Use of Waste Building Materials in Architecture and Urban Planning—A Review of Selected Examples

Abstract

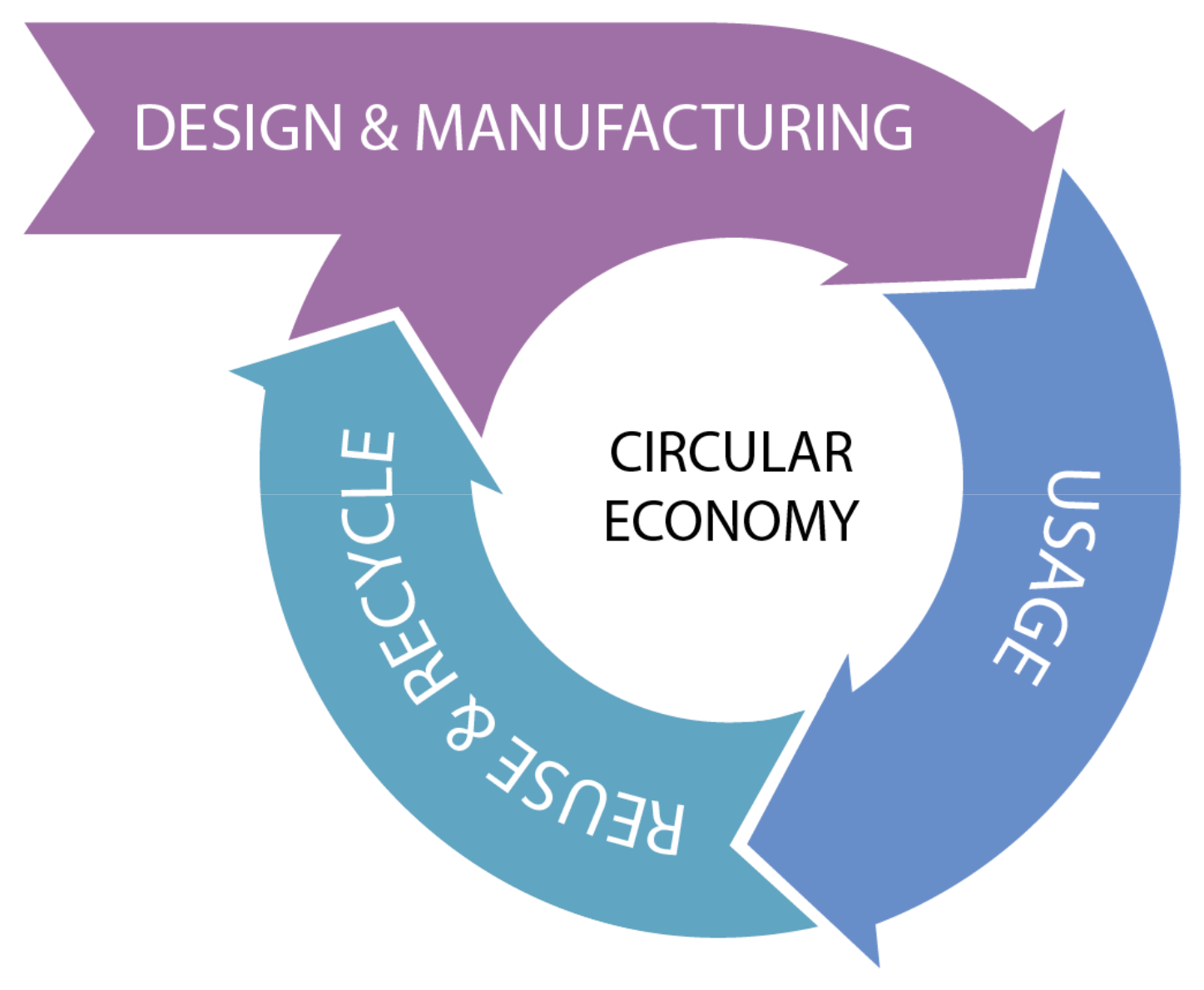

1. Introduction

2. Materials and Methods

- For metal materials—TITLE-ABS-KEY (“recycled” AND “metal” AND “architecture” OR “urban design”). A total of 79 papers based on this Scopus search were found;

- For wood materials—TITLE-ABS-KEY (“recycled” AND “wood” AND “architecture” OR “urban design”). A total of 37 papers based on this Scopus search were found;

- For ceramics materials—TITLE-ABS-KEY (“recycled” AND “ceramics” AND “architecture” OR “urban design”). A total of 18 papers based on this Scopus search were found;

- For plastic materials—TITLE-ABS-KEY (“recycled” AND “plastic” AND “architecture” OR “urban design”). A total of 72 papers based on this Scopus search were found;

- For stone materials—TITLE-ABS-KEY (“recycled” AND “stone” AND “architecture” OR “urban design”). A total of 17 papers based on this Scopus search were found;

- For glass materials—TITLE-ABS-KEY (“recycled” AND “glass” AND “architecture” OR “urban design”). A total of 49 papers based on this Scopus search were found.

3. Results

3.1. Wood

3.2. Plastic

3.3. Concrete

- I.

- The crushing of rubble—concrete rubble → primary crushing → secondary grains;

- II.

- Refining—thermal and mechanical treatment;

- III.

- Products—(i) coarse fractions (d ≥ 4 mm) (aggregate for high-quality concrete), (ii) fine fractions (d < 4 mm) (active additive for cement composites, component in the cement production process, active ingredient for autoclave).

