Study on Mechanical Properties and Microstructure of Basalt Fiber-Modified Red Clay

Abstract

:1. Introduction

2. Experimental Material and Methods

2.1. Material Selection

2.2. Specimen Preparation

2.2.1. Preparation of Direct Shear Test Specimens

2.2.2. Preparation of Specimens for the Unconfined Compressive Strength Test

3. Mechanical Properties of Basalt Fiber-Modified Red Clay

3.1. Direct Shear Test

3.2. Effect of Blending Basalt Fibers into Red Clay on Shear Strength

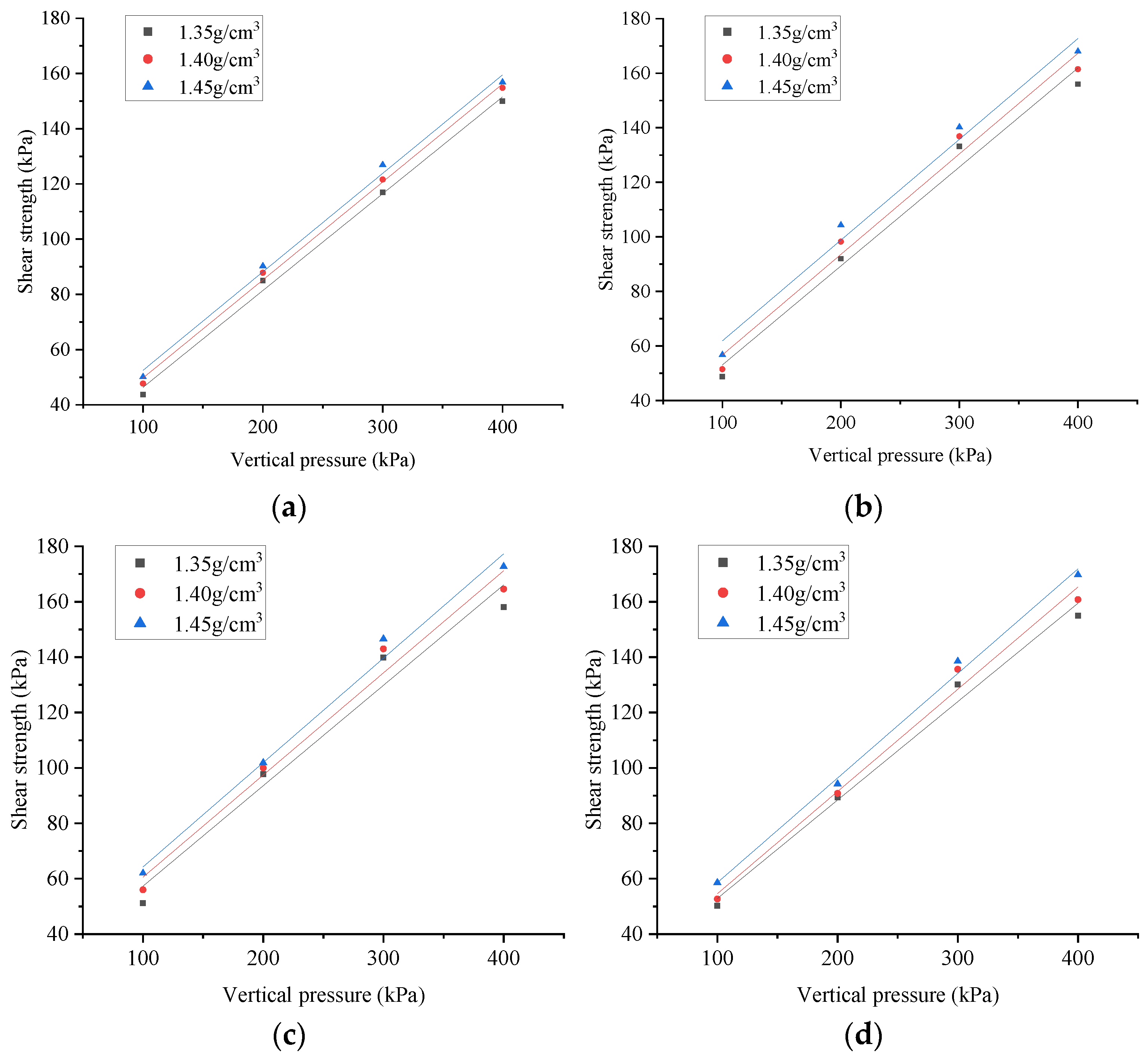

- Ensure that the basalt fiber incorporation rate is constant and study the variation of the effect on its shear strength under different dry density cases.

- 2.

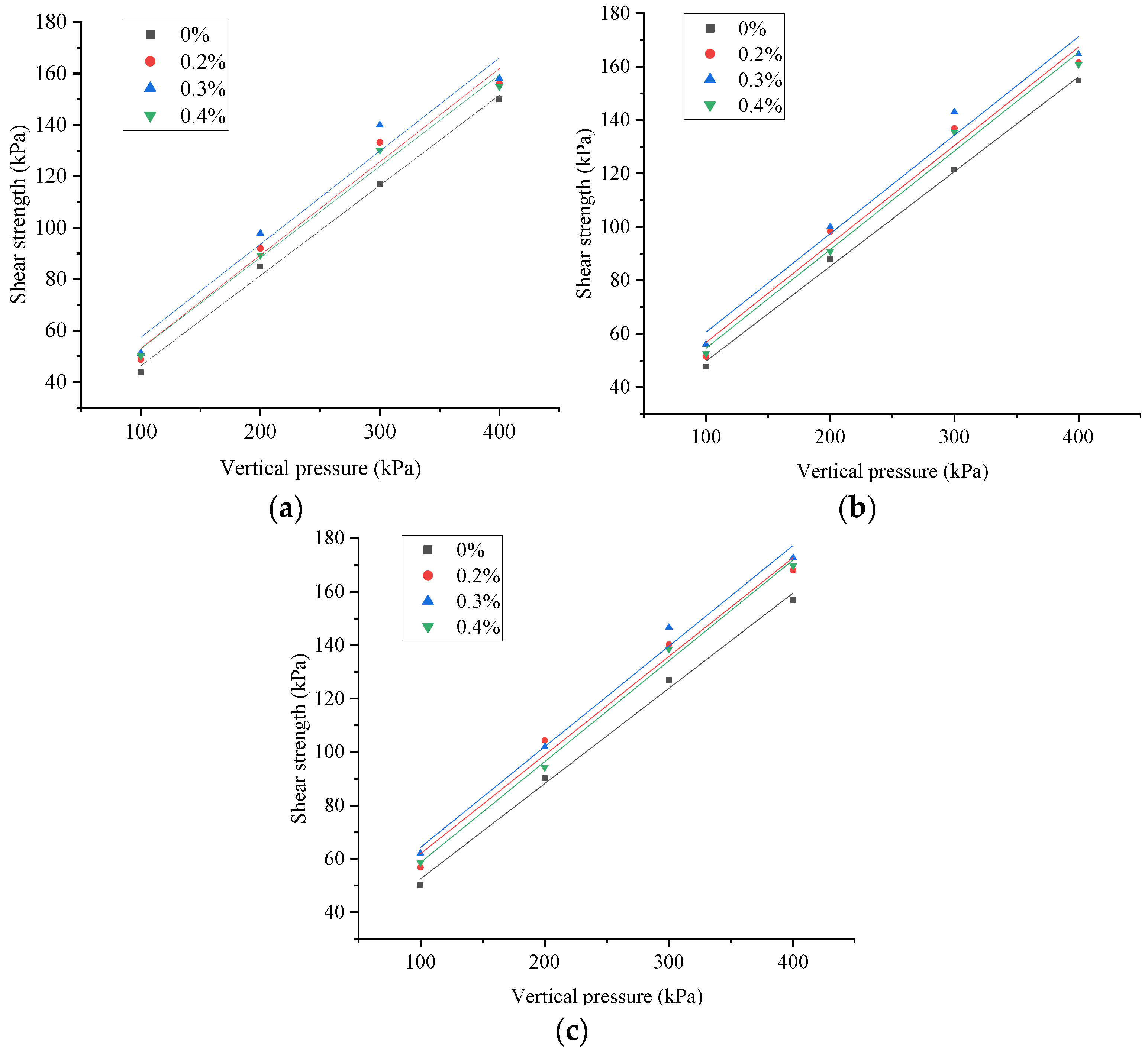

- Keeping the dry density constant, the effect of different fiber incorporation rates on the shear strength was studied.

