The GHG Intensities of Wind Power Plants in China from a Life-Cycle Perspective: The Impacts of Geographical Location, Turbine Technology and Management Level

Abstract

1. Introduction

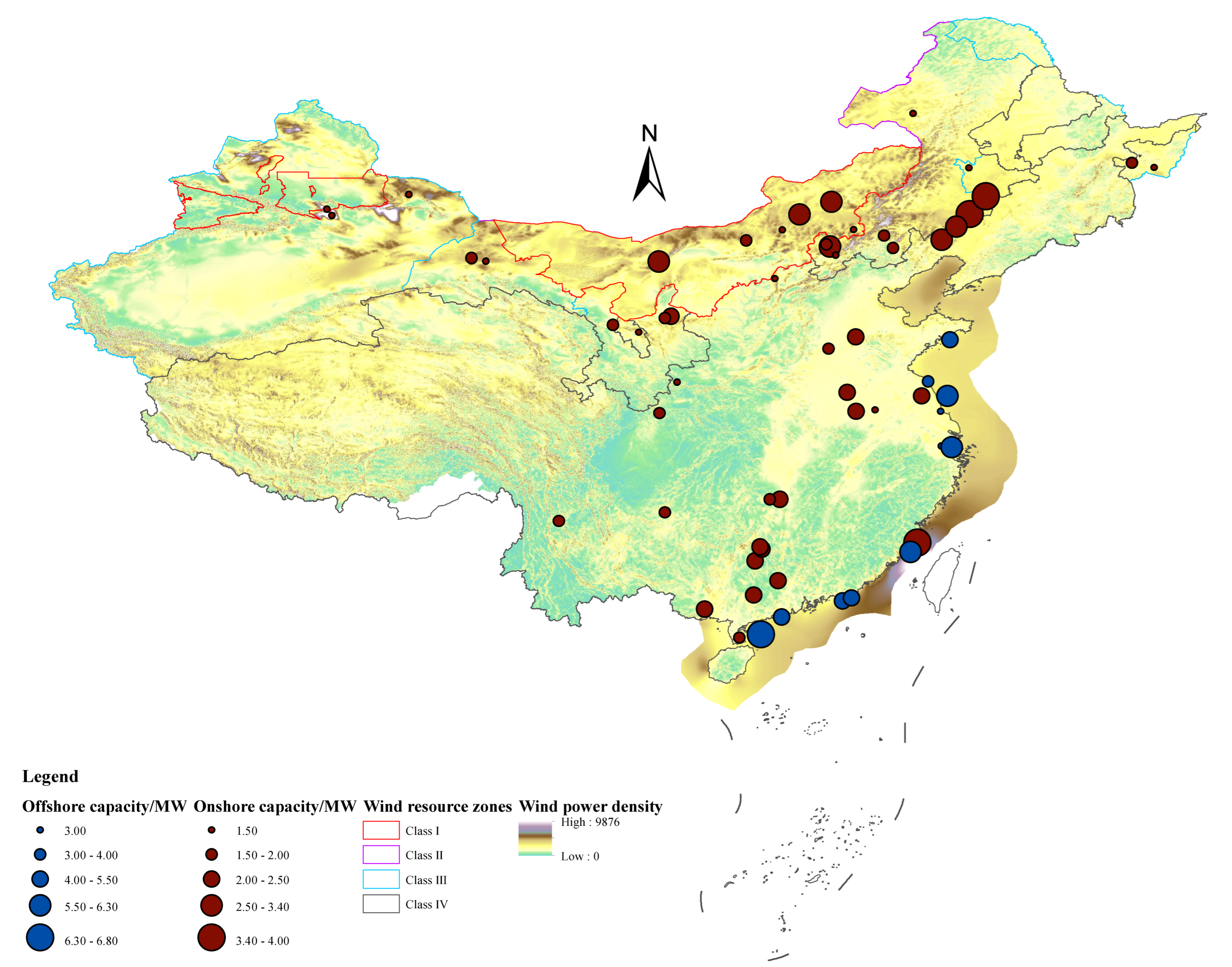

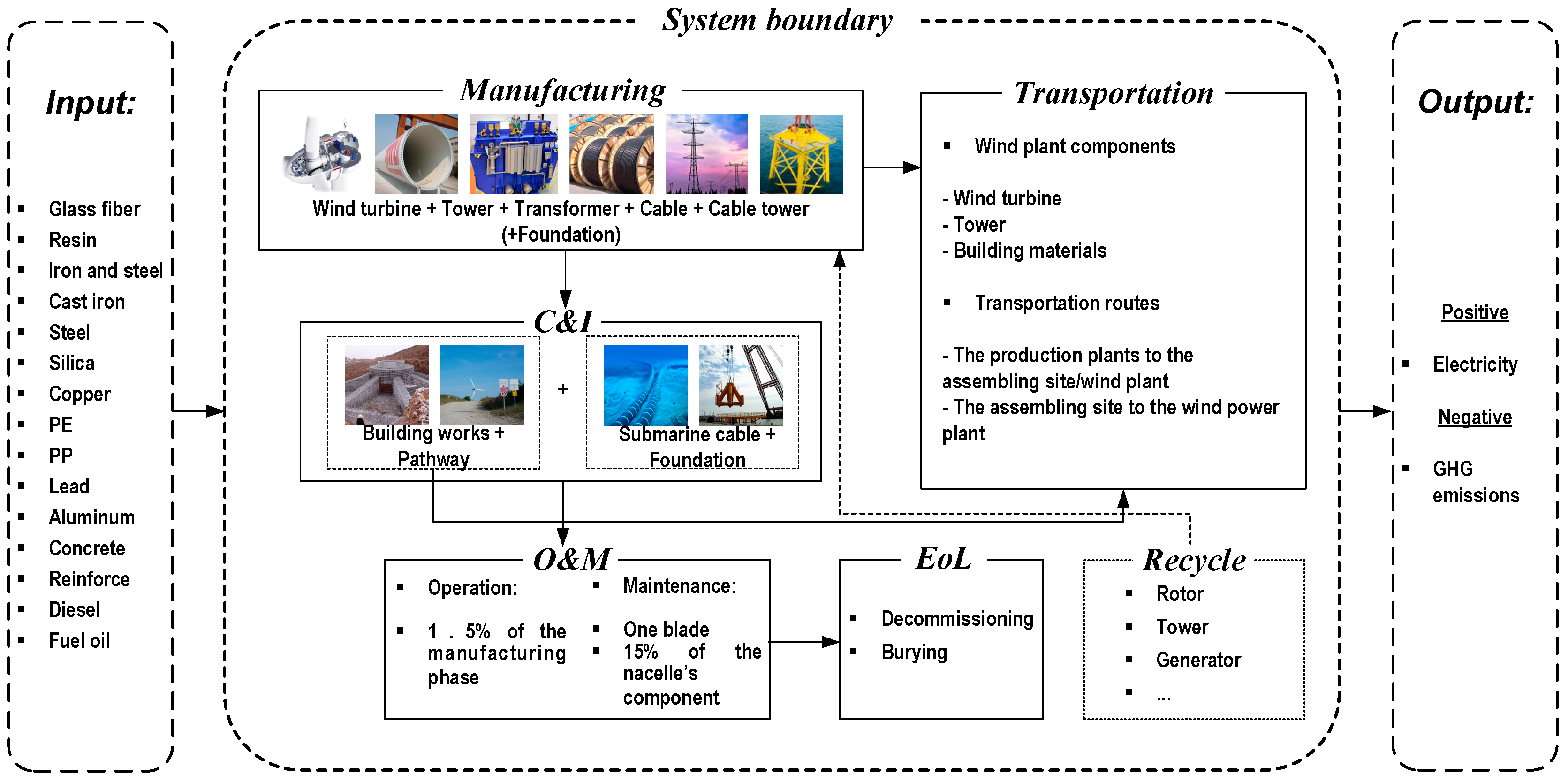

2. Material and Methods

2.1. Goal and Scope Definition

2.2. Assumptions for Calculation

