Abstract

The agricultural production technical efficiency is the key to improving the sustainability of an agricultural section. Taking survey data of 314 grape growers in Fujian Province, China, this paper presents the impact of operation scale on their technical efficiency under a rain-shelter cultivation mode. Through the threshold effect model, we find an inverted U-shape trend between operation scale and the growers’ technical efficiency, and the threshold is 18 mu. We also further introduce the employee input to analyze the mediating effect. The test results show that with the expansion of operation scale, the efficiency loss caused by greater employee input gradually suppresses the positive impact of economies of scale on technical efficiency—that is, there is a significant suppressing effect. Hence, this paper argues that, in the process of promoting agricultural green production, the government should guide farmers to a ‘natural flow’ to moderate scale management by reducing transaction costs, such as land transfer costs, and should not blindly encourage growers to expand their scale. At the same time, research and development of labor-saving technologies should be enhanced to reduce labor demand and cost in the production process.

1. Introduction

Fruit is an important source of vitamins and dietary fiber for nearly all people, and grapes are one of the most popular foods. China is the world’s largest producer and consumer of table grapes, as evidenced in 2021 when grape production hit 14.998 million tons with a domestic output value of about 400 billion US dollars (Source: Bric Agricultural Data Intelligent Terminal. http://www.agdata.cn, accessed on 20 December 2022). The grape planting industry has gradually become a pillar industry of agricultural production in many villages and towns in China and is also an important way to increase the income of local farmers. Indeed, 90% of grapes produced domestically are fresh varieties, and the traditional cultivation areas are mainly concentrated in temperate regions, such as the northwest and the Yellow River old riverway. Fujian, Guangxi, Yunnan, and other southern producing areas are located in subtropical and tropical humid areas with a rainy and humid climate. They are originally unsuitable or sub-suitable areas. The limitation of climatic conditions leads to the occurrence of downy mildew diseases, gray mold, anthracnose, cockchafers, snails, and other pests and diseases during the growth of grapes. Therefore, under the traditional open-field cultivation mode, growers can only control pests and diseases and increase production by spraying a large amount of pesticides and applying chemical fertilizers. This extensive planting technology not only leads to excessive pesticide residues in grapes, affecting the health of consumers, but also seriously pollutes the agricultural ecological environment, such as soil and water.

With the continuous innovation of agricultural technology, facility agriculture has gradually emerged. In order to break through the limitations of rainy and humid climatic conditions in the southern region, agricultural technicians have applied rain-shelter facilities to grape cultivation there, using physical means, such as plastic greenhouses and shading paper bags, to isolate most disease sources and pests. This can reduce more than two-thirds of the application of pesticides and chemical fertilizers, and also significantly lowers the pollution of the agricultural environment during the cultivation process (Yu et al., 2022 [1]). Compared with open-field cultivation, grapes grown under rain-shelter have fewer pesticide residues and higher sugar levels, making them healthier and tastier. The fruit are more uniform in size and coloring, without scars and cracks. The inviting appearance makes them more attractive to consumers. The average cost of rain-shelter cultivation is about twice that of open-air cultivation, but at the same time, the sales price and income have also increased by 2–3 times. Therefore, this new technology has significantly improved the economic benefits of growers.

The huge market demand and profit space have greatly stimulated the enthusiasm of growers to adopt new technologies. According to the survey data from the Ministry of Agriculture and Rural Affairs of China, a series of green production technologies, such as rain-shelters and shading and bagging, have been rapidly popularized in southern China in just over a decade. The area and yield of grape rain-shelter cultivation have also increased rapidly. The trend of large-scale operation of various new agricultural economic entities such as family farms and agricultural companies through land transfer has become increasingly obvious. It should be noted that compared with traditional open-field cultivation, although the rain-shelter cultivation mode is greener and environmentally friendly, the dependence on capital, labor, and other market factors is also significantly enhanced. Moreover, the technical difficulties and risks in the management of grape flowers, fruits, leaves, and trees, the temperature and humidity control of the park, ecological environment maintenance, and other aspects are also higher. Therefore, higher requirements are put forward for the resource endowment, cultivation experience, technical level, resource allocation, and field management ability of growers. If growers cannot meet the optimal factor ratio or technical requirements required for large-scale production in actual production, then it will be difficult to achieve the production frontier of rain-shelter cultivation, which will lead to different degrees of technical efficiency loss. At present, the development of China’s factor market reform, farmland infrastructure construction, agricultural supporting services, farmers’ technical training, and other aspects obviously lag behind the speed of green agriculture. Under such realistic constraints, can growers use rain-shelter cultivation techniques to scale grape cultivation and improve their production technical efficiency? This is the research question of concern in this paper.

This study contributes to the existing literature in two respects. First, focusing on the application and development of rain-shelter cultivation techniques in China’s grape planting industry, this research re-examines the impact of grape growers’ operating scale on their production technical efficiency from the perspective of green production, uses the threshold regression model to demonstrate the relationship between the two, and obtains the specific threshold of the threshold effect, thus, providing a reference for grape growers to determine the appropriate operating scale when carrying out rain-shelter cultivation. Second, we pay attention to the important role of farmers in the application of rain-shelter cultivation technology in the process of large-scale operation and introduce agricultural employees as mediating variables to test the mediating effect.

2. Literature Review and Theoretical Hypotheses

The measurement of farmers’ production technical efficiency and its influencing factors have long been the focus of scholars’ attention. In the measurement of production technical efficiency, the existing research mainly applies two methods, namely stochastic frontier analysis and data envelopment analysis (Wang, 2002 [2]; Diaz, 2014 [3]; Chiona et al., 2014 [4]; Ai et al., 2018 [5]; Chen et al., 2022a,b,c,d [6,7,8,9]; Parthiban et al., 2019 [10]). In terms of the influencing factors of production technical efficiency, scholars have focused on factors, such as agricultural cooperative membership (Abebaw and Haile, 2013 [11]; Ma et al., 2018 [12]), the adoption of mobile phones to collect agricultural information (Mwalupaso et al., 2019 [13]), investment in agricultural research and development (Perez and Rosegrant, 2015 [14]; Zhang et al., 2022 [15]), water and nutrient management practices (Yami et al., 2013 [16]), agricultural support services (Kelemu and Negatu, 2016 [17]), insurance adoption and risk aversion on agricultural production (Simone et al., 2022 [18]), land rental markets (Liu et al., 2022 [19]; Li and Ito, 2023 [20]), urbanization process (Zhao et al., 2022a,b,c,d [21,22,23,24]), financial access (Chen et al., 2022b [7]; Wang et al., 2023 [25]; Lin et al., 2023 [26]), and other key factors on the technical efficiency of farmers’ production.

The relationship between farm size and productivity is a broad topic of debate in development economics. Scholars from various countries have studied the relationship between the two using data from different regions and different crops, and the conclusions vary. Renato and Euan (2006) [27] believe that compared with small farmers, large-scale farmers have higher production technical efficiency. Sushma et al. (2022) [28] and Dhinesh et al. (2022) [29] also note that large-scale farmers in rice production can greatly improve technical efficiency through mechanization. However, Oppong (2018) [30] argues that increasing the operation scale leads to a higher loss of technical efficiency. Kumar et al. (2022) [31] confirm that small farmers in arid areas are more effective in rainwater resource management and technical efficiency of maize and wheat. Sheng et al. (2019) [32] present a mild U-shape relationship between maize yield and cropping area from the apparent inverse U-shape curve. Their result suggests that an inverse farm size-productivity relationship persists for most small-sized farms. Zhong et al. (2019) [33] find that households’ engagement in concurrent business (CB) could affect the farm size-technical efficiency (TE) relationship. This nexus has an inverted U-shape relationship for all CB engagement levels higher than 5%, and the most technically efficient farm size increases with the level of household CB engagement. At the same time, TE varies with the level of CB engagement depends on farm size.

In the existing literature on the relationship between operation scale and production technical efficiency, most research objects are rice, corn, and other food crops, while there are few research results on cash crops, such as fruits. Townsend et al. (1998) [34] use data on South African wine grapes to find that the inverse relationship between farm size and both land productivity and total factor productivity is weak, is not consistently negative, and differs between regions. However, Conradie et al. (2006) [35] make use of the panel data of farms in South Africa’s wine-grape producing areas in 2003–2004. Zhang et al. (2018) [36] analyze micro-data of apple growers in Shanxi Province, China, and find that large-scale farmers have higher technical efficiency than small-scale farmers. Li and Sun (2021) [37] based on the study of table grapes in Jiangsu Province, China, found that although technical efficiency would increase with the expansion of operation scale, its growth rate would slow down gradually. Based on survey data of kiwifruit in Shaanxi Province, China, Liu and Cai (2013) [38] find an inverted U-shape relationship between operation scale and farmers’ technical efficiency.

