Research on Biomass Waste Utilization Based on Pollution Reduction and Carbon Sequestration

Abstract

1. Introduction

2. Materials and Methods

2.1. Biomass Waste Utilization Based on Pollution Reduction and Carbon Sequestration

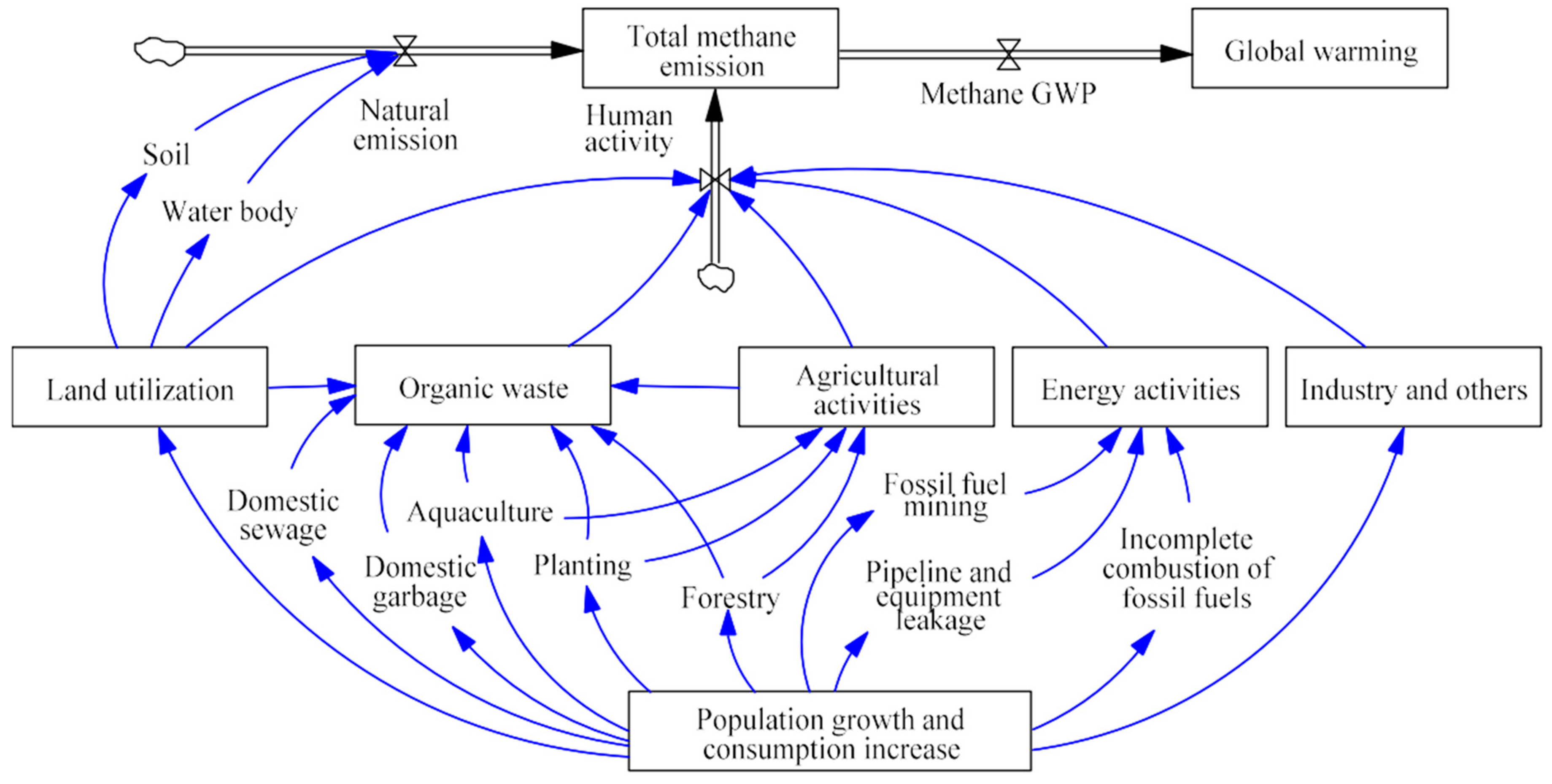