2.2.1. Manufacturing Phase

2.2.2. Transportation Phase

2.2.3. C&I Phase

2.2.4. O&M Phase

2.2.5. EoL Phase

2.2.6. Recycle Phase

3. Results

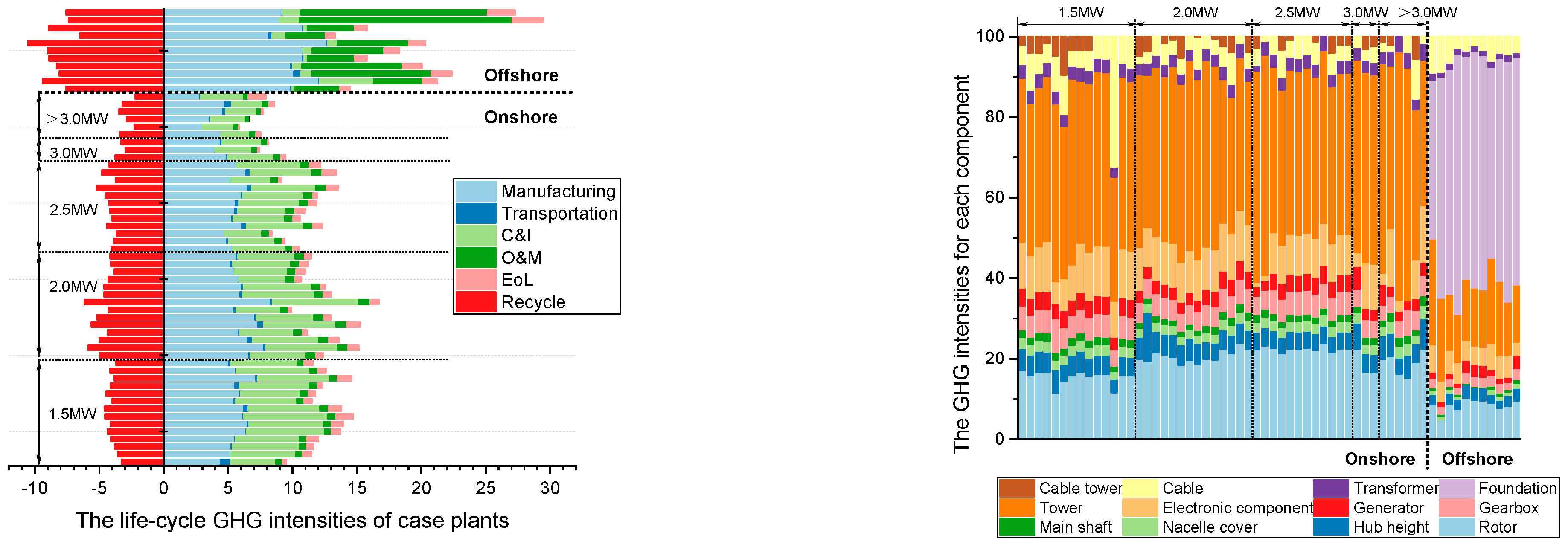

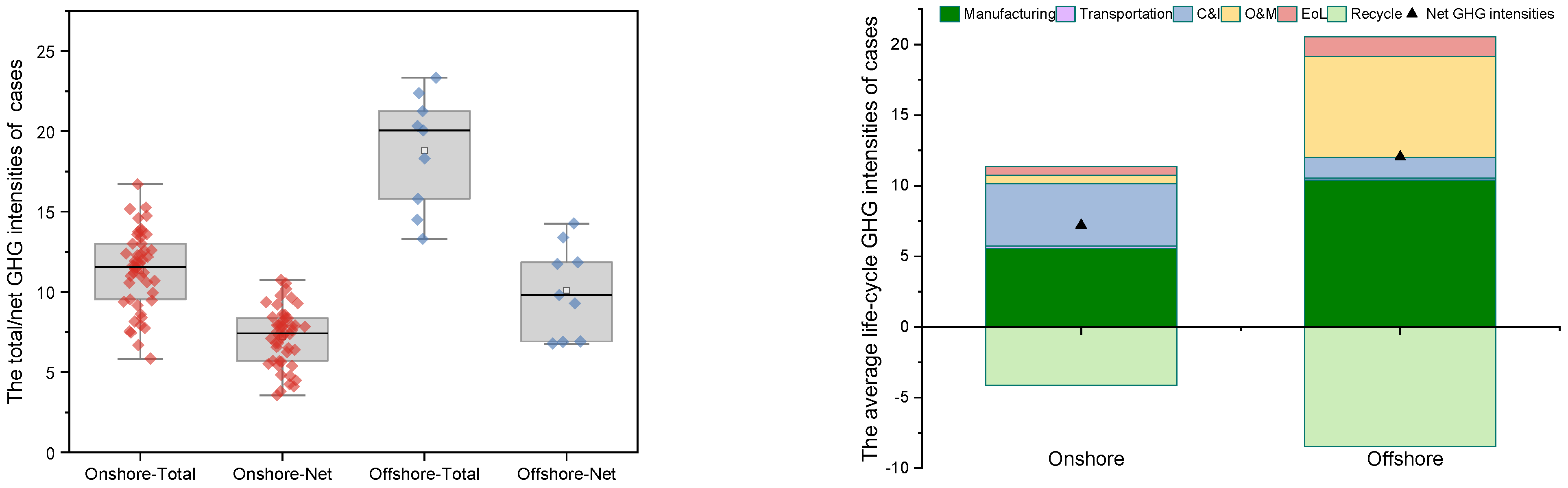

3.1. The Life-Cycle GHG Intensities of Wind Power Plants

3.2. The First Dimension: Geographical Location