Nuhfil and Djoko (2018) [39] apply microscopic data of sugarcane growers in Indonesia and present that farmers with low technical efficiency often over-invest in various production factors, which do not necessarily relate to their planting scale. It can be seen that the relationship between operation scale and production technical efficiency varies under different conditions, such as research object, geographical region, and technical level. Therefore, the relationship between operation scale and technical efficiency of grape growers under the condition of rain-shelter cultivation technology needs to be further studied in combination with its technical characteristics.

Compared with open-field cultivation, rain-shelter cultivation of grapes has the following three characteristics. First, there is higher upfront capital investment, and growers need to build a plastic greenhouse and purchase film, reflective film, shading paper bags, and other means of production. Second, the degree of refinement is high, and the mechanization substitution rate is low. The rain-shelter cultivation of grapes has higher requirements for the fine operation of flower thinning, fruit thinning, leaf management, tree management, and other links. In the production process, timely irrigation and drainage are needed to maintain the humidity and biodiversity of the park, and the fruits are bagged many times. These tasks are almost completed manually, and the mechanical substitution rate is low (Yoshida et al., 2022 [40]), and so the demand for labor is greater. Third, the difficulty and risk is greater. Because the ecological environment under the plastic greenhouse is very complex, the humidity under the greenhouse is high in rainy weather, and the fruit trees easily breed diseases, while the high temperature under the greenhouse is hot in summer, and the fruit also easily burns and deteriorates. Therefore, it is difficult to manage the temperature and humidity under the greenhouse. If the growers improper management affects grape quality and yield, then technical risk is higher.

In the production practice of grape cultivation under rain-shelter, small-scale growers are in a state of shortage of production factors, such as labor force, and so it is difficult to reach the forefront of production technology, and there is a high loss of technical efficiency. At this time, land transfer can be used to expand operation scale, labor constraints can be eased through labor production, and professional division of labor and cooperation advantages are conducive to reducing average costs and improving economic returns. The ratio of land, labor, capital, and other factors is closer to the optimal ratio required by the production frontier, and technical efficiency will be improved.

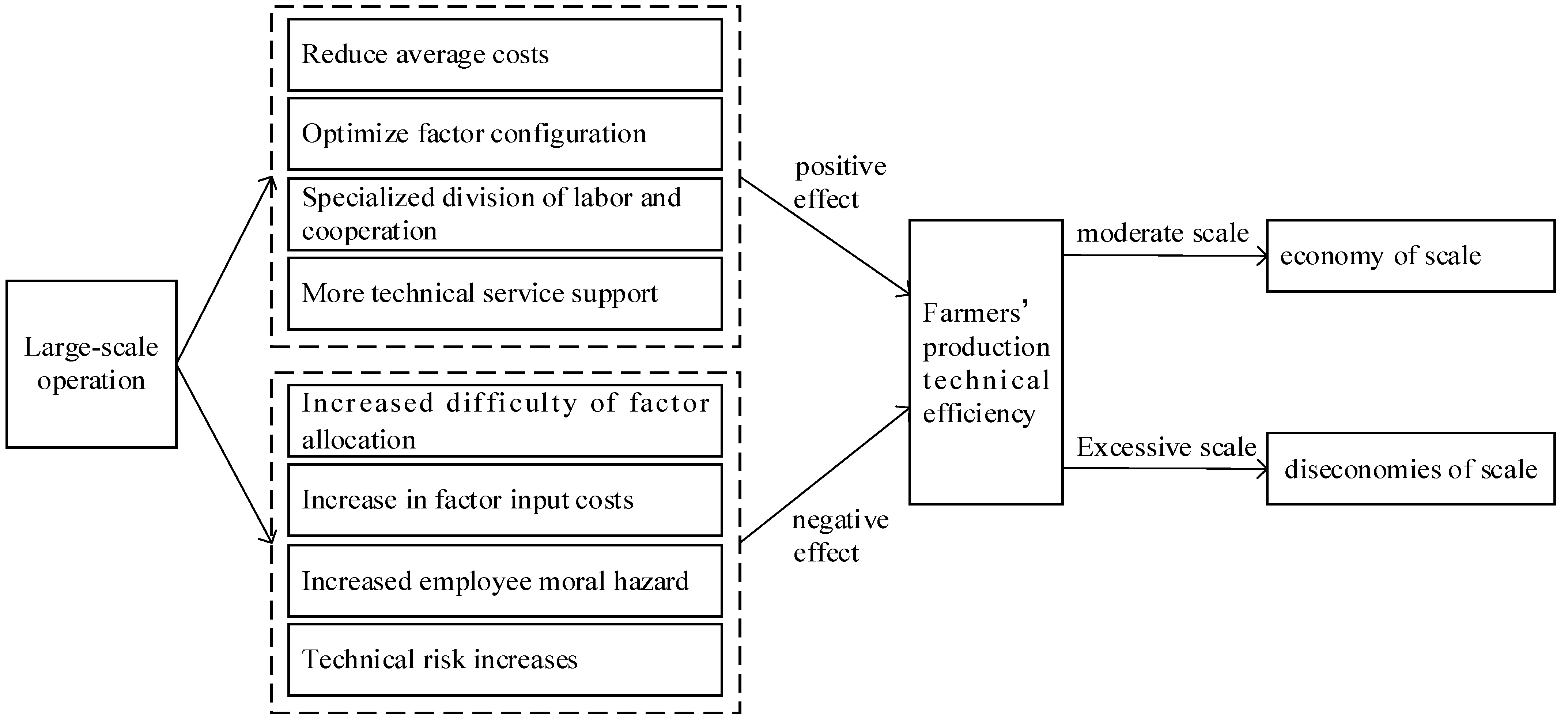

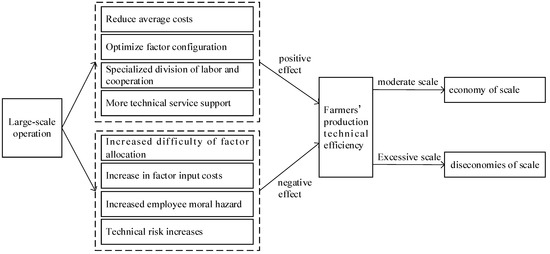

With the continuous expansion of operation scale, however, a variety of negative problems also ensues. On the one hand, with the continuous increase in factor input, the marginal returns of factors begin to decline, and the ratio of land, labor, capital, and other factors gradually exceeds the optimal range. Continuing to increase operation scale will not only raise the difficulty of coordinated allocation of various resources, but also cause greater pressure on operators’ factor input cost. On the other hand, with the increasing labor input ratio of employees, the difficulty of supervision gradually increases, and the opportunistic behaviors of employees, such as “hitchhiking”, become more and more serious. The decline in labor quality affects the precision of planting process and also increases the uncertainty and risk to production technology, which makes it difficult for output to reach the production frontier and, thus, leads to the decline of technical efficiency. Therefore, there may not be a simple linear relationship between scale and technical efficiency in the large-scale operation of rain-sheltered grape cultivation by growers, whose action path can be shown in Figure 1.

Figure 1.

Action path diagram of operation scale on technical efficiency of farmers under rain-shelter cultivation. Source—drawn by the authors.

Based on the above discussion, we propose the following hypotheses.

Hypothesis 1 (H1).

Under the rain-shelter cultivation mode of grapes, the moderate expansion of operation scale can improve the technical efficiency of growers.

Hypothesis 2 (H2).

The influence of operation scale on the efficiency of rain-shelter cultivation technology is not monotonous. With the continuous expansion of operation scale, technical efficiency will rise first and then fall, showing an inverted U-shape trend.

Hypothesis 3 (H3).

The quality of hired labor has a significant impact on the technical efficiency of grape rain-shelter cultivation. With the expansion of operation scale, the proportion of hired labor input increases, and low work efficiency and rising supervision costs caused by the moral hazard of hired labor will gradually suppress the positive effect of the operation scale on technical efficiency.

3. Methodology

3.1. Data Sources

Fujian Province is one of the emerging fresh grape planting areas in southern China. It has the largest area of grape cultivation and large-scale contiguous and standardized rain-shelter cultivation base along the southeast coast. The popularization rate of rain-shelter cultivation technology has reached more than 80% (Source: Fujian Provincial Department of Agriculture and Rural Affairs. http://nynct.fujian.gov.cn/, accessed on 5 May 2021). This has formed an industrialization, standardization, and branding ecological planting mode and industrial development pattern. Of all the table grapes produced in Fujian Province, 90% are European and American hybrid Kyoho grapes. With their high sweetness, full aroma, thick fruit powder, string-like beauty, and other characteristics, they have been awarded the national geographical indication of agricultural products and have a high reputation in China and Southeast Asia. This paper takes those farmers who apply rain-shelter cultivation techniques to plant Kyoho grapes in Fujian Province as the research object, which can help avoid the impact of grape variety differences on the production frontier.

