Developing a Conceptual Framework Model for Effective Perishable Food Cold-Supply-Chain Management Based on Structured Literature Review

Abstract

1. Introduction

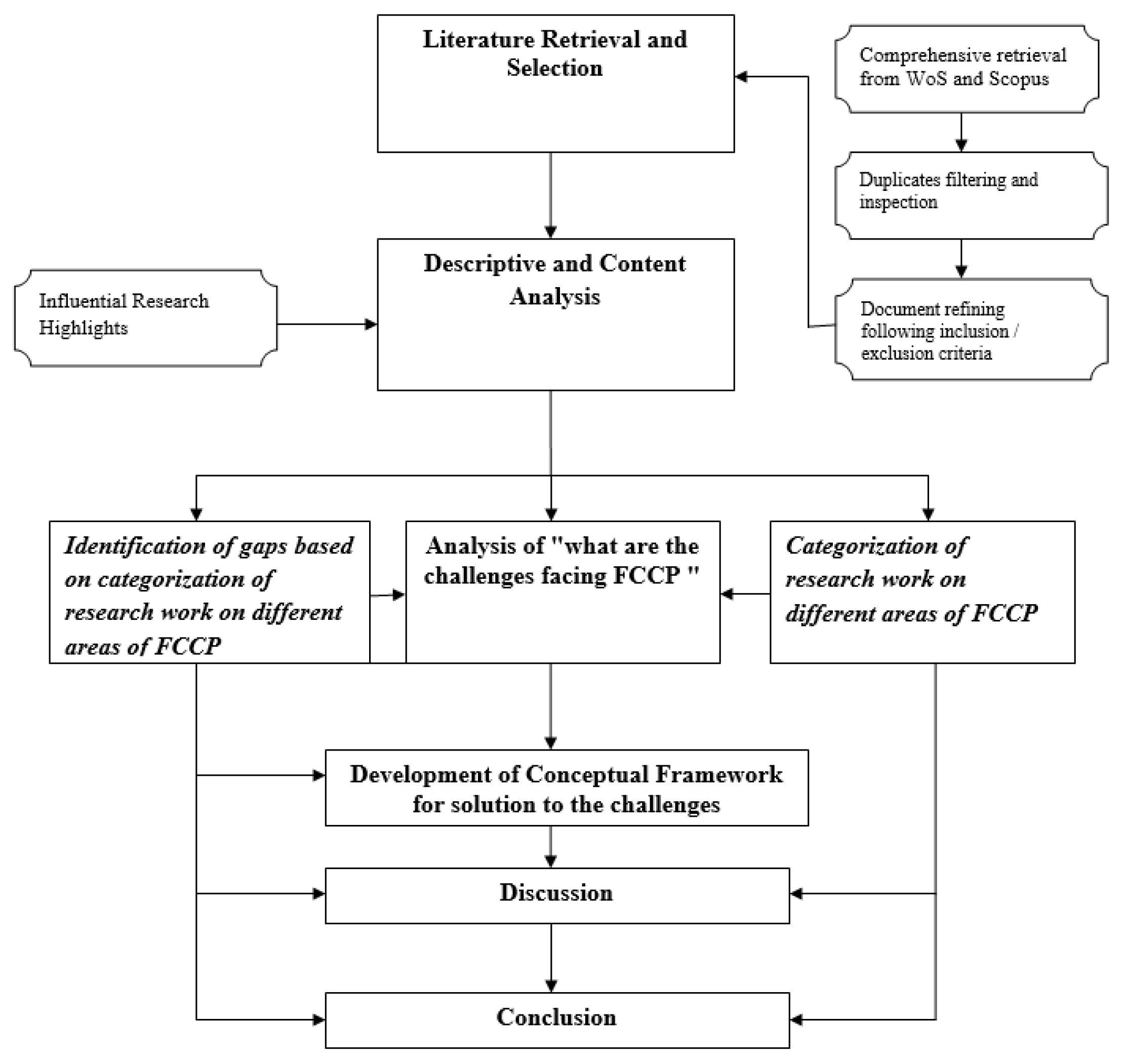

2. Research Methodology

2.1. Stage1: Literature Exploration

2.2. Stage2: Selection of Papers

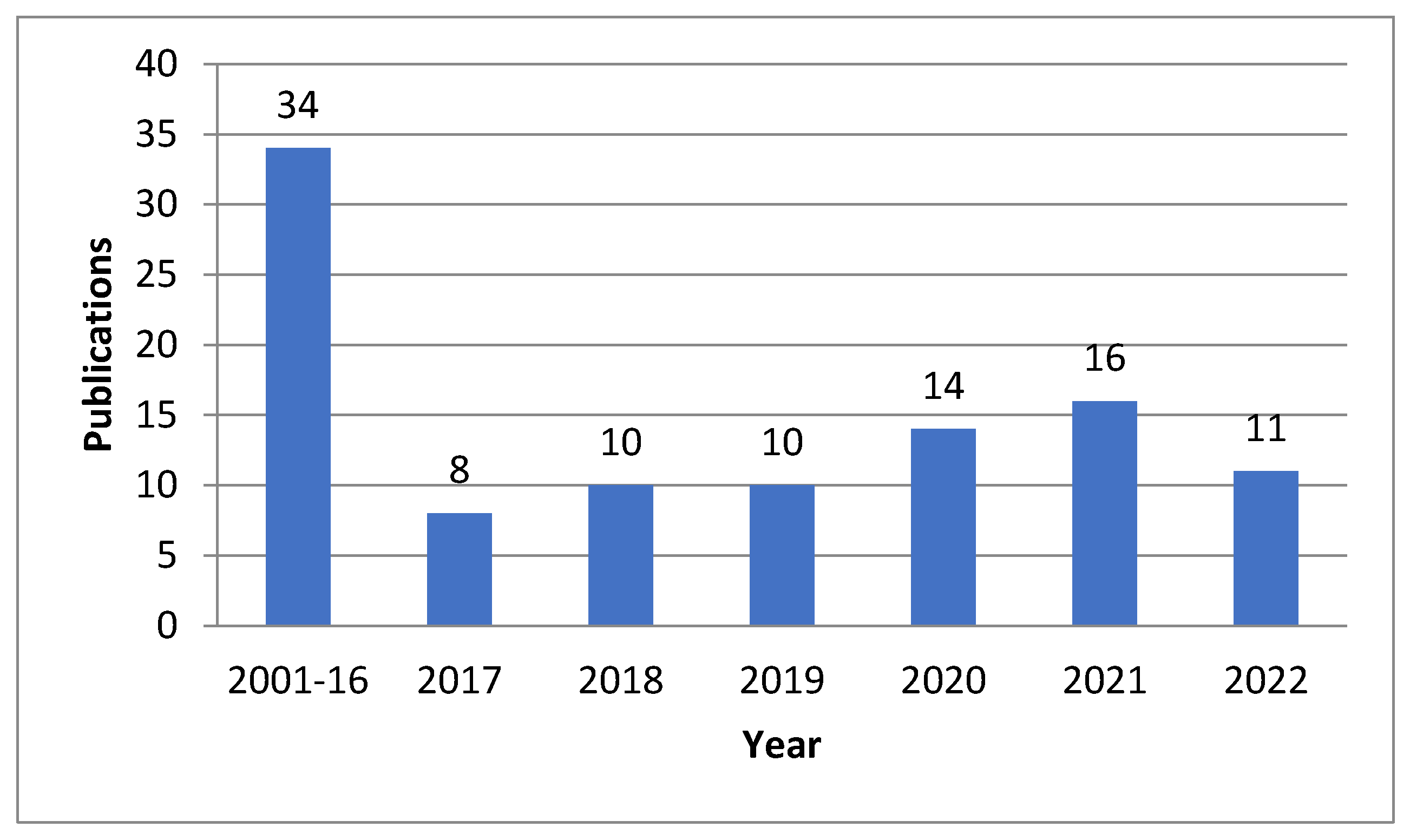

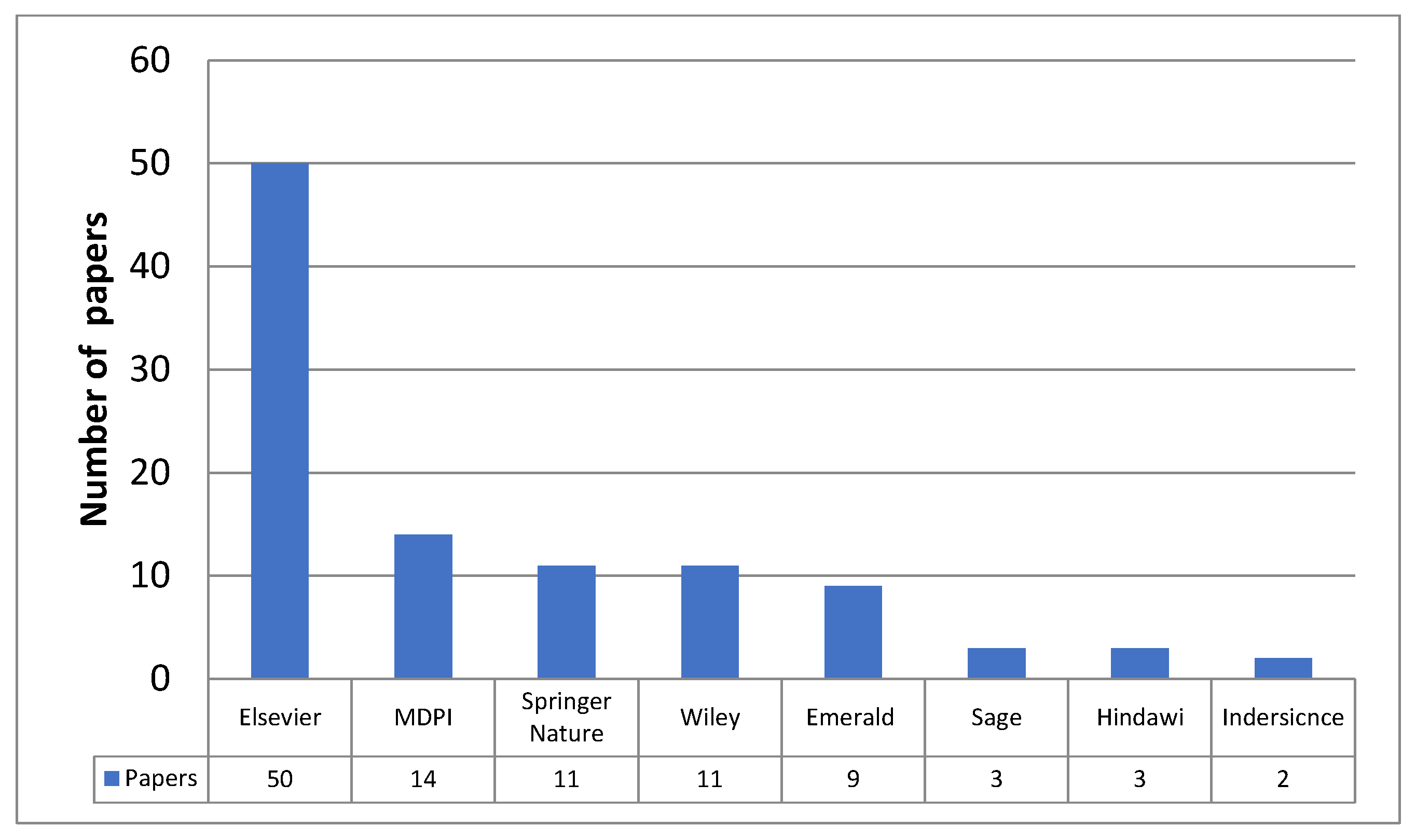

2.3. Descriptive Analysis Stage

2.4. Content Analysis Stage

3. Analysis of the Content and Development of Conceptual Framework

3.1. Analysis of the Content

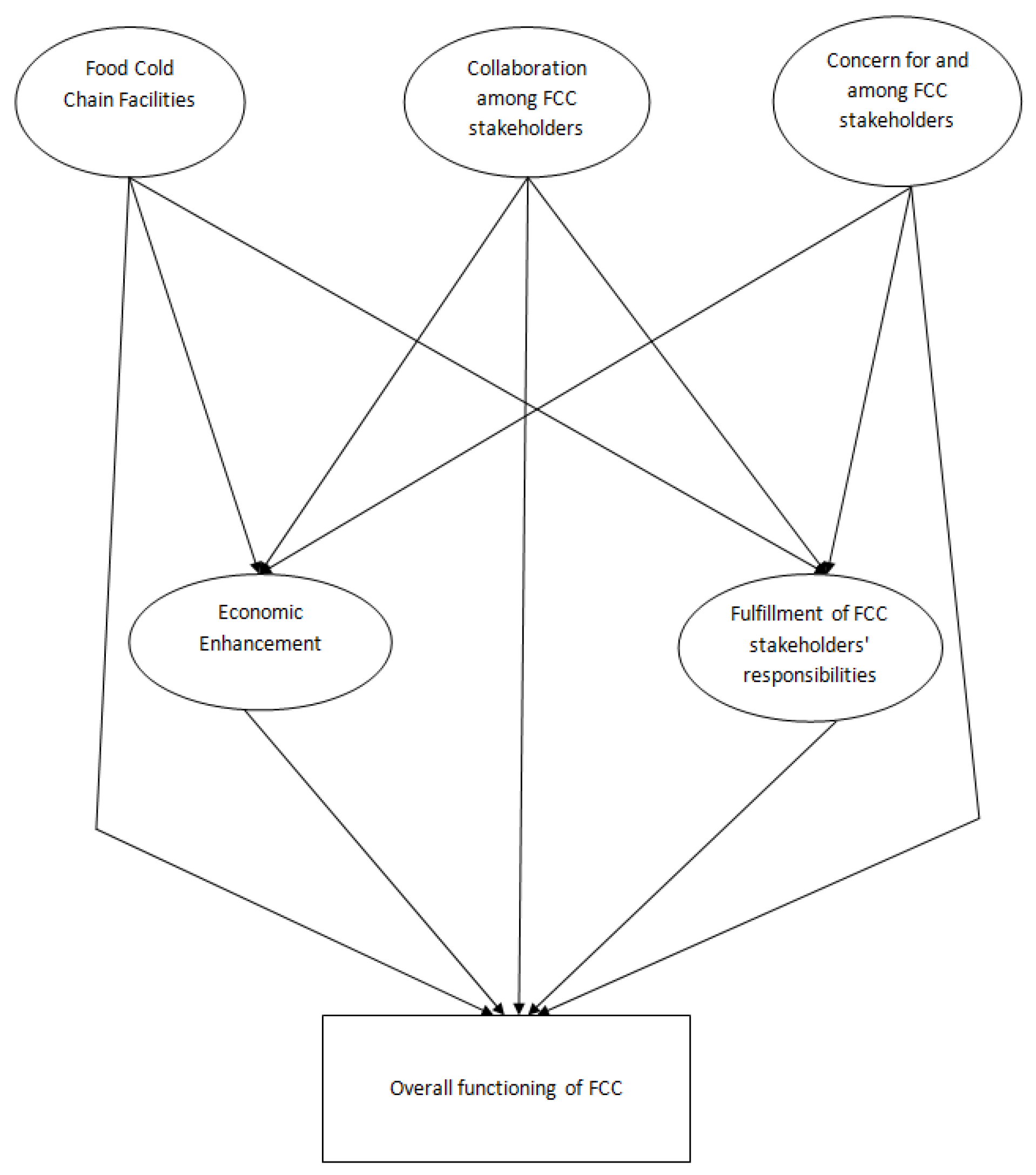

3.2. Development of Conceptual Framework

3.2.1. FCC Facilities, Economic Enhancement, Fulfilment of FCC Stakeholders’ Responsibilities, and Overall Functioning of FCC

3.2.2. Collaboration among FCC Stakeholders, Economic Enhancement, Fulfilment of FCC Stakeholders’ Responsibilities, and Overall Functioning of FCC

3.2.3. Concern for and among FCC Stakeholders, Economic Enhancement, Fulfilment of FCC Stakeholders’ Responsibilities, and Overall Functioning of FCC

4. Discussion

- Exploring the use of advanced systems and technology to improve the efficiency of logistical processes in the food cold-chain;

- Studying the impact of refrigeration equipment with increased energy efficiency on product volume, quality, and carbon emissions reduction;

- Examining the benefits of using energy sources with zero carbon emissions for sustainability in the FCC industry;

- Exploring innovations in the packaging of food products and their impact on distributors and product integrity;

- Investigating the drivers of customer preference for generic food products and the potential of branded foodstuffs to increase customer satisfaction and loyalty;

- Exploring the effectiveness of lean manufacturing procedures and implementing recycling practices in improving administrative and stakeholder benefits for firms;

- Investigating the effectiveness of integrated IT frameworks in addressing FCC problems related to insufficient chain integration, collaboration, sharing of information, shipping precision, and expertise;

- Identifying strategies to raise awareness among both partners in the chain and consumers about how to handle perishable foodstuffs properly in emerging economies.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Research Areas | Sub-Areas | Name of Authors | Title of the Paper | Journal |

|---|---|---|---|---|

| 1. Factors causing the inefficiency of FCCP |

| [124] | Changes in beef consumption and retailing competitiveness in Brazil: a rapid appraisal | Agribusiness: An International Journal |

| [125] | A resilience model for cold chain logistics of perishable products | The International Journal of Logistics Management | ||

| [126] | A two-stage decision-support approach for improving sustainable last-mile cold chain logistics operations of COVID-19 vaccine | Annals of Operations Research | ||

