Effects of Freeze-Thaw Cycles on Permeability Behavior and Desiccation Cracking of Dalian Red Clay in China Considering Saline Intrusion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

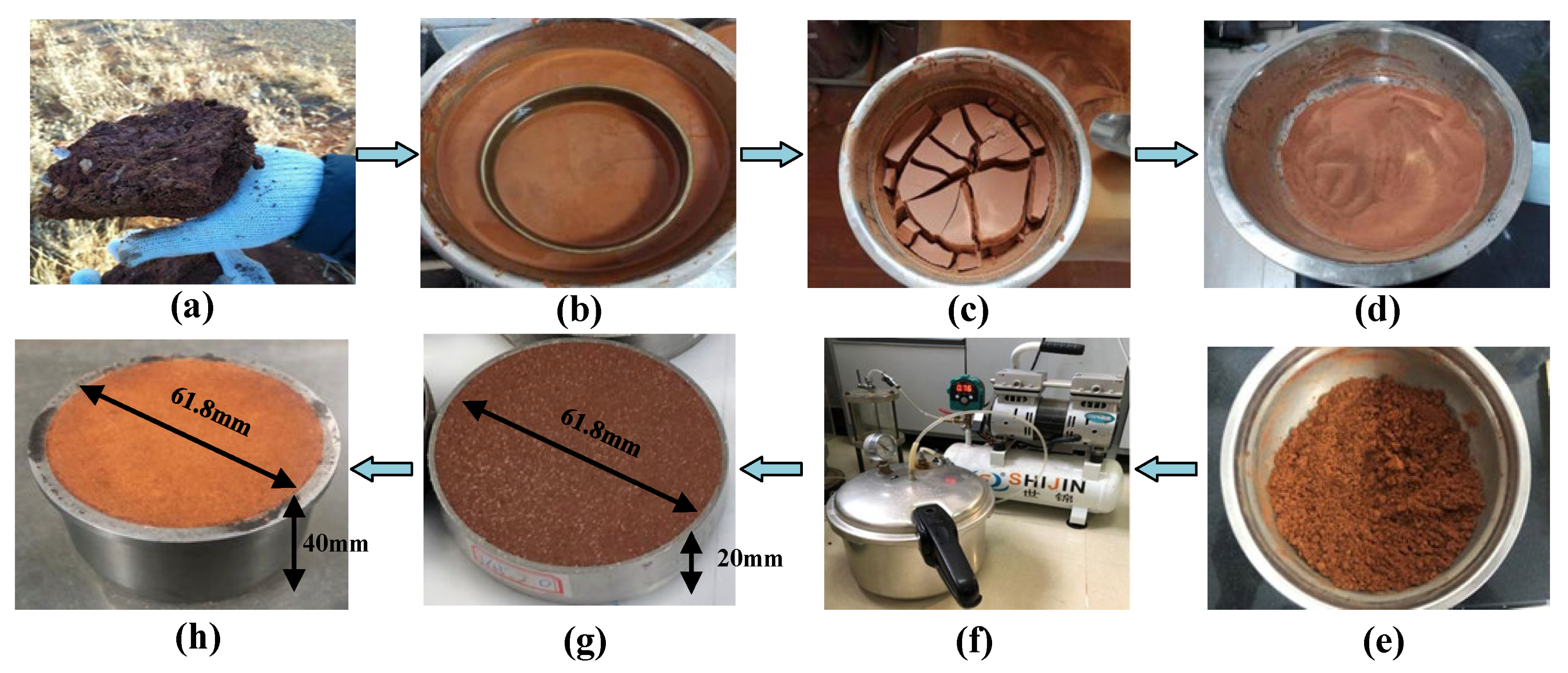

2.2. Specimen Preparation

2.3. Testing Procedures

2.3.1. Freeze-Thaw Cycles

2.3.2. Wetting-Drying Cycles

2.3.3. Permeability Measurement

2.3.4. DIC Technology

3. Results and Analyses

3.1. Permeability Characteristic

3.2. Desiccation Cracking

3.2.1. Crack Observation

3.2.2. Effect of Dry Density on Cracks of Saturated Red Clay

3.2.3. Effect of Freeze-Thaw Cycles on Cracks of Saturated Red Clay

3.2.4. Effect of Salt Concentration on Cracks of Saturated Red Clay

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lang, L.; Chen, B.; Chen, B. Strength evolutions of varying water content-dredged sludge stabilized with alkali-activated ground granulated blast-furnace slag. Constr. Build Mater. 2021, 275, 122111. [Google Scholar] [CrossRef]