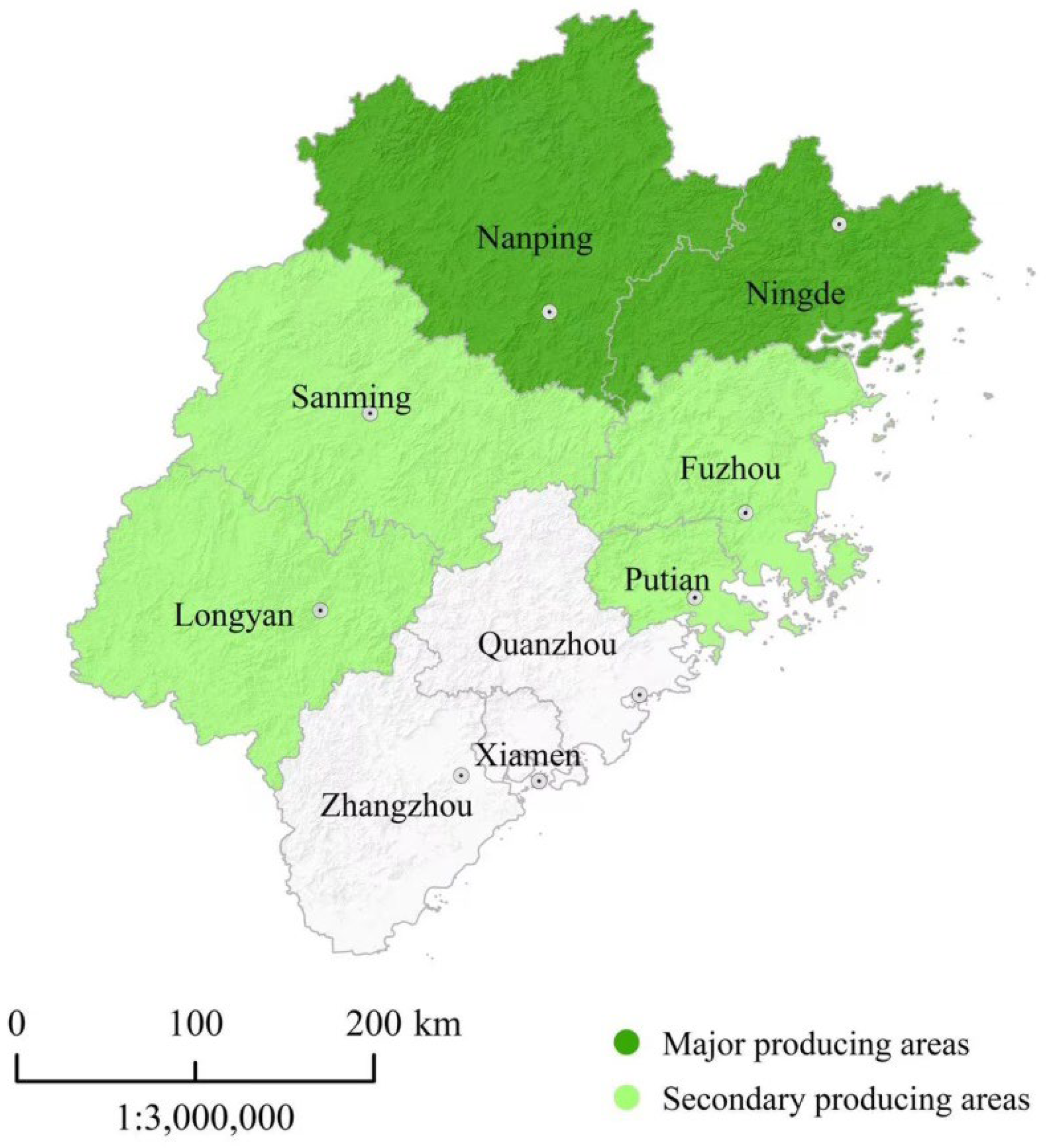

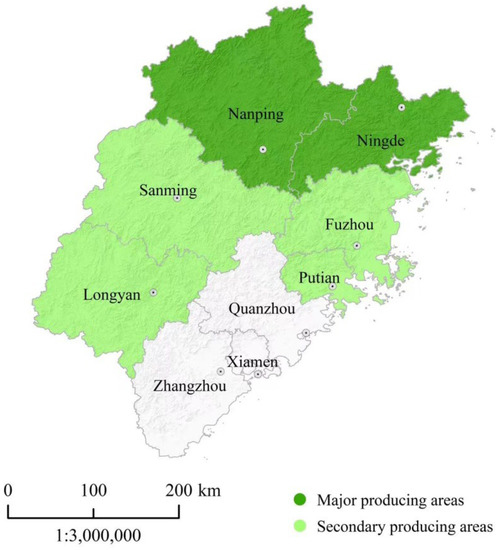

There are six origins of Kyoho grape in Fujian province, namely Ningde, Nanping, Sanming, Longyan, Fuzhou, and Putian (as Figure 2). In the third quarter of each year, the Fujian Quality and Technique Supervision Bureau will send a safety investigation team to sample grapes from these six regions. In 2021, the safety investigation team planned to obtain 400 samples in the province. The sampling method is multi-stage stratified sampling. First, the sampling number of each city is determined according to the proportion of six production areas in the province’s output. Second, two–four counties are randomly selected from each production area, one–two townships are randomly selected from each county, and one–two administrative villages are randomly selected from each township. Finally, according to the sample size, several plots are randomly selected from the grape planting base of each village for sampling.

Figure 2.

Distribution of Kyoho grape cultivation in Fujian province. Source—drawn by the authors.

In 2021, the sampling of grapes by the safety investigation team involved 17 counties, 29 townships, and 37 villages. The sampling time was arranged from early July to mid-August (grape ripening time varies in different regions). During this period, the members of the research team followed the security investigation team on several occasions to conduct a sample survey in the above villages and towns. We interviewed the growers when the staff sampled and registered the grapes. The questions include basic facts of farmers, land circulation, income and costs, etc. Finally, 314 valid samples were obtained after excluding non-Kyoho grape varieties, open-field cultivation, and incomplete data samples. The empirical analysis of this paper will be based on the survey data of these sample growers.

3.2. Model Specification

3.2.1. Input-Output Model

In the measurement of technical efficiency, the stochastic frontier production (SFA) function method as a parametric method, and data envelopment analysis (DEA) as a non-parametric method, are the mainstream approaches. Because most fruits, such as grapes, need to strictly control the yield in the planting process to ensure quality and income, their output should be measured at least from both yield and output value, and so it is more suitable to choose DEA to measure the technical efficiency of grape growers [41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66]. Since this paper focuses on the impact of factor input (especially labor factor input) on output [67,68,69,70,71], it adopts an input-oriented variable model of returns to scale, namely the BCC model. Table 1 shows the input and output indicators of computational technical efficiency.

Table 1.

Input and output of the technical efficiency model.

In Table 1, the self-employment input refers to the average wage level of the local labor market, while the employment input includes short-term and long-term employees. For capital input, self-owned land is corrected according to the average level of local land rent. To eliminate the interference of the differences in factor input prices and grape sales prices on technical efficiency, the input and output data are processed by noise reduction. The data of all variables were obtained from the sample growers. Pure technical efficiency and scale efficiency is obtained by the BCC model. The product of these two parts of efficiency is comprehensive technical efficiency .

3.2.2. Threshold Effect Model

Considering that there may be a non-linear relationship between the operational scale and the technical efficiency of farmers under the rain-shelter cultivation mode, the threshold effect model is used for empirical analysis. We set up the following model:

where is the technical efficiency, is the key explanatory variables, I is the indicator function, is the threshold variable, and is the threshold to be estimated.

In addition to the scale factors, other factors, including farmers’ resource endowment characteristics, production, and management characteristics, and regional characteristics, have an impact on technical efficiency of grape cultivation. To avoid endogeneity problems caused by missing variables that affect model estimates, the following variables are selected as control variables Z:

- (1)

- Resource endowment characteristics of growers, including age (), education (), technical training (), and family population ().

- (2)

- Characteristics of production and operation, including impact of production and operation characteristics on technical efficiency controlled by years of establishment (), whether the farmer has joined or cooperated with new agricultural operators (), and distance from the plantation to the local logistics center ().

- (3)

- Regional characteristics, including a regional dummy variable () which is added to the technical efficiency model to control the impact of geographical conditions, climate, cultivation history, and other factors on technical efficiency in different regions.