| [29] | Blockchain-enabled pharmaceutical cold chain: Applications, key challenges, and future trends | Journal of Cleaner Production | ||

| [90] | Food cold chain management: what we know and what we deserve | Supply Chain Management: An International Journal | ||

| [127] | The study of cold storage and temperature controlled transportation: A case study of a chain restaurant in Thailand | PamukkaleÜniversitesi MühendislikBilimleriDergisi | ||

| [128] | The implications of socialization and integration in supply chain management | Journal of operations management | ||

| [129] | Applying marketing channel theory to food marketing in developing countries: Vertical disintegration model for horticultural marketing channels in kenya | Agribusiness: An International Journal | ||

| [130] | Management of COVID-19 vaccines cold chain logistics: a scoping review | Journal of pharmaceutical policy and practice | ||

| [131] | Analysis of challenges inhibiting the reduction of waste in food supply chain | Journal of cleaner production | |

| [132] | Modeling the key factors influencing the reduction of food loss and waste in fresh produce supply chains | Journal of Environmental Management | ||

| [133] | supply chain failure in the agri-food sector: A case study from Moldova | Food Policy | ||

| [134] | Consumers’ awareness of food safety from shopping to eating. | Food control | ||

| [135] | Indian cold chain: modeling the inhibitors | British Food Journal | ||

| [136] | Developing an advanced multi-temperature joint distribution system for the food cold chain | Food control | ||

| [108] | Why is the food traceability system unsuccessful in Taiwan? Empirical evidence from a national survey of fruit and vegetable farmers | Food Policy | ||

| [137] | Characterization of cooling equipment in the food industry: Case study of the Colombian meat, dairy, and fruit and vegetable sectors | Environmental Development | ||

| [30] | The Canadian food cold chain: A legislative, scientific, and prospective overview | International Journal of Refrigeration | ||

| [138] | Losses in the grain supply chain: Causes and solutions | Sustainability | ||

| [139] | Factors affecting food waste at the downstream entities of the supply chain: A critical review | Journal of Cleaner Production | |

| [140] | Modelling the enablers of food supply chain for reduction in carbon footprint | Journal of Cleaner Production | ||

| [141] | Food supply chain management (FSCM): a structured literature review and future research agenda | Journal of Advances in Management Research | ||

| [142] | Evaluation of public private partnerships in perishable food supply chain in India | Journal of Supply Chain Management Systems | ||

| [143] | Ensuring the quality of meat in cold chain logistics: A comprehensive review | Trends in Food Science & Technology | ||

| [144] | Third party logistics (3PL) selection for cold chain management: a fuzzy AHP and fuzzy TOPSIS approach | Annals of Operations Research | ||