- 3.

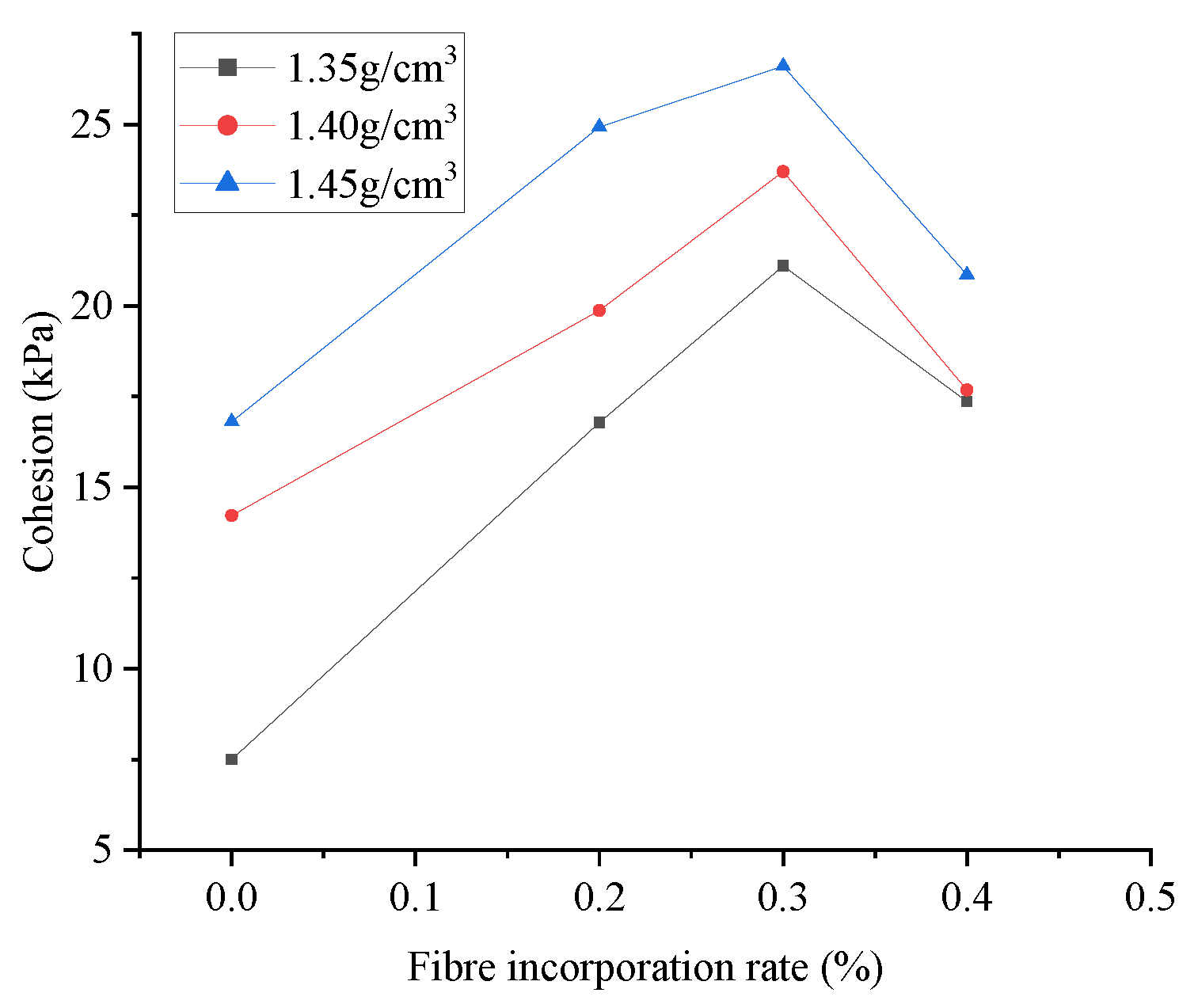

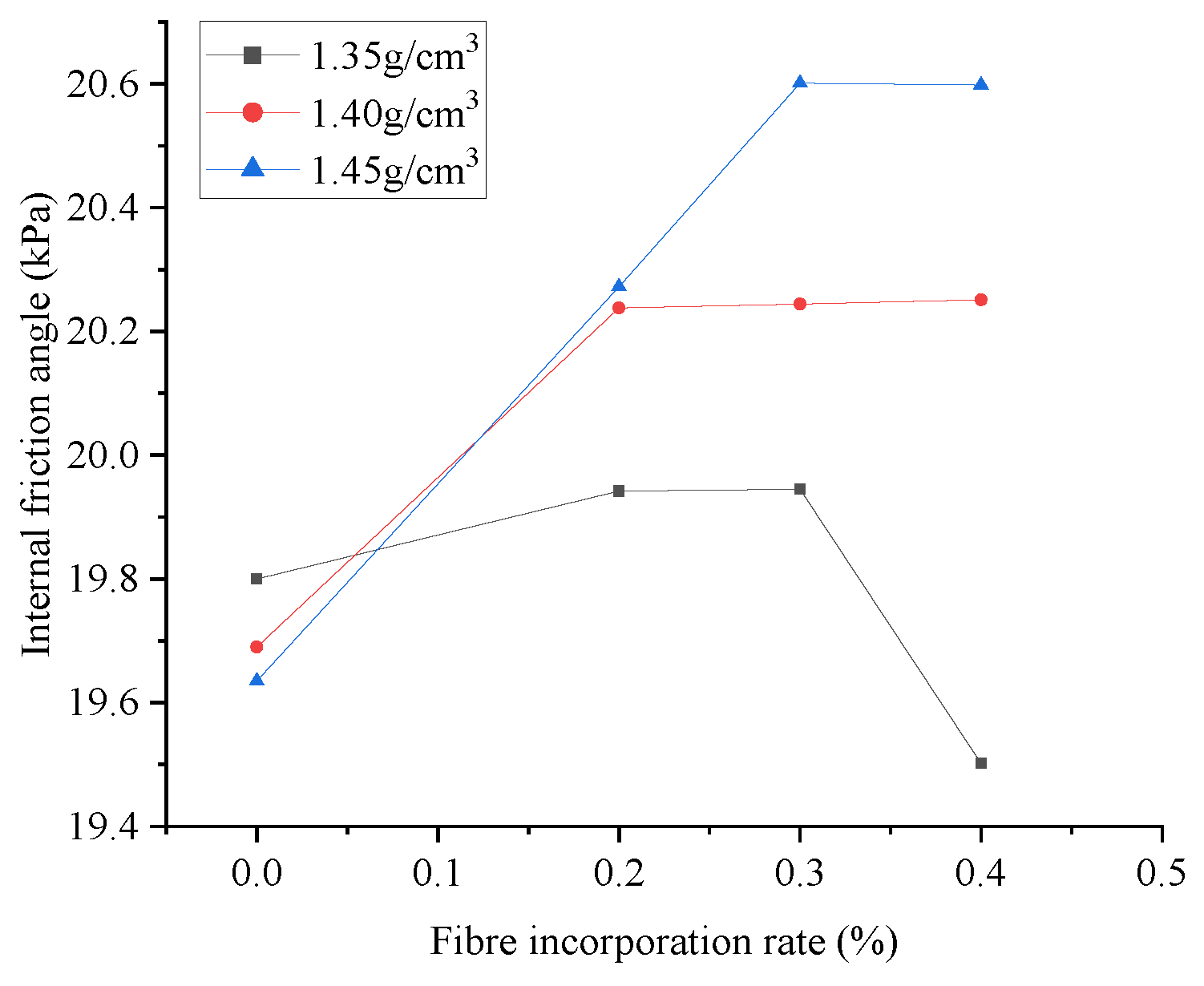

- Effect of fiber incorporation rate on the cohesion and internal friction angle of basalt fiber-modified red clay.

3.3. Unconfined Compressive Strength Test

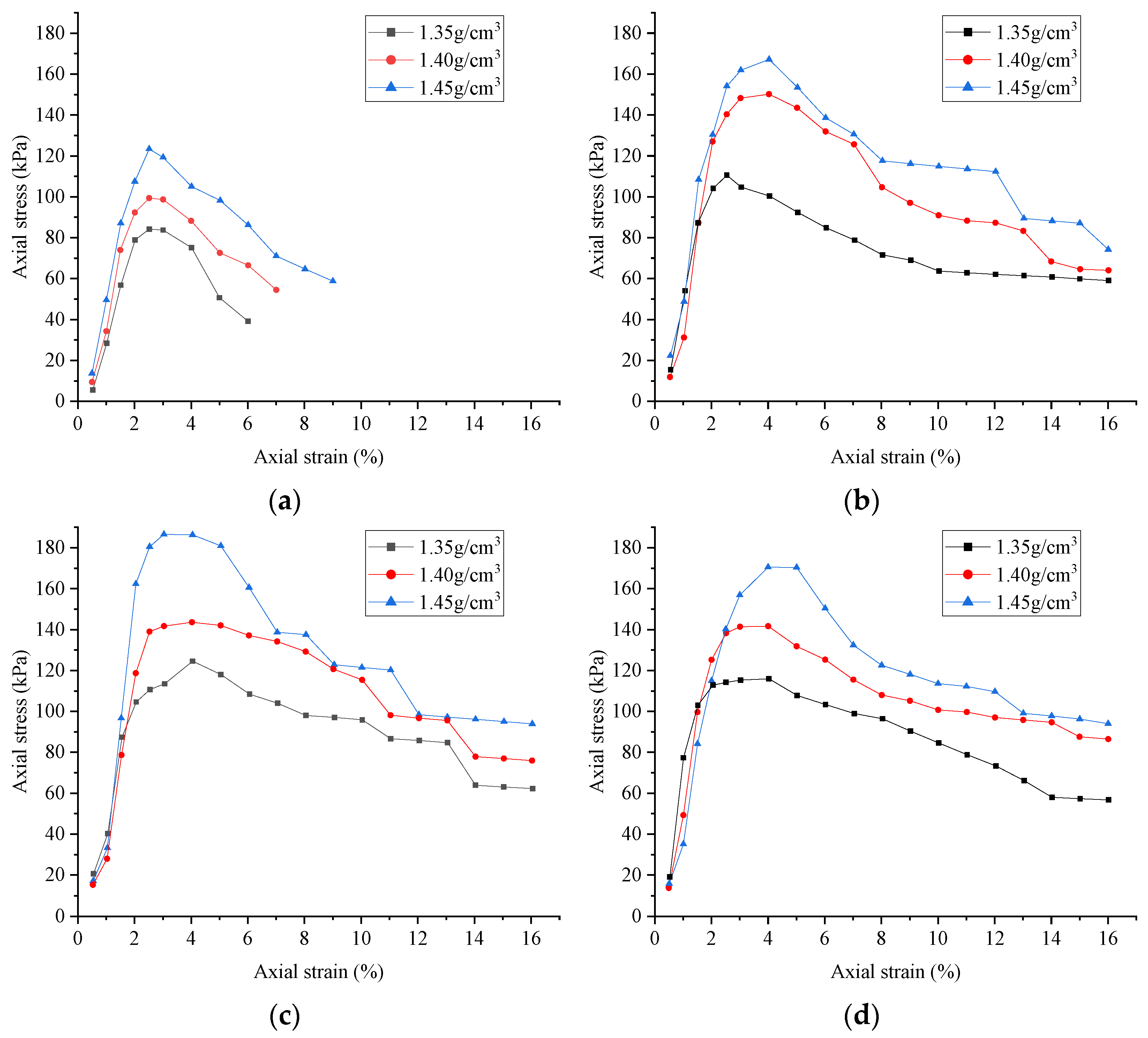

3.4. Effect of Basalt Fibers on Unconfined Compressive Stress and Strain Curves of Red Clay

- Variation of stress–strain curves for different dry densities at the same admixture rate.

- 2.

- The stress–strain curve changes under different fiber incorporation contents under the same dry density conditions.