In view of the fact that the technical efficiency level of farmers may have a certain impact on their operation scale, in order to alleviate the endogenous problem of the model, the area under lease is selected as the instrumental variable of operation scale. The area under lease directly affects the scale of farmers’ operation and so has an indirect impact on their technical efficiency. We test to see if the leased area is a strong instrumental variable of operation scale, which meets the requirement that instrumental variables highly correlate with key variables. At the same time, to test the robustness of the estimation results of the threshold effect model, the Tobit model is established, and the square term of the operation scale is introduced for regression. The model form is as follows in (2), and the meaning of the variable is the same as the Table 2. The data of variables were obtained from the sample growers.

Table 2.

Variables’ description.

3.2.3. Mediation Effect Model

In the process of grape rain-shelter cultivation, growers need to invest a lot of manpower in trimming and pruning, soil and fertilizer management, fruit bagging, irrigation and drainage, weed control, and integrated disease and pest control, and the mechanical replacement rate is very low. In addition, the daily work also includes the maintenance of biodiversity in the park, timely adjustment of greenhouse temperature and humidity, and various kinds of waste disposal. Therefore, compared with traditional open-air cultivation, rain-shelter cultivation has a greater demand for labor.

With the expansion of operation scale, a typical family’s own labor force is insufficient, and production and operation are increasingly relying on the input of hired labor. Table 3 shows the proportion of hired labor input of farmers with different operation scales in this survey. It can be seen that with the expansion of operation scale, the proportion of hired labor input rises sharply. The influence of hired labor input and its labor quality on the technical efficiency of farmers is very important, and so it is selected as an intermediary variable for further analysis.

Table 3.

Proportion of labor input of growers with different sample sizes.

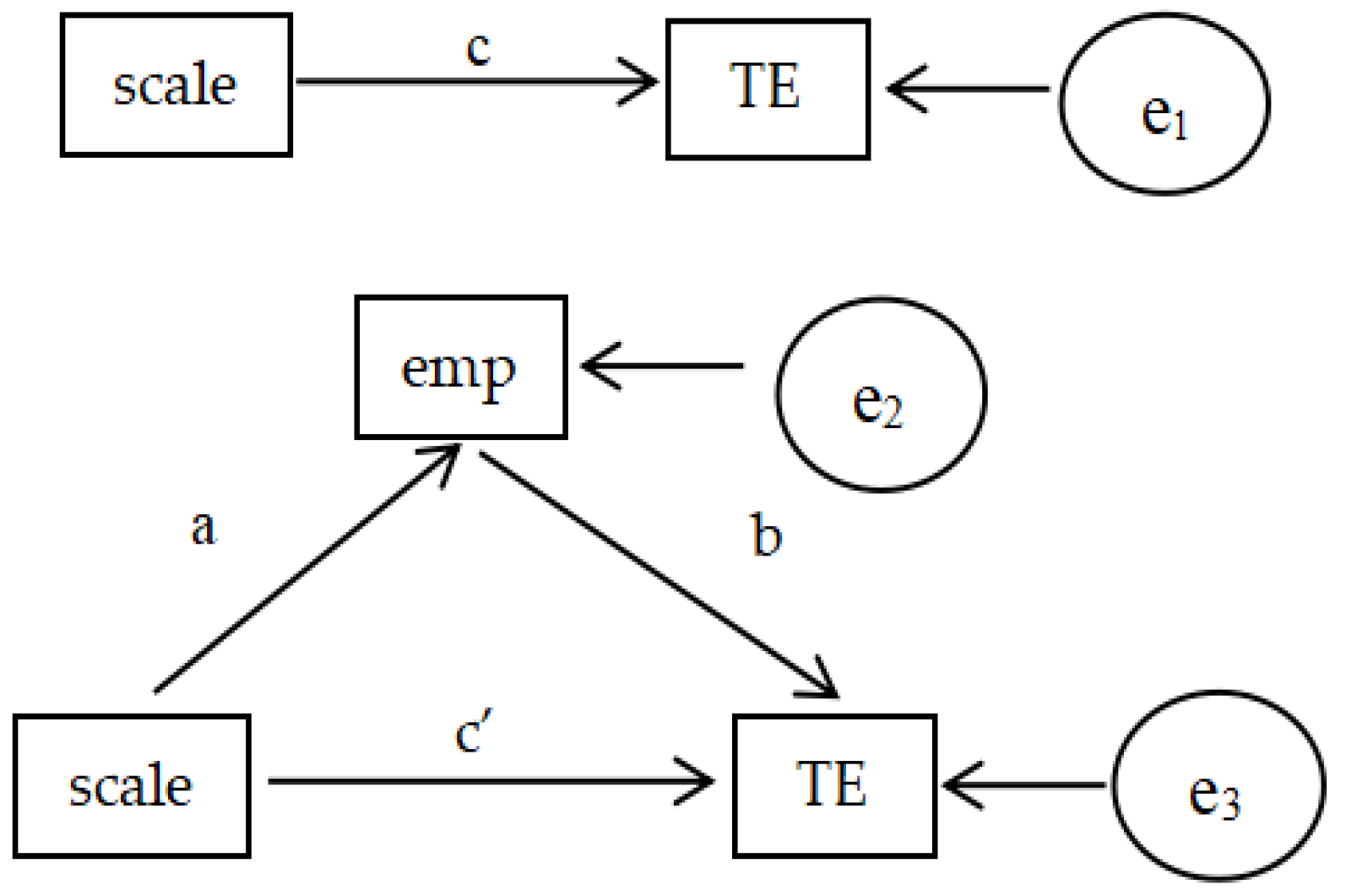

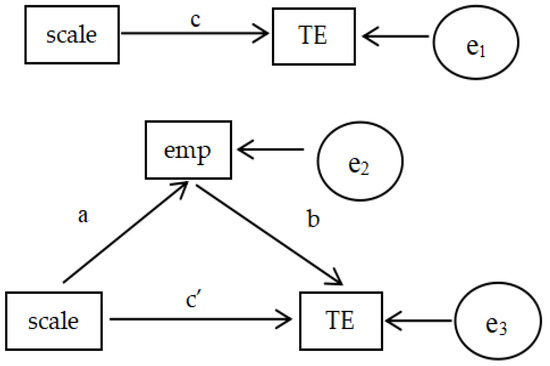

Considering the impact of operation scale on the technical efficiency of growers, if operation scale affects technical efficiency via the input of agricultural employees, then the input of employees is regarded as an intermediary variable. The relationship between the three can be expressed by the following equation:

where coefficient c in Formula (3) is the total effect of scale on TE (technical efficiency). Formula (4) is the effect of scale on the mediating variable (employee input ratio). Coefficient b in Formula (5) is the effect of the mediating variable on TE after controlling the influence of scale. Coefficient is the direct effect of scale on TE after controlling the influence of , and the mediating effect is the indirect effect, which is equal to the product of ab. The relationship between the total effect, direct effect, and indirect effect is . Figure 3 illustrates the relationship between operation scale, employee input, and technical efficiency.

Figure 3.

Diagram of mediating effect. Source: Drawn by the authors.

4. Empirical Results

4.1. Results of Production Technical Efficiency

Table 4 shows the descriptive statistics of the combined technical efficiency and pure technical efficiency of rain-shelter cultivation techniques for growers of different sizes.

Table 4.

Descriptive statistics of technical efficiency of farmers with different size samples.

From the results of descriptive statistics, we see that with the expansion of planting scale, the comprehensive technical efficiency, and pure technical efficiency of grape rain-shelter cultivation exhibits a trend of rising first and then falling. Because the ecological environment, such as temperature and humidity of the whole park, is more complicated than that of open-air cultivation after the construction of rain-shelter greenhouses, more manpower is needed in water supply and drainage, ecological environment maintenance of the park, etc. In addition, fruit bagging, flower thinning and fruit thinning, fruit tree pruning, and other jobs cannot be replaced by machinery. Thus, the intensive demand of green production technologies, such as rain-shelter cultivation, in manpower terms leads to the expansion of planting scale and the demand for a labor force.

