Usability of Discarded Lignocellulosic Fibers in Paper for Secondary Green Packaging and Labeling

Abstract

:1. Introduction

2. Materials and Methods

2.1. Soda Pulping of Straw

2.2. Production of Paper Substrates with Straw Pulp

2.3. Printing Paper Substrates with Offset and Gravure Techniques

2.4. Evaluation of the Printing Quality

2.4.1. Analysis of Ink Penetration Depth

2.4.2. Analysis of Integral Optical Ink Density

2.4.3. Analysis of Graininess Value

2.4.4. Analysis of Mottling Value

3. Results

4. Discussion

5. Conclusions

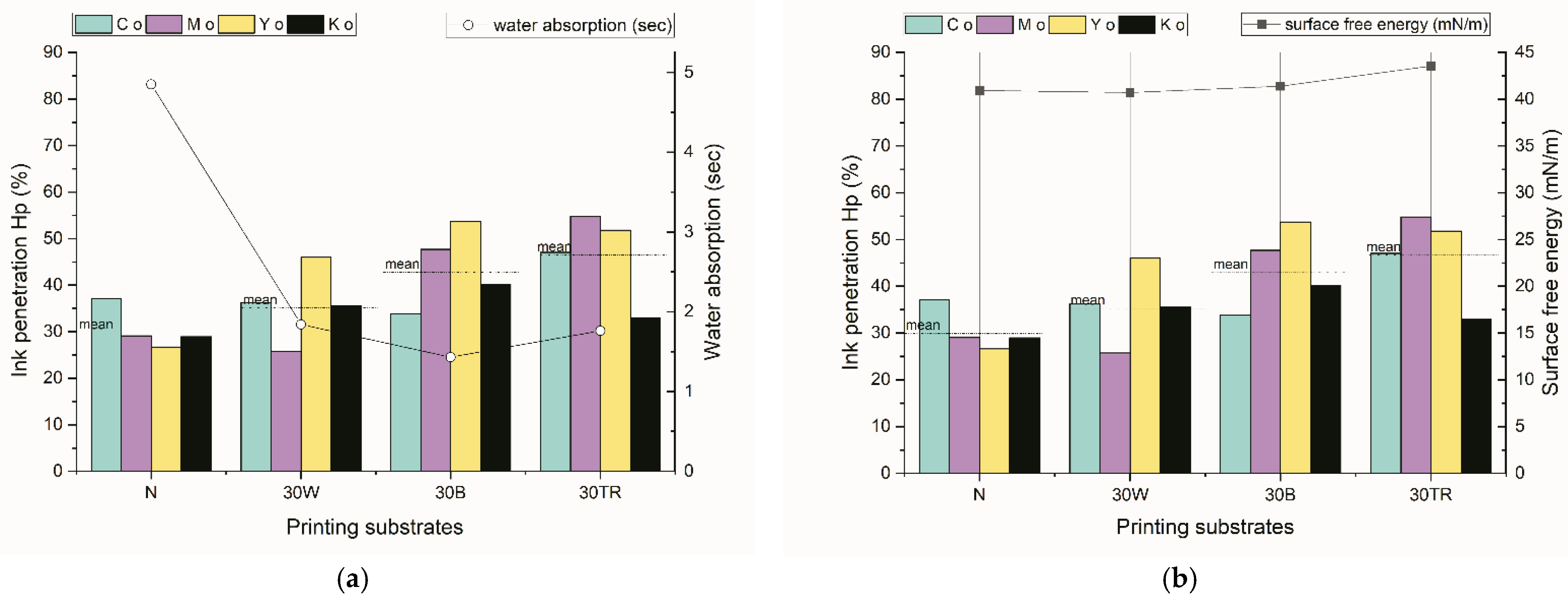

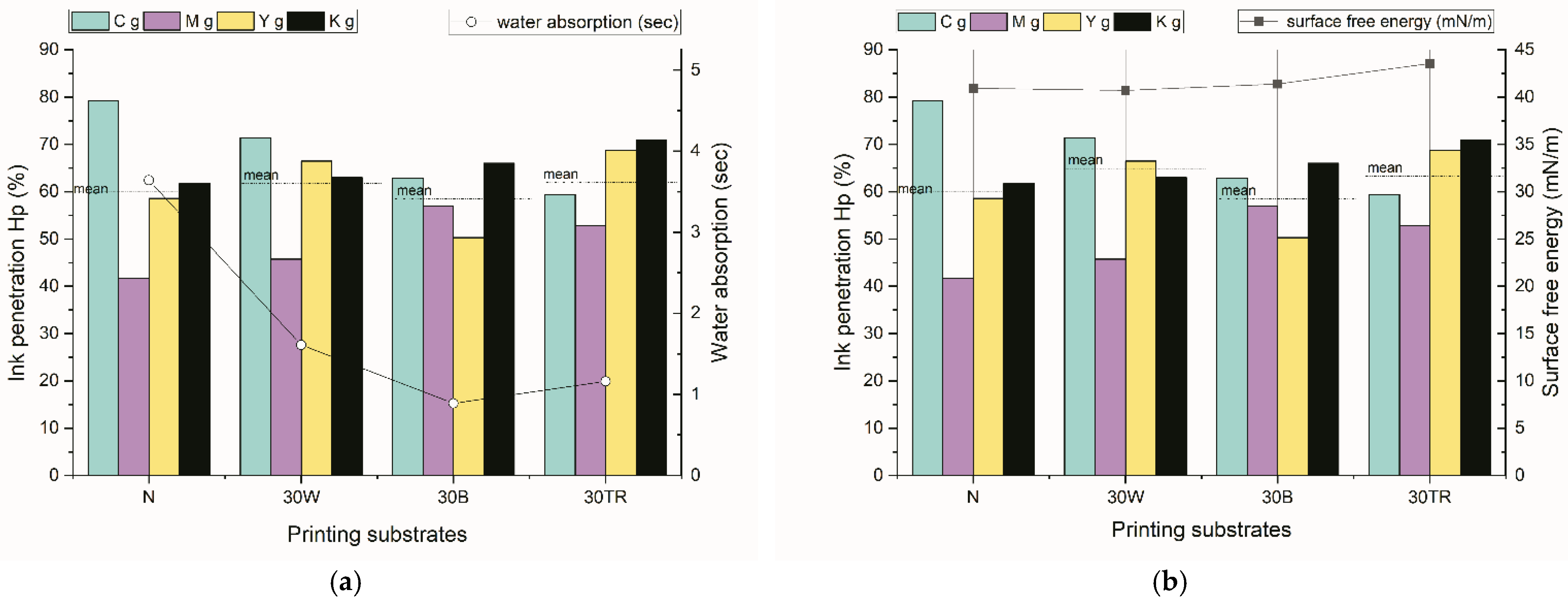

- The addition of discarded lignocellulosic fibers to the pulp of printing substrates increased the surface free energy of the substrate by up to 6.43% and the mean penetration value of ink inside the printing substrate by up to 53.29% compared to printing substrates without the addition of lignocellulosic fibers.

- The increase in the depth of penetration of offset inks into printing substrates with discarded lignocellulosic fibers was due to a smaller amount of ash, i.e., an increased amount of hydrophilic lignocellulosic fibers inside the printing substrate, which was also confirmed by the results of water absorption inside the printing substrate.

