Effect of Aggregates Packing with the Maximum Density Methodology in Pervious Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

2.2.1. Aggregates Characterization and Packing Procedure

2.2.2. Pervious Concrete Production

2.2.3. Porosity and Density of Pervious Concrete

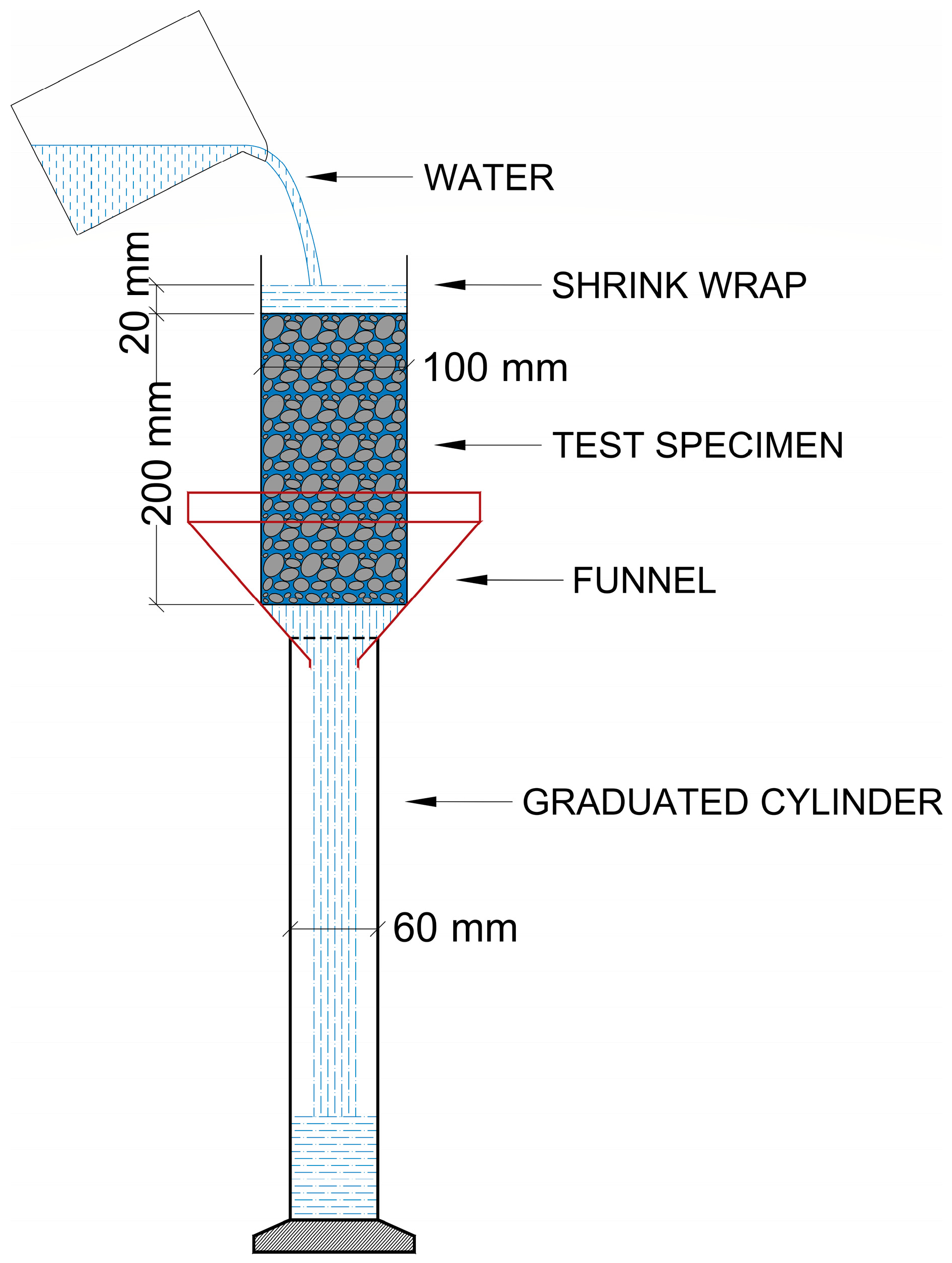

2.2.4. Infiltration Rate

2.2.5. Compressive Strength

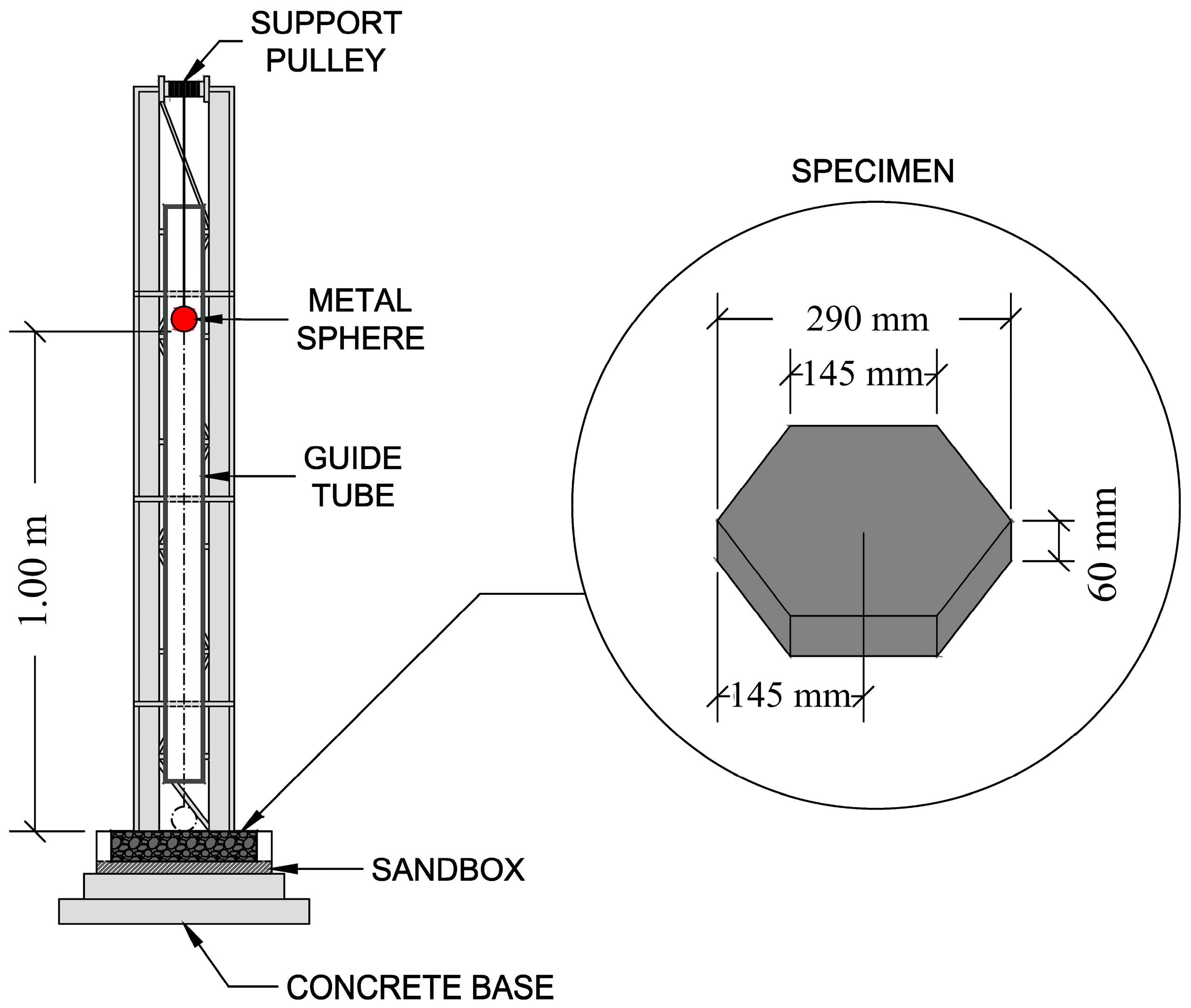

2.2.6. Drop-Weight Impact Resistance Test

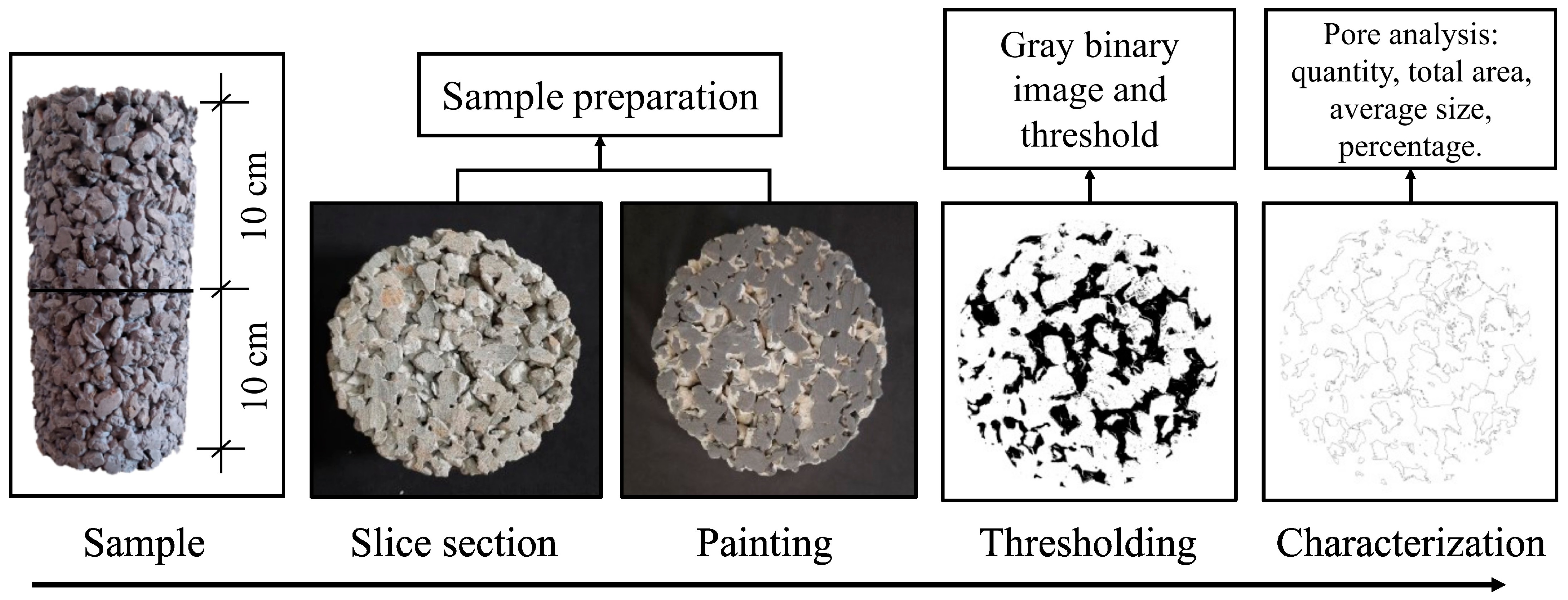

2.2.7. Pore Structure Characterization

2.2.8. Correlations among Pervious Concrete Properties

3. Results and Discussions

3.1. Aggregates Characterization and Packing Results

3.2. Pervious Concrete Properties