- Zeng, L.; Yu, H.; Gao, Q.; Liu, J.; Liu, Z. Evolution of Tensile Properties of Compacted Red Clay under Wet and Dry Cycles. Ksce J. Civ. Eng. 2022, 26, 606–618. [Google Scholar] [CrossRef]

- Ding, L.; Han, Z.; Zou, W.; Wang, X. Characterizing hydro-mechanical behaviours of compacted subgrade soils considering effects of freeze-thaw cycles. Transp. Geotech. 2020, 24, 100392. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, S.; Weng, L.; Wang, L.; Li, Z.; Xu, L. Fractal analysis of cracking in a clayey soil under freeze–thaw cycles. Eng. Geol. 2016, 208, 93–99. [Google Scholar] [CrossRef]

- Lyu, H.; Gu, J.; Li, W.; Liu, F. Analysis of compressibility and mechanical behavior of red clay considering structural strength. Arab. J. Geosci. 2020, 13, 411. [Google Scholar] [CrossRef]

- Zhang, Y.; Johnson, A.E.; White, D.J. Freeze-thaw performance of cement and fly ash stabilized loess. Transp. Geotech. 2019, 21, 100279. [Google Scholar] [CrossRef]

- Wu, H.; Jin, F.; Du, Y. Influence of wet-dry cycles on vertical cutoff walls made of reactive magnesia-slag-bentonite-soil mixtures. J. Zhejiang Univ-Sc a 2019, 20, 948–960. [Google Scholar] [CrossRef]

- Wu, H.; Du, Y.; Yu, J.; Yang, Y.; Li, V.C. Hydraulic conductivity and self-healing performance of Engineered Cementitious Composites exposed to Acid Mine Drainage. Sci. Total Environ. 2020, 716, 137095. [Google Scholar] [CrossRef]

- Lai, F.; Zhang, N.; Liu, S.; Yang, D. A generalised analytical framework for active earth pressure on retaining walls with narrow soil. Géotechnique 2022, 1–46. [Google Scholar] [CrossRef]

- Lin, J.; Zou, W.; Han, Z.; Zhang, Z.; Wang, X. Structural, volumetric and water retention behaviors of a compacted clay upon saline intrusion and freeze-thaw cycles. J. Rock Mech. Geotech. 2022, 14, 953–966. [Google Scholar] [CrossRef]

- Mishra, P.N.; Scheuermann, A.; Bore, T.; Li, L. Salinity effects on soil shrinkage characteristic curves of fine-grained geomaterials. J. Rock Mech. Geotech. 2019, 11, 181–191. [Google Scholar] [CrossRef]

- Thyagaraj, T.; Das, A.P. Physico-chemical effects on collapse behaviour of compacted red soil. Géotechnique 2017, 67, 559–571. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B. Strength Properties of Cement-Stabilized Dredged Sludge Incorporating Nano-SiO2 and Straw Fiber. Int. J. Geomech. 2021, 21, 04021119. [Google Scholar] [CrossRef]

- Sagidullina, N.; Abdialim, S.; Kim, J.; Satyanaga, A.; Moon, S. Influence of Freeze–Thaw Cycles on Physical and Mechanical Properties of Cement-Treated Silty Sand. Sustainability 2022, 14, 7000. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B.; Li, J. High-efficiency stabilization of dredged sediment using nano-modified and chemical-activated binary cement. J. Rock. Mech. Geotech. 2023. [Google Scholar] [CrossRef]