| [11] | trade-offs in fresh-fruit cold chains by combining virtual cold chains with life cycle assessment | Applied Energy | ||

| [145] | A Systematic Review of Factors Affecting Food Loss and Waste and Sustainable Mitigation Strategies: A Logistics Service Providers’ Perspective | Sustainability | ||

| [146] | Economic analysis of a traceability system for a two-level perishable food supply chain. | Sustainability | ||

| 2. Issues relating to FCC sustainability |

| [147] | Performance measurement in agri-food supply chains: a case study. | Supply chain management: an international Journal |

| [148] | RFID-An Emerging Technology for Cold Chain Sustainability. | ZENITH International Journal of Business Economics & Management Research | ||

| [149] | New trends in cold chain monitoring applications-A review | Food Control | ||

| [150] | Assessment of the economic and environmental sustainability of a food cold supply chain | IFAC-PapersOnLine | ||

| [151] | Towards integrated performance evaluation of future packaging for fresh produce in the cold chain. | Trends in food science & technology | ||

| [152] | Assessing the lifecycle greenhouse gas (GHG) emissions of perishable food products delivered by the cold chain in China | Journal of Cleaner Production | ||

| [153] | Sustainable supply chain management in emerging economies: Trade-offs between environmental and cost performance. | International Journal of Production Economics | ||

| [154] | Trading off cost, emission, and quality in cold chain design: A simulation approach | Computers & Industrial Engineering | ||

| [155] | Food chain management for sustainable food system development: a European research agenda. | Agribusiness: An International Journal | ||

| [156] | Designing sustainable cold chains for long-range food distribution: Energy-effective corridors on the Silk Road Belt | Sustainability | |

| [157] | A sustainable distribution design for multi-quality multiple-cold-chain products: An integrated inspection strategies approach | Energies | ||

| [7] | Challenges in perishable food supply chains for sustainability management: A developing economy perspective. | Business Strategy and the Environment | ||

| [158] | Reducing greenhouse gas emissions through operations and supply chain management. | Energy Economics | ||

| [159] | Food cold chain management improvement: A conjoint analysis on COVID-19 and food cold chain systems | Food Control | ||

| [127] | The study of cold storage and temperature controlled transportation: A case study of a chain restaurant in Thailand | PamukkaleÜniversitesi MühendislikBilimleriDergisi | ||

| [160] | When challenges impede the process: For circular economy-driven sustainability practices in food supply chain. | Management Decision | ||

| [161] | Sustainable marketing innovation and consumption: Evidence from cold chain food online retail | Journal of Cleaner Production | ||

| [162] | A conceptual framework model for an effective cold food chain management in sustainability environment | Journal of Modelling in Management | |

| [163] | Is it food or is it waste? The materiality and relational agency of food waste across the value chain | Journal of Cultural Economy | ||

| [164] | Literature review analytics (LRA) on sustainable cold-chain for perishable food products: research trends and future directions. | Opsearch | ||

| [165] | Optimization of a low-carbon two-echelon heterogeneous-fleet vehicle routing for cold chain logistics under mixed time window | Sustainability | ||

| [166] | Sustainable solar powered battery-free wireless sensing for food cold chain management. | Sensors International | ||

| [167] | A systematic literature review of the agro-food supply chain: Challenges, network design, and performance measurement perspectives. | Sustainable Production and Consumption | ||

| [168] | Super cold chain—a high quality, energy-efficient, and environmentfriendly method | International Journal of Energy Research | ||

| [169] | The effect of transportation disruptions on cold chain sustainability | Evergreen | ||

| 3. Important measures for measuring FCCP |

| [124] | Changes in beef consumption and retailing competitiveness in Brazil: a rapid appraisal | Agribusiness: An International Journal |

| [147] | Performance measurement in agri-food supply chains: a case study | Supply chain management: an international Journal | ||

| [170] | Refrigerated container versus bulk: evidence from the banana cold chain. | Maritime Policy & Management | ||

| [171] | Temperature management for the quality assurance of a perishable food supply chain | Food Control | ||

| [172] | Promoting food security and enhancing Nigeria’s small farmers’ income through value-added processing of lesser-known and under-utilized indigenous fruits and vegetables. | Food Research International | ||

| [173] | Stability of perishable goods in cold logistic chains. | International journal of production economics | ||

| [174] | Firm size and sustainable performance in food supply chains: Insights from Greek SMEs. | International Journal of Production Economics | ||

| [35] | Prophage induction reduces Shiga toxin producing Escherichia coli (STEC) and Salmonella enterica on tomatoes and spinach: A model study | Food Control | ||

| [104] | Decision-making in cold chain logistics using data analytics: a literature review. | The International Journal of Logistics Management | ||

| [152] | Assessing the lifecycle greenhouse gas (GHG) emissions of perishable food products delivered by the cold chain in China | Journal of Cleaner Production | |

| [175] | Make to stock or make to order: The decoupling point in the food processing industries | International Journal of Production Economics | ||

| [176] | Inventory control of perishables in supermarkets. | International journal of production economics | ||

| [177] | Combining quantitative risk assessment of human health, food waste, and energy consumption: The next step in the development of the food cold chain? | Risk Analysis | ||

| [178] | Investigating last food mile deliveries: A case study approach to identify needs of food delivery demand. | Research in transportation economics | ||

| [179] | Modeling and evaluation on WSN-enabled and knowledge-based HACCP quality control for frozen shellfish cold chain | Food Control | ||

| [180] | Blockchain-based traceability system that ensures food safety measures to protect consumer safety and COVID-19 free supply chains | Foods | ||

| [33] | Using confocal laser scanning microscopy to probe the milk fat globule membrane and associated proteins. | Journal of Agricultural and food Chemistry | ||

| [34] | Effect of relative humidity on the oxidative and physical stability of encapsulated milk fat. | Journal of the American Oil Chemists’ Society | ||

| [181] | The food cold-chain and climate change. | Food Research International | ||

| [182] | Use of cold chains for reducing food losses in developing countries | The Postharvest Education Foundation | |

| [136] | Developing an advanced multi-temperature joint distribution system for the food cold chain | Food control | ||

| [108] | Why is the food traceability system unsuccessful in Taiwan? Empirical evidence from a national survey of fruit and vegetable farmers | Food Policy | ||

| [183] | Cold chain transportation decision in the vaccine supply chain. | European Journal of Operational Research | ||

| [184] | Cold-chain transportation in the frozen food industry may have caused a recurrence of COVID-19 cases in destination: successful isolation of SARS-CoV-2 virus from the imported frozen cod package surface. | Biosafety and health | ||

| [185] | Co-regulation as a possible model for food safety governance: Opportunities for public–private partnerships. | Food Policy | ||

| [31] | Food cold chain in indonesia during the Covid-19 pandemic: A current situation and mitigation. | JurnalRekayasaSistemIndustri | ||

| [186] | The effect of traceability system and managerial initiative on Indonesian food cold chain performance: A Covid-19 pandemic perspective. | Global Journal of Flexible Systems Management | ||

| [4] | Cold chain tracking: a managerial perspective. | Trends in Food Science &Technology | |

| [187] | Time-temperature abuse in the food cold chain: Review of issues, challenges, and recommendations. | Food Control | ||

| [188] | Ensuring supply chain safety through time temperature integrators. | The international journal of logistics management | ||

| [189] | Research on the evaluation system of agricultural product cold chain logistics based on analytic hierarchy process (AHP) | Applied Mathematics, Modelling, and Intelligent Computing | ||

| [190] | Food quality and safety risk diagnosis in the food cold chain through failure mode and effect analysis | Food Control | ||

| [191] | Improving traceability and transparency of table grapes cold chain logistics by integrating WSN and correlation analysis | Food Control | ||

| [192] | Supplier integration and firm performance: the moderating effects of internal integration and trust. | Production Planning & Control | ||

| [193] | Cold chain distribution: how to deal with node and arc time windows? | Annals of Operations Research | ||

| 4. Key methods of improving FCCP |

| [36] | A resilience model for cold chain logistics of perishable products. | The International Journal of Logistics Management |

| [105] | Reducing global supply chains’ waste of overproduction by using lean principles: a conceptual approach | International Journal of Quality and Service Sciences | ||

| [194] | A comprehensive review on impacts of COVID-19 in food preservation and cold chain: An approach towards implementing green energy technologies | Environmental Progress & Sustainable Energy | ||

| [38] | A model for measuring the performance of the meat supply chain. | British Food Journal | ||

| [195] | A review of application status and replacement progress of refrigerants in the Chinese cold chain industry | International Journal of Refrigeration | ||

| [196] | Improving performance of cold-chain insulated container with phase change material: an experimental investigation | Applied Sciences | ||

| [9] | Utilization of vegetable and fruit by-products as functional ingredient and food. | Frontiers in nutrition | ||

| [37] | Biobjective low-carbon location-routing problem for cold chain logistics: Formulation and heuristic approaches. | Journal of Cleaner Production | ||

| [197] | Optimization of cold chain logistics distribution network terminal | EURASIP Journal on Wireless Communications and Networking | |

| [198] | Cold chain break detection and analysis: Can machine learning help? | Trends in Food Science &Technology | ||

| [199] | Decision modelling of critical success factors for cold chains using the DEMATEL approach: a case study | Measuring Business Excellence | ||

| [103] | Improvement in the food losses in fruits and vegetable supply chain-a perspective of cold third-party logistics approach. | Operations Research Perspectives | ||

| [143] | Ensuring the quality of meat in cold chain logistics: A comprehensive review. | Trends in Food Science & Technology | ||

| [200] | An IoT-based cargo monitoring system for enhancing operational effectiveness under a cold chain environment. | International Journal of Engineering Business Management | ||

| [28] | Sustainable tourism: a comprehensive literature review on frameworks and applications. | Economic research-Ekonomska istraživanja |

References

- Cerchione, R.; Singh, R.; Centobelli, P.; Shabani, A. Food cold chain management: From a structured literature review to a conceptual framework and research agenda. Int. J. Logist. Manag. 2018, 29, 792–821. [Google Scholar]

- Joshi, R.; Banwet, D.K.; Shankar, R. A Delphi-AHP-TOPSIS based benchmarking framework for performance improvement of a cold chain. Expert Syst. Appl. 2011, 38, 10170–10182. [Google Scholar] [CrossRef]

- Taghikhah, F.; Voinov, A.; Shukla, N.; Filatova, T.; Anufriev, M. Integrated modeling of extended agro-food supply chains: A systems approach. Eur. J. Oper. Res. 2021, 288, 852–868. [Google Scholar] [CrossRef] [PubMed]

- Montanari, R. Cold chain tracking: A managerial perspective. Trends Food Sci. Technol. 2008, 19, 425–431. [Google Scholar] [CrossRef]

- WEF. These Countries Will Be the World’s Most Populous Countries by 2030. 2022. Available online: https://www.weforum.org/agenda/2022/08/world-population-countries-india-china-2030/#:~:text=The%20world’s%20population%20is%20expected,the%20end%20of%20the%20century (accessed on 16 November 2022).