3.2.1. Onshore Versus Offshore Wind Power Plants

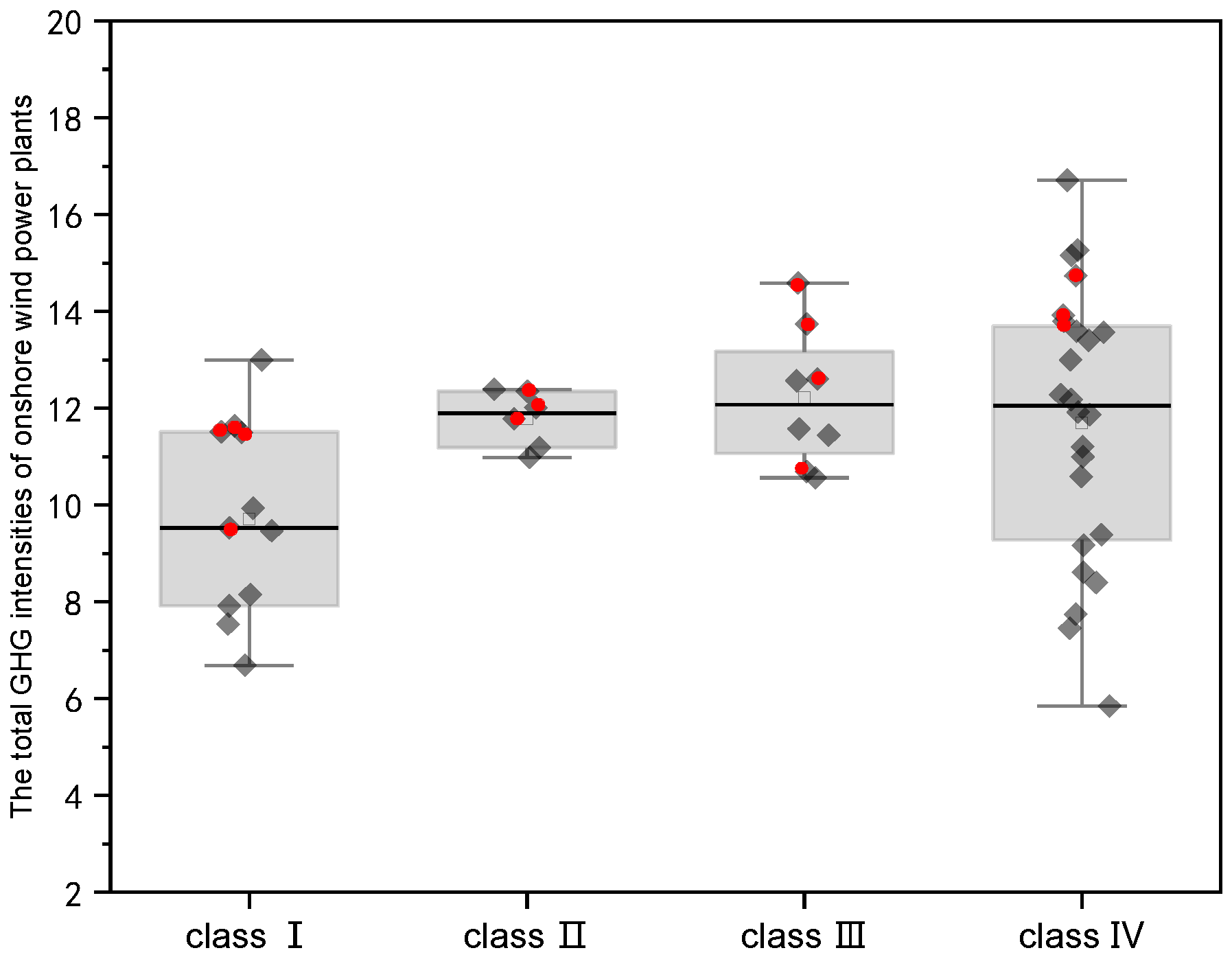

3.2.2. Four Classes of Wind Resource Zones of Onshore Wind Power Plants

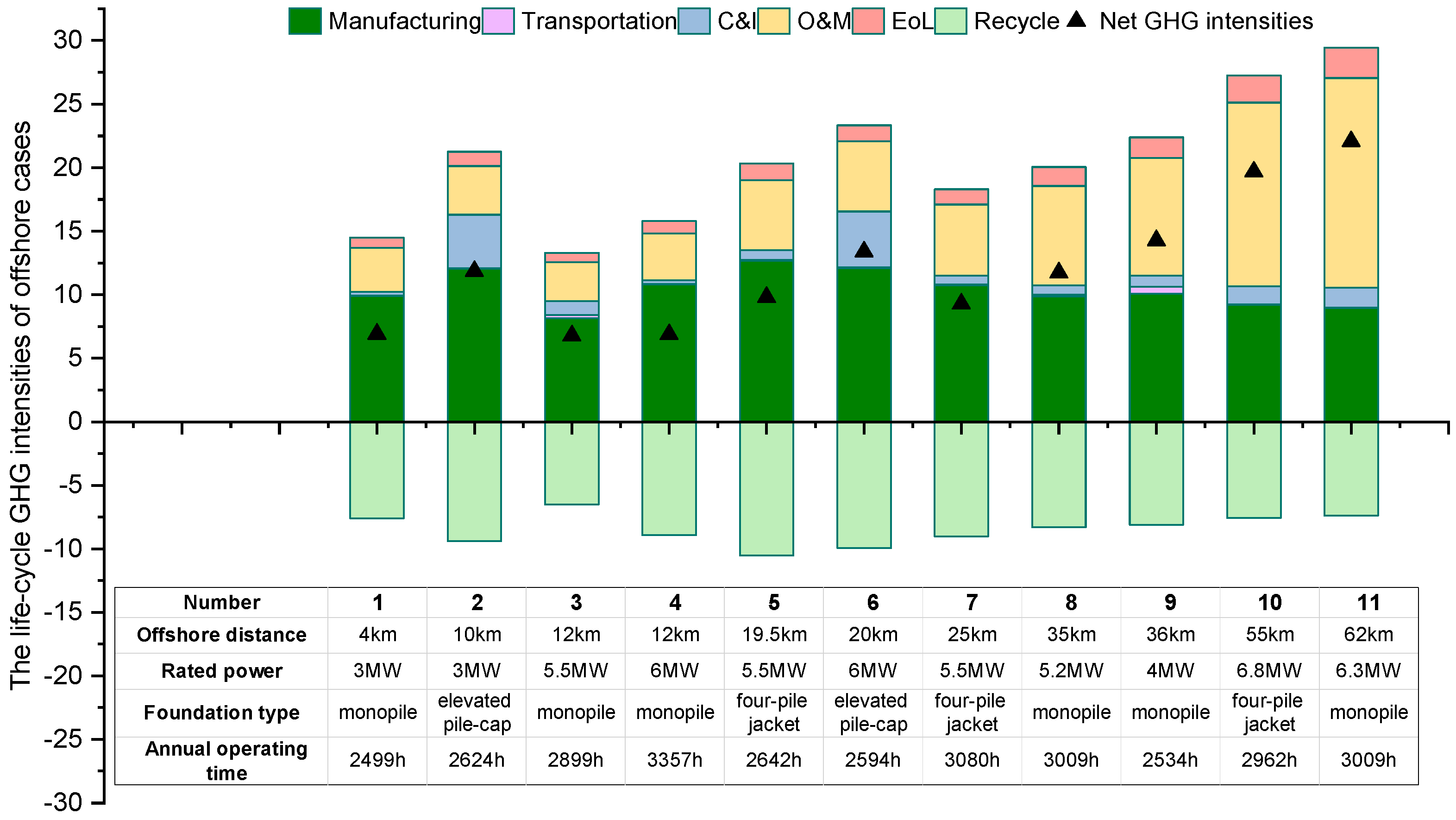

3.2.3. Different Offshore Distance of Offshore Wind Power Plants

3.3. The Second Dimension: Wind Turbine Technology

