Technology Gap Efficiency of Small-Scale Rice Processors in Anambra State, Nigeria

Abstract

1. Introduction

1.1. Background to the Study

1.2. Statement of the Problem

- i.

- Estimating the group-specific processing function for the participants and non-participants of the agricultural intervention program;

- ii.

- Estimating the economic-specific processing function for the rice industry;

- iii.

- Describing the TGR, TE and MTE of the small-scale rice processors in the study;

- iv.

- Identifying the challenges of small-scale rice processing in the study area.

2. Literature Review

2.1. Conceptual Review

2.1.1. Small-Scale Rice Processing

2.1.2. Technical Efficiency of Small-Scale Rice Processing

2.1.3. Technological Gap Ratio (TGR) in Small-Scale Rice Processing

2.1.4. Meta-Technical Efficiency (MTE) of Small-Scale Rice Processing

2.1.5. Challenges of Rice Production and Processing in Nigeria

- Lack of infrastructure: inadequate roads, rail, or water infrastructure to facilitate the transportation of paddy and milled rice to and from production sites makes it difficult to efficiently source and distribute rice.

- Poor milling capacity: there are inadequate modern rice mills in Nigeria and the existing ones are using outdated, inefficient technology, which makes the milling process slow and costly.

- Inadequate storage and preservation facilities: poor storage and preservation infrastructure prevent the effective use of modern storage technologies, leading to a significant loss of paddy and milled rice due to deterioration and spoilage.

- Low yield and productivity of farms: Nigerian farmers continue to use traditional methods of cultivation and low-yielding varieties of rice, which reduces potential yields.

- Lack of access to finance: small-scale rice processors often lack access to the credit and capital needed to purchase the necessary processing equipment to improve their operations.

- Environmental degradation: unsustainable methods of rice farming have led to serious soil and water degradation in many areas, leading to reduced productivity.

- Increasing competition from other countries and imports: rice importation increased since the 1990s, causing the local industry to suffer. With these challenges, the rice industry is growing, with many public and private initiatives being put in place to improve yields and processing. Similarly, with the right investment and innovation, the industry has the potential to substantially increase its production to remain competitive in regional markets.

- Skills and technical know-how: even with the help of the government, which provided few processing machines at a subsidized price, the processors still need training on how to operate the machines.

- Limited access to information and innovation: the inability to get timely information about innovation by the rice processors is also a constraint to the processing of rice because processors are not up to date about the newest and latest method of processing; this could be attributed to the inability of the extension advisors to quickly locate smallholder farmers and small millers with information on current events in the industry.