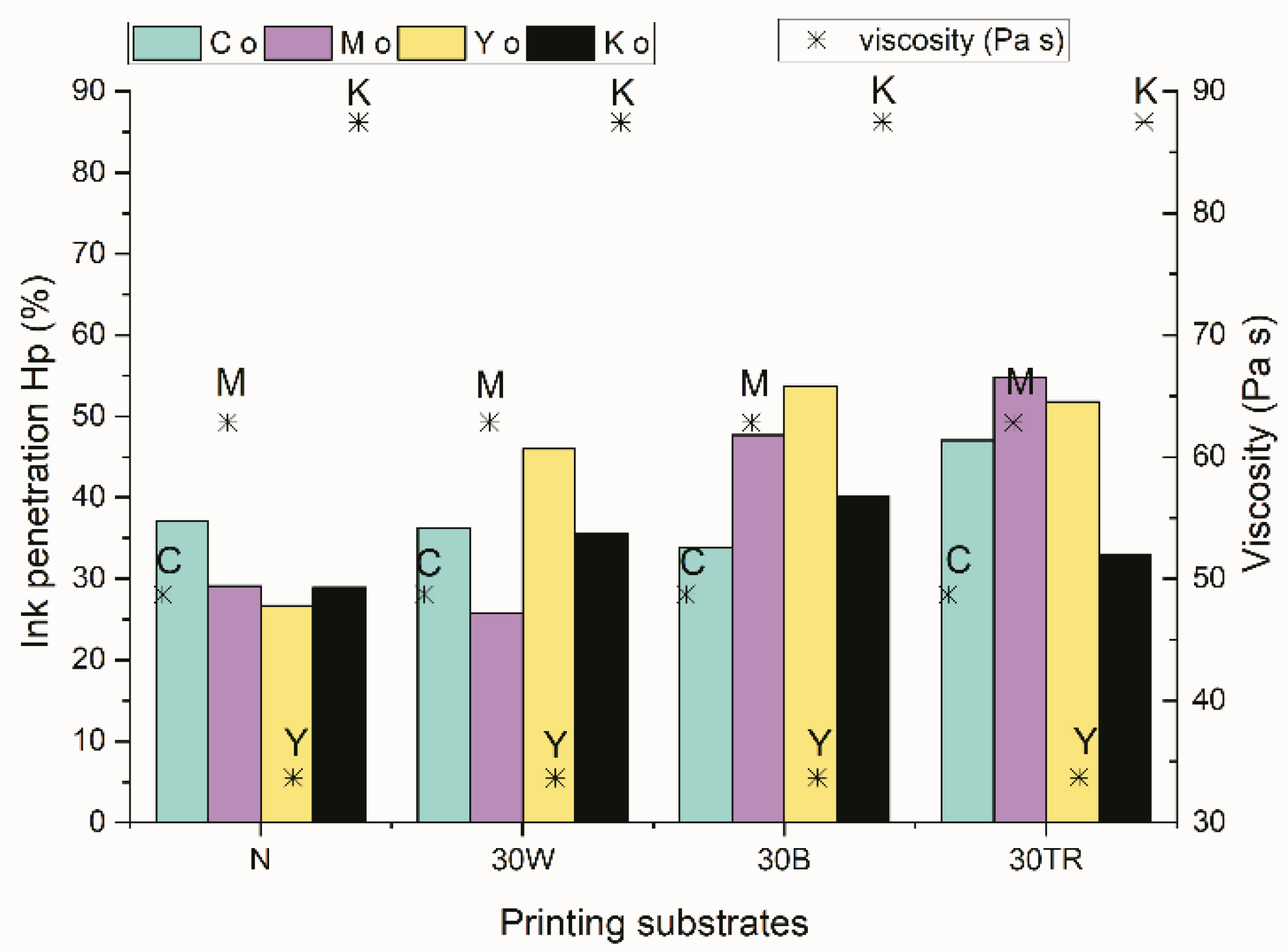

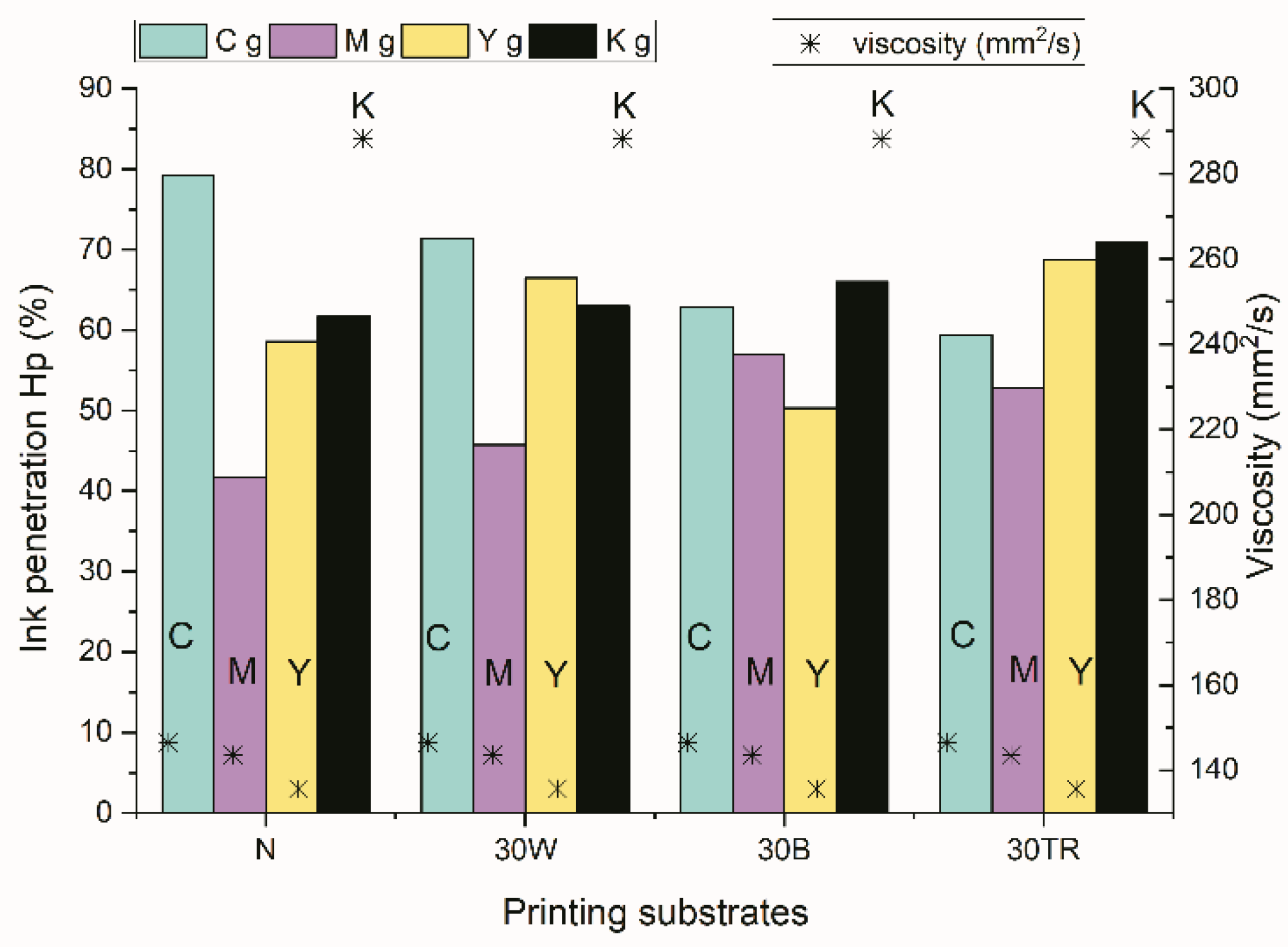

- In the case of prints obtained with offset thick-paste ink, it was proven that the ink with low viscosity had a greater penetration depth than the ink with higher viscosity.

- Gravure prints contain more significant ink penetration into the printing substrate compared to offset inks, where the viscosity of the ink and the printing process itself have the greatest influence.

- Both types of printing processes produced prints with nearly the same values of integral optical density, from which it can be concluded that the same reproduction of the ink application on the printing substrates was achieved.