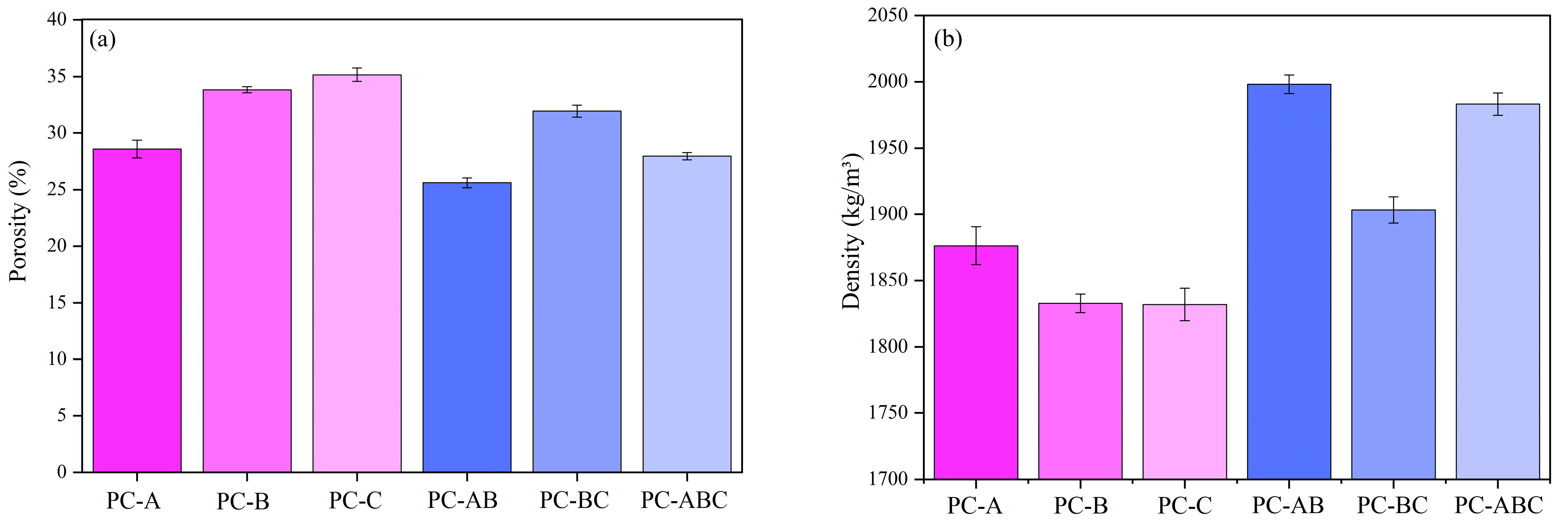

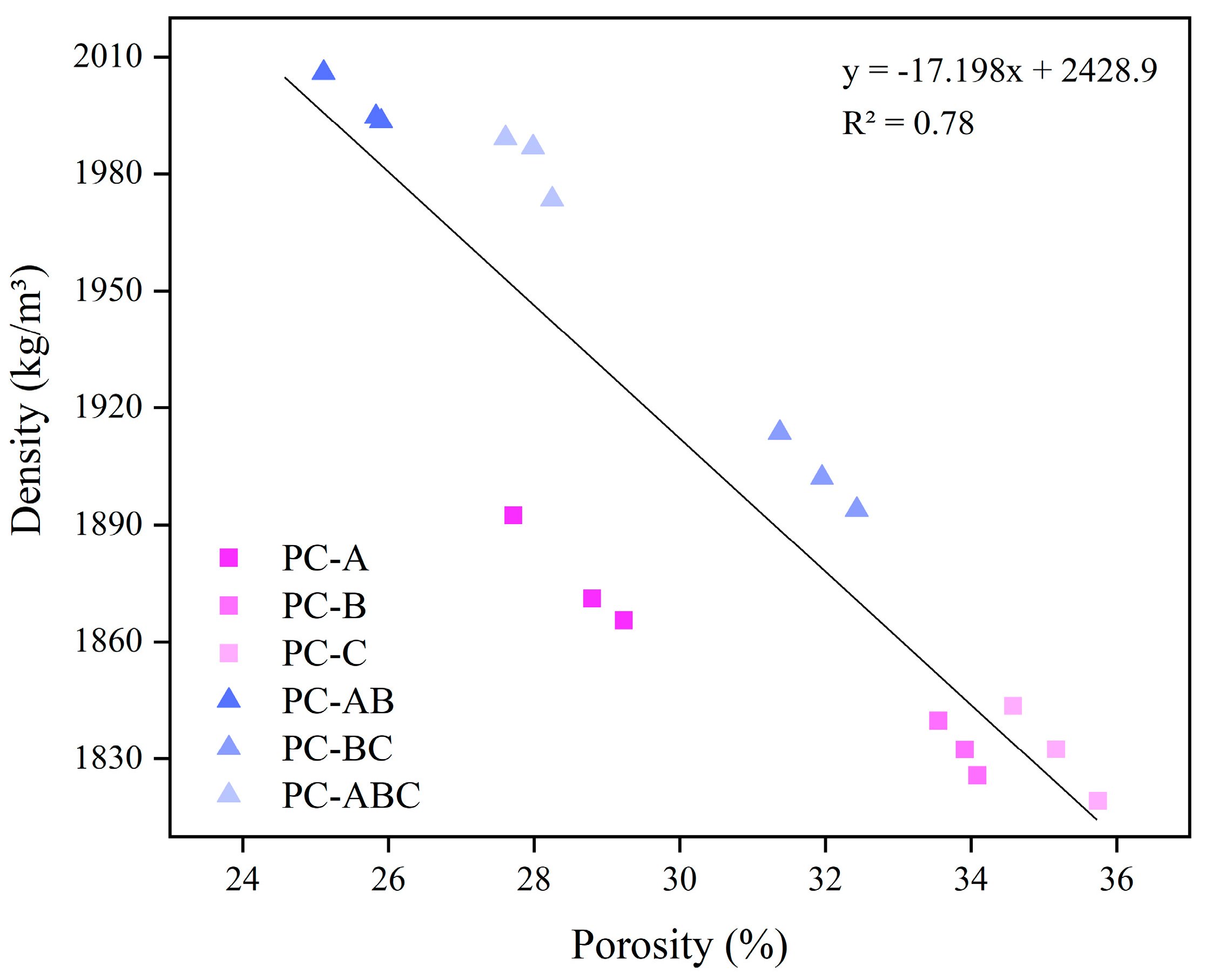

3.2.1. Porosity and Density

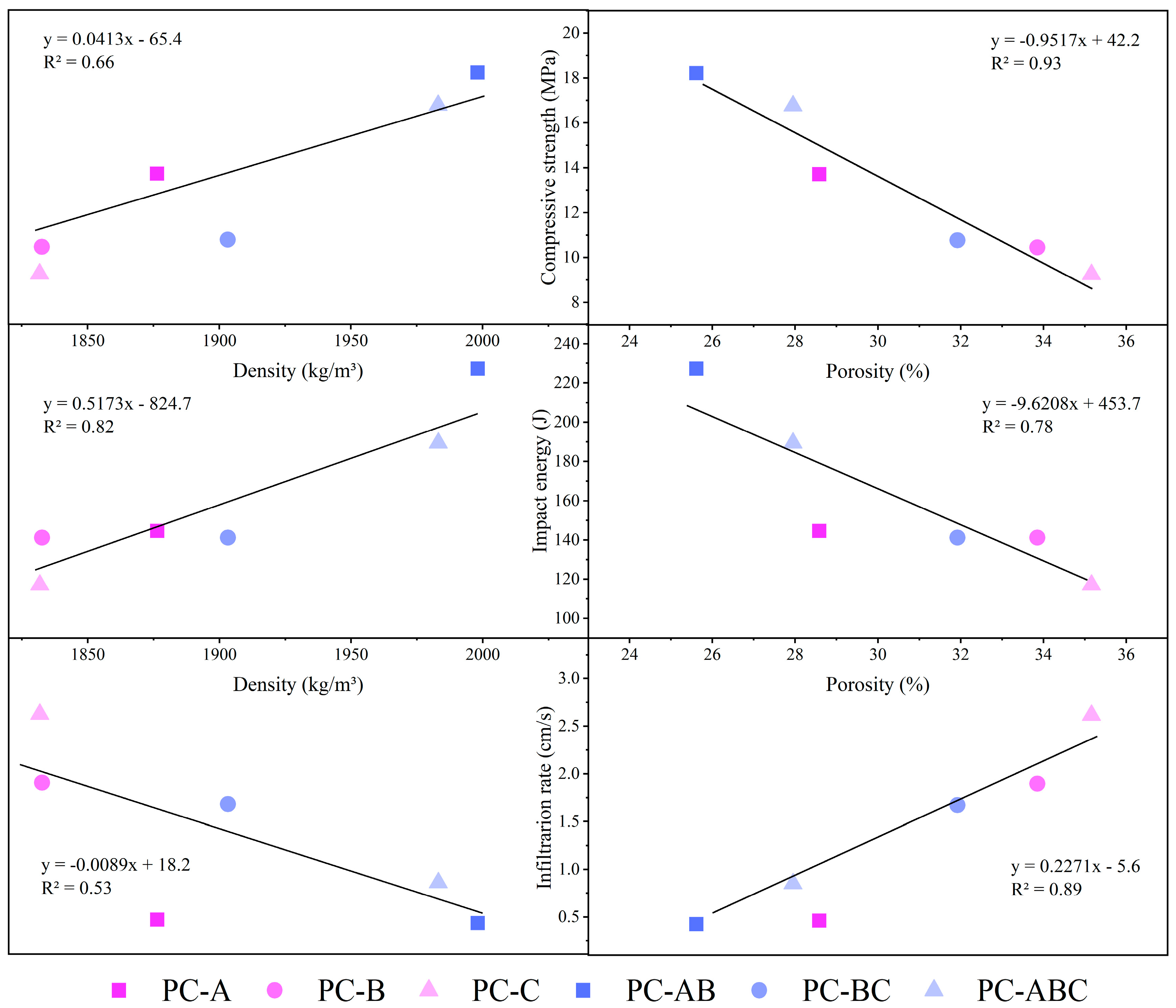

3.2.2. Infiltration Rate

3.2.3. Compressive Strength and Drop-Weight Impact Resistance

3.2.4. Pore Structure Characterization by Digital Image Analyses

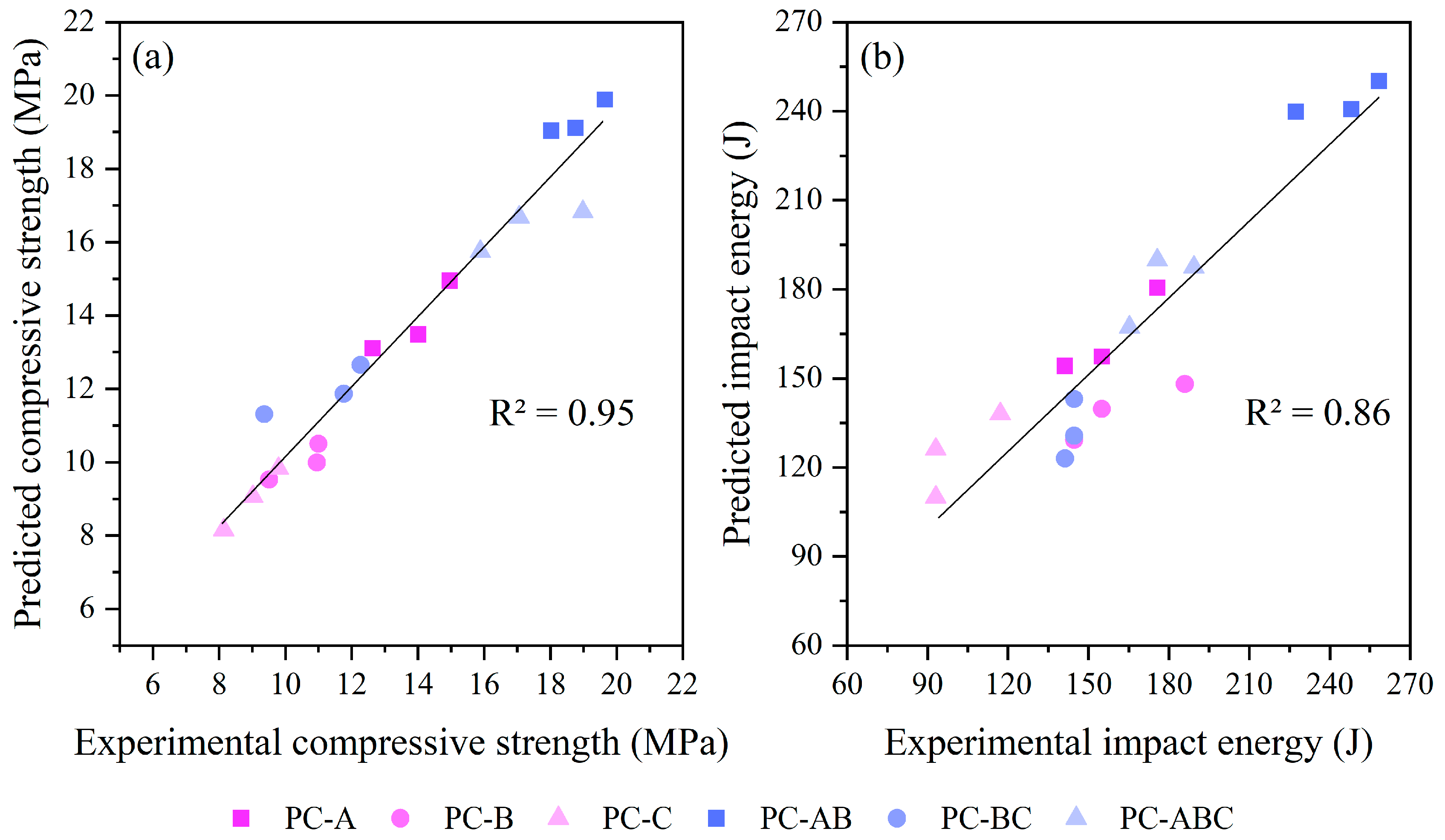

3.3. Correlations among Pervious Concrete Properties

4. Conclusions

- -

- Aggregate size directly impacts PC’s properties. Packing smaller aggregates makes concrete denser by reducing its porosity by up to 24.3%.

- -

- Aggregate size and porosity both affect the infiltration rate, with smaller aggregates leading to lower infiltration rates due to narrower seepage flow paths and more efficient