- Qi, J.; Vermeer, P.A.; Cheng, G. A review of the influence of freeze-thaw cycles on soil geotechnical properties. Permafr. Periglac. 2006, 17, 245–252. [Google Scholar] [CrossRef]

- Liu, J.; Chang, D.; Yu, Q. Influence of freeze-thaw cycles on mechanical properties of a silty sand. Eng. Geol. 2016, 210, 23–32. [Google Scholar] [CrossRef]

- Dalla Santa, G.; Cola, S.; Secco, M.; Tateo, F.; Sassi, R.; Galgaro, A. Multiscale analysis of freeze–thaw effects induced by ground heat exchangers on permeability of silty clays. Géotechnique 2019, 69, 95–105. [Google Scholar] [CrossRef]

- Chamberlain, E.J.; Gow, A.J. Effect of freezing and thawing on the permeability and structure of soils. Eng. Geol. 1979, 13, 73–92. [Google Scholar] [CrossRef]

- Eigenbrod, K.D. Effects of cyclic freezing and thawing on volume changes and permeabilities of soft fine-gained soils. Can. Geotech. J. 1996, 33, 529–537. [Google Scholar] [CrossRef]

- Othman, M.A. Effect of Freeze-Thaw on the Structure and Hydraulic Conductivity of Compacted Clays; The University of Wisconsin-Madison: Madison, WI, USA, 1992. [Google Scholar]

- Benson, C.H.; Othman, M.A. Hydraulic Conductivity of Compacted Clay Frozen and Thawed In Situ. J. Geotech. Eng. 1993, 119, 276–294. [Google Scholar] [CrossRef]

- Thyagaraj, T.; Thomas, S.R.; Das, A.P. Physico-Chemical Effects on Shrinkage Behavior of Compacted Expansive Clay. Int. J. Geomech. 2017, 17, 06016013. [Google Scholar] [CrossRef]

- Mokni, N.; Romero, E.; Olivella, S. Chemo-hydro-mechanical behaviour of compacted Boom Clay: Joint effects of osmotic and matric suctions. Géotechnique 2014, 64, 681–693. [Google Scholar] [CrossRef]

- Rao, S.M.; Thyagaraj, T.; Thomas, H.R. Swelling of compacted clay under osmotic gradients. Géotechnique 2006, 56, 707–713. [Google Scholar] [CrossRef]

- Palomino, A.M.; Santamarina, J.C. Fabric map for kaolinite: Effects of pH and ionic concentration on behavior. Clays Clay Miner. 2005, 53, 211–223. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, S.; Zhang, D.; Lai, F.; Lu, T.; Liu, Y. A modified equal-strain solution for consolidation behavior of composite foundation reinforced by precast concrete piles improved with cement-treated soil. Comput. Geotech. 2022, 150, 104905. [Google Scholar] [CrossRef]

- Barbour, S.L.; Fredlund, D.G. Mechanisms of osmotic flow and volume change in Clay soils. Can. Geotech. J. 1989, 26, 551–562. [Google Scholar] [CrossRef] [Green Version]

- Wan, Y.; Xue, Q.; Liu, L.; Wang, S. Relationship between the shrinkage crack characteristics and the water content gradient of compacted clay liner in a landfill final cover. Soils Found 2018, 58, 1435–1445. [Google Scholar] [CrossRef]

- Chong, B. Simulation of crack growth using cohesive crack method. Ksce J. Civ. Eng. 2010, 14, 765–772. [Google Scholar] [CrossRef]

- Tang, C.; Cheng, Q.; Leng, T.; Shi, B.; Zeng, H.; Inyang, H.I. Effects of wetting-drying cycles and desiccation cracks on mechanical behavior of an unsaturated soil. Catena 2020, 194, 104721. [Google Scholar] [CrossRef]