3.4. Glass

3.5. Ceramics

3.6. Metals

4. Discussion

- Essentially, in the case of recycling wood waste from construction and demolition, the technology of their production and connection is indicated. In the first case, attention is paid to the welding of wood using the high-frequency oscillation or linear friction of adjacent wooden surfaces as a replacement for wet glues. This joining method is being studied for moment joints in softwood structures. Another element is the use of higher-strength fiber-reinforced wood in construction in order to obtain more resilient wooden structures with a better stiffness and strength-to-weight ratio;

- Recycled plastic waste is still relatively rarely used in construction. Its use requires further in-depth quantitative and qualitative research. Considering the huge amounts of plastic in the environment, it would be worth expanding on the possibilities of the widest use of recycled plastic in mixtures that are components of building materials;

- In the case of using recycled concrete in construction, attention should be paid to issues related to the reuse of reinforced concrete elements. In addition, it would be advisable to develop research in relation to modern composite materials that show preferential technical properties and could be more widely used in construction. Another element is recycled aggregates, which would require additional research on the introduction of an optimized amount of RCAs (recycled concrete aggregates) into the concrete mix as a partial replacement of NCA (natural concrete aggregates). Their application seems the most efficient and promising strategy for a more sustainable construction and concrete industry. On the other hand it is known that aggregates significantly affect both the fresh and hardened properties of concrete, and especially its durability in an aggressive environment. RCAs, due to the attached layer of mortar on the primary aggregate, have a lower density and lower strength, and higher crushing value and water absorption compared to NCA;

- Recycled glass has a wide range of applications as a material reinforcing the parameters of cement and concrete mixes. It can even be used as a substitute for cement. Currently, research is underway on the wider use of GP as a component of building materials. The potential of using recycled glass as a finishing material in building interiors is also worth noting;

- Recycled ceramics are also used in the interior finishing of buildings, and work well as external cladding used in architectural projects. Like GP, this material can also be used as a powder to reinforce the concrete mix. Due to the large storage volumes of ceramics, their recycling is highly recommended and should be developed in further research;

- Recycled metal waste can be melted, depending on the mix, into new building materials, or after burning, it can be used in the form of slag as a component of building material mixes. As is the case of other materials indicated in this study, further research is needed on the use of recycled metal in construction.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bianchi, M.; Cordella, M. Does circular economy mitigate the extraction of natural resources? Empirical evidence based on analysis of 28 European economies over the past decade. Ecol. Econ. 2022, 203, 107607. [Google Scholar] [CrossRef]

- Eurostat. Waste Statistics. Total Waste Generation. 2020. Available online: www.ec.europa.eu/eurostat/statistics-explained/index.php/Waste_statistics#Total_waste_generation (accessed on 18 December 2022).

- Hertwich, E.; Lifset, R.; Pauliuk, S.; Heeren, N. Resource Efficiency and Climate Change: Material Efficiency Strategies for a Low-Carbon Future; IRP United Nations Environment Programme: Paris, France, 2019. [Google Scholar]

- Schaubroeck, S.; Dewil, R.; Allacker, K. Circularity of building stocks: Modelling building joints and their disassembly in a 3D city model. Procedia CIRP 2022, 105, 712–720. [Google Scholar] [CrossRef]

- De Wolf, C.; Cordella, M.; Dodd, N.; Byers, B.; Donatello, S. Whole life cycle environmental impact assessment of buildings: Developing software tool and database support for the EU framework Level(s). Res. Cons. Recycl. 2022, 188, 106642. [Google Scholar] [CrossRef]

- United Nations Economic Commission for Europe/Food and Agriculture Organization of the United Nations. A Review of Leading Public Policies in Europe and North America; United Nations: Geneva, Switzerland, 2016. [Google Scholar]

- Horvath, M.; Trachte, S. New circular building composite material to upcycle building wastes. J. Phys. Conf. Ser. 2021, 1, 012167. [Google Scholar] [CrossRef]

- Singh, V. An Overview on Construction and Demolition Waste Regulation and Strategies. In Advances in Construction Safety; Springer: Singapore, 2022; pp. 163–175. [Google Scholar] [CrossRef]

- FAOLEX. National Action Plan on Sustainable Consumption and Production (2021–2030); Food and Agriculture Organization of the United Nations: Rome, Italy, 2020. [Google Scholar]

- Baldo, G.; Cesarei, G.; Minestrini, S.; Sordi, L. The EU Ecolabel scheme and its application to construction and building materials. Eco-Effic. Constr. Build. Mater. 2014, 98–124. [Google Scholar] [CrossRef]

- EP, Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Available online: https://eur-lex.europa.eu/eli/dir/2008/98/oj (accessed on 10 March 2023).

- EP, Decision 2000/532/WE replacing Decision 94/3/WE establishing a list of wastes pursuant to Article 1 a) of Council Directive 75/442/EWG on waste and Council Decision 94/904/WE establishing a list of hazardous waste pursuant to Article 1.4 of Council Directive 91/689/EWG on hazardous waste. Available online: https://eur-lex.europa.eu/eli/dec/2000/532/2015-06-01 (accessed on 10 March 2023).

- Chi, B.; Lu, W.; Ye, M.; Bao, Z.; Zhang, X. Construction waste minimization in green building: A comparative analysis of LEED-NC 2009 certified projects in the US and China. J. Clean. Prod. 2020, 256, 120749. [Google Scholar] [CrossRef]

- Ng, W.; Chau, C. New Life of the Building Materials—Recycle, Reuse and Recovery. Energy Procedia 2015, 75, 2884–2891. [Google Scholar] [CrossRef]

- UN DESA. Division for Sustainable Development United Nations Department of Economic and Social Affairs, 17 Sustainable Development Goals 17 Partnerships. 2015. Available online: https://sustainabledevelopment.un.org/content/documents/211617%20Goals%2017%20Partnerships.pdf (accessed on 10 March 2023).

