Process Cooling Market in Europe: Assessment of the Final Energy Consumption for the Year 2016

Abstract

1. Introduction

- Data inventory;

- Data reliability;

- Data definition and comparability.

1.1. Data Inventory

1.2. Data Reliability

1.3. Data Definition and Comparability

2. Materials and Methods

2.1. Materials

2.2. Methods

- Chiller (air-to-water) < 400 kW;

- Chiller (air-to-water) > 400 kW;

- Chiller (water-to-water) < 400 kW; and

- Chiller (water-to-water) > 400 kW.

- Number of installed cooling units;

- Equivalent full load hours (EFLHs);

- Installed capacity; and

- Energy efficiency levels (Seasonal energy performance ratio-SEPR).

- Nrunits is intended as the number of installed units at EU MS, in the industry sector for a certain type of machinery for PC purposes;

- Tequivalent full load hours are intended as the yearly (2016) operative hours of a certain PC system;

- Welectricity is considered as the work input of the space PC system. Notably it is considered as the fraction of the system power capacity and its respective energy efficiency level. It is worth noting that electricity is the energy input that allows the cold as output.

- (i.)

- The LST data were retrieved using the Copernicus Global Land Service [50]. The data collection was based on instantaneous observations. Therefore, the product was computed globally every hour and made available to the user within 4 h. The LST product user manual can be found in further detail [27]. Cloud cover and data consistency issues that affect the LST information were filtered, and only cloud-free areas were selected. Moreover, the CDD (cooling degree days) data were acquired at the NUTS2 resolution from the H2020 HotMaps project’s public repositories and were clustered into five different sets to fill incomplete data [28]. The clustering was performed using the k-means algorithm [51]. If no data were available for a defined hour (h) and a specific NUTS2 (NUTS2i), then the missing LST data was estimated by considering the median value of obtainable LST values (for h, i) according to its cluster.

- (ii.)

- The following measures were applied since data related to the elaborated temporal series were missing:

- The missing LST values were identified.

- The average value substituted the identified missing values, for the same hour of the day, before and after.

- A 7-h window and a polynomial order equal to 2 were applied to the Savitzky-Golay filter [52], which was used to create a continuous LST time series.

- (iii.)

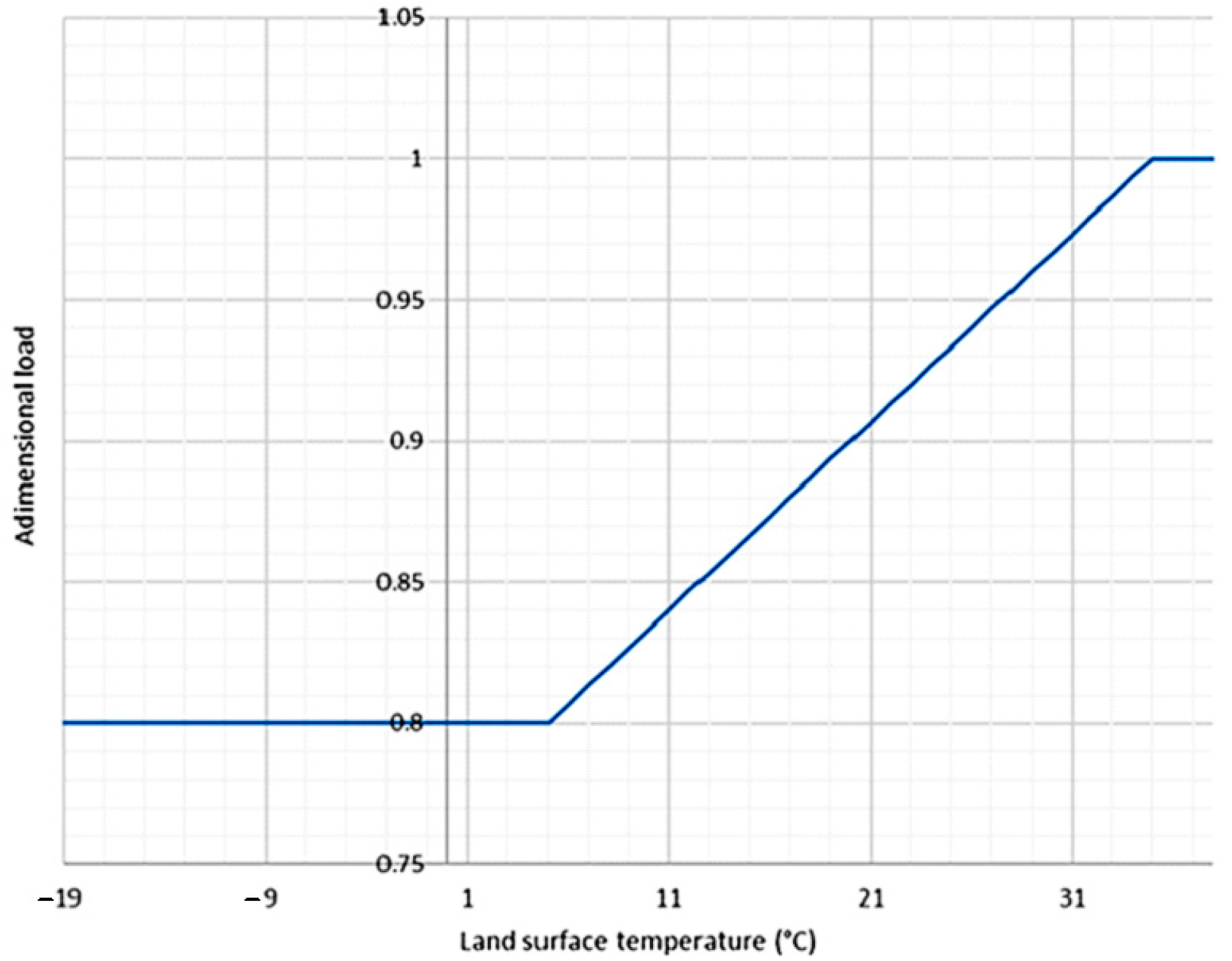

- A complete hourly LST dataset was available at each (i) NUTS2 level (LSTNUTS2). These data were used to calculate a normalized hourly time series for each (i) NUTS2 (LOADNUTS2). A constant-linear-constant hourly load law was utilized, with LST (temperature and temperature levels) expressed in degrees Celsius (°C) as presented in Equation (2) [49] results in Figure 1.