2.2. Empirical Review of Related Studies

2.3. Analytical Framework

2.3.1. Stochastic Frontier Model

2.3.2. Stochastic Meta-Frontier Model

3. Materials and Methods

3.1. Data

3.1.1. Area of the Study

3.1.2. Sampling Techniques and Sample Size

3.1.3. Data Analysis

3.1.4. Model Specification

3.1.5. Test of Hypotheses

3.2. Summary of Data

4. Results and Discussions

4.1. Parameter Estimates for Group-Specific Stochastic Frontiers

4.2. Estimation of Parameters of the Stochastic Meta-Frontier (SMF)

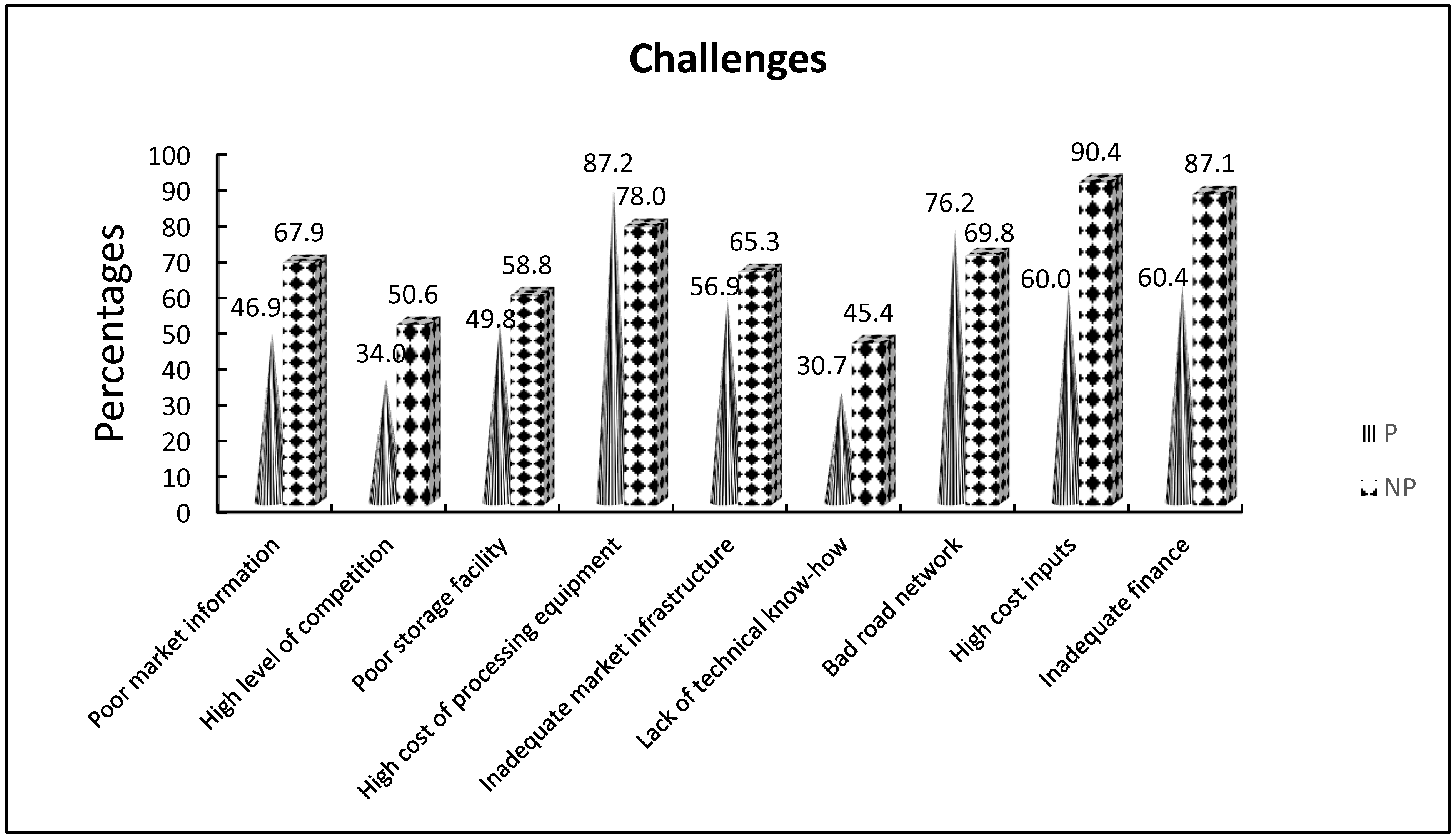

4.3. Estimation of the Technical Efficiency and Technological Gap Ratio

4.4. Challenges of Small-Scale Rice Processing

5. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raheem, D.; Dayoub, M.; Birech, R.; Nakiyemba, A. ‘The Contribution of Cereal Grains to Food Security and Sustainability in Africa: Potential Application of UAV in Ghana, Nigeria, Uganda, and Namibia’. Urban Sci. 2021, 5, 8. [Google Scholar] [CrossRef]

- Edia, H. Economic Importance of Rice Farming in Nigeria. Available online: www.blog.farmcrowdy.com (accessed on 13 January 2023).

- Obianefo, C.A.; Okoroji, N.O.; Obiekwe, N.J.; Osuafor, O.O.; Shah, Z.A. Economics of Good Agronomic Practices Adoption by Rice Farmers in Value Chain Development Programme, Anambra State, Nigeria. Afr. J. Food Agric. Nutr. Dev. 2022, 22, 21309–21412. [Google Scholar] [CrossRef]

- Danbaba, M. Nigeria Can Be Self-Sufficient in Rice in 8 Years. National Accord. 2023. Available online: https://www.nationalaccordnewspaper.com/nigeria-can-be-self-sufficient-in-rice-in-8-years-if-research/ (accessed on 19 January 2023).

- Foyeku and Rice Millers, Importers and Distributors Association of Nigeria. Nigeria Cannot Attain Self-Sufficiency in Rice Production by 2018—Group. 2019. Available online: https://shipsandports.com.ng/nigeria-cannot-attain-selfsufficiency-rice-production-2018-group/ (accessed on 19 January 2023).