- Chen, W.; Jin, R.; Xu, Y.; Wanatowski, D.; Li, B.; Yan, L.; Pan, Z.; Yang, Y. Adopting recycled aggregates as sustainable construction materials: A review of the scientific literature. Constr. Build. Mater. 2019, 218, 483–496. [Google Scholar] [CrossRef]

- Nußholz, J.; Rasmussen, F.; Whalen, K.; Plepys, A. A circular business model for material reuse in buildings: Implications on value creation. J. Clean. Prod. 2020, 245, 118546. [Google Scholar] [CrossRef]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.K.M. Circular Economy on Construction and Demolition Waste: A Literature Review on Material Recovery and Production. Materials 2020, 13, 2970. [Google Scholar] [CrossRef]

- Ruiz, L.; Ramón, X.; Domingo, S. The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector: A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- Zhang, L.; Sojobi, A.; Kodur, V.; Liew, K. Effective utilization and recycling of mixed recycled aggregates for a greener environment. J. Clean. Prod. 2019, 236, 117600. [Google Scholar] [CrossRef]

- Baldassarre, B.; Schepers, M.; Bocken, N.; Cuppen, E.; Krevaar, G.; Calabretta, G. Industrial symbiosis: Towards a design process for eco-industrial clusters by integrating circular economy and industrial ecology perspectives. J. Clean. Prod. 2019, 216, 446–460. [Google Scholar] [CrossRef]

- Bocken, N.; Pauw, I.; Bakker, C.; Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Pun, S.; Liu, C. A framework for material management in the building demolition industry. Archit. Sci. Rev. 2006, 49, 391–398. [Google Scholar] [CrossRef]

- Lucertini, G.; Musco, F. Circular Urban Metabolism Framework. One Earth 2020, 2, 138–142. [Google Scholar] [CrossRef]

- Mazur, Ł. Circular economy in housing architecture: Methods of implementation. Acta Sci. Polonorum. Ser. Archit. 2021, 20, 65–74. [Google Scholar] [CrossRef]

- Munaro, M.R.; Tavares, S.F.; Bragança, L. Towards circular and more sustainable buildings: A systematic literature review on the circular economy in the built environment. J. Clean. Prod. 2020, 260, 121134. [Google Scholar] [CrossRef]

- Verhagen, T.J.; Sauer, M.L.; van der Voet, E.; Sprecher, B. Matching Demolition and Construction Material Flows, an Urban Mining Case Study. Sustainability 2021, 13, 653. [Google Scholar] [CrossRef]

- Levac, D.; Colquhoun, H.; O’Brien, K.K. Scoping studies: Advancing the methodology. Implement. Sci. 2010, 5, 69. [Google Scholar] [CrossRef] [PubMed]

- Fahlstedt, O.; Temeljotov-Salaj, A.; Lohne, L.; Bohne, R.A. Holistic assessment of carbon abatement strategies in building refurbishment literature—A scoping review. Renew. Sustain. Energy Rev. 2022, 167, 112636. [Google Scholar] [CrossRef]

- Bahers, J.-B.; Athanassiadis, A.; Perrotti, D.; Kampelmann, S. The place of space in urban metabolism research: Towards a spatial turn? A review and future agenda. Landsc. Urban Plan. 2022, 221, 104376. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Weiss, M.; Haufe, J.; Carus, M.; Brandão, M.; Bringezu, S.; Hermann, B.; Patel, M.K. A Review of the Environmental Impacts of Biobased Materials. J. Ind. Ecol. 2012, 16, 169–181. [Google Scholar] [CrossRef]

- Yadav, M.; Agarwal, M. Biobased Building Materials for Sustainable Future: An Overview. Mater. Today Proc. 2021, 43, 2895–2902. [Google Scholar] [CrossRef]

- Asif, M. Sustainability of Timber, Wood and Bamboo in Construction. In Sust. of Construction Materials; Khatib, J., Ed.; Elsevier: Amsterdam, The Netherlands, 2009; pp. 31–54. ISBN 978-1-84569-349-7. [Google Scholar]

- Ormondroyd, G.A.; Spear, M.J.; Skinner, C. The Opportunities and Challenges for Re-Use and Recycling of Timber and Wood Products Within the Construction Sector. In Environmental Impacts of Traditional and Innovative Forest-Based Bioproducts; Kutnar, A., Muthu, S.S., Eds.; Springer: Singapore, 2016; pp. 45–103. ISBN 978-981-10-0653-1. [Google Scholar]

- Jahan, I.; Zhang, G.; Bhuiyan, M.; Navaratnam, S. Circular Economy of Construction and Demolition Wood Waste—A Theoretical Framework Approach. Sustainability 2022, 14, 10478. [Google Scholar] [CrossRef]

- Cochran, K.M.; Townsend, T.G. Estimating Construction and Demolition Debris Generation Using a Materials Flow Analysis Approach. Waste Manag. 2010, 30, 2247–2254. [Google Scholar] [CrossRef]

- Da Azambuja, R.; de Castro, V.G.; Trianoski, R.; Iwakiri, S. Recycling Wood Waste from Construction and Demolition to Produce Particleboards. Maderas. Cienc. Tecnol. 2018, 20, 681–690. [Google Scholar] [CrossRef]

- Irle, M.; Privat, F.; Couret, L.; Belloncle, C.; Déroubaix, G.; Bonnin, E.; Cathala, B. Advanced Recycling of Post-Consumer Solid Wood and MDF. Wood Mater. Sci. Eng. 2019, 14, 19–23. [Google Scholar] [CrossRef]

- Merli, F.; Belloni, E.; Buratti, C. Eco-Sustainable Wood Waste Panels for Building Applications: Influence of Different Species and Assembling Techniques on Thermal, Acoustic, and Environmental Performance. Buildings 2021, 11, 361. [Google Scholar] [CrossRef]

- Pandey, S. Wood Waste Utilization and Associated Product Development from Under-Utilized Low-Quality Wood and Its Prospects in Nepal. SN Appl. Sci. 2022, 4, 168. [Google Scholar] [CrossRef]