2.1.1. Necessity Analysis of Carbon Transfer

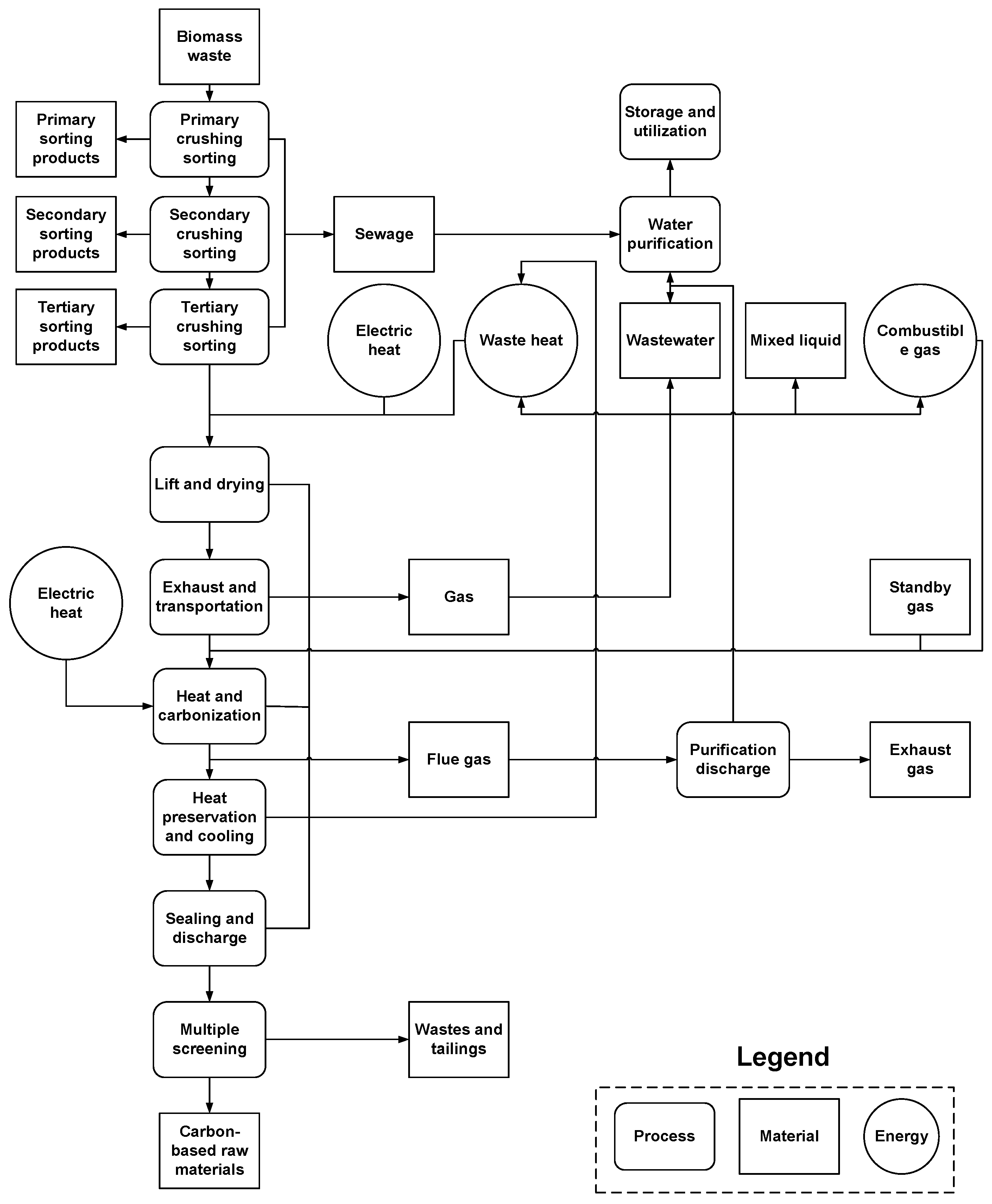

2.1.2. A New Biomass Waste Utilization Mode

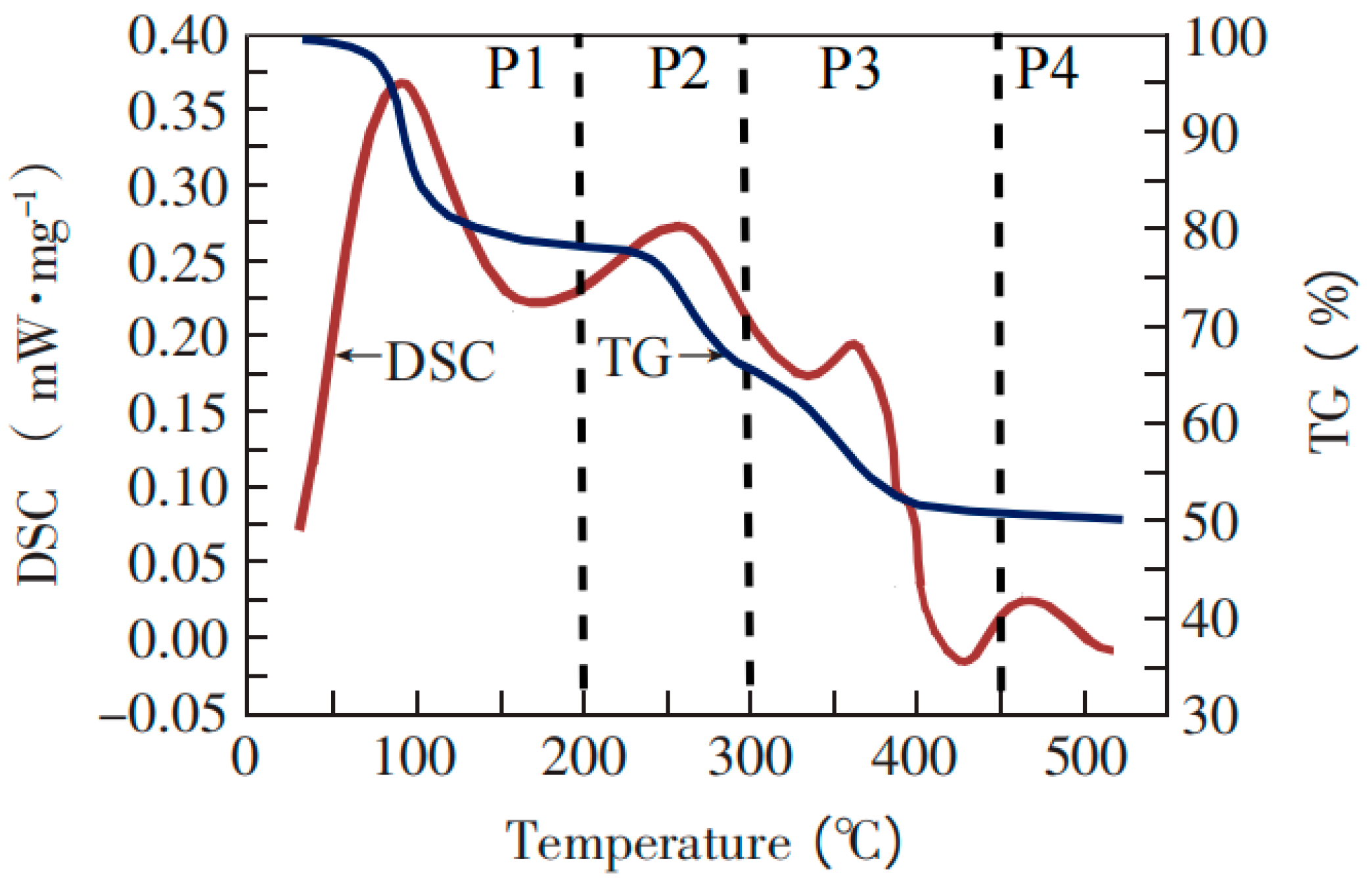

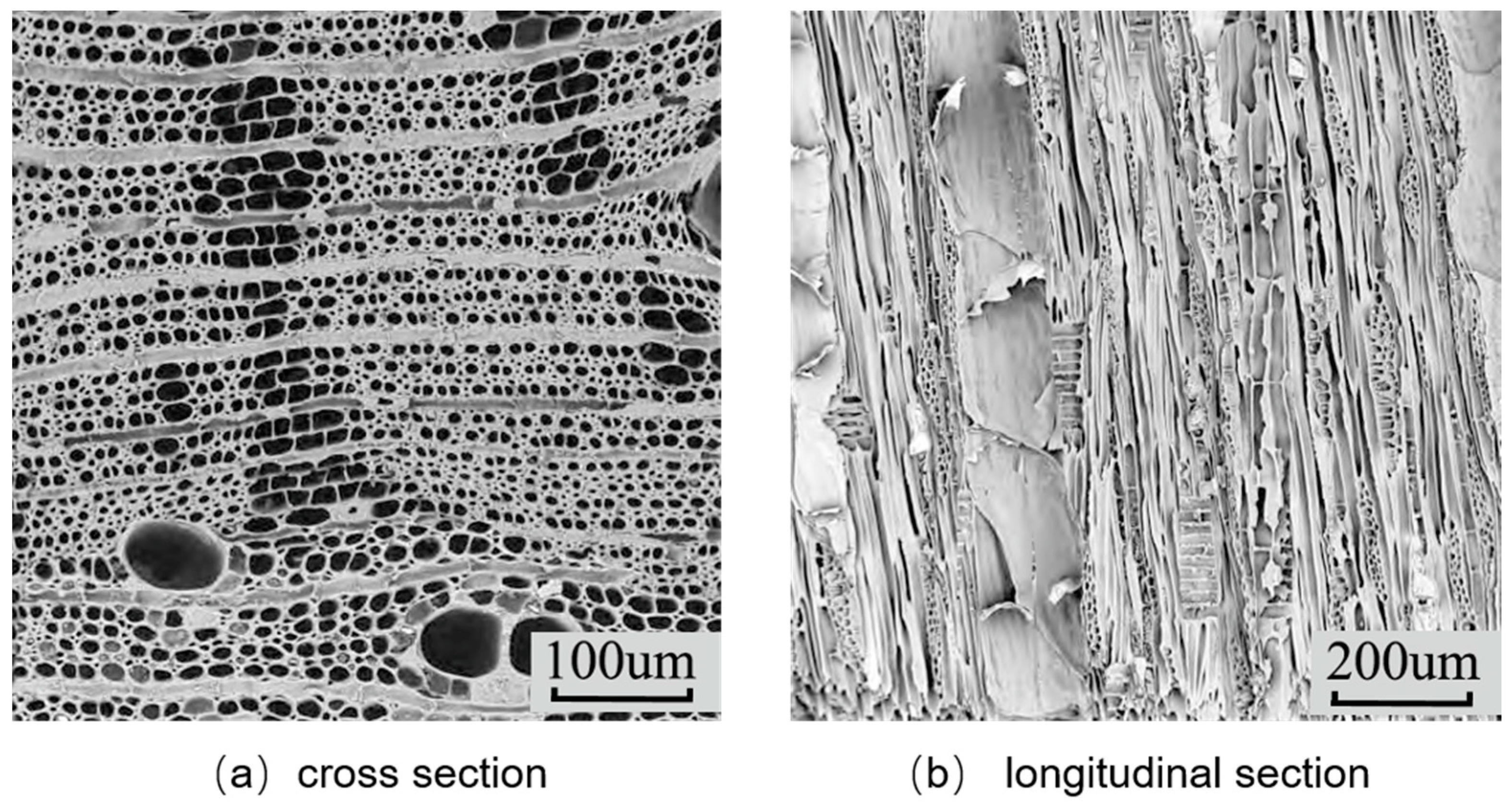

2.1.3. Experimental Study on Carbonization

3. Results and Discussion

3.1. Methods and Procedures of the Carbonization Experiment

3.2. Experimental Results and Analysis

3.3. In-Situ Carbonization Process of Biomass Waste

3.4. Resource Utilization of Biomass Waste Carbonization Products

4. Conclusions

- This paper proposes an in-situ, harmlessness, homogenization, reduction, automation, inorganic transformation, resource utilization, and carbon sequestration biomass waste utilization mode to reduce waste recycling costs, promote resource utilization, achieve pollution reduction, and carbon sequestration.