- Ibitoye, S.J.; Idoko, D.; Shaibu, U.M. Economic Assessment of Rice Processing in Bassa Local Government Area of Kogi State, Nigeria. Asian J. Basic Appl. Sci. 2014, 1, 8–17. [Google Scholar]

- USAID. Agricultural Value Chain Financing in Kenya. An Assessment of Potential Opportunities for Growth. 2019. Available online: https://pdf.usaid.gov/pdf_docs/pa00m2s4.pdf (accessed on 19 January 2023).

- Akolgoa, J.A.; Asumboya, G.A. Economic Analysis of Rice Processing by Women in Navrongo Municipality of Upper East Region of Ghana. Int. J. Sci. Basic Appl. Res. 2016, 26, 221–230. [Google Scholar]

- Osabuohien, E.; Okorie, U.; Osabohien, R. Rice Production and Processing in Ogun State, Nigeria: Qualitative Insights from Farmers’ Association. In Food Systems Sustainability and Environmental Policies in Modern Economics; Obayelu, E., Ed.; IGI Global: Hershey, PA, USA, 2018; pp. 188–215. [Google Scholar] [CrossRef]

- Okeh, C.; Onwosi, C.O.; Fredrick, J.O.C. Biogas Production from Rice HusksGenerated from Various Rice Mills in Ebonyi State, Nigeria. Renew. Energy 2014, 62, 204–208. [Google Scholar] [CrossRef]

- Obianefo, C.A.; Okoh, B.C.; Nwigwe, C.A.; Anumudu, O.O.; Toyin, F.A. Assessment of the Knowledge and Use of Briquettes for Climate Change Option Among Rice Processors In Anambra State, Nigeria. Covenant J. Entrep. 2020, 4, 1–15. [Google Scholar]

- Ng’ombe, J.N. Technical efficiency of smallholder maize production in Zambia: A stochastic meta-frontier approach. Agrekon 2017, 56, 347–365. [Google Scholar] [CrossRef]

- Brown, M. Cobb—Douglas Functions. In The New Palgrave Dictionary of Economics, Palgrave Macmillan; Palgrave Macmillan: London, UK, 2017. [Google Scholar] [CrossRef]

- Yevgeniya, M.; Elima, I.; Taras, M. Technological Gap Concept: Theoretical and Methodological Rethinking. International Conference on Finance, Entrepreneurship and Technologies in Digital Economy. Eur. Proc. Soc. Behav. Sci. 2020, 103, 614–622. [Google Scholar] [CrossRef]

- IFAD. Rural Poverty Report 2012: The Challenges of Ending Rural Poverty; International Fund for Agricultural Development/Value Chain Development Programme; Oxford University Press Inc.: New York, NY, USA, 2014; pp. 1–7. [Google Scholar]

- Obianefo, C.A.; Ng’ombe, J.N.; Mzyece, A.; Masasi, B.; Obiekwe, N.J.; Anumudu, O.O. Technical Efficiency and Technological Gaps of Rice Production in Anambra State, Nigeria. Agriculture 2021, 11, 1240. [Google Scholar] [CrossRef]

- Asravor, J.; Wiredu, A.N.; Siddig, K.; Onumah, E.E. Evaluating the Environmental-Technology Gaps of Rice Farms in Distinct Agro-Ecological Zones of Ghana. Sustainability 2019, 11, 2072. [Google Scholar] [CrossRef]

- USDA—United State Department of Agriculture. Agricultural Statistic; U.S. Government Printing Office: Washington, DC, USA, 2014; Volume 202, pp. 512–1800.

- Obianefo, C.A.; Nwigwe, C.A.; Meludu, T.N.; Anyasie, I.C. Technical efficiency of rice farmers in Anambra State value chain development program. J. Dev. Agric. Econ. 2020, 12, 67–74. [Google Scholar] [CrossRef]

- Bime, M.J.; Fon, D.E.; Ngalim, S.B.; Ongla, J. Profitability and Efficiency Analyses of Small-scale Rice processing units in Ngoketunjia Division, North West Region, Cameroon. J. Adv. Agric. 2014, 3, 177–182. [Google Scholar]

- Bolarin, O.; Adebayo, S.A.; Akubo, R.A.; Komolafe, S.E. Perceived effectiveness of Japan international cooperation agency– rice processing technologies utilization among rice processors in Kogi State, Nigeria. SVU-Int. J. Agric. Sci. 2022, 4, 58–67. [Google Scholar] [CrossRef]

- Uchemba, V.U.; Nenna, G.M.; Obianefo, C.A. Adoption of Improved Cassava Production Technologies among small-scale Farmers in Anambra State, Nigeria. J. Plant Sci. 2021, 9, 119–127. [Google Scholar]