- (iv.)

- Besides, by applying Equation (3) with 8760 (the number of hours in a year), the EFLHs at each (i) NUTS2 level (EFLHsNUTS2) were derived:

3. Results

4. Discussion

5. Conclusions

- The final energy consumption in the European process cooling sector accounted for more than 110 TWh/year. It is important to state that around half of the European member states make up nearly the entire final energy consumption for process cooling. Notably, the highest percentage, which is about 90%, is detained by Italy, France, Spain, Germany, the United Kingdom, Netherlands, Greece, Poland, Belgium, Austria, Sweden, Cyprus, Hungary, Finland, and Portugal. The remaining 13 member states share the residual of 10%.

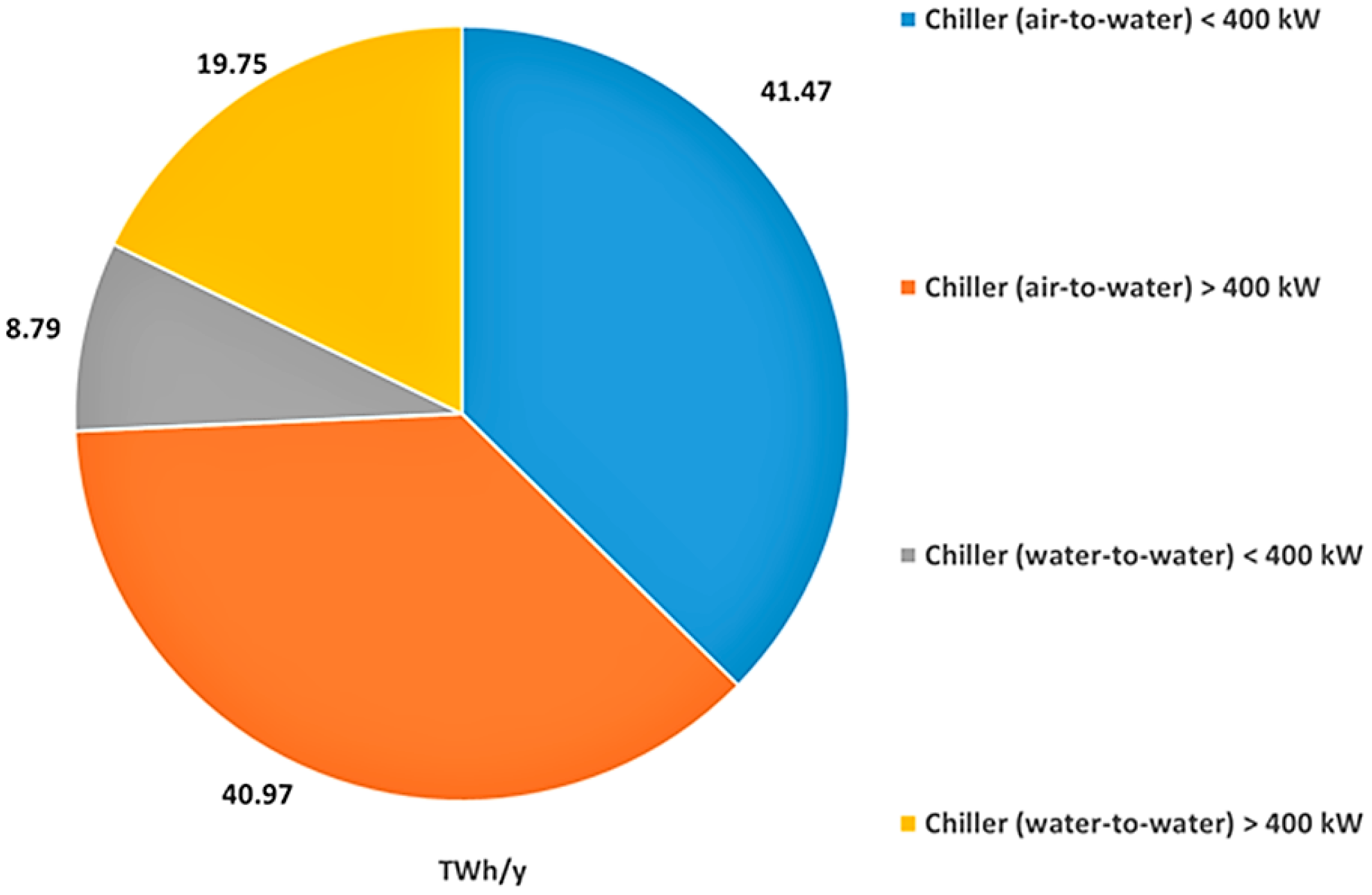

- In regard to the applied cooling technologies in the process cooling sector, chiller (air-to-water) < 400 kW accounts for the greatest part of the European process cooling sector with almost 0.5 million installed devices.