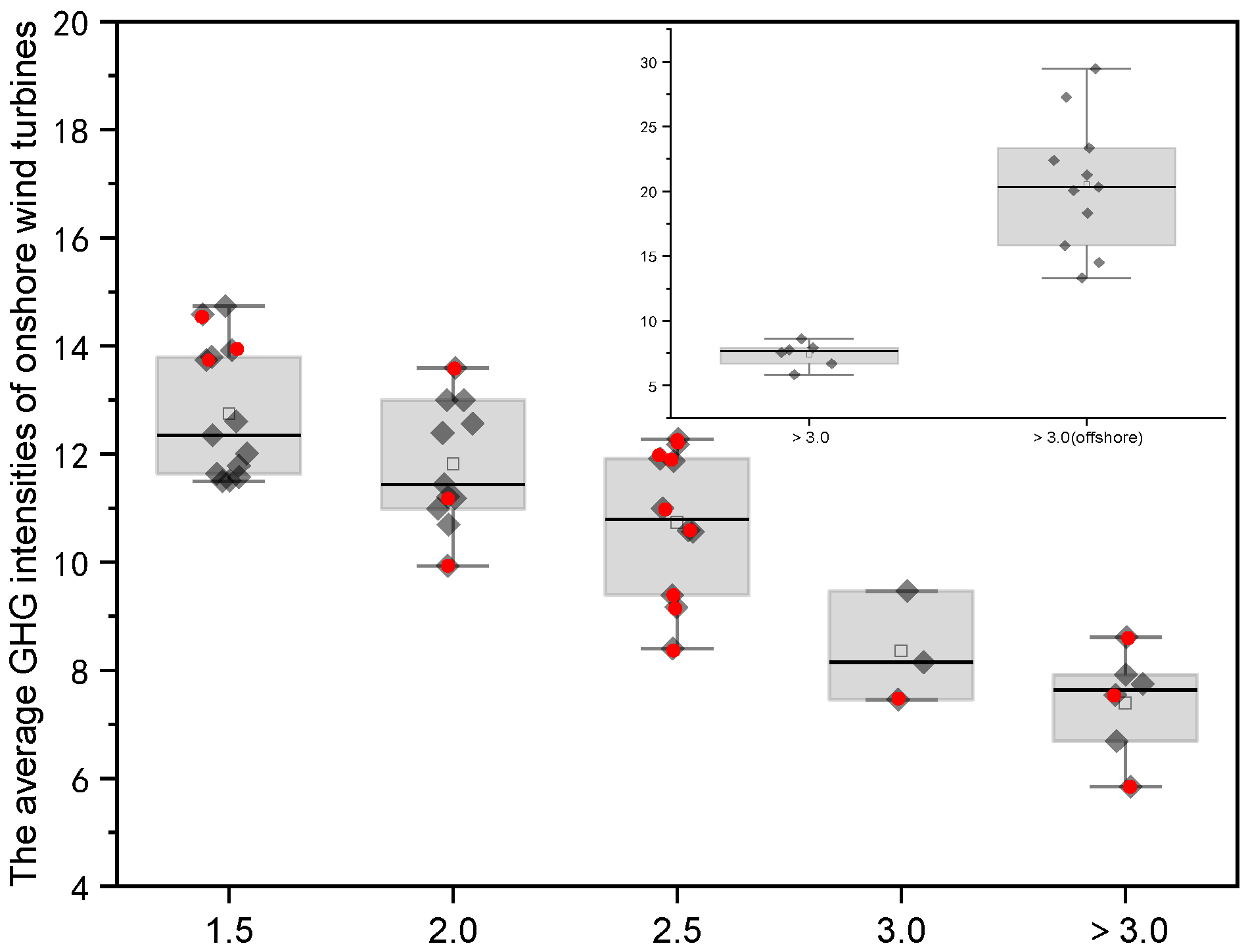

3.3.1. Different Rated Power of Per Wind Turbine

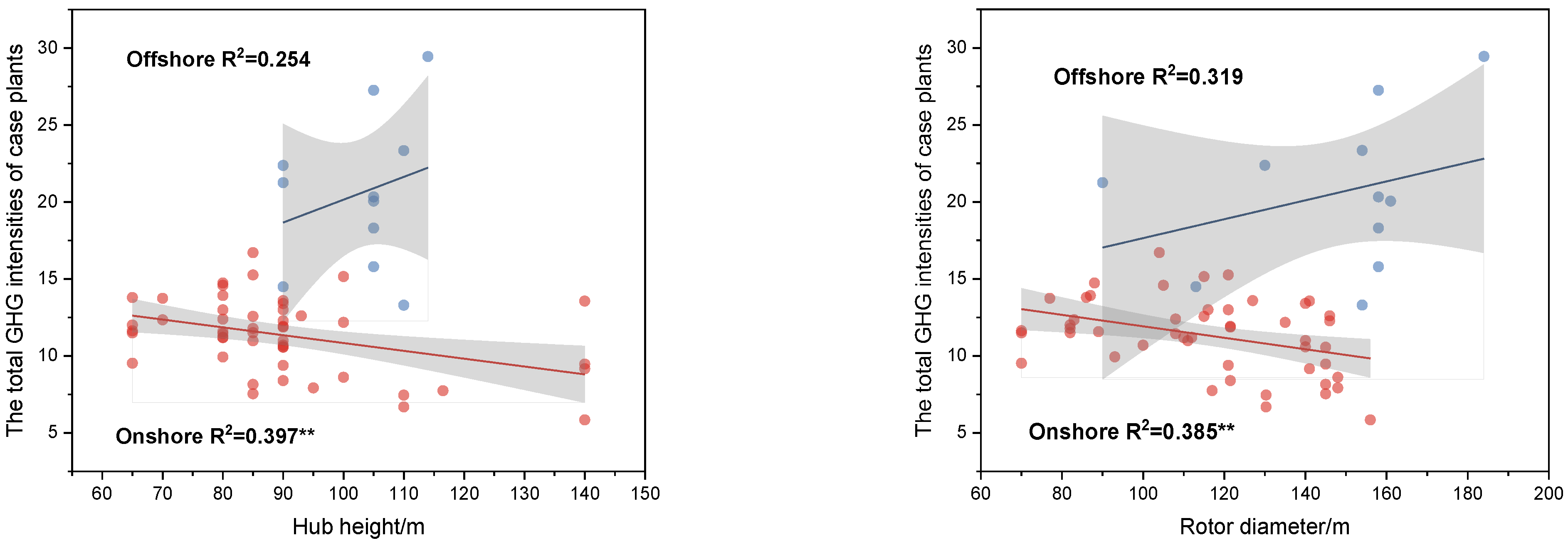

3.3.2. Different Rotor Diameter and Hub Height

3.4. The Third Dimension: Management Level

4. Further Discussions

5. Conclusions and Policy Implications

5.1. Conclusions

5.2. Policy Implications

Author Contributions

Funding

Conflicts of Interest

References

- NEA. China Electric Power Statistical Compilation; NEA: Beijing, China, 2021. [Google Scholar]

- CWP. Beijing Declaration on Wind Energy, Beijing, China on 14 October 2020. 2020. Available online: https://gwec.net/wp-content/uploads/2020/11/Beijing-Declaration-EN.pdf (accessed on 20 October 2022).

