Quantification of Floc Growth for Sediment with Mixing Intensity

Abstract

1. Introduction

2. Material and Methods

2.1. Mixing Intensity (GT)

2.2. Experiments for Flocculation

2.3. Equipment and Experimental Conditions

3. Results of the Experiments

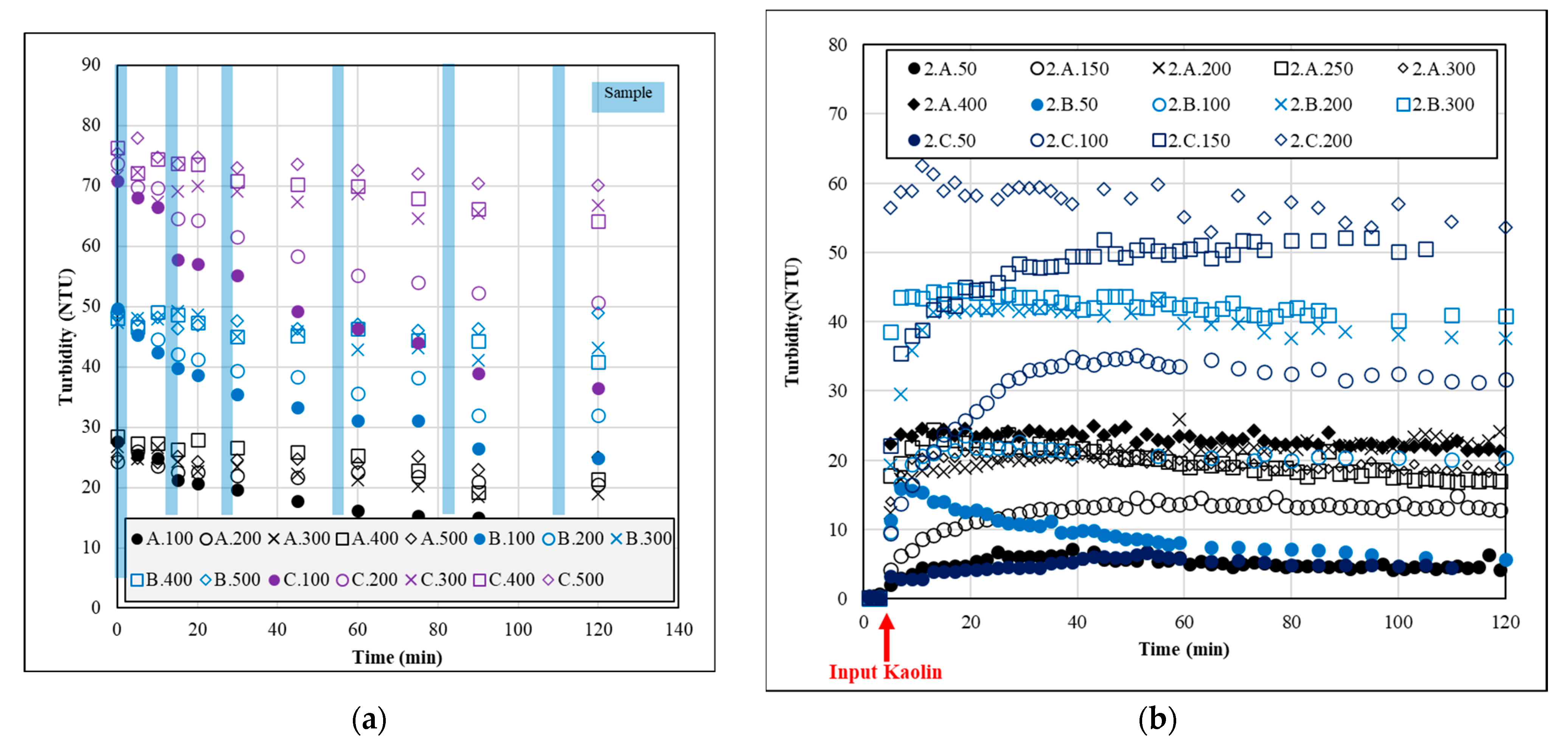

3.1. Turbidity

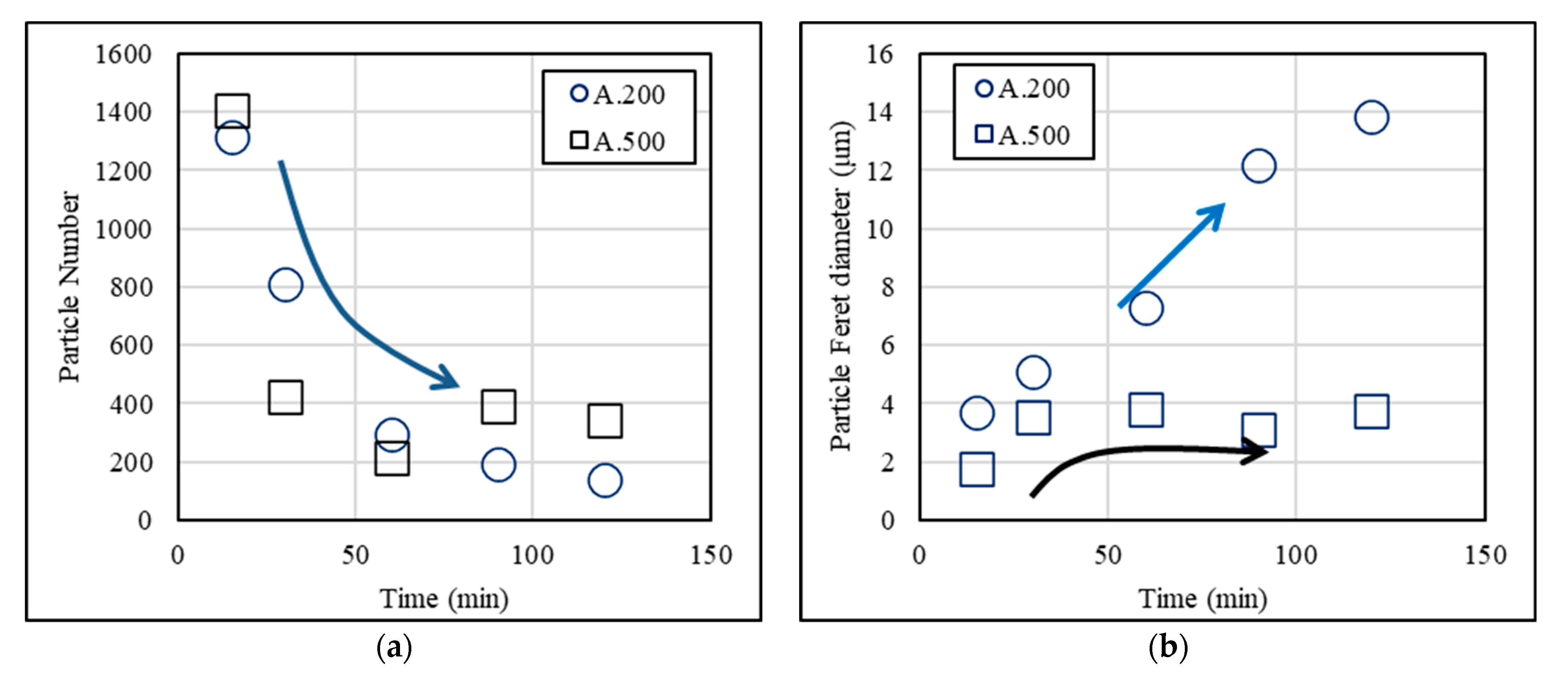

3.2. Particle Measurement

4. Discussion

5. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahlf, W.; Hollert, H.; Neumann-Hensel, H.; Ricking, M. A guidance for the assessment and evaluation of sediment quality a German Approach based on ecotoxicological and chemical measurements. J. Soils Sediments 2002, 2, 37–42. [Google Scholar] [CrossRef]

- Bubakova, P.; Pivokonsky, M.; Filip, P. Effect of shear rate on aggregate size and structure in the process of aggregation and at steady state. Powder Technol. 2013, 235, 540–549. [Google Scholar] [CrossRef]