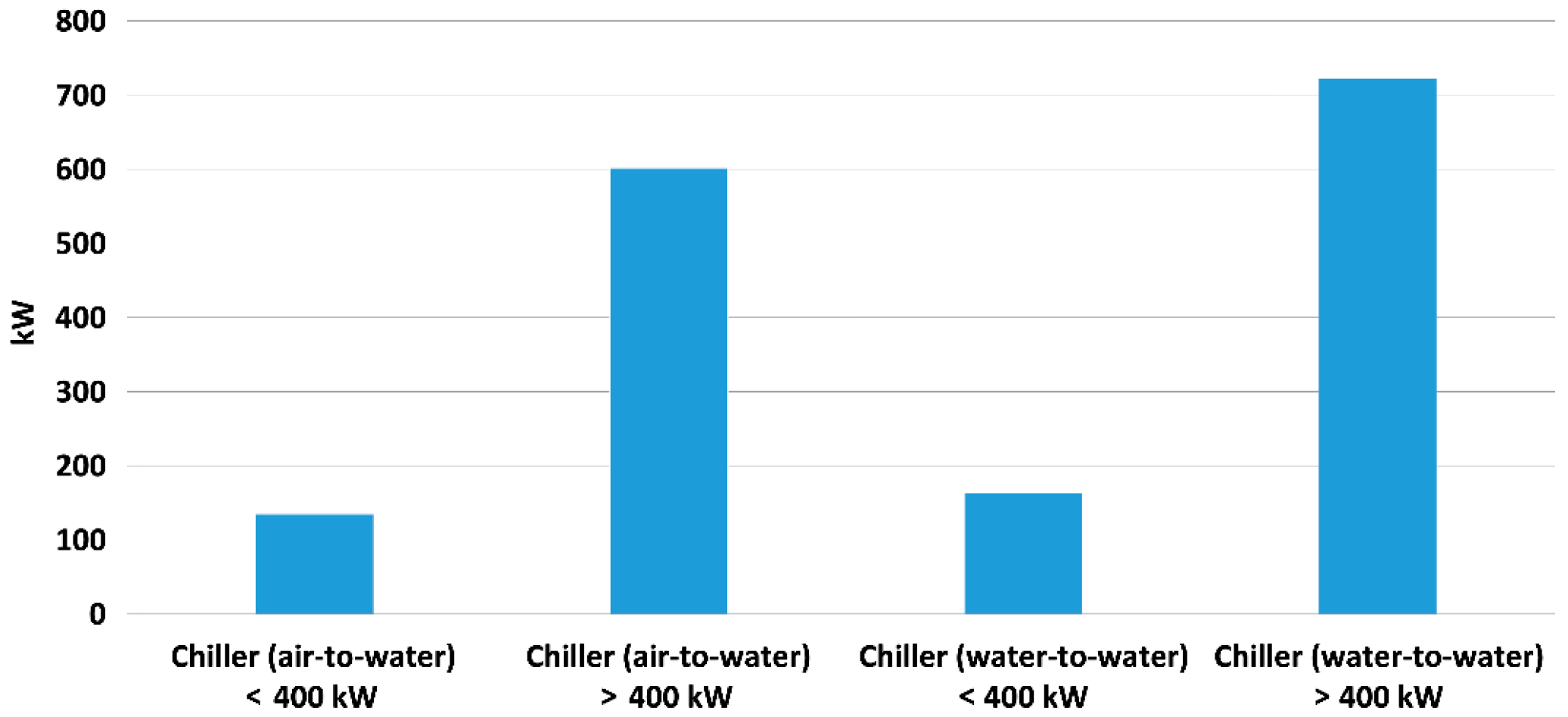

- Moreover, chiller (water-to-water) > 400 kW results in having the most considerable installed mean value with more than 700 kW.

- In addition, the most efficient process cooling technology type in this study emerges to be chiller (water-to-water) > 400 kW with a seasonal energy performance factor value of 7.5.

- Lastly, the EFLH of the industrial sector are all over 7000 for each European member state, particularly with peaks reached by Cyprus and Malta.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Acronym | Name |

|---|---|

| AC | Air conditioning |

| ASHRAE | American Society of heating, refrigerating and air-conditioning engineers |

| CACs | Centralized air-conditioners |

| CDD | Cooling degree day |

| DC | District cooling |

| DHW | Domestic hot water |

| EEA | European Environment Agency |

| EED | Energy Efficiency Directive |

| EER | Energy efficiency ratio |

| EFLHs | Equivalent full load hours |

| Eq | Equation |

| ETS | Emission trading system |

| EU | European Union |

| FEC | Final energy consumption |

| GHG | Greenhouse gas |

| H&C | Heating and cooling |

| H2020 | Horizon 2020 |

| HDD | Heating degree day |

| IDS | Integrated surface database |

| NUTS | Nomenclature of territorial units for statistics |

| PC | Process cooling |

| R&D | Research and development |

| RACs | Room air-conditioners |

| RED | Renewable energy directive |

| RES | Renewable energy sources |

| SC | Space cooling |

| SEPR | Seasonal energy performance ratio |

| TDHP | Thermally driven heat pump |

| UED | Useful energy demand |

| VC | Vapour compression |

| VRF | Variable refrigerant flow |

| Wh | Watt-hour |

| Sector | Subsector | Process | Technology |

|---|---|---|---|

| INDUSTRY | Food & Beverages data | Freeze | Mechanical vapour compression freezing [79] |

| Cryogenic freezing [79] | |||

| Cold Storage | Mechanical vapour compression refrigeration [80] | ||

| Cooling of products | Absorption (TDHP) [81] | ||

| Condensation | Cryogenic freezing process [82] | ||

| Refrigeration | Rapid evaporative cooling (Vacuum systems) [83] | ||

| Wineries | Ambient air cooling | Chiller (water-to-water) [14] | |

| Humidification | Evaporative cooling [84] | ||

| Ambient air cooling | Absorption (TDHP) [85] | ||

| Small split (>5 kW) and Big split (<5 kW) [64] | |||

| Tobacco | Ambient air control | Packaged [65] | |

| Cooling hydrocarbon rundown | Cooling tower [86] | ||

| Shall and plate heat exchanger [86] | |||

| Plastic moulding | System or infrastructure cooling | Chiller (air-to-water) [87] | |