- Arvesen, A.; Hertwich, E.G. Environmental implications of large-scale adoption of wind power: A scenario-based life cycle assessment. Environ. Res. Lett. 2011, 6, 045102. [Google Scholar] [CrossRef]

- Bi, X.; Yang, J.; Yang, S. LCA-Based Regional Distribution and Transference of Carbon Emissions from Wind Farms in China. Energies 2022, 15, 198. [Google Scholar] [CrossRef]

- Xu, K.; Chang, J.; Zhou, W.; Li, S.; Shi, Z.; Zhu, H.; Chen, Y.; Guo, K. A comprehensive estimate of life cycle greenhouse gas emissions from onshore wind energy in China. J. Clean. Prod. 2022, 338, 130683. [Google Scholar] [CrossRef]

- Roy, S.; Lam, Y.F.; Hossain, M.U.; Chan, J.C.L. Comprehensive evaluation of electricity generation and emission reduction potential in the power sector using renewable alternatives in Vietnam. Renew. Sustain. Energy Rev. 2022, 157, 112009. [Google Scholar] [CrossRef]

- Liao, X.; Tan, Q.; Zhang, W.; Ma, X.; Ji, J. Analysis of life-cycle greenhouse gas emission reduction potential and cost for China’s power generation sector. Acta Sci. Nat. Univ. Pekin. 2013, 49, 885–891. [Google Scholar]

- Li, H.; Jiang, H.-D.; Dong, K.-Y.; Wei, Y.-M.; Liao, H. A comparative analysis of the life cycle environmental emissions from wind and coal power: Evidence from China. J. Clean. Prod. 2020, 248, 119192. [Google Scholar] [CrossRef]

- Zhao, X.; Cai, Q.; Zhang, S.; Luo, K. The substitution of wind power for coal-fired power to realize China’s CO2 emissions reduction targets in 2020 and 2030. Energy 2017, 120, 164–178. [Google Scholar] [CrossRef]

- Tremeac, B.; Meunier, F. Life cycle analysis of 4.5MW and 250W wind turbines. Renew. Sustain. Energy Rev. 2009, 13, 2104–2110. [Google Scholar] [CrossRef]

- Chen, G.Q.; Yang, Q.; Zhao, Y.H. Renewability of wind power in China: A case study of nonrenewable energy cost and greenhouse gas emission by a plant in Guangxi. Renew. Sustain. Energy Rev. 2011, 15, 2322–2329. [Google Scholar] [CrossRef]

- Wagner, H.-J.; Baack, C.; Eickelkamp, T.; Epe, A.; Lohmann, J.; Troy, S. Life cycle assessment of the offshore wind farm alpha ventus. Energy 2011, 36, 2459–2464. [Google Scholar] [CrossRef]

- Wiedmann, T.O.; Suh, S.; Feng, K.; Lenzen, M.; Acquaye, A.; Scott, K.; Barrett, J.R. Application of Hybrid Life Cycle Approaches to Emerging Energy Technologies—The Case of Wind Power in the UK. Environ. Sci. Technol. 2011, 45, 5900–5907. [Google Scholar] [CrossRef] [PubMed]

- Arvesen, A.; Birkeland, C.; Hertwich, E.G. The Importance of Ships and Spare Parts in LCAs of Offshore Wind Power. Environ. Sci. Technol. 2013, 47, 2948–2956. [Google Scholar] [CrossRef] [PubMed]

- Oebels, K.B.; Pacca, S. Life cycle assessment of an onshore wind farm located at the northeastern coast of Brazil. Renew. Energy 2013, 53, 60–70. [Google Scholar] [CrossRef]

- Yang, J.; Chen, B. Integrated evaluation of embodied energy, greenhouse gas emission and economic performance of a typical wind farm in China. Renew. Sustain. Energy Rev. 2013, 27, 559–568. [Google Scholar] [CrossRef]

- Raadal, H.L.; Vold, B.I.; Myhr, A.; Nygaard, T.A. GHG intensity and energy performance of offshore wind power. Renew. Energy 2014, 66, 314–324. [Google Scholar] [CrossRef]

- Reimers, B.; Özdirik, B.; Kaltschmitt, M. Greenhouse gas emissions from electricity generated by offshore wind farms. Renew. Energy 2014, 72, 428–438. [Google Scholar] [CrossRef]

- Noori, M.; Kucukvar, M.; Tatari, O. Economic Input–Output Based Sustainability Analysis of Onshore and Offshore Wind Energy Systems. Int. J. Green Energy 2015, 12, 939–948. [Google Scholar] [CrossRef]

- Bonou, A.; Laurent, A.; Olsen, S.I. Life cycle assessment of onshore and offshore wind energy-from theory to application. Appl. Energy 2016, 180, 327–337. [Google Scholar] [CrossRef]

- Atilgan, B.; Azapagic, A. Renewable electricity in Turkey: Life cycle environmental impacts. Renew. Energy 2016, 89, 649–657. [Google Scholar] [CrossRef]

- Ji, S.; Chen, B. LCA-based Carbon Footprint of a Typical Wind Farm in China. Energy Procedia 2016, 88, 250–256. [Google Scholar] [CrossRef]

- Kumar, I.; Tyner, W.E.; Sinha, K.C. Input–output life cycle environmental assessment of greenhouse gas emissions from utility scale wind energy in the United States. Energy Policy 2016, 89, 294–301. [Google Scholar] [CrossRef]

- Nagashima, S.; Uchiyama, Y.; Okajima, K. Hybrid input–output table method for socioeconomic and environmental assessment of a wind power generation system. Appl. Energy 2017, 185, 1067–1075. [Google Scholar] [CrossRef]

- Yang, J.; Chang, Y.; Zhang, L.; Hao, Y.; Yan, Q.; Wang, C. The life-cycle energy and environmental emissions of a typical offshore wind farm in China. J. Clean. Prod. 2018, 180, 316–324. [Google Scholar] [CrossRef]

- Gao, C.-K.; Na, H.-M.; Song, K.-H.; Dyer, N.; Tian, F.; Xu, Q.-J.; Xing, Y.-H. Environmental impact analysis of power generation from biomass and wind farms in different locations. Renew. Sustain. Energy Rev. 2019, 102, 307–317. [Google Scholar] [CrossRef]

- Lundie, S.; Wiedmann, T.; Welzel, M.; Busch, T. Global supply chains hotspots of a wind energy company. J. Clean. Prod. 2019, 210, 1042–1050. [Google Scholar] [CrossRef]

- Xie, J.-B.; Fu, J.-X.; Liu, S.-Y.; Hwang, W.-S. Assessments of carbon footprint and energy analysis of three wind farms. J. Clean. Prod. 2020, 254, 120159. [Google Scholar] [CrossRef]