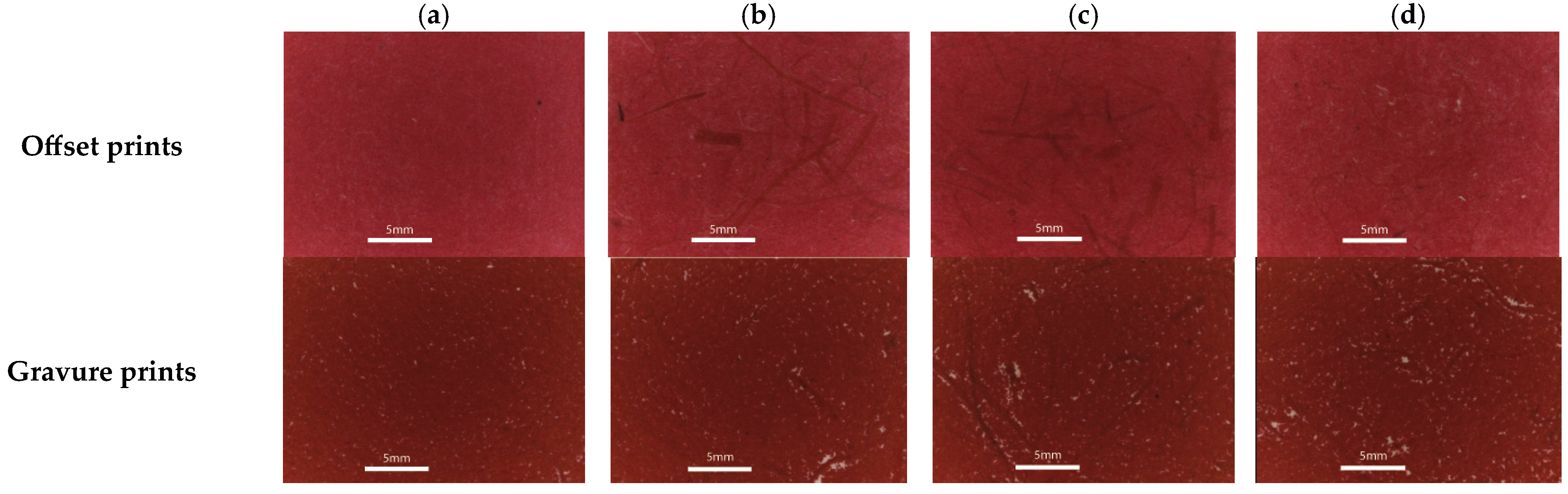

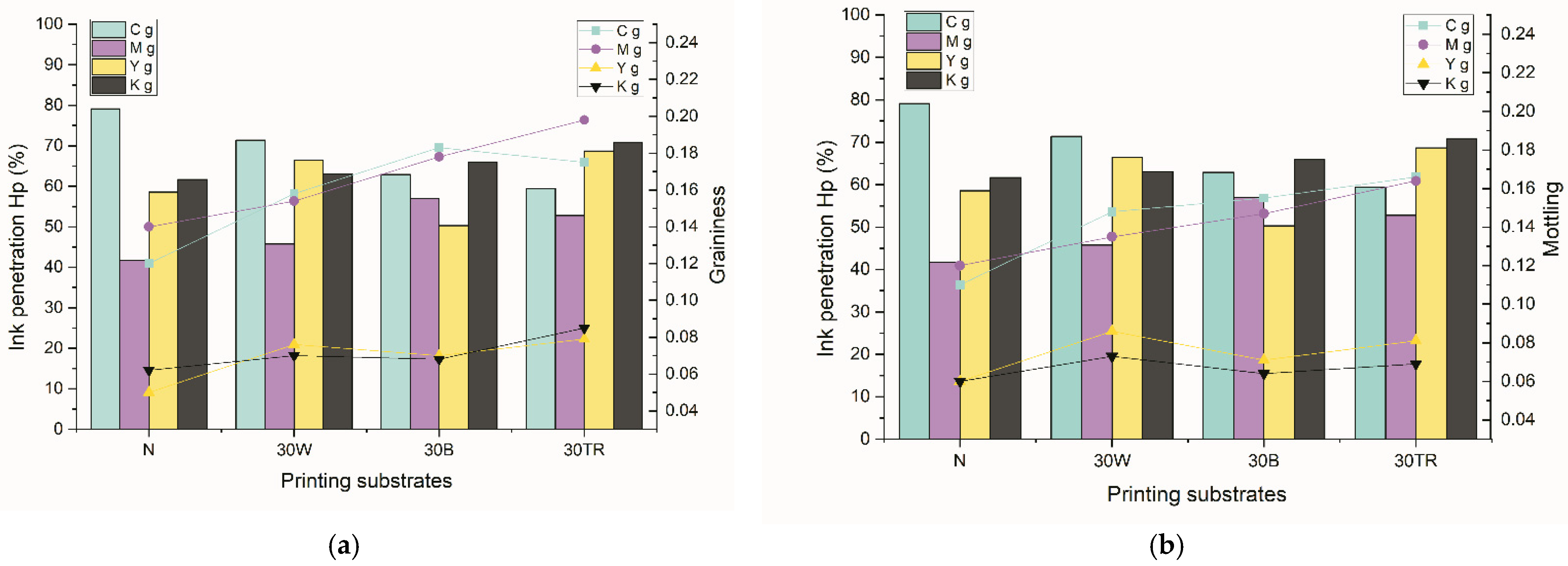

- In gravure printing, the greater penetration depth of the printing ink into the substrate leads to uneven surface coverage with printing ink.