| Evaporative cooling [88] | |||

| Plastic machine cooling–Hydraulic cooling | Chiller (water-to-water) [83,84] | ||

| Chiller (water-to-water) [83,84] | |||

| Plastic mould or tool cooling | Chiller (air-to-water) [83,84] | ||

| Chiller (water-to-water) [83,84] | |||

| Plastic product cooling | Chiller (air-to-water) [83,84] | ||

| Chiller (water-to-water) [83,84] | |||

| Iron & Steel | Water cooling | Cooling tower [89] | |

| Waste gas energy recovery | Waste gas cooling plant Hisarna process [90] | ||

| Cooling plants for converter waste gases oxygen steel plants [90] | |||

| Sinter cooler for energy recovery sintering plants [90] | |||

| Waste heat boilers in coke dry quenching plants [90] | |||

| Cooling stack for Hismelt plants [90] | |||

| Automotive | Temperature control of laser machines | Chiller (air-to-water) [91] | |

| Chiller (water-to-water) [91] | |||

| Thermostatic control of painting baths | Chiller (air-to-water) [91] | ||

| Chiller (water-to-water) [91] | |||

| Cement | Compressors cooling | Chiller (air-to-water) [92] | |

| Heat neutralization | Chiller (air-to-water) [92] | ||

| Cooling of excess gases | Cooling tower [93] | ||

| Glass | Blowing | Blowers (ventilation) [94] | |

| Paper, pulp, and printing | Cooling of printing machinery | Mechanical ventilation [95] | |

| Evaporative cooling [95] | |||

| Packaged [96] | |||

| Pharmaceutical | Preservation of thermolabile materials | Evaporative cooling [97] | |

| Absorption (TDHP) [63,94] | |||

| TERTIARY | Telecommunications | Shelter cooling | Natural convection [98,99] |

| Vortex tube [99] | |||

| Small split (<5 kW) and Big split [67] | |||

| Internal racks cooling | Mechanical ventilation [99] | ||

| Warehouses | Ambient air cooling | Evaporative cooling [76] | |

| Mechanical ventilation [100] | |||

| Adiabatic cooling | Adiabatic cooling [100] | ||

| Ambient air cooling | Variable refrigerant flow systems [81] | ||

| Rooftop [69] | |||

| Supermarket freezers and cells | Refrigeration and freezing | Small split (<5 kW) and Big split [70] | |

| Data centres | Electronic equipment cooling | Indirect evaporative cooling [71] | |

| Natural conduction (heat exchanger) [71] | |||

| Natural convection [71] | |||

| Immersion cooling [71] | |||

| Packaged computer room air conditioners (CRAC) [34] | |||

| TRANSPORTATION | Marine | Cooling of batteries | Absorption (TDHP) [100] |

| Engine cooling | Natural conduction (heat exchanger) [100] | ||

| Natural conduction–Raw water cooling system [100] | |||

| AGRICULTURE | Greenhouses | Humidification | Evaporative cooling & fans [73] |

| Ambient air cooling | Natural ventilation [74] | ||

| Cooling of indoor greenhouse temperature | Absorption (TDHP) [75] | ||

| Ambient air cooling | Mechanical ventilation [76] |

References

- European Commission. L 328. Off. J. Eur. Union 2018, 61, 1–230. [Google Scholar]

- Energy Efficiency Targets. Available online: https://ec.europa.eu/energy/topics/energy-efficiency/targets-directive-and-rules/eu-targets-energy-efficiency_en (accessed on 1 January 2023).

- 2020 Climate & Energy Package. Available online: https://ec.europa.eu/clima/policies/strategies/2020_en (accessed on 1 January 2023).

- European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council on the Promotion of the Use of Energy from Renewable Sources. Off. J. Eur. Union 2018, 2018, 82–209. [Google Scholar]

- Pezzutto, S.; Toleikyte, A.; De Felice, M. Assessment of the Space Heating and Cooling Market in the EU28: A Comparison between EU15 and EU13 Member States. Int. J. Contemp. Energy 2015, 1, 39–52. [Google Scholar] [CrossRef]

- Pezzutto, S.; Fazeli, R.; De Felice, M.; Sparber, W. Future Development of the Air-Conditioning Market in Europe: An Outlook until 2020. Wiley Interdiscip. Rev. Energy Environ. 2016, 5, 649–669. [Google Scholar] [CrossRef]

- Primary Energy Consumption. Available online: https://ec.europa.eu/eurostat/databrowser/view/t2020_33/default/table?lang=en (accessed on 1 January 2023).

- A European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 12 October 2020).

- International Energy Agency (IEA). Data Service. Available online: http://wds.iea.org/WDS/Common/Login/login.aspx (accessed on 19 November 2020).

- Vinnova. H2020 Visualization. Available online: https://h2020viz.vinnova.se/#/ (accessed on 19 November 2020).

- European Commission. Energy Research and Innovation. Available online: https://ec.europa.eu/info/research-and-innovation/research-area/energy-research-and-innovation_en (accessed on 19 November 2020).

- Rehfeldt, M.; Fleiter, T.; Toro, F. A bottom-up estimation of the heating and cooling demand in European industry. Energy Effic. 2018, 11, 1057–1082. [Google Scholar] [CrossRef]

- Pezzutto, S. Analysis of the Space Heating and Cooling Market in Europe. Int. J. Contemp. Energy 2014, 2, 6652. [Google Scholar]

- Pezzutto, A.S.; Sparber, W.; Fedrizzi, R. Analysis of the Space Heating and Cooling Market in Europe. Int. J. Contemp. Energy 2020, 2012, 6652. [Google Scholar]

- Energy Savings Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php/Energy_saving_statistics#Final_energy_consumption_and_distance_to_2020_and_2030_targets (accessed on 13 October 2020).