- Battese, G.E.; Rao, D.P. Technology gap, efficiency, and a stochastic meta-frontier function. Int. J. Bus. Econ. 2008, 1, 87. [Google Scholar]

- Joseph, E.A.; Michael, D.O. Promoting Small and Medium Enterprises in the Nigerian Oil and Gas Industry. Eur. Sci. J. 2013, 9, 244–260. [Google Scholar]

- Mohammed, S.M.H. Development of Small-Scale Enterprises: The Role of Engineering Personnel. In Proceedings of the 22nd Council for the Regulation of Engineering in Nigeria (Coren) Engineering Assembly, Abuja, Nigeria, 20–21 August 2013. [Google Scholar] [CrossRef]

- Ocheni, S. Oil and Gas Industry and the Growth of Small and Medium Enterprises in Nigeria: Local Content Policy Implications. J. Small Bus. Entrep. Dev. 2015, 3, 66–75. [Google Scholar] [CrossRef]

- Shambhu, G. Micro, Small and Medium Enterprises (MSMEs) in India: An Appraisal. 2013. Available online: www.legalpundits.com/Content-folder/SME.Arti1506010.pdf (accessed on 19 January 2023).

- Bose, A.A.; Jatbong, J.N.; Danwanka, H.A.; Zayyad, B. Assessment of Small-Scale Paddy Rice Processing and Marketing in Dass Local Government Area, Bauchi State, Nigeria. Int. J. Sci. Adv. Innov. Res. 2020, 5, 29–41. [Google Scholar]

- Ujang, P.; Shigeki, I.; Susumu, U. Power Availability and Requirements for Small-Scale Rice farm Operations: A Case in Riau Province, Indonesia. Am. J. Agric. Sci. Eng. Technol. 2012, 1, 27–36. [Google Scholar]

- Hlophe-Ginindza, S.N.; Mpandeli, N.S. The Role of Small-Scale Farmers in Ensuring Food Security in Africa. Food Secur. Afr. 2020. [Google Scholar] [CrossRef]

- Ajala, A.S.; Gana, A. Analysis of Challenges Facing Rice Processing in Nigeria. J. Food Process. 2015, 6, 893673. [Google Scholar] [CrossRef]

- Okunola, A.A.; Adekanye, T.A.; Adewumi, D.A.; Ashamu, F.F. Assessment of rice processing operations in Ekiti State, Nigeria. Int. J. Civ. Eng. Technol. 2019, 10, 2197–2204. [Google Scholar]

- Sennuga, S.O.; Adeniran, B.T.; Olorunniyi, A.A. Assessment of the Constraints Associated with the Processing of Paddy Rice: A Case Study of Smallholder Farmers in Gwagwalada, Abuja. J. Curr. Trends Agric. Environ. Sustain. 2021, 2, 1–7. [Google Scholar]

- Abu, B.S.; Abdur, R.S.; Mohammad, C.R.; Afroza, C.; Shajedur, R.; Limon, D. Rice farmers’ technical efficiency under abiotic stresses in Bangladesh. Asian J. Agric. Rural Dev. 2017, 7, 219–232. [Google Scholar]

- Ehirim, N.; Onyeagocha, S.; Ben-Chendo, G.; Essien, U.; Osuji, E.; Okwara, M. Farming Techniques, Environmental Challenges, and Technical Efficiency of Sweet Potato Production in Abia State, Nigeria. Int. J. Agric. Manag. Dev. 2016, 6, 409–420. [Google Scholar]

- Diarra, S.B.; Staatz, J.M.; Bingen, R.J.; Dembélé, N.N. The Reform of Rice Milling and Marketing in the Office Du Niger: Catalyst For an Agricultural Success Story In Mali. Res. Agric. Appl. Econ. 1999, 99, 1–20. [Google Scholar]

- Asmiya, A.; Sivarajah, P. Paddy Processing Efficiency and Output Level of Rice Mills in Ampara District. 2021. Available online: https://www.researchgate.net/publication/354918225 (accessed on 19 January 2023).