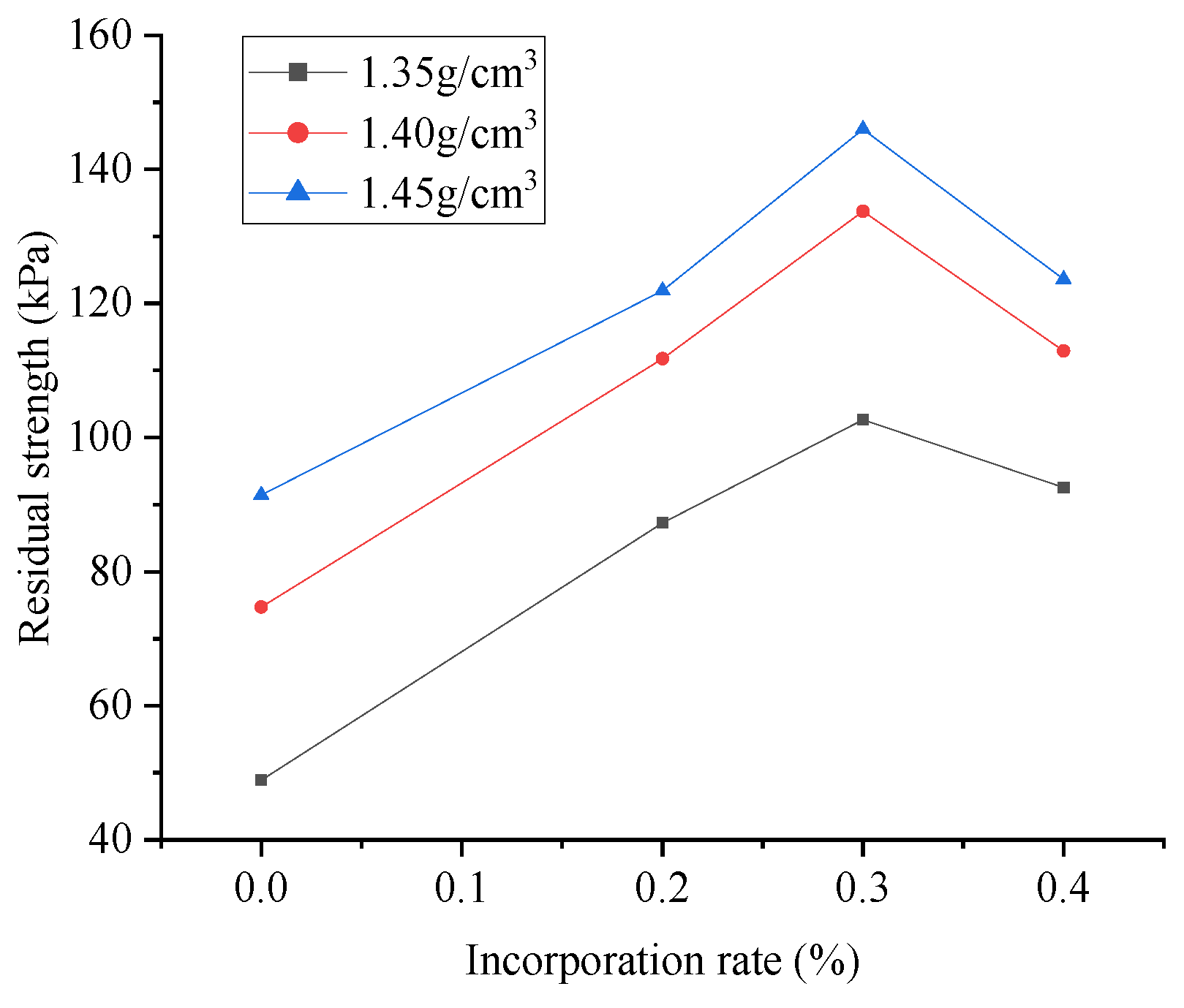

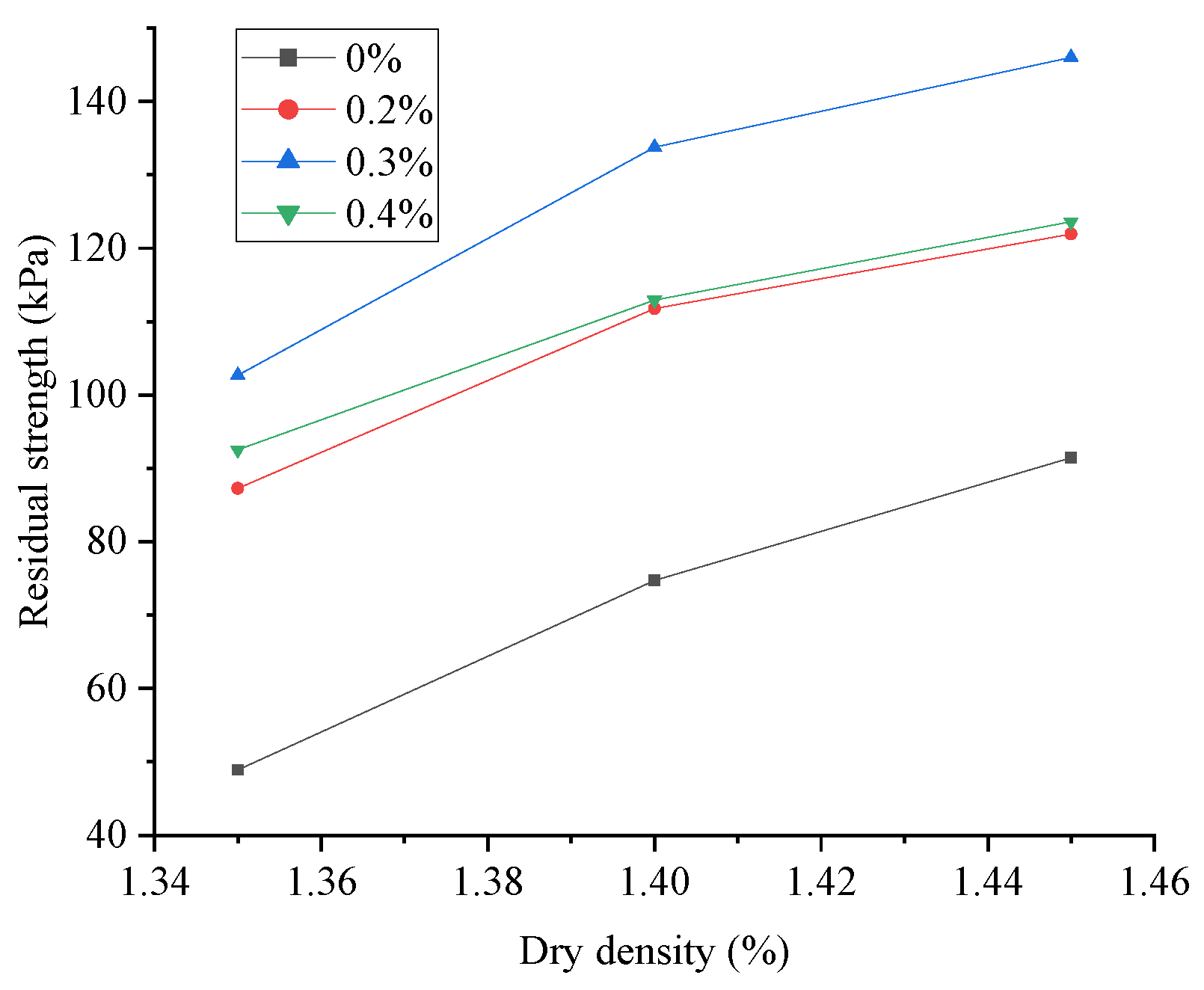

3.5. Analysis of the Effect Law of Blending Basalt Fibers into Red Clay on the Variation of Unconfined Compressive Strength and Residual Strength