- Risse, M.; Weber-Blaschke, G.; Richter, K. Eco-Efficiency Analysis of Recycling Recovered Solid Wood from Construction into Laminated Timber Products. Sci. Total Environ. 2019, 661, 107–119. [Google Scholar] [CrossRef]

- Myllyviita, T.; Hurmekoski, E.; Kunttu, J. Substitution Impacts of Nordic Wood-Based Multi-Story Building Types: Influence of the Decarbonization of the Energy Sector and Increased Recycling of Construction Materials. Carbon Balance Manag. 2022, 17, 4. [Google Scholar] [CrossRef]

- Mazur, Ł.; Bać, A.; Vaverková, M.D.; Winkler, J.; Nowysz, A.; Koda, E. Evaluation of the Quality of the Housing Environment Using Multi-Criteria Analysis That Includes Energy Efficiency: A Review. Energies 2022, 15, 7750. [Google Scholar] [CrossRef]

- Kamboj, M. Degradation of plastics for clean environment. Int. J. Adv. Res. Eng. Appl. Sci. 2016, 5, 10–19. [Google Scholar]

- Radwan, A.H. Containers Architecture Reusing Shipping Containers in making creative Architectural Spaces. Int. J. Sci. Eng. Res. 2015, 6, 1562–1577. [Google Scholar] [CrossRef]

- Wagner, T. Antyestetyzm w architekturze. In Proceedings of the Piękno w Architekturze—Tradycja i Współczesność, I Międzynarodowa Interdyscyplinarna Konferencja Naukowo Techniczna, Nysa, Poland, 6–7 June 2018. [Google Scholar]

- Wagner, T. Śmieci i Odpady w Architekturze. Systemy Wspomagania w Inżynierii Produkcji Technika i Sztuka—Obszary Wspólne. Redakcja Naukowa: Mak-Sobota, B.; Łazarz, B. 2018. Available online: https://yadda.icm.edu.pl/yadda/element/bwmeta1.element.baztech-2e062c02-1ff0-4e59-b2f1-a7a72885e20c/c/wagner_SWwIP_2018_3.pdf (accessed on 19 December 2022).

- Krajewski, M. Śmieci w sztuce. Sztuka jako śmieć. Zesz. Artyst. 2004, 13, 50–65. [Google Scholar]

- Pankaj, V.P. Sustainable model of plastic waste management. Int. J. ChemTech Res. 2015, 7, 440–458. [Google Scholar]

- Kognole, R.S.; Shipkule, K.; Patil, M.; Patil, L.; Survase, U. Utilization of Plastic waste for Making Plastic Bricks. Int. J. Trend Sci. Res. Dev. 2019, 3, 878–880. [Google Scholar] [CrossRef]

- Javaprakash, M.; Deeksha, I.; Soumya, M. R3 PET Bottles for Eco-friendly Building in Sustainable Development. Int. J. Curr. Trends Eng. Res. 2016, 2, 318–326. [Google Scholar]

- Chaurasia, A.; Gangwar, S. Reuse of Plastic Bottles as a Construction Material. Int. J. Eng. Tech. Res. 2019, 9, 25–30. [Google Scholar]

- Abukasim, S.M.; Zuhria, F.; Saing, Z. Alternative management of plastic. J. Phys. Conf. Ser. 2020, 1517, 012041. [Google Scholar] [CrossRef]

- Priyanka, G. Management of plastic waste: A step towards clean environment. Int. J. Renew. Energy Technol. 2017, 8, 387–392. [Google Scholar]

- Bajpai, R.; Khan, A.; Bin Sami, O.; Yadav, P.; Srivastava, P. A Study on the Plastic Waste Treatment Methods for Road Construction. Int. J. Adv. Res. Ideas Innov. Technol. 2017, 3, 559–566. [Google Scholar]

- Skowroński, M. Rekonsumpcja materiałowa w architekturze. Ph.D. Thesis, Wrocław University of Technology, Wrocław, Poland, 2015. Available online: https://dbc.wroc.pl/Content/31098/PDF/skowronski_rekonsumpcja_PhD.pdf (accessed on 12 December 2022).

- Świątek, L. Projektowanie Architektoniczne a Gospodarka Odpadami w Świetle Założeń Ekorozwoju na Przykładzie Budownictwa Mieszkaniowego. Ph.D. Thesis, Wrocław University of Technology, Wrocław, Poland, 2000. [Google Scholar]

- Kawecka-Zygadło, B. Stal konstrukcyjna i wyroby stalowe w służbie zrównoważonego rozwoju, Muratorplus. 2011. Available online: https://www.muratorplus.pl/technika/konstrukcje/stal-konstrukcyjna-i-wyroby-stalowe-w-sluzbie-zrownowazonego-rozwoju-aa-dQWc-pidA-oBiZ.html (accessed on 19 December 2022).

- Adamczyk, J.; Dylewski, R. Recykling odpadów budowlanych w kontekście budownictwa zrównoważonego. Probl. Ekorozw. 2010, 2, 125–131. [Google Scholar]

- Kalinowska-Wichrowska, K. Stosowanie spoiwa recyklingowego jako przykład redukcji CO2. Bud. I Inżynieria Sr. 2017, 8, 41–46. Available online: https://bibliotekanauki.pl/articles/402817.pdf (accessed on 19 December 2022).

- Dworzańczyk-Krzywiec, D. Wpływ zawartości kruszywa z recyklingu na wybrane właściwości betonów. Bud. Inżynieria Sr. 2011, 2, 229–233. Available online: https://yadda.icm.edu.pl/baztech/element/bwmeta1.element.baztech-article-BPB2-0054-0004 (accessed on 19 December 2022).