- Ishangulyyev, R.; Kim, S.; Lee, S.H. Understanding food loss and waste—Why are we losing and wasting food? Foods 2019, 8, 297. [Google Scholar] [CrossRef]

- Kumar, A.; Mangla, S.K.; Kumar, P.; Karamperidis, S. Challenges in perishable food supply chains for sustainability management: A developing economy perspective. Bus. Strategy Environ. 2020, 29, 1809–1831. [Google Scholar] [CrossRef]

- Mwaniki, F.N.; Nyamu, F.K. Reducing Food Loss in Kenya for a Sustainable Food Future. In Sustainable Agriculture and Food Security; Springer: Cham, Switzerland, 2022; pp. 311–326. [Google Scholar]

- Lau, K.Q.; Sabran, M.R.; Shafie, S.R. Utilization of vegetable and fruit by-products as functional ingredient and food. Front. Nutr. 2021, 8, 261. [Google Scholar] [CrossRef] [PubMed]

- Panahi, H.K.S.; Dehhaghi, M.; Guillemin, G.J.; Gupta, V.K.; Lam, S.S.; Aghbashlo, M.; Tabatabaei, M. Bioethanol production from food wastes rich in carbohydrates. Curr. Opin. Food Sci. 2022, 43, 71–81. [Google Scholar] [CrossRef]

- Wu, W.; Beretta, C.; Cronje, P.; Hellweg, S.; Defraeye, T. Environmental trade-offs in fresh-fruit cold chains by combining virtual cold chains with life cycle assessment. Appl. Energy 2019, 254, 113586. [Google Scholar] [CrossRef]

- Naylor, R.L.; Kishore, A.; Sumaila, U.R.; Issifu, I.; Hunter, B.P.; Belton, B.; Bush, S.R.; Cao, L.; Gelcich, S.; Gephart, J.A.; et al. Blue food demand across geographic and temporal scales. Nat. Commun. 2021, 12, 5413. [Google Scholar] [CrossRef] [PubMed]

- Skawińska, E.; Zalewski, R.I. Economic Impact of Temperature Control during Food Transportation—A COVID-19 Perspective. Foods 2022, 11, 467. [Google Scholar] [CrossRef] [PubMed]

- Stella, G.; Torquati, B.; Paffarini, C.; Giordani, G.; Cecchini, L.; Poletti, R. “Food Village”: An Innovative Alternative Food Network Based on Human Scale Development Economic Model. Foods 2022, 11, 1447. [Google Scholar] [CrossRef] [PubMed]

- Todd, E. Food-borne disease prevention and risk assessment. Int. J. Environ. Res. Public Health 2020, 17, 5129. [Google Scholar] [CrossRef] [PubMed]

- Son, N.M.; Nguyen, T.L.; Huong, P.T.; Hien, L.T. Novel system using blockchain for origin traceability of agricultural products. Sens. Mater. 2021, 33, 601–613. [Google Scholar] [CrossRef]

- León-Bravo, V.; Caniato, F.; Caridi, M. Sustainability assessment in the food supply chain: Study of a certified product in Italy. Prod. Plan. Control. 2021, 32, 567–584. [Google Scholar] [CrossRef]

- Yoo, S.R.; Lee, S.W.; Jeon, H.M. The role of customer experience, food healthiness, and value for revisit intention in Grocerant. Sustainability 2020, 12, 2359. [Google Scholar] [CrossRef]

- Oncioiu, I.; Bunget, O.C.; Türkeș, M.C.; Căpușneanu, S.; Topor, D.I.; Tamaș, A.S.; Hint, M.Ș. The impact of big data analytics on company performance in supply chain management. Sustainability 2019, 11, 4864. [Google Scholar] [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Cerchione, R.; Esposito, E. A systematic review of supply chain knowledge management research: State of the art and research opportunities. Int. J. Prod. Econ. 2016, 182, 276–292. [Google Scholar] [CrossRef]

- Kummer, S.; Herold, D.M.; Dobrovnik, M.; Mikl, J.; Schäfer, N. A systematic review of blockchain literature in logistics and supply chain management: Identifying research questions and future directions. Future Internet 2020, 12, 60. [Google Scholar] [CrossRef]

- Petticrew, M.; Roberts, H. Exploring heterogeneity and publication bias. In Systematic Reviews in the Social Sciences: A Practical Guide; Blackwell Publishing: Malden, MA, USA, 2006; pp. 215–246. [Google Scholar]

- Swanson, D.; Goel, L.; Francisco, K.; Stock, J. Applying theories from other disciplines to logistics and supply chain management: A systematic literature review. Transp. J. 2017, 56, 299–356. [Google Scholar] [CrossRef]

- Dumay, J.; Bernardi, C.; Guthrie, J.; Demartini, P. Integrated reporting: A structured literature review. Account. Forum 2016, 40, 166–185. [Google Scholar] [CrossRef]

- Campion, M.A.; Palmer, D.K.; Campion, J.E. A review of structure in the selection interview. Pers. Psychol. 1997, 50, 655–702. [Google Scholar] [CrossRef]

- Pittaway, L.; Robertson, M.; Munir, K.; Denyer, D.; Neely, A. Networking and innovation: A systematic review of the evidence. Int. J. Manag. Rev. 2004, 5, 137–168. [Google Scholar] [CrossRef]

- Zolfani, S.H.; Sedaghat, M.; Maknoon, R.; Zavadskas, E.K. Sustainable tourism: A comprehensive literature review on frameworks and applications. Econ. Res. Ekon. Istraživanja 2015, 28, 1–30. [Google Scholar] [CrossRef]

- Bamakan, S.M.H.; Moghaddam, S.G.; Manshadi, S.D. Blockchain-enabled pharmaceutical cold chain: Applications, key challenges, and future trends. J. Clean. Prod. 2021, 302, 127021. [Google Scholar] [CrossRef]

- Mercier, S.; Mondor, M.; Villeneuve, S.; Marcos, B. The Canadian food cold chain: A legislative, scientific, and prospective overview. Int. J. Refrig. 2018, 88, 637–645. [Google Scholar] [CrossRef]

- Masudin, I.; Safitri, N.T. Food cold chain in Indonesia during the COVID-19 pandemic: A current situation and mitigation. J. Rekayasa Sist. Ind. 2020, 9, 99–106. [Google Scholar] [CrossRef]

- Meneghetti, A.; Monti, L. Greening the food supply chain: An optimisation model for sustainable design of refrigerated automated warehouses. Int. J. Prod. Res. 2015, 53, 6567–6587. [Google Scholar] [CrossRef]

- Gallier, S.; Gragson, D.; Jiménez-Flores, R.; Everett, D. Using confocal laser scanning microscopy to probe the milk fat globule membrane and associated proteins. J. Agric. Food Chem. 2010, 58, 4250–4257. [Google Scholar] [CrossRef]

- Hardas, N.; Danvirivakul, S.; Foley, J.L.; Nawar, W.W.; Chinachoti, P. Effect of relative humidity on the oxidative and physical stability of encapsulated milk fat. J. Am. Oil Chem. Soc. 2002, 79, 151–158. [Google Scholar] [CrossRef]

- Cadieux, B.; Colavecchio, A.; Jeukens, J.; Freschi, L.; Emond-Rheault, J.G.; Kukavica-Ibrulj, I.; Goodridge, L.D. Prophage induction reduces Shiga toxin producing Escherichia coli (STEC) and Salmonella enterica on tomatoes and spinach: A model study. Food Control. 2018, 89, 250–259. [Google Scholar] [CrossRef]

- Aiello, G.; La Scalia, G.; Micale, R. Simulation analysis of cold chain performance based on time–temperature data. Prod. Plan. Control. 2012, 23, 468–476. [Google Scholar] [CrossRef]

- Leng, L.; Zhang, C.; Zhao, Y.; Wang, W.; Zhang, J.; Li, G. Biobjective low-carbon location-routing problem for cold chain logistics: Formulation and heuristic approaches. J. Clean. Prod. 2020, 273, 122801. [Google Scholar] [CrossRef]

- Fattahi, F.; Nookabadi, A.S.; Kadivar, M. A model for measuring the performance of the meat supply chain. Br. Food J. 2013, 115, 1090–1111. [Google Scholar] [CrossRef]

- Chen, J.; Gui, P.; Ding, T.; Na, S.; Zhou, Y. Optimization of transportation routing problem for fresh food by improved ant colony algorithm based on tabu search. Sustainability 2019, 11, 6584. [Google Scholar] [CrossRef]

- Mercier, S.; Villeneuve, S.; Mondor, M.; Uysal, I. Time–temperature management along the food cold chain: A review of recent developments. Compr. Rev. Food Sci. Food Saf. 2017, 16, 647–667. [Google Scholar] [CrossRef] [PubMed]

- Duan, J.; Zhang, C.; Gong, Y.; Brown, S.; Li, Z. A content-analysis based literature review in blockchain adoption within food supply chain. Int. J. Environ. Res. Public Health 2020, 17, 1784. [Google Scholar] [CrossRef] [PubMed]

- McCarthy, U.; Uysal, I.; Badia-Melis, R.; Mercier, S.; O’Donnell, C.; Ktenioudaki, A. Global food security—Issues, challenges and technological solutions. Trends Food Sci. Technol. 2018, 77, 11–20. [Google Scholar] [CrossRef]