- Li, Q.; Duan, H.; Xie, M.; Kang, P.; Ma, Y.; Zhong, R.; Gao, T.; Zhong, W.; Wen, B.; Bai, F.; et al. Life cycle assessment and life cycle cost analysis of a 40 MW wind farm with consideration of the infrastructure. Renew. Sustain. Energy Rev. 2021, 138, 110499. [Google Scholar] [CrossRef]

- Vélez-Henao, J.-A.; Vivanco, D.F. Hybrid life cycle assessment of an onshore wind farm including direct and indirect services: A case study in Guajira, Colombia. J. Environ. Manag. 2021, 284, 112058. [Google Scholar] [CrossRef]

- Yildiz, N.; Hemida, H.; Baniotopoulos, C. Life Cycle Assessment of a Barge-Type Floating Wind Turbine and Comparison with Other Types of Wind Turbines. Energies 2021, 14, 5656. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, T. Life cycle assessment of CO2 emissions from wind power plants: Methodology and case studies. Renew. Energy 2012, 43, 30–36. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Apostolou, D. Life cycle energy and carbon footprint of offshore wind energy. Comparison with onshore counterpart. Renew. Energy 2017, 108, 72–84. [Google Scholar] [CrossRef]

- Mendecka, B.; Lombardi, L. Life cycle environmental impacts of wind energy technologies: A review of simplified models and harmonization of the results. Renew. Sustain. Energy Rev. 2019, 111, 462–480. [Google Scholar] [CrossRef]

- Lu, X.; McElroy, M.B.; Peng, W.; Liu, S.; Nielsen, C.P.; Wang, H. Challenges faced by China compared with the US in developing wind power. Nat. Energy 2016, 1, 16061. [Google Scholar] [CrossRef]

- Hertwich Edgar, G.; Gibon, T.; Bouman Evert, A.; Arvesen, A.; Suh, S.; Heath Garvin, A.; Bergesen Joseph, D.; Ramirez, A.; Vega Mabel, I.; Shi, L. Integrated life-cycle assessment of electricity-supply scenarios confirms global environmental benefit of low-carbon technologies. Proc. Nat. Acad. Sci. USA 2015, 112, 6277–6282. [Google Scholar] [CrossRef] [PubMed]

- Arvesen, A.; Hertwich, E.G. Assessing the life cycle environmental impacts of wind power: A review of present knowledge and research needs. Renew. Sustain. Energy Rev. 2012, 16, 5994–6006. [Google Scholar] [CrossRef]

- Yang, J. Study on Resource Flow and Life Cycle Environmental Impacts of Wind Power System in China. Ph.D. Thesis, College of Environment, Beijing Normal University, Beijing, China, 2020. [Google Scholar]

- NEA. China Electric Power Statistical Compilation; NEA: Beijing, China, 2016. [Google Scholar]

- Sherman, P.; Chen, X.; McElroy, M. Offshore wind: An opportunity for cost-competitive decarbonization of China’s energy economy. Sci. Adv. 2020, 6, eaax9571. [Google Scholar] [CrossRef]

- Schreiber, A.; Marx, J.; Zapp, P. Comparative life cycle assessment of electricity generation by different wind turbine types. J. Clean. Prod. 2019, 233, 561–572. [Google Scholar] [CrossRef]

- Tsai, L.; Kelly, J.C.; Simon, B.S.; Chalat, R.M.; Keoleian, G.A. Life Cycle Assessment of Offshore Wind Farm Siting: Effects of Locational Factors, Lake Depth, and Distance from Shore. J. Ind. Ecol. 2016, 20, 1370–1383. [Google Scholar] [CrossRef]

- Martínez, E.; Sanz, F.; Pellegrini, S.; Jiménez, E.; Blanco, J. Life cycle assessment of a multi-megawatt wind turbine. Renew. Energy 2009, 34, 667–673. [Google Scholar] [CrossRef]

- Xu, L.; Pang, M.; Zhang, L.; Poganietz, W.-R.; Marathe, S.D. Life cycle assessment of onshore wind power systems in China. Resour. Conserv. Recycl. 2018, 132, 361–368. [Google Scholar] [CrossRef]

- Wang, W.-C.; Teah, H.-Y. Life cycle assessment of small-scale horizontal axis wind turbines in Taiwan. J. Clean. Prod. 2017, 141, 492–501. [Google Scholar] [CrossRef]

- Ou, X.; Zhang, X.; Chang, S. Life-Cycle Analysis of Energy Consumption, GHG Intensity and Regulated Pollutants Emissions of Automotive Fuel Pathways in China; Center of Automotive Energy Research Center, Tsinghua University: Beijing, China, 2008. [Google Scholar]

- NBS. China Energy Statistical Yearbook 2019; NBS: Beijing, China, 2020. [Google Scholar]

- Birkeland, C. Assessing the Life Cycle Environmental Impacts of Offshore Wind Power Generation and Power Transmission in the North Sea, Science in Energy and Environment. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2011. [Google Scholar]

- Huang, Y.-F.; Gan, X.-J.; Chiueh, P.-T. Life cycle assessment and net energy analysis of offshore wind power systems. Renew. Energy 2017, 102, 98–106. [Google Scholar] [CrossRef]

- Topham, E.; McMillan, D. Sustainable decommissioning of an offshore wind farm. Renew. Energy 2017, 102, 470–480. [Google Scholar] [CrossRef]

- Chermak, C. The Environmental Impacts of Wind Integration and Comparison to Conventional Energy Sources: Life Cycle Analysis of Wind Generation and Transmission in Texas. Master’s Thesis, Southern Methodist University, Dallas, TX, USA, 2009. [Google Scholar]

- Mello, G.; Ferreira Dias, M.; Robaina, M. Evaluation of the environmental impacts related to the wind farms end-of-life. Energy Rep. 2022, 8, 35–40. [Google Scholar] [CrossRef]

- Garrett, P.; Rønde, K. Life Cycle Assessment of Electricity Production from an Onshore V90-3.0 MW Wind Plant. PE North West Europe ApS, Copenhagen, Denmark. 2013. Available online: https://www.vestas.com/content/dam/vestas-com/global/en/sustainability/reports-and-ratings/lcas/LCA_V903MW_version_1_1.pdf.coredownload.inline.pdf (accessed on 20 October 2022).