- Tabe-Ojong, M.P.; Molua, E.L. Technical efficiency of smallholder tomato production in semi-urban farms in Cameroon: A stochastic frontier production approach. J. Manag. Sustain. 2007, 7, 27–35. [Google Scholar] [CrossRef]

- Obianefo, C.A.; Onyekineso, J.C.; Okafor, P.I.; Okoroji, O.N. On the Efficiency Performance of Bitter Leaf Farming by Cooperative Members in Anambra State, Nigeria. Int. J. Agric. Biol. Sci. 2021, 5, 27–40. [Google Scholar]

- Diosdado, C.C.; Biley, E.T. Factors Influencing Productivity and Technical Efficiency of Rice Farmers in Isabela, Philippines. J. Adv. Agric. Technol. 2017, 4, 111–122. [Google Scholar]

- Mohammad, C.R.; Abu, B.S.; Abdus, S.; Ariful, I.; Shawkat, A. Assessment of Technical Efficiency of Rice Farmers in a Selected Empoldered Area of Bangladesh. Eur. J. Agric. Sci. 2013, 10, 102–110. [Google Scholar]

- Manoj, T.; Amin, M.; Ben, W. Production Efficiency and Technology Gap in Irrigated and Rain-fed Rice Farming Systems in Sri Lanka: Non-Parametric Approach. In Proceedings of the 57th AARES Annual Conference, Sydney, NSW, Australia, 5–8 February 2013. [Google Scholar]

- Assaf, A.; Matawieb, K.M. A bootstrapped meta-frontier model. Appl. Econ. Lett. 2010, 17, 613–617. [Google Scholar] [CrossRef]

- Chiaka, J.C.; Zhen, L.; Yunfeng, H.; Xiao, Y.; Muhirwa, F.; Lang, T. Smallholder Farmers Contribution to Food Production in Nigeria. Front. Nutr. 2022, 9, 916678. [Google Scholar] [CrossRef]

- Korotoumou, M.; Moussa, M.; Li, X.; Eunice, M.; John-Philippe, E.A.; Ekram, A.E.; Osewe, M.O. Stochastic meta-frontier analysis of smallholder rice farmers’ technical efficiency. J. Agric. Sci. 2019, 11, 31–44. [Google Scholar]

- Kanis, F.F.; Anton, A.K.; Azizul, B.; Adli, M. Technical efficiency and meta-technology ratios of regional firms in Bangladesh: A stochastic meta-frontier model. Sci. Res. Essays. 2011, 6, 6120–6131. [Google Scholar]

- Xiangfei, X.; Yi, Z.; Jimin, W.; John, A.N. Effects of Farm Size on Technical Efficiency in China’s Broiler Sector: A Stochastic Meta-Frontier Approach. Can. J. Agric. Econ. 2015, 64, 493–516. [Google Scholar]

- Nan, J.; Basil, S. Technical efficiency and technological gap of New Zealand dairy farms: A stochastic meta-frontier model. J. Product. Anal. 2015, 44, 39–49. [Google Scholar]

- Akinniran, T.N.; Faleye, G.R. Economics Analysis of Rice Production and Processing in Nigeria (1981—2019). Int. J. Agric. Environ. Bioresearch 2020, 5, 113–132. [Google Scholar]

- Ampadu-Ameyaw, R.; Omari, R.; Owusu, E.G. Development and Analysis of the Rice Value Chain for the Hohoe and Jasikan Districts of the Volta Region, Ghana. FARA Res. Result 2017, 1, 1–48. [Google Scholar]

- Nakanoa, D.; Muniz, J.J. Writing the literature review for empirical papers. Production 2018, 28, e20170086. [Google Scholar] [CrossRef]

- Majiwa, E.; Mugodo, C. Technical Efficiency and Technology Gap Ratios among Rice Farmers in Kenya. In Proceedings of the Joint International Conference of Agricultural Economics, Vancouver, BS, Canada, 28 July–2 August 2018; Available online: https://ideas.repec.org/p/ags/iaae18/277209.html (accessed on 20 January 2023).

- Olasehinde, S.; Fangbin, Q.; Shiping, M. Performance of Nigerian Rice Farms from 2010 to 2019: A Stochastic Metafrontier Approach Toba: A Stochastic Metafrontier Approach. Agriculture 2020, 12, 1000. [Google Scholar] [CrossRef]

- Aigner, D.J.; Lovell, C.A.; Schmidt, P. Formulation and estimation of stochastic frontier production function model. J. Econom. 1977, 1, 21–37. [Google Scholar] [CrossRef]

- Battese, G.E.; Coelli, T.J. Frontier production functions, technical efficiency and panel data: With application to paddy farmers in India. J. Prod. Anal. 1992, 3, 153–169. [Google Scholar] [CrossRef]