- Ambra, T.; Caris, A.; Macharis, C. Towards freight transport system unification: Reviewing and combining the advancements in the physical internet and synchromodal transport research. Int. J. Prod. Res. 2019, 57, 1606–1623. [Google Scholar] [CrossRef]

- Sheffi, Y. The New (Ab)Normal: Reshaping Business and Supply Chain Strategy beyond COVID-19; MIT CTL Media: Cambridge, MA, USA, 2020. [Google Scholar]

- Manglani, H.; Hodge, G.L.; Oxenham, W. Application of the internet of things in the textile industry. Text. Prog. 2019, 51, 225–297. [Google Scholar] [CrossRef]

- Gligor, D.; Tan, A.; Nguyen, T.N.T. The obstacles to cold chain implementation in developing countries: Insights from Vietnam. Int. J. Logist. Manag. 2018, 29, 942–958. [Google Scholar] [CrossRef]

- Che, S.; Kim, J.; Chang, D. Liquid Air as an Energy Carrier for Liquefied Natural Gas Cold Energy Distribution in Cold Storage Systems. Energies 2021, 14, 272. [Google Scholar] [CrossRef]

- Nechaev, A.; Skorobogatova, Y.; Nechaeva, M. Toolkit for the transportation and logistics infrastructure. Transp. Res. Procedia 2021, 54, 637–644. [Google Scholar] [CrossRef]

- de Moraes, C.C.; de Oliveira Costa, F.H.; Pereira, C.R.; da Silva, A.L.; Delai, I. Retail food waste: Mapping causes and reduction practices. J. Clean. Prod. 2020, 256, 120124. [Google Scholar] [CrossRef]

- Dora, M.; Biswas, S.; Choudhary, S.; Nayak, R.; Irani, Z. A system-wide interdisciplinary conceptual framework for food loss and waste mitigation strategies in the supply chain. Ind. Mark. Manag. 2021, 93, 492–508. [Google Scholar] [CrossRef]

- Sylim, P.; Liu, F.; Marcelo, A.; Fontelo, P. Blockchain technology for detecting falsified and substandard drugs in distribution: Pharmaceutical supply chain intervention. JMIR Res. Protoc. 2018, 7, e10163. [Google Scholar] [CrossRef] [PubMed]

- Prajogo, D.; Toy, J.; Bhattacharya, A.; Oke, A.; Cheng, T.C.E. The relationships between information management, process management and operational performance: Internal and external contexts. Int. J. Prod. Econ. 2018, 199, 95–103. [Google Scholar] [CrossRef]

- Cagliano, R.; Caniato, F.; Spina, G. The linkage between supply chain integration and manufacturing improvement programmes. Int. J. Oper. Prod. Manag. 2006, 26, 282–299. [Google Scholar] [CrossRef]

- Frank, A.G.; Mendes, G.H.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Change 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Kaeothep, W. A Service Design for an Air Cargo Business. J. Supply Chain. Manag. Res. Pract. 2017, 11, 24–38. [Google Scholar]

- Al-Talib, M.; Melhem, W.Y.; Anosike, A.I.; Reyes, J.A.G.; Nadeem, S.P. Achieving resilience in the supply chain by applying IoT technology. Procedia CIRP 2020, 91, 752–757. [Google Scholar] [CrossRef]

- Yan, Y.; Gupta, S.; Licsandru, T.C.; Schoefer, K. Integrating machine learning, modularity and supply chain integration for Branding 4.0. Ind. Mark. Manag. 2022, 104, 136–149. [Google Scholar] [CrossRef]

- Chang, W.; Ellinger, A.E.; Kim, K.K.; Franke, G.R. Supply chain integration and firm financial performance: A meta-analysis of positional advantage mediation and moderating factors. Eur. Manag. J. 2016, 34, 282–295. [Google Scholar] [CrossRef]

- Radzi, R.M.; Saidon, I.M.; Ab Ghani, N. Japanese Food Company Supply Chain in Malaysia: Its Structure and Risk Management Strategies. In Ethics, Governance and Risk Management in Organizations; Springer: Singapore, 2020; pp. 151–168. [Google Scholar]

- Ni, W.; Sun, H. The effect of sustainable supply chain management on business performance: Implications for integrating the entire supply chain in the Chinese manufacturing sector. J. Clean. Prod. 2019, 232, 1176–1186. [Google Scholar] [CrossRef]

- Ataseven, C.; Nair, A. Assessment of supply chain integration and performance relationships: A meta-analytic investigation of the literature. Int. J. Prod. Econ. 2017, 185, 252–265. [Google Scholar] [CrossRef]

- Zhang, M.; Lettice, F.; Chan, H.K.; Nguyen, H.T. Supplier integration and firm performance: The moderating effects of internal integration and trust. Prod. Plan. Control. 2018, 29, 802–813. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Parekh, H.; Mani, V.; Belhadi, A.; Sharma, R. Digital twin for sustainable manufacturing supply chains: Current trends, future perspectives, and an implementation framework. Technol. Forecast. Soc. Chang. 2022, 176, 121448. [Google Scholar] [CrossRef]

- Goswami, M.; De, A.; Habibi, M.K.K.; Daultani, Y. Examining freight performance of third-party logistics providers within the automotive industry in India: An environmental sustainability perspective. Int. J. Prod. Res. 2020, 58, 7565–7592. [Google Scholar] [CrossRef]

- Parmar, B.B.L.; Wicks, A.C.; Freeman, R.E. Stakeholder Management & The Value of Human-Centred Corporate Objectives. J. Manag. Stud. 2022, 59, 569–582. [Google Scholar]

- Barro, F. Stakeholder theory and dynamics in supply chain collaboration. Int. J. Oper. Prod. Manag. 2009, 29, 591–611. [Google Scholar]

- Andriof, J.; Waddock, S. Unfolding stakeholder engagement. In Unfolding Stakeholder Thinking; Routledge: Abingdon-on-Thames, UK, 2017; pp. 19–42. [Google Scholar]

- Khan, S.A.R.; Godil, D.I.; Jabbour, C.J.C.; Shujaat, S.; Razzaq, A.; Yu, Z. Green data analytics, blockchain technology for sustainable development, and sustainable supply chain practices: Evidence from small and medium enterprises. Ann. Oper. Res. 2021, 1–25. [Google Scholar] [CrossRef]

- Michalski, M.; Montes-Botella, J.L.; Narasimhan, R. The impact of asymmetry on performance in different collaboration and integration environments in supply chain management. Supply Chain. Manag. Int. J. 2018, 23, 33–49. [Google Scholar] [CrossRef]

- Ferrell, W.; Ellis, K.; Kaminsky, P.; Rainwater, C. Horizontal collaboration: Opportunities for improved logistics planning. Int. J. Prod. Res. 2020, 58, 4267–4284. [Google Scholar] [CrossRef]

- Santos, H.; Lannelongue, G.; Gonzalez-Benito, J. Integrating green practices into operational performance: Evidence from Brazilian manufacturers. Sustainability 2019, 11, 2956. [Google Scholar] [CrossRef]

- Galbreath, J. Does primary stakeholder management positively affect the bottom line? Some evidence from Australia. Manag. Decis. 2006, 44, 1106–1121. [Google Scholar] [CrossRef]

- Naciti, V. Corporate governance and board of directors: The effect of a board composition on firm sustainability performance. J. Clean. Prod. 2019, 237, 117727. [Google Scholar] [CrossRef]

- Villazón, C.C.; Pinilla, L.S.; Olaso, J.R.O.; Gandarias, N.T.; de Lacalle, N.L. Identification of key performance indicators in project-based organisations through the lean approach. Sustainability 2020, 12, 5977. [Google Scholar] [CrossRef]

- Parhi, S.; Joshi, K.; Gunasekaran, A.; Sethuraman, K. Reflecting on an empirical study of the digitalization initiatives for sustainability on logistics: The concept of Sustainable Logistics 4.0. Clean. Logist. Supply Chain. 2022, 4, 100058. [Google Scholar] [CrossRef]

- Esmaeel, R.I.; Zakuan, N.; Jamal, N.M.; Taherdoost, H. Understanding of business performance from the perspective of manufacturing strategies: Fit manufacturing and overall equipment effectiveness. Procedia Manuf. 2018, 22, 998–1006. [Google Scholar] [CrossRef]

- Tavana, M.; Shabani, A.; Singh, R. The impact of interwoven integration practices on supply chain value addition and firm performance. J. Ind. Eng. Int. 2019, 15, 39–51. [Google Scholar]

- Kumar, M.; Srai, J.; Pattinson, L.; Gregory, M. Mapping of the UK food supply chains: Capturing trends and structural changes. J. Adv. Manag. Res. 2013, 10, 299–326. [Google Scholar] [CrossRef]

- Hill, N.; Alexander, J. The Handbook of Customer Satisfaction and Loyalty Measurement; Routledge: Abingdon-on-Thames, UK, 2017. [Google Scholar]

- Farrukh, A.; Mathrani, S.; Sajjad, A. A natural resource and institutional theory-based view of green-lean-six sigma drivers for environmental management. Bus. Strategy Environ. 2022, 31, 1074–1090. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.; Jabbour, C.J.C.; Gunasekaran, A.; Ndubisi, N.O.; Venkatesh, M. Manufacturing and service supply chain resilience to the COVID-19 outbreak: Lessons learned from the automobile and airline industries. Technol. Forecast. Soc. Change 2021, 163, 120447. [Google Scholar] [CrossRef]

- Aday, S.; Aday, M.S. Impact of COVID-19 on the food supply chain. Food Qual. Saf. 2020, 4, 167–180. [Google Scholar] [CrossRef]

- Govindan, K.; Mangla, S.K.; Luthra, S. Prioritising indicators in improving supply chain performance using fuzzy AHP: Insights from the case example of four Indian manufacturing companies. Prod. Plan. Control. 2017, 28, 552–573. [Google Scholar] [CrossRef]

- Di Maio, F.; Rem, P.C.; Baldé, K.; Polder, M. Measuring resource efficiency and circular economy: A market value approach. Resour. Conserv. Recycl. 2017, 122, 163–171. [Google Scholar] [CrossRef]