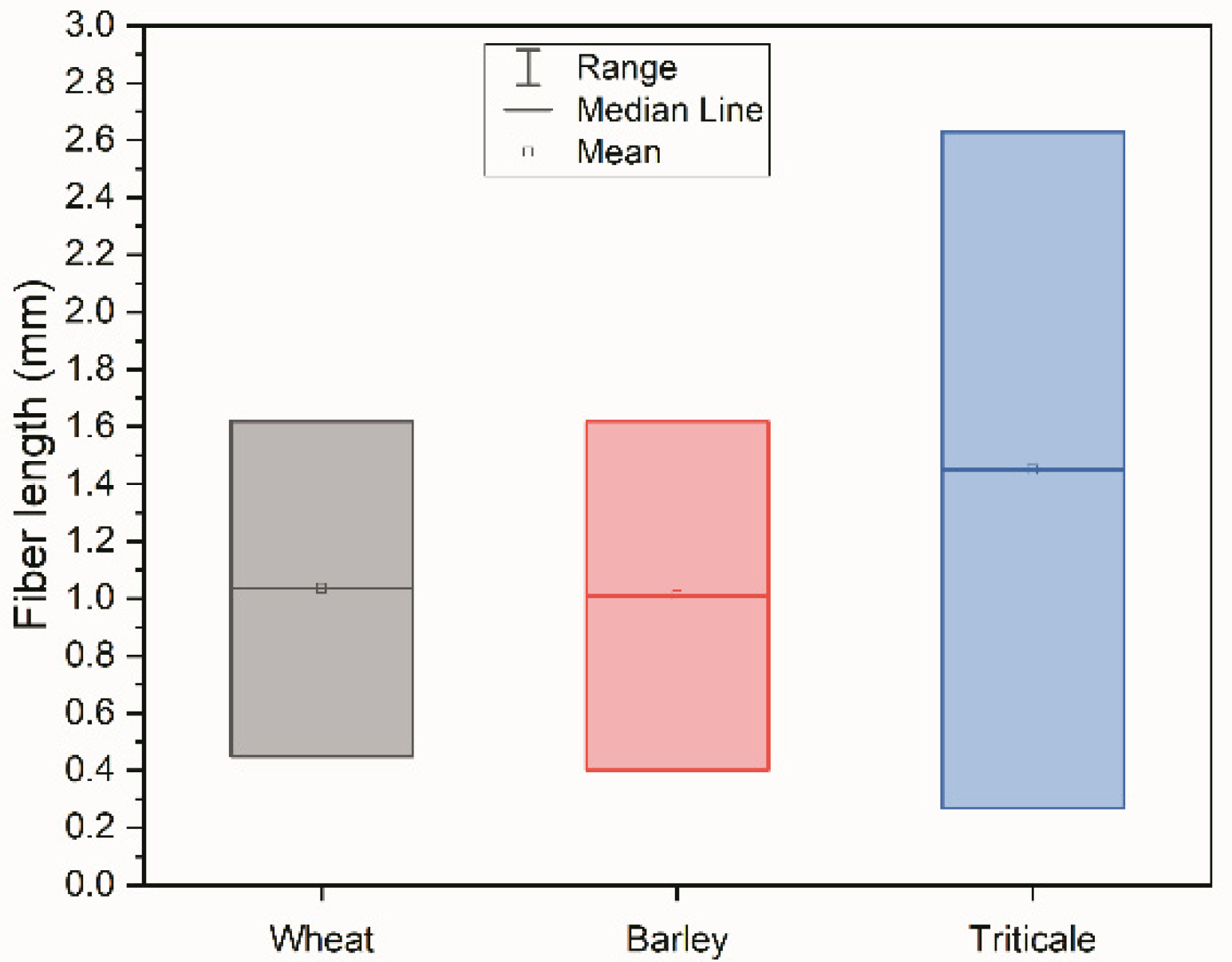

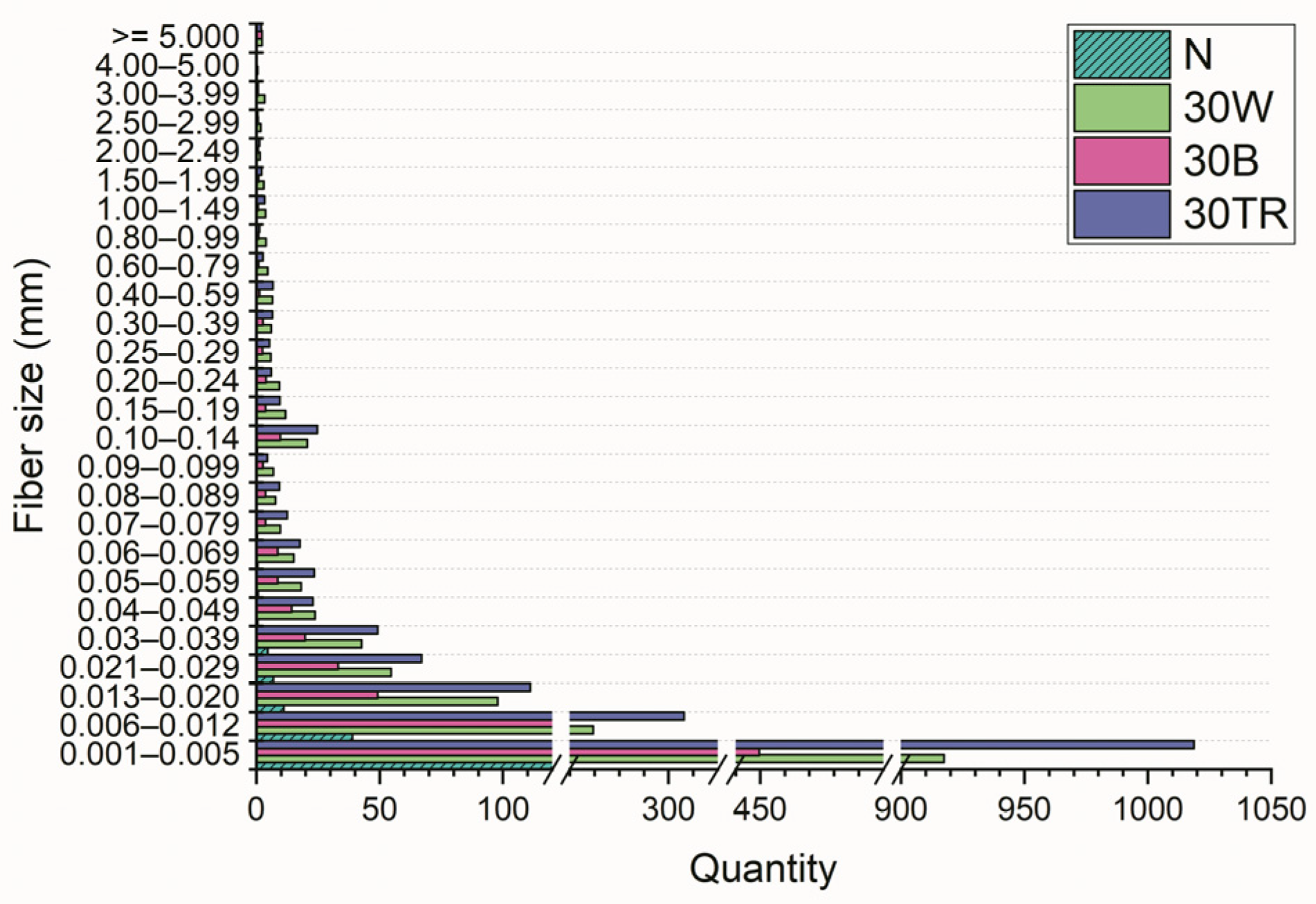

- It was proven that the highest ink penetration was achieved on printing substrates with a triticale pulp which consists of the longest cellulose fibers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vujković, I.; Galić, K.; Vereš, M. Ambalaža za Prehrambene Namirnice; Tectus: Zagreb, Croatia, 2007; pp. 9–47. [Google Scholar]

- Smyth, S. 2017 The Future of Global Printing to 2022; Smithers Pira: Leatherhead, UK, 2017. [Google Scholar]

- David, A.; Thangavel, Y.; Sankriti, R. Recover, Recycle and Reuse: An Efficient Way to Reduce the Waste. Int. J. Mech. Prod. Eng. Res. Dev. (IJMPERD) 2019, 9, 31–42. [Google Scholar]

- Fahzy, A.-R. Reduce, Reuse, Recycle: Alternatives for Waste Management, Guide G-314, College of Agricultural, Consumer and Environmental Sciences, New Mexico State University. Available online: https://pubs.nmsu.edu/_g/G314/ (accessed on 8 February 2022).

- Salem, K.S.; Naithani, V.; Jameel, H.; Lucia, L.; Pal, L. Lignocellulosic Fibers from Renewable Resources Using Green Chemistry for a Circular Economy. Glob. Chall. 2020, 4, 2000065. [Google Scholar] [CrossRef] [PubMed]

- Roth, S.L.; Zetterberg, L.; AcWorth, W.; Kangas, H.-L.; Neuhoff, K.; Zipperer, V. The pulp and paper overview paper. Clim. Strateg. 2016, 42, 43. Available online: http://climatestrategies.org/wp-content/uploads/2016/05/CS-The-pulp-and-paper-report-april-2016-formatted3.docx.pdf (accessed on 5 November 2022).

- Ashori, A. Nonwood Fibers—A Potential Source of Raw Material in Papermaking. Polym.-Plast. Technol. Eng. 2006, 45, 1133–1136. [Google Scholar] [CrossRef]

