Performance Assessment of an Ice-Production Hybrid Solar CPV/T System Combining Both Adsorption and Vapor-Compression Refrigeration Systems

Abstract

1. Introduction

2. Methodology

2.1. The CPV/T Model

Numerical Simulation of the CPV/T Assembly

- Based on monthly average irradiance data taken from the European Commission PVGIS [35], the direct incoming solar radiation on the Fresnel lens was calculated to be uniform.

- Germanium material was depicted as a single layer, 0.1 mm thick, that makes up the CPV cell.

- The heat sink’s entrance flow was a fully developed turbulent flow with a velocity of 0.5 m/s. At the exit, atmospheric pressure was considered.

- Apart from the CPV assembly sections, the heat sink was assumed to be thermally insulated.

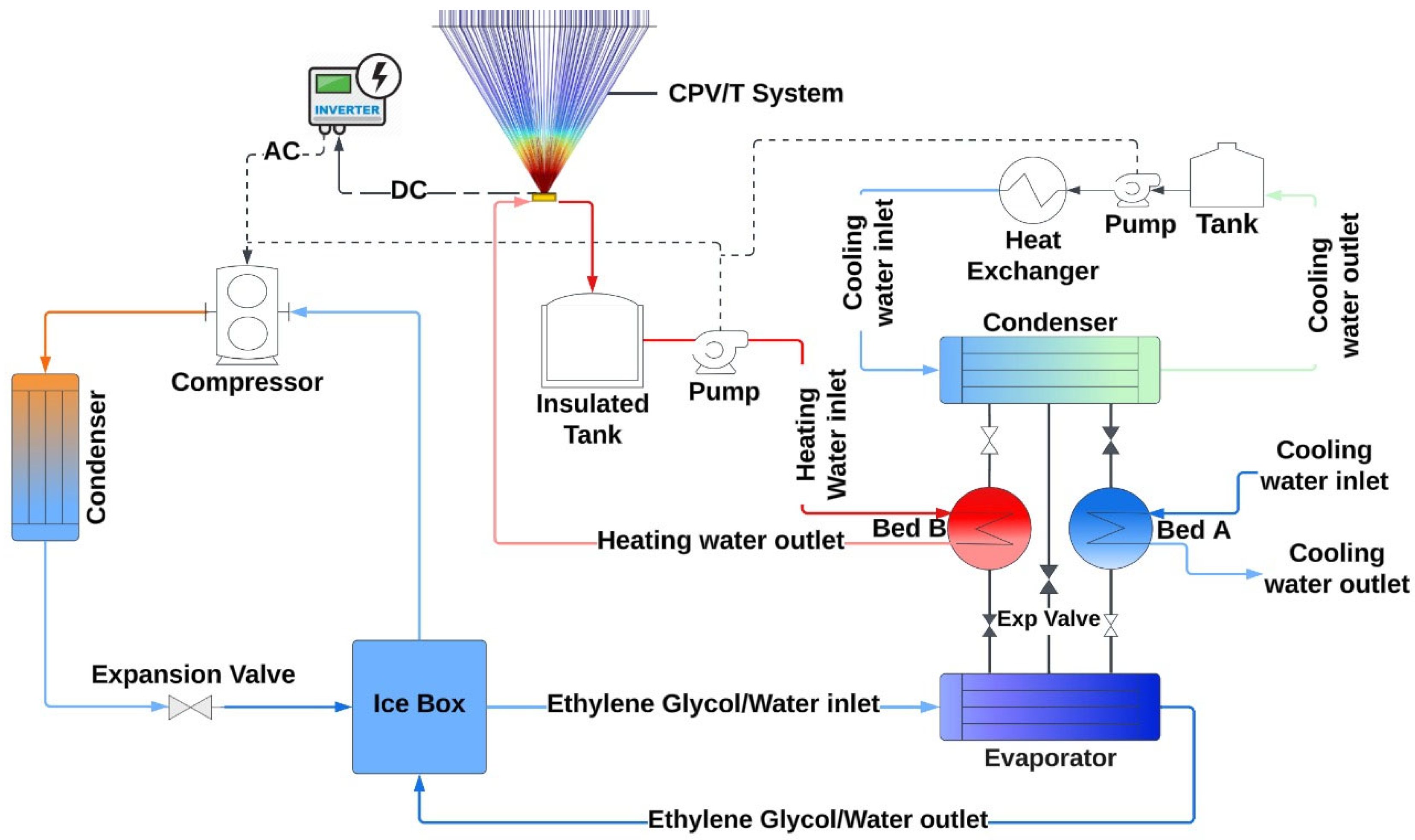

2.2. Integration of Refrigeration Subsystems

2.2.1. Adsorption Refrigeration System

- Bed model

- b.