- Chiona, S.; Kalinda, T.; Tembo, G. Stochastic frontier analysis of the technical efficiency of smallholder maize farmers in Central Province, Zambia. J. Agric. Sci. 2014, 6, 108–118. [Google Scholar] [CrossRef]

- Ng’ombe, J.; Kalinda, T.A. Stochastic frontier analysis of technical efficiency of maize production under minimum tillage in Zambia. Sustain. Agric. Res. 2015, 25, 31–46. [Google Scholar] [CrossRef]

- Mzyece, A.; Ng’ombe, J.N. Crop diversification improves technical efficiency and reduces income variability in Northern Ghana. J. Agric. Food Res. 2020, 5, 100162. [Google Scholar] [CrossRef]

- Forsund, F.R.; Lovell, C.A.K.; Schmidt, P.A. Survey of frontier production functions and their relationships to efficiency measurement. J. Econom. 1980, 13, 5–25. [Google Scholar] [CrossRef]

- Ume, S.I.; Ochiaka, J.S. Technical efficiency of catfish production among smallholder Farmers in Anambra State of Nigeria. Case Stud. J. 2016, 5, 147–155. [Google Scholar]

- Farrel, M. The measurement of productive efficiency. J. R. Stat. Soc. 1957, 3, 253–290. [Google Scholar] [CrossRef]

- Huang, C.J.; Huang, T.H.; Liu, N.H. A new approach to estimating the meta-frontier production function based on a stochastic frontier framework. J. Prod. Anal. 2014, 42, 241–254. [Google Scholar] [CrossRef]

- Battese, G.E.; Rao, D.P.; O’donnell, C.J.A. Meta-frontier production function for estimation of technical efficiencies and technology gaps for firms operating under different technologies. J. Prod. Anal. 2004, 21, 91–103. [Google Scholar] [CrossRef]

- O’Donnell, C.J.; Rao, D.P.; Battese, G.E. Metafrontier frameworks for the study of firm-level efficiencies and technology ratios. Empir. Econ. 2008, 34, 231–255. [Google Scholar] [CrossRef]

- Osawe, O.W.; Adeqeye-Bolarin, A.J.; Omonona-Bolarin, O. Technical efficiency of small-scale farmers: An application of the stochastic frontier production function on fish farmers in Ibadan Metropolis. J. Econ. Rural Dev. 2008, 16, 71–82. [Google Scholar] [CrossRef]

- Assa, M.M.; Abdi-Khalil, E.; Matchaya, G.C. Unexploited Profit among smallholder farmers in Central Malawi: What are the sources? Int. J. Appl. Econ. 2012, 9, 83–95. [Google Scholar]

- Weather and Climate. Anambra Climate Summary. Available online: https://tcktcktck.org/nigeria/anambra#:~:text=Anambra%20Climate%20Summary,0.47%25%20lower%20than%20Nigeria’s%20averages (accessed on 19 January 2023).

- Kumbhakar, S.C.; Wang, H.J.; Horncastle, A. A Practitioner’s Guide to Stochastic Frontier Analysis Using Stata; Cambridge University Press: Cambridge, UK, 2015; Available online: www.cambridge.org/9781107609464 (accessed on 23 February 2023).

- Lee, L.; Tyler, F.W.G. The stochastic frontier production function and average efficiency: An empirical analysis. J. Econom. 1978, 7, 385–389. [Google Scholar] [CrossRef]

- Kumbhakar, S.C.; Gudbrand, L.; Hardaker, J.B. Technical efficiency in competing panel data models: A study of Norwegian grain farming. J. Prod. Anal. 2012, 41, 321–337. [Google Scholar] [CrossRef]

- Mensah, A.; Brümmer, B. Drivers of technical efficiency and technology gaps in Ghana’s mango production sector: A stochastic meta-frontier approach. Afr. J. Agric. Resour. Econ. 2016, 11, 101–117. [Google Scholar]

- Sadiya, S.S.; Hassan, I.I. Postharvest Loss in Rice: Causes, Stages, Estimates and Policy Implications. Agric. Res. Technol. 2018, 15, 555964. [Google Scholar] [CrossRef]

- Shah, Z.A.; Dar, M.A.; Dar, E.A.; Obianefo, C.A.; Bhat, A.H.; Ali, M.T.; Alatawi, H.A.; Ghamry, H.I.; Shukry, M.; Sayed, S. A Multinomial Approach to Sustainable and Improved Agricultural Technologies vis-a-vis Socio-personal Determinants in Apple (Malus domestica) Cultivation. J. King Saud Univer. Sci. 2022, 34, 102286. [Google Scholar] [CrossRef]