pore filling when packed with larger aggregates. However, even the lowest infiltration rate (0.43 cm/s) meets the recommendations that appear in the literature.

- -

- Employing smaller aggregates tends to increase mechanical PC properties. Both compressive strength and impact resistance improve with smaller packed aggregates. The statistical analysis shows that density and aggregate size are the primary parameters that influence mechanical properties.

- -

- Using smaller aggregates increases the total number of pores, but reduces both the average pore diameter and the average pore area, as observed with the image analysis.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Notations

| PC | pervious concrete |

| SSD | saturated-surface-dry |

| OD | oven-dry |

| md | mass of oven-dried samples (kg) |

| ms | mass of samples submerged in bath (kg) |

| ρw | density of water at the water bath temperature (kg/m3) |

| Vd | specimen’s volume (m3) |

| k | infiltration rate (cm/s) |

| t | time required for the water percolation (s) |

| V | volume of water poured (cm3) |

| A | specimen’s cross-sectional area (cm2) |

| IE | impact energy (J) |

| h | drop height (m) |

| m | steel ball’s mass (kg) |

| g | gravity constant (9.81 m/s2) |

References

- Gartland, L. Heat Islands: Understanding and Mitigating Heat in Urban Areas, 1st ed.; Routledge: London, UK, 2010; pp. 2–22. [Google Scholar]

- Hung, V.V.; Seo, S.Y.; Kim, H.W.; Lee, G.C. Permeability and Strength of Pervious Concrete According to Aggregate Size and Blocking Material. Sustainability 2021, 13, 426. [Google Scholar] [CrossRef]

- Sandoval, G.F.B.; Galobardes, I.; Campos, A.; Toralles, B.M. Assessing the Phenomenon of Clogging of Pervious Concrete (Pc): Experimental Test and Model Proposition. J. Build. Eng. 2020, 29, 101203. [Google Scholar] [CrossRef]

- NRMCA. Pervious concrete: Guideline. Concrete in Practice—What, Why, How?—CIP 38; NRMCA: Silver Spring, MD, USA, 2004. [Google Scholar]

- Ferguson, B.K. Porous Pavements—Integrative Studies in Water Management and Land Development, 1st ed.; France, R.L., Ed.; Taylor & Francis: Boca Raton, FL, USA, 2005; ISBN 0-8493-2670-2. [Google Scholar]