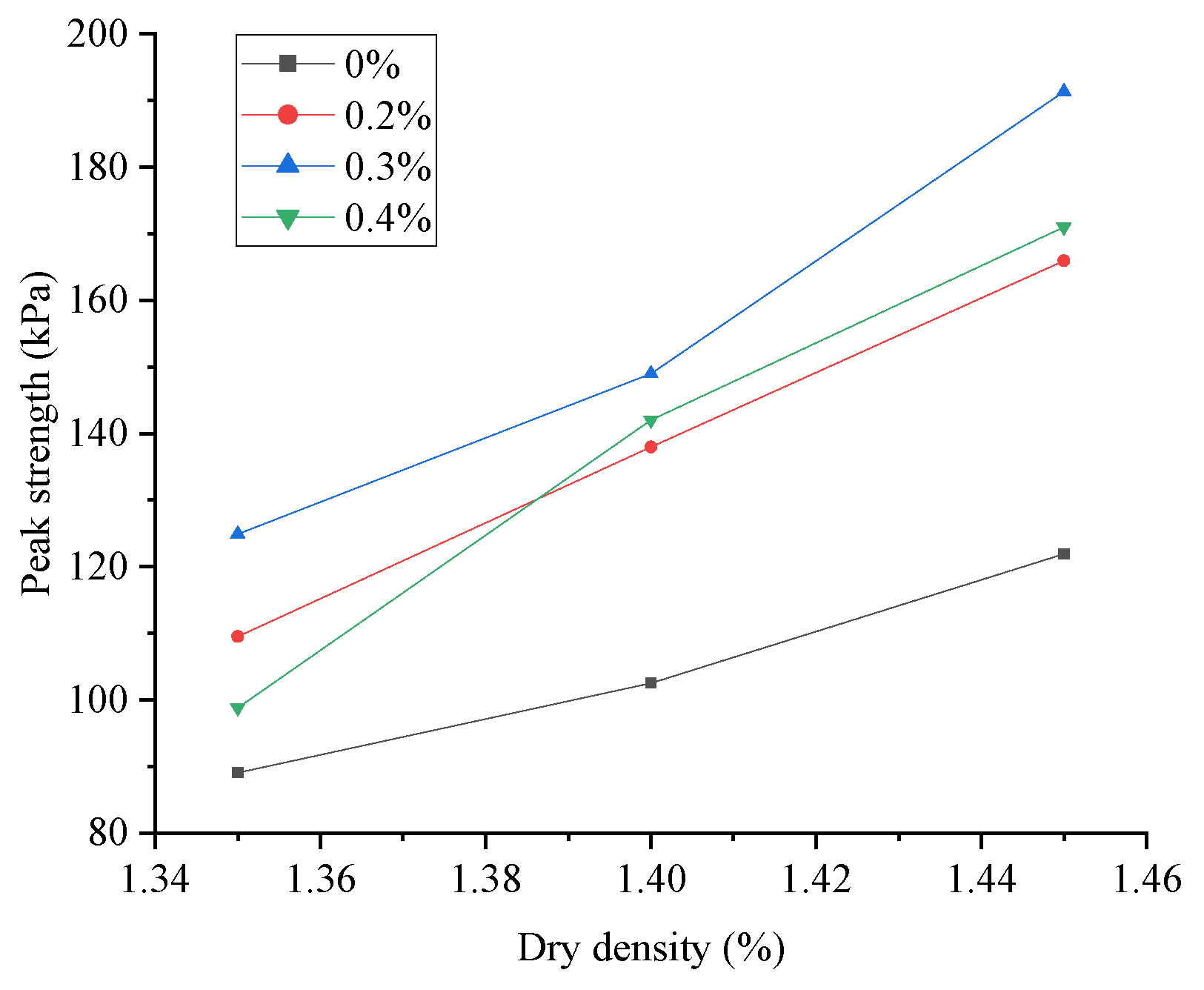

3.5.1. Effect of Fiber Incorporation Rate on Unconfined Compressive Strength

3.5.2. Effect of Dry Density on Unconfined Compressive Strength

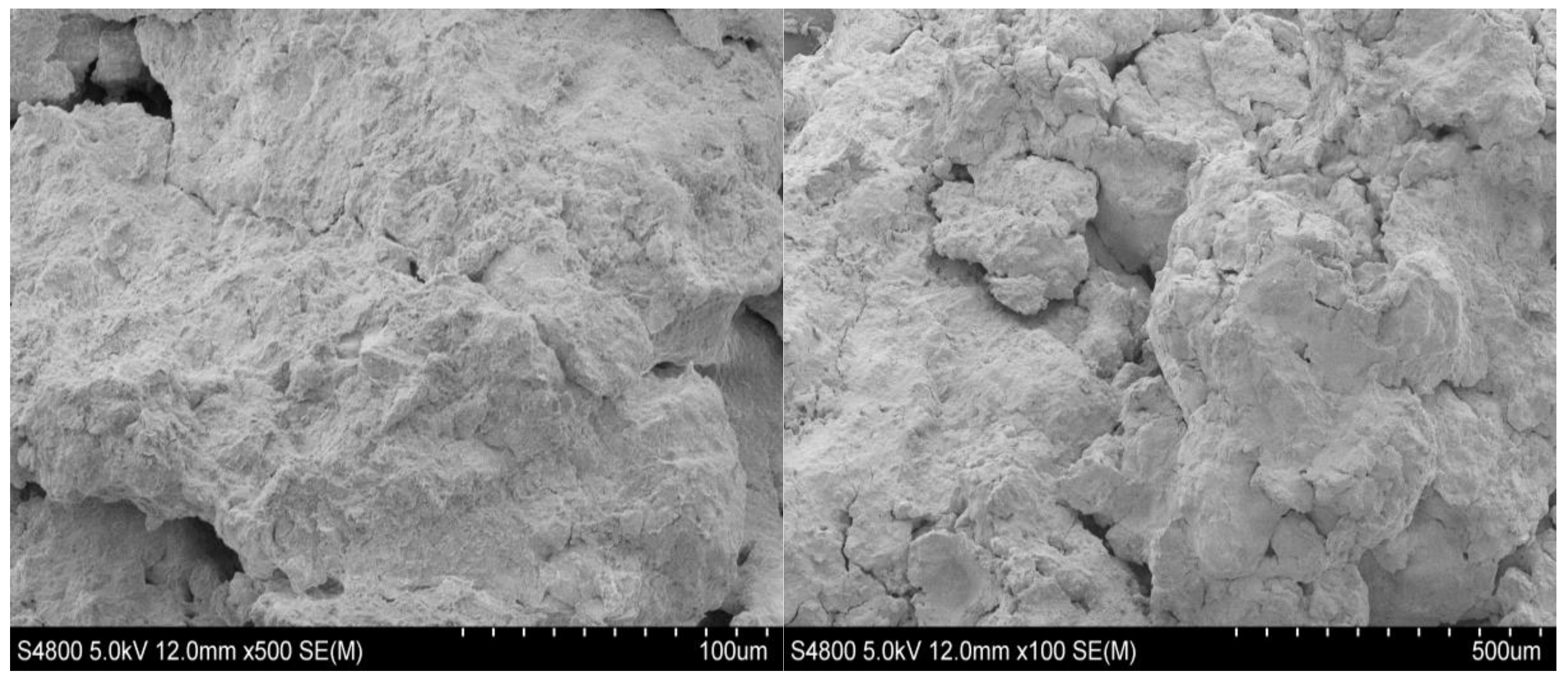

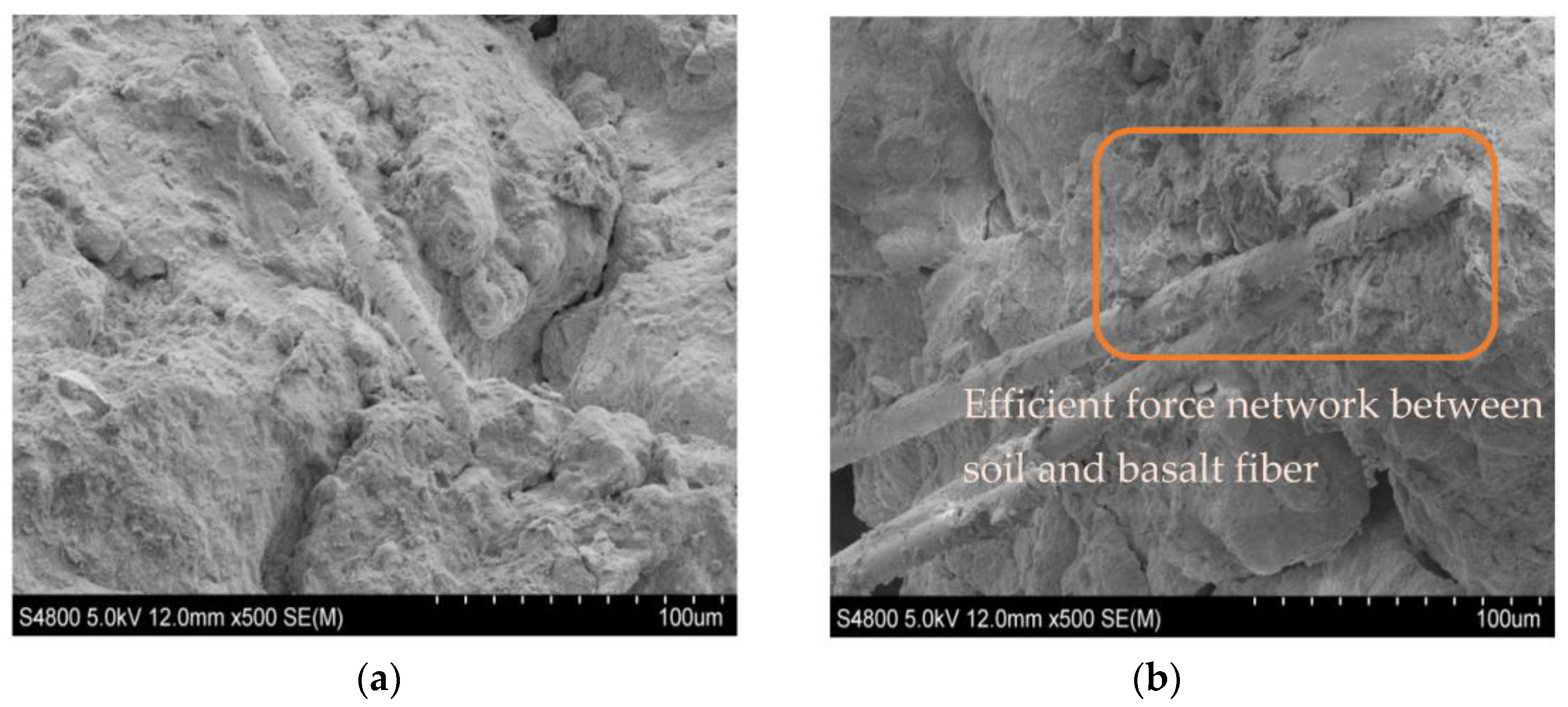

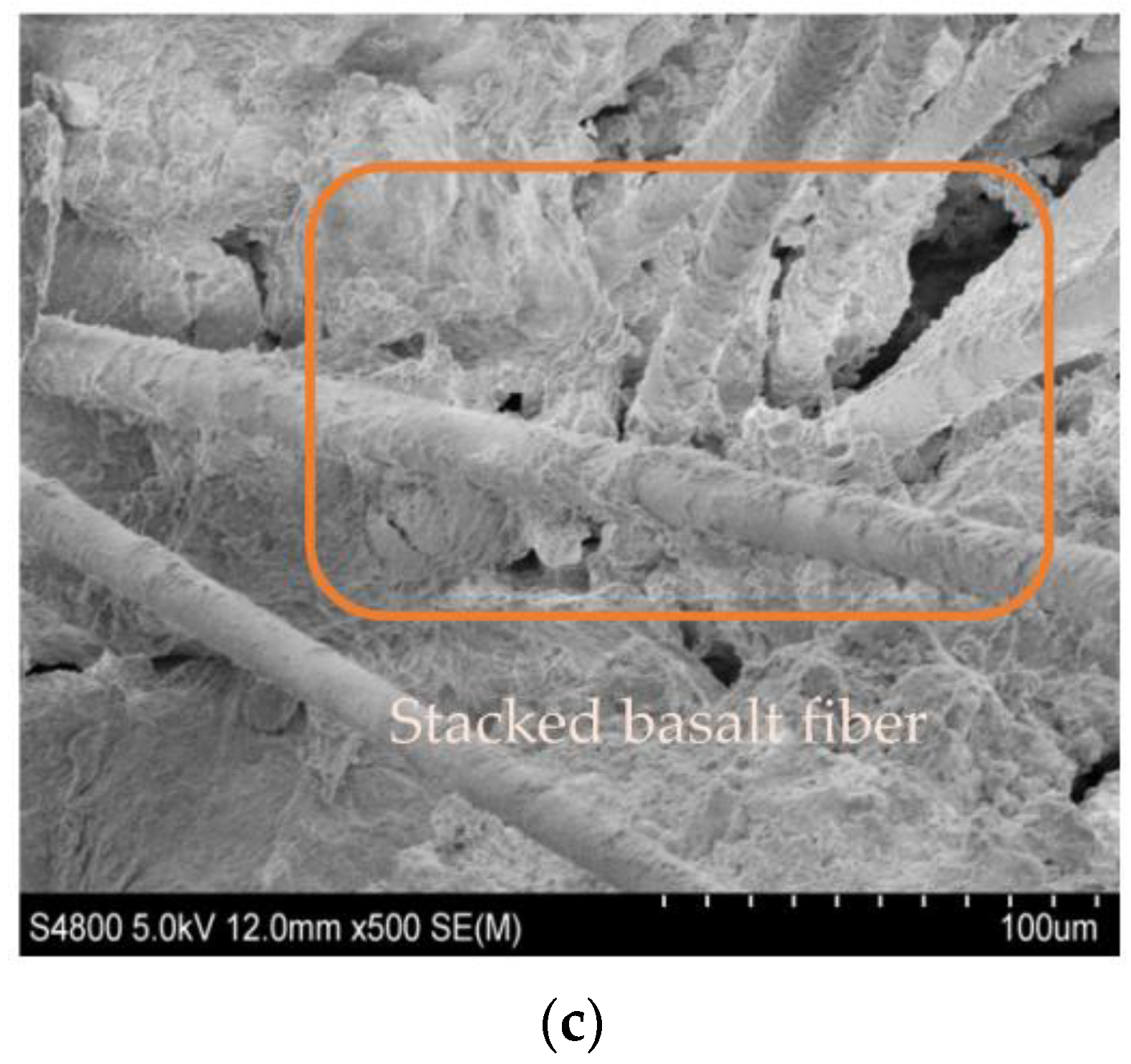

4. Microstructure Analysis

5. Conclusions

- Compared with the plain red clay, the red clay mixed with basalt fibers exhibited a considerable improvement in the compressive strength and shear strength, which peaked at the optimal admixture content of 0.3%.

- At the optimum incorporation level, the basalt fibers fill the pores in the soil and the cohesion and internal friction angle of the soil are maximized.

- After compression, it was found that the stress–strain curve of the soil containing basalt fibers remained unchanged, but the strength change on both sides of the optimal incorporation content increased and then decreased. The strength increased with the increase in the dry density for the same admixture content, but the magnitude was small.

- After the incorporation of basalt fiber, the initial form of damage was transformed into ductile damage, which can maintain high residual strength at the end.