- Schlickmann, M.N.; Ferreira, J.C.E.; Pereira, A.C. Method for assessing the obsolescence of manufacturing equipment based on the triple bottom line. Production 2020, 30, e20190003. [Google Scholar] [CrossRef]

| Assumptions | Ho | H1 | LR-cal. | LR-tab. | DF | Decision |

|---|---|---|---|---|---|---|

| Existence of Homogenous technology | −163.894 | −137.169 | 53.356 | 16.812 | 6 | Rejected |

| No presence of an inefficiency component | ||||||

| Participants | −35.396 | −30.422 | 9.948 | 9.210 | 2 | Rejected |

| Non-participants | −39.960 | −29.172 | 21.576 | 2 | Rejected | |

| No presence of external component | −102.764 | −96.187 | 13.154 | 9.210 | 2 | Rejected |

| Participants | Non-Participants | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SI Unit | Mean | Std, Dev. | Min | Max | Mean | Std, Dev. | Min | Max | |

| Output | Kg | 388,354.0 | 826,664.2 | 2000.0 | 4,000,000.0 | 363,524.1 | 864,968.2 | 2000.0 | 4,000,000.0 |

| Rice paddy | Kg | 517,805.3 | 1,102,218.9 | 2666.7 | 5,333,333.3 | 484,698.9 | 1,153,291.0 | 2666.7 | 5,333,333.3 |

| Firewood | ₦ | 30,022.4 | 25,159.8 | 6822.0 | 90,291.0 | 42,570.1 | 27,070.5 | 5982.0 | 95,066.0 |

| Water | Liter | 61,926.0 | 56,558.5 | 12,500.0 | 187,500.0 | 31,304.6 | 37,273.6 | 12,500.0 | 187,500.0 |

| Labor wage | ₦ | 155,780.9 | 111,557.5 | 48,592.0 | 420,000.0 | 221,361.3 | 93,180.4 | 51,000.0 | 420,000.0 |

| Diesel | Liter | 52.7 | 27.3 | 25.0 | 100.0 | 63.4 | 22.1 | 25.0 | 100.0 |

| Dep. Huller | ₦ | 20,548.9 | 10,892.1 | 3662.3 | 37,500.0 | 58,190.0 | 60,608.4 | 4029.8 | 200,000.0 |

| Cost of sorting grading and packing | ₦ | 27,251.5 | 14,814.6 | 5000.0 | 49,500.0 | 27,656.6 | 14,144.8 | 5000.0 | 49,500.0 |

| Dep. false bottom | ₦ | 9834.0 | 11,560.1 | 0.0 | 35,000.0 | 9971.5 | 12,854.0 | 0.0 | 40,000.0 |

| Dep. of other assets | ₦ | 127,533.3 | 66,892.7 | 16,310.0 | 277,886.0 | 116,116.3 | 62,865.6 | 16,310.0 | 251,217.0 |