- Min, S.; Zacharia, Z.G.; Smith, C.D. Defining supply chain management: In the past, present, and future. J. Bus. Logist. 2019, 40, 44–55. [Google Scholar] [CrossRef]

- Mindur, M.; Pawęska, M. Basic Determinants in Integrated Supply Chains. Logist. Transp. 2019, 41, 31–40. [Google Scholar] [CrossRef]

- Hassanzadeh, A.; Rasti-Barzoki, M. Minimizing total resource consumption and total tardiness penalty in a resource allocation supply chain scheduling and vehicle routing problem. Appl. Soft Comput. 2017, 58, 307–323. [Google Scholar] [CrossRef]

- Han, G.; Yan, S.; Fan, B. Regional regulations and public safety perceptions of quality-of-life issues: Empirical study on food safety in China. Healthcare 2020, 8, 275. [Google Scholar] [CrossRef] [PubMed]

- Nammour, F.L. Clinical Intelligence Framework for Decision-Support. Ph.D. Thesis, Kingston University, London, UK, 2018. [Google Scholar]

- Sharma, P.; Gunasekaran, A.; Subramanian, G. Distributor Opportunism Toward the Supplier: A Social Network Perspective. J. Comput. Inf. Syst. 2022, 1–16. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Ertz, M. Food cold chain management: What we know and what we deserve. Supply Chain. Manag. Int. J. 2020, 26, 102–135. [Google Scholar]

- Phillips, F.K. Sustainable Bio-Based Supply Chains in Light of the Nagoya Protocol. In Implementing Triple Bottom Line Sustainability into Global Supply Chains; Routledge: Abingdon-on-Thames, UK, 2017; pp. 294–316. [Google Scholar]

- Poulsen, R.T.; Sampson, H. A swift turnaround? Abating shipping greenhouse gas emissions via port call optimization. Transp. Res. Part D Transp. Environ. 2020, 86, 102460. [Google Scholar] [CrossRef]

- Koh, L.; Dolgui, A.; Sarkis, J. Blockchain in transport and logistics–paradigms and transitions. Int. J. Prod. Res. 2020, 58, 2054–2062. [Google Scholar] [CrossRef]

- Li, Y.; Li, B.; Deng, F.; Yang, Q.; Zhang, B. Research on the Application of Cold Energy of Largescale Lng-Powered Container Ships to Refrigerated Containers. Pol. Marit. Res. 2021, 28, 107–121. [Google Scholar] [CrossRef]

- Raihan, A.; Tuspekova, A. Toward a sustainable environment: Nexus between economic growth, renewable energy use, forested area, and carbon emissions in Malaysia. Resour. Conserv. Recycl. Adv. 2022, 15, 200096. [Google Scholar] [CrossRef]

- Reardon, T.; Heiman, A.; Lu, L.; Nuthalapati, C.S.; Vos, R.; Zilberman, D. “Pivoting” by food industry firms to cope with COVID-19 in developing regions: E-commerce and “copivoting” delivery intermediaries. Agric. Econ. 2021, 52, 459–475. [Google Scholar] [CrossRef]

- Varadarajan, R. Innovating for sustainability: A framework for sustainable innovations and a model of sustainable innovations orientation. J. Acad. Mark. Sci. 2017, 45, 14–36. [Google Scholar] [CrossRef]

- Gielens, K.; Ma, Y.; Namin, A.; Sethuraman, R.; Smith, R.J.; Bachtel, R.C.; Jervis, S. The future of private labels: Towards a smart private label strategy. J. Retail. 2021, 97, 99–115. [Google Scholar] [CrossRef]

- Rana, J.; Paul, J. Consumer behavior and purchase intention for organic food: A review and research agenda. J. Retail. Consum. Serv. 2017, 38, 157–165. [Google Scholar] [CrossRef]

- Rueda, X.; Garrett, R.D.; Lambin, E.F. Corporate investments in supply chain sustainability: Selecting instruments in the agri-food industry. J. Clean. Prod. 2017, 142, 2480–2492. [Google Scholar] [CrossRef]

- Nandakumar, N.; Saleeshya, P.G.; Harikumar, P. Bottleneck identification and process improvement by lean six sigma DMAIC methodology. Mater. Today Proc. 2020, 24, 1217–1224. [Google Scholar] [CrossRef]

- Raut, R.D.; Gardas, B.B.; Narwane, V.S.; Narkhede, B.E. Improvement in the food losses in fruits and vegetable supply chain-a perspective of cold third-party logistics approach. Oper. Res. Perspect. 2019, 6, 100117. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Dukovska-Popovska, I.; Subramanian, N.; Chan, H.K.; Bai, R. Decision-making in cold chain logistics using data analytics: A literature review. Int. J. Logist. Manag. 2018, 29, 839–861. [Google Scholar] [CrossRef]

- Chen, C.K.; Palma, F.; Reyes, L. Reducing global supply chains’ waste of overproduction by using lean principles: A conceptual approach. Int. J. Qual. Serv. Sci. 2019, 11, 441–454. [Google Scholar] [CrossRef]

- Ray, B. The Need for Food Biopreservation. In Food Biopreservatives of Microbial Origin; CRC Press: Boca Raton, FL, USA, 2019; pp. 1–23. [Google Scholar]

- Chegere, M.J. Post-harvest losses reduction by small-scale maize farmers: The role of handling practices. Food Policy 2018, 77, 103–115. [Google Scholar] [CrossRef]

- Liao, P.A.; Chang, H.H.; Chang, C.Y. Why is the food traceability system unsuccessful in Taiwan? Empirical evidence from a national survey of fruit and vegetable farmers. Food Policy 2011, 36, 686–693. [Google Scholar] [CrossRef]

- Khayatnezhad, M.; Nasehi, F. Industrial pesticides and a methods assessment for the reduction of associated risks: A review. Adv. Life Sci. 2021, 8, 202–210. [Google Scholar]

- Alsayegh, M.F.; Abdul Rahman, R.; Homayoun, S. Corporate economic, environmental, and social sustainability performance transformation through ESG disclosure. Sustainability 2020, 12, 3910. [Google Scholar] [CrossRef]

- Fekete, H.; Kuramochi, T.; Roelfsema, M.; den Elzen, M.; Forsell, N.; Höhne, N.; Gusti, M. A review of successful climate change mitigation policies in major emitting economies and the potential of global replication. Renew. Sustain. Energy Rev. 2021, 137, 110602. [Google Scholar] [CrossRef]

- Vieira, N.D.B.; Nogueira, L.A.H.; Haddad, J. An assessment of CO2 emissions avoided by energy-efficiency programs: A general methodology and a case study in Brazil. Energy 2018, 142, 702–715. [Google Scholar] [CrossRef]

- Camilleri, A.R.; Larrick, R.P.; Hossain, S.; Patino-Echeverri, D. Consumers underestimate the emissions associated with food but are aided by labels. Nat. Clim. Change 2019, 9, 53–58. [Google Scholar] [CrossRef]

- Ageron, B.; Gunasekaran, A.; Spalanzani, A. Sustainable supply management: An empirical study. Int. J. Prod. Econ. 2012, 140, 168–182. [Google Scholar] [CrossRef]

- Zhu, G.; Chou, M.C.; Tsai, C.W. Lessons learned from the COVID-19 pandemic exposing the shortcomings of current supply chain operations: A long-term prescriptive offering. Sustainability 2020, 12, 5858. [Google Scholar] [CrossRef]

- Krishnan, R.; Yen, P.; Agarwal, R.; Arshinder, K.; Bajada, C. Collaborative innovation and sustainability in the food supply chain-evidence from farmer producer organisations. Resour. Conserv. Recycl. 2021, 168, 105253. [Google Scholar] [CrossRef]

- Huo, B.; Ye, Y.; Zhao, X.; Zhu, K. Supply chain quality integration: A taxonomy perspective. Int. J. Prod. Econ. 2019, 207, 236–246. [Google Scholar] [CrossRef]

- Ferronato, N.; Torretta, V. Waste mismanagement in developing countries: A review of global issues. Int. J. Environ. Res. Public Health 2019, 16, 1060. [Google Scholar] [CrossRef]

- Abdel-Shafy, H.I.; Mansour, M.S. Solid waste issue: Sources, composition, disposal, recycling, and valorization. Egypt. J. Pet. 2018, 27, 1275–1290. [Google Scholar] [CrossRef]

- Ali, M.H.; Suleiman, N.; Khalid, N.; Tan, K.H.; Tseng, M.L.; Kumar, M. Supply chain resilience reactive strategies for food SMEs in coping to COVID-19 crisis. Trends Food Sci. Technol. 2021, 109, 94–102. [Google Scholar] [CrossRef]

- Xu, D.; Long, Y. The role of supply chain integration in the transformation of food manufacturers: A case study from China. Int. J. Logist. Res. Appl. 2021, 24, 198–212. [Google Scholar] [CrossRef]

- Rostamzadeh, R.; Ghorabaee, M.K.; Govindan, K.; Esmaeili, A.; Nobar, H.B.K. Evaluation of sustainable supply chain risk management using an integrated fuzzy TOPSIS-CRITIC approach. J. Clean. Prod. 2018, 175, 651–669. [Google Scholar] [CrossRef]

- Astill, J.; Dara, R.A.; Campbell, M.; Farber, J.M.; Fraser, E.D.; Sharif, S.; Yada, R.Y. Transparency in food supply chains: A review of enabling technology solutions. Trends Food Sci. Technol. 2019, 91, 240–247. [Google Scholar] [CrossRef]

- Aguiar, D.R.; Silva, A.L.D. Changes in beef consumption and retailing competitiveness in Brazil: A rapid appraisal. Agribus. Int. J. 2002, 18, 145–161. [Google Scholar] [CrossRef]

- Ali, I.; Nagalingam, S.; Gurd, B. A resilience model for cold chain logistics of perishable products. Int. J. Logist. Manag. 2018, 29, 922–941. [Google Scholar] [CrossRef]

- Andoh, E.A.; Yu, H. A two-stage decision-support approach for improving sustainable last-mile cold chain logistics operations of COVID-19 vaccines. Ann. Oper. Res. 2022, 1–31. [Google Scholar] [CrossRef]