- Topham, E.; McMillan, D.; Bradley, S.; Hart, E. Recycling offshore wind farms at decommissioning stage. Energy Policy 2019, 129, 698–709. [Google Scholar] [CrossRef]

- Lozano-Minguez, E.; Kolios, A.J.; Brennan, F.P. Multi-criteria assessment of offshore wind turbine support structures. Renew. Energy 2011, 36, 2831–2837. [Google Scholar] [CrossRef]

- Caduff, M.; Huijbregts, M.A.J.; Althaus, H.-J.; Koehler, A.; Hellweg, S. Wind Power Electricity: The Bigger the Turbine, The Greener the Electricity? Environ. Sci. Technol. 2012, 46, 4725–4733. [Google Scholar] [CrossRef]

- Dammeier, L.C.; Loriaux, J.M.; Steinmann, Z.J.N.; Smits, D.A.; Wijnant, I.L.; van den Hurk, B.; Huijbregts, M.A.J. Space, Time, and Size Dependencies of Greenhouse Gas Payback Times of Wind Turbines in Northwestern Europe. Environ. Sci. Technol. 2019, 53, 9289–9297. [Google Scholar] [CrossRef]

- Nugent, D.; Sovacool, B.K. Assessing the lifecycle greenhouse gas emissions from solar PV and wind energy: A critical meta-survey. Energy Policy 2014, 65, 229–244. [Google Scholar] [CrossRef]

- Li, J.; Li, S.; Wu, F. Research on carbon emission reduction benefit of wind power project based on life cycle assessment theory. Renew. Energy 2020, 155, 456–468. [Google Scholar] [CrossRef]

- Luo, G.-L.; Li, Y.-L.; Tang, W.-J.; Wei, X. Wind curtailment of China׳s wind power operation: Evolution, causes and solutions. Renew. Sustain. Energy Rev. 2016, 53, 1190–1201. [Google Scholar] [CrossRef]

- Arvesen, A.; Nes, R.N.; Huertas-Hernando, D.; Hertwich, E.G. Life cycle assessment of an offshore grid interconnecting wind farms and customers across the North Sea. Int. J. Life Cycle Assess. 2014, 19, 826–837. [Google Scholar] [CrossRef]

| Reference | Country | Turbine Type | Methods | GHG Intensity g CO2eq/kWh |

|---|---|---|---|---|

| [10] | France | 250 kW-onshore | Process-based LCA | 46.40 |

| 4.5 MW-onshore | 15.80 | |||

| [11] | China | 1.25 MW-onshore | Process-based LCA | 7.20 |

| [12] | Germany | 5 MW-offshore | Process-based LCA | 32.00 |

| [13] | Britain | 2 MW-offshore | Process-based LCA | 13.40 |

| Hybrid LCA | 28.70 | |||

| IO-LCA | 29.70 | |||

| [14] | Norway | 5 MW-offshore | Hybrid LCA | 35.10 |

| [15] | Brazil | 1.5 MW-onshore | Process-based LCA | 7.10 |

| [16] | China | 1.5 MW-onshore | Process-based LCA | 7.20 |

| [17] | Britain | 5 MW-offshore | Process-based LCA | 18.00–31.40 |

| [18] | Germany | 5 MW-offshore | Process-based LCA | 16.80 |

| [19] | America | 2 MW, 3 MW-onshore | Hybrid LCA | 17.30 |

| [20] | Europe | 2.3 MW, 3.2 MW-onshore | Process-based LCA | 7.00 |

| 4.0 MW, 6.0 MW-offshore | Process-based LCA | 11.00 | ||

| [21] | Turkey | 2 MW-onshore | Process-based LCA | 7.30 |

| [22] | China | 2 MW-onshore | IO-LCA | 7.55 |

| [23] | America | 1.5 MW-onshore | IO-LCA | 14.50–28.50 |

| [24] | Japan | 1.65 MW-onshore | IO-LCA | 22.77 |

| [25] | China | 3.6 MW, 5 MW-offshore | Process-based LCA | 25.50 |

| [26] | China | 850 kW-onshore | Process-based LCA | 86.50 |

| [27] | Germany | 2 MW, 3 MW-onshore | Process-based LCA | 11.70–18.30 |

| [28] | China | 600 kW-onshore | Process-based LCA | 2.02 |

| [29] | China | 2 MW-onshore | Process-based LCA | 16.40–28.20 |

| [30] | Colombia | 1.3 MW-onshore | Hybrid LCA | 12.93 |

| [31] | Europe | 2 MW-offshore | Process-based LCA | 9.49–18.60 |

| 2 MW-onshore | Process-based LCA | 7.09 | ||

| 5 MW-offshore | Process-based LCA | 11.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Zhang, L. The GHG Intensities of Wind Power Plants in China from a Life-Cycle Perspective: The Impacts of Geographical Location, Turbine Technology and Management Level. Sustainability 2023, 15, 4449. https://doi.org/10.3390/su15054449

Feng Y, Zhang L. The GHG Intensities of Wind Power Plants in China from a Life-Cycle Perspective: The Impacts of Geographical Location, Turbine Technology and Management Level. Sustainability. 2023; 15(5):4449. https://doi.org/10.3390/su15054449

Chicago/Turabian StyleFeng, Yashuang, and Lixiao Zhang. 2023. "The GHG Intensities of Wind Power Plants in China from a Life-Cycle Perspective: The Impacts of Geographical Location, Turbine Technology and Management Level" Sustainability 15, no. 5: 4449. https://doi.org/10.3390/su15054449

APA StyleFeng, Y., & Zhang, L. (2023). The GHG Intensities of Wind Power Plants in China from a Life-Cycle Perspective: The Impacts of Geographical Location, Turbine Technology and Management Level. Sustainability, 15(5), 4449. https://doi.org/10.3390/su15054449