In the traditional family business model, the planting area is generally less than 10 mu, the labor force is only a husband and wife, and factor allocation fails to reach the optimal state. Hence, the technical efficiency level is low. With the expansion of the planting area, the proportion of labor and other elements has increasingly been optimized, but in the 10 mu to 30 mu scale, technical efficiency begins to increase. When the planting area is expanded to the range of 30~50 mu and 50~100 mu, the cost advantage brought by economies of scale gradually appears, and both comprehensive technical efficiency and pure technical efficiency improve. However, due to the expansion of the operation scale, the shortage of a famer’s own labor force will lead to a large increase in the input of employees, and the resulting moral hazard and supervision costs also increase. The attitude of employees is significantly lower than that of self-employment. Therefore, with the expansion of scale, the moral hazard of employees will cause a decline of product quality and price, which leads to a certain degree of technical efficiency loss, and the value of comprehensive technical efficiency at this stage is lower than that of pure technical efficiency. When the planting scale continues to expand to more than 100 acres, the decline in the quality of the labor force caused by the higher proportion of labor input obscures the advantages of economies of scale, resulting in lower comprehensive technical efficiency and pure technical efficiency. Table 4 only describes the statistical results. Since statistics, such as the mean, are susceptible to extreme values, more objective laws need to be further measured by the empirical model.

4.2. Threshold Regression Results

The threshold regression model is used to test the search threshold and to determine whether there are differences in parameters on both sides of the threshold. In order to facilitate the observation and analysis of regression coefficient values, the regression of the original data is divided by 100, and the model variables are consistent with Table 2. Table 5 lists the threshold effect test results.

Table 5.

Threshold effect test.

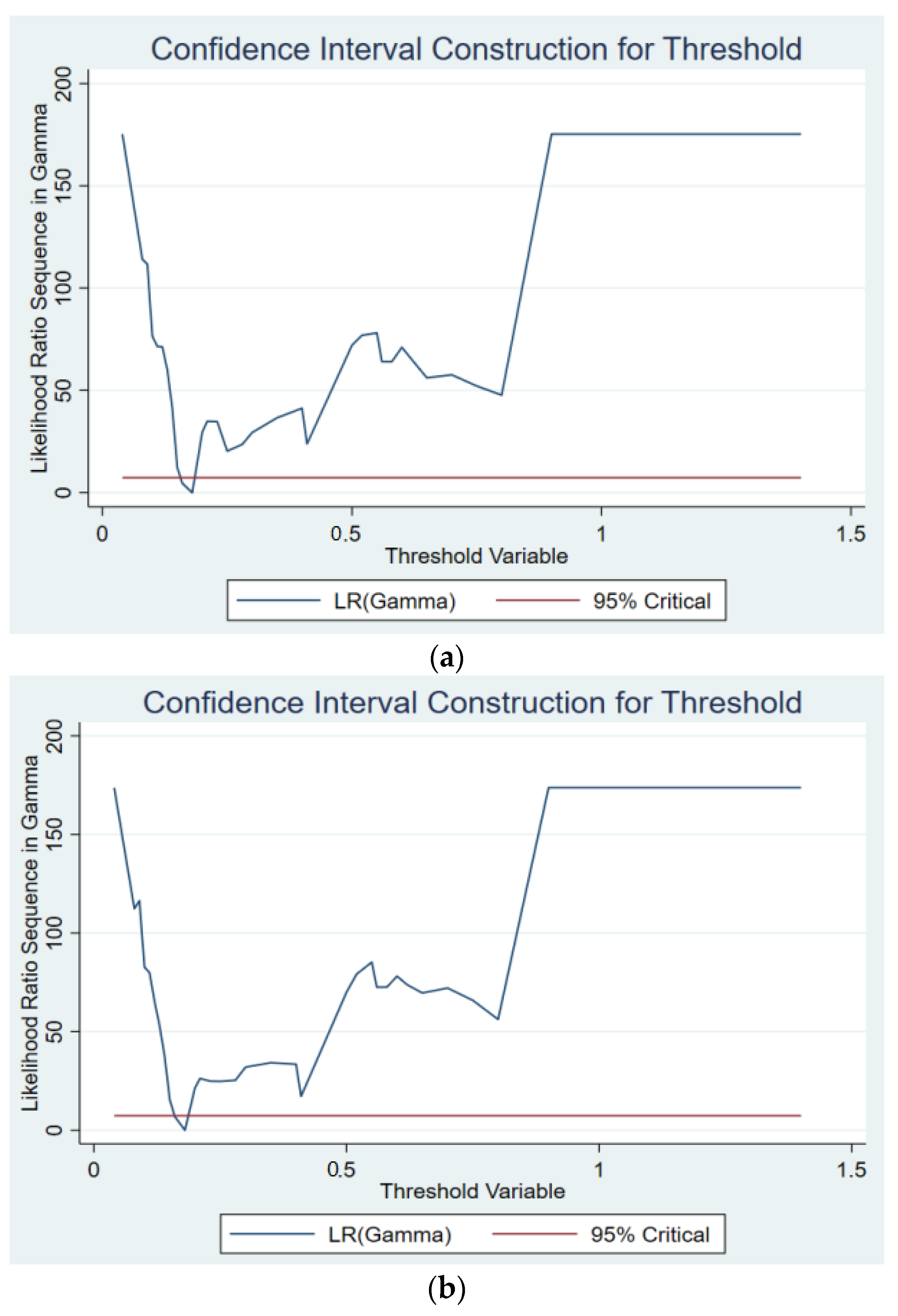

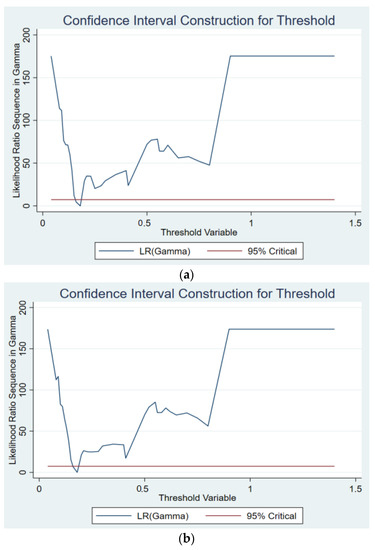

Figure 4a,b shows the single threshold estimators and confidence intervals of comprehensive technical efficiency and pure technical efficiency, respectively.

Figure 4.

(a) Single threshold estimators and confidence intervals of comprehensive technical efficiency; (b) single threshold estimators and confidence intervals of pure technical efficiency. Source—drawn by the authors.

The test results show that the maximum likelihood ratio decreases first and then increases. The intersection with a 95% confidence interval is the confidence interval of the threshold value. There is a significant threshold effect on the impact of operation scale on technical efficiency, and the threshold value is 18 mu. Taking the comprehensive technical efficiency and pure technical efficiency as the explanatory variables, respectively, the threshold regression results of the operation scale affecting the technical efficiency appear in Table 6. The left column is the regression result less than the threshold of 18 mu, and the right column is the regression result greater than the threshold of 18 mu. From the estimation results, we see that when the operation scale is less than the threshold, the coefficient of the operation scale is positive and is significant at the 1% level in the regression of pure technical efficiency. The results support H1, whereby the technical efficiency of small-scale growers can significantly improve when they expand the operation scale moderately. When the operating scale is greater than the threshold, it is significantly negative at the 5% level, which means the technical efficiency begins to decline if the operating scale continues to expand. There is an inverted U-shape relationship between the two variables, and the threshold is 18 mu. The results support H2.

Table 6.

Estimation results of threshold model of operation scale affecting technical efficiency.

The results of the threshold regression are basically consistent with the actual situation of grape production in Fujian Province. The operation scale is too small, and grape growers find it difficult to connect with the big consumer market in terms of yield and quality, which is not conducive to the improvement of production technical efficiency. Appropriately expanding the operation scale of small-scale growers can help optimize the allocation of factors, improve operating income, and promote technical efficiency. However, with the continuous expansion of the operation scale, the difficulty of factor allocation increases, the cost of factor input increases, the moral hazard and supervision cost of employees increase, and the technical risk increases. The positive impact of operation scale on improving technical efficiency gradually decreases, and the efficiency loss will gradually increase. From the results of threshold regression, we can see that the moderate operation scale of grape growers in Fujian Province is about 20 mu. At present, the planting scale of more than 60% of grape growers in Fujian Province is below 10 mu, and there is still room for improvement in their technical efficiency level. The production scale can be appropriately expanded through land transfer to improve technical efficiency and economic benefits. In addition to the key variables of the operation scale, the age of the head of the household, the level of education, and participation or cooperation with new agricultural economic entities all have a significantly positive impact on the technical efficiency of farmers. The three variables of family population, years of garden construction, and regional characteristics have a significantly negative impact on the technical efficiency of farmers, while the impact of technical training and distance from logistics center is not significant.

4.3. Robustness Test

In order to test the robustness of the results of the threshold regression model, this paper also uses the Tobit model for regression and introduces the square term of the key variable operating scale. The results are in Table 7.

Table 7.

Tobit model estimation results of operation scale affecting technical efficiency.

The results of Tobit regression show that the operation scale is significantly positive at the 1% level, and the square term is significantly negative at the 1% and 10% levels, which is consistent with the threshold regression conclusion. The results also support both H1 and H2.