- Azeez, M.A. Pulp and Paper Production, Chapter 3; Kazi, N.S., Ed.; IntechOpen: London, UK, 2018; pp. 55–86. [Google Scholar]

- Fahmy, Y.; Fahmy, T.Y.A.; Mobarak, F.; El-Sakhawy, M.; Fadl, M.H. Agricultural residues (wastes) for manufacture of paper, board, and miscellaneous products: Background overview and future prospects. Int. J. ChemTech Res. 2017, 10, 424–448. [Google Scholar]

- Fengel, D.; Wegener, G. Wood, Chemistry, Ultrastructure, Reactions; Waster & Grugter: New York, NY, USA, 1984; p. 613. [Google Scholar]

- Eugenia Eugenio, M.; Ibarra, D.; Martín-Sampedro, R.; Espinosa, E.; Bascón, I.; Rodríguez, A. Cellulose Alternative Raw Materials for Pulp and Paper Production in the Concept of a Lignocellulosic Biorefinery; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef] [Green Version]

- Nagarajaganesh, B.; Rekha, B. A Comparative Study on Tensile Behaviour of Plant and Animal Fiber Reinforced Composites. Int. J. Innov. Appl. Stud. 2013, 2, 645–648. [Google Scholar]

- Gautam, S.P.; Bundela, P.S.; Pandey, A.K.; Jamaluddin, J.; Awasthi, M.K.; Sarsaiya, S. A review on systematic study of cellulose. J. Appl. Nat. Sci. 2010, 2, 330–343. [Google Scholar] [CrossRef] [Green Version]

- Nieschlag, H.J.; Nelson, G.H.; Wolff, J.A.; Perdue, R.E. A Search for New Fiber Crops. TAPPI J. 1960, 43, 193–201. [Google Scholar]

- Dutt, D.; Tyagi, C.H. Comparison of various Eucalyptus species for their morphological, chemical, pulp and paper making characteristics. Indian J. Chem. Technol. 2011, 18, 145–151. [Google Scholar]

- Bates, I.; Plazonić, I.; Radić Seleš, V.; Barbarić-Mikočević, Ž. Determining the quality of paper substrates containing triticale pulp for printing industry. Nord. Pulp Pap. Res. J. 2020, 35, 272–278. [Google Scholar] [CrossRef]