- 450–600 °C is a reasonable temperature for in-situ carbonization, which can meet the needs of harmlessness, inorganic transformation, homogenization, and reduction.

- The solid carbonization products of biomass waste can make the soil fertile through fertilization. Carbonization products by raw materialization can realize the resource utilization of biomass waste and carbon sequestration. Particularly, building materials by carbonization products reduce the use of high pollution and high energy consumption materials such as cement and steel, moreover, they store carbon in buildings for a long time and construct an artificial carbon pool.

- The benefits of using carbonization products to produce building materials, economic benefits, carbon trading benefits, and the social benefits of saving resources and reducing pollution need to be calculated totally.

- The implementation of pollution reduction and carbon reduction cannot be a quick success, and the long physical, chemical, and biological effects of secondary emissions of organic carbon and the harm of methane emission must be considered. In short, in order to achieve the goal of carbon peak and carbon neutrality, the scientific utilization of biomass waste is necessary and urgent.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- IPCC. IPCC Fifth Assessment Report—Synthesis Report; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Fang, K.; Tang, Y.; Zhang, Q.; Song, J.; Wen, Q.; Sun, H.; Ji, C.; Xu, A. Will China peak its energy-related carbon emissions by 2030? Lessons from 30 Chinese provinces. Appl. Energy 2019, 255, 113852–113864. [Google Scholar] [CrossRef]

- Shindell, D.; Smith, C.J. Climate and air-quality benefits of a realistic phase-out of fossil fuels. Nature 2019, 573, 408–411. [Google Scholar] [CrossRef] [PubMed]

- Olivier, J.; Peters, J. Trends in Global CO2 and Total Greenhouse Gas Emissions: 2020 Report; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2020. [Google Scholar]

- IEA. Global Methane Tracker 2022. Available online: https://www.iea.org/reports/global-methane-tracker-2022 (accessed on 4 February 2023).

- He, C.; Chi, Y.; Xiang, P.; Xu, Y.; Wu, Y. CH4 emission scenario analysis for China: IPAC results. Trans. Atmos. Sci. 2022, 45, 414–427. [Google Scholar]

- Hu, W.; Huang, M.; Wang, H. Methane emission and mitigation strategy of animal husbandry under low carbon background. J. Huazhong Agric. Univ. 2022, 41, 115–123. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Emissions Gap Report; United Nations Environment Programme: Nairobi, Kenya, 2020. [Google Scholar]

- Liu, L.; Zhang, Y.; Li, P.; Fang, X.; Liang, C. Progress on Landfill Methane Oxidation in the Cover Soil. Shandong Chem. Ind. 2022, 51, 198–200. [Google Scholar] [CrossRef]

- IPCC. The Final Draft Report of the Working Group I Contribution to the IPCC 5th Assessment Report; IPCC: Geneva, Switzerland, 2013. [Google Scholar]

- EPA. Global Mitigation of non-CO2 Greenhouse Gases: 2010–2030; Environmental Protection Agency: Washington, DC, USA, 2013. [Google Scholar]

- Cai, C.; He, C.; Hu, B. Progresses in the classification and mechanism of methane-oxidizing bacteria. J. Zhejiang Univ. Agric. Life Sci. 2016, 42, 273–281. [Google Scholar]

- Wang, Z.; Li, Y.; Huang, H. Research on Calculation Carbon Emission of Urban Residents’ Food Consumption: The Case of the Provincial Capitals in the Middle Reaches of Yangtze Rive. Ecol. Econ. 2022, 38, 38–44+52. [Google Scholar]

- Ministry of Agriculture and Rural Affairs of the People’s Republic of China. National Crop Straw Comprehensive Utilization Report. Available online: http://www.moa.gov.cn/xw/zwdt/202210/t20221010_6412962.htm (accessed on 4 February 2023).