- Pawluczuk, E. Możliwości zastosowania odpadowego wypełniacza betonowego jako spoiwa w kompozytach cementowych. Mater. Bud. 2017, 5, 81–82. [Google Scholar] [CrossRef]

- Pawluczuk, E. A fine fraction from the recycled concrete as an addition in the cement composites. Sci. Rev. Eng. Environ. Sci. 2018, 27, 338–347. [Google Scholar] [CrossRef]

- Pawluczuk, E.; Kalinowska-Wichrowska, K.; Bołtryk, M.; Jiménez, J.R.; Fernández, J.M. The Influence of Heat and Mechanical Treatment of Concrete Rubble on the Properties of Recycled Aggregate Concrete. Materials 2019, 12, 367. [Google Scholar] [CrossRef]

- Matiasa, D.; de Brito, J.; Rosa, A.; Pedro, D. Mechanical properties of concrete produced with recycled coarse aggregates—Influence of the use of superplasticizers. Constr. Build. Mater. 2013, 44, 101–109. [Google Scholar] [CrossRef]

- López-Mesa, B.; Pitarch, A.; Tomás, A.; Gallego, T. Comparison of environmental impacts of building structures with in situ cast floors and with precast concrete floors. Build. Environ. 2009, 4, 699–712. [Google Scholar] [CrossRef]

- Jin, R.; Yuan, H.; Chen, Q. Science mapping approach to assisting the review of construction and demolition waste management research published between 2009 and 2018. Resour. Conserv. Recycl. 2019, 140, 175–188. [Google Scholar] [CrossRef]

- Voronkova, I. Types of architectural glass to improve the energy efficiency of glass buildings. Acta Sci. Polonorum. Archit. 2022, 21, 77–83. [Google Scholar] [CrossRef]

- Shayan, A.; Xu, A. Value-added utilisation of waste glass in concrete. Cem. Concr. Res. 2004, 34, 81–89. [Google Scholar] [CrossRef]

- Ting, G.H.; Tay, Y.W.; Tan, M.J. Experimental measurement on the effects of recycled glass cullets as aggregates for construction 3D printing. J. Clean. Prod. 2021, 300, 126919. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. SProperties of self-compacting concrete prepared with recycled glass aggregate. Cem. Concr. Compos. 2009, 31, 107–113. [Google Scholar] [CrossRef]

- Khmiri, A.; Chaabouni, M.; Samet, B. Chemical behaviour of ground waste glass when used as partial cement replacement in mortars. Constr. Build. Mater. 2013, 44, 74–80. [Google Scholar] [CrossRef]

- Nasier, S. Utilization of recycled form of concrete, E-wastes, glass, quarry rock dust and waste marble powder as reliable construction materials. Mater. Today Proc. 2021, 45, 3231–3234. [Google Scholar] [CrossRef]

- Reindl, J. Report by Recycling Manager; Department of Public Works: Dane County, WI, USA, 2018. [Google Scholar]

- Lee, H.; Hanif, A.; Usman, M.; Sim, J.; Oh, H. Performance evaluation of concrete incorporating glass powder and glass sludge wastes as supplementary cementing material. J. Clean. Prod. 2018, 170, 683–693. [Google Scholar] [CrossRef]

- Parthiban, D.; Vijayan, D.S.; Koda, E.; Vaverkova, M.D.; Piechowicz, K.; Osinski, P.; Van Duc, B. Role of industrial based precursors in the stabilization of weak soils with geopolymer—A review. Case Stud. Constr. Mater. 2022, 16, e00886. [Google Scholar] [CrossRef]

- Chen, C.H.; Huang, R.; Wu, J.K.; Yang, C.C. Waste E-glass particles used in cementitious mixtures. Cem. Concr. Res. 2006, 36, 449–456. [Google Scholar] [CrossRef]

- Kats, M.É.; Kvyatkovskaya, K.K. Low temperature flux compositions for the production of cast ceramic tile. Glass Ceram. 1972, 29, 101–103. [Google Scholar] [CrossRef]

- Gabaldón-Estevan, D. Innovation Diffusion in the European Ceramic Tile Industry Supply Chain. Supply Chain. Strateg. Eng.-Order Approach 2016, 1, 76–97. [Google Scholar] [CrossRef]

- Zanelli, C.; Conte, S.; Molinari, C.; Soldati, R.; Dondi, M. Waste recycling in ceramic tiles: A technological outlook. Resour. Conserv. Recycl. 2021, 168, 2016–2019. [Google Scholar] [CrossRef]

- Sokolar, R.; Smetanova, L. Dry pressed ceramic tiles based on fly ash-clay body: Influence of fly ash granulometry and pentasodium triphosphate addition. Ceram. Int. 2010, 36, 215–221. [Google Scholar] [CrossRef]

- Taha, N.; Arandah, W.; Hasan, S. Bringing Ceramic Recycling into Circular Economy in Egypt for Concrete Structural Elements. IOSR J. Mech. Civ. Eng. 2021, 18, 38–47. [Google Scholar] [CrossRef]

- Mangi, S.A.; Raza, M.S.; Khahro, S.H.; Qureshi, A.S.; Kumar, R. Recycling of ceramic tiles waste and marble waste in sustainable production of concrete: A review. Environ. Sci. Pollut. Res. 2022, 29, 18311–18332. [Google Scholar] [CrossRef]

- Samadi, M.; Warid Hussin, M.; Mohd Sam, A.R.; Lim, H.S. Effect of Ceramic Powder on Mortar Concrete. Adv. Mater. Res. 2015, 1113, 62–67. [Google Scholar] [CrossRef]

- Akkalatham, W.; Taghipour, A. Pro-environmental behavior model creating circular economy in steel recycling market, empirical study in Thailand. Environ. Chall. 2021, 4, 100112. [Google Scholar] [CrossRef]