4.4. Mediating Effect Test

The main methods to test the mediating effect are Baron and Kenny’s step-by-step test regression coefficient method, the bootstrap method to directly test the product of coefficients, and so on. Here, we refer to the test process modified and summarized by Wen and Ye (2014) [72] on the basis of these common methods. In the test of the mediating effect, two control variables are added, namely the number of the family-owned labor force () and type of growers (). Among the types of growers, traditional family operation = 0, family farm = 1, and large growers = 2; other variables are consistent with the previous text. The explained variable technical efficiency and the proportion of labor input are continuous variables between 0 and 1. The Tobit model is, thus, still used to estimate the parameters, and the land transfer area is still used as the instrumental variable of the operation scale. Considering that the input of employees will impact the resource allocation and management of growers, comprehensive technical efficiency, including scale efficiency, represents technical efficiency level. The estimation results of Equations (3)–(5) are in Table 8.

Table 8.

Test of the mediating effect of operation scale on technical efficiency through agricultural employees.

In Table 8, a = 0.00803, b = −0.0861, c = 0.000965, and c′ = 0.00113. Except for b being significant at the 10% level, the other three coefficients are significant at the 1% level. We present the test steps of Wen and Ye (2014) [72] as follows.

In the first step, c = 0.000965 is significant at the 1% level, and so the mediating effect exists.

In the second step, a = 0.00803 is significant at the 1% level, and b = −0.0861 is significant at the 10% level, indicating that the indirect effect is significant.

Directly into the fourth step, c′ = 0.00113, which is also significant at the 1% level, indicating that the direct effect is also significant.

In the fifth step, ab is negative, c′ is positive, and so the two symbols are different—that is, there is a significant suppressing effect in the process of operation scale affecting technical efficiency through agricultural employees, and the absolute value of the ratio of the indirect effect and direct effect is 0.6118.

The test results show an inverted U-shape relationship between farm size and farmers’ technical efficiency. At the beginning of the expansion of the operation scale, due to the lack of labor supply at this time, increasing the input of employees can alleviate the efficiency loss caused by labor supply constraints on production. At the same time, the increase in employees will also bring the advantages in terms of division of labor and professional cooperation, thus, presenting a significantly positive impact on technical efficiency. However, with the further expansion of the operation scale, the number of employees and the proportion of investment have increased sharply, the moral hazard and labor quality problems of employees have gradually become prominent, and the supervision and management of growers have become more difficult. It is often necessary to allocate energy or specially hire supervisors to supervise the labor process of employees, resulting in a rapid decline in the marginal remuneration of the labor force of employees and triggering a decline in technical efficiency. In other words, when the operation scale and the proportion of labor input exceed a reasonable range, the labor input will have a negative impact on the technical efficiency of grape green production. There is a significant suppressing effect. In the test of the mediating effect, when the operation scale and the input of employees are put into Equation (5) to estimate technical efficiency, the coefficient b in Formula (5) of the input of employees on the technical efficiency is negative, which just confirms this. The mediating effect test results also support H3.

With the continuous outflow of China’s agricultural labor force and the increasingly perfect land transfer market, operation scale has become the future trend of agricultural management. Agricultural employees can properly solve the problem of shortage of their own labor in operation scale and alleviate the efficiency loss caused by labor constraints. However, employment is essentially a principal–agent problem with moral hazard. If farmers cannot effectively supervise and manage their employees, then the suppressing effect of employees will become increasingly prominent with the expansion of operation scale, which will have a significantly negative impact on the improvement of growers’ technical efficiency.

5. Conclusions and Recommendations

5.1. Research Conclusions

Based on micro-survey data of 314 Kyoho grape growers in Fujian Province, China, this paper presents the BCC-DEA method to measure the efficiency level of growers’ rain-shelter cultivation techniques. The threshold model and Tobit model help to empirically test the impact of operation scale on growers’ technical efficiency, and employee input is introduced as an intermediary variable to analyze the intermediary effect of operation scale on technical efficiency through employee input. The results are as follows:

- (1)

- There is an inverted U-shape relationship between operation scale and technical efficiency of grape growers in rain-shelter cultivation. The regression results of the threshold regression model and Tobit model confirm this trend. The most optimum operation scale is 18 mu. Growers who are near this scale not only can enjoy the advantages of decreasing costs and increasing market power brought by economies of scale, but also can effectively supervise and manage the employed labor force and reduce the efficiency loss caused by moral hazard.

- (2)

- The results of threshold regression show that age, education level, and whether a farmer has joined cooperatives or cooperated with agricultural companies all have a significantly positive impact on the technical efficiency of rain-shelter cultivation, while family size and years of garden construction have a significantly negative impact on technical efficiency.

- (3)

- Employed labor input has a significant impact on the efficiency of rain-shelter cultivation techniques, and there is a significant suppressing effect when the operation scale affects technical efficiency through employed labor input. When the operation scale begins to expand, the employment of labor can effectively alleviate the output shortage and efficiency loss caused by labor constraints. At this time, the employment of labor has a positive effect on technical efficiency and output. However, with the expansion of the operation scale, the marginal return of employees is decreasing, and the difficulties of supervision and moral hazard are increasing. The efficiency loss caused by employment will gradually suppress the positive impact it brings.

5.2. Rrecommendationss

Based on the above research conclusions, the following policy suggestions are put forward:

- (1)

- There is still at present a large number of small-scale family growers with under 10 mu of grape rain-shelter cultivation in China. Moderate scale production has more advantages than traditional family small-scale farming and is more conducive to the implementation of green agricultural production technology. Therefore, the government should actively promote the development of the rural land leasing market, reduce transaction costs, such as land transfer, and reasonably guide small-scale farmers to the natural flow of appropriate scale management.

- (2)

- Rain-shelter cultivation and other green production technologies have high requirements in terms of market factors, agricultural services, farmers’ planting experience, farm management level, etc. Therefore, attention should be paid to their technical environment, technical attributes, and technical risks in the promotion process, and subsidies and incentives should not be used to induce farmers to blindly expand production scale. The loss of technical efficiency and economic income is caused by exceeding the appropriate operation scale.

- (3)

- Incentives can be initiated to increase the research, development, and popularization of labor-saving technologies to reduce agricultural production costs. With the deepening of aging in China, labor shortages and rising labor costs have become inevitable. For cash crops, such as fruits and vegetables with a low mechanical replacement rate and high labor-intensive degree, relevant agricultural technical departments should increase the research, development, and promotion of labor-saving technologies and machinery. Doing so can help to reduce labor demand and labor cost in the process of increasing farmers’ operation scale.

- (4)

- Guidance should be given to farmers to improve the labor supervision and security mechanism and to make full use of the means of information to reduce supervision costs. Employment contracts in rural areas are mostly verbal. Without clear punishment mechanisms and binding clauses, moral hazard is more likely to occur, affecting labor quality and technical efficiency. Therefore, employers should clarify labor standards and any corresponding punishment mechanism with employees and dismiss employees with serious moral corruption, so as to ensure the labor quality of the team. At the same time, operators who do not participate or rarely participate in production labor should make full use of modern monitoring equipment to supervise the labor process of employees. This can help increase the intensity of supervision and also save the labor cost of supervision.

Author Contributions

F.S., conceptualization, software, resources, writing—original draft preparation, methodology, data curation, validation, investigation; X.X., validation, writing—reviewing and editing, supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research is a phased research result of the National Social Science Fund Project of China “Statistical Analysis of the Evaluation Index and Formation Mechanism of Rural Revitalization in China” (No. 19BTJ047).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets used or analyzed during the current study are available from the yearbooks or the corresponding author on reasonable request.