- Fleiter, T.; Steinbach, J.; Ragwitz, M.; Arens, M.; Aydemir, A.; Elsland, R.; Frassine, C.; Herbst, A.; Hirzel, S. Mapping and Analyses of the Current and Future (2020–2030) Heating/Cooling Fuel Deployment (Fossil/Renewables); European Commision: Brussels, Belgium, 2016. [CrossRef]

- Braungardt, D.S.; Bürger, D.V.; Zieger, J.; Kenkmann, T. Contribution of Renewable Cooling to the Renewable Energy Target of the EU; Ministry of Foreign Affairs: Berlin, Germany, 2018; pp. 16–24.

- Mantzos, L.; Matei, N.A.; Mulholland, E.; Rózsai, M.; Tamba, M.; Wiesenthal, T. JRC-IDEES 2015. Available online: https://data.jrc.ec.europa.eu/dataset/jrc-10110-10001 (accessed on 19 November 2020).

- Pezzutto, S.; De Felice, M.; Fazeli, R.; Kranzl, L.; Zambotti, S. Status Quo of the Air-Conditioning Market in Europe: Assessment of the Building Stock. Energies 2017, 10, 1253. [Google Scholar] [CrossRef]

- Pezzutto, S. Analysis of the Space Heating and Cooling Market in Europe; Universität f. Bodenkultur Wien: Vienna, Austria, 2014. [Google Scholar]

- Pezzutto, S.; Zambotti, S.; Croce, S.; Zambelli, P.; Scaramuzzino, C.; Pascuas, R.P.; Zubaryeva, A.; Eurac, D.E.; Müller, A.; Tuw, M.H.; et al. HOTMAPS D2.3 WP2 Report—Open Data Set for the EU28; European Commision: Brussels, Belgium, 2019.

- Energy Efficiency and Certification of Central Air Conditioners. Available online: https://www.researchgate.net/publication/274048785_Energy_Efficiency_and_Certification_of_Central_Air_Conditioners (accessed on 15 February 2023).

- Euroheat & Power. District Heating and Cooling—Country by Country—2015 Survey. Available online: http://www.euroheat.org/wp-content/uploads/2016/03/2015-Country-by-country-Statistics-Overview.pdf (accessed on 23 November 2020).

- Martins, J.P.; Trigo, I.; Freitas, S.C.E. Copernicus Global Land Operations “Vegetation and Energy” “CGLOPS-1”; Copernicus Global Land Operations: Brussels, Belgium, 2020; pp. 1–93. [Google Scholar]

- Zambelli, P. Climate Context—Heating Degree Days and Cooling Degree Days. Available online: https://gitlab.com/hotmaps/climate/climate_heating_cooling_degreeday (accessed on 23 November 2020).

- International Geothermal Association. Our Databases. Available online: https://www.geothermal-energy.org/explore/our-databases/ (accessed on 23 November 2020).

- European Heat Pump Association. The Online Stats Tool. Available online: http://www.stats.ehpa.org/hp_sales/country_cards/ (accessed on 23 November 2020).

- EUROVENT. Market Intelligence. Available online: https://www.eurovent-marketintelligence.eu/ (accessed on 15 October 2020).

- HRE4 Project. Horizon 2020 Heat Roadmap Europe 4—HRE4—Project. Available online: https://heatroadmap.eu/ (accessed on 25 November 2020).

- European Union’s Horizon 2020. HotMaps—The Open Source Mapping and Planning Tool for Heating and Cooling. Available online: https://www.hotmaps-project.eu/ (accessed on 21 November 2020).

- Evans, T. The Different Technologies for Cooling Data Centers. Schneider Electr. White Pap. 2012, 59, 1–16. [Google Scholar]

- Kapoor, K.; Powell, K.M.; Cole, W.J.; Kim, J.S.; Edgar, T.F. Improved Large-Scale Process Cooling Operation through Energy Optimization. Processes 2013, 1, 312–329. [Google Scholar]

- Popov, D.; Fikiin, K.; Stankov, B.; Alvarez, G.; Youbi-Idrissi, M.; Damas, A.; Evans, J.; Brown, T. Cryogenic Heat Exchangers for Process Cooling and Renewable Energy Storage: A Review. Appl. Therm. Eng. 2019, 153, 275–290. [Google Scholar] [CrossRef]

- Ebrahimi, M. The Environ-Thermo-Economical Potentials of Operating Gas Turbines in Industry for Combined Cooling, Heating, Power and Process (CCHPP). J. Clean. Prod. 2017, 142, 4258–4269. [Google Scholar] [CrossRef]

- Ko, J.S.; Huh, J.H.; Kim, J.C. Improvement of Energy Efficiency and Control Performance of Cooling System Fan Applied to Industry 4.0 Data Center. Electronics 2019, 8, 582. [Google Scholar] [CrossRef]

- Best, R.B.; Aceves, J.M.H.; Islas, J.M.S.; Manzini, F.L.P.; Pilatowsky, I.F.; Scoccia, R.; Motta, M. Solar Cooling in the Food Industry in Mexico: A Case Study. Appl. Therm. Eng. 2013, 50, 1447–1452. [Google Scholar] [CrossRef]

- Meijer, G.I. Cooling Energy-Hungry Data Centers. Science 2010, 328, 318–320. [Google Scholar] [CrossRef] [PubMed]

- States, E.U.M. Competitiveness of Renewable Heating and Cooling Industry and Services Annex B to Part 1 of the Study on the Competitiveness of the Renewable Energy Sector Overview of the 2030 Targets and Policies of the EU Member States in the Context of Heating and Coo; European Commision: Brussels, Belgium, 2019; pp. 1–39.