- Li, V.C. High-Performance and Multifunctional Cement-Based Composite Material. Engineering 2019, 5, 250–260. [Google Scholar] [CrossRef]

- Tennis, P.D.; Leming, M.L.; Akers, D.J. Pervious Concrete Pavements; Portland Cement Association: Skokie, IL, USA; National Ready Mixed Concrete Association: Silver Spring, MD, USA, 2004. [Google Scholar]

- Wang, J.; Meng, Q.; Zhang, L.; Zhang, Y.; He, B.J.; Zheng, S.; Santamouris, M. Impacts of the Water Absorption Capability on the Evaporative Cooling Effect of Pervious Paving Materials. Build. Environ. 2019, 151, 187–197. [Google Scholar] [CrossRef]

- Xie, X.; Zhang, T.; Wang, C.; Yang, Y.; Bogush, A.; Khayrulina, E.; Huang, Z.; Wei, J.; Yu, Q. Mixture Proportion Design of Pervious Concrete Based on the Relationships between Fundamental Properties and Skeleton Structures. Cem. Concr. Compos. 2020, 113, 103693. [Google Scholar] [CrossRef]

- American Concrete Institute. ACI 522R-10 Report on Pervious Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2011. [Google Scholar]

- Chandrappa, A.K.; Biligiri, K.P. Effect of Pore Structure on Fatigue of Pervious Concrete. Road Mater. Pavement Des. 2018, 14, 1525–1547. [Google Scholar] [CrossRef]

- Pereira da Costa, F.B.; Haselbach, L.M.; da Silva Filho, L.C.P. Pervious Concrete for Desired Porosity: Influence of w/c Ratio and a Rheology-Modifying Admixture. Constr. Build. Mater. 2020, 268, 121084. [Google Scholar] [CrossRef]

- Yap, S.P.; Chen, P.Z.C.; Goh, Y.; Ibrahim, H.A.; Mo, K.H.; Yuen, C.W. Characterization of Pervious Concrete with Blended Natural Aggregate and Recycled Concrete Aggregates. J. Clean. Prod. 2018, 181, 155–165. [Google Scholar] [CrossRef]

- Debnath, B.; Sarkar, P.P. Permeability Prediction and Pore Structure Feature of Pervious Concrete Using Brick as Aggregate. Constr. Build. Mater. 2019, 213, 643–651. [Google Scholar] [CrossRef]

- Ćosić, K.; Korat, L.; Ducman, V.; Netinger, I. Influence of Aggregate Type and Size on Properties of Pervious Concrete. Constr. Build. Mater. 2015, 78, 69–76. [Google Scholar] [CrossRef]

- Shen, P.; Zheng, H.; Liu, S.; Lu, J.X.; Poon, C.S. Development of High-Strength Pervious Concrete Incorporated with High Percentages of Waste Glass. Cem. Concr. Compos. 2020, 114, 103790. [Google Scholar] [CrossRef]

- Lori, A.R.; Hassani, A.; Sedghi, R. Investigating the Mechanical and Hydraulic Characteristics of Pervious Concrete Containing Copper Slag as Coarse Aggregate. Constr. Build. Mater. 2019, 197, 130–142. [Google Scholar] [CrossRef]

- Deo, O.; Neithalath, N. Compressive Response of Pervious Concretes Proportioned for Desired Porosities. Constr. Build. Mater. 2011, 25, 4181–4189. [Google Scholar] [CrossRef]

- Yu, F.; Sun, D.; Wang, J.; Hu, M. Influence of Aggregate Size on Compressive Strength of Pervious Concrete. Constr. Build. Mater. 2019, 209, 463–475. [Google Scholar] [CrossRef]

- Liu, R.; Liu, H.; Sha, F.; Yang, H.; Zhang, Q.; Shi, S.; Zheng, Z. Investigation of the Porosity Distribution, Permeability, and Mechanical Performance of Pervious Concretes. Processes 2018, 6, 78. [Google Scholar] [CrossRef]

- Ferić, K.; Kumar, V.S.; Romić, A.; Gotovac, H. Effect of Aggregate Size and Compaction on the Strength and Hydraulic Properties of Pervious Concrete. Sustainability 2023, 15, 1146. [Google Scholar] [CrossRef]

- Yahia, A.; Kabagire, K.D. New Approach to Proportion Pervious Concrete. Constr. Build. Mater. 2014, 62, 38–46. [Google Scholar] [CrossRef]

- Meddah, M.S.; Al-Jabri, K.; Hago, A.W.; Al-Hinai, A.S. Effect of Granular Fraction Combinations on Pervious Concrete Performance. Mater. Today Proc. 2017, 4, 9700–9704. [Google Scholar] [CrossRef]

- Huang, J.; Luo, Z.; Khan, M.B.E. Impact of Aggregate Type and Size and Mineral Admixtures on the Properties of Pervious Concrete: An Experimental Investigation. Constr. Build. Mater. 2020, 265, 120759. [Google Scholar] [CrossRef]

- Wu, F.; Yu, Q.; Brouwers, H.J.H. Mechanical, Absorptive and Freeze–Thaw Properties of Pervious Concrete Applying a Bimodal Aggregate Packing Model. Constr. Build. Mater. 2022, 333, 127445. [Google Scholar] [CrossRef]

- Neithalath, N.; Sumanasooriya, M.S.; Deo, O. Characterizing Pore Volume, Sizes, and Connectivity in Pervious Concretes for Permeability Prediction. Mater. Charact. 2010, 61, 802–813. [Google Scholar] [CrossRef]

- O’Reilly, D.V. Método de Dosagem de Concreto de Elevado Desempenho, 1st ed.; PINI: São Paulo, Brazil, 1998. [Google Scholar]

- Associação Brasileira de Normas Técnicas. NBR 16697—Portland Cement—Requirements; Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- ASTM C150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C127; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C29/C29M-09; Standard Test Method for Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2009.