- Through microstructure tests, the fiber‒soil network produced by the fibers and the soil can most effectively function only at the optimal fiber incorporation amount, which means the mechanical properties of the improved soil can be enhanced to the greatest extent.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bahadori, H.; Hasheminezhad, A.; Mohamadi Asl, S. Stabilisation of Urmia Lake peat using natural and artificial pozzolans. Proc. Inst. Civ. Eng. Ground Improv. 2022, 175, 104–113. [Google Scholar] [CrossRef]

- Bahadori, H.; Hasheminezhad, A.; Taghizadeh, F. Experimental study on marl soil stabilization using natural pozzolans. J. Mater. Civ. Eng. 2019, 31, 04018363. [Google Scholar] [CrossRef]

- Li, N.; Liu, Y.; Choi, J.H.; Dragon, T.; Jiang, L. Properties of basalt fibers and their applications. Synth. Fibers 2022, 51, 16–23. [Google Scholar] [CrossRef]

- Li, Z.; Ma, J.; Ma, H.; Xu, X. Properties and applications of basalt fiber and its composites. IOP Conference Series: Earth and Environmental Science. IOP Publ. 2018, 186, 012052. [Google Scholar]

- Ayub, T.; Shafiq, N.; Nuruddin, M.F. Mechanical properties of high-performance concrete reinforced with basalt fibers. Procedia Eng. 2014, 77, 131–139. [Google Scholar] [CrossRef] [Green Version]

- Zhou, H.; Jia, B.; Huang, H.; Mou, Y. Experimental study on basic mechanical properties of basalt fiber reinforced concrete. Materials 2020, 13, 1362. [Google Scholar] [CrossRef] [Green Version]

- Dias, D.P.; Thaumaturgo, C. Fracture toughness of geopolymeric concretes reinforced with basalt fibers. Cem. Concr. Compos. 2005, 27, 49–54. [Google Scholar] [CrossRef]

- Wu, Y.; Cui, J.; Huang, J.; Zhang, W.; Yoshimoto, N.; Wen, L. Correlation of critical state strength properties with particle shape and surface fractal dimension of clinker ash. Int. J. Geomech. 2021, 21, 04021071. [Google Scholar] [CrossRef]

- Kosior-Kazberuk, M.; Krassowska, J. Fracture toughness of concrete with basalt fiber. MATEC Web of Conferences. EDP Sci. 2019, 265, 01008. [Google Scholar]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Hybrid fiber concrete with different basalt fiber length and content. Struct. Concr. 2022, 23, 346–364. [Google Scholar] [CrossRef]

- Yan, R.; Yan, M.; Yu, H.; Yang, D. Influence of Temperature and Pore Pressure on Geomechanical Behavior of Methane Hydrate-Bearing Sand. Int. J. Geomech. 2022, 22, 04022201. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, G.; Li, H. Effects of elevated temperatures on the mechanical properties of basalt fibers and BFRP plates. Constr. Build. Mater. 2016, 127, 1029–1036. [Google Scholar] [CrossRef]

- Hyodo, T.; Wu, Y.; Hyodo, M. Influence of fines on the monotonic and cyclic shear behaviour of volcanic soil “Shirasu”. Eng. Geol. 2022, 301, 106591. [Google Scholar] [CrossRef]

- Shen, D.; Yang, Q.; Jiao, Y.; Cui, Z.; Zhang, J. Experimental investigations on reinforced concrete shear walls strengthened with basalt fiber-reinforced polymers under cyclic load. Constr. Build. Mater. 2017, 136, 217–229. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Chaopeng, X.; Ali, M. Experimental and analytical study of hybrid fiber reinforced concrete prepared with basalt fiber under high temperature. Fire Mater. 2022, 46, 205–226. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, B.; Xie, A.; Qi, Y. Experimental study on dynamic mechanical properties and constitutive model of basalt fiber reinforced concrete. Constr. Build. Mater. 2017, 152, 154–167. [Google Scholar] [CrossRef]

- Yan, R.; Lu, D.; Song, Y.; Yu, H.; Zhang, Q.; Zhou, J. Modeling the Mechanical Behavior of Methane Hydrate-Bearing Soil Considering the Influences of Temperature and Pore Pressure. Energy Fuels 2022, 36, 12510–12523. [Google Scholar] [CrossRef]

- Yan, R.; Zhang, Q. A constitutive model of expansive clay considering thermo-hydro-mechanical coupling effect. Environ. Earth Sci. 2019, 78, 1–12. [Google Scholar] [CrossRef]

- Sun, X.; Gao, Z.; Cao, P.; Zhou, C. Mechanical properties tests and multiscale numerical simulations for basalt fiber reinforced concrete. Constr. Build. Mater. 2019, 202, 58–72. [Google Scholar] [CrossRef]

- Ndepete, C.P.; Sert, S. Use of basalt fibers for soil improvement. Acta Phys. Pol. A 2016, 130, 355–356. [Google Scholar] [CrossRef]

- Gao, L.; Hu, G.; Yang, C.; Xiang, C.; Fu, J.-Y.; Xu, N. Shear strength properties of basalt fiber reinforced clay. J. Geotech. Eng. 2016, 38, 231–237. [Google Scholar]

- Zhuang, X.S.; Zhou, T.; You, P. Experimental study on the improvement of swelling soil by basalt fibers. J. Hubei Univ. Technol. 2016, 31, 89–92. [Google Scholar]

- Hu, L. Experimental Study on Tensile Properties of Fiber-Reinforced Cohesive Soils; Nanjing University: Nanjing, China, 2018. [Google Scholar]

- Guo, S.L.; Lu, Q.; Lin, Y.L.; Liu, Y.Z. Experiments on the influence of freeze-thaw cycles on mechanical properties of basalt fiber cement soil. Adv. Sci. Technol. Water Resour. 2020, 40, 36–43. [Google Scholar]

- Alneasan, M.; Alzo’ubi, A.K. Comprehensive investigation of rock fracture behaviour in clay-rich rocks under the effect of temperature: Experimental study under three loading modes (I, I/II, II). Eng. Fract. Mech. 2022, 276, 108933. [Google Scholar] [CrossRef]

- Alzo’ubi, A.K.; Alneasan, M. Experimental study on the effect of thermal treatment on the mechanical properties of clay-rich rocks (mudstone). Results Eng. 2022, 16, 100728. [Google Scholar] [CrossRef]

- Alneasan, M.; Alzo’Ubi, A.K.; Behnia, M.; Mughieda, O. Experimental observations on the effect of thermal treatment on the crack speed and mode I and II fracture toughness in brittle and ductile rocks. Theor. Appl. Fract. Mech. 2022, 121, 103525. [Google Scholar] [CrossRef]

- Zhou, W.J.; Wang, Q.Z.; Fei, J.H.; Wang, K.J.; Zhao, X.Q. Study of the Mechanical and Microscopic Properties of Modified Silty Clay under Freeze-Thaw Cycles. Geofluids 2022, 2022, 9613176. [Google Scholar]

- Yan, R. BBM-type constitutive model for coupled chemomechanical behavior of saturated soils. Int. J. Geomech. 2018, 18, 06018023. [Google Scholar] [CrossRef]

- Gao, L.; Hu, G.; Qin, S. Numerical Simulation and Mechanism of Basalt Fiber-Reinforced Clay. J. Eng. Geol. 2021, 29, 237–246. [Google Scholar]

- Xu, J.; Wu, Z.; Chen, H. Triaxial shear behavior of basalt fiber reinforced loess under drying-wetting cycles. Rock Soil Mech. 2022, 43, 28–36. [Google Scholar]

- Wang, W.; Cao, G.; Li, Y.; Zhou, Y.; Lu, T.; Zheng, B.; Geng, W. Effects of Freeze-Thaw Cycles on Strength and Wave Velocity of Lime-Stabilized Basalt Fiber-Reinforced Loess. Polymers 2022, 14, 1465. [Google Scholar] [CrossRef] [PubMed]

