literature gives some insight into how ACAP may impact DCAPs, thus impacting DI, this study implies that the incentive for disaster relief activities after the pandemic stems from SC dynamic capacities. Using DCAPs to boost a company’s performance is one of the primary goals of this study. Although DCAPs are not required, they will help companies move toward innovativeness. The DI (mediating variable) exerts a beneficial influence on SCIP based on SC DCAP.

The empirical findings present an interesting picture of the interrelationships and complementarities between ACAP and SCA, SCR, and DCAPs for companies affected by the pandemic. This research examines the concept of ACAP and how it benefits SC. The capability to absorb data can enhance SCA and SCR for an increased sustainable advantage in the long term. SCA helps an organization respond quickly to changes in consumer demand volume, product variety, and delivery schedule. Meanwhile, SCR permits the SC to execute innovatively despite any limits caused by disruptions in supply or during a pandemic. Once the ACAP-oriented innovative digital technologies process is implemented, it can enhance a firm’s ability to respond to changes in client demand at any given moment, hence increasing a firm’s long-term competitive edge.

This discussion hinges on the premise that SCA and SCR are two dynamic SC characteristics. Initially, they were often considered alternatives, given the shortage of resources and the constraints of the management scope. As per the conventional perspective, firms benefit from refining their SCA capabilities or expanding their SCR capability.

6.2. Managerial Implications

This study offers several insights for managers and practices to enhance SC innovation. First, keeping the company’s information flow and knowledge base up to date is essential. The company’s ability to react to the dynamic environment hinges on the acquisition, assimilation, and transformation of such knowledge, which may stem from staff, suppliers, consumers, or even rivals. Thus, ACAP is a valuable dynamic capacity; managers should focus their efforts on fostering this capacity and allocating sufficient resources to boost their company’s success. Therefore, by embracing digital technology, companies can boost their performance. The considerable impact of DI is crucial in transforming DCAP into improved performance. Firms’ digital strengths must be utilized for DI.

Second, the findings may provide practitioners involved in disaster relief operations with some intriguing recommendations. During the post-pandemic phase, an organization’s flexibility can help prioritize its reactive skills, such as speed and recovery. SC partners must collaborate to survive amid disruptions. Hence, improving the information system by investing in ACAP may be an effective way to collect quality data that can help organizations to increase SCA and SCR and to be better equipped to manage SC interruptions. These factors may help firms continue to deliver services, resulting in continuous customer satisfaction and long-time success. In uncertain environment, managers can find ways to improve the company’s productivity and performance and its competitive advantage by improving SC capability and resilience. Successful deployment of dynamic capabilities like ACAP is necessary to grow, maintain, and apply SCA and SCR capacity to react rapidly to market disturbances. The findings accord with best practices for creating robust and flexible SCs. They may be put to use by supply chain managers who choose to apply ACAP to attain SCIP via the enhancement of DCAP, DI, SCA, and SCR. ACAP may help managers develop fundamental capabilities in response to the ever-changing environment, ultimately giving them a distinct edge. Therefore, this study reveals the importance of ACAP in creating and attaining SCR and SCA. Additionally, it shows that ACAP has an indirect effect on the SCIP of the organizations.

6.3. Limitations and Future Research Directions

Despite the implications, it is important to be aware of the study’s possible limitations. This study was conducted in the context of the COVID-19 pandemic; thus, the findings of this study are limited. First, the sample study was small, which can affect generalizability. Second, this study was conducted in Saudi Arabia, which has a different experience of the pandemic relative to other countries. It is unclear whether the study can be applied to other crises or specific sectors, but it is worth investigating in the future. Future studies must collect more data and compare two countries to see the impact of a digitalized SC on performance during the pandemic. Third, future studies can probe the impact of digital orientation and technological culture on innovation. Others could implement longitudinal or case-based studies to further understand and explain how organizations learn from and enhance their SC operations. Nevertheless, the findings of this study are adequately robust to offer empirical support for the explanation of SCIP by showing the impact of ACAP on DCAP, DI, agility, and resilience.