- Surna Cultivation Technologies. Comfort Cooling vs Process Cooling: What you Need to Know. Available online: https://surna.com/comfort-cooling-vs-process-cooling-what-you-need-to-know/ (accessed on 23 November 2020).

- Howard, D.A.; Jørgensen, B.N.; Ma, Z. Multi-Method Simulation and Multi-Objective Optimization for Energy-Flexibility-Potential Assessment of Food-Production Process Cooling. Energies 2023, 16, 1514. [Google Scholar] [CrossRef]

- UN Environment Programme. Cooling Industry Supports Fight against COVID-19, Steps Up Climate Action. Available online: https://www.unenvironment.org/news-and-stories/story/cooling-industry-supports-fight-against-covid-19-steps-climate-action (accessed on 23 November 2020).

- Nouvel, R.; Zirak, M.; Coors, V.; Eicker, U. The Influence of Data Quality on Urban Heating Demand Modeling Using 3D City Models. Comput. Environ. Urban Syst. 2017, 64, 68–80. [Google Scholar] [CrossRef]

- Dittmann, F.; Rivière, P.; Stabat, P. Space Cooling Technology in Europe; European Commision: Brussels, Belgium, 2017.

- European Union. Commission Regulation (EU) 2015/1095 of 5 May 2015 Implementing Directive 2009/125/EC of the European Parliament and of the Council with Regard to Ecodesign Requirements for Professional Refrigerated Storage Cabinets, Blast Cabinets, Condensing Units and Process Chillers. Available online: http://data.europa.eu/eli/reg/2015/1095/oj/eng (accessed on 18 December 2020).

- European Union. Commission Regulation (EU) 2016/2281 of 30 November 2016 Implementing Directive 2009/125/EC of the European Parliament and of the Council Establishing a Framework for the Setting of Ecodesign Requirements for Energy-Related Products, with Regard to Ecodes. Available online: http://data.europa.eu/eli/reg/2016/2281/oj/eng (accessed on 18 December 2020).

- CEN—EN 14825; Air Conditioners, Liquid Chilling Packages and Heat Pumps, with Electrically Driven Compressors, for Space Heating and Cooling—Testing and Rating at Part Load Conditions and Calculation of Seasonal Performance. European Commision: Brussels, Belgium, 2018.

- Copernicus. Copernicus Global Land Services. Available online: https://land.copernicus.eu/global/products/lst (accessed on 26 November 2020).

- SciPg.org. scipy.cluster.vq.kmeans. Available online: https://docs.scipy.org/doc/scipy-0.14.0/reference/generated/scipy.cluster.vq.kmeans2.html (accessed on 26 November 2020).

- SciPg.org. scipy.signal.savgol_filte. Available online: https://docs.scipy.org/doc/scipy-0.16.1/reference/generated/scipy.signal.savgol_filter.html (accessed on 26 November 2020).

- Eurostat. Regional Gross Domestic Product (PPS per Inhabitant) by NUTS 2 Regions. Available online: https://ec.europa.eu/eurostat/web/products-datasets/-/tgs00005 (accessed on 26 November 2020).

- EUSTACE. E-OBS Gridded Dataset. Available online: https://www.ecad.eu/download/ensembles/download.php (accessed on 25 November 2020).

- Bansal, P.; Vineyard, E.; Abdelaziz, O. Status of Not-in-Kind Refrigeration Technologies for Household Space Conditioning, Water Heating and Food Refrigeration. Int. J. Sustain. Built Environ. 2012, 1, 85–101. [Google Scholar] [CrossRef]

- Schulz, M.; Kourkoulas, D. Regulation (EU) No 517/2014 of the European Parliament and of the Council of 16 April 2014 on Fluorinated Greenhouse Gases and Repealing Regulation (EC) No 842/2006. Off. J. Eur. Union 2014, 2014, L150/195-230. [Google Scholar]

- Commission, E. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions on an EU Strategy for Heating and Cooling. J. Chem. Inf. Model. 2016, 2016, 101. [Google Scholar] [CrossRef]

- Kühnbach, M. Load Profile Tertiary Cooling Yearlong 2010. Available online: https://gitlab.com/hotmaps/load_profile/load_profile_tertiary_cooling_yearlong_2010 (accessed on 26 November 2020).

- Hechavarría, R.; López, G. Review of Available Information—EU Strategy for Heating and Cooling—Part 2. J. Chem. Inf. Model. 2016, 53, 1689–1699. [Google Scholar]

- BSRIA. European Market for Air Conditioning Chillers—Spain, Report 50572/5A; BSRIA: Bracknell, UK, 2019. [Google Scholar]

- Arora, C.P. Refrigeration and Air Conditioning; McGraw-HIll International Editions: Mechanical Technology Series; Tata McGraw-Hill: New York, NY, USA, 2000. [Google Scholar]

- Daikin. Process Cooling Systems. Available online: https://www.daikin.eu/en_us/solutions/industrial-process-cooling.html (accessed on 27 November 2020).

- Mitsubishi Electric Hydronics & IT Cooling Systems S.p.A. Products. Available online: https://www.melcohit.com/en/products (accessed on 25 November 2020).

- Montec. Bacco—The Wine Cellar Cooling Unit. Available online: http://www.mon-tec.it/en/bacco-the-wine-cellar-cooling-unit/ (accessed on 25 November 2020).

- Lingdo Industrial Limited. R407 Air Cooled Scroll Chiller, Air Cooled Packaged Chiller Unit for Tobacco Factory. Available online: http://industriallingdo.sell.everychina.com/p-107233510-r407-air-cooled-scroll-chiller-air-cooled-packaged-chiller-unit-for-tobacco.html (accessed on 25 November 2020).

- ScienceDirect. Absorption Cooling. Available online: https://www.sciencedirect.com/topics/engineering/absorption-cooling (accessed on 25 November 2020).