- Ajdukiewicz, A.; Kliszczewicz, A. Recykling betonu konstrukcyjnego—Cz. I. Inżynier Budownictwa 2009, 2, 49–53. [Google Scholar]

- Oda, J.; Akimoto, K.; Tomoda, T. Long-term global availability of steel scrap. Resour. Conserv. Recycl. 2013, 81, 81–91. [Google Scholar] [CrossRef]

- Lederer, J.; Gassner, A.; Fellner, J.; Mollay, U.; Schremmer, C. Raw materials consumption and demolition waste generation of the urban building sector 2016-2050: A scenario-based material flow analysis of Vienna. J. Clean. Prod. 2021, 288, 125566. [Google Scholar] [CrossRef]

- Iżykowska-Kujawa, M. Zagospodarowanie odpadów budowlanych, technologie z których korzystamy. Inżynieria Ekol. 2013, 33, 49–60. Available online: https://www.infona.pl/resource/bwmeta1.element.baztech-29ef9534-07fb-453c-b11b-e36ea06badfa (accessed on 10 December 2022). [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Akinade, O.O.; Ajayi, A.O.; Davila Delgado, M.; Bilal, M.; Bello, S.A. Salvaging building materials in a circular economy: A BIM-based whole-life performance estimator. Resour. Conserv. Recycl. 2018, 129, 175–186. [Google Scholar] [CrossRef]

- Guerra, B.; Leite, F.; Faust, K. 4D-BIM to enhance construction waste reuse and recycle planning: Case studies on concrete and drywall waste streams. Waste Manag. 2020, 116, 79–90. [Google Scholar] [CrossRef]

- Janiak, J. Recycling i upcycling w służbie architektury. Estetyka obiektów z materiałów wtórnych. Przegląd Bud. 2017, 88, 27–33. [Google Scholar]

- Rybak-Niedziółka, K.; Grochulska-Salak, M.; Maciejewska, E. Resilience of riverside areas as an element of the green deal strategy—Evaluation ofwaterfront models in relation to re-urbanization and the city landscape of Warsaw. Desalination Water Treat. 2021, 232, 357–371. [Google Scholar] [CrossRef]

- Koda, E.; Rybak-Niedziółka, K.; Winkler, J.; Černý, M.; Osiński, P.; Podlasek, A.; Kawalec, J.; Vaverková, M.D. Space Redevelopment of Old Landfill Located in the Zone between Urban and Protected Areas: Case Study. Energies 2022, 15, 146. [Google Scholar] [CrossRef]

- Shah, P.J.; Anagnostopoulos, T.; Zaslavsky, A.; Behdad, S. A stochastic optimization framework for planning of waste collection and value recovery operations in smart and sustainable cities. Waste Manag. 2018, 78, 104–114. [Google Scholar] [CrossRef] [PubMed]

- Intergovernmental Panel on Climate Change. Land Use, Land-Use Change, and Forestry: Summary for Policymakers; Report; Intergovernmental Panel on Climate Change (IPCC): Geneva, Switzerland, 2000.

- Kissinger, G.; Herold, M.; de Sy, V. Drivers of Deforestation and Forest Degradation: A Synthesis Report for REDD+ Policymakers; Report; Lexeme Consulting: Vancouver, BC, Canada, 2012. [Google Scholar]

- Food and Agriculture Organization. State of the World’s Forests: Enhancing the Socioeconomic Benefits from Forests; Report; Food and Agriculture Organization of the United Nations: Rome, Italy, 2014.

- United Nations Economic Commission for Europe/Food and Agriculture Organization of the United Nations. Forest Products: Annual Market Review 2013–2014; Report; United Nations Economic Commission for Europe: Geneva, Switzerland; Food and Agriculture Organization of the United Nations: Rome, Italy, 2014.

- FCPF. Forest Carbon Partnership Facility—2015 Annual Report; Report; The World Bank: Washington, DC, USA, 2015.

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Monahan, J.; Powell, J.C. An Embodied Carbon and Energy Analysis of Modern Methods of Construction in Housing: A Case Study Using a Lifecycle Assessment Framework. Energy Build. 2011, 43, 179–188. [Google Scholar] [CrossRef]

- Hahn, B.; Vallée, T.; Stamm, B.; Weinand, Y. Moment Resisting Connections Composed of Friction-welded Spruce Boards: Experimental Investigations and Numerical Strength Prediction. Eur. J. Wood Wood Prod. 2014, 72, 229–241. [Google Scholar] [CrossRef]

- Thompson, H. A Process Revealed/Auf dem Howlzweg, 1st ed.; Stadthaus FUEL: London, UK, 2009. [Google Scholar]

- Skidmore, Owings and Merrill LLP. Timber Tower Research Project. In Technical Report; Skidmore, Owings and Merrill LLP: Chicago, IL, USA, 2013. [Google Scholar]

- Abrahamsen, R.B.; Malo, K.A. Structural design and assembly of treet—A 14-storey timber residential building in Norway. In Proceedings of the world conference on timber engineering, Quebec City, QC, Canada, 10–14 August 2014; Available online: http://www.timberdesign.org.nz/wp-content/uploads/2018/05/2014Vol22Iss3-Abrahamsen-Paper.pdf (accessed on 15 December 2022).