- ISO 17785-2; Testing Methods for Pervious Concrete—Part 2: Density and Void Content. International Organization for Standardization: Vernier, Geneva, 2018.

- ISO/DIS 17785-1; International Organization for Standardization—Test Methods for Pervious Concrete—Part 1: Infiltration Rate. Chiswick: London, UK, 2014.

- NBR 5739; Associação Brasileira de Normas Técnicas—Concrete—Compression Test of Cylindrical Specimens. Associação Brasileira de Normas Técnicas: Rio de Janeiro, RJ, Brazil, 2018.

- Rossignolo, J.A. Concreto Leve de Alto Desempenho Modificado Com SB Para Pré-Fabricados Esbeltos—Dosagem, Produção, Propriedades e Microestrutura. Ph.D. Thesis, São Paulo University, São Paulo, Brazil, 2003. [Google Scholar]

- Abid, S.R.; Abdul Hussein, M.L.; Ali, S.H.; Kazem, A.F. Suggested Modified Testing Techniques to the ACI 544-R Repeated Drop-Weight Impact Test. Constr. Build. Mater. 2020, 244, 118321. [Google Scholar] [CrossRef]

- Rajakarunakaran, S.A.; Lourdu, A.R.; Muthusamy, S.; Panchal, H.; Jawad Alrubaie, A.; Musa Jaber, M.; Ali, M.H.; Tlili, I.; Maseleno, A.; Majdi, A.; et al. Prediction of Strength and Analysis in Self-Compacting Concrete Using Machine Learning Based Regression Techniques. Adv. Eng. Softw. 2022, 173, 103267. [Google Scholar] [CrossRef]

- Zheng, M.; Chen, S.; Wang, B. Mix Design Method for Permeable Base of Porous Concrete: I. J. Pav. Res. Tech. 2012, 5, 102–107. [Google Scholar]

- Silva, R.G.; Bortoletto, M.; Bigotto, S.A.M.; Akasaki, J.L.; Soriano, L. Effect of Wastes from Sugar Cane Industry on the Mechanical and Hydraulic Properties of Pervious Concrete. Road Mater. Pavement Des. 2022, 23, 1–18. [Google Scholar] [CrossRef]

- Shen, P.; Lu, J.X.; Zheng, H.; Liu, S.; Sun Poon, C. Conceptual Design and Performance Evaluation of High Strength Pervious Concrete. Constr. Build. Mater. 2021, 269, 121342. [Google Scholar] [CrossRef]

- NBR 16416l; Brasileira de Normas Técnicas Pavimentos Permeaveis de Concreto Requisitos e Procedimentos. Associação Brasileira de Normas Técnicas: Rio de Janeiro, RJ, Brazil, 2015.

- Kant Sahdeo, S.; Ransinchung, G.D.; Rahul, K.L.; Debbarma, S. Effect of Mix Proportion on the Structural and Functional Properties of Pervious Concrete Paving Mixtures. Constr. Build. Mater. 2020, 255, 119260. [Google Scholar] [CrossRef]

- Yu, F.; Sun, D.; Hu, M.; Wang, J. Study on the Pores Characteristics and Permeability Simulation of Pervious Concrete Based on 2D/3D CT Images. Constr. Build. Mater. 2019, 200, 687–702. [Google Scholar] [CrossRef]

- Ibrahim, H.A.; Goh, Y.; Ng, Z.A.; Yap, S.P.; Mo, K.H.; Yuen, C.W.; Abutaha, F. Hydraulic and Strength Characteristics of Pervious Concrete Containing a High Volume of Construction and Demolition Waste as Aggregates. Constr. Build. Mater. 2020, 253, 119251. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A. The Impact Resistance and Mechanical Properties of Self-Compacting Concrete Reinforced with Recycled CFRP Pieces. Compos. B. Eng. 2016, 92, 360–376. [Google Scholar] [CrossRef]

- Lu, J.X.; Yan, X.; He, P.; Poon, C.S. Sustainable Design of Pervious Concrete Using Waste Glass and Recycled Concrete Aggregate. J. Clean. Prod. 2019, 234, 1102–1112. [Google Scholar] [CrossRef]

- Sumanasooriya, M.S.; Neithalath, N. Pore Structure Features of Pervious Concretes Proportioned for Desired Porosities and Their Performance Prediction. Cem. Concr. Compos. 2011, 33, 778–787. [Google Scholar] [CrossRef]

- Kia, A.; Wong, H.S.; Cheeseman, C.R. Clogging in Permeable Concrete: A Review. J. Environ. Manag. 2017, 193, 221–233. [Google Scholar] [CrossRef] [PubMed]

| Author/Year | Aggregate Size | Use of Aggregates | Main Findings |

|---|---|---|---|

| Yahia & Kabagire, 2014 [22] | 2.5–10 mm 5–14 mm 10–20 mm | Three mixtures with single-sized aggregates and three mixtures composed of 50/50% 2.5–10 mm with 5–14 mm; 75/25% 5–14 mm with 10–20 mm and 25/75% 5–14 mm with 10–20 mm. | The combination of aggregates improved mechanical properties due to increased packing density. |

| Meddah et al., 2017 [23] | 20 mm 10 mm | Four combinations of 10 mm and 20 mm limestone aggregate mixtures: 50/50%, 25/75%, 75/25%, 60/40%. | Granular combinations of aggregates are one of the main factors that affect strength development and porosity. |