- Mitsubishi Electric. IT Cooling. Available online: https://www.melcohit.com/EN/Products/3/ITCooling/ (accessed on 25 November 2020).

- Melograno, P.N.; Pezzutto, S. IEA ANNEX 34 Italian Country Report; EURAC Research: Bolzano, Italy, 2010. [Google Scholar]

- Daikin. Rooftop. Available online: https://www.daikin.eu/en_us/solutions/rooftop.html (accessed on 25 November 2020).

- Karampour, M.; Sawalha, S.; Arias, J. Eco-Friendly Supermarkets—An Overview; European Union: Brussels, Belgium, 2016. [Google Scholar] [CrossRef]

- Research, G. Europe Data Center Cooling Market. Available online: https://www.graphicalresearch.com/industry-insights/1127/europe-data-center-cooling-market (accessed on 25 November 2020).

- Castellazzi, L.; Maria, A.; Bertoldi, P. Trends in Data Centre Energy Consumption under the European Code of Conduct for Data Centre Energy Efficiency. Energies 2017, 10, 1470. [Google Scholar] [CrossRef]

- Euro Cooling Systems. Greenhouse Humidification. Available online: https://www.eurocooling.it/en/index.html (accessed on 25 November 2020).

- Benni, S.; Tassinari, P.; Bonora, F.; Barbaresi, A.; Torreggiani, D. Efficacy of Greenhouse Natural Ventilation: Environmental Monitoring and CFD Simulations of a Study Case. Energy Build. 2016, 125, 276–286. [Google Scholar] [CrossRef]

- Vox, G.; Blanco, I.; Scarascia Mugnozza, G.; Schettini, E.; Bibbiani, C.; Viola, C.; Campiotti, C.A. Solar Absorption Cooling System for Greenhouse Climate Control: Technical Evaluation. Acta Hortic. 2014, 1037, 533–538. [Google Scholar]

- EcoCooling. Warehouse Cooling. Available online: https://www.ecocooling.co.uk/applications/warehouses/ (accessed on 25 November 2020).

- De Negri, J.F.; Pezzutto, S.; Gantioler, S.; Moser, D.; Sparber, W. A Comprehensive Analysis of Public and Private Funding for Photovoltaics Research and Development in the European Union, Norway, and Turkey. Energies 2020, 13, 2743. [Google Scholar] [CrossRef]

- Mallett, C.P. Frozen Food Technology/by CP Mallett; Springer: Berlin/Heidelberg, Germany, 1993. [Google Scholar]

- Brown, D.; Stout, T.B.; Dirks, J.; Fernandez, N. The Prospects of Alternatives to Vapor Compression Technology for Space Cooling and Food Refrigeration Applications. Energy Eng. 2012, 109, 7–20. [Google Scholar] [CrossRef]

- Carrier Corporation. Integrating VRF Systems for Improved Efficiency and Comfort; Carrier Corporation: Palm Beach Gardens, FL, USA, 2014; Volume 2. [Google Scholar]

- Stipp, G.K. Direct Condensation of Food Volatiles onto a Food Substrate at Cryogenic Temperatures. U.S. Patent 4335149A, 15 June 1982. [Google Scholar]

- McDonald, K.; Sun, D.-W. Vacuum Cooling Technology for the Food Processing Industry: A Review. J. Food Eng. 2000, 45, 55–65. [Google Scholar] [CrossRef]

- MGF. Humidification in Cellars and Barrel Room: The Right Humidity for Wine. Available online: https://www.nebulizzare.com/en/fields/misting-agriculture/395-humidification-cellars-barrel-room-humidity-wine (accessed on 25 November 2020).

- Cardemil, J. Combined Generation of Heat and Cooling for a Winemaking Process Using a Solar-Assisted Absorption Chiller. Available online: http://proceedings.ises.org/?doi=swc.2015.10.43 (accessed on 25 November 2020).

- Aggreko. Cooling to Meet Increased Market Demand during Warmer Summer Weather. Available online: https://www.aggreko.com/en-gb/case-studies/petrochemical-and-refining/cooling-tower-to-meet-increased-market-demand-during-warmer-summer-weather (accessed on 25 November 2020).

- MTA. Process Cooling Solutions for Plastics—MTA. Available online: https://www.mta-it.com/eng/applications/process-cooling-solutions/plastics.php (accessed on 25 November 2020).

- British Plastic Federation. Process Cooling. Available online: https://www.bpf.co.uk/plastipedia/processes/Process_Cooling.aspx (accessed on 25 November 2020).

- Boldrocchi, T.E. Cooling Towers in Steel Plant: How They Work? Available online: https://www.btetorri.com/cooling-tower-in-steel-plant.php (accessed on 25 November 2020).

- Oschatz Christof Industries. Cooling Systems for Steel Plants. Available online: https://www.oschatz.com/en/sector/mining-metals/steel-works/ (accessed on 25 November 2020).

- MTA. Process Cooling Solutions for Automotive. Available online: https://www.mta-it.com/eng/applications/process-cooling-solutions/automotive-1.php (accessed on 25 November 2020).

- Daikin. Holcim Cement Plant. Available online: https://www.daikin.eu/en_us/about/case-studies/holcim.html (accessed on 25 November 2020).

- Boldyryev, S.; Mikulčić, H.; Krajačić, G.; Duić, N. Waste Heat Utilisation of Croatian Cement Industry Accounting Total Site Demands. In Proceedings of the 26th European Symposium on Computer Aided Process Engineering, Portoroz, Slovenia, 12–15 June 2016; Kravanja, Z., Bogataj, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 38, pp. 2223–2228. [Google Scholar] [CrossRef]

- Stiavelli. Glass Industry Applications—Catalogue. Available online: https://www.stiavelli.com/prds/industrial-fans-manufacturers-and-blowers-for-glass-industry-and-tempering/ (accessed on 25 November 2020).