- Chaitangjit, P.; Ongkunaruk, P. The study of cold storage and temperature controlled transportation: A case study of a chain restaurant in Thailand. Pamukkale Univ. J. Eng. Sci. 2019, 25, 1014–1019. [Google Scholar] [CrossRef]

- Cousins, P.D.; Menguc, B. The implications of socialization and integration in supply chain management. J. Oper. Manag. 2006, 24, 604–620. [Google Scholar] [CrossRef]

- Dijkstra, T.; Meulenberg, M.; Van Tilburg, A. Applying marketing channel theory to food marketing in developing countries: Vertical disintegration model for horticultural marketing channels in Kenya. Agribus. Int. J. 2001, 17, 227–241. [Google Scholar] [CrossRef]

- Fahrni, M.L.; Ismail, I.A.N.; Refi, D.M.; Almeman, A.; Yaakob, N.C.; Saman, K.M.; Mansor, N.F.; Noordin, N.; Babar, Z.-U.-D. Management of COVID-19 vaccines cold chain logistics: A scoping review. J. Pharm. Policy Pract. 2022, 15, 16. [Google Scholar] [CrossRef] [PubMed]

- Gokarn, S.; Kuthambalayan, T.S. Analysis of challenges inhibiting the reduction of waste in food supply chain. J. Clean. Prod. 2017, 168, 595–604. [Google Scholar] [CrossRef]

- Gokarn, S.; Choudhary, A. Modeling the key factors influencing the reduction of food loss and waste in fresh produce supply chains. J. Environ. Manag. 2021, 294, 113063. [Google Scholar] [CrossRef]

- Gorton, M.; Dumitrashko, M.; White, J. Overcoming supply chain failure in the agri-food sector: A case study from Moldova. Food Policy 2006, 31, 90–103. [Google Scholar] [CrossRef]

- Jevšnik, M.; Hlebec, V.; Raspor, P. Consumers’ awareness of food safety from shopping to eating. Food Control 2008, 19, 737–745. [Google Scholar] [CrossRef]

- Joshi, R.; Banwet, D.K.; Shankar, R. Indian cold chain: Modeling the inhibitors. Br. Food J. 2009, 111, 1260–1283. [Google Scholar] [CrossRef]

- Kuo, J.C.; Chen, M.C. Developing an advanced multi-temperature joint distribution system for the food cold chain. Food Control. 2010, 21, 559–566. [Google Scholar] [CrossRef]

- Martínez, C.I.P.; Poveda, A.C. Characterization of cooling equipment in the food industry: Case study of the Colombian meat, dairy, and fruit and vegetable sectors. Environ. Dev. 2022, 41, 100693. [Google Scholar] [CrossRef]

- Mesterházy, Á.; Oláh, J.; Popp, J. Losses in the grain supply chain: Causes and solutions. Sustainability 2020, 12, 2342. [Google Scholar] [CrossRef]

- Özbük, R.M.Y.; Coşkun, A. Factors affecting food waste at the downstream entities of the supply chain: A critical review. J. Clean. Prod. 2020, 244, 118628. [Google Scholar] [CrossRef]

- Parashar, S.; Sood, G.; Agrawal, N. Modelling the enablers of food supply chain for reduction in carbon footprint. J. Clean. Prod. 2020, 275, 122932. [Google Scholar] [CrossRef]

- Patidar, S.; Shukla, A.C.; Sukhwani, V.K. Food supply chain management (FSCM): A structured literature review and future research agenda. J. Adv. Manag. Res. 2021, 19, 272–299. [Google Scholar] [CrossRef]

- Rais, M.; Kaul, A.; Jain, A. Evaluation of public private partnerships in perishable food supply chain in India. J. Supply Chain. Manag. Syst. 2019, 8, 52–63. [Google Scholar]

- Ren, Q.S.; Fang, K.; Yang, X.T.; Han, J.W. Ensuring the quality of meat in cold chain logistics: A comprehensive review. Trends Food Sci. Technol. 2022, 119, 133–151. [Google Scholar] [CrossRef]

- Singh, R.K.; Gunasekaran, A.; Kumar, P. Third party logistics (3PL) selection for cold chain management: A fuzzy AHP and fuzzy TOPSIS approach. Ann. Oper. Res. 2018, 267, 531–553. [Google Scholar] [CrossRef]

- Yan, H.; Song, M.J.; Lee, H.Y. A Systematic Review of Factors Affecting Food Loss and Waste and Sustainable Mitigation Strategies: A Logistics Service Providers’ Perspective. Sustainability 2021, 13, 11374. [Google Scholar] [CrossRef]

- Zhu, L. Economic analysis of a traceability system for a two-level perishable food supply chain. Sustainability 2017, 9, 682. [Google Scholar] [CrossRef]

- Aramyan, L.H.; Lansink, A.G.O.; Van Der Vorst, J.G.; Van Kooten, O. Performance measurement in agri-food supply chains: A case study. Supply Chain. Manag. Int. J. 2007, 12, 304–315. [Google Scholar] [CrossRef]

- Arora, M.; Panda, B.P. RFID-An Emerging Technology for Cold Chain Sustainability. ZENITH Int. J. Bus. Econ. Manag. Res. 2018, 8, 136–145. [Google Scholar]

- Badia-Melis, R.; McCarthy, U.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Villalba, J.R. New trends in cold chain monitoring applications-A review. Food Control. 2018, 86, 170–182. [Google Scholar] [CrossRef]

- Bottani, E.; Casella, G.; Nobili, M.; Tebaldi, L. Assessment of the economic and environmental sustainability of a food cold supply chain. IFAC-PapersOnLine 2019, 52, 367–372. [Google Scholar] [CrossRef]

- Defraeye, T.; Cronjé, P.; Berry, T.; Opara, U.L.; East, A.; Hertog, M.; Verboven, P.; Nicolai, B. Towards integrated performance evaluation of future packaging for fresh produce in the cold chain. Trends Food Sci. Technol. 2015, 44, 201–225. [Google Scholar] [CrossRef]

- Dong, Y.; Miller, S.A. Assessing the lifecycle greenhouse gas (GHG) emissions of perishable food products delivered by the cold chain in China. J. Clean. Prod. 2021, 303, 126982. [Google Scholar] [CrossRef]

- Esfahbodi, A.; Zhang, Y.; Watson, G. Sustainable supply chain management in emerging economies: Trade-offs between environmental and cost performance. Int. J. Prod. Econ. 2016, 181, 350–366. [Google Scholar] [CrossRef]

- Fan, Y.; de Kleuver, C.; de Leeuw, S.; Behdani, B. Trading off cost, emission, and quality in cold chain design: A simulation approach. Comput. Ind. Eng. 2021, 158, 107442. [Google Scholar] [CrossRef]

- Fritz, M.; Schiefer, G. Food chain management for sustainable food system development: A European research agenda. Agribus. Int. J. 2008, 24, 440–452. [Google Scholar] [CrossRef]

- Gallo, A.; Accorsi, R.; Baruffaldi, G.; Manzini, R. Designing sustainable cold chains for long-range food distribution: Energy-effective corridors on the Silk Road Belt. Sustainability 2017, 9, 2044. [Google Scholar] [CrossRef]

- Khan, A.S.; Salah, B.; Zimon, D.; Ikram, M.; Khan, R.; Pruncu, C.I. A sustainable distribution design for multi-quality multiple-cold-chain products: An integrated inspection strategies approach. Energies 2020, 13, 6612. [Google Scholar] [CrossRef]

- Plambeck, E.L. Reducing greenhouse gas emissions through operations and supply chain management. Energy Econ. 2012, 34, S64–S74. [Google Scholar] [CrossRef]

- Qian, J.; Yu, Q.; Jiang, L.; Yang, H.; Wu, W. Food cold chain management improvement: A conjoint analysis on COVID-19 and food cold chain systems. Food Control. 2022, 137, 108940. [Google Scholar] [CrossRef] [PubMed]

- Sharma, Y.K.; Mangla, S.K.; Patil, P.P.; Liu, S. When challenges impede the process: For circular economy-driven sustainability practices in food supply chain. Manag. Decis. 2019, 57, 995–1017. [Google Scholar] [CrossRef]

- Su, M.; Fang, M.; Kim, J.; Park, K.S. Sustainable marketing innovation and consumption: Evidence from cold chain food online retail. J. Clean. Prod. 2022, 340, 130806. [Google Scholar] [CrossRef]

- Turan, C.; Ozturkoglu, Y. A conceptual framework model for an effective cold food chain management in sustainability environment. J. Model. Manag. 2021, 17, 1262–1279. [Google Scholar] [CrossRef]

- Van Bemmel, A.; Parizeau, K. Is it food or is it waste? The materiality and relational agency of food waste across the value chain. J. Cult. Econ. 2020, 13, 207–220. [Google Scholar] [CrossRef]

- Vrat, P.; Gupta, R.; Bhatnagar, A.; Pathak, D.K.; Fulzele, V. Literature review analytics (LRA) on sustainable cold-chain for perishable food products: Research trends and future directions. Opsearch 2018, 55, 601–627. [Google Scholar] [CrossRef]

- Wang, Z.; Wen, P. Optimization of a low-carbon two-echelon heterogeneous-fleet vehicle routing for cold chain logistics under mixed time window. Sustainability 2020, 12, 1967. [Google Scholar] [CrossRef]

- Xiao, X.; Fu, Y.; Yang, Y.; Zhang, X. Sustainable solar powered battery-free wireless sensing for food cold chain management. Sens. Int. 2022, 3, 100157. [Google Scholar] [CrossRef]

- Yadav, V.S.; Singh, A.R.; Gunasekaran, A.; Raut, R.D.; Narkhede, B.E. A systematic literature review of the agro-food supply chain: Challenges, network design, and performance measurement perspectives. Sustain. Prod. Consum. 2022, 29, 685–704. [Google Scholar] [CrossRef]

- Zhang, X.R. Super cold chain—A high quality, energy-efficient, and environment-friendly method. Int. J. Energy Res. 2017, 41, 1225–1228. [Google Scholar] [CrossRef]

- Zulkefly, N.S.; Hishamuddin, H.; Rashid, F.A.A.; Razali, N.; Saibani, N.; Ab Rahman, M.N. The effect of transportation disruptions on cold chain sustainability. Evergreen 2021, 8, 262–270. [Google Scholar] [CrossRef]