- Evaporator model

- c.

- Condenser model

- d.

- Adsorption isotherms and kinetics

- e.

- Adsorption-system coupling and performance indicators

2.2.2. Vapor Compression System

3. Results and Discussions

3.1. Validation of the CPV/T Simulation Model

3.2. Thermal and Electrical Outputs of the CPV/T System

3.3. Daily Ice Production of the Integrated System

3.4. Energy Balance Sheet

- Optical solar losses from the Fresnel lens.

- Inverter losses.

- Thermal losses from CPV assembly surfaces.

- VCS electrical losses.

- ARS losses.

4. Conclusions

- The integrated system managed to achieve a maximum DIP of about 573 , on average, in October, while the minimum DIP was in May of 416.7 , affected by the low DNI along with higher ambient temperature in May compared to April.

- The VCS contributed to about 84.5% of the total ice production over the year, utilized from its higher COP compared to the ARS.

- The average solar COP of 0.875 was attained using the proposed hybrid ice-production system.

- The solar ice maker suggested in this study can replace intermittent solar cooling systems, which produce chilled water, by providing cooling both during the day and at night using the cooling power stored in the ice.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Area | |

| Pre-exponential factor | |

| Specific heat | |

| CR | Concentration ratio |

| Activation energy of surface diffusion | |

| Focal length (mm) | |

| Convective heat transfer coefficient | |

| 3D ray vector | |

| Thermal conductivity of the material | |

| Overall intra-particle mass transfer coefficient ( | |

| Latent heat | |

| Mass () | |

| Mass flow rate | |

| Refractive index (-) | |

| Saturation pressure | |

| Pressure (Pa) | |

| Convective heat ( | |

| Heat extracted by the heat sink ( | |

| Radiation heat ( | |

| Adsorption heat | |

| Conduction heat transfer ( | |

| Input energy converted to heat | |

| Solar radiations | |

| Distance between incident light and the optical axis | |

| Universal gas constant | |

| Temperature (°C) | |

| Time (s) | |

| Heat transfer conductance | |

| Uptake | |

| Equilibrium adsorption uptake | |

| Maximum adsorption uptake | |

| Greek Symbols: | |

| Emissivity of the material (-) | |

| The evaporator effectiveness (-) | |

| The condenser effectiveness (-) | |

| Cell-efficiency coefficient ( | |

| Cell efficiency (%) | |

| Optical efficiency (%) | |

| Reference cell efficiency at 25 °C | |

| Prism angle | |

| An operator used for the programming of Equations (15) and (16) (-) | |

| Effectiveness (-) | |

| The angle between the refractive ray and the perpendicular direction to the prism Surface | |

| Stefan–Boltzmann constant | |

| ω | Angular frequency |

| Subscripts and superscripts: | |

| ads | Adsorption refrigeration |

| amp | Ambient temperature |

| b1 | First bed |

| b2 | Second bed |

| bed | Adsorption bed |

| ca | Cooling water to adsorber |

| cond | Condenser |

| cw | Cooling water |

| Eth,Gly | Ethylene Glycol |

| eva | Evaporator |

| foam | Al foam on bed tubes |

| h | Hot water |

| hw | Heating water |

| i | Inlet |

| met | Metal |

| out | Outlet |

| rl | Refrigerant liquid |

| rv | Refrigerant vapor |

| s | Sorption material |

| s,in | Heat-sink fluid inlet |

| s,out | Heat-sink fluid outlet |

| surf | Surface temperature |

| surr | Surrounding |

| vc | Vapor compression refrigeration |

| w | Water |

| Abbreviations: | |

| v | Adsorption refrigeration system |

| COP | Coefficient of performance |

| CPV | Concentrated photovoltaic |

| CPV/T | Concentrated photovoltaic thermal |

| DIP | Daily ice production |

| DNI | Direct normal irradiance |

| GCR | Geometrical concentration ratio |

| MJSC | Multi-junction solar cells |

| PFFL | Point-focus Fresnel lens |

| PMMA | Polymethyl methacrylate |

| SCP | Specific cooling power |

| VCS | Vapor compression refrigeration system |

References

- Almasoud, A.H.; Gandayh, H.M. Future of solar energy in Saudi Arabia. J. King Saud Univ. Eng. Sci. 2015, 27, 153–157. [Google Scholar] [CrossRef]