| Huang et al., 2020 [24] | 5–10 mm 10–15 mm | Two mixtures with single-sized granite aggregates and one mixture made with 50% of each single-sized aggregate. | The combination of aggregates resulted in up to 98% improved compressive strength and up to a 53% lower infiltration rate. |

| Hung et al., 2021 [2] | 2–5 mm 5–10 mm | Three mixtures. Mix 1: 100% aggregate 5–10 mm; Mix 2: 80% (5–10 mm) + 15% (2–5 mm) + 5% sand; Mix 3: 50% aggregate (5–10 mm) + 45% aggregate (2–5 mm) + 5% sand. | The combination of aggregates resulted in up to 67% improved compressive strength, and reductions of up to 48% and 94% in porosity and the infiltration rate, respectively. |

| Wu F., Yu. Q., Brouwers, H.J.H., 2022 [25] | 1–2 mm 2–5 mm | Control mix made with 2–5 mm basalt and four combinations by replacing the aggregate with 1–2 mm steel slag of 0% to 50% ratio replacement with an increment of 12.5%. | The combination of aggregates resulted in up to 150.8% improved compressive strength, and reductions of up to 35.7% and 63.4% in porosity and the infiltration rate, respectively. |

| SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | K2O | SO3 | MgO | Others | LOI |

|---|---|---|---|---|---|---|---|---|---|

| 19.9 | 4.4 | 4.6 | 62.8 | 0.1 | 1.0 | 1.6 | 1.1 | 0.2 | 4.3 |

| Mixture ID | Aggregate (kg/m3) | Cement (kg/m3) | Water (kg/m3) | Water/Cement | Cement/Aggregate | ||

|---|---|---|---|---|---|---|---|

| A | B | C | |||||

| PC-A | 1581.25 | - | - | 316.25 | 82.23 | 0.26 | 1:5 |

| PC-B | - | 1530.79 | - | 306.16 | 79.60 | ||

| PC-C | - | - | 1523.96 | 304.79 | 79.25 | ||

| PC-AB | 841.78 | 841.78 | - | 336.71 | 87.54 | ||

| PC-BC | - | 633.10 | 949.65 | 316.55 | 82.30 | ||

| PC-ABC | 333.73 | 333.73 | 1001.20 | 333.73 | 86.77 | ||

| Properties | A | B | C | AB | BC | ABC | Standard |

|---|---|---|---|---|---|---|---|

| Water absorption (%) | 4.45 | 2.31 | 1.97 | 3.38 | 2.11 | 2.53 | ASTM C127 [30] |

| Specific gravity | 2.97 | 3.04 | 3.03 | 3.01 | 3.03 | 3.02 | ASTM C127 [30] |

| Specific gravity OD * | 2.62 | 2.84 | 2.86 | 2.73 | 2.85 | 2.81 | ASTM C127 [30] |

| Specific gravity SSD ** | 2.74 | 2.91 | 2.92 | 2.83 | 2.92 | 2.88 | ASTM C127 [30] |

| Unit weight (g/cm3) | 1.75 | 1.68 | 1.69 | 1.86 | 1.76 | 1.84 | ASTM C29 [31] |

| % Voids | 40.96 | 44.63 | 44.11 | 38.22 | 41.72 | 39.09 | ASTM C29 [31] |

| Mixture ID | Number of Pores | Average Pore Diameter (mm) | Average Pore Area (mm2) |

|---|---|---|---|

| PC-A | 263 | 2.52 | 7.39 |

| PC-B | 89 | 3.45 | 25.79 |

| PC-C | 61 | 4.08 | 40.22 |

| PC-AB | 144 | 3.03 | 13.45 |

| PC-BC | 61 | 4.09 | 33.56 |

| PC-ABC | 77 | 3.61 | 26.56 |

| Coefficients | p-Value | |||

|---|---|---|---|---|

| Compressive Strength | Impact Energy | Compressive Strength | Impact Energy | |

| ANOVA | - | - | 0.000 | 0.000 |

| R2 | 0.95 | 0.86 | - | - |

| Intercept (β0) | −118.831 | −4299.440 | 0.058 | 0.003 |

| Density (a1) | 0.071 | 2.095 | 0.014 | 0.001 |

| Porosity (a2) | 0.043 | 19.981 | 0.910 | 0.022 |

| Aggregate size (a3) | −0.987 | −38.692 | 0.056 | 0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arcolezi, K.H.; da Silva, R.G.; Soriano, L.; Borrachero, M.V.; Monzó, J.; Payá, J.; Tashima, M.M.; Akasaki, J.L. Effect of Aggregates Packing with the Maximum Density Methodology in Pervious Concrete. Sustainability 2023, 15, 4939. https://doi.org/10.3390/su15064939

Arcolezi KH, da Silva RG, Soriano L, Borrachero MV, Monzó J, Payá J, Tashima MM, Akasaki JL. Effect of Aggregates Packing with the Maximum Density Methodology in Pervious Concrete. Sustainability. 2023; 15(6):4939. https://doi.org/10.3390/su15064939

Chicago/Turabian StyleArcolezi, Karina H., Rodrigo G. da Silva, Lourdes Soriano, Maria V. Borrachero, José Monzó, Jordi Payá, Mauro M. Tashima, and Jorge Luis Akasaki. 2023. "Effect of Aggregates Packing with the Maximum Density Methodology in Pervious Concrete" Sustainability 15, no. 6: 4939. https://doi.org/10.3390/su15064939

APA StyleArcolezi, K. H., da Silva, R. G., Soriano, L., Borrachero, M. V., Monzó, J., Payá, J., Tashima, M. M., & Akasaki, J. L. (2023). Effect of Aggregates Packing with the Maximum Density Methodology in Pervious Concrete. Sustainability, 15(6), 4939. https://doi.org/10.3390/su15064939