- Vrabič-Brodnjak, U.; Možina, K. Invasive alien plant species for use in paper and packaging materials. Fibers 2022, 10, 94. [Google Scholar] [CrossRef]

- Plazonic, I.; Bates, I.; Barbaric-Mikocevic, Z. The Effect of Straw Fibers in Printing Papers on Dot Reproduction Attributes, as Realized by UV Inkjet Technology. BioResources 2016, 11, 5033–5049. [Google Scholar] [CrossRef] [Green Version]

- Kipphan, H. Handbook of Print Media: Technologies and Production Methods; Springer: Berlin, Germany, 2001; pp. 206–372. [Google Scholar]

- NIIR Board of Consultants & Engineers. Handbook on Printing Technology (Offset, Flexo, Gravure, Screen, Digital, 3D Printing with Book Binding and CTP), 4th ed.; Asia Pacific Business Press Inc.: Delhi, India, 2019; pp. 63–73. [Google Scholar]

- Mohamad, N.A.N.; Jai, J. Response surface methodology for optimization of cellulose extraction from banana stem using NaOH-EDTA for pulp and papermaking. Heliyon 2022, 8, e09114. [Google Scholar] [CrossRef]

- Španić, N.; Plazonić, I.; Jambreković, V.; Barbarić-Mikočević, Ž. Wood and nonwood fibres length as main factor affecting their suitabillity as raw materials for papermaking industry. In Proceedings of the Natural Resources, Green Technology and Sustainable Development, Zagreb, Croatia, 5–8 June 2018; pp. 121–125. [Google Scholar]

- Bates, I.; Plazonić, I.; Petric Maretić, K.; Rudolf, M.; Radić Seleš, V. Assessment of the UV inkjet ink penetration into laboratory papers within triticale pulp and its influence on print quality. Color. Technol. 2022, 138, 16–27. [Google Scholar] [CrossRef]

- Plazonić, I.; Rudolf, M.; Radić Seleš, V.; Bates, I.; Petric Maretić, K. Potentials of lignocellulosic agricultural residues in paper production. Holist. Approach Environ. 2021, 11, 72–77. [Google Scholar] [CrossRef]

- Owens, D.; Wendt, R. Estimation of the Surface Free Energy of Polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Leach, R.H.; Pierce, R.J. The Printing Ink Manual, 5th ed.; Springer: Dordrecht, The Netherlands, 1993; pp. 766–797. [Google Scholar]

- DIN 53211; Determination of Floe Time Using the DIN Flow Cup. Deutsche Institut für Normung e.V.: Berlin, Germany, 1987.

- Li, R.; Zhang, Y.; Cao, Y.; Liu, Z. Ink penetration of uncoated inkjet paper and impact on printing quality. BioResources 2015, 10, 8135–8147. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.G.; Hu, S.; Liu, F. Establishment of Ink Penetration Model and the Calculation of Penetration Depth inside Paper. Adv. Mater. Res. 2011, 295–297, 2028–2032. [Google Scholar] [CrossRef]

- Milošević, R.; Kašiković, N.; Novaković, D.; Stančić, M.; Adamović, S. Investigation of the printing pressure level application influence on sheet-fed offset print quality. Reproduction 2013, 5, 171–176. [Google Scholar]

- ISO/IEC 13660; Information Technology—Office Equipment—Measurement of Image Quality Attributes—Binary Monochrome Text and Graphic Images. ISO: Geneva, Switzerland, 2001.

- Valdec, D.; Hajdek, K.; Majnarić, I.; Čerepinko, D. Influence of Printing Substrate on Quality of Line and Text Reproduction in Flexography. Appl. Sci. 2021, 11, 7827. [Google Scholar] [CrossRef]

- Theohari, S.; Fraggedakis, E.; Tsimis, D.; Mandis, D. Effect of paper properties on print quality by flexographic method. In Proceedings of the 46th Annual International Conference on Graphic Arts and Media Technology, Athens, Greece, 25–29 May 2014; pp. 25–29. [Google Scholar]

- Fairley, M. Encyclopedia of Labels, and Label Technology, 1st ed.; Tersus Publishing Ltd.: London, UK, 2004; p. 201. [Google Scholar]

- Yang, Y.G.; Liu, F.P. The Effects of Ink Viscosity on the Ink Permeability inside Newsprint and Offset Paper. Advanced Materials Research. Trans. Tech. Publ. 2011, 314–316, 1359–1362. [Google Scholar] [CrossRef]

- Krainer, S.; Smit, C.; Hirn, U. The effect of viscosity and surface tension on inkjet printed picoliter dots. RSC Adv. 2019, 9, 31708–31719. [Google Scholar] [CrossRef] [Green Version]

- Cassel, N.; Chalancon, J.; Pisaroni, H.; Plazonić, I.; Radić Seleš, V.; Bates, I. Utilization of Laboratory Papers with Non-Wood Fibres as Printing Substrates Observed Through the Maximum Ink Penetration Depth. Teh. Glas. Tech. J. 2023, 17, 32–37. [Google Scholar] [CrossRef]

- Kappel, C.; Hirn, U.; Donoser, M.; Bauer, W. Measurement of printing ink penetration in uncoated papers and is influence on print quality. In Proceedings of the 94th Annual Meeting, Pulp and Paper Technical Association of Canada, Montreal, Canada, 5 February 2008; pp. B539–B542. [Google Scholar]

- Karlovits, I.; Kavčič, U. Flexo printability of agro and invasive papers. Cellulose 2022, 29, 4613–4627. [Google Scholar] [CrossRef]