- Arduino, G.; Murillo, D.C.; Parola, F. Refrigerated container versus bulk: Evidence from the banana cold chain. Marit. Policy Manag. 2015, 42, 228–245. [Google Scholar] [CrossRef]

- Aung, M.M.; Chang, Y.S. Temperature management for the quality assurance of a perishable food supply chain. Food Control. 2014, 40, 198–207. [Google Scholar] [CrossRef]

- Aworh, O.C. Promoting food security and enhancing Nigeria’s small farmers’ income through value-added processing of lesser-known and under-utilized indigenous fruits and vegetables. Food Res. Int. 2015, 76, 986–991. [Google Scholar] [CrossRef]

- Bogataj, M.; Bogataj, L.; Vodopivec, R. Stability of perishable goods in cold logistic chains. Int. J. Prod. Econ. 2005, 93, 345–356. [Google Scholar] [CrossRef]

- Bourlakis, M.; Maglaras, G.; Aktas, E.; Gallear, D.; Fotopoulos, C. Firm size and sustainable performance in food supply chains: Insights from Greek SMEs. Int. J. Prod. Econ. 2014, 152, 112–130. [Google Scholar] [CrossRef]

- Van Donk, D.P. Make to stock or make to order: The decoupling point in the food processing industries. Int. J. Prod. Econ. 2001, 69, 297–306. [Google Scholar] [CrossRef]

- Van Donselaar, K.; Van Woensel, T.; Broekmeulen, R.; Fransoo, J. Inventory control of perishables in supermarkets. Int. J. Prod. Econ. 2006, 104, 462–472. [Google Scholar] [CrossRef]

- Duret, S.; Hoang, H.M.; Derens-Bertheau, E.; Delahaye, A.; Laguerre, O.; Guillier, L. Combining quantitative risk assessment of human health, food waste, and energy consumption: The next step in the development of the food cold chain? Risk Anal. 2019, 39, 906–925. [Google Scholar] [CrossRef]

- Fancello, G.; Paddeu, D.; Fadda, P. Investigating last food mile deliveries: A case study approach to identify needs of food delivery demand. Res. Transp. Econ. 2017, 65, 56–66. [Google Scholar] [CrossRef]

- Feng, H.; Chen, J.; Zhou, W.; Rungsardthong, V.; Zhang, X. Modeling and evaluation on WSN-enabled and knowledge-based HACCP quality control for frozen shellfish cold chain. Food Control. 2019, 98, 348–358. [Google Scholar] [CrossRef]

- Iftekhar, A.; Cui, X. Blockchain-based traceability system that ensures food safety measures to protect consumer safety and COVID-19 free supply chains. Foods 2021, 10, 1289. [Google Scholar] [CrossRef] [PubMed]

- James, S.J.; James, C. The food cold-chain and climate change. Food Res. Int. 2010, 43, 1944–1956. [Google Scholar] [CrossRef]

- Kitinoja, L. Use of Cold Chains for Reducing Food Losses in Developing Countries. 2013. Available online: http://postharvest.org/Use%20of%20cold%20chains%20PEF%20white%20paper%2013-03%20final.pdf (accessed on 6 December 2022).

- Lin, Q.; Zhao, Q.; Lev, B. Cold chain transportation decision in the vaccine supply chain. Eur. J. Oper. Res. 2020, 283, 182–195. [Google Scholar] [CrossRef]

- Liu, P.; Yang, M.; Zhao, X.; Guo, Y.; Wang, L.; Zhang, J.; Lei, W.; Han, W.; Jiang, F.; Liu, W.J.; et al. Cold-chain transportation in the frozen food industry may have caused a recurrence of COVID-19 cases in destination: Successful isolation of SARS-CoV-2 virus from the imported frozen cod package surface. Biosaf. Health 2020, 2, 199–201. [Google Scholar] [CrossRef]

- Martinez, M.G.; Fearne, A.; Caswell, J.A.; Henson, S. Co-regulation as a possible model for food safety governance: Opportunities for public–private partnerships. Food Policy 2007, 32, 299–314. [Google Scholar] [CrossRef]

- Masudin, I.; Ramadhani, A.; Restuputri, D.P.; Amallynda, I. The effect of traceability system and managerial initiative on Indonesian food cold chain performance: A COVID-19 pandemic perspective. Glob. J. Flex. Syst. Manag. 2021, 22, 331–356. [Google Scholar] [CrossRef] [PubMed]

- Ndraha, N.; Hsiao, H.I.; Vlajic, J.; Yang, M.F.; Lin, H.T.V. Time-temperature abuse in the food cold chain: Review of issues, challenges, and recommendations. Food Control. 2018, 89, 12–21. [Google Scholar] [CrossRef]

- Sahin, E.; Babaï, M.Z.; Dallery, Y.; Vaillant, R. Ensuring supply chain safety through time temperature integrators. Int. J. Logist. Manag. 2007, 18, 102–124. [Google Scholar] [CrossRef]

- Sun, J.; Pan, H. Research on the Evaluation System of Agricultural Product Cold Chain Logistics Based on Analytic Hierarchy Process (AHP). In Proceedings of the 2nd International Conference on Applied Mathematics, Modelling, and Intelligent Computing (CAMMIC 2022), Kunming, China, 25–27 March 2022; Volume 12259, pp. 1576–1580. [Google Scholar]

- Wu, J.Y.; Hsiao, H.I. Food quality and safety risk diagnosis in the food cold chain through failure mode and effect analysis. Food Control 2021, 120, 107501. [Google Scholar] [CrossRef]

- Xiao, X.; He, Q.; Li, Z.; Antoce, A.O.; Zhang, X. Improving traceability and transparency of table grapes cold chain logistics by integrating WSN and correlation analysis. Food Control. 2017, 73, 1556–1563. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, N.; Song, X.; Yang, J. Optimizing decision-making of regional cold chain logistics system in view of low-carbon economy. Transp. Res. Part A Policy Pract. 2019, 130, 844–857. [Google Scholar] [CrossRef]

- Zhang, Y.; Hua, G.; Cheng, T.C.E.; Zhang, J. Cold chain distribution: How to deal with node and arc time windows? Ann. Oper. Res. 2020, 291, 1127–1151. [Google Scholar] [CrossRef]

- Edwin, M.; Nair, M.S.; Sekhar, S.J. A comprehensive review on impacts of COVID-19 in food preservation and cold chain: An approach towards implementing green energy technologies. Environ. Prog. Sustain. Energy 2022, 41, e13820. [Google Scholar] [CrossRef]

- Gao, E.; Cui, Q.; Jing, H.; Zhang, Z.; Zhang, X. A review of application status and replacement progress of refrigerants in the Chinese cold chain industry. Int. J. Refrig. 2021, 128, 104–117. [Google Scholar] [CrossRef]

- Huang, L.; Piontek, U. Improving performance of cold-chain insulated container with phase change material: An experimental investigation. Appl. Sci. 2017, 7, 1288. [Google Scholar] [CrossRef]

- Liu, H.; Pretorius, L.; Jiang, D. Optimization of cold chain logistics distribution network terminal. EURASIP J. Wirel. Commun. Netw. 2018, 2018, 158. [Google Scholar] [CrossRef]

- Loisel, J.; Duret, S.; Cornuéjols, A.; Cagnon, D.; Tardet, M.; Derens-Bertheau, E.; Laguerre, O. Cold chain break detection and analysis: Can machine learning help? Trends Food Sci. Technol. 2021, 112, 391–399. [Google Scholar] [CrossRef]

- Prakash, S.; Jasti, N.V.K.; Chan, F.T.S.; Sharma, V.P.; Sharma, L.K. Decision modelling of critical success factors for cold chains using the DEMATEL approach: A case study. Meas. Bus. Excell. 2021, 26, 263–287. [Google Scholar] [CrossRef]

- Tsang, Y.P.; Choy, K.L.; Wu, C.H.; Ho, G.T.S.; Lam, H.Y.; Koo, P.S. An IoT-based cargo monitoring system for enhancing operational effectiveness under a cold chain environment. Int. J. Eng. Bus. Manag. 2017, 9, 1847979017749063. [Google Scholar] [CrossRef]

| Search Terms | Period | Total Number of Papers Retrieved from the Databases of Scopus and Web of Science |

|---|---|---|

| “food cold chain” “sustainable food supply chain” OR “perishable food supply chain” OR “cold chain performance” OR “cold supply chain” OR “foodtractability” | 2000–2022 | 1077 |

| Selection Criteria: 1 | Selection Criteria: 2 | Selection Criteria: 3 |

|---|---|---|

| All papers whose abstracts concentrated on FCCM were included. | Papers having a mention of FCCM in the body were included. | Papers which were cited in the literature on FCCM were included. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akram, H.W.; Akhtar, S.; Ahmad, A.; Anwar, I.; Sulaiman, M.A.B.A. Developing a Conceptual Framework Model for Effective Perishable Food Cold-Supply-Chain Management Based on Structured Literature Review. Sustainability 2023, 15, 4907. https://doi.org/10.3390/su15064907

Akram HW, Akhtar S, Ahmad A, Anwar I, Sulaiman MABA. Developing a Conceptual Framework Model for Effective Perishable Food Cold-Supply-Chain Management Based on Structured Literature Review. Sustainability. 2023; 15(6):4907. https://doi.org/10.3390/su15064907

Chicago/Turabian StyleAkram, Hafiz Wasim, Samreen Akhtar, Alam Ahmad, Imran Anwar, and Mohammad Ali Bait Ali Sulaiman. 2023. "Developing a Conceptual Framework Model for Effective Perishable Food Cold-Supply-Chain Management Based on Structured Literature Review" Sustainability 15, no. 6: 4907. https://doi.org/10.3390/su15064907

APA StyleAkram, H. W., Akhtar, S., Ahmad, A., Anwar, I., & Sulaiman, M. A. B. A. (2023). Developing a Conceptual Framework Model for Effective Perishable Food Cold-Supply-Chain Management Based on Structured Literature Review. Sustainability, 15(6), 4907. https://doi.org/10.3390/su15064907