- Alawaji, S.H. Evaluation of solar energy research and its applications in Saudi Arabia—20 years of experience. Renew. Sustain. Energy Rev. 2001, 5, 59–77. [Google Scholar] [CrossRef]

- Asif, M. Growth and sustainability trends in the buildings sector in the GCC region with particular reference to the KSA and UAE. Renew. Sustain. Energy Rev. 2016, 55, 1267–1273. [Google Scholar] [CrossRef]

- KAPSARC. The Future of Cooling in Saudi Arabia: Technology, Market and Policy Options; King Abdullah Petroleum Studies and Research Center: Riyadh, Saudi Arabia, 2020. [Google Scholar]

- Wang, R.Z.; Pan, Q.W.; Xu, Z.Y. 12—Solar-powered adsorption cooling systems. In Advances in Solar Heating and Cooling; Wang, R.Z., Ge, T.S., Eds.; Woodhead Publishing: Sawston, UK, 2016; pp. 299–328. [Google Scholar]

- Kumar, A.; Kapilan, N.; Dinesh, P.A.; Kasthurirengan, S. Experimental studies on solar assisted activated carbon based adsorption refrigeration system. Mater. Today Proc. 2022, 62, 5258–5265. [Google Scholar] [CrossRef]

- Kılıç, M. Evaluation of Combined Thermal–Mechanical Compression Systems: A Review for Energy Efficient Sustainable Cooling. Sustainability 2022, 14, 13724. [Google Scholar] [CrossRef]

- Attalla, M.; Sadek, S.; Ahmed, M.S.; Shafie, I.M.; Hassan, M. Experimental study of solar powered ice maker using adsorption pair of activated carbon and methanol. Appl. Therm. Eng. 2018, 141, 877–886. [Google Scholar] [CrossRef]

- Luo, H.; Dai, Y.; Wang, R.; Tang, R.; Li, M. Year round test of a solar adsorption ice maker in Kunming, China. Energy Convers. Manag. 2005, 46, 2032–2041. [Google Scholar] [CrossRef]

- Wang, Y.; Li, M.; Ji, X.; Yu, Q.; Li, G.; Ma, X. Experimental study of the effect of enhanced mass transfer on the performance improvement of a solar-driven adsorption refrigeration system. Appl. Energy 2018, 224, 417–425. [Google Scholar] [CrossRef]

- Ambarita, H.; Kawai, H. Experimental study on solar-powered adsorption refrigeration cycle with activated alumina and activated carbon as adsorbent. Case Stud. Therm. Eng. 2016, 7, 36–46. [Google Scholar] [CrossRef]

- Elsheniti, M.B.; Rezk, A.; Shaaban, M.; Roshdy, M.; Nagib, Y.M.; Elsamni, O.A.; Saha, B.B. Performance of a solar adsorption cooling and desalination system using aluminum fumarate and silica gel. Appl. Therm. Eng. 2021, 194, 117116. [Google Scholar] [CrossRef]

- Shaaban, M.; Elsheniti, M.B.; Rezk, A.; Elhelw, M.; Elsamni, O.A. Performance investigation of adsorption cooling and desalination systems employing thermally enhanced copper foamed bed coated with SAPO-34 and CPO-27(Ni). Appl. Therm. Eng. 2022, 205, 118056. [Google Scholar] [CrossRef]

- Gado, M.; Megahed, T.; Ookawara, S.; Nada, S.; Hassan, H. Performance assessment of photovoltaic/thermal (PVT) hybrid adsorption-vapor compression refrigeration system. J. Energy Syst. 2022, 6, 209–220. [Google Scholar] [CrossRef]

- Aghakhani, S.; Afrand, M. Experimental study of the effect of simultaneous application of the air- and water-cooled flow on efficiency in a Photovoltaic thermal solar collector with porous plates. Appl. Therm. Eng. 2022, 217, 119161. [Google Scholar] [CrossRef]

- Ju, X.; Xu, C.; Han, X.; Du, X.; Wei, G.; Yang, Y. A review of the concentrated photovoltaic/thermal (CPVT) hybrid solar systems based on the spectral beam splitting technology. Appl. Energy 2017, 187, 534–563. [Google Scholar] [CrossRef]