Acknowledgments

The authors are grateful to the editor and the anonymous reviewers of this paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yu, S.; Li, B.; Guan, T.; Liu, L.; Wang, H.; Liu, C.; Zang, C.; Huang, Y.; Liang, C. A Comparison of Three Types of “Vineyard Management” and Their Effects on the Structure of Plasmopara viticola Populations and Epidemic Dynamics of Grape Downy Mildew. Plants 2022, 11, 2175. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.-J. Heteroscedasticity and Non-Monotonic Efficiency Effects of a Stochastic Frontier Model. J. Prod. Anal. 2002, 18, 241–253. [Google Scholar] [CrossRef]

- Diaz, M.A.; Sánchez, R. Firm size and productivity in Spain: A stochastic frontier analysis. Small Bus. Econ. 2008, 30, 315–323. [Google Scholar] [CrossRef]

- Chiona, S.; Kalinda, T.; Tembo, G. Stochastic Frontier Analysis of the Technical Efficiency of Smallholder Maize Farmers in Central Province, Zambia. J. Agric. Sci. 2014, 6, 108. [Google Scholar] [CrossRef]

- Ai, X.; Liu, J.; Sirisrisakulchai, J.; Sriboonchitta, S. Technical efficiency analysis of major agriculture production provinces in China: A stochastic frontier model with entropy. J. Phys. Conf. Ser. 2018, 1053, 012101. [Google Scholar] [CrossRef]

- Chen, H.; Shi, Y.; Xu, M.; Xu, Z.; Zou, W. China’s industrial green development and its influencing factors under the background of carbon neutrality. Environ. Sci. Pollut. Res. Int. 2022. [Google Scholar] [CrossRef]

- Chen, H.; Shi, Y.; Zhao, X. Investment in renewable energy resources, sustainable financial inclusion and energy efficiency: A case of US economy. Resour. Policy 2022, 77, 102680. [Google Scholar] [CrossRef]

- Chen, H.; Yang, Y.; Yang, M.; Huang, H. The impact of environmental regulation on China’s industrial green development and its heterogeneity. Front. Ecol. Evol. 2022, 10, 967550. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Y.; Zhou, L. Has financial access improved agricultural technical efficiency?—Evidence from two family farm demonstration zones in China. China Agric. Econ. Rev. 2022, 14, 142–164. [Google Scholar] [CrossRef]

- Parthiban, J.J.; Rajesh, R.; Sundar, G.S. Resource Use Efficiency and Technical Efficiency, Determinants of Technical Efficiency in Groundnut Production in Tiruchirappalli District—Data Envelopement Analysis (DEA) Approach. Int. J. Agric. Sci. Res. 2019, 9, 119–130. [Google Scholar] [CrossRef]

- Abebaw, D.; Haile, M.G. The impact of cooperatives on agricultural technology adoption: Empirical evidence from Ethiopia. Food Policy 2013, 38, 82–91. [Google Scholar] [CrossRef]

- Ma, W.; Renwick, A.; Yuan, P.; Ratna, N. Agricultural cooperative membership and technical efficiency of apple farmers in China: An analysis accounting for selectivity bias. Food Policy 2018, 81, 122–132. [Google Scholar] [CrossRef]

- Mwalupaso, G.E.; Wang, S.; Rahman, S.; Alavo, E.J.-P.; Tian, X. Agricultural Informatization and Technical Efficiency in Maize Production in Zambia. Sustainability 2019, 11, 2451. [Google Scholar] [CrossRef]

- Perez, N.; Rosegrant, M.W. The Impact of Investment in Agricultural Research and Development and Agricultural Productivity; IFPRI Discussion Paper 01447; Environment and Production Technology Division of the International Food Policy Research Institute (IFPRI): Washington, DC, USA, 2015; Available online: https://ssrn.com/abstract=2631730 (accessed on 16 February 2022).

- Zhang, L.; Ma, X.; Ock, Y.-S.; Qing, L. Research on Regional Differences and Influencing Factors of Chinese Industrial Green Technology Innovation Efficiency Based on Dagum Gini Coefficient Decomposition. Land 2022, 11, 122. [Google Scholar] [CrossRef]

- Yami, M. Sustaining participation in irrigation systems of Ethiopia: What have we learned about water user associations? Water Policy 2013, 15, 961–984. [Google Scholar] [CrossRef]

- Kelemu, K.; Negatu, W. Analysis of levels and determinants of technical efficiency of wheat producing farmers in Ethiopia. Afr. J. Agric. Res. 2016, 11, 3391–3403. [Google Scholar] [CrossRef]

- Simone, R.; Francesco, C.; Cristina, S. Effects of Insurance Adoption and Risk Aversion on Agricultural Production and Technical Efficiency: A Panel Analysis for Italian Grape Growers. Economies 2022, 10, 20. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, L.; Tarbert, H.; Yan, Z. Analysis on Spatio-Temporal Characteristics and Influencing Factors of Industrial Green Innovation Efficiency—From the Perspective of Innovation Value Chain. Sustainability 2021, 14, 342. [Google Scholar] [CrossRef]

- Li, X.; Ito, J. Determinants of technical efficiency and farmers’ crop choice rationality: A case study of rural Gansu, China. J. Asian Econ. 2023, 84, 101558. [Google Scholar] [CrossRef]

- Zhao, J.; He, G. Research on the Impact of Digital Finance on the Green Development of Chinese Cities. Discret. Dyn. Nat. Soc. 2022, 2022, 3813474. [Google Scholar] [CrossRef]

- Zhao, X.; Ma, X.; Shang, Y.; Yang, Z.; Shahzad, U. Green economic growth and its inherent driving factors in Chinese cities: Based on the Metafrontier-global-SBM super-efficiency DEA model. Gondwana Res. 2022, 106, 315–328. [Google Scholar] [CrossRef]

- Zhao, X.; Nakonieczny, J.; Jabeen, F.; Shahzad, U.; Jia, W. Does green innovation induce green total factor productivity? Novel findings from Chinese city level data. Technol. Forecast. Soc. Chang. 2022, 185, 122021. [Google Scholar] [CrossRef]

- Zhao, Z.; Peng, P.; Zhang, F.; Wang, J.; Li, H. The Impact of the Urbanization Process on Agricultural Technical Efficiency in Northeast China. Sustainability 2022, 14, 12144. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, H.; Teng, Y.-P. Role of greener energies, high tech-industries and financial expansion for ecological footprints: Implications from sustainable development perspective. Renew. Energy 2023, 202, 1424–1435. [Google Scholar] [CrossRef]

- Lin, R.; Wang, Z.; Gao, C. Re-examining resources taxes and sustainable financial expansion: An empirical evidence of novel panel methods for China’s provincial data. Resour. Policy 2023, 80, 103284. [Google Scholar] [CrossRef]

- Renato, V.; Euan, F. Technical Inefficiency and Production Risk in Rice Farming: Evidence from Central Luzon Philippines. Asian Econ. J. 2006, 20, 29–46. [Google Scholar] [CrossRef]

- Sushma, K.N.; Thilagavathi, M.; Parimalarangan, S.; Vasanthi, R. Adoption Pattern of Mechanization of Paddy Farms in West Godavari District of Andhra Pradesh, India. Asian J. Agric. Ext. Econ. Sociol. 2022, 40, 653–658. [Google Scholar] [CrossRef]

- Dhinesh, M.; Dhamodaran, T.; Muralidharan, C.; Selvarani, G.; Prabakaran, K. Adoption of Farm Mechanization in Rice Cultivation in Villupuram District. Asian J. Agric. Ext. Econ. Sociol. 2022, 40, 195–201. [Google Scholar] [CrossRef]

- Oppong, A.B. Technical efficiency and production risk of maize production: Evidence from Ghana. J. Energy Nat. Resour. Manag. 2018, 3, 74–80. [Google Scholar] [CrossRef]

- Kumar, V.; Sharma, V.; Singh, M.; Sharma, S.C. Impact of low cost interventions through frontline demonstrations on crop productivity and profitability of small and marginal farmers under dryland conditions. Agric. Res. J. 2022, 59, 531–536. [Google Scholar] [CrossRef]

- Sheng, Y.; Ding, J.; Huang, J. The Relationship between Farm Size and Productivity in Agriculture: Evidence from Maize Production in Northern China. Am. J. Agric. Econ. 2018, 101, 790–806. [Google Scholar] [CrossRef]

- Zhong, M.; Zhu, Y.; Chen, Q.; Liu, T.; Cai, Q. Does household engagement in concurrent business affect the farm size-technical efficiency relationship in grain production? Evidence from Northern China. China Agric. Econ. Rev. 2019, 11, 125–142. [Google Scholar] [CrossRef]

- Townsend, R.; Kirsten, J.; Vink, N. Farm size, productivity and returns to scale in agriculture revisited: A case study of wine producers in South Africa. Agric. Econ. 1998, 19, 175–180. [Google Scholar] [CrossRef]

- Conradie, B.; Cookson, G.; Thirtle, C. Efficiency and farm size in Western Cape grape production: Pooling small datasets. S. Afr. J. Econ. 2006, 74, 334–343. [Google Scholar] [CrossRef]

- Zhang, C.; Chang, Q.; Huo, X. Can the Moderate-scale Management Really Reduce the Production Costs of Agricultural Products?—An Empirical Analysis Based on 661 Shaanxi Apple Farmers. J. Agrotech. Econ. 2018, 282, 26–35. [Google Scholar] [CrossRef]

- Li, F.; Sun, H. Can Large-scale Management Increase the Production Technical Efficiency of Table Grape Growers?—Based on Survey Data of 344 Farmers from Jiangsu Grape Production Base. J. Agrotech. Econ. 2021, 313, 133–143. [Google Scholar] [CrossRef]