- Ye, W.M.; Wan, M.; Chen, B.; Chen, Y.G.; Cui, Y.J.; Wang, J. An unsaturated hydraulic conductivity model for compacted GMZ01 bentonite with consideration of temperature. Environ. Earth Sci. 2014, 71, 1937–1944. [Google Scholar] [CrossRef]

- Li, J.H.; Lu, Z.; Guo, L.B.; Zhang, L.M. Experimental study on soil-water characteristic curve for silty clay with desiccation cracks. Eng. Geol. 2017, 218, 70–76. [Google Scholar] [CrossRef]

- Li, J.H.; Zhang, L.M. Study of desiccation crack initiation and development at ground surface. Eng. Geol. 2011, 123, 347–358. [Google Scholar] [CrossRef]

- Lakshmikantha, M.R.; Prat, P.C.; Ledesma, A. Experimental evidence of size effect in soil cracking. Can Geotech. J. 2012, 49, 264–284. [Google Scholar] [CrossRef]

- Costa, S.; Kodikara, J.; Barbour, S.L.; Fredlund, D.G. Theoretical analysis of desiccation crack spacing of a thin, long soil layer. Acta Geotech. 2018, 13, 39–49. [Google Scholar] [CrossRef]

- Pouya, A.; Vo, T.D.; Hemmati, S.; Tang, A.M. Modeling soil desiccation cracking by analytical and numerical approaches. Int. J. Numer Anal Met. 2019, 43, 738–763. [Google Scholar] [CrossRef]

- Tang, C.; Cui, Y.; Shi, B.; Tang, A.; Liu, C. Desiccation and cracking behaviour of clay layer from slurry state under wetting–drying cycles. Geoderma 2011, 166, 111–118. [Google Scholar] [CrossRef] [Green Version]

- Tang, C.; Pei, X.; Wang, D.; Shi, B.; Li, J. Tensile Strength of Compacted Clayey Soil. J. Geotech. Geoenviron. 2015, 141, 04014122. [Google Scholar] [CrossRef]

- ASTM D2487-11; Standard Practice for Classification of Soils for Engineering Purpose (Unified Soil Classification System). ASTM International: West Conshohocken, PE, USA, 2011.

- ASTM D854-10, 2010; Standard Methods for Specific Gravity of Soils by Water Pycnometer. ASTM International: West Conshohocken, PE, USA, 2010.

- ASTM D560; Standard Test Methods for Freezing and Thawing Compacted Soil-Cement Mixures. ASTM International: West Conshohocken, PE, USA, 2016.

- Cai, G.H.; Liu, S.Y.; Zheng, X. Effects of Drying-Wetting Cycles on Durability of Carbonated Reactive Magnesia-Admixed Clayey Soil. J. Mater. Civil. Eng. 2019, 31, 4019276. [Google Scholar] [CrossRef]

- Cai, G.; Liu, S.; Zheng, X. Influence of drying-wetting cycles on engineering properties of carbonated silt admixed with reactive MgO. Constr. Build Mater. 2019, 204, 84–93. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. 2019.

- Li, H.; Tan, Y.; Xie, Z.; Sun, D.; Sun, W. Method for measuring the saturated permeability coefficient of compacted bentonite at temperatures exceeding 100 °C. Prog. Nucl. Energ. 2021, 141, 103958. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Liu, C.; Zhao, L.; Wang, B. Influencing factors of geometrical structure of surface shrinkage cracks in clayey soils. Eng. Geol. 2008, 101, 204–217. [Google Scholar] [CrossRef]

- Tran, D.K.; Ralaizafisoloarivony, N.; Charlier, R.; Mercatoris, B.; Léonard, A.; Toye, D.; Degré, A. Studying the effect of desiccation cracking on the evaporation process of a Luvisol–From a small-scale experimental and numerical approach. Soil Tillage Res. 2019, 193, 142–152. [Google Scholar] [CrossRef]

- Liu, C.; Tang, C.; Shi, B.; Suo, W. Automatic quantification of crack patterns by image processing. Comput. Geosci.-Uk 2013, 57, 77–80. [Google Scholar] [CrossRef]