- Lamba, P.; Kaur, D.P.; Raj, S.; Sorout, J. Recycling/reuse of plastic waste as construction material for sustainable development: A review. Environ. Sci. Pollut. Res. 2022, 29, 86156–86179. [Google Scholar] [CrossRef]

- Aneke, F.I.; Shabangu, C. Green-efficient masonry bricks produced from scrap plastic waste and foundry sand. Case Stud. Constr. Mater. 2021, 14, e00515. [Google Scholar] [CrossRef]

- Leng, Z.; Padhan, R.K.; Sreeram, A. Production of a sustainable paving material through chemical recycling of waste PET into crumb rubber modified asphalt. J. Clean. Prod. 2018, 180, 682–688. [Google Scholar] [CrossRef]

- Khan, I.M.; Kabir, S.; Alhussain, M.A.; Almansoor, F. Asphalt design using recycled plastic and crumb-rubber waste for sustainable pavement construction. Proc. Eng. 2016, 145, 1557–1564. [Google Scholar] [CrossRef]

- Seghiri, M.; Boutoutaou, D.; Kriker, A.; Hachani, M.I. The possibility of making a composite material from waste plastic. Energy Procedia 2017, 119, 163–169. [Google Scholar] [CrossRef]

- Hameed, A.M.; Fatah Ahmed, B.A. Employment the plastic waste to produce the light weight concrete. Energy Procedia 2019, 157, 30–38. [Google Scholar] [CrossRef]

- Azhdarpour, A.M.; Nikoudel, M.R.; Taheri, M. The effect of using polyethylene terephthalate particles on physical and strength-related properties of concrete; a laboratory evaluation. Constr. Build. Mater. 2016, 109, 55–62. [Google Scholar] [CrossRef]

- Brambilla, G.; Lavagna, M.; Vasdravellis, G.; Castiglioni, C.A. Environmental benefits arising from demountable steel-concrete composite floor systems in buildings. Resour. Conserv. Recycl. 2019, 140, 133–142. [Google Scholar] [CrossRef]

- Pavlović, M.; Marković, Z.; Veljković, M.; Buđevac, D. Bolted shear connectors vs. headed studs behaviour in pushout tests. J. Constr. Steel Res. 2013, 88, 134–149. [Google Scholar] [CrossRef]

- Wang, L.; Brown, C.; Webster, M.D.; Hajjar, J.F. Deconstructable Steel-Concrete Shear Connection for Sustainable Composite Floor Systems; Engineering Mechanics Institute Conference, American Society of Civil Engineers: Hamilton, ON, Canada, 2014; Available online: https://coe.northeastern.edu/research/dfd/Wang,%20Brown,%20Webster,%20Hajjar%20-%20Design%20for%20Deconstruction%20-%20EMI%202014%20-%20Presentation.pdf (accessed on 15 December 2022).

- Moynihan, M.C.; Allwood, J.M. Viability and performance of demountable composite connectors. J. Constr. Steel Res. 2014, 88, 47–56. [Google Scholar] [CrossRef]

- Lam, D.; Dai, X.; Ashour, A.; Rahman, N. Recent research on composite beams with demountable shear connectors. Steel Constr. 2017, 10, 125–134. [Google Scholar] [CrossRef]

- Feidaki, E.; Vasdravellis, G. Push Out Tests of a Novel Shear Connection Mechanism for Use in Demountable Precast Composite Beams. In Proceedings of the Eurosteel 2017, Copenhagen, Denmark, 13–15 September 2017; pp. 13–15. [Google Scholar] [CrossRef]

- Suwaed, A.S.H.; Karavasilis, T.L. Novel demountable shear connector for accelerated disassembly, repair, or replacement of precast steel-concrete composite bridges. J. Bridge Eng. 2017, 22, 04017052. [Google Scholar] [CrossRef]

- Makul, N.; Fediuk, R.; Amran, M.; Zeyad, A.M.; de Azevedo, A.R.G.; Klyuev, S.; Vatin, N.; Karelina, M. Capacity to Develop Recycled Aggregate Concrete in South East Asia. Buildings 2021, 11, 234. [Google Scholar] [CrossRef]

- Meddah, M.S.; Al-Harthy, A.; Ismail, M. Recycled Concrete Aggregates and Their Influences on Performances of Low and Normal Strength Concretes. Buildings 2020, 10, 167. [Google Scholar] [CrossRef]

- Al-Mosawe, H.; Albayati, A.; Wang, Y.; Mashaan, N.S. An Experimental Study of Granular Material Using Recycled Concrete Waste for Pavement Roadbed Construction. Buildings 2022, 12, 1926. [Google Scholar] [CrossRef]

- Al-Bayati, H.K.A.; Tighe, S.L.; Achebe, J. Influence of recycled concrete aggregate on volumetric properties of hot mix asphalt. Resour. Conserv. Recycl. 2018, 130, 200–214. [Google Scholar] [CrossRef]

- Afaf, A.H.M. Effect of aggregate gradation and type on hot asphalt concrete mix properties. J. Eng. Sci. 2014, 42, 567–574. [Google Scholar]

- Ghareeb, K.S.; Ahmed, H.E.; El-Affandy, T.H.; Deifalla, A.F.; El-Sayed, T.A. The Novelty of Using Glass Powder and Lime Powder for Producing UHPSCC. Buildings 2022, 12, 684. [Google Scholar] [CrossRef]

- El-Sayed, T.A.; Algash, Y.A. Flexural behavior of ultra-high performance geopolymer RC beams reinforced with GFRP bars. Case Stud. Constr. Mat. 2021, 15, e00604. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, A.O.; Oyedele, L.O.; Salami, R.O. Deep learning model for demolition waste prediction in a circular economy. J. Clean. Prod. 2020, 274, 122843. [Google Scholar] [CrossRef]

- Cabrera-Covarrubias, F.G.; Gómez-Soberón, J.M.; Almaral-Sánchez, J.L.; Corral-Higuera, R.; Gómez-Soberón, M.C. Implementation of interaction diagram of the properties in fresh for mortars with ceramic aggregates. Period. Polytech. Civ. Eng. 2017, 61, 335–340. [Google Scholar] [CrossRef]

- Rambaldi, E. Pathway towards a High Recycling Content in Traditional Ceramics. Ceramics 2021, 4, 486–501. [Google Scholar] [CrossRef]