| Technology prowess | % | 65.3 | 9.3 | 47.5 | 85 | 64.7 | 8.9 | 46.3 | 85 |

| Sex | Dummy | 0.5 | 0.5 | 0 | 1 | 0.7 | 0.5 | 0 | 1 |

| Age | Years | 44.6 | 11.2 | 26 | 62 | 46.0 | 9.8 | 25 | 65 |

| Marital status | Dummy | 1.5 | 0.5 | 1 | 2 | 1.5 | 0.5 | 1 | 2 |

| Years of formal education | Year | 11.6 | 5.0 | 4 | 20 | 10.6 | 4.9 | 4 | 20 |

| Processing experience | Year | 10.7 | 6.0 | 5 | 25 | 9.5 | 2.6 | 5 | 20 |

| Household size | No | 8.2 | 2.8 | 4 | 12 | 7.2 | 2.2 | 4 | 12 |

| Participants (n = 50) | Non-Participants (n = 50) | |||||

|---|---|---|---|---|---|---|

| Variable Names | Estimates | Std. Err. | Z | Estimates | Std. Err. | Z |

| Log-Paddy-input (kg) | 1.003 | 0.108 | 9.26 *** | −0.086 | 0.126 | −0.68 |

| Log-Cost of Firewood (N) | 0.118 | 0.036 | 3.28 *** | 0.144 | 0.111 | 1.30 |

| Log water (Liter) | −0.680 | 0.147 | −4.61 *** | 0.124 | 0.399 | 0.31 |

| Log-Cost of labor (N) | −0.199 | 0.281 | −0.71 | 0.455 | 0.422 | 1.08 |

| Log-Diesel (Liter) | 0.002 | 0.003 | 0.76 | 0.000 | 0.005 | −0.04 |

| Depreciation on Huller (N) | −0.060 | 0.096 | −0.63 | 0.196 | 0.172 | 1.14 |

| Constant | 9.307 | 1.514 | 6.15 *** | 7.586 | 2.755 | 2.75 ** |

| Group-specific variables | ||||||

| Age (year) | 0.063 | 0.050 | 1.27 | −0.023 | 0.045 | −0.5 |

| Years of formal education | 0.191 | 0.114 | 1.68 * | 0.020 | 0.090 | 0.22 |

| Processing experience (years) | −0.105 | 0.138 | −0.76 | 0.003 | 0.171 | 0.02 |

| Household size (No) | −0.292 | 0.226 | −1.29 | 0.599 | 0.255 | 2.35 *** |

| Constant | −3.667 | 3.240 | −1.13 | −4.327 | 3.109 | −1.39 |

| Model statistics | ||||||

| Log-likelihood | −29.462 | −99.227 | ||||

| Gamma | 0.641 | 0.410 | ||||

| Anambra State, Nigeria | |||

|---|---|---|---|

| Variable Names | Estimates | Std. Err. | z |

| Log-Paddy-input (kg) | 0.520 | 0.171 | 3.05 *** |

| Log-Cost of Firewood (N) | 0.135 | 0.052 | 2.58 ** |

| Log-water (Liter) | −0.725 | 0.182 | −3.98 *** |

| Log-Cost of labor (N) | 0.383 | 0.308 | 1.24 |

| Log-Diesel (Liter) | 0.001 | 0.004 | 0.32 |

| Depreciation on Huller (N) | 0.196 | 0.119 | 1.65 * |

| Constant | 6.398 | 1.744 | 3.67 *** |

| Economic-specific variables | |||

| Economic cost of grading and sorting | 1.960 | 1.129 | 1.74 * |

| Depreciation on False bottom technology | −0.044 | 0.151 | −0.29 |

| Depreciation of other assets | 2.219 | 1.305 | 1.70 * |

| Technology prowess | 0.003 | 0.030 | 0.11 |

| Constant | −20.075 | 8.841 | −2.27 ** |

| Model statistics | |||

| Log-likelihood | −160.000 | ||

| Gamma | 0.557 | ||

| Mean | Std. Dev. | Min | Max | ||

|---|---|---|---|---|---|

| Rice industry | TE | 0.506 | 0.196 | 0.001 | 0.844 |

| MTE | 0.498 | 0.200 | 0.002 | 0.843 | |

| TGR | 1.000 | 0.199 | 0.318 | 1.678 | |

| Participants | TE | 0.700 | 0.217 | 0.145 | 0.929 |

| MTE | 0.751 | 0.196 | 0.167 | 0.949 | |

| TGR | 0.924 | 0.140 | 0.557 | 1.153 | |

| Non-participants | TE | 0.544 | 0.214 | 0.009 | 0.845 |

| MTE | 0.566 | 0.229 | 0.008 | 0.868 | |

| TGR | 0.983 | 0.322 | 0.408 | 1.870 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obianefo, C.A.; Ezeano, I.C.; Isibor, C.A.; Ahaneku, C.E. Technology Gap Efficiency of Small-Scale Rice Processors in Anambra State, Nigeria. Sustainability 2023, 15, 4840. https://doi.org/10.3390/su15064840

Obianefo CA, Ezeano IC, Isibor CA, Ahaneku CE. Technology Gap Efficiency of Small-Scale Rice Processors in Anambra State, Nigeria. Sustainability. 2023; 15(6):4840. https://doi.org/10.3390/su15064840

Chicago/Turabian StyleObianefo, Chukwujekwu A., Ike C. Ezeano, Chinwe A. Isibor, and Chinwendu E. Ahaneku. 2023. "Technology Gap Efficiency of Small-Scale Rice Processors in Anambra State, Nigeria" Sustainability 15, no. 6: 4840. https://doi.org/10.3390/su15064840

APA StyleObianefo, C. A., Ezeano, I. C., Isibor, C. A., & Ahaneku, C. E. (2023). Technology Gap Efficiency of Small-Scale Rice Processors in Anambra State, Nigeria. Sustainability, 15(6), 4840. https://doi.org/10.3390/su15064840