- Ju, X.; Xu, C.; Liao, Z.; Du, X.; Wei, G.; Wang, Z.; Yang, Y. A review of concentrated photovoltaic-thermal (CPVT) hybrid solar systems with waste heat recovery (WHR). Sci. Bull. 2017, 62, 1388–1426. [Google Scholar] [CrossRef]

- De Pascale, A.; Ferrari, C.; Melino, F.; Morini, M.; Pinelli, M. Integration between a thermophotovoltaic generator and an Organic Rankine Cycle. Appl. Energy 2012, 97, 695–703. [Google Scholar] [CrossRef]

- Albaik, I.; Alamri, Y.A.; Elsheniti, M.B.; Al-Dadah, R.; Mahmoud, S.; Ismail, M.A. Assessment of a novel multi-generation solar CPV/T system combining adsorption and organic rankine cycle subsystems. Sol. Energy 2022, 236, 455–472. [Google Scholar] [CrossRef]

- Lin, L.; Tian, Y.; Luo, Y.; Chen, C.; Jiang, L. A novel solar system integrating concentrating photovoltaic thermal collectors and variable effect absorption chiller for flexible co-generation of electricity and cooling. Energy Convers. Manag. 2020, 206, 112506. [Google Scholar] [CrossRef]

- Kasaeian, A.; Nouri, G.; Ranjbaran, P.; Wen, D. Solar collectors and photovoltaics as combined heat and power systems: A critical review. Energy Convers. Manag. 2018, 156, 688–705. [Google Scholar] [CrossRef]

- Xu, Z.; Kleinstreuer, C. Concentration photovoltaic–thermal energy co-generation system using nanofluids for cooling and heating. Energy Convers. Manag. 2014, 87, 504–512. [Google Scholar] [CrossRef]

- Alamri, Y.A.; Albaik, I.; Mahmoud, S.; Al-Dadah, R.; Ismail, M.A. Integration of concentrated multi-junction solar cells with small-scale organic rankine cycle. Energy Convers. Manag. 2021, 239, 114235. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Palombo, A. Solar heating and cooling systems by absorption and adsorption chillers driven by stationary and concentrating photovoltaic/thermal solar collectors: Modelling and simulation. Renew. Sustain. Energy Rev. 2018, 82, 1874–1908. [Google Scholar] [CrossRef]

- Elsheniti, M.B.; Eissa, M.S.; Al-Ansary, H.; Orfi, J.; Elsamni, O.; El-Leathy, A. Examination of Using Aluminum-Foam/Finned-Tube Beds Packed with Maxsorb III for Adsorption Ice Production System. Energies 2022, 15, 2757. [Google Scholar] [CrossRef]

- Azurspace. The Use of the Concentrated Sun: Concentrator Triple Junction Solar Cell. 2021. Available online: https://www.azurspace.com/index.php/en/products/products-cpv/cpv-solar-cells (accessed on 10 February 2022).

- Zhuang, Z.; Yu, F. Optimization design of hybrid Fresnel-based concentrator for generating uniformity irradiance with the broad solar spectrum. Opt. Laser Technol. 2014, 60, 27–33. [Google Scholar] [CrossRef]

- Leutz, R.; Suzuki, A. Nonimaging Fresnel Lenses: Design and Performance of Solar Concentrators; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Fresnel Factory. Fresnel Lens Suppliers: Technical Information. 2022. Available online: https://www.fresnelfactory.com/cpv-cell-cpv-panel-cp250-25248-cpv-f250mm-fresnel-lens-suppliers.html (accessed on 12 February 2022).

- Shatnawi, H.; Aldossary, A. Outdoor Investigation of High Concentrator Photovoltaic Under Uniform and Non-Uniform Illumination. J. Daylighting 2020, 7, 1–12. [Google Scholar] [CrossRef]

- Hassanzadeh, A.; Jiang, L.; Winston, R. Coupled optical-thermal modeling, design and experimental testing of a novel medium-temperature solar thermal collector with pentagon absorber. Sol. Energy 2018, 173, 1248–1261. [Google Scholar] [CrossRef]

- Kerzmann, T.; Schaefer, L. System simulation of a linear concentrating photovoltaic system with an active cooling system. Renew. Energy 2012, 41, 254–261. [Google Scholar] [CrossRef]

- Evans, D.L. Simplified method for predicting photovoltaic array output. Sol. Energy 1981, 27, 555–560. [Google Scholar] [CrossRef]

- Wu, L.; Zhao, B.; Ao, X.; Yang, H.; Ren, X.; Yu, Q.; Guo, K.; Hu, M.; Pei, G. Performance analysis of the aerogel-based PV/T collector: A numerical study. Sol. Energy 2021, 228, 339–348. [Google Scholar] [CrossRef]

- European Commission. Photovoltaic Geographical Information System. 2022. Available online: https://re.jrc.ec.europa.eu/pvg_tools/en/#api_5.2 (accessed on 20 February 2022).