- Ros-Dosdà, T.; Fullana-i-Palmer, P.; Mezquita, A.; Masoni, P.; Monfort, E. How can the European ceramic tile industry meet the EU’s low-carbon targets? A life cycle perspective. J. Clean. Prod. 2018, 199, 554–564. [Google Scholar] [CrossRef]

- Barreto, E.d.S.; Stafanato, K.V.; Marvila, M.T.; de Azevedo, A.R.G.; Ali, M.; Pereira, R.M.L.; Monteiro, S.N. Clay Ceramic Waste as Pozzolan Constituent in Cement for Structural Concrete. Materials 2021, 14, 2917. [Google Scholar] [CrossRef]

- Dondi, M. Feldspathic fluxes for ceramics: Sources, production trends and technological value. Resour. Conserv. Recycl. 2018, 133, 191–205. [Google Scholar] [CrossRef]

- Gawell, E.; Grabowiecki, K. Modern Details in Meaningful Architecture. Sustainability 2021, 13, 13691. [Google Scholar] [CrossRef]

- Celadyn, M.; Celadyn, W. Apparent Destruction Architectural Design for the Sustainability of Building Skins. Buildings 2022, 12, 1220. [Google Scholar] [CrossRef]

- Ruggeri, M.; Pantini, S.; Rigamonti, L. Assessing the impact of selective demolition techniques on C&D waste management. InIOP Conf. Ser. Earth Environ. Sci. 2019, 296, 012005. [Google Scholar] [CrossRef]

- Ortiz, O.; Pasqualino, J.; Castells, F. Environmental performance of construction waste: Comparing three scenarios from a case study in Catalonia, Spain. Waste Manag. 2010, 30, 646–654. [Google Scholar] [CrossRef]

- Pantini, S.; Rigamonti, L. Is selective demolition always a sustainable choice? Waste Manag. 2020, 103, 169–176. [Google Scholar] [CrossRef]

- Eberhardt, L.M.; Stijn, A.; Rasmussen, F.; Birkved, M.; Birgisdottir, H. Towards circular life cycle assessment for the built environment: A comparison of allocation approaches. InIOP Conf. Ser. Earth Environ. Sci. 2020, 588, 03026. [Google Scholar] [CrossRef]

- Van der Harst, E.; Potting, J.; Kroeze, C. Comparison of different methods to include recycling in LCAs of aluminium cans and disposable polystyrene cups. Waste Manag. 2016, 48, 565–583. [Google Scholar] [CrossRef]

- Gaudillat, P.; Antonopoulos, I.; Canfora, P.; Dri, M. Best Environmental Management Practice for the Waste Management Sector Learning from Frontrunners; Publications Office of the European Union: Luxembourg, 2018. [CrossRef]

- Rosales, J.; Agrela, F.; Entrenas, J.A.; Cabrera, M. Potential of Stainless Steel Slag Waste in Manufacturing Self-Compacting Concrete. Materials 2020, 13, 2049. [Google Scholar] [CrossRef]

- Sheen, Y.-N.; Wang, H.-Y.; Sun, T.-H. Properties of green concrete containing stainless steel oxidizing slag resource materials. Constr. Build. Mater. 2014, 50, 22–27. [Google Scholar] [CrossRef]

- Türkmen, İ. Influence of different curing conditions on the physical and mechanical properties of concretes with admixtures of silica fume and blast furnace slag. Mater. Lett. 2003, 57, 4560–4569. [Google Scholar] [CrossRef]

- Mróz, J.; Konstanciak, A.; Warzecha, M.; Więcek, M.; Hutny, A.M. Research on Reduction of Selected Iron-Bearing Waste Materials. Materials 2021, 14, 1914. [Google Scholar] [CrossRef]

- Todd, J.; Brown, E.J.G.; Wells, E. Ecological design applied. Ecol. Eng. 2003, 20, 421–440. [Google Scholar] [CrossRef]

| Type of Material | Risks Related to Building Material Remainders | Possibilities and Advantages Related to the Reuse of Recycled Material |

|---|---|---|

| Wood |

|

|

| Plastic |

|

|

| Concrete |

|

|

| Glass |

|

|

| Ceramics |

|

|

| Metal |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rybak-Niedziółka, K.; Starzyk, A.; Łacek, P.; Mazur, Ł.; Myszka, I.; Stefańska, A.; Kurcjusz, M.; Nowysz, A.; Langie, K. Use of Waste Building Materials in Architecture and Urban Planning—A Review of Selected Examples. Sustainability 2023, 15, 5047. https://doi.org/10.3390/su15065047

Rybak-Niedziółka K, Starzyk A, Łacek P, Mazur Ł, Myszka I, Stefańska A, Kurcjusz M, Nowysz A, Langie K. Use of Waste Building Materials in Architecture and Urban Planning—A Review of Selected Examples. Sustainability. 2023; 15(6):5047. https://doi.org/10.3390/su15065047

Chicago/Turabian StyleRybak-Niedziółka, Kinga, Agnieszka Starzyk, Przemysław Łacek, Łukasz Mazur, Izabela Myszka, Anna Stefańska, Małgorzata Kurcjusz, Aleksandra Nowysz, and Karol Langie. 2023. "Use of Waste Building Materials in Architecture and Urban Planning—A Review of Selected Examples" Sustainability 15, no. 6: 5047. https://doi.org/10.3390/su15065047

APA StyleRybak-Niedziółka, K., Starzyk, A., Łacek, P., Mazur, Ł., Myszka, I., Stefańska, A., Kurcjusz, M., Nowysz, A., & Langie, K. (2023). Use of Waste Building Materials in Architecture and Urban Planning—A Review of Selected Examples. Sustainability, 15(6), 5047. https://doi.org/10.3390/su15065047