- Xu, F.; Xu, C.; Yang, Y.; Zhang, Z. Advances in hydrothermal fertilizer production technology from biomass waste. Appl. Chem. Ind. 2022, 51, 1833–1838. [Google Scholar] [CrossRef]

- Shi, X.; Zheng, G.; Gao, D.; Chen, T. Quantity of available nutrient in livestock manure and its potential of replacing chemical fertilizers in China. Resour. Sci. 2021, 43, 403–411. [Google Scholar] [CrossRef]

- Song, D.; Hou, S.; Wang, X.; Liang, G.; Zhou, W. Nutrient resource quantity of crop straw and its potential of substituting. J. Plant Nutr. Fertil. 2018, 24, 1–21. [Google Scholar] [CrossRef]

- Bian, R.; Li, L. Biomass waste treatment and agricultural carbon neutralization. China Sci. 2021, 73, 22–26. [Google Scholar]

- Fang, J.; Guo, Z.; Hu, H.; Kato, T.; Muraoka, H.; Son, Y. Forest biomass carbon sinks in East Asia, with special reference to the relative contributions of forest expansion and forest growth. Glob. Chang. Biol. 2014, 20, 2019–2030. [Google Scholar] [CrossRef] [PubMed]

- Weng, L.; Li, W.; Zhang, M.; Tan, J. Spatial-temporal Evolution of Net Carbon Sink of Farmland Ecosystem in Jiangsu Province. Resour. Environ. Yangtze Basin 2022, 31, 1584–1594. [Google Scholar]

- Luo, Y.; Qiu, L.; Long, J.; Chen, H.; Wu, T.; Li, J. Research on the Carbon Sink Contribution of Subtropical Paddy Field Soil Under Different Straw Return Rates. Acta Pedol. Sin. 2023, 1, 1–18. [Google Scholar] [CrossRef]

- Khan, T.A.; Saud, A.S.; Jamari, S.S.; Rahim, M.H.A.; Park, J.-W.; Kim, H.-J. Hydrothermal carbonization of lignocellulosic biomass for carbon rich material preparation: A review. Biomass Bioenergy 2019, 130, 105384–105400. [Google Scholar] [CrossRef]

- Torres-Mayanga, P.C.; Lachos-Perez, D.; Mudhoo, A.; Kumar, S.; Brown, A.B.; Tyufekchiev, M.; Dragone, G.; Mussatto, S.I.; Rostagno, M.A.; Timko, M.; et al. Production of biofuel precursors and value-added chemicals from hydrolysates resulting from hydrothermal processing of biomass: A review. Biomass Bioenergy 2019, 130, 105397–105422. [Google Scholar] [CrossRef]

- He, C.; Chen, C.-L.; Giannis, A.; Yang, Y.; Wang, J.-Y. Hydrothermal gasification of sewage sludge and model compounds for renewable hydrogen production: A review. Renew. Sustain. Energy Rev. 2014, 39, 1127–1142. [Google Scholar] [CrossRef]

- Ding, P.; Ye, F.; Zhang, K.; Huang, Z.; Zhang, S. Utilization status and development prospect of agricultural biomass energy in China. Agric. Henan 2020, 19, 22–23. [Google Scholar] [CrossRef]

- Bai, J.; Wang, W.; Li, Y.; Li, Z.; Zhao, L. Advances in residues of tetracyclines and its degradation by aerobic composting in pig manure in China. Soil Fertil. Sci. China 2022, 3, 231–238. [Google Scholar] [CrossRef]

- Xu, W.; Wu, J.; Zhang, S. Transportation cost accounting on straw fuel and optimization analysis for straw power plants. Technol. Econ. Areas Commun. 2019, 21, 70–74. [Google Scholar]

- Dong, S. Development Status and Prospect of Carbon Capture, Utilization and Storage (CCUS) Technology in China. Guangdong Chem. Ind. 2021, 48, 69–70. [Google Scholar]