- Rejeb, O.; Radwan, A.; Abo-Zahhad, E.M.; Ghenai, C.; Serageldin, A.A.; Ahmed, M.; El-Shazly, A.A.; Bettayeb, M.; Abdelrehim, O. Numerical analysis of passive cooled ultra-high concentrator photovoltaic cell using optimal heat spreader design. Case Stud. Therm. Eng. 2020, 22, 100757. [Google Scholar] [CrossRef]

- Theristis, M.; Sarmah, N.; Khalid, T.; O’Donovan, T.S. Design and Numerical Analysis of Enhanced Cooling Techniques for a High Concentration Photovoltaic (HCPV) System. In Proceedings of the 27th European Photovoltaic Solar Energy Conference and Exhibition, Frankfurt, Germany, 24–28 September 2012. [Google Scholar]

- Levinshtein, M.; Rumyantsev, S.; Shur, M. Handbook Series on Semiconductor Parameters; World Scientific: Singapore, 1996. [Google Scholar]

- Saha, B.B.; Chakraborty, A.; Koyama, S.; Aristov, Y.I. A new generation cooling device employing CaCl2-in-silica gel–water system. Int. J. Heat Mass Transf. 2009, 52, 516–524. [Google Scholar] [CrossRef]

- El-Sharkawy, I.; AbdelMeguid, H.; Saha, B. Towards an optimal performance of adsorption chillers: Reallocation of adsorption/desorption cycle times. Int. J. Heat Mass Transf. 2013, 63, 171–182. [Google Scholar] [CrossRef]

- Jribi, S.; Miyazaki, T.; Saha, B.B.; Koyama, S.; Maeda, S.; Maruyama, T. Corrected adsorption rate model of activated carbon–ethanol pair by means of CFD simulation. Int. J. Refrig. 2016, 71, 60–68. [Google Scholar] [CrossRef]

- El-Sharkawy, I.I.; Uddin, K.; Miyazaki, T.; Saha, B.B.; Koyama, S.; Miyawaki, J.; Yoon, S.-H. Adsorption of ethanol onto parent and surface treated activated carbon powders. Int. J. Heat Mass Transf. 2014, 73, 445–455. [Google Scholar] [CrossRef]

- Elsheniti, M.B.; Hassab, M.A.; Attia, A.-E. Examination of effects of operating and geometric parameters on the performance of a two-bed adsorption chiller. Appl. Therm. Eng. 2018, 146, 674–687. [Google Scholar] [CrossRef]

- Emerson. Copeland ScrollTM 1-5 HP ZPK5. 2022. Available online: https://climate.emerson.com/en-us/shop/1/copeland-sku-zp42k5e-pfv-800 (accessed on 10 March 2022).

- Aldossary, A.; Mahmoud, S.; Al-Dadah, R. Technical feasibility study of passive and active cooling for concentrator PV in harsh environment. Appl. Therm. Eng. 2016, 100, 490–500. [Google Scholar] [CrossRef]

- Wu, Y.; Cui, J.; Xu, X.; Deng, D. Experimental study on active cooling for concentrating photovoltaic cells working at high concentration ratios. Int. J. Energy Res. 2021, 45, 10682–10695. [Google Scholar] [CrossRef]

- Wang, Y.; Li, M.; Du, W.; Ji, X.; Xu, L. Experimental investigation of a solar-powered adsorption refrigeration system with the enhancing desorption. Energy Convers. Manag. 2018, 155, 253–261. [Google Scholar] [CrossRef]

- Papoutsis, E.; Koronaki, I.; Papaefthimiou, V. Numerical simulation and parametric study of different types of solar cooling systems under Mediterranean climatic conditions. Energy Build. 2017, 138, 601–611. [Google Scholar] [CrossRef]