- Aslannejad, H.; Hassanizadeh, S.M.; Celia, M.A. Characterization of the Interface Between Coating and Fibrous Layers of Paper. Transp. Porous Media 2019, 127, 143–155. [Google Scholar] [CrossRef] [Green Version]

| Soda Pulping–Cooking in Autoclave | Decantation and Pulp Washing | Defibration in Holländer Valley Mill | ||

|---|---|---|---|---|

| NaOH charge | 16% | In two stages using 10 L of tap water each | Volume of added tap water | 23 L |

| Alkali to straw ratio | 10:1 | Pulp consistency | 1.5% | |

| Pulping temperature | 120 °C | pH | 8.5–9.0 | |

| Temperature | 24 °C | |||

| Pulping pressure | 170 kPa | Speed of rotation | 500 rpm | |

| Pulping time | 60 min | Time | 40 min | |

| Disintegration | Homogenisation | Paper Substrate | |||

|---|---|---|---|---|---|

| m (pulp) | 80 g | Weight | 42.5 g/m2 | ||

| V (H2O) | 1.6 l | V (H2O) | 10 L | ||

| pH | 8 | pH | 7.5 | Diameter | 200 mm |

| Temperature | 45 °C | Temperature | 45 °C | ||

| Disintegration time | 20 min | Homogenisation time | 5 min | ||

| Paper Substrate | Thickness (µm) | Air Permeability (mL/min) | Ash (%) | Roughness, Ra (µm) | Surface Free Energy, σs (mN/m) |

|---|---|---|---|---|---|

| N | 90.10 ± 2.13 | 221.12 ± 0.90 | 4.73 ± 0.22 | 4.15 ± 0.34 | 40.92 |

| 30W | 101.67 ± 17.22 | 406.92 ± 2.28 | 3.64 ± 0.07 | 4.59 ± 0.51 | 40.70 |

| 30B | 91.67 ± 4.08 | 426.88 ± 2.47 | 3.32 ± 0.67 | 4.24 ± 0.41 | 41.38 |

| 30TR | 101.67 ± 14.72 | 371.25 ± 5.44 | 3.99 ± 0.15 | 4.40 ± 0.39 | 43.55 |

| Printing Ink | Dynamic Viscosity (Pa·s) (Laray Viscometer) | Printing Ink | Kinematic Viscosity (mm2/s) (DIN 4 Cup) | ||

|---|---|---|---|---|---|

| Offset | C o | 48.70 ± 3.64 | Gravure | C g | 146.54 ± 5.29 |

| M o | 62.85 ± 9.85 | M g | 143.62 ± 8.11 | ||

| Y o | 33.69 ± 2.27 | Y g | 135.61 ± 4.13 | ||

| K o | 87.47 ± 2.74 | K g | 288.23 ± 8.35 | ||

| Paper Substrate | Cyan Offset Print (Co) | Magenta Offset Print (Mo) | Yellow Offset Print (Yo) | Black Offset Print (Ko) |

|---|---|---|---|---|

| N | 0.78 ± 0.03 | 0.82 ± 0.02 | 0.68 ± 0.01 | 1.02 ± 0.01 |

| 30W | 0.86 ± 0.03 | 0.85 ± 0.04 | 0.77 ± 0.01 | 0.96 ± 0.04 |

| 30B | 0.88 ± 0.03 | 0.85 ± 0.02 | 0.85 ± 0.02 | 1.02 ± 0.03 |

| 30TR | 0.87 ± 0.02 | 0.86 ± 0.03 | 0.77 ± 0.02 | 0.91 ± 0.04 |

| Paper Substrate | Cyan Gravure Print (Cg) | Magenta Gravure Print (Mg) | Yellow Gravure Print (Yg) | Black Gravure Print (Kg) |

|---|---|---|---|---|

| N | 1.06 ± 0.01 | 1.01 ± 0.02 | 0.91 ± 0.01 | 1.01 ± 0.01 |

| 30W | 1.04 ± 0.02 | 0.97 ± 0.04 | 0.82 ± 0.03 | 0.98 ± 0.04 |

| 30B | 1.03 ± 0.02 | 0.98 ± 0.02 | 0.84 ± 0.01 | 0.99 ± 0.02 |

| 30TR | 1.03 ± 0.03 | 0.94 ± 0.03 | 0.81 ± 0.02 | 0.99 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bates, I.; Plazonić, I.; Radić Seleš, V.; Petric Maretić, K.; Rudolf, M. Usability of Discarded Lignocellulosic Fibers in Paper for Secondary Green Packaging and Labeling. Sustainability 2023, 15, 5378. https://doi.org/10.3390/su15065378

Bates I, Plazonić I, Radić Seleš V, Petric Maretić K, Rudolf M. Usability of Discarded Lignocellulosic Fibers in Paper for Secondary Green Packaging and Labeling. Sustainability. 2023; 15(6):5378. https://doi.org/10.3390/su15065378

Chicago/Turabian StyleBates, Irena, Ivana Plazonić, Valentina Radić Seleš, Katja Petric Maretić, and Maja Rudolf. 2023. "Usability of Discarded Lignocellulosic Fibers in Paper for Secondary Green Packaging and Labeling" Sustainability 15, no. 6: 5378. https://doi.org/10.3390/su15065378

APA StyleBates, I., Plazonić, I., Radić Seleš, V., Petric Maretić, K., & Rudolf, M. (2023). Usability of Discarded Lignocellulosic Fibers in Paper for Secondary Green Packaging and Labeling. Sustainability, 15(6), 5378. https://doi.org/10.3390/su15065378