- Zhou, Y.; Cai, B.; Cao, L. Study on environmental emergency managment of China’s carbon sequestration projects. Environ. Eng. 2018, 36, 1–5. [Google Scholar]

- Wei, N.; Liu, S.; Li, X.; Zhang, X.; Jia, G. Key technologies inventory of CO2 geological utilization and storage. Clean Coal Technol. 2022, 28, 14–25. [Google Scholar]

- Fu, Y.; Tian, D.; Hou, Z.; Wang, M.; Zhang, N. Review on the evaluation of global forest carbon sink function. J. Beijing For. Univ. 2022, 44, 1–10. [Google Scholar] [CrossRef]

- Yu, G.; Chen, Z.; Piao, S.; Peng, C.; Ciais, P.; Wang, Q.; Li, X.; Zhu, X. High carbon dioxide uptake by subtropical forest ecosystems in the East Asian monsoon region. Proc. Natl. Acad. Sci. USA 2014, 111, 4910–4915. [Google Scholar] [CrossRef]

- Trumbore, S.; Brando, P.; Hartmann, H. Forest health and global change. Science 2015, 349, 814–818. [Google Scholar] [CrossRef]

- IPCC. Climate Change 2014: Mitigation of Climate Change; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Guo, L.; Zhang, L.; Liu, L.; Sheng, F.; Cao, C.; Li, C. Effects of long-term no tillage and straw return on greenhouse gas emissions and crop yields from a rice-wheat system in central China. Agric. Ecosyst. Environ. 2021, 322, 107650–107659. [Google Scholar] [CrossRef]

- Xu, Z.; Xue, Y.; Zhang, J.; Sun, R.; Shi, Z. Research hotspots and frontiers of comprehensive utilization of straw on bibliometric analysis. Ecol. Environ. Sci. 2021, 30, 1310–1320. [Google Scholar] [CrossRef]

- Lei, Z.; Yang, S.; Li, Y.Y.; Wen, W.; Wang, X.C.; Chen, R. Application of anaerobic membrane bioreactors to municipal wastewater treatment at ambient temperature: A review of achievements, challenges, and perspectives. Bioresour. Technol. 2018, 267, 756–768. [Google Scholar] [CrossRef]

- Yuan, F.; Wang, L.; Sheng, M. The application of crop phytoliths for reviewing occluded organic carbon. Chin. J. Eco-Agric. 2020, 28, 1932–1940. [Google Scholar] [CrossRef]

- National Bureau of Statistics. National Data. Available online: https://data.stats.gov.cn/easyquery.htm?cn=C01 (accessed on 4 February 2023).

- Yan, D.; Xue, Y.; Xu, Z.; Sun, Y.; Sun, R.; Hu, X. Current utilization status, technical models and development proposals for direct crop straw returning to field in China. Chin. J. Agric. Resour. Reg. Plan. 2023, 1, 1–17. [Google Scholar]

- Li, S.; Wu, Y.; Chen, J. The Industrial Opportunities of Renewable Resources Utilization in China’s Zero Carbon Picture; Rocky Mountain Institute: Basalt, CO, USA, 2021. [Google Scholar]

- Min, C.; Wang, Y.; Xu, H.; Wang, L.; Kang, M.; Wang, M. Progress of rural solid waste resource utilization in China. J. Agric. Resour. Environ. 2020, 37, 151–160. [Google Scholar] [CrossRef]

- Yang, Z. Experimental Study on Physical and Mechanical Properties of Wood After High Temperature; Xi’an University of Architecture and Technology: Xi’an, China, 2015. [Google Scholar]

- Friquin, K.L. Material properties and external factors influencing the charring rate of solid wood and glue-laminated timber. Fire Mater. 2011, 35, 303–327. [Google Scholar] [CrossRef]

- Zhang, X.; Qin, W.; Li, F.; Yang, Z. Study on thermal decomposition characteristics of ancient building wood. Fire Tech. Prod. Inf. 2008, 12, 3–5. [Google Scholar]

- Wang, P.; Cheng, X.; Yan, X.; Zhou, F. Preparation and Study of Wood Ceramics from Wood Powder and Epoxy Resin. Bull. Chin. Ceram. Soc. 2008, 27, 34–37+54. [Google Scholar] [CrossRef]