- Camp, T.R.; Stein, P.C. Velocity gradients and internal work in fluid motion. J. Boston Soc. Civ. Eng. 1943, 30, 219–237. [Google Scholar]

- Chapman, P.M. Current approaches to developing sediment quality criteria. Environ. Toxicol. Chem. Int. J. 1989, 8, 589–599. [Google Scholar] [CrossRef]

- Christie, M.C.; Quartley, C.P.; Dyer, K.R. The development of the POST system for in-situ intertidal measurements. In Proceedings of the 7th International Conference on Electrical Engineering in Oceanography, Southampton, UK, 23–25 June 1997; IET: London, UK, 1997; Volume 439, pp. 39–45. [Google Scholar]

- Ditschke, D.; Markofsky, M. A non-equilibrium, multi-class flocculation model. In Proc. SEDYMO International Symposium; Hamburg University of Technology: Hamburg, Germany, 2006. [Google Scholar]

- Dyer, K.R. Sediment processes in Estuaries: Future research requirements. J. Geophys. Res 1989, 94, 14327–14332. [Google Scholar] [CrossRef]

- Forstner, U.; Muller, G. Schwermetalle in Flussen und Seen; Springer: Heidelberg, Germany, 1974; p. 225. [Google Scholar]

- Gippel, C.J. The use of turbidimeters in suspended sediment research. Hydrobiologia 1989, 176, 465–480. [Google Scholar] [CrossRef]

- Gippel, C.J. Potential use of turbidity monitoring for measuring the transport of suspended solids in streams. Hydrol. Process. 1995, 9, 83–99. [Google Scholar] [CrossRef]

- Gonzalez, R.; Ciavola, P.; Corbau, C.; Falati, S.; Ferreira, O. Mixing depth experiments on an estuarine dissipative beach; St.Georges Beach, Gironde (France). J. Coast. Eng. 2004, 20, 43–52. [Google Scholar]

- Hollert, H.; Duerr, M.; Erdinger, L.; Braunbeck, T. Cytotoxicity of settling particulate matter and sediments of the Neckar River (Germany) during a winter flood. Environ. Toxicol. Chem. 2000, 19, 528–534. [Google Scholar] [CrossRef]

- Hollert, H.; Keiter, S.; König, N.; Rudolf, M.; Ulrich, M.; Braunbeck, T. A new sediment contact assay to assess particle-bound pollutants using zebrafish (Danio rerio) embryos. J. Soils Sediments 2003, 3, 197–207. [Google Scholar] [CrossRef]

- Kapsimalis, V.; Masse, L.; Tastet, J.P. Tidal impact on modern sedimentary facies in the Gironde Estuary, southwestern France. J. Coast. Res. 2004, 20, 1–11. [Google Scholar]

- KOSHA, Material Safety Data Sheet. Kaolin. 2022. Available online: https://msds.kosha.or.kr/ (accessed on 1 January 2023.).

- Kühn, G.; Jirka, G.H. Fine Sediment Behavior in Open Channel Turbulence: An Experimental Study; Vortrag: Saga, Japan, 2005. [Google Scholar]

- Lawler, D.M.; Brown, R.M. A simple and inexpensive turbidity meter for the estimation of suspended sediment concentrations. Hydrol. Process. 1992, 6, 159–168. [Google Scholar] [CrossRef]

- Manning, A.J.; Dyer, K.R.; Lafite, R.; Mikes, D. Flocculation Measured by video based instruments in the Gironde estuary during the european commission SWAMIEE project. J. Coast. Res. 2004, 20, 58–69. [Google Scholar]

- Müller, V.; Seibel, A.; Kisacik, D.; Gust, G. Simulation of Water Column Hydrodynamics by Benthic Chambers. Analysis 2007, 16, 3113–3130. [Google Scholar]

- Riley, S.J. The sediment concentration—Turbidity relation: Its value in monitoring at Ranger Uranium Mine. Northern Territory, Australia. Catena 1998, 32, 1–14. [Google Scholar] [CrossRef]

- Samcheon Pure Chemical Co., Ltd. Specification Sheet, Kaolin. 2022. Available online: http://www.samchun.com/ (accessed on 1 January 2023.).