- Xu, D.; Liu, J.; Yan, X.-G.; Yan, W. A Novel Adaptive Neural Network Constrained Control for a Multi-Area Interconnected Power System with Hybrid Energy Storage. IEEE Trans. Ind. Electron. 2017, 65, 6625–6634. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Fresnel-lens area (mm2) | 230 mm × 230 mm |

| Focal length | 220 mm |

| Thickness | 5 mm |

| Groove pitch | 0.5 mm |

| Transmissivity (%) | 92% |

| Parameter | Value |

|---|---|

| The reference efficiency of the CPV Cell | 42% |

| The optical efficiency ( | 92% |

| The refractive index of Fresnel lens | 1.49 |

| The refractive index of exterior domains (air) | 1 |

| Heat capacity of water | 4200 J∙kg−1 K−1 |

| The cell-efficiency coefficient ( | 0.047% K−1 |

| Material | Area | Thickness |

|---|---|---|

| Germanium layer | 10 mm × 10 mm | 0.1 mm |

| Copper layer | 29 mm × 29 mm | 0.3 mm |

| Al2O3 layer | 30 mm × 30 mm | 0.4 mm |

| Bottom copper layer | 29 mm × 29 mm | 0.3 mm |

| Aluminum heat-sink channel (1800 mm length) | 30 mm × 10 mm | 1.5 mm |

| Material | Density (kg∙m−3) | Heat Capacity (J∙kg−1∙K−1) | Thermal Conductivity (W∙m−1∙K−1) |

|---|---|---|---|

| Germanium | 5323 | 310 | 60 |

| Copper | 8960 | 385 | 400 |

| Al2O3 ceramic | 3700 | 880 | 20 |

| Aluminum | 2700 | 900 | 170 |

| Thermal paste | 4000 | 800 | 10 |

| Polymethyl methacrylate | 1190 | 1420 | 0.19 |

| Cooling water | 1000 | 4200 | 0.59 |

| Parameter | Value | Unit |

|---|---|---|

| Activated-carbon density ( | 2200 | |

| Activated-carbon specific heat ( | 1375 | |

| Aluminum-foam density ( | 270 | |

| Aluminum-foam specific heat ( | 895 | |

| Bulk density ( | 2775 | |

| The geometrical and operating parameters of the beds | ||

| Adsorbent mass for each bed | 1.25 | |

| Heating-water mass flowrate ( | 5.394 | |

| Cooling-water mass flowrate ( | 2.543 | |

| Inlet cooling-water temperature ( | 25 | |

| Tube length | 0.4 | m |

| Tube inner radius | 3.15 | mm |

| Tube outer radius | 3.96 | mm |

| Aluminum-foam thickness | 2 | mm |

| Number of tubes | 100 | -- |

| Symbols | Value | Unit |

|---|---|---|

| 25 | ||

| 6 | ||

| –2 |

| Parameter | Value | Unit |

|---|---|---|

| Power input | 0.9–3.7 | kW |

| Cooling capacity ( | 2.6–11.3 | kW |

| Condensing temperature | 50 | |

| Evaporating temperature | −5 | |

| COP | 2.89–3.05 | - |

| Refrigerant | R410a | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elsheniti, M.B.; AlRabiah, A.; Al-Ansary, H.; Almutairi, Z.; Orfi, J.; El-Leathy, A. Performance Assessment of an Ice-Production Hybrid Solar CPV/T System Combining Both Adsorption and Vapor-Compression Refrigeration Systems. Sustainability 2023, 15, 3711. https://doi.org/10.3390/su15043711

Elsheniti MB, AlRabiah A, Al-Ansary H, Almutairi Z, Orfi J, El-Leathy A. Performance Assessment of an Ice-Production Hybrid Solar CPV/T System Combining Both Adsorption and Vapor-Compression Refrigeration Systems. Sustainability. 2023; 15(4):3711. https://doi.org/10.3390/su15043711

Chicago/Turabian StyleElsheniti, Mahmoud Badawy, Abdulrahman AlRabiah, Hany Al-Ansary, Zeyad Almutairi, Jamel Orfi, and Abdelrahman El-Leathy. 2023. "Performance Assessment of an Ice-Production Hybrid Solar CPV/T System Combining Both Adsorption and Vapor-Compression Refrigeration Systems" Sustainability 15, no. 4: 3711. https://doi.org/10.3390/su15043711

APA StyleElsheniti, M. B., AlRabiah, A., Al-Ansary, H., Almutairi, Z., Orfi, J., & El-Leathy, A. (2023). Performance Assessment of an Ice-Production Hybrid Solar CPV/T System Combining Both Adsorption and Vapor-Compression Refrigeration Systems. Sustainability, 15(4), 3711. https://doi.org/10.3390/su15043711