- Liu, T.; Cai, Q. Analysis of production technical efficiency of farmers with different operation scale: Based on the data of 210 farmers in kiwifruit production base County of Shaanxi Province. Chin. Rural. Econ. 2013, 37–46. [Google Scholar]

- Nuhfil, H.; Djoko, K. Technical efficiency and scale efficiency of sugarcane production. Russ. J. Agric. Socio-Econ. Sci. 2018, 5, 304–308. [Google Scholar] [CrossRef]

- Yoshida, T.; Onishi, Y.; Kawahara, T.; Fukao, T. Automated harvesting by a dual-arm fruit harvesting robot. ROBOMECH J. 2022, 9, 19. [Google Scholar] [CrossRef]

- Baležentis, T.; Li, T.; Chen, X. Has agricultural labor restructuring improved agricultural labor productivity in China? A decomposition approach. Socio-Econ. Plan. Sci. 2020, 76, 100967. [Google Scholar] [CrossRef]

- Battese, G.E.; Rao, D.S.P.; O’Donnell, C.J. A Metafrontier Production Function for Estimation of Technical Efficiencies and Technology Gaps for Firms Operating Under Different Technologies. J. Product. Anal. 2004, 21, 91–103. [Google Scholar] [CrossRef]

- Bellit, S.; Dessendre, C.D. Agricultural employees: Between sectoral attachment and precarity. Écon. Rural. 2014, 342, 87–106. [Google Scholar] [CrossRef][Green Version]

- Bojnec, Š.; Fertő, I. Farm income sources, farm size and farm technical efficiency in Slovenia. Post-Communist Econ. 2013, 25, 343–356. [Google Scholar] [CrossRef]

- Chen, H.; Lin, H.; Zou, W. Research on the Regional Differences and Influencing Factors of the Innovation Efficiency of China’s High-Tech Industries: Based on a Shared Inputs Two-Stage Network DEA. Sustainability 2020, 12, 3284. [Google Scholar] [CrossRef]

- Shi, Y.; Xie, Y.; Chen, H.; Zou, W. Spatial and Temporal Differences in the Health Expenditure Efficiency of China: Reflections Based on the Background of the COVID-19 Pandemic. Front. Public Health 2022, 10, 879698. [Google Scholar] [CrossRef] [PubMed]

- Emerick, K. Agricultural productivity and the sectoral reallocation of labor in rural India. J. Dev. Econ. 2018, 135, 488–503. [Google Scholar] [CrossRef]

- Emran, S.; Shilpi, F. Agricultural Productivity, Hired Labor, Wages, and Poverty: Evidence from Bangladesh. World Dev. 2018, 109, 470–482. [Google Scholar] [CrossRef]

- Fan, S. Technological change, technical and allocative efficiency in Chinese agriculture: The case of rice production in Jiangsu. J. Int. Dev. 2000, 12, 1–12. [Google Scholar] [CrossRef]

- Farrell, M.J. The Measurement of Productive Efficiency. J. R. Stat. Soc. 1957, 120, 253–290. [Google Scholar] [CrossRef]

- Gao, R.; Yan, H.; Duan, J.; Gao, Y.; Cao, C.; Li, L.; Guo, L. Study on the nonfatigue and fatigue states of orchard workers based on electrocardiogram signal analysis. Sci. Rep. 2022, 12, 4858. [Google Scholar] [CrossRef]

- Gbadebo, A.; Martins, M.O. Constraints of Women Farmer’s Access to Information and Communication Technologies (ICTs) for Agricultural Information in Oyo State, Nigeria. NASS J. Agric. Sci. 2020, 2, 4–8. [Google Scholar] [CrossRef]

- Huang, C.M.; Zhu, Z. The effects of contract-labors on technical efficiency of grain production: Based on a survey data of rice farms in three provinces. Res. Agric. Mod. 2018, 39, 229–238. [Google Scholar] [CrossRef]

- Jacoby, H.G.; Mansuri, G. Incentives, supervision, and sharecropper productivity. J. Dev. Econ. 2009, 88, 232–241. [Google Scholar] [CrossRef]

- Li, C.; Guo, G. The Influence of Large-Scale Agricultural Land Management on the Modernization of Agricultural Product Circulation: Based on Field Investigation and Empirical Study. Sustainability 2022, 14, 13967. [Google Scholar] [CrossRef]

- Li, M.; Sicular, T. Aging of the labor force and technical efficiency in crop production: Evidence from Liaoning province, China. China Agric. Econ. Rev. 2013, 5, 342–359. [Google Scholar] [CrossRef]

- Mesay, Y.; Tesafye, S.; Bedada, B.; Fekadu, F.; Tolesa, A.; Dawit, A. Source of technical inefficiency of smallholder wheat farmers in selected waterlogged areas of Ethiopia: A translog production function approach. Int. J. Agrochem. Plant Prot. 2013, 1, 25–34. [Google Scholar] [CrossRef]

- Muyanga, M.; Jayne, T.S. Revisiting the Farm Size-Productivity Relationship Based on a Relatively Wide Range of Farm Sizes: Evidence from Kenya. Am. J. Agric. Econ. 2019, 101, 1140–1163. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Hoang, V.-N.; Seo, B. Cost and environmental efficiency of rice farms in South Korea. Agric. Econ. 2012, 43, 369–378. [Google Scholar] [CrossRef]

- Rezek, J.P.; Perrin, R.K. Environmentally adjusted agricultural productivity in the great plains. J. Agric. Resour. Econ. 2004, 29, 346–369. [Google Scholar] [CrossRef]

- Rocha, A.B. Does the technical assistance impact technical efficiency of Brazilian family farmers. In Proceedings of the 2021 Agricultural & Applied Economics Association Annual Meeting, Austin, TX, USA, 1–3 August 2021. [Google Scholar]

- Zou, W.; Yang, Y.; Yang, M.; Zhang, X.; Lai, S.; Chen, H. Analyzing efficiency measurement and influencing factors of China’s marine green economy: Based on a two-stage network DEA model. Front. Mar. Sci. 2023, 10, 1020373. [Google Scholar] [CrossRef]

- Wang, N.; Gao, Y.; Li, X.; Wang, Y. Efficiency Analysis of Grain Production Inputs: Utilization in China from an Agricultural Sustainability Perspective. Agric. Res. 2018, 7, 37–50. [Google Scholar] [CrossRef]

- Wang, X.; Xu, D.; Zhang, Y.; Yang, J. The relevance of farm scale, labor inputs and technical efficiency. Resour. Sci. 2016, 38, 476–484. [Google Scholar] [CrossRef]

- Zewdie, M.; Moretti, M.; Tenessa, D.; Ayele, Z.; Nyssen, J.; Tsegaye, E.; Minale, A.; Van Passel, S. Agricultural Technical Efficiency of Smallholder Farmers in Ethiopia: A Stochastic Frontier Approach. Land 2021, 10, 246. [Google Scholar] [CrossRef]

- Zou, W.; Shi, Y.; Xu, Z.; Ouyang, F.; Zhang, L.; Chen, H. The Green Innovative Power of Carbon Neutrality in China: A Perspective of Innovation Efficiency in China’s High-Tech Industry Based on Meta-Frontier DEA. Front. Environ. Sci. 2022, 10, 256. [Google Scholar] [CrossRef]

- Al-Bahli, E.F.N.; Al-Jumaili, M.H.J. The Factors of Deterioration of Natural Pastures From The View Point of Agricultural Employees in Al-Muthanna Governorate. IOP Conf. Ser. Earth Environ. Sci. 2021, 923, 012066. [Google Scholar] [CrossRef]

- Altalb, A.A.T. The Knowledge Level of Agricultural Employees/ Nineveh Province towards the Tasks of Agricultural Extension. Asian J. Agric. Ext. Econ. Sociol. 2017, 17, 1–8. [Google Scholar] [CrossRef][Green Version]

- Alvarez, J.A. The Agricultural Wage Gap: Evidence from Brazilian Micro-data. Am. Econ. J. Macroecon. 2020, 12, 153–173. [Google Scholar] [CrossRef]

- Kaewdok, T.; Norkaew, S.; Sirisawasd, S.; Choochouy, N.; Taptagaporn, S. Anthropometric Measurement of Thai Older Farmers for Agricultural Tools and Workplace Design. Designs 2022, 6, 81. [Google Scholar] [CrossRef]

- Susanto, D.; Rosson, C.; Anderson, D.; Adcock, F. Immigration policy, foreign agricultural labor, and exit intentions in the United States dairy industry. J. Dairy Sci. 2010, 93, 1774–1781. [Google Scholar] [CrossRef]

- Wen, Z.; Ye, B. Analyses of Mediating Effects: The Development of Methods and Models. Adv. Psychol. Sci. 2014, 22, 731. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).