- ScienceDirect. Chiller. Available online: https://www.sciencedirect.com/topics/engineering/chiller (accessed on 25 November 2020).

- United Nations Environment Programme. Environmental Management in the Pulp and Paper Industry; UNEP: Nairobi, Kenya, 1996. [Google Scholar]

- Carel. Evaporative Cooling; Carel: Padova, Italy, 2020. [Google Scholar]

- EcoCooling. Pharmaceutical Cooling. Available online: https://www.ecocooling.co.uk/applications/pharmaceutical/ (accessed on 25 November 2020).

- EBMPapst. Telecommunication Base Station Cooling; EBMPapst: Mulfingen, Germany, 2016. [Google Scholar]

- Broughton Electro Air Products Ltd. Warehouse Fans & Ventilation. Available online: https://www.broughtoneap.co.uk/products/fans-ventilation/ (accessed on 25 November 2020).

- BV, O.F.A. Adiabatic Cooling. Industrial Climate Control. Available online: https://www.oxy-com.com/en/solutions/intrcooll/?gclid=EAIaIQobChMI3pmYyuH56AIVArd3Ch1vbAxKEAMYASAAEgL96fD_BwE (accessed on 25 November 2020).

- Cool4Sea. Marine Air-Conditioning Technology Powered by Waste Heat. Available online: https://www.cool4sea.com/ (accessed on 25 November 2020).

- CP Performance. Marine Closed “Freshwater” Cooling Systems. Available online: https://www.cpperformance.com/t-marine-closed-cooling-systems.aspx (accessed on 25 November 2020).

- Boatbuy. Marine Cooling Systems—What You Need to Know About Your Boat. Available online: https://boatbuy.com.au/marine-cooling-systems/ (accessed on 2 January 2023).

| Technology | Final Energy Consumption [TWh/y] |

|---|---|

| Chiller (air-to-water) < 400 kW | 41.47 |

| Chiller (air-to-water) > 400 kW | 40.97 |

| Chiller (water-to-water) < 400 kW | 8.79 |

| Chiller (water-to-water) > 400 kW | 19.75 |

| TWh/y per EU27+UK MS–PC–Industrial Sector | Percentage | |

|---|---|---|

| Austria | 2.56 | 2.31% |

| Belgium | 3.06 | 2.76% |

| Bulgaria | 0.64 | 0.57% |

| Croatia | 0.35 | 0.32% |

| Cyprus | 1.88 | 1.70% |

| Czech Republic | 1.11 | 1.00% |

| Denmark | 0.53 | 0.48% |

| Estonia | 0.08 | 0.07% |

| Finland | 1.35 | 1.22% |

| France | 17.62 | 15.88% |

| Germany | 11.43 | 10.30% |

| Greece | 2.87 | 2.58% |

| Hungary | 1.38 | 1.24% |

| Ireland | 0.15 | 0.13% |

| Italy | 27.13 | 24.44% |

| Latvia | 0.17 | 0.15% |

| Lithuania | 0.47 | 0.42% |

| Luxembourg | 0.05 | 0.04% |

| Malta | 0.65 | 0.59% |

| Netherlands | 4.24 | 3.82% |

| Poland | 3.06 | 2.76% |

| Portugal | 1.34 | 1.21% |

| Romania | 1.01 | 0.91% |

| Slovakia | 0.70 | 0.63% |

| Slovenia | 0.13 | 0.12% |

| Spain | 15.63 | 14.09% |

| Sweden | 1.90 | 1.71% |

| United Kingdom | 9.49 | 8.55% |

| EU27+UK | 110.98 | 100% |

| Sector | Subsector | Process | Technology |

|---|---|---|---|

| INDUSTRY | Wineries | Ambient air cooling | Small split (<5 kW) and Big split (>5 kW) [64] |

| Tobacco | Ambient air control | Packaged [65] | |

| Paper, pulp, and printing | Cooling of printing machinery | Packaged [66] | |

| TERTIARY | Telecommunications | Shelter cooling | Small split (<5 kW) and Big split (>5 kW) [67] |

| Warehouses | Ambient air cooling | Variable refrigerant flow systems [68] | |

| Rooftop [69] | |||

| Supermarket freezers and cells | Refrigeration and freezing | Small split (<5 kW) and Big split [70] | |

| Data centres | Electronic equipment cooling | Packaged computer room air conditioners (CRAC) [31,68] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pezzutto, S.; Quaglini, G.; Riviere, P.; Kranzl, L.; Novelli, A.; Zambito, A.; Bottecchia, L.; Wilczynski, E. Process Cooling Market in Europe: Assessment of the Final Energy Consumption for the Year 2016. Sustainability 2023, 15, 3698. https://doi.org/10.3390/su15043698

Pezzutto S, Quaglini G, Riviere P, Kranzl L, Novelli A, Zambito A, Bottecchia L, Wilczynski E. Process Cooling Market in Europe: Assessment of the Final Energy Consumption for the Year 2016. Sustainability. 2023; 15(4):3698. https://doi.org/10.3390/su15043698

Chicago/Turabian StylePezzutto, Simon, Giulio Quaglini, Philippe Riviere, Lukas Kranzl, Antonio Novelli, Andrea Zambito, Luigi Bottecchia, and Eric Wilczynski. 2023. "Process Cooling Market in Europe: Assessment of the Final Energy Consumption for the Year 2016" Sustainability 15, no. 4: 3698. https://doi.org/10.3390/su15043698

APA StylePezzutto, S., Quaglini, G., Riviere, P., Kranzl, L., Novelli, A., Zambito, A., Bottecchia, L., & Wilczynski, E. (2023). Process Cooling Market in Europe: Assessment of the Final Energy Consumption for the Year 2016. Sustainability, 15(4), 3698. https://doi.org/10.3390/su15043698