- Zhang, W. Design and Experimental Study of Biomass Carbonization Furnace Structure; Shihezi University: Shihezi, China, 2013. [Google Scholar]

- Sun, W. Towards the Harmonious Architecture; Hefei University of Technology Press: Hefei, China, 2013; pp. 144–147. [Google Scholar]

- Wang, S.; Ai, S.; Nzediegwu, C.; Kwak, J.H.; Islam, M.S.; Li, Y.; Chang, S.X. Carboxyl and hydroxyl groups enhance ammonium adsorption capacity of iron (III) chloride and hydrochloric acid modified biochars. Bioresour. Technol. 2020, 309, 123390. [Google Scholar] [CrossRef] [PubMed]

- Roy, H.; Islam, M.S.; Arifin, M.T.; Firoz, S.H. Chitosan-ZnO decorated Moringa oleifera seed biochar for sequestration of methylene blue: Isotherms, kinetics, and response surface analysis. Environ. Nanotechnol. Monit. Manag. 2022, 18, 100752. [Google Scholar] [CrossRef]

- Zhu, J.; Chen, F.; Huang, Y.; Xiong, D.; Liu, Y. Effect of activated carbon on methane production in the mixed anaerobic fermentation with straw and pig manure. Hubei Agric. Sci. 2022, 61, 44–49. [Google Scholar] [CrossRef]

- Fu, W.; Xu, X.; Wei, L.; Ye, Z.; Ouyang, X. The effect of biochar agricultural application on the carbon sequestration and emission reduction: A review. J. Nanjing Univ. Inf. Sci. Technol. 2023, 1, 1–21. [Google Scholar]

- Shi, W.; Ju, Y.; Bian, R.; Li, L.; Joseph, S.; Mitchell, D.R.G.; Munroe, P.; Taherymoosavi, S.; Pan, G. Biochar bound urea boosts plant growth and reduces nitrogen leaching. Sci. Total Environ. 2020, 701, 134424–134433. [Google Scholar] [CrossRef]

- Zhang, Y.; Chi, X.; Kang, R. Research, Development and Application Trends of CCS Technology Worldwide. Sino-Glob. Energy 2020, 25, 1–10. [Google Scholar]

| Gas Products (%) | Carbonization Temperature (°C) | |||

|---|---|---|---|---|

| 200 | 300 | 450 | 600 | |

| Water | 23.75 | 30.37 | 31.14 | 31.83 |

| Carbon dioxide | 0.06 | 1.74 | 3.77 | 3.95 |

| Methane | 0.01 | 0.15 | 2.67 | 2.58 |

| Carbon monoxide | 0.01 | 0.72 | 2.16 | 2.25 |

| Hydrogen | 0.01 | 0.03 | 0.11 | 0.17 |

| Others | 0.15 | 1.55 | 7.42 | 7.63 |

| Total 1 | 23.99 | 34.56 | 47.27 | 48.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, W.; Sun, Y.; Hong, X.; Zhang, Y.; Liu, C. Research on Biomass Waste Utilization Based on Pollution Reduction and Carbon Sequestration. Sustainability 2023, 15, 4535. https://doi.org/10.3390/su15054535

Sun W, Sun Y, Hong X, Zhang Y, Liu C. Research on Biomass Waste Utilization Based on Pollution Reduction and Carbon Sequestration. Sustainability. 2023; 15(5):4535. https://doi.org/10.3390/su15054535

Chicago/Turabian StyleSun, Wanghu, Yuning Sun, Xiaochun Hong, Yuan Zhang, and Chen Liu. 2023. "Research on Biomass Waste Utilization Based on Pollution Reduction and Carbon Sequestration" Sustainability 15, no. 5: 4535. https://doi.org/10.3390/su15054535

APA StyleSun, W., Sun, Y., Hong, X., Zhang, Y., & Liu, C. (2023). Research on Biomass Waste Utilization Based on Pollution Reduction and Carbon Sequestration. Sustainability, 15(5), 4535. https://doi.org/10.3390/su15054535