- Zhao, N.; Wu, H.; Huang, Z. Strength behavior of red clay reinforced by basalt chopped fiber. Arab. J. Geosci. 2021, 14, 1–9. [Google Scholar] [CrossRef]

- Xu, L.N.; Niu, L.; Zhang, Y. Study on mechanical properties of basalt fiber-cement soil under freeze-thaw cycles. Ind. Constr. 2020, 50, 109–113. [Google Scholar]

- Chen, B.; Peng, F.; Zhang, L.; Sun, D.A. Investigation on swelling characteristics of GMZ bentonite with different initial water contents. Ann. Nucl. Energy 2023, 181, 109565. [Google Scholar] [CrossRef]

- Grasley, J.; Rahmani, M.; Azzam, A.; Nsengiyumva, G.; Kim, Y.-R.; Eun, J.; Kim, S. Experimental Investigation of Desiccation Behavior in Inorganic Microfiber-Reinforced Engineered Barrier Materials (IMEBM) for Geological Repository of Nuclear Spent Fuel. In Proceedings of the 56th US Rock Mechanics/Geomechanics Symposium, Santa Fe, NM, USA, 26 June 2022. [Google Scholar]

- Ma, Q.; Cao, Z.; Yuan, P. Experimental research on microstructure and physical-mechanical properties of expansive soil stabilized with fly ash, sand, and basalt fiber. Adv. Mater. Sci. Eng. 2018, 2018, 9125127. [Google Scholar] [CrossRef] [Green Version]

- Gao, L.; Hu, G.; Xu, N.; Fu, J.; Xiang, C.; Yang, C. Experimental study on unconfined compressive strength of basalt fiber reinforced clay soil. Adv. Mater. Sci. Eng. 2015, 2015, 561293. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Xu, J.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Shear strength and mesoscopic characteristics of basalt fiber–reinforced loess after dry–wet cycles. J. Mater. Civ. Eng. 2022, 34, 04022083. [Google Scholar] [CrossRef]

- GB/T 50123-1999; Standard for Geotechnical Test Methods. Chinese Standard: Beijing, China, 1999.

| Liquid Limit | Plastic Limit | Plasticity Index | Optimum Moisture Content | Maximum Dry Density | Specific Gravity |

|---|---|---|---|---|---|

| WL/% | WP/% | IP | GS | ||

| 54.63 | 34.82 | 19.81 | 30 | 1.54 | 2.72 |

| Length mm | Density (g × cm−3) | Diameter μm | Melting Point | Tensile Strength | Tensile Modulus of Elasticity |

|---|---|---|---|---|---|

| 6 | 2.699 | 17.4 | 1450 °C | >2000 Mpa | >85 Gpa |

| Soil Sample Status | Shear Strength Corresponding to Different Vertical Pressures/kPa | C/kPa | φ | ||||

|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | ||||

| Red clay | 1.35 g/cm3 | 43.74 | 85 | 117 | 150 | 7.5 | 19.8 |

| 1.40 g/cm3 | 47.7 | 87.84 | 121.6 | 154.8 | 14.22 | 19.69 | |

| 1.45 g/cm3 | 50.09 | 90.24 | 126.9 | 156.8 | 16.81 | 19.635 | |

| Soil Sample Status | Shear Strength for Different Vertical Pressures/kPa | C/kPa | φ | ||||

|---|---|---|---|---|---|---|---|

| 100 | 200 | 300 | 400 | ||||

| 0.2% basalt fiber-modified red clay | 1.35 g/cm3 | 48.78 | 92 | 133.2 | 156 | 16.78 | 19.942 |

| 1.40 g/cm3 | 51.49 | 98.25 | 136.9 | 161.5 | 19.87 | 20.238 | |

| 1.45 g/cm3 | 56.78 | 104.3 | 140.2 | 168 | 24.93 | 20.272 | |

| 0.3% basalt fiber-modified red clay | 1.35 g/cm3 | 51.22 | 97.76 | 139.88 | 158 | 21.10 | 19.945 |

| 1.40 g/cm3 | 56 | 100 | 143 | 164.6 | 23.70 | 20.244 | |

| 1.45 g/cm3 | 62 | 101.9 | 146.6 | 172.7 | 26.60 | 20.601 | |

| 0.4% basalt fiber-modified red clay | 1.35 g/cm3 | 50.2 | 89.32 | 130.2 | 155 | 17.36 | 19.502 |

| 1.40 g/cm3 | 52.69 | 90.79 | 135.6 | 160.8 | 17.68 | 20.251 | |

| 1.45 g/cm3 | 58.6 | 94.2 | 138.5 | 169.7 | 20.85 | 20.598 | |

| Soil Sample | Dry Density | Reinforcement Rate% | Peak Intensity σ/kPa | Residual Strength σ/kPa | Peak Strain ε/% |

|---|---|---|---|---|---|

| Vegetable red clay | 1.35 g/cm3 | 0% | 89.08 | 48.90 | 2.5% |

| 1.40 g/cm3 | 0% | 102.52 | 74.72 | 2.5% | |

| 1.45 g/cm3 | 0% | 121.91 | 91.43 | 2.5% |

| Soil Sample | Dry Density | Reinforcement Rate% | Peak Intensity σ/kPa | Residual Strength σ/kPa |

|---|---|---|---|---|

| 0.2% basalt fiber-modified red clay | 1.35 g/cm3 | 0.2% | 109.50 | 87.26 |

| 1.40 g/cm3 | 0.2% | 137.98 | 111.78 | |

| 1.45 g/cm3 | 0.2% | 165.93 | 121.91 | |

| 0.3% basalt fiber-modified red clay | 1.35 g/cm3 | 0.3% | 124.90 | 102.66 |

| 1.40 g/cm3 | 0.3% | 149.00 | 133.76 | |

| 1.45 g/cm3 | 0.3% | 191.33 | 145.97 | |

| 0.4% basalt fiber-modified red clay | 1.35 g/cm3 | 0.4% | 98.81 | 92.53 |

| 1.40 g/cm3 | 0.4% | 142.01 | 112.92 | |

| 1.45 g/cm3 | 0.4% | 171.01 | 123.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Geng, Y.; Dong, S.; Ding, S.; Xu, K.; Yan, R.; Liu, F. Study on Mechanical Properties and Microstructure of Basalt Fiber-Modified Red Clay. Sustainability 2023, 15, 4411. https://doi.org/10.3390/su15054411

Song Y, Geng Y, Dong S, Ding S, Xu K, Yan R, Liu F. Study on Mechanical Properties and Microstructure of Basalt Fiber-Modified Red Clay. Sustainability. 2023; 15(5):4411. https://doi.org/10.3390/su15054411

Chicago/Turabian StyleSong, Yu, Yukun Geng, Shuaishuai Dong, Song Ding, Keyu Xu, Rongtao Yan, and Fengtao Liu. 2023. "Study on Mechanical Properties and Microstructure of Basalt Fiber-Modified Red Clay" Sustainability 15, no. 5: 4411. https://doi.org/10.3390/su15054411

APA StyleSong, Y., Geng, Y., Dong, S., Ding, S., Xu, K., Yan, R., & Liu, F. (2023). Study on Mechanical Properties and Microstructure of Basalt Fiber-Modified Red Clay. Sustainability, 15(5), 4411. https://doi.org/10.3390/su15054411