- van Leussen, W. Estuarine Macroflocs and Their Role in Fine-Grained Sediment Transport. Ph. D. Thesis, University of Utrecht, Utrecht, The Netherlands, 1994. [Google Scholar]

- Yahaya, S.; Jikan, S.S.; Badarulzaman, N.A.; Adamu, A.D. Chemical composition and particle size analysis of Kaolin. Path Sci. 2017, 3, 1001–1004. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, H.; Yu, J.; Dou, J. On the kaolinite floc size at the steady state of flocculation in a turbulent flow. PLoS ONE 2016, 11, e0148895. [Google Scholar] [CrossRef] [PubMed]

| Case 1 | Kaolin | RPM | Remarks | Case 2 | Kaolin | RPM | Remarks |

|---|---|---|---|---|---|---|---|

| 1.A.30 | 0.05g/L (0.02g(A)) | 30 | ⊙ | 2.A.50 | 0.05g/L (0.02g(A)) | 50 | ⊙ |

| 1.A.60 | 60 | ⊙ | 2.A.100 | 100 | ⊙ | ||

| 1.A.90 | 90 | ⊙ | 2.A.150 | 150 | ⊙ | ||

| 1.A.100 | 100 | ⊙★ | 2.A.200 | 200 | ⊙ | ||

| 1.A.120 | 120 | ⊙ | 2.A.250 | 250 | ⊙ | ||

| 1.A.150 | 150 | ⊙ | 2.A.300 | 300 | ⊙ | ||

| 1.A.200 | 200 | ⊙★ | 2.A.400 | 400 | ⊙ | ||

| 1.A.250 | 250 | ⊙ | - | - | - | ||

| 1.A.300 | 300 | ⊙★ | - | - | - | ||

| 1.A.400 | 400 | ⊙★ | - | - | - | ||

| 1.A.500 | 500 | ⊙★ | - | - | - | ||

| 1.B.100 | 0.04g(B) | 100 | ⊙★ | 2.B.50 | 0.04g(B) | 50 | ⊙ |

| 1.B.200 | 200 | ⊙★ | 2.B.100 | 100 | ⊙ | ||

| 1.B.300 | 300 | ⊙★ | 2.B.200 | 200 | ⊙ | ||

| 1.B.400 | 400 | ⊙★ | 2.B.300 | 300 | ⊙ | ||

| 1.B.500 | 500 | ⊙★ | - | - | - | - | |

| 1.C.100 | 0.06g(C) | 100 | ⊙★ | 2.C.50 | 0.06g(C) | 50 | ⊙ |

| 1.C.200 | 200 | ⊙★ | 2.C.100 | 100 | ⊙ | ||

| 1.C.300 | 300 | ⊙★ | 2.C.200 | 200 | ⊙ | ||

| 1.C.400 | 400 | ⊙★ | 2.C.300 | 300 | ⊙ | ||

| 1.C.500 | 500 | ⊙★ | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.H.; Yoo, H.J.; Bang, Y.J.; Lee, S.O. Quantification of Floc Growth for Sediment with Mixing Intensity. Sustainability 2023, 15, 4073. https://doi.org/10.3390/su15054073

Kim DH, Yoo HJ, Bang YJ, Lee SO. Quantification of Floc Growth for Sediment with Mixing Intensity. Sustainability. 2023; 15(5):4073. https://doi.org/10.3390/su15054073

Chicago/Turabian StyleKim, Dong Hyun, Hyung Ju Yoo, Young Jun Bang, and Seung Oh Lee. 2023. "Quantification of Floc Growth for Sediment with Mixing Intensity" Sustainability 15, no. 5: 4073. https://doi.org/10.3390/su15054073

APA StyleKim, D. H., Yoo, H. J., Bang, Y. J., & Lee, S. O. (2023). Quantification of Floc Growth for Sediment with Mixing Intensity. Sustainability, 15(5), 4073. https://doi.org/10.3390/su15054073