- Ying, Z.; Cui, Y.; Benahmed, N.; Duc, M. Salinity effect on the compaction behaviour, matric suction, stiffness and microstructure of a silty soil. J. Rock Mech. Geotech. 2021, 13, 855–863. [Google Scholar] [CrossRef]

- Ying, Z.; Benahmed, N.; Cui, Y.; Duc, M. Determining osmotic suction through electrical conductivity for unsaturated low-plasticity soils. J. Rock Mech Geotech. 2022, 6, 1946–1955. [Google Scholar] [CrossRef]

- Newson, T.A.; Fahey, M. The effect of soil suction on evaporative fluxes from soil surfaces: Discussion. Can. Geotech. J. 1998, 35, 692–694. [Google Scholar] [CrossRef]

- Young, R. Soil Properties and Behaviour; Elsevier: Amsterdam, The Netherlands, 2012; Volume 5. [Google Scholar]

- Ying, Z.; Cui, Y.; Benahmed, N.; Duc, M. Drying effect on the microstructure of compacted salted silt. Géotechnique 2021, 73, 62–70. [Google Scholar] [CrossRef]

- Tan, Y.; Hu, Y.; Deng, Y.; Cao, L.; Zuo, Q.; Ming, H. Behavior and mechanism of laterite shrinkage inhibition with lime and meta-kaolin mixture. Rock Soil Mech. 2019, 40, 4213–4219. [Google Scholar]

| Property | Values |

|---|---|

| Unit weight, γ (kN/m3) | 16.0 |

| Specific gravity, Gs | 2.72 |

| Initial water content, (%) | 15.5 |

| Liquid limit, wL (%) | 39.73 |

| Plastic limit, wP (%) | 22.3 |

| Optimum water content, (%) | 19.7 |

| Grain size distribution (%) | - |

| Clay (<0.005 mm) | 1.6 |

| Silt (0.005–0.075 mm) | 39.8 |

| Sand (>0.075 mm) | 58.6 |

| Uniformity coefficient, Cu | 4.3 |

| Maximum dry density, ρ(g/cm3) | 1.55 |

| Specimen Number | Dry Density, ρd (g/cm3) | Salt Concentration, Tsalt (%) | Number of Freeze-Thaw Cycles, NF-T |

|---|---|---|---|

| RC-1.35-0-0 | 1.35 | 0 | 0 |

| RC-1.35-1-2 | 1.35 | 2 | 1 |

| RC-1.35-2-4 | 1.35 | 4 | 2 |

| RC-1.45-1-0 | 1.45 | 0 | 1 |

| RC-1.45-0-2 | 1.45 | 2 | 0 |

| RC-1.45-4-4 | 1.45 | 4 | 4 |

| RC-1.55-2-0 | 1.55 | 0 | 2 |

| RC-1.55-4-2 | 1.55 | 2 | 4 |

| RC-1.55-0-4 | 1.55 | 4 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Zhang, C.; Liu, X.; Pan, X.; Pan, Y.; Jia, P. Effects of Freeze-Thaw Cycles on Permeability Behavior and Desiccation Cracking of Dalian Red Clay in China Considering Saline Intrusion. Sustainability 2023, 15, 3858. https://doi.org/10.3390/su15043858

Chen C, Zhang C, Liu X, Pan X, Pan Y, Jia P. Effects of Freeze-Thaw Cycles on Permeability Behavior and Desiccation Cracking of Dalian Red Clay in China Considering Saline Intrusion. Sustainability. 2023; 15(4):3858. https://doi.org/10.3390/su15043858

Chicago/Turabian StyleChen, Chen, Chaozhe Zhang, Xiao Liu, Xiaona Pan, Yenan Pan, and Pengjiao Jia. 2023. "Effects of Freeze-Thaw Cycles on Permeability Behavior and Desiccation Cracking of Dalian Red Clay in China Considering Saline Intrusion" Sustainability 15, no. 4: 3858. https://